1. Introduction

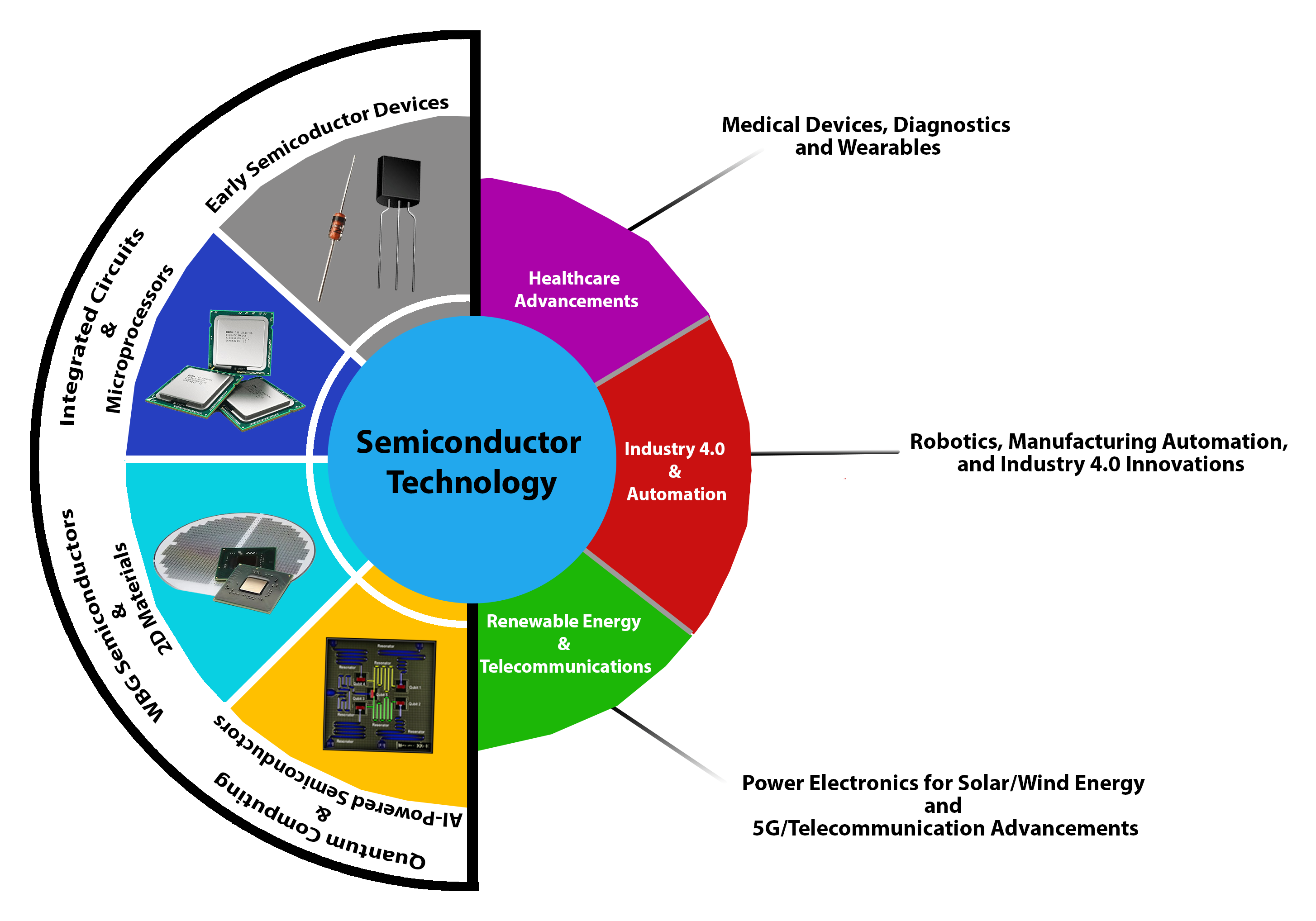

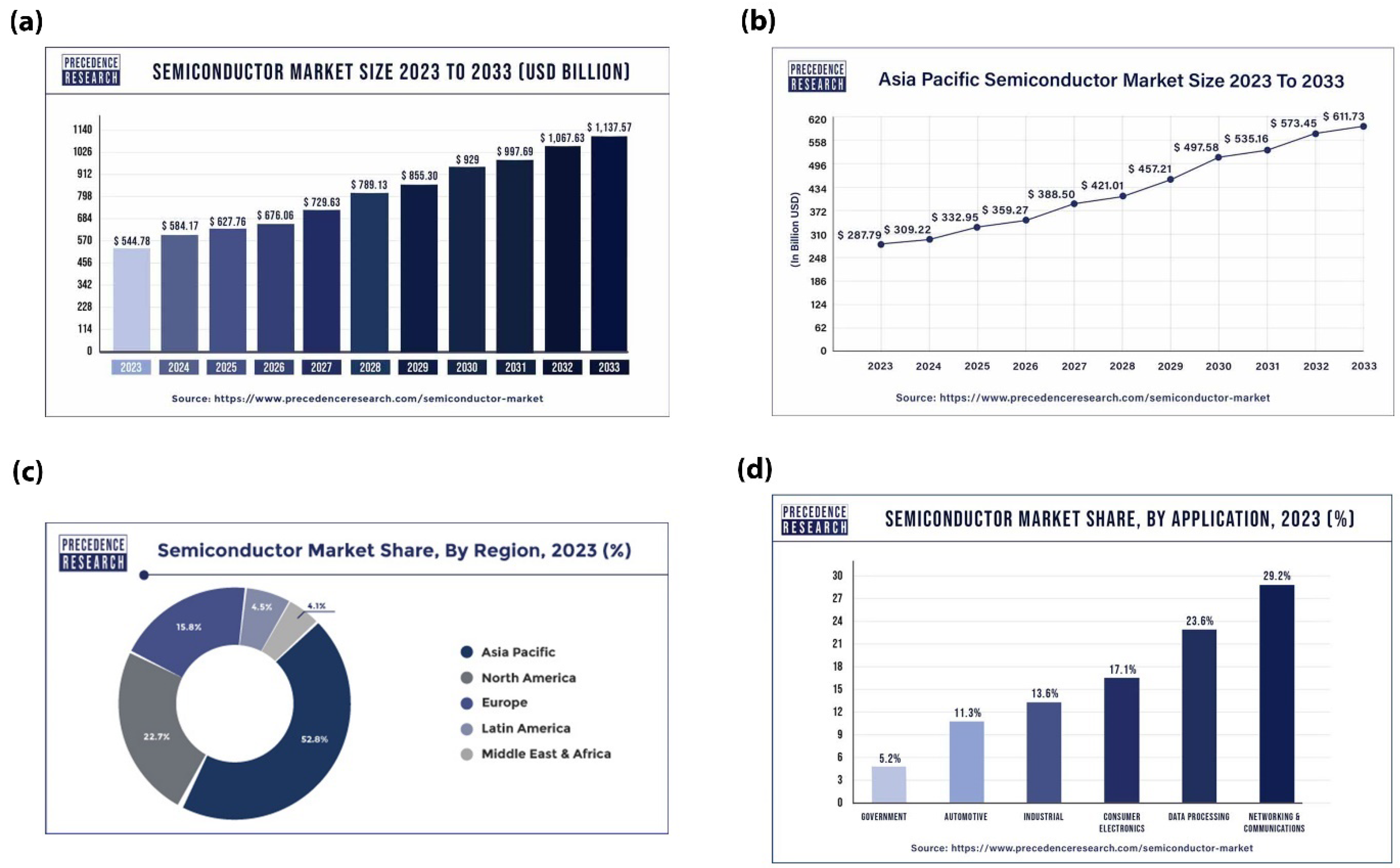

Semiconductor technology serves as the backbone of modern advancements in electronics, telecommunications, and renewable energy, playing an increasingly vital role in global economic and technological progress. Since the invention of transistors, semiconductors have revolutionized electronics due to their unique properties, acting as the fundamental building blocks for various devices. Over the past several decades, these technologies have transformed global communication and data-processing powers, accelerating innovations in sectors such as electric vehicles, renewable energy, healthcare, and advanced computing.

From early transistors to modern integrated circuits, the exponential growth of the semiconductor industry has made electronic chips indispensable in system solutions, driving applications like GPS positioning and autonomous vehicles (robocabs) [

1,

2]. Semiconductors are essential not only in electronics but also in renewable energy systems and other industries, where their efficient power conversion and signal modulation capabilities are crucial [

1]. These solids continue to propel the expansion of fields such as artificial intelligence (AI), nanotechnology, and quantum computing, promising to redefine the speed, efficiency, and potential of electronic devices across multiple sectors.

Diodes and transistors are semiconductor devices that are crucial for contemporary technologies in developing functionalities from smartphones, and computers, to medical equipment. Since they are built on semiconductor materials such as silicon, their nature allows for efficient power conversion and signal modulation. The applications of diodes involve rectification; thus, they convert alternating current (AC) to direct current (DC), which is critical for powering an electronic device [

3]. They are applied to communication systems, where they help in the modulation of signals for transmission [

4]. Transistors act as switches and amplifiers and are building blocks of integrated circuits that are applied to most electronic devices [

5]. The ability to alter semiconductor properties through doping enhances transistor performance, allowing for the creation of various electronic components [

4]. The applications of semiconductors are still growing through developments in artificial intelligence, nanotech, and quantum computing that have spread their use to other fields such as healthcare and energy. The study and development of semiconductors are important as they make up the foundation on which technological enhancements are built in a bid to enhance multiple sectors. It is critical for people inclined to make a difference in contemporary electronics, energy, or communication to know semiconductors.

The surge in global demand for high-performance computing and digital transformation is significantly propelled by innovations in semiconductor technologies, particularly in quantum computing, AI, and nanotechnology. Quantum dots (QDs) in semiconductor devices enhance functionalities, enabling efficient communication and advanced data processing, which are crucial for AI-powered diagnostics in healthcare [

6]. Furthermore, the integration of AI and machine learning into semiconductor design enhances system efficiency and reliability, addressing challenges in testing and dependability [

7]. In energy applications, the development of wide-bandgap semiconductors offers superior efficiency compared to traditional silicon, facilitating the creation of more effective power systems. Additionally, the digital transformation driven by these technologies presents both opportunities and risks, necessitating robust cybersecurity measures to protect sensitive information [

8]. Collectively, these advancements position semiconductors as essential enablers of breakthroughs across various fields, including medical diagnostics and autonomous vehicles [

8,

9].

The semiconductor industry faces significant challenges, particularly highlighted by the recent global chip shortage exacerbated by the COVID-19 pandemic, which has revealed the critical role of semiconductors in global supply chains and the urgent need for resilient production frameworks [

1,

10]. This shortage, alongside geopolitical tensions, especially between the U.S. and China, underscores the fragility of the semiconductor supply chain. Asia, particularly China, has emerged as a crucial hub for semiconductor manufacturing due to lower costs and supportive government policies [

1], yet its reliance on U.S. technology for advanced designs illustrates the sector's global interdependence [

11,

12]. As the U.S.-China technological rivalry escalates, with the U.S. implementing export restrictions to safeguard its dominance [

11,

13,

14], the future of semiconductor geopolitics will hinge on how these nations navigate their intertwined interests and dependencies.

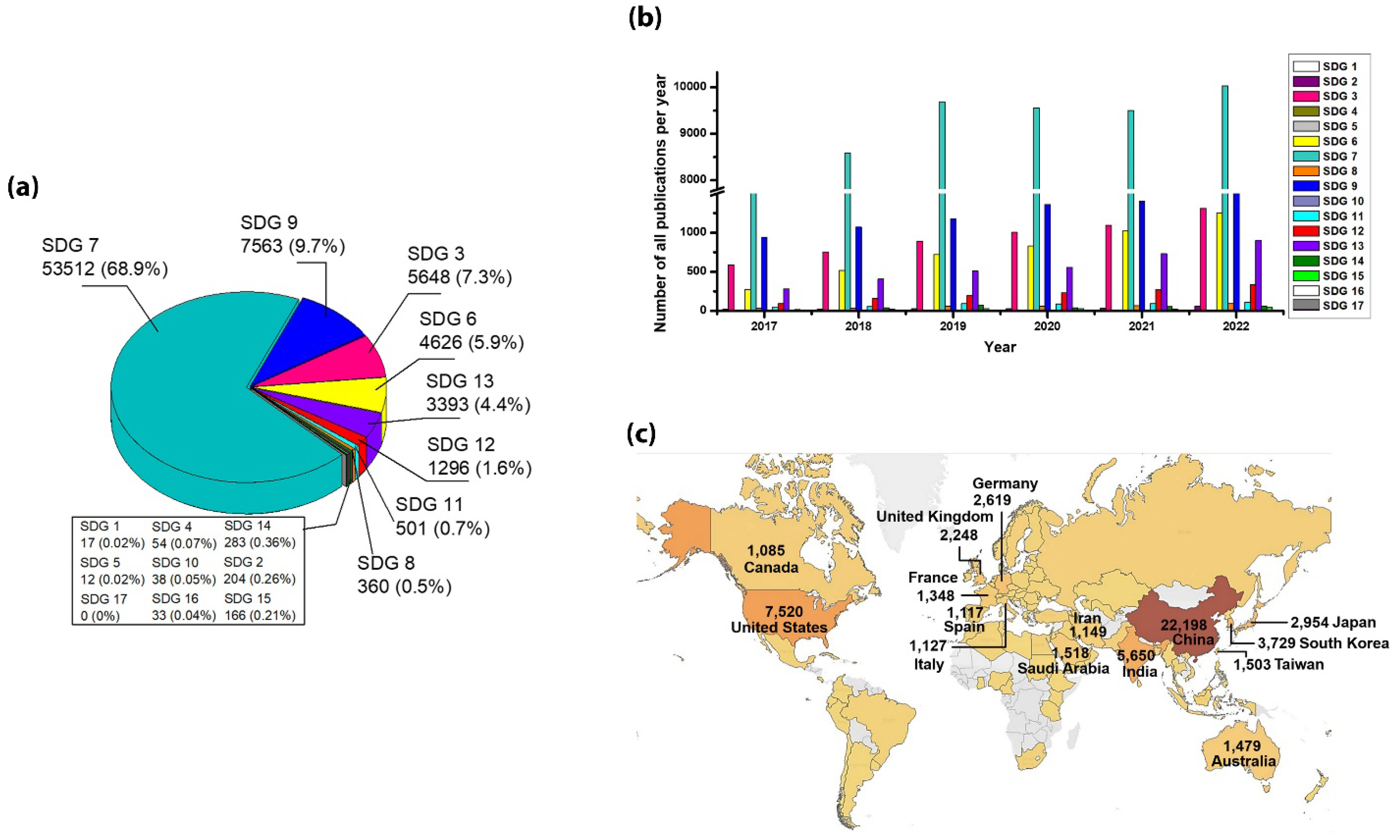

The semiconductor industry is undergoing a transformative evolution, focusing on long-term sustainability and continuous innovation, particularly through the development of advanced technologies such as tunnel gate transistors, graphene, and wide-bandgap and ultrawide-bandgap semiconductors. These innovations are crucial for enhancing functionality while reducing costs, aligning with global sustainability goals, including the United Nations Sustainable Development Goals (SDGs) [

15]. The integration of artificial intelligence (AI) is expected to further propel growth, enabling smarter manufacturing processes and improved device performance [

16]. Additionally, the industry's commitment to sustainable development is evident in its efforts to minimize electronic waste and enhance energy efficiency, which are vital for addressing environmental concerns [

17]. Despite challenges, such as geopolitical tensions and technological barriers, the semiconductor sector remains a pivotal player in driving economic growth and achieving sustainability objectives [

18].

