Submitted:

12 September 2024

Posted:

12 September 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Taxel Design

2.3. Ink Formulation and Coating Process

2.4. Mechanical Characterization

2.5. Electrical Measurements

2.6. Ink Characterization

2.7. Electronics Test on the Skin Device

3. Results

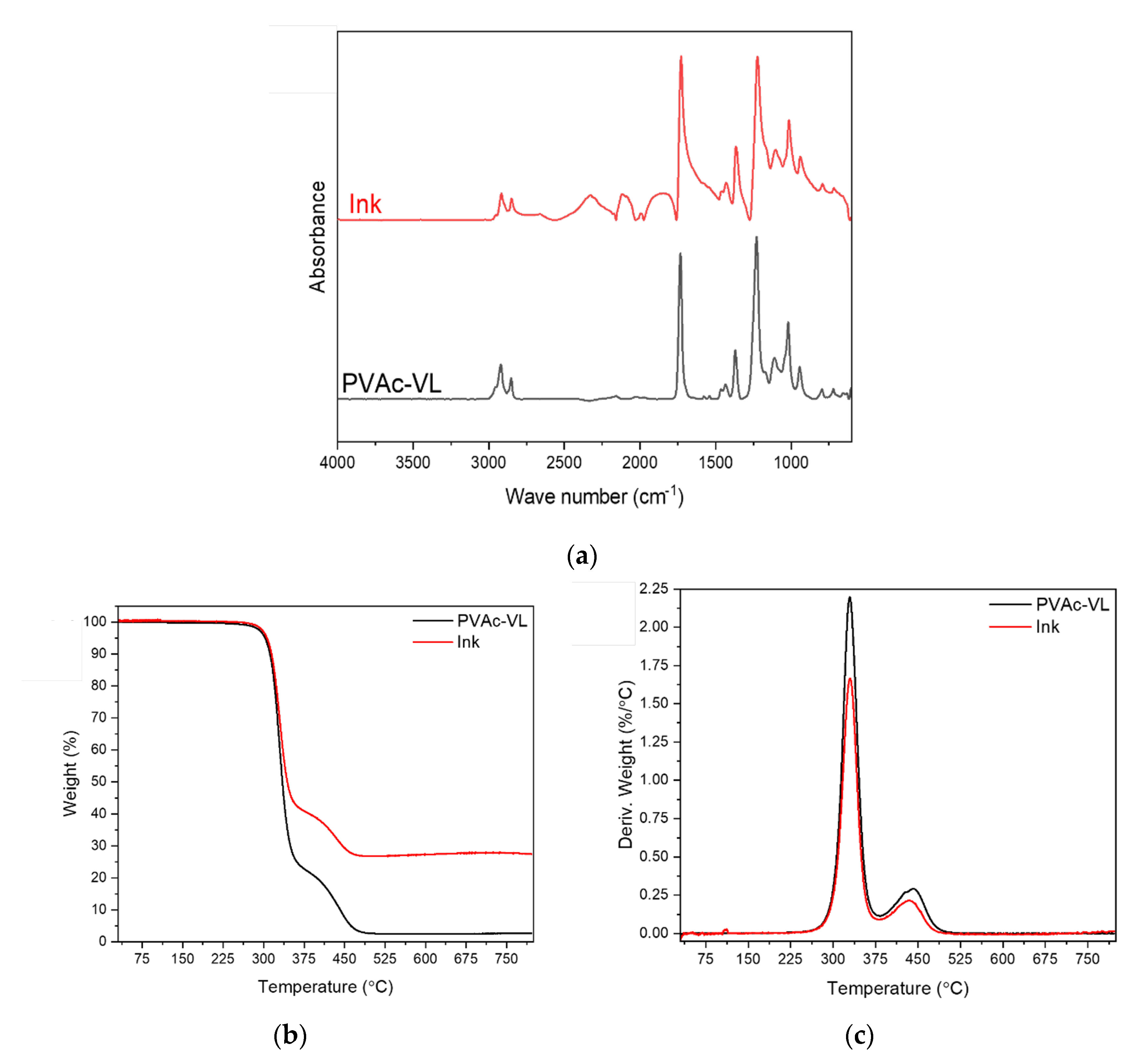

3.1. Characterization of the Ink