This review delves into the evolving landscape of semiconductor technologies, tracing their foundational properties, historical evolution, and the most recent innovations. It places a special emphasis on sustainability, a key challenge that the semiconductor industry faces in the 21st century as environmental impacts and supply chain disruptions force manufacturers to adopt more resilient and eco-friendly production methods. By highlighting recent developments, including wide-bandgap and ultrawide-bandgap semiconductors, AI integration, and sustainable practices, this review provides a comprehensive and timely overview of semiconductor technologies. In doing so, it offers insights into how these advancements align with sustainability and innovation, while paving the way for future research and industrial progress.

2. Overview of the Historical Development Semiconductor Fundamentals

Semiconductors, characterized by their unique ability to conduct electricity under specific conditions, form the foundation of modern electronic devices. Their intrinsic properties, governed by crystal structure and electronic band gaps, can be significantly enhanced through doping processes, wherein impurities are introduced to modify electrical behavior. Recent advances in defect engineering and impurity control have enabled improvements in conductivity and carrier generation, particularly through the strategic manipulation of point defects in materials like silicon and gallium arsenide [

19,

20].

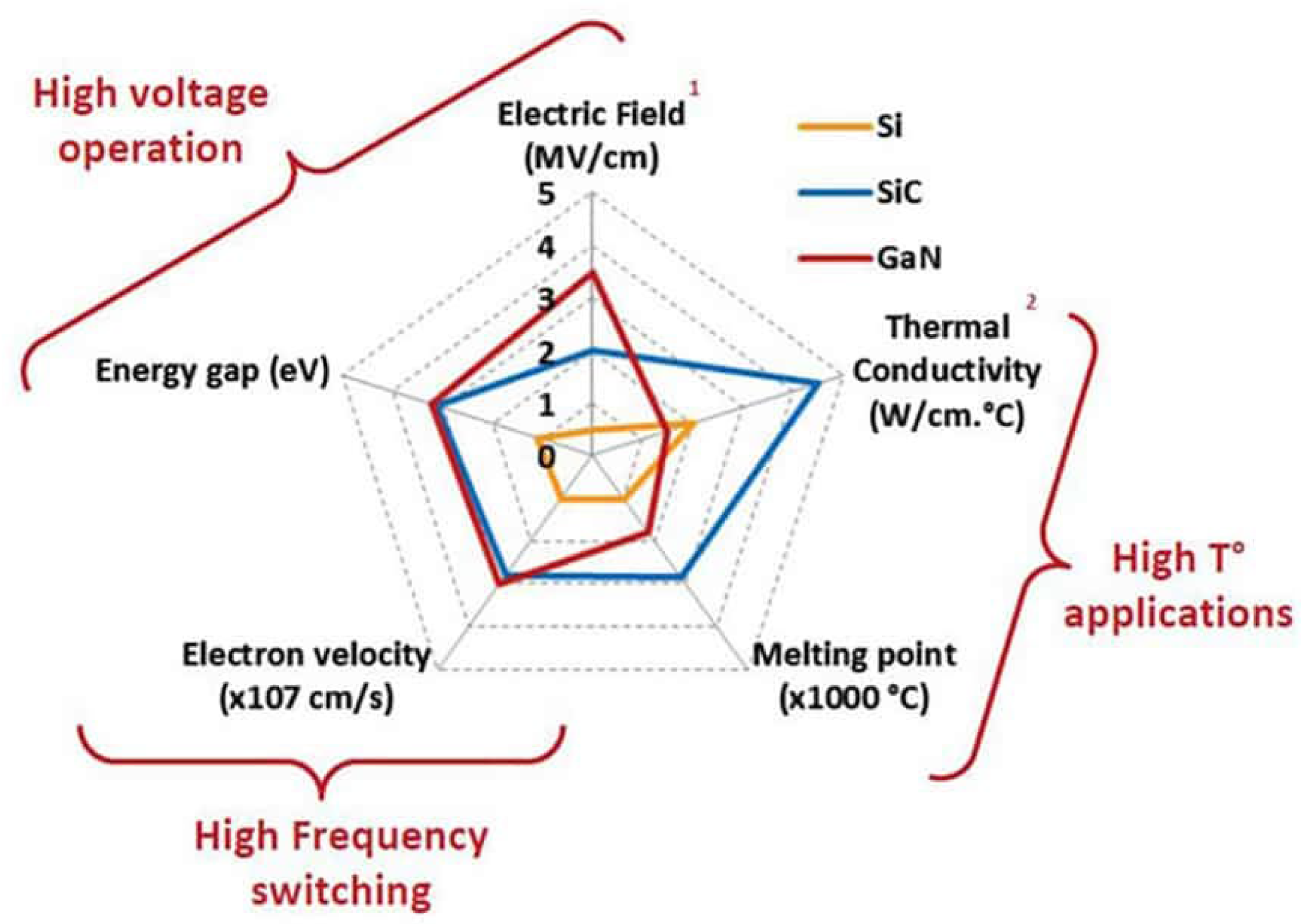

Emerging materials such as Wide-bandgap semiconductors, particularly silicon carbide (SiC) and gallium nitride (GaN), are revolutionizing high-efficiency, high-power electronic applications due to their exceptional thermal and electrical properties (

Figure 1). These materials exhibit significantly higher breakdown voltages and lower on-resistance compared to traditional silicon, making them ideal for power electronics and high-frequency applications [

21]. GaN, in particular, is noted for its high electron mobility and thermal stability (

Figure 1), which enhance the performance of devices such as high-electron-mobility transistors (HEMTs) and LEDs [

22,

23]. Additionally, 2D materials like graphene are emerging as promising candidates for flexible electronics and quantum computing, thanks to their remarkable conductivity and mechanical properties, which could complement the advancements in wide-bandgap semiconductor technologies [

24]. The evolution of semiconductor technologies from early materials like silicon to these advanced compounds has been pivotal in driving innovations across industries. Together, these materials are paving the way for innovative solutions in various high-performance fields.

2.1. Historical Development in Semiconductors

The history of semiconductors traces from the Pre-Transistor Era. According to G. Busch the term “semiconducting” was used for the first time by Alessandro Volta in 1872. The first documented observation of a semiconductor effect is that of Faraday (1833), who noticed that the resistance of silver sulfide decreased with temperature, which was different from the behavior observed in metals [

26]. Johann Hittorf published an extensive quantitative analysis of the temperature dependence of the electrical conductivity of Ag

2S and Cu

2S in 1851. The history of semiconductors initially focused on two crucial properties; rectification of metal-semiconductor junctions and sensitivity of semiconductors to light [

27,

28].

2.1.1. Rectification

Ferdinand Braun invented the solid-state rectifier in 1874, laying the foundation for solid-state electronics [

29]. He observed the conduction and rectification in metal sulfides probed with a metal point whisker. Although not immediately appreciated, Braun’s discovery later played a significant role in the development of radio and microwave radar systems during World War II. In 1874, Arthur Schuster also observed rectification in a circuit made of copper wires bound by screws. He discovered copper oxide as a new semiconductor when cleaning the ends of the wires, removed the rectification effect. In 1929, Walter Schottky experimentally confirmed the presence of a barrier in a metal-semiconductor junction [

28].

2.1.2. Photoconductivity and Photovoltaic

The photovoltaic effect at a junction between a semiconductor and an electrolyte was discovered by Alexander Edmund Becquerel (the father of a great scientist Henri Becquerel) [

30]. Willoughby Smith discovered photoconductivity in solids in 1873 while working on submarine cable testing [

30]. Adams and Day were the first to discover the photovoltaic effect in a solid material (selenium) in 1876. They noticed that the presence of light could change the direction of the current flowing through the selenium connected to a battery. Charles Fritts constructed the first working solar cell in 1883, consisting of a metal plate and a thin layer of selenium covered with a very thin layer of gold, with an efficiency below 1% [

28,

30].

2.1.3. Theory of Semiconductor

In 1879, Edwin Herbert Hall discovered that charge carriers in solids are deflected in a magnetic field (Hall effect), which was later used to study semiconductor properties [

31]. Several scientists proposed theories of electron-based conduction in metals shortly after the discovery of the electron by J.J. Thomson. Eduard Riecke's theory (1899) assumed the presence of both negative and positive charge carriers with different concentrations and mobilities. Around 1908, Karl Baedeker observed the dependence of the conductivity of copper iodide on stoichiometry (iodine content) and measured the Hall effect in this material, indicating carriers with positive charge. In 1914, Johan Koenigsberger divided solid-state materials into three groups based on their conductivity: metals, insulators, and "variable conductors" [

32]. Ferdinand Bloch developed the theory of electrons in lattices in 1928 [

28].

In 1930, Rudolf Peierls presented the concept of forbidden gaps, which was applied to realistic solids by Brillouin the same year. Kronig and Penney developed a simple, analytical model of periodic potential in 1930. Alan Wilson developed the band theory of solids based on the idea of empty and filled energy bands in 1931. He also confirmed that the conductivity of semiconductors was due to impurities. In the same year, Werner Heisenberg developed the concept of holes. Walter Schottky and Neville F. Mott independently developed models of the potential barrier and current flow through a metal-semiconductor junction in 1938. Schottky improved his model the following year, including the presence of space charge. Boris Davydov presented a theory of a copper-oxide rectifier in 1938, including the presence of a p-n junction in the oxide, excess carriers, recombination, and the importance of surface states. Hans Bethe developed the theory of thermionic emission in 1942 [

33,

34].

2.1.4. Earlier Semiconductor Devices

2.1.4.1. Point-Contact Rectifiers

The point-contact rectifier was one of the earliest semiconductor devices. This device relied on the rectifying behavior of a small metal wire in contact with a semiconductor material, typically germanium or silicon. J.C. Bose obtained a patent for lead sulfide (PbS) point-contact rectifiers in 1904. G. Pickard was the first to show that silicon point-contact rectifiers were useful in detecting radio waves (patent in 1906). Selenium and copper oxide rectifiers were developed by E. Presser in 1925 and L.O. Grondahl in 1926, respectively. Selenium rectifiers were heavily used in military communications and radar equipment during World War II [

28].

These early rectifiers led to the development of the cat’s-whisker detector, a simple semiconductor diode that used a fine metal wire (the "whisker") to make contact with a crystal, typically made of lead sulfide (galena). The device was pivotal in the early 20th century, particularly in radio receivers, as it demonstrated how semiconductor materials could rectify current. Ferdinand Braun, a German physicist, first discovered the rectification effect in 1874 when he observed that current flowed only in one direction at the contact point between a metal wire and a galena crystal [

29]. This discovery, although not immediately applied, became significant with the rise of radio technology, and the term "cat’s-whisker detector" was derived from the delicate wire used to make electrical contact with the crystal surface. While revolutionary at the time, the

cat’s-whisker detector had its limitations due to the inconsistency of the semiconductor material, which affected the quality and performance of the device.

2.1.4.2. The P-N Junction

Building on the early semiconductor developments, Russel Ohl made a breakthrough in addressing the limitations of the cat’s-whisker detectors. He realized that the inconsistent performance of these detectors was caused by the poor quality of the semiconductor material. Ohl improved the process by melting silicon in quartz tubes and allowing it to cool, creating polycrystalline silicon with much more uniform electrical properties. This improved material quality helped stabilize the performance of silicon detectors.

During his experiments, Ohl accidentally discovered the p-n junction, which occurs when two differently doped regions (one p-type, one n-type) form a junction within a semiconductor. This junction created a new level of control over electrical conduction, leading to the development of the p-n junction diode, which could rectify current more reliably and efficiently than the earlier point-contact or cat’s-whisker detectors. Ohl identified the role of impurities in forming this junction and went on to hold four patents related to silicon detectors and the p-n junction, which became foundational in semiconductor technology [

28].

2.1.4.3. Bipolar Transistor

Lilienfeld invented the concept of the field-effect transistor (FET) in 1926 [

35]. Mervin Kelly at Bell Labs initiated a solid-state device group in 1936 foreseeing the limitations of vacuum tubes. Russell Ohl’s work on silicon crystals in the 1940s led to the understanding of n-type and p-type silicon.

The Transistor Invention era occurred in 1947. John Bardeen and Walter Brattain at Bell Laboratories invented the point-contact semiconductor amplifier (transistor action) which exhibited power gain [

36]. They discovered transistor action while investigating surface states in polycrystalline germanium which is also observed in polycrystalline silicon. Shortly after, William Shockley developed the theory of bipolar junction transistor in a creative burst, earning him the title of the father of Silicon Valley. However, Bill Shockley was not a co-patent holder on Bardeen and Brattain’s point-contact semiconductor amplifier patent since Julius Lilienfeld had already received a patent in 1930 for what would have been Shockley’s contribution; namely, the field-effect methodology. Shockley received patents for both his minority-carrier injection concept and junction transistor theory, however, and deservedly shared the Nobel prize with Bardeen and Brattain for his seminal contributions to injection, p-n junction theory, and junction transistor theory [

28].

In February 1948, John Shive demonstrated a correctly operating point-contact transistor with the emitter and collector placed on opposite sides of a very thin slice of germanium, indicating that conduction was taking place in the bulk. Point-contact transistors were unstable and had hard-to-control electrical characteristics. The first grown junction transistors were manufactured in 1952, although the production process was challenging. In the same year, the alloyed junction transistor was introduced with a simpler production process. In 1954, the first diffused germanium transistor with a characteristic "mesa" shape was reported, featuring a base width of 1 μm and a cut-off frequency of 500 MHz. That same year, Gordon Teal manufactured the first commercially available silicon devices (grown junction), marking a significant breakthrough for electronics. These transistors could amplify and switch electronic signals, paving the way for the development of modern electronic devices [

28].

2.1.4.4. Metal-Oxide-Semiconductor Field-Effect Transistor (MOSFET)

Julius Lilienfeld obtained patents for devices resembling today's MESFET (Metal Semiconductor Field-Effect Transistor) and MOSFET (Metal-Oxide-Semiconductor Field-Effect Transistor) in 1930 and 1933, respectively. Oskar Heil applied for a patent for his theoretical work on capacitive control in field-effect transistors in 1934. A group directed by M.M. Atalla worked on the problem of semiconductor surface passivation and found that a layer of silicon dioxide could be the answer. They developed a new concept of a field-effect transistor and manufactured the actual device [

37].

In 1963, Steven Hofstein and Fredric Heiman published a paper on a silicon MOSFET. In the same year, Frank Wanlass proposed the first CMOS circuit. The development of a poly-Si gate led to a self-aligned MOSFET device, where the gate itself constitutes the mask for source and drain diffusion. Reduction of device size led to short-channel effects, which were addressed by reducing the depth of source and drain, using a lightly doped drain, elevated source/drain, or Schottky barrier source/drain [

28].

2.1.4.5. The Integrated Circuit

In 1958, two engineers independently developed the integrated circuit (IC), a revolutionary electronic device that combined multiple transistors and other components on a single semiconductor chip. Jack Kilby at Texas Instruments sketched an oscillator circuit that formed in situ in a semiconductor substrate. He fabricated a working model and several logic circuits in the early fall of 1958 and his invention launched the entire field of modern microelectronics [

38].

Robert Noyce at Fairchild Semiconductor independently showed how to form interconnected transistors, diodes, resistors, capacitors, and other components on a single piece of silicon in 1958-59. Noyce co-invented the integrated circuit, the electronic heart of every modern computer automobile, cellular telephone, advanced weapon, and video games. He co-founded Fairchild Semiconductor and Intel and earned 16 patents in addition to the IC [

28].

The integrated circuit revolutionized electronics, allowing for tremendous advantages in power consumption, speed, reliability, cost, weight, and size compared to circuits made from discrete components. It launched the semiconductor industry, which has grown to over $250 billion in annual sales. The invention of the integrated circuit is considered one of the most important technological breakthroughs of the 20th century.

2.1.4.6. Semiconductor Laser

Semiconductors are crucial for the emission and detection of radiation. The first known phenomenon of light emission in semiconductor material was in 1907 by H. J. Round, with significant contributions from Losev. Semiconductor lasers were, in principle, invented around 1962 by four American research groups. Subsequent research focused on expanding the range of materials and developing new device structures [

28].

Herbert Kroemer and Zhores Alferov independently proposed using heterostructures for semiconductor lasers. Alferov, who contributed to the development of the first soviet p-n junction transistor in the same year 1953, understood the possibility of employing double heterostructures in these devices. He developed the first practical heterostructure laser and, along with Kroemer, was awarded the Nobel Prize in Physics in 2000 for advancements in semiconductor heterostructures. The use of quantum wells and new materials, particularly gallium nitride, has significantly advanced semiconductor laser technology [

28].

2.1.5. Advanced Devices

2.1.5.1. Tunnel Diode

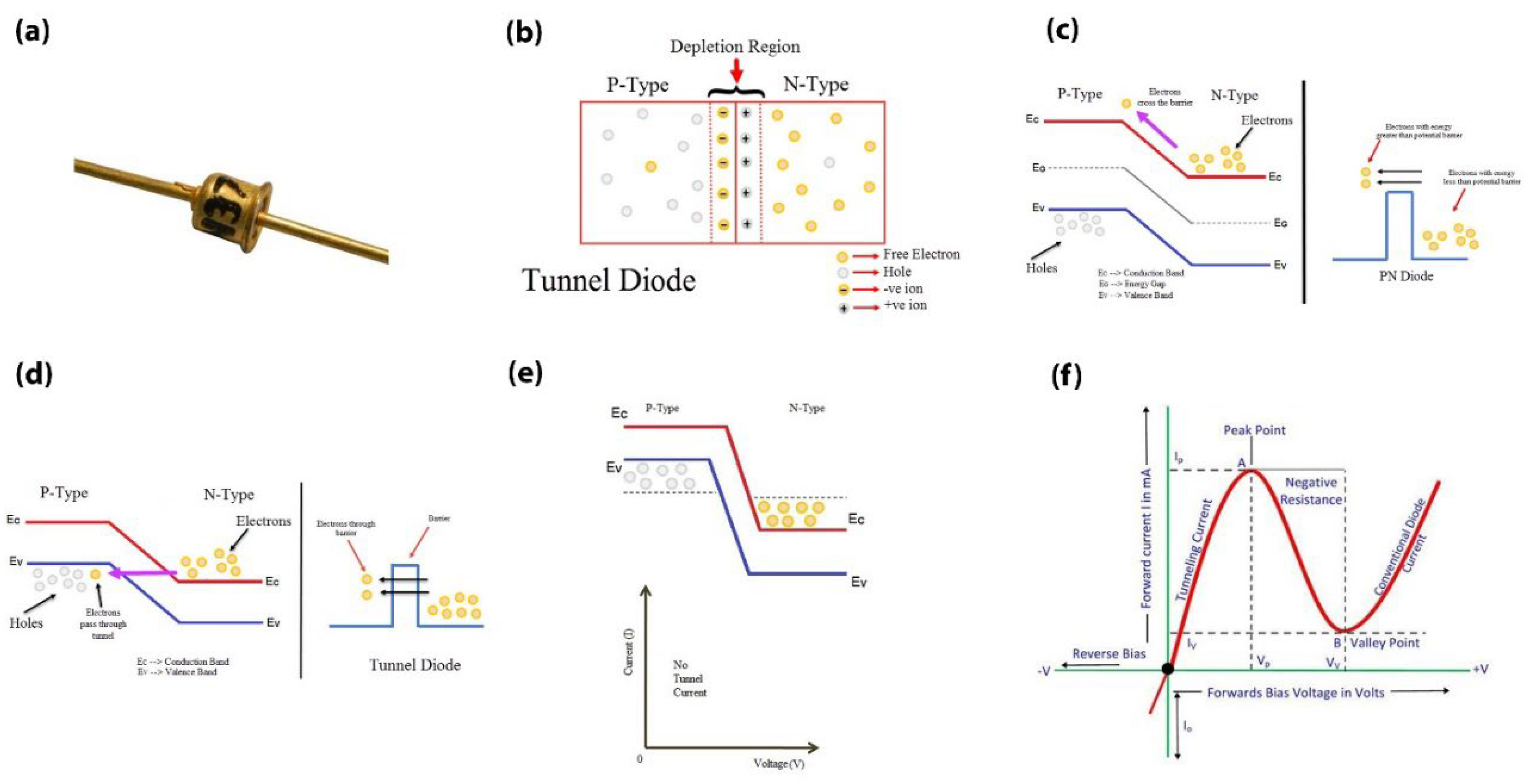

In 1957 Leo Esaki designed the first germanium tunnel diode, then a silicon tunnel diode in 1958 revealing electron tunneling in heavily doped p-n junctions (

Figure 2). Esaki was awarded the Nobel Prize in Physics in 1973 for his work, though Robert Noyce also claimed to have conceived the idea. The materials used for this diode are Germanium, Gallium arsenide, and other silicon materials.

Tunneling behavior stems from the tunneling effect which involves the movement of electrons through a thin depletion layer region (

Figure 2). In an unbiased tunnel diode, the conduction band of the n-region is coaxial with the valence band of the p-region thereby making it possible for electrons to tunnel in the absence of any voltage and thus making the flow of charge carriers balanced (

Figure 2) [

39]. When a small forward voltage is used, electrons in the n-region move in the p-region resulting in a forward current. As the voltage increases, the overlap between the bands grows, peaking at a certain point (Ip). Beyond this voltage, the current decreases, creating a region of negative resistance (See

Figure 2) [

39,

40]. The tunnel diode, known for its negative resistance due to quantum mechanical tunneling, operates at high speeds and is used in oscillators, amplifiers, and radio frequency (RF) applications [

41]. Recent research explores its use in terahertz frequency devices and superconducting spintronic devices, highlighting its versatility and significance in modern electronics [

42,

43,

44,

45].

Figure 2.

Analysis of Tunnel Diode Characteristics and Working Principles. (a) Physical appearance of a tunnel diode. (b) Schematic diagram showing the structure of a tunnel diode, including the depletion region between the P-type and N-type materials. (c) Illustration of the tunneling effect in a PN junction, showing electron movement across the energy bands. (d) Detailed depiction of the tunneling effect in a tunnel diode, highlighting electron and hole movement through the narrow depletion region, enabling quantum tunneling. (e) Energy band diagram of an unbiased tunnel diode, indicating the alignment of the conduction band and valence band in P-type and N-type materials, and the absence of tunneling current. (f) Current-voltage (I-V) characteristics of a tunnel diode, demonstrating the peak current (Ip), valley current (Iv), and the region of negative resistance, highlighting the distinct tunneling current, negative resistance region, and conventional diode behavior. [

41].

Figure 2.

Analysis of Tunnel Diode Characteristics and Working Principles. (a) Physical appearance of a tunnel diode. (b) Schematic diagram showing the structure of a tunnel diode, including the depletion region between the P-type and N-type materials. (c) Illustration of the tunneling effect in a PN junction, showing electron movement across the energy bands. (d) Detailed depiction of the tunneling effect in a tunnel diode, highlighting electron and hole movement through the narrow depletion region, enabling quantum tunneling. (e) Energy band diagram of an unbiased tunnel diode, indicating the alignment of the conduction band and valence band in P-type and N-type materials, and the absence of tunneling current. (f) Current-voltage (I-V) characteristics of a tunnel diode, demonstrating the peak current (Ip), valley current (Iv), and the region of negative resistance, highlighting the distinct tunneling current, negative resistance region, and conventional diode behavior. [

41].

2.1.5.2. Silicon-on-Insulator (SOI) MOSFET

Silicon-on-insulator (SOI) MOSFETs offer advantages such as reduced parasitic capacitances, improved device isolation, and reduced short-channel effects due to their structure of a thin silicon layer atop an insulating silicon dioxide (SiO

2) layer. Some of the issues that were discovered that limit their use include the deterioration of carrier mobility and the floating body effects [

46,

47]. Various extensions and modifications have been proposed to rectify these challenges [

48].

Quasi-SOI MOSFETs are a further improvement of SOI MOSFETs which incorporate the features of both SOI and bulk devices. In this structure, the source/drain regions are partially surrounded by an insulator, and the channel is connected to the bulk substrate. This design minimizes the short-channel effects, parasitic capacitances, and self-heating while maintaining effective heat dissipation. Quasi-SOI MOSFETs can be fabricated using epitaxial technology and thermal oxidation, and simulations show they have good scaling capability and can achieve high cut-off frequencies, up to 220 GHz for NMOS and 130 GHz for PMOS (P-type Metal-Oxide Semiconductor) at a 20 nm effective channel length [

49].

Localized-SOI MOSFETs include two variants: quasi-SOI MOSFETs and source-drain-on-nothing (SDON) / source-drain-on-insulator (SDOI) MOSFETs. The quasi-SOI structure is analogous to previously described designs, and the SDON/SDOI devices have recessed source/drain regions on partially buried layers. These structures maintain the advantages of quasi-SOI MOSFETs, such as reduced short-channel effects and parasitic capacitances, and are more compatible with standard CMOS (Complementary Metal-Oxide Semiconductor) fabrication processes, making them suitable for highly scaled devices [

49].