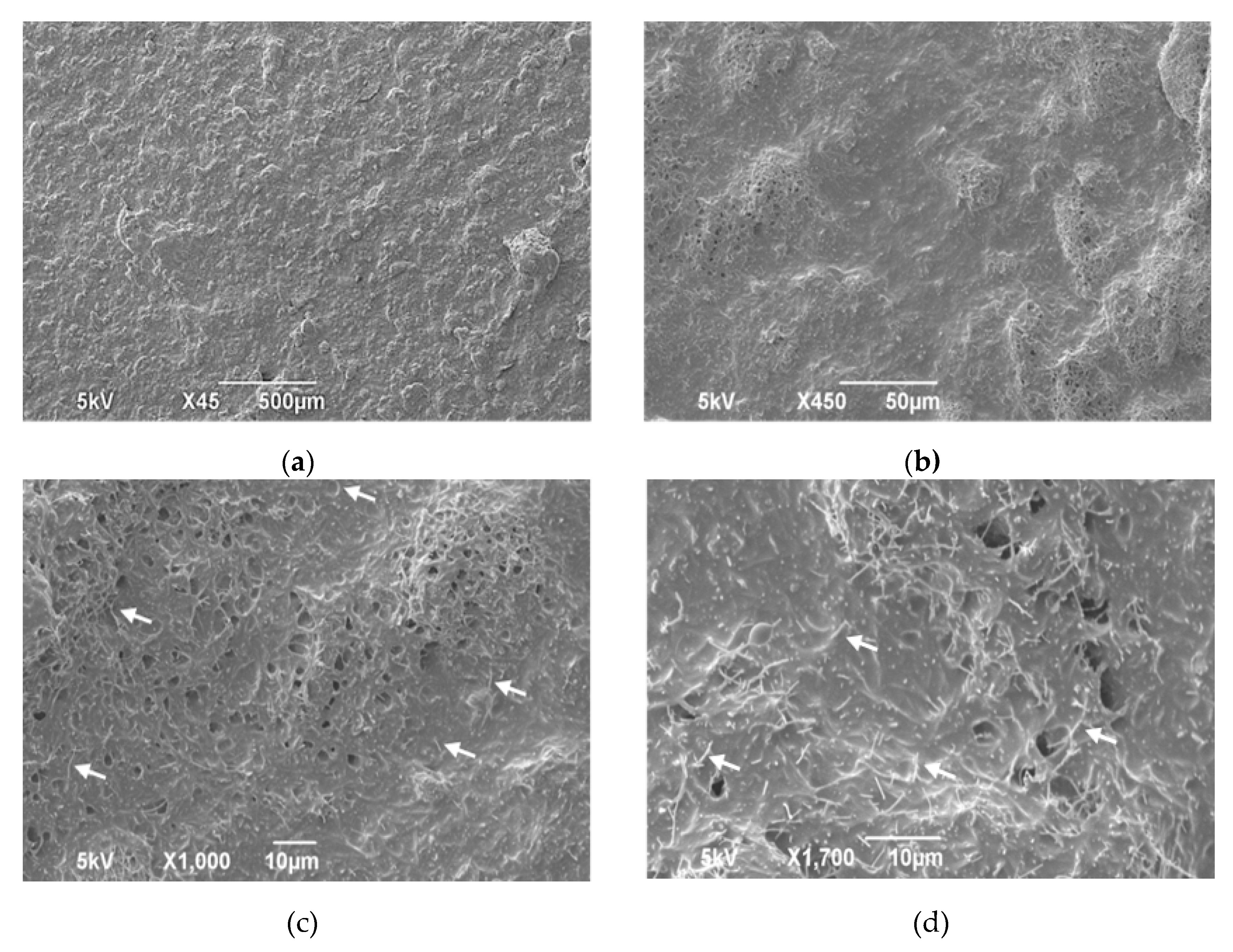

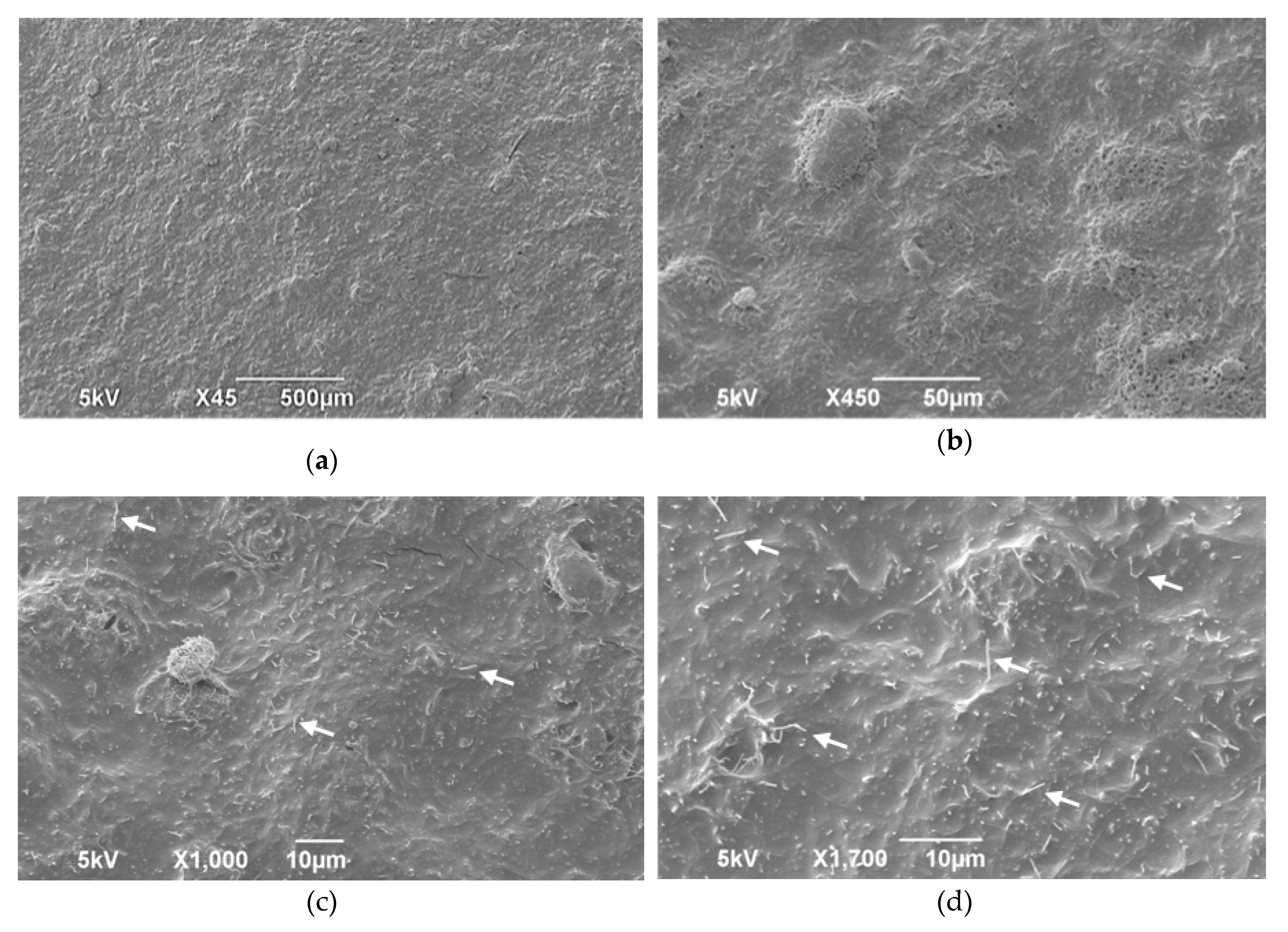

3.2. Surface Morphology before Compression and Stretch-Release Cycles

3.3. Electrical Response under Mechanical Testing

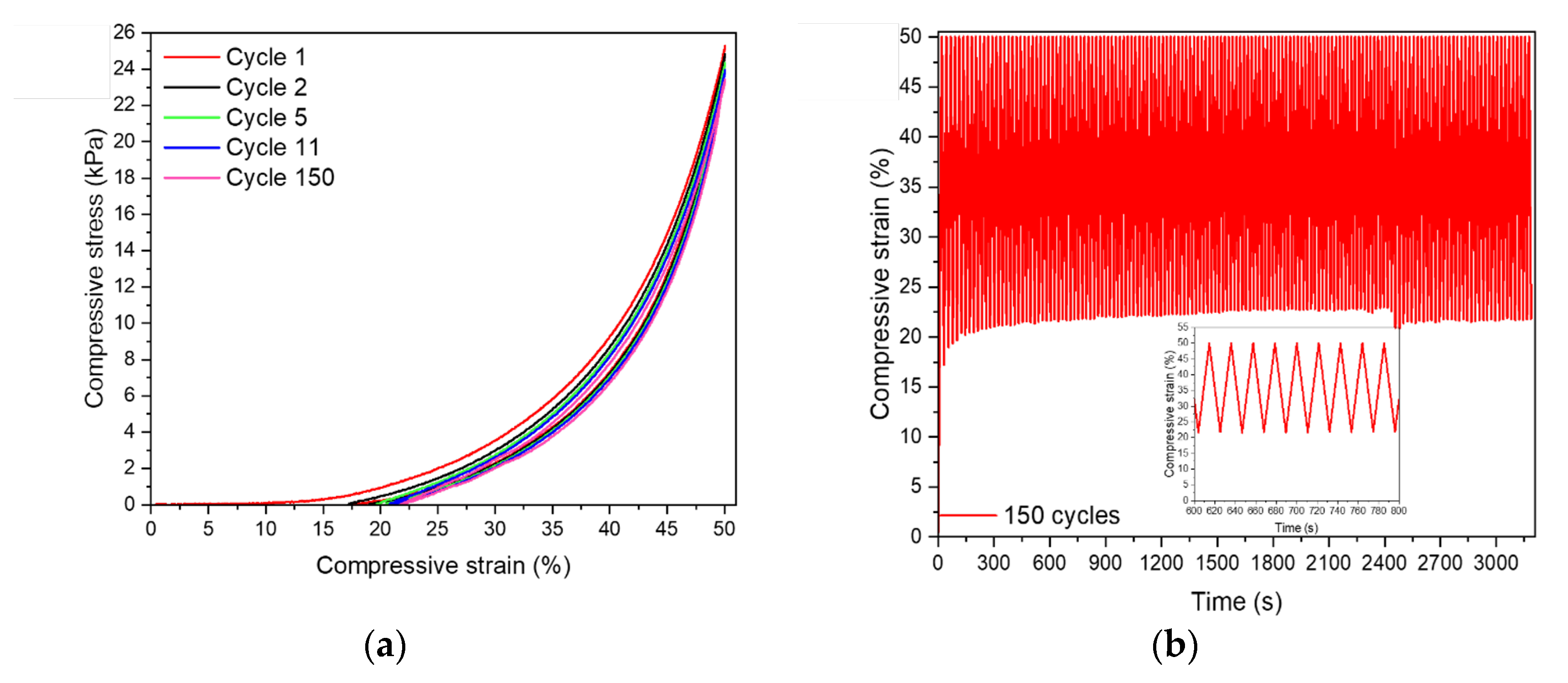

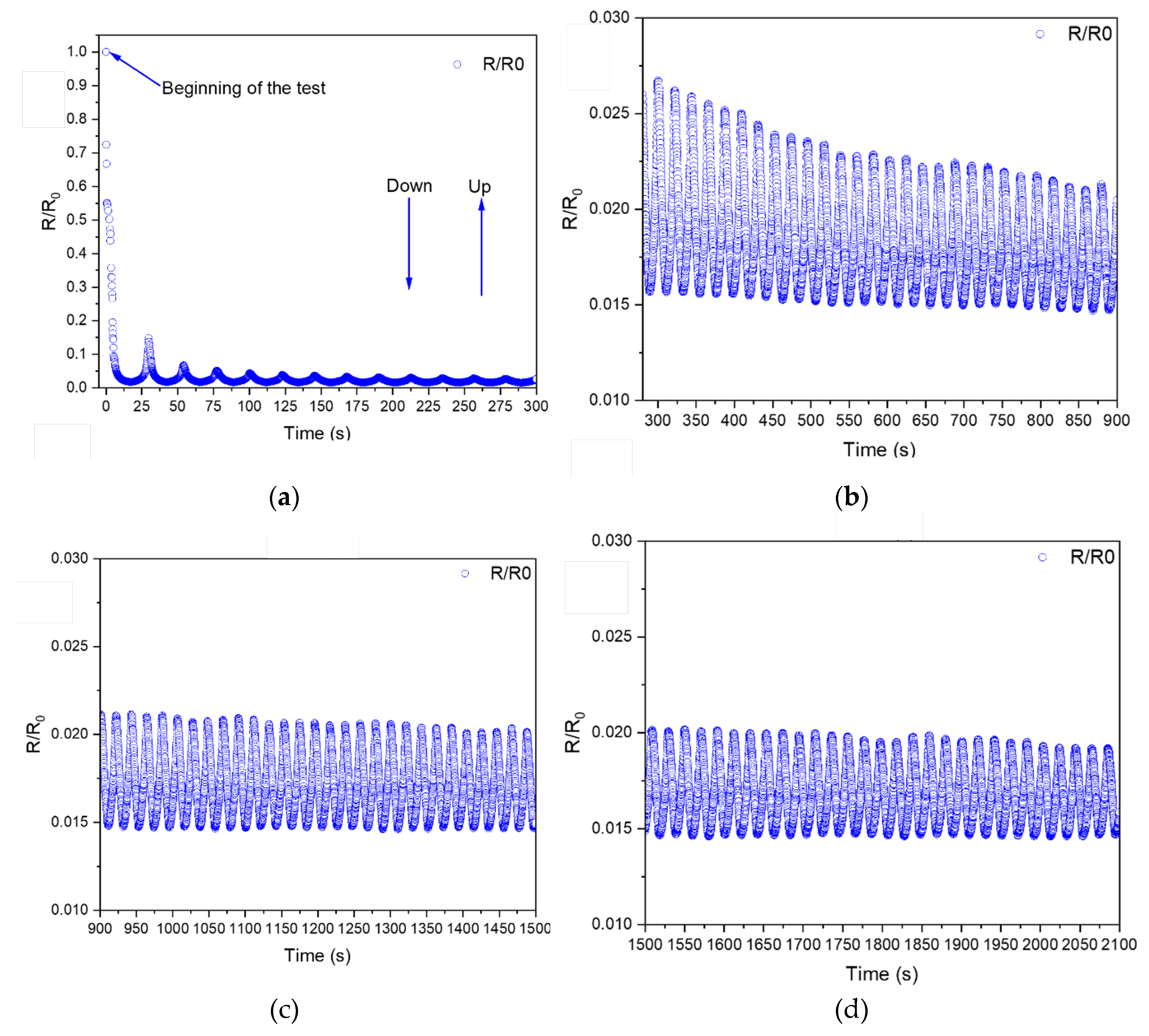

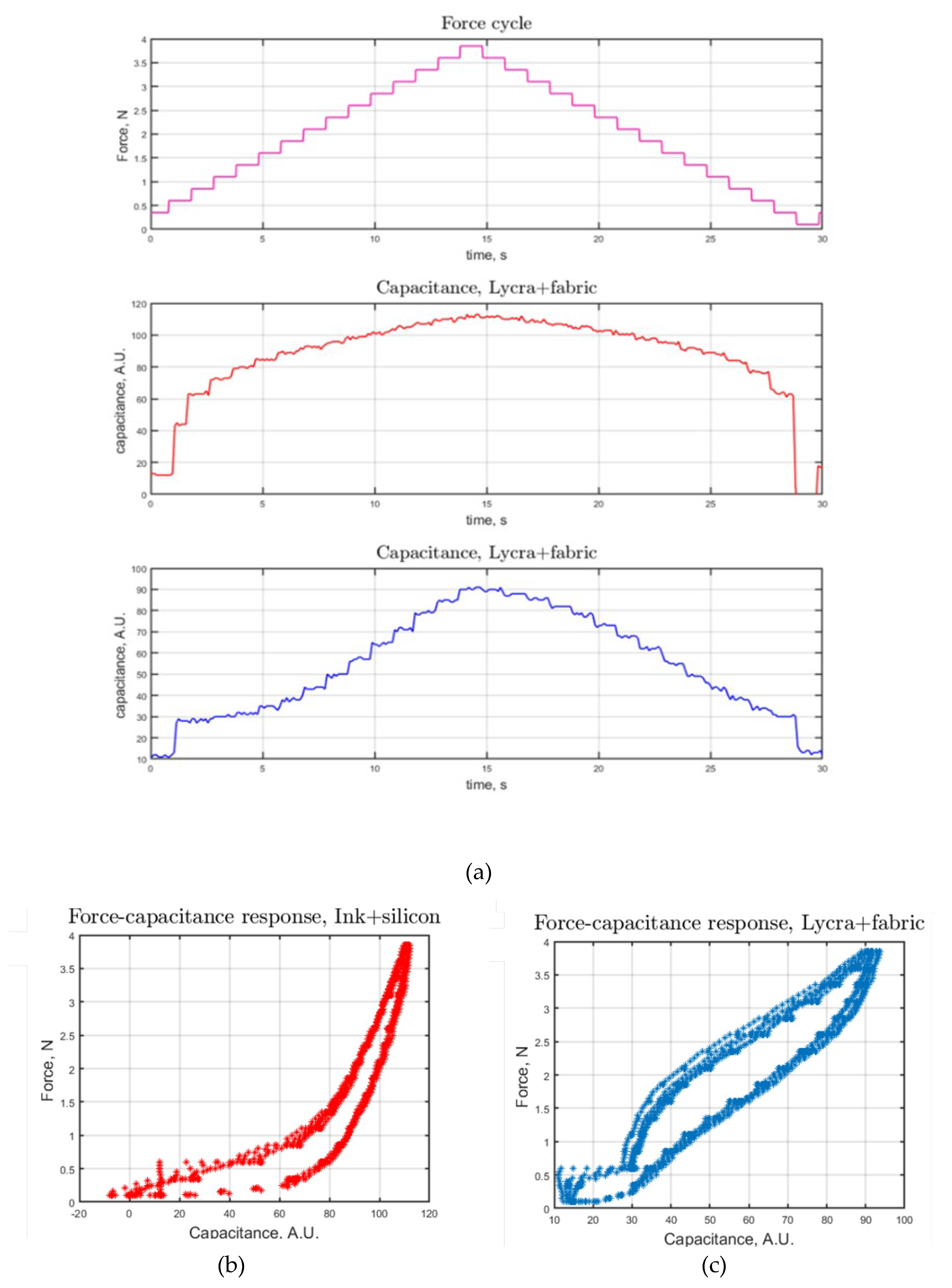

3.3.1. Compression Cycles

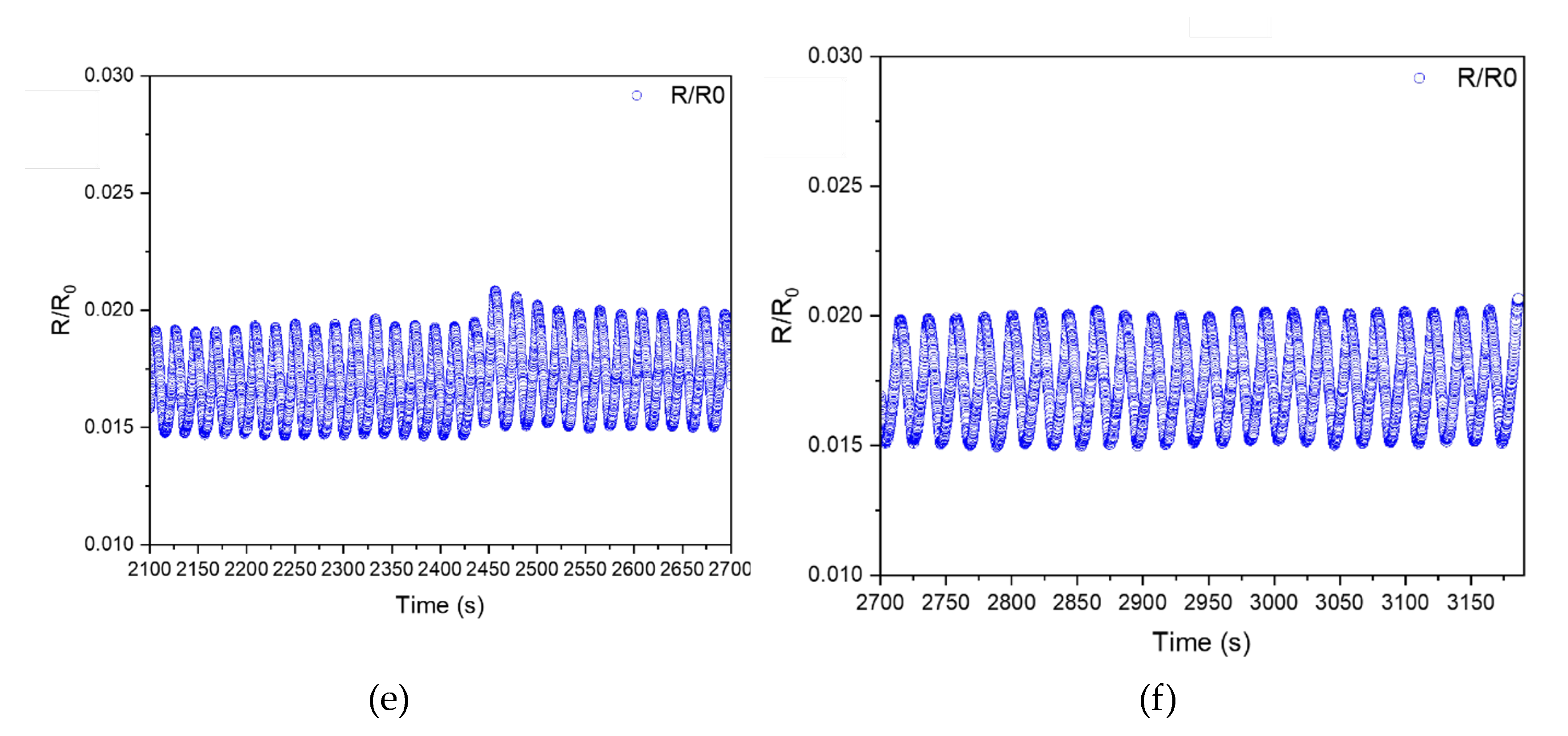