DSSB, Dopant-segregated Schottky Barrier SOI MOSFETs utilize the properties of both SOI and Schottky barrier devices, which include incorporating a thin layer of heavily doped material in the source-to-channel interface. This decreases the Schottky barrier height and increases on-state improvement. DSSB SOI MOSFETs have features like low short-channel effects (SCE), high scalability, and better analog/RF characteristics. However, optimizing the segregation layer density and length is crucial to balance trade-offs between leakage current, drive current, and variability [

49].

2.1.5.3. Multigate Transistors

Advanced structures of transistors, Multigate transistors, which include double gate, FinFET, and surrounding gate structures, significantly improve the electrostatic control and mitigate short-channel effects in metal-oxide-semiconductor field-effect transistors (MOSFETs). These devices, by employing multiple gates, enhance the control of the electric field within the channel, key for scaling down. FinFETs, with their three-dimensional structure and vertically positioned fins, possess better gate control compared to planar devices. Moreover, the double gate transistors lessen the short channel effects like Drain-Induced Barrier Lowering (DIBL), achieve better ON/OFF current ratios, and reduced subthreshold swings which are effective features in low-power devices (

Table 1) [

50,

51,

52,

53,

54].

Double Gate Transistors; These are the devices that have two gates to control the channel so that the channel can be independently biased, hence better electrostatic control. This configuration may improve the overall performance of both analog and digital applications, as confirmed and shown in various simulations [

55].

Fin Field-Effect Transistor (FinFET); FinFET technology is proven as a promising solution for sub-22 nm technology nodes. The FinFET's three-dimensional structure allows for a significant decrease in short-channel effects while achieving high drive currents (

Table 1). Research highlights that FinFETs are capable of providing superior electrical performance, making them ideal for high-frequency applications [

52,

56].

Gate-All-Around Transistor / Surrounding Gate Structures; These structures, such as Gate-All-Around (GAA) transistors, offer even better control compared to FinFETs by surrounding the channel on all sides. This design minimizes short-channel effects (SCE) and allows for further scaling of device dimensions without significant performance degradation (

Table 1) [

51,

57].

2.1.6. Other Advanced Devices

Heterostructure Field-Effect Transistors (HFETs), particularly those utilizing AlGaN/GaN materials, are recognized for their exceptional performance in high-frequency applications due to their high electron mobility and saturation velocity, which significantly surpass traditional MOSFETs [

58]. The AlGaN/GaN heterostructures are engineered to achieve high power and speed, making them ideal for applications in satellite communication and radar systems [

58]. Furthermore, these devices exhibit high breakdown voltages and low noise levels, which are critical for low-power and high-speed electronic applications. The integration of ferroelectric materials like BaTiO

3 into the gate structure of GaN-based high-electron-mobility transistors (HEMTs) significantly enhances their performance, efficiency, and reliability. The extreme permittivity of BaTiO

3 contributes to excellent electrostatic control, as evidenced by a high peak transconductance of 141 mS/mm and a large ON/OFF current ratio of 4.1 × 10

9, which are crucial for high-performance applications in power electronics [

59]. Additionally, the use of ferroelectric gate stacks, such as Hf

0.5Zr

0.5O

2, has shown improvements in RF switching applications, achieving low insertion loss and high isolation at mm-wave frequencies, which is essential for future wireless communication systems [

60,

61]. The combination of these materials not only optimizes energy efficiency but also addresses the limitations of traditional silicon-based devices, making GaN HEMTs a leading choice for advanced electronic devices in demanding environments [

61,

62].

Heterostructure Bipolar Transistors (HBTs) utilize emitter-base heterojunctions, which significantly enhance their performance compared to conventional bipolar junction transistors (BJTs). The incorporation of advanced materials, such as III-V compounds (e.g., GaAs and AlGaAs) and 2D materials (e.g., MoS

2 and WSe

2), allows HBTs to achieve high current amplification and improved electrical characteristics, making them suitable for high-frequency applications like wireless communication and power electronics [

63,

64]. HBT technology has evolved to address challenges such as lattice mismatch and interface quality, which are critical for maintaining device performance [

64,

65]. Additionally, innovations like strained silicon layers in the emitter region enhance carrier emission efficiency, further boosting current and frequency performance. Overall, HBTs demonstrate remarkable reliability and efficiency, positioning them as a preferred choice for demanding applications in modern electronics [

65].

Wide Bandgap Semiconductors, like Gallium Nitride and Silicon Carbide, have been accelerating an entirely new frontier of electronics wherein devices can be operated at higher power densities, voltages, and frequencies than conventional silicon-based technologies [

66,

67]. These materials have larger power density, high efficiency, and thermal stability, with high-voltage operation, making them very suitable for power electronics, renewable energy systems, and electric vehicles [

68,

69]. GaN, owing to superior electron mobility, offers high-frequency performance in RF amplifiers and power converters; on the other hand, SiC excels only in realms of high-power applications adjudged vital by thermal management, like power supplies and industrial motor drives [

69]. Wide bandgap semiconductors are finding applications in renewable energy, electric vehicles, and telecommunications, significantly impacting these industries by enabling more efficient, powerful, and compact electronic devices [

68,

69].

Resistive RAM (RRAM) is an advanced memory technology that employs semiconductor principles, using metal oxides like Titanium Oxide (TiO

x) as the switching layer. RRAM operates through resistive switching, where conductive filaments form and rupture within the oxide layer, enabling data storage [

70,

71]. Key advantages include non-volatility, high speed, low power consumption, and scalability. Recent advancements integrate RRAM with AI to boost performance and unleash forms of computing paradigms, such as neuromorphic computing [

72,

73]. Not being a conventional semiconductor device itself, RRAM exploits semiconductor materials and principles to achieve better memory performance.

Nanowire transistors are high-performance semiconductor devices that utilize quantum confinement effects to increase carrier mobility and electrostatic control while reducing power consumption and increasing switching speeds. Their vertical surround-gate architecture maximizes gate control while minimizing channel length, essential for maintaining performance as devices shrink. Nanowire transistors can perform multiple functions, such as in neuromorphic computing by controlling charge carriers in different regions. They also address thermal management challenges by optimizing thermal conductivity, crucial for sub-5 nm technology nodes. These innovations make nanowire transistors a significant advancement in semiconductor technology [

74,

75].

Resonant tunneling devices (RTDs) leverage quantum tunneling through a double-barrier quantum well structure, enabling them to achieve resonant peaks in their current-voltage characteristics, which facilitate operation at terahertz frequencies—far exceeding the capabilities of traditional transistors [

76]. This unique property allows RTDs to simplify circuit designs by reducing the number of components needed, thereby enhancing efficiency and lowering power consumption [

76]. Furthermore, RTDs can be integrated with other semiconductor technologies, such as heterostructure field-effect transistors (HFETs), to develop hybrid circuits tailored for ultra-high-speed applications [

77]. The exploration of both electron and magnon resonant tunneling further underscores the versatility of RTDs, opening new avenues for device applications in optoelectronics and logic circuits. Overall, the reliance on quantum mechanics in RTDs represents a significant leap forward in semiconductor technology, promising advancements in high-speed communication systems [

77].

2.2. Significance of Semiconductors (Technological, Economic, and Societal Impact)

Semiconductors are one of the core materials and form the backbone of modern electronic devices, which make a wide range of functionalities possible in contemporary technology. Their unique properties and versatility help to a great extent in different applications, ranging from consumer electronics to industrial systems. Key roles of semiconductors in electronics include:

Transistor Functionality; Semiconductors are the primary material used in making transistors, which act as the simplest and building blocks of every electronic circuit. Transistors can function as switches or amplifiers, controlling the flow of electrical current. Such functionality is so very essential to logic operations in a digital circuit and signal processing for microprocessors and memory devices [

78].

Integrated Circuits (ICs); Semiconductors have facilitated the miniaturization of electronic components by inventing integrated circuits. ICs integrate thousands to millions of transistors onto a single chip, thus allowing compact and efficient designs that power everything from smartphones to computers. It highly improves performance at reduced size and cost [

79].

Energy Efficiency; Modern semiconductors, more specifically wide-bandgap materials such as SiC and GaN, have been designed for high efficiency in power electronics. Such materials have superior voltage, frequency, and thermal tolerance compared to conventional silicon, hence having the potential for reduced energy losses and improved thermal management in applications like electric vehicles and renewable energy systems [

80,

81].

Optoelectronics; Semiconductors have an incredibly large role in optoelectronic devices. They are majorly used for the transformation of electrical signals into optical signals and vice versa. Such devices include light-emitting diodes, laser diodes, and photodetectors. The manipulation of light by semiconductor materials has changed display technology, telecommunications, and lighting solutions completely [

82,

83,

84].

Flexible and Organic Electronics; Advancements in organic semiconductors have led to the development of flexible electronic devices, such as organic light-emitting diodes (OLEDs) and organic photovoltaics. These materials allow for lightweight, bendable, and even wearable electronics, expanding the possibilities for consumer products and applications in health monitoring [

85,

86].

Sensors and IoT Devices; Semiconductors drive the development of sensors that detect physical phenomena, such as temperature, light, and motion. These inherently form a part of the Internet of Things, which enables smart devices to capture data and send them to improve areas like automation and connectivity in healthcare, agriculture, or smart cities [

82,

87,

88].

High-Speed Communication; Semiconductors have found use in different kinds of communication devices, including fiber optics and wireless networks, which have facilitated data transfer at higher speeds. Semiconductor lasers and photonic devices aid high-speed information transfer; this forms part of the internet structure and mobile communication [

82,

89].

The semiconductor industry is vital to the global economy, driving economic growth, job creation, and technological advancement [

90]. It supports various sectors, such as IT, telecommunications, and automotive, and has shown resilience during challenges like the COVID-19 pandemic [

91,

92]. Its role in international trade, particularly between major economies like the US and China, underscores its significance [

93]. The industry's innovation and adaptability are crucial for sustaining economic growth.

2.3. Focus on Semiconductor Sustainability

Many more sustainable materials are being considered for production within the semiconductor industry to decrease environmental impact and dependence on toxic compounds. Major examples of such attempts are the development of Kankyo-Semiconductors based on abundant and less toxic elements, such as silicon, iron, aluminum, calcium, and magnesium, in lieu of the traditional materials in optoelectronics. Additionally, there is a high demand for environmentally friendly solvents and components free from lead during the process of fabrication of perovskite solar cells to achieve devices with better performance while having a minimum detrimental impact on the environment [

94].

Alternative substrate materials for printed circuit boards (PCB), such as polyimide and paper-based substrates, along with lower-temperature solders, are also being explored to reduce the environmental impact of electronic products [

95]. Niobium-based semiconductor materials are being researched for their potential in the utilization of photocatalytic applications, such as solar fuel production, which can contribute to renewable energies and decrease dependency on fossil fuel sources [

96].

2.4. Bridging Historical Development and Emerging Trends

The evolution of semiconductor technology, from early point-contact rectifiers and p-n junctions to the widespread use of integrated circuits and transistors, has set the stage for the groundbreaking innovations we see today. Historical advancements provided the essential understanding of how materials like silicon and gallium arsenide behave under various conditions, leading to the development of modern semiconductor devices that power everything from consumer electronics to advanced computing systems.

The evolution of material doping and defect management has been pivotal in advancing technologies such as wide-bandgap semiconductors and quantum computing. Doping techniques have been refined to enhance the electronic properties of materials, as seen in ultra-wide band-gap nitrides where quantum engineering methods have significantly improved p-doping efficiency, facilitating the development of high-performance devices like deep-ultraviolet light-emitting diodes [

97]. Additionally, the design of defect-based qubits in materials like 4H-SiC and ww-AlN demonstrates how understanding defects can lead to promising candidates for quantum information technologies [

98]. The ability to visualize and manipulate defects at the atomic scale has further deepened our understanding of structure-property relationships, which is essential for optimizing devices such as MOSFETs [

99]. This comprehensive approach to defect management and doping is crucial for meeting the demands of modern electronics and sustaining Moore’s Law [

100,

101]. Furthermore, the exploration of quantum materials, which exhibit unique behaviors due to quantum interactions, has opened new avenues for device miniaturization and performance enhancement [

100,

102]. The identification of defects that can serve as qubits in quantum computing, such as the nitrogen-vacancy center in diamond, exemplifies the potential of these advancements. Additionally, the rise of two-dimensional materials like graphene showcases the ongoing innovation in semiconductor technology, driven by the principles established through historical research [

102].

As we transition into a future dominated by high-efficiency, high-power applications, the lessons learned from historical developments remain crucial. Today’s research into gallium nitride (GaN) and silicon carbide (SiC) for power electronics, as well as the exploration of quantum dots and nanowires, is directly informed by the material science and device physics established decades ago. These innovations represent a natural progression of semiconductor technology, continuing to build on the foundation of knowledge established during the industry's formative years.

Thus, the boundary between historical and emerging trends is not rigid but fluid, with historical advances forming the backbone of today’s cutting-edge research. Exploring the emerging trends in semiconductor technologies, focusing on how these developments are poised to address contemporary challenges in computing, energy, and sustainability are very essential.