3.3.2. Stretching

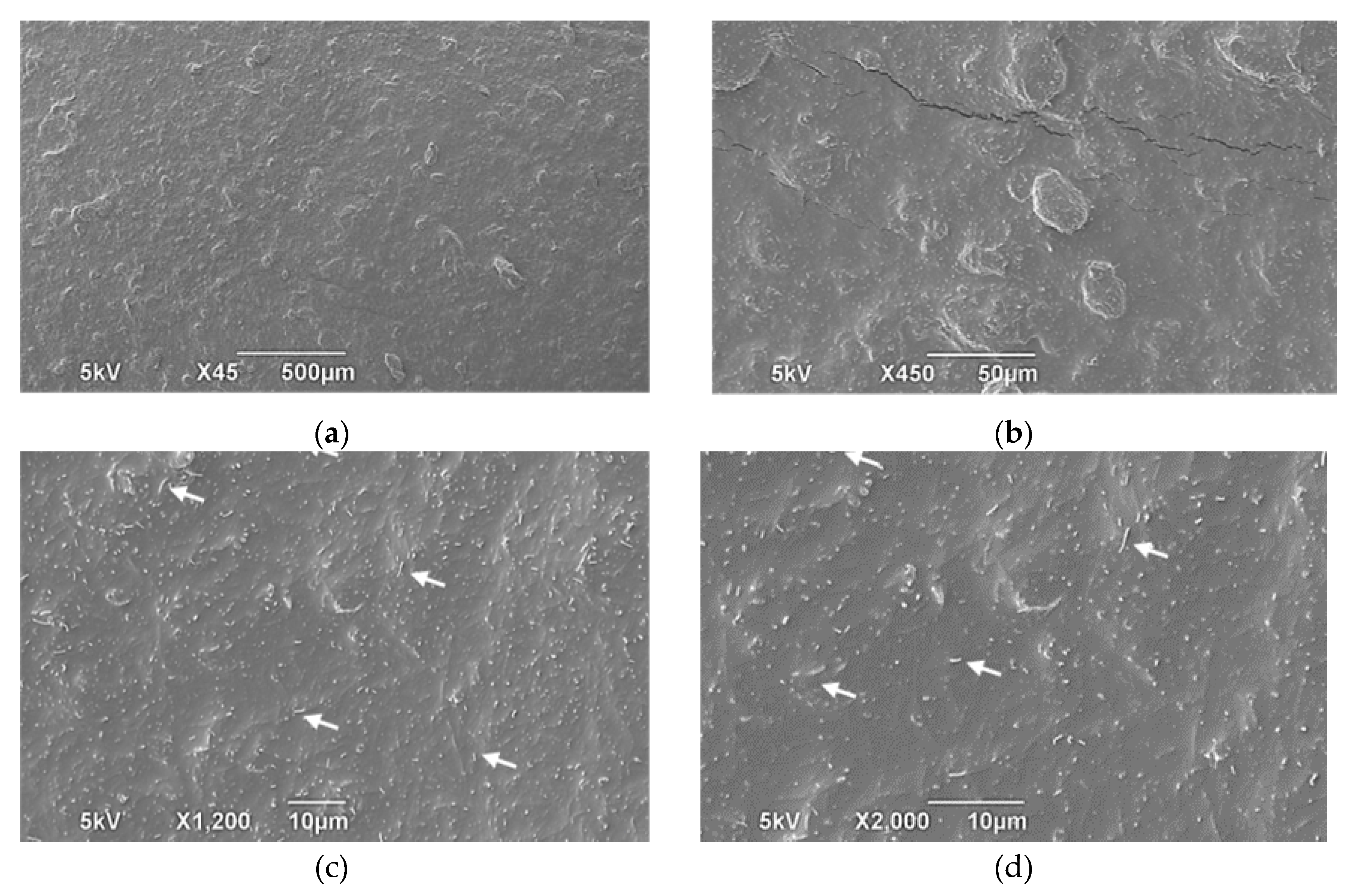

3.3.3. Surface Micro-Morphology of the Coating after Mechanical Solicitation

3.4. Applications

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Harmsen, P.F.H.; Hackmann, M.M.; Bos, H.L. Green Building Blocks for Bio-Based Plastics. Biofuels, Bioproducts and Biorefining 2014, 8, 306–324. [CrossRef]