3. Emerging Semiconductors

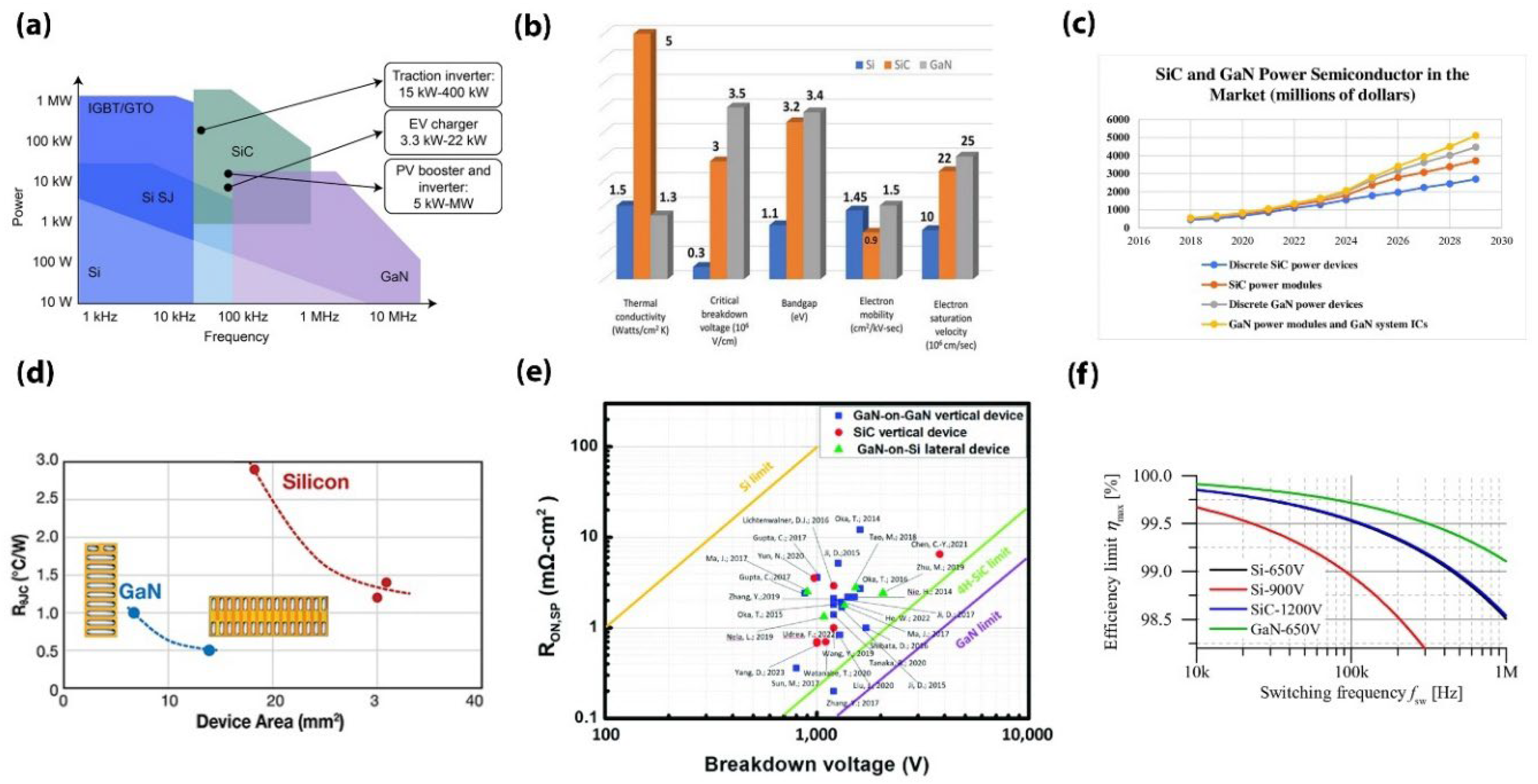

3.1. Wide-Bandgap Semiconductors

Wide-bandgap (WBG) semiconductors, especially silicon carbide (SiC) and gallium nitride (GaN), are emerging as third-generation semiconductor materials; they possess superior properties compared to conventional semiconductors like silicon [

103]. These materials have high saturated drift velocity and a high critical breakdown field (

Figure 3). These materials are also appropriate for high-power, high-temperature, and high-frequency applications (

Figure 4) [

103].

While both SiC and GaN have proven superior to silicon in high-power and high-frequency applications, the choice between them depends on specific industry needs.

Table 2 provides a comparison of SiC and GaN in terms of performance, cost, and fabrication complexity.

Silicon Carbide (SiC) and Gallium Nitride (GaN) each have distinct advantages that cater to different industry requirements. SiC is renowned for its high thermal conductivity and breakdown voltage (Table 2), making it particularly suitable for high-power applications such as electric vehicles and industrial power systems, where devices can operate at elevated temperatures and voltages without significant losses. In contrast, GaN excels in high-frequency applications, such as RF amplifiers, due to its superior electron mobility (Table 2), which allows for higher power densities and efficiency at microwave frequencies. Additionally, GaN's lower fabrication costs make it an attractive option for commercial applications. Thus, the choice between SiC and GaN ultimately hinges on the specific performance requirements and cost considerations of the intended application.

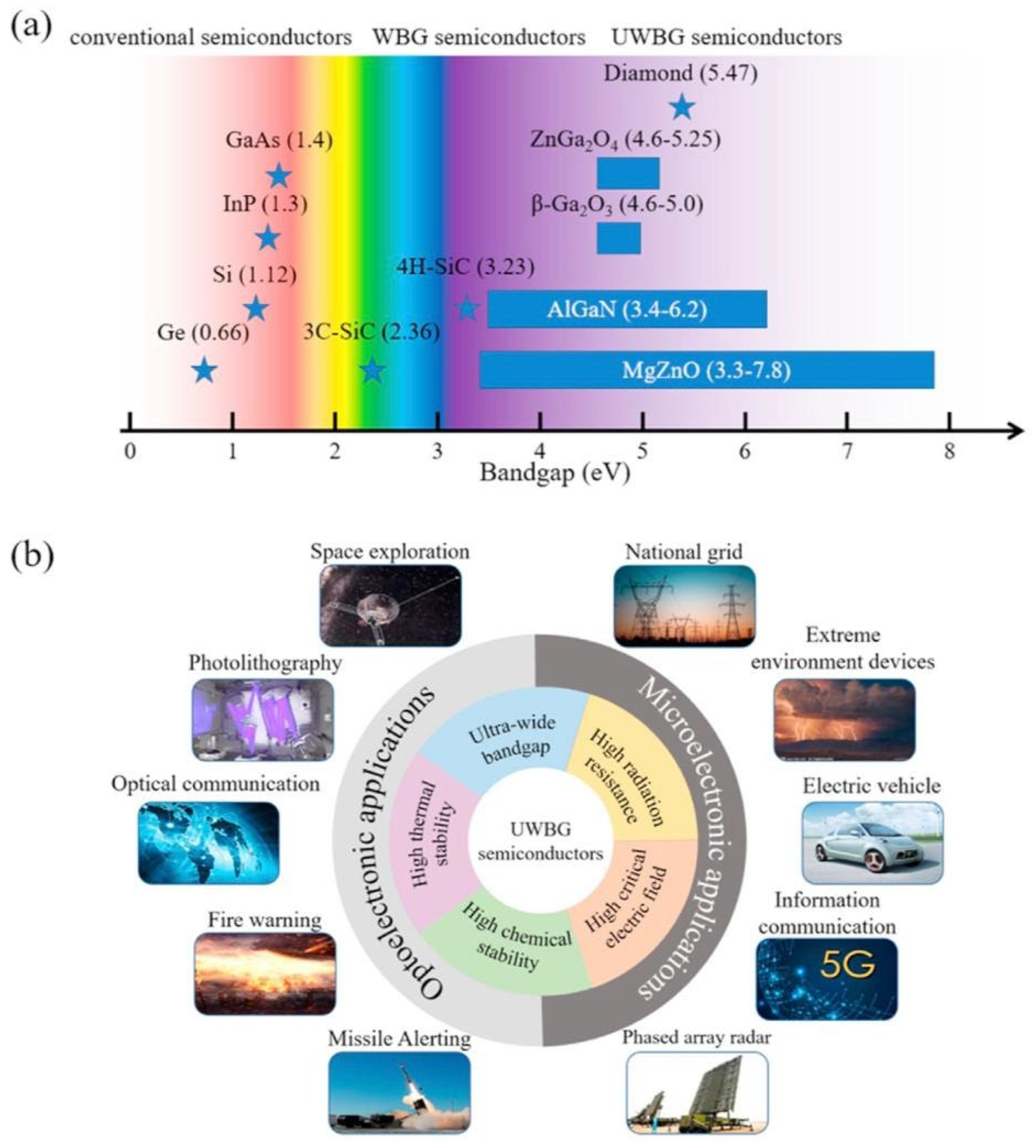

Recent research has also focused on ultrawide bandgap (UWBG) semiconductors, which have bandgaps wider than 3.4eV of GaN, including high Al-content AlGaN, diamond, and Ga

2O

3 [

104]. Recent advancements in ultrawide bandgap (UWBG) semiconductors have garnered significant attention due to their potential applications in high-power and RF electronics, deep-UV optoelectronics, quantum information, and extreme-environment scenarios. These materials, characterized by bandgaps exceeding 3.4 eV, offer superior performance metrics, including enhanced thermal stability and efficiency in power-switching applications, as highlighted in various studies [

105,

106]. However, challenges remain, particularly in achieving bipolar electrical conductivity and managing defects, which are critical for their practical implementation [

107]. The systematic analysis of these materials underscores their advantages, such as improved efficiency and operational capabilities, while also addressing the manufacturing hurdles that need to be overcome for widespread adoption in power electronics [

24]. Furthermore, UWBG semiconductors are being explored for innovative applications in ultraviolet photodetectors, enhancing their utility across diverse fields [

108]. Ongoing research aims to address challenges and advance the state-of-the-art in WBG and UWBG semiconductor technologies.

Figure 3.

Wide-bandgap Semiconductors analysis; (a) Comparing various semiconductor devices over power and frequency, highlighting the advantages of SiC and GaN over conventional silicon devices [

109]. (b) Key differences between Si, SiC and GaN materials [

110]. (c) Comparison of SiC and GaN devices in the market [

111]. (d) Heat dissipation capabilities of GaN devices compared to SiC and Si, emphasizing the thermal advantages of GaN [

112]. (e) Benchmarking vertical GaN devices against lateral GaN MOSFET devices and vertical SiC devices, illustrating the comparative performance metrics.[

113]. (f) Fundamental efficiency limits of Si, SiC, and GaN technologies in bidirectional DC/DC converters, demonstrating the superior efficiency of SiC and GaN [

114].

Figure 3.

Wide-bandgap Semiconductors analysis; (a) Comparing various semiconductor devices over power and frequency, highlighting the advantages of SiC and GaN over conventional silicon devices [

109]. (b) Key differences between Si, SiC and GaN materials [

110]. (c) Comparison of SiC and GaN devices in the market [

111]. (d) Heat dissipation capabilities of GaN devices compared to SiC and Si, emphasizing the thermal advantages of GaN [

112]. (e) Benchmarking vertical GaN devices against lateral GaN MOSFET devices and vertical SiC devices, illustrating the comparative performance metrics.[

113]. (f) Fundamental efficiency limits of Si, SiC, and GaN technologies in bidirectional DC/DC converters, demonstrating the superior efficiency of SiC and GaN [

114].

Figure 4.

(a) Bandgap energies of various semiconductors. (b) Characteristics and applications of UWBG semiconductor materials. [

83].

Figure 4.

(a) Bandgap energies of various semiconductors. (b) Characteristics and applications of UWBG semiconductor materials. [

83].

3.2. Quantum Dot Semiconductors

Quantum dot semiconductors are nanomaterials that have special electronic and optical properties attributed to their size-dependent quantum effects. These semiconductor nanostructures confine excitons in three spatial dimensions, exhibiting discrete energy levels akin to atoms [

115]. Quantum dots have been endeavored in a wide range of applications, like photoelectrochemistry sensors, with simple, fast, and miniaturized solutions for analyte detection [

116]. One of the factors that makes this class so attractive for organic photoredox transformations is the tunability of its redox properties [

117].

Initially cadmium-based, quantum dots have evolved to include alternative materials with reduced toxicity such as germanium, silicon, and carbon, while retaining unique photonic properties in drug development and delivery [

118]. A small change in one of the parameters, like size or shape, will alter the electronic and optical properties of quantum dots, therefore making them tuneable for desired applications that range from optoelectronics to biomedical diagnostics.

3.3.2. D Materials

Two-dimensional (2D) materials, such as Transition Metal Dichalcogenides (TMDCs), graphene, and black phosphorus, have emerged as promising semiconductors for electronic and optoelectronic applications due to their unique properties like atomic thickness, excellent electronic structure, and high mobility [

119,

120,

121,

122,

123,

124]. These materials adhere to other substances through van der Waals interactions, enabling compatibility with different material platforms for on-chip light sources and photodetectors, potentially offering a universal on-chip light source scheme for Photonic Integrated Circuits (PICs) [

121].

2D semiconductors have several advantages in ultra-thin devices with atomic scale thicknesses and allow the creation of nanoribbons and heterostructures [

125]. These materials have a highly tunable bandgap, which may be engineered with controlling layer numbers, strain engineering, chemical doping, and external electric fields, thus offering an alternative for applications that lie within various spectral regions from terahertz to ultraviolet [

126]. Engineering atomic-scale defects in TMDCs can enhance carrier transport and improve future electronic technologies, pointing out the need for understanding electron-defect interactions of these materials [

127].

Even though the performance is high and energy-efficient, several challenges remain to be overcome in terms of stability, material quality, dielectric integration, contact formation, and preparation methods before 2D semiconductor materials find large-scale production and application [

120]. Ongoing research focuses on improving growth techniques, understanding charge carrier scattering mechanisms, and addressing short-channel effects to realize the full potential of 2D semiconductors in future electronic devices [

124,

125]. With such challenges being surmounted, prospects presented by 2D materials in revolutionizing semiconductor technology are very high, and their potential to foster advancements in the development of high-performance and energy-efficient electronic and optoelectronic devices is at its inception stage.

3.4. Organic Semiconductors

Organic semiconductors, primarily composed of carbon-hydrogen bonds, exhibit semiconductor behavior and can be doped to create N- and P-type materials, enabling the construction of devices like organic light-emitting diodes (OLEDs), organic field-effect transistors (OFETs), and organic solar cells [

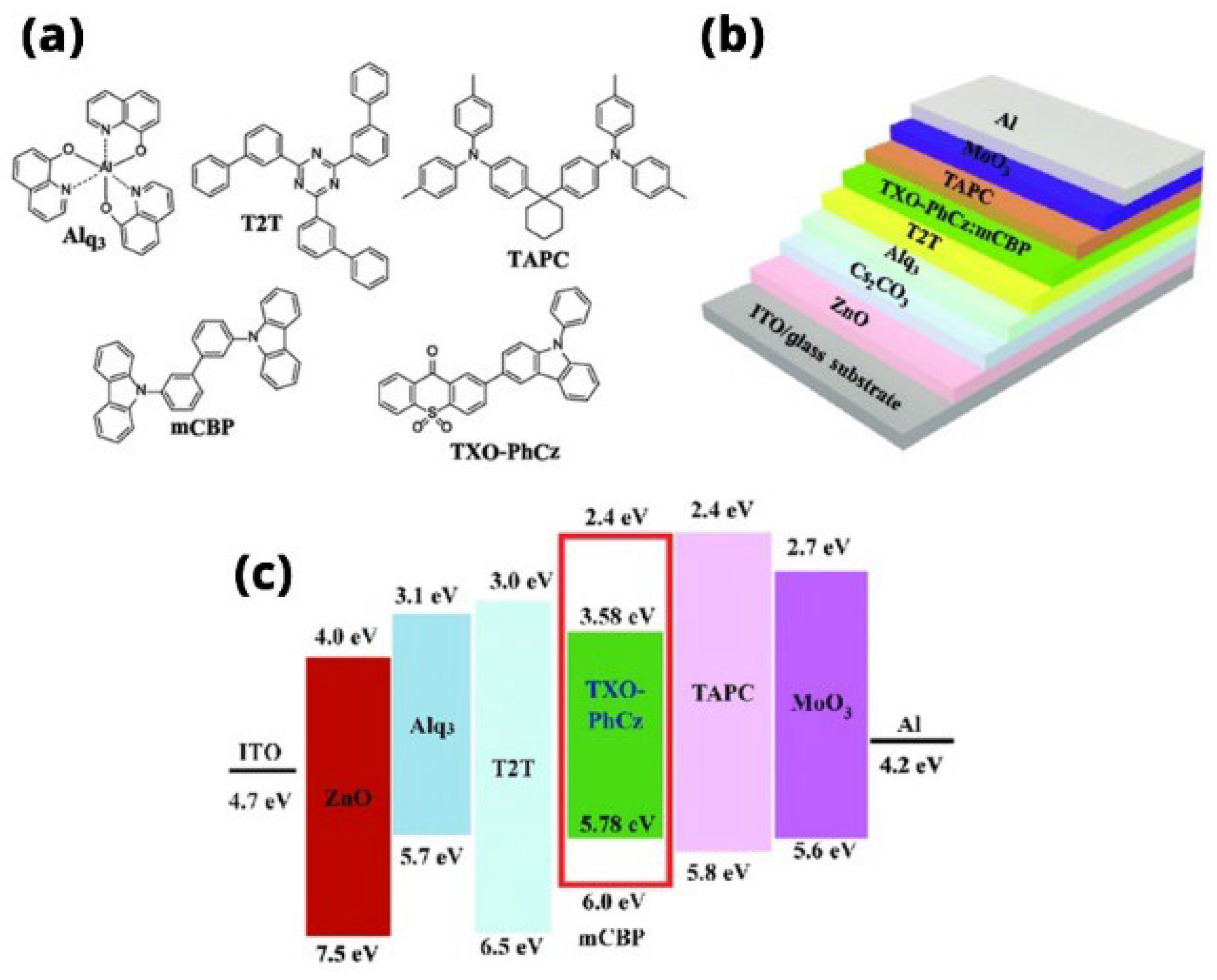

128]. These materials are made up of π-bonded molecules or polymers, often including heteroatoms like nitrogen, sulfur, and oxygen, and can exist as molecular crystals or amorphous thin films (

Figure 5). They typically behave as insulators but become semiconducting upon charge injection, doping, or photoexcitation. They hold a large bandgap and a low dielectric constant [

129].

The carrier mobility of organic semiconductors is influenced by factors such as energy, morphology, and solvent choice, impacting crystallinity and molecular ordering. Techniques like cyclic voltammetry and ultraviolet electron spectroscopy are essential for understanding charge transport mechanisms [

130]. Single-crystal organic semiconductors are recognized as central to high-performance devices attributed to unique optoelectronic properties because of weak van der Waals interactions [

131]. Hyperbranched polymers (HBPs) are also notable for regulating charge transport and film morphology [

132].

Figure 5.

Organic Semiconductors; (a) Molecular structures of the organic semiconductors for the inverted OLEDs; (b) scheme of the inverted OLEDs; and (c) the energy levels of the materials involved in the inverted OLEDs [

133].

Figure 5.

Organic Semiconductors; (a) Molecular structures of the organic semiconductors for the inverted OLEDs; (b) scheme of the inverted OLEDs; and (c) the energy levels of the materials involved in the inverted OLEDs [

133].

Techniques to fabricate organic semiconductors include vacuum deposition, solution processing, and self-assembly, with methods such as spin-coating and inkjet printing enabling the realization of flexible/wearable electronics [

134]. Applications include OLEDs, organic photovoltaic cells, OFETs, and biosensing devices. Organic semiconductors have some very attractive features associated with them, relating to mechanical flexibility, low cost, and ease of fabrication that make them very attractive in a wide range of electronic and optoelectronic applications [

129].

3.5. Perovskite Semiconductors

Perovskite semiconductors, with their remarkable optoelectronic properties and versatile applications, have emerged as a promising class of materials, particularly in photovoltaics and other optoelectronic devices [

135]. Characterized by a general formula of ABX

3, with A and B as cations and X as an anion, usually a halide or oxygen, these materials have high optical absorption, high carrier mobility, long diffusion lengths, and unique ambipolar charge transport properties [

136,

137].

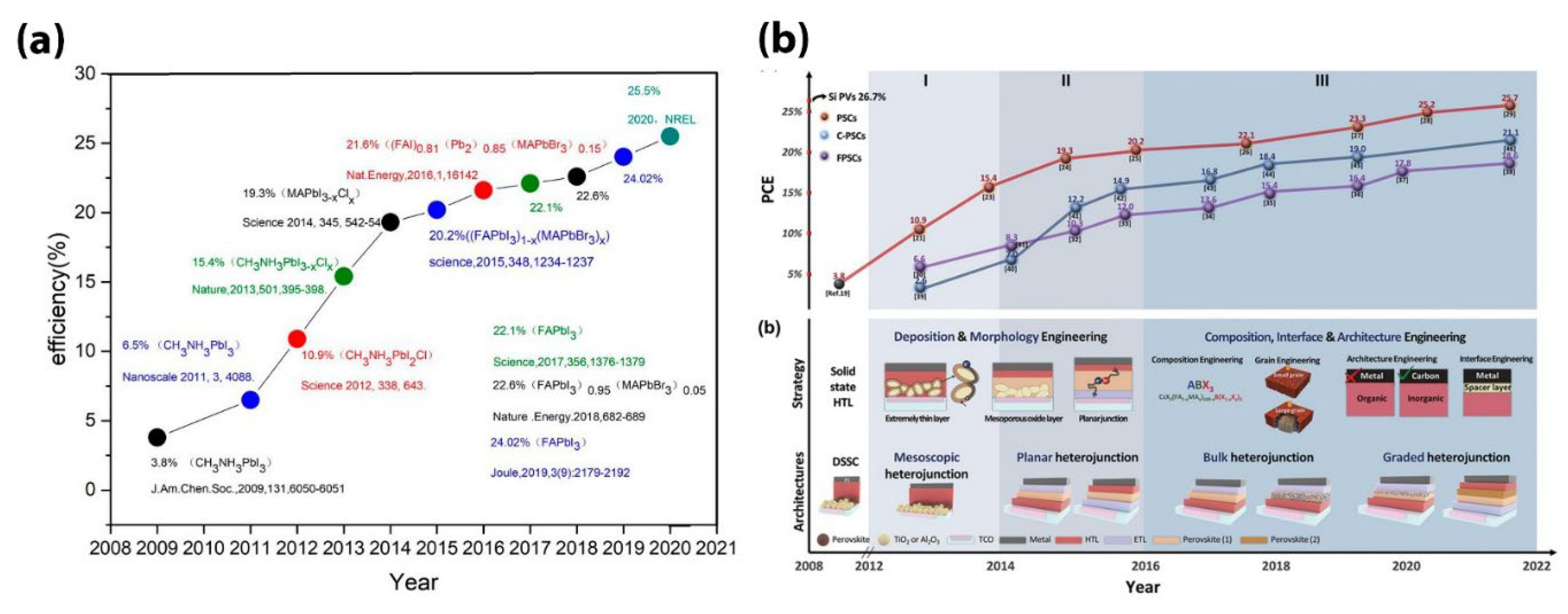

Perovskite solar cells have seen rapid advancements (

Figure 6), achieving power conversion efficiencies exceeding 25% in just over a decade [

138]. Their excellent photophysical properties and solution-processability have also led to applications in light-emitting diodes, photodetectors, lasers, and X-ray scintillators [

138]. The ability to tailor perovskite properties by manipulating their crystal structure, size, and composition has further enhanced their functionalities, making them valuable in applications like photocatalysis and radiation detection [

139]. In the domain of radiation detectors, lead halide perovskites like CsPbBr

3 demonstrated high efficiency in X-ray and gamma-ray detection and thus can be an important material for imaging applications [

140].

Figure 6.

Perovskite Semiconductors; (a) The evolution of the efficiency of perovskite solar cells (PSCs) from 2008 to 2020 [

141]. (b) Chronological evolution of the PCE of perovskite solar cells (PSCs), C-PSCs, and FPSCs and a brief history of schematics for fabrication strategies and device architectures in PSCs (HTL: hole-transport layer, ETL: electron-transport layer, TCO: transparent conductive oxides, PV: photovoltaic) [

142].

Figure 6.

Perovskite Semiconductors; (a) The evolution of the efficiency of perovskite solar cells (PSCs) from 2008 to 2020 [

141]. (b) Chronological evolution of the PCE of perovskite solar cells (PSCs), C-PSCs, and FPSCs and a brief history of schematics for fabrication strategies and device architectures in PSCs (HTL: hole-transport layer, ETL: electron-transport layer, TCO: transparent conductive oxides, PV: photovoltaic) [

142].

Despite their rapid progress, perovskites face challenges in stability, reproducibility, and toxicity. Issues such as ionic transport can introduce defects and degrade performance, necessitating strategies to mitigate these challenges [

143]. Understanding the fundamental chemistry and physics of perovskites is essential for addressing these issues and guiding future developments [

135].

Environmental concerns have heightened interest in finding alternatives to lead-based perovskites. Research is still focused on developing the stability, efficiency, and scalability of perovskite-based technologies. The incorporation of PbS quantum dots into perovskite matrices, for instance, enables sub-bandgap photocurrent generation; this could fundamentally open up prospects for overcoming traditional efficiency limits in solar cells [

144]. As the field progresses, the development of stable, high-performance perovskite devices holds great promise for revolutionizing optoelectronics and renewable energy technologies.

3.6. Hybrid Semiconductors

In particular, hybrid semiconductor materials that have gained much attention today are porous metal halide semiconductors and organic-inorganic hybrid semiconductors, owing to their great properties and potential applications. PMHS spanned by the Spanopoulos group [

145] reveal excellent water stability and broadband light emission, which makes them very promising for solid-state batteries and photonic crystals. On the other hand, organic-inorganic hybrid semiconductors, such as the ones explored by Yawen Li et al. [

146] in their paper, exhibit specific optoelectronic properties and thermodynamic stability that enable next-generation optoelectronic applications. Such hybrid materials take advantage of the assets of both organic and inorganic components in terms of tailored properties and functionalities, making them very promising for several technological innovations related to, among others, electronics, photonics, and energy storage technologies [

147,

148,

149].