- Zhang, N.; Liu, P.; Yi, Y.; Gibril, M.E.; Wang, S.; Kong, F. Application of Polyvinyl Acetate/Lignin Copolymer as Bio-Based Coating Material and Its Effects on Paper Properties. Coatings 2021, Vol. 11, Page 192 2021, 11, 192. [CrossRef]

- Liauw, C.M.; Slate, A.J.; Butler, J.A.; Wilson-Nieuwenhuis, J.S.T.; Deisenroth, T.; Preuss, A.; Verran, J.; Whitehead, K.A. The Effect of Surface Hydrophobicity on the Attachment of Fungal Conidia to Substrates of Polyvinyl Acetate and Polyvinyl Alcohol. J Polym Environ 2020, 28, 1450–1464. [CrossRef]

- Petković, G.; Vukoje, M.; Bota, J.; Preprotić, S.P. Enhancement of Polyvinyl Acetate (PVAc) Adhesion Performance by SiO2 and TiO2 Nanoparticles. Coatings 2019, 9. [CrossRef]

- Silva, M.F.; Pineda, E.A.G.; Hechenleitner, A.A.W.; Fernandes, D.M.; Lima, M.K.; Bittencourt, P.R.S. Characterization of Poly(Vinyl Acetate)/Sugar Cane Bagasse Lignin Blends and Their Photochemical Degradation. J Therm Anal Calorim 2011, 106, 407–413. [CrossRef]

- van Acker, F.; Messinger, H.; Bär, A. Evaluation of Vinyl Laurate in a Battery of in Vitro and in Vivo Tests for Genotoxicity. Regulatory Toxicology and Pharmacology 2015, 72, 77–84. [CrossRef]

- Lina, B.A.R.; Messinger, H.; Bär, A. 13-Week Oral Toxicity Study of Vinyl Laurate in Rats. Regulatory Toxicology and Pharmacology 2015, 71, 101–107. [CrossRef]

- Messinger, H.; Bär, A. Subchronic Toxicity, Toxicity to Reproduction and Prenatal Developmental Toxicity of Vinyl Laurate. Regulatory Toxicology and Pharmacology 2014, 70, 80–86. [CrossRef]

- VERSA ® 12 Vinyl Laurate.

- Fadda, M.; Contardi, M.; Dante, S.; Di Carlo, M.; Galizzi, G.; Athanassiou, A.; Bayer, I.S. Antioxidant Coatings from Elastomeric Vinyl Acetate-Vinyl Laurate Copolymers with Reduced Bacterial Adhesion. Prog Org Coat 2022, 168, 106883. [CrossRef]

- Yu, C.; Choi, K.; Yin, L.; Grunlan, J.C. Light-Weight Flexible Carbon Nanotube Based Organic Composites with Large Thermoelectric Power Factors. ACS Nano 2011, 5, 7885–7892. [CrossRef]

- Zgueb, R.; Brichni, A.; Yacoubi, N. Improvement of the Thermal Properties of Sorel Cements by Polyvinyl Acetate: Consequences on Physical and Mechanical Properties. Energy Build 2018, 169, 1–8. [CrossRef]

- Shirbhate, N. V.; Yawale, S.P.; Tambakhe, S. V.; Bobade, R.S.; Pakade, S. V. Structural Investigation of Conducting Polythiophene Composites. Journal of Polymer Engineering 2011, 31, 289–292. [CrossRef]

- Winterton, N. The Green Solvent: A Critical Perspective. Clean Technologies and Environmental Policy 2021 23:9 2021, 23, 2499–2522. [CrossRef]

- Vergaelen, M.; Verbraeken, B.; Van Guyse, J.F.R.; Podevyn, A.; Tigrine, A.; De La Rosa, V.R.; Monnery, B.D.; Hoogenboom, R. Ethyl Acetate as Solvent for the Synthesis of Poly(2-Ethyl-2-Oxazoline). Green Chemistry 2020, 22, 1747–1753. [CrossRef]

- Rafiee, H.R.; Sadeghi, S. The Study of Excess Molar Volumes and Related Properties for Binary Mixtures Containing Benzyl Alcohol and 1,3-Dichloro-2-Propanol with Vinyl Acetate, Ethyl Acetate and t-Butyl Acetate at T = 293.15 to 313.15 K and P = 0.087 MPa. Thermochim Acta 2016, 633, 149–160. [CrossRef]

- Forestier, E.; Najafi, M.; Dussoni, S.; Maggiali, M.; Athanassiou, A.; Bayer, I.S. Characterization and Performance of Silicone Modified Polylactic Acid (PLA)-Graphene Nanoplatelet Ink Coatings for Flexible Elastomeric Substrates. Prog Org Coat 2023, 174, 107251. [CrossRef]

- Yadav, D.; Amini, F.; Ehrmann, A. Recent Advances in Carbon Nanofibers and Their Applications – A Review. Eur Polym J 2020, 138, 109963. [CrossRef]

- Huang, X. Fabrication and Properties of Carbon Fibers. Materials 2009, Vol. 2, Pages 2369-2403 2009, 2, 2369–2403. [CrossRef]

- Das, T.K.; Ghosh, P.; Das, N.C. Preparation, Development, Outcomes, and Application Versatility of Carbon Fiber-Based Polymer Composites: A Review. Adv Compos Hybrid Mater 2019, 2, 214–233. [CrossRef]

- Cheng, H.Y.; Zhu, Y.A.; Sui, Z.J.; Zhou, X.G.; Chen, D. Modeling of Fishbone-Type Carbon Nanofibers with Cone-Helix Structures. Carbon N Y 2012, 50, 4359–4372. [CrossRef]

- Hammel, E.; Tang, X.; Trampert, M.; Schmitt, T.; Mauthner, K.; Eder, A.; Pötschke, P. Carbon Nanofibers for Composite Applications. Carbon N Y 2004, 42, 1153–1158. [CrossRef]

- Gupta, N.S.; Lee, K.S.; Labouriau, A. Tuning Thermal and Mechanical Properties of Polydimethylsiloxane with Carbon Fibers. Polymers 2021, Vol. 13, Page 1141 2021, 13, 1141. [CrossRef]

- Mehrabi, A.; Baheiraei, N.; Adabi, M.; Amirkhani, Z. Development of a Novel Electroactive Cardiac Patch Based on Carbon Nanofibers and Gelatin Encouraging Vascularization. Appl Biochem Biotechnol 2020, 190, 931–948. [CrossRef]

- Huang, H.D.; Guo, Z.; Yang, P. yan; Chen, P.; Wu, J. Electrical Conductivity and Hydrophobicity of Graphene Oxide-Modified Carbon Nanofibers. Chem Phys Lett 2021, 771, 138551. [CrossRef]

- Sui, G.; Jana, S.; Zhong, W.H.; Fuqua, M.A.; Ulven, C.A. Dielectric Properties and Conductivity of Carbon Nanofiber/Semi-Crystalline Polymer Composites. Acta Mater 2008, 56, 2381–2388. [CrossRef]

- Sharma, M.; Gao, S.; Mäder, E.; Sharma, H.; Wei, L.Y.; Bijwe, J. Carbon Fiber Surfaces and Composite Interphases. Compos Sci Technol 2014, 102, 35–50. [CrossRef]

- Yaragalla, S.; Dussoni, S.; Zahid, M.; Maggiali, M.; Metta, G.; Athanasiou