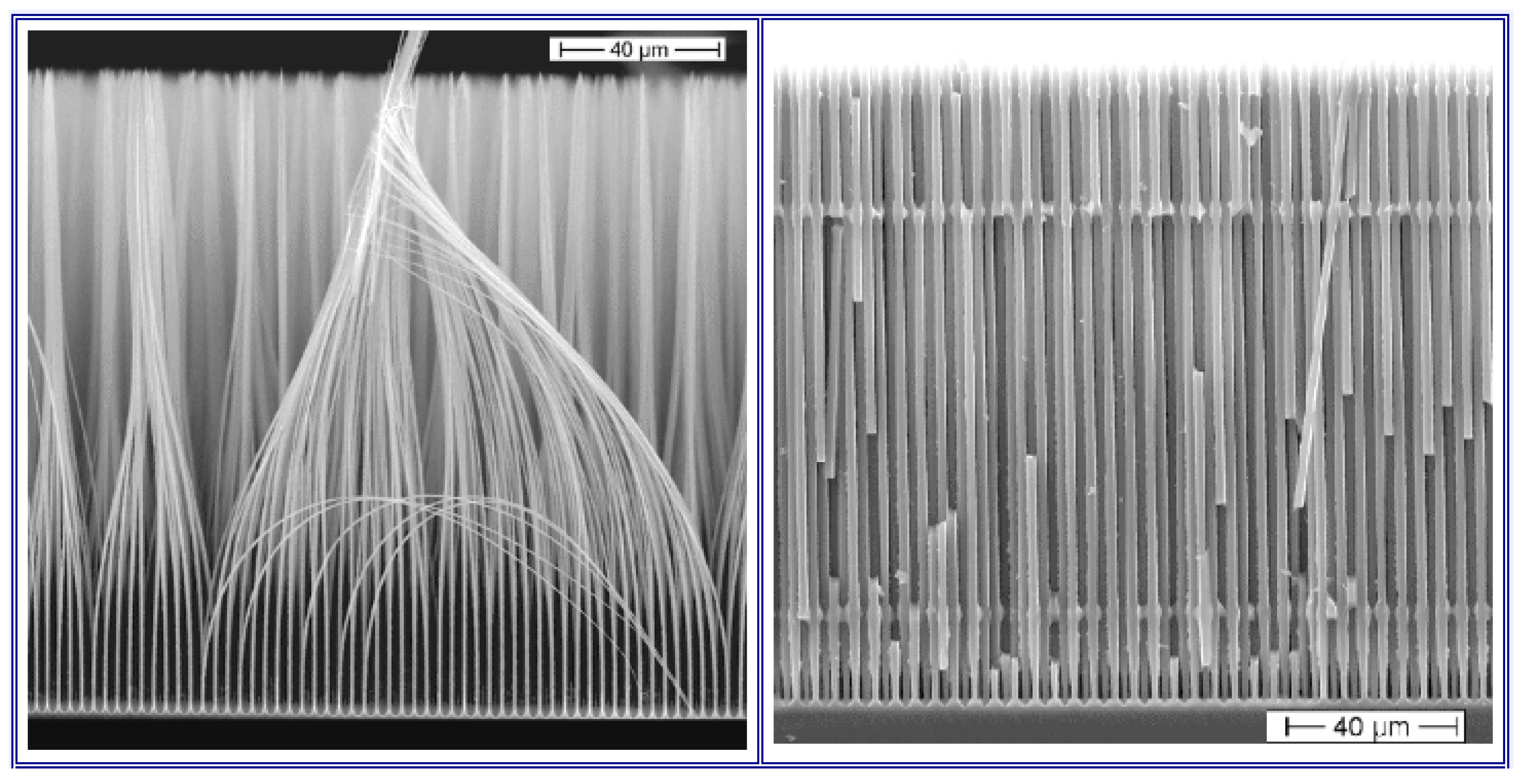

3.7. Porous Semiconductors

Porous semiconductors have garnered significant research attention attributed to their unique properties due to their porous structure (

Figure 7) and potential applications. Some key properties include increased surface area [

150], quantum confinement effects, reduced thermal conductivity [

151], improved luminescence [

150] and enhanced photoconductivity, second harmonic generation, and THz emission [

150]. Studies have focused on creating controlled porous structures in various semiconductor compounds, leading to advancements in fields such as optoelectronics and photocatalysis [

152,

153,

154,

155]. These porous materials exhibit diverse morphologies and topologies, impacting their physical characteristics like luminescence, optical properties, and hydrophobicity or hydrophilicity. The use of porous silicon as a template for filling with other materials has shown promise in altering its electrophysical parameters, making it versatile for display technologies. Additionally, the incorporation of halogens into organic porous semiconductors has been explored for enhancing photocatalytic performance, highlighting the importance of composition and electronic nature in achieving efficient energy conversion.

Porous semiconductors are typically fabricated by electrochemical etching techniques (

Figure 7). For example, microporous silicon can easily be produced by running current through a silicon anode in an electrochemical cell under the right conditions [

151]. Other semiconductors like II-Vs, II-Vis, and SiC can also be made porous using similar electrochemical dissolution methods [

150].

Porous semiconductors have a wide variety of potential applications, including energy storage [

151], optoelectronics [

150], sensing, and thermoelectric [

151]. Porous (metal)-organic semiconductors are being explored as alternatives to silicon with tunable structures for various applications [

156]. However, most porous semiconductor applications are still at the research stage and not yet commercialized [

151]. Ongoing research aims to further understand and optimize their unique properties for practical applications.

Figure 7.

Si "nanowires" made via electrochemical pore etching [

151].

Figure 7.

Si "nanowires" made via electrochemical pore etching [

151].

4. Semiconductor Manufacturing and Emerging Technologies

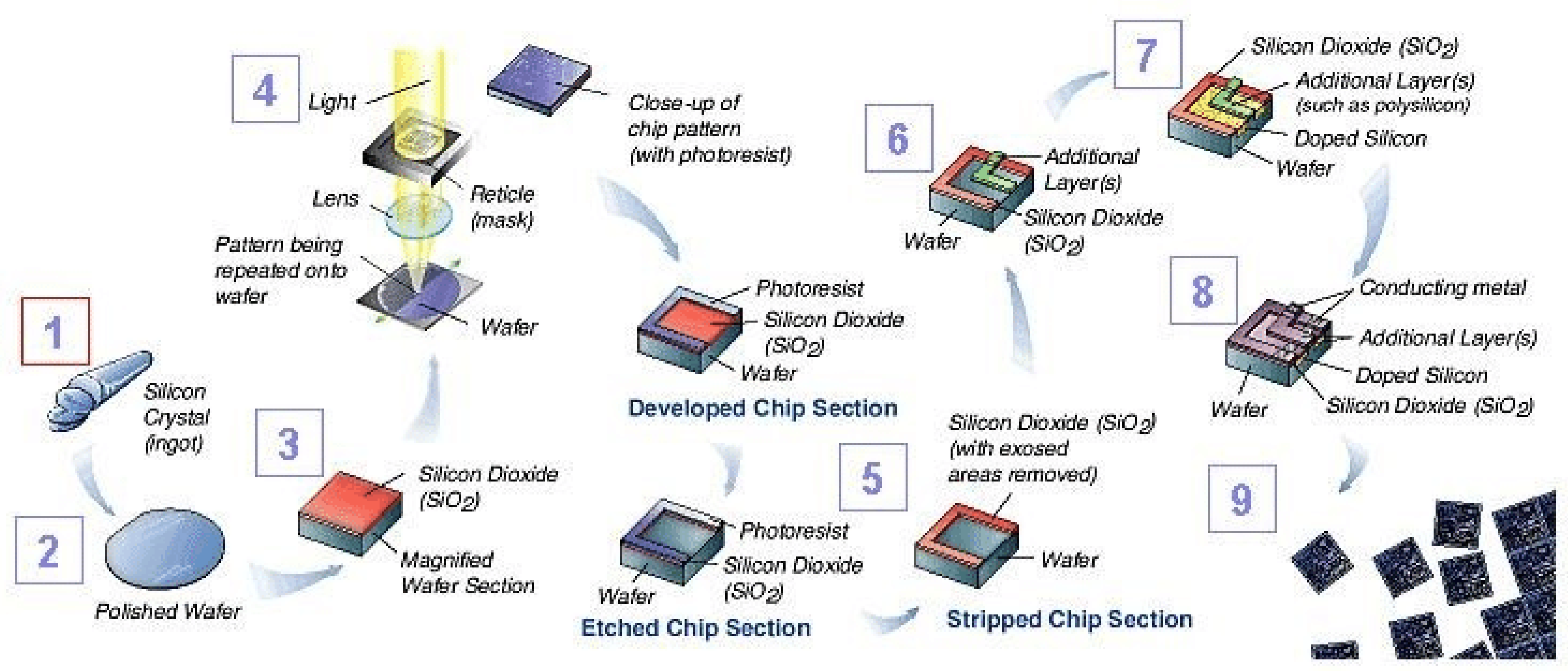

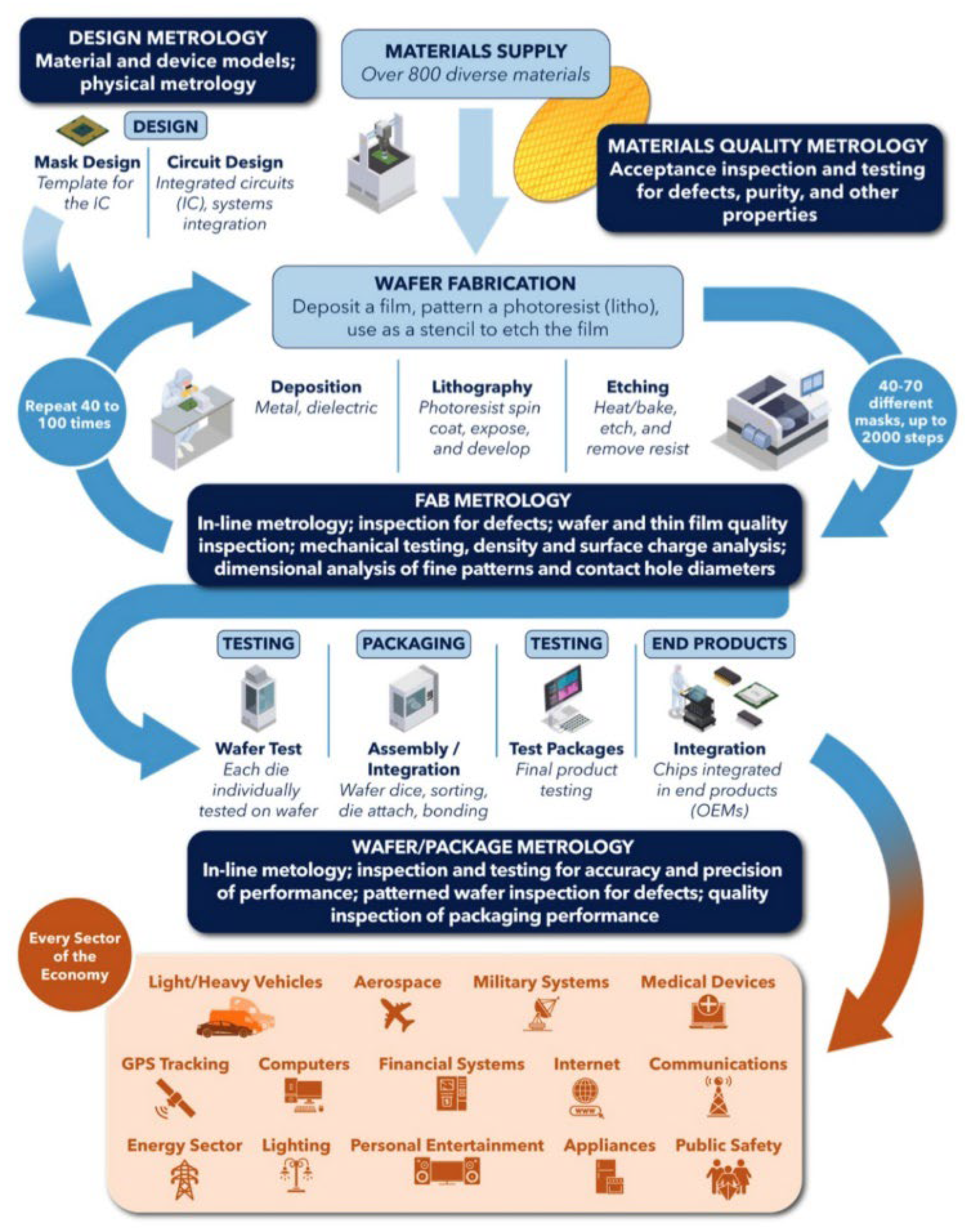

Semiconductor manufacturing involves crucial processes like wafer fabrication, doping, lithography, etching, and deposition (

Figure 8) [

157,

158]. Various doping methods, such as ion implantation and diffusion, alter the electrical properties of semiconductors significantly. Lithography is essential for patterning at the nanometer scale, while etching allows for defining structures on the semiconductor surface. Deposition is a very vital process in adding thin films to the semiconductor substrate. Some of the new techniques that are evolving in the semiconductor manufacturing process include the use of plasma etching technology in flattening surfaces, as well as terminating the deposition of thin films at desired positions [

157]. Additionally, advancements in semiconductor manufacturing involve addressing uncertainties and disturbances through control schemes like run-to-run control based on discrete active disturbance rejection control, which effectively suppresses disturbances and uncertainties in the manufacturing process [

159]. These processes collectively contribute to the intricate and precise production of semiconductor devices in modern manufacturing environments [

160].

4.1. Semiconductor Manufacturing Process

4.1.1. Wafer Fabrication

The foundation of semiconductor devices begins with wafer fabrication. First, a single crystal ingot like pure silicon is pulled and sliced into thin wafers. The wafers are polished to create a smooth surface. To analyze the defects such as stress fields in the crystal lattice, the wafer undergoes thermal treatments in which a radial temperature gradient acts on the wafer. This preparation is important because even minor defects will result in flaws in the final product. The wafers serve as the substrate for subsequent processing steps [

161,

162].

4.1.2. Doping

Doping is an essential process in semiconductor processing/manufacturing since it defines the electronic features of this material. Several methods are implemented to introduce impurities into semiconductor materials. These processes can change the resistivity, mobility, energy band gap, and light absorption coefficients [

163]. Doping refers to introducing certain impurities into the wafer to alter its electrical properties. It can be done through a process of thermal diffusion or by ion implantation. Doping allows the creation of n-type and p-type semiconductors; this aspect is very important in forming p-n junctions that are basic to transistor operations [

164].

Figure 8.

Semiconductor Manufacturing Process Flowchart [

165]. This figure illustrates the key steps involved in the fabrication of integrated circuits using photolithography. Starting from a polished silicon wafer, it shows the application of silicon dioxide (SiO₂) layers, the deposition of photoresist, and exposure to light through a patterned reticle mask. The process highlights how light is used to transfer the mask pattern onto the wafer, leading to the development of etched sections that form the foundation for semiconductor chips. The final steps involve adding additional conducting and insulating layers to create the desired circuit patterns. This detailed visual serves as a guide to understanding the photolithography sequence, a core technique in semiconductor manufacturing.

Figure 8.

Semiconductor Manufacturing Process Flowchart [

165]. This figure illustrates the key steps involved in the fabrication of integrated circuits using photolithography. Starting from a polished silicon wafer, it shows the application of silicon dioxide (SiO₂) layers, the deposition of photoresist, and exposure to light through a patterned reticle mask. The process highlights how light is used to transfer the mask pattern onto the wafer, leading to the development of etched sections that form the foundation for semiconductor chips. The final steps involve adding additional conducting and insulating layers to create the desired circuit patterns. This detailed visual serves as a guide to understanding the photolithography sequence, a core technique in semiconductor manufacturing.

4.1.3. Thermal Oxidation

The thermal oxidation step in semiconductor manufacturing processes is a fundamental process for the creation of silicon dioxide layers on silicon wafers; these are integral components in most electronic devices [

166,

167]. This process helps in creating gate dielectrics, which are vital for the proper functioning of transistors and other semiconductor devices [

167]. Optimized gas flow rate, oxidation time, and temperature in the thermal oxidation process guarantee that high-quality oxide layers are formed with the necessary thickness, which relates to semiconductor device performance and reliability [

166]. Besides, it aids in reducing stress on wafers, enhances IC yield, and improves the quality of semiconductor products as a whole [

168,

169]. The precise control and optimization of the thermal oxidation process are essential for achieving high-quality semiconductor devices with optimal performance characteristics. Thermal oxidation essentially involves the step of heating semiconductors on silicon wafers in an environment rich in oxygen at temperatures usually within the range of 800°C to 1200°C. It is within this temperature limit that the oxygen molecules diffuse into the silicon substrate and react to form silicon dioxide. There are two major techniques of thermal oxidation: Dry Oxidation and Wet Oxidation. Dry oxidation uses pure oxygen, and the oxide layer is thinner with higher quality (Si + O

2 → SiO

2).

They are characterized by slow growth, high density, and high breakdown voltage. Wet oxidation involves the use of steam, which may grow thicker oxide layers more quickly but of lesser quality compared with dry oxidation. Fast growth even at low temperatures is their characteristic feature and they permit thicker oxides [

170].

4.1.4. Lithography

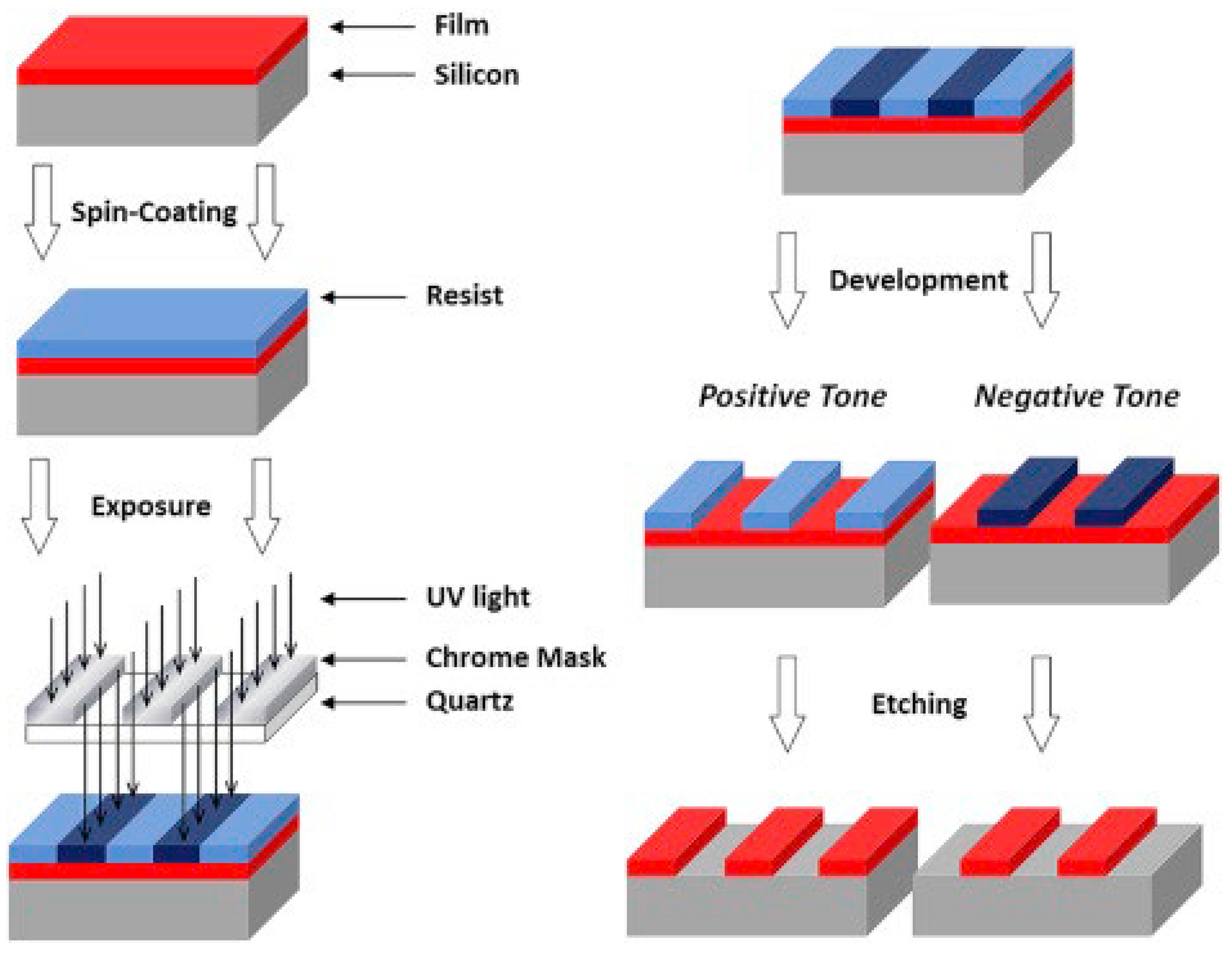

Lithography is one of the most important patterning techniques in defining the geometric shapes of semiconductor devices on a substrate. After preparing the wafer, its surface is coated with a photoresist, a light-sensitive material that changes the chemical properties of the wafer to make it suitable for circuit printing [

171]. There are two main types of photoresists based on their ultraviolet light (UV) reactivity: positive and negative. The positive photoresist becomes soluble upon exposure to UV light, and the exposed resist gets dissolved, leaving the unexposed resist remaining. On the other side, negative photoresists harden when exposed to UV light. Positive photoresist is more widely applied in the semiconductor manufacturing process due to its better thermal stability and resolution capability (

Figure 9) [

161].

The various steps in the photolithography process include the application of a layer of photoresist, coating with an adhesion promoter, pre and post-baking, light exposure, and finally the development of the exposed material. A photosensitive substance known as "photoresist" is applied to the wafer. Afterward, the photoresist-coated wafer is pre-baked from 90 to 120°C to fix the binding of the photoresist and evaporate the extra photoresist solvent. Then the photoresist is exposed to a pattern of intense light following the prebake. In optical lithography, UV light is commonly used. A post-exposure bake is conducted at 60 - 120°C to fix the pattern before development. Afterward, a developer is applied to the photoresist layer. The substance can be such that it is able to dissolve either the irradiated or non-irradiated photoresist [

172].

Photolithography refers to the process of drawing a circuit design onto a wafer. This is the step where the wafer is introduced to the photolithographic equipment and exposed to UV light. This light draws the pattern from the mask, containing the blueprint of the circuit, onto the wafer coated with a photoresist film. Using light, photolithography transfers a geometric pattern from a photomask onto the photoresist applied to a substrate. Variants of lithography include e-beam lithography, which uses a focused beam of electrons to create extremely fine patterns for small-scale devices, and extreme ultraviolet lithography (EUV), which uses EUV light to achieve smaller feature sizes essential for advanced semiconductor nodes. Refraction and defects can occur in the lithography process, which is why robust quality control is necessary. This is a critical step in defining the layout of electronic components, as well as creating complex patterns on the surface of the wafer [

161,

173].

Figure 9.

The lithography and etching process [

174]. This figure illustrates the photolithography steps in semiconductor device fabrication. A silicon wafer is coated with a photoresist layer and exposed to UV light through a mask. In positive-tone resists, the exposed areas are dissolved during development, while negative-tone resists harden. The process concludes with etching, where unwanted material is removed to create precise patterns on the wafer surface. This figure highlights the differences between positive and negative resists and the role of etching in defining geometric shapes.

Figure 9.

The lithography and etching process [

174]. This figure illustrates the photolithography steps in semiconductor device fabrication. A silicon wafer is coated with a photoresist layer and exposed to UV light through a mask. In positive-tone resists, the exposed areas are dissolved during development, while negative-tone resists harden. The process concludes with etching, where unwanted material is removed to create precise patterns on the wafer surface. This figure highlights the differences between positive and negative resists and the role of etching in defining geometric shapes.

4.1.5. Etching

After printing the circuit diagram on the wafer through lithography, the etching process follows to remove excess materials from the surface, creating the desired patterns (

Figure 9). The two main primary types of etching include wet and dry etching. Wet etching involves chemical solutions that mostly dissolve material equally in all directions and are less precise. Dry etching, also known as plasma etching, uses ionized gases to remove the material and thus provides better resolution and anisotropy, which results in highly defined structures [

161,

162,

173].

Emerging techniques like atomic layer etching (ALE) and cryogenic etching are critical in advanced semiconductor manufacturing. ALE provides atomic-level precision by alternating between etching and passivation steps, while cryogenic etching, performed at very low temperatures, enables the creation of high-aspect-ratio features with smooth sidewalls. These methods are of vital importance in advanced semiconductor devices. Semiconductors often require repeating the photolithography and etching processes several times on all layers of the wafer to achieve the final product; hence, precision is required, and close process control is necessary to prevent damage to the chip structure. Various methods in semiconductor processing, such as using atomized droplets with etching solutions at high temperatures, curing photoresists to reduce consumption, conducting multiple etch cycles with gas and purge gas introductions, and employing specific gas mixtures for plasma processing, aim to achieve precise and controlled material removal, enhancing efficiency and reducing costs [

175,

176].

4.1.6. Deposition

Deposition involves adding thin films of materials onto the semiconductor substrate to form layers necessary for device functionality. Various techniques are used in this process including Chemical Vapor Deposition (CVD), Physical Vapor Deposition (PVD) and Atomic Layer Deposition. In chemical vapor deposition, chemical reactions in a vapor phase deposit materials onto the substrate. Variants of CVD include low-pressure CVD (LPCVD) and plasma-enhanced CVD (PECVD). Physical vapor deposition (PVD), which involves physical processes like sputtering or evaporation, is widely used for depositing metals. Another method, atomic layer deposition (ALD), deposits materials one atomic layer at a time, providing excellent control over thickness and uniformity. These deposited films serve multiple purposes, such as forming insulating layers, conducting paths, or active components like transistors [

161,

162,

173].

4.1.7. Assembly and Packaging

The semiconductor manufacturing process (

Figure 8,

Figure 10) is intricate and can span up to 26 weeks from design to production, culminating in the dicing of wafers into individual chips and their subsequent bonding onto substrates. This final stage is critical as it involves separating the chips, which is often achieved through methods like laser stealth dicing, followed by grinding and thinning to ensure precision and quality. The packaging of these chips serves multiple essential functions: it protects against mechanical damage, provides barriers against moisture and chemical contaminants, and ensures robust electrical connections through strong leads. Materials such as plastic and ceramic are commonly used to create protective layers that encapsulate the chips, safeguarding the electrical circuits from potential damage due to heat or physical stress. Ultimately, these processes ensure that the semiconductor chips are reliable and ready for integration into electronic devices.

Figure 10.

A comprehensive overview of the semiconductor fabrication process, detailing the steps from materials supply and wafer fabrication to testing and integration. The diagram highlights the critical role of metrology in ensuring quality and precision at each stage, from design through to end products utilized across various sectors of the economy [

177].

Figure 10.

A comprehensive overview of the semiconductor fabrication process, detailing the steps from materials supply and wafer fabrication to testing and integration. The diagram highlights the critical role of metrology in ensuring quality and precision at each stage, from design through to end products utilized across various sectors of the economy [

177].

The semiconductor manufacturing process involves other steps, like testing and inspecting chips [

178]. Among the most common problems that create issues for manufacturers are:

Product Quality; The difficulty in ensuring quality products can arise as semiconductor products become more sophisticated and their demand increases. Defects; There are several steps from assembling to testing that can lead to defects in the products. These defects can hardly be noticed considering the size of each chip and the number of its layers.

Cost; The cost associated with the semiconductor manufacturing process continues to rise, with new technologies coming out and shortages occurring that make it harder for manufacturers to break even in revenue.

Equipment; Advances within the industry will require manufacturers to keep pace with new equipment and technologies, which can be a struggle and an added cost. Time; Even minor production faults render hundreds of chips useless, and there is almost always a challenge of minimizing the downtime in case of quality compromise and delay [

161].

4.2. Emerging Techniques in Semiconductor Manufacturing

As the semiconductor industry evolves, several emerging techniques are gaining traction. Such Techniques include Extreme Ultraviolet Lithography (EUV), Atomic Layer Deposition (ALD), 3D Integration, Quantum Dots and Nanowires.

Extreme Ultraviolet Lithography (EUV); The technique under modern lithography uses shorter wavelengths of light to create smaller features on chips, underlying more powerful, more efficient devices on the market. Compared to conventional optical lithography, this technique uses a shorter wavelength of light, 13.5 nm. This allows for smaller features to be carried on chips, enabling the production of devices that are more powerful and efficient. EUV lithography has the potential to overcome the limitations of optical lithography, which is getting to the end of its resolution, and to make it possible to manufacture features in the sub-10 nm scale. [

179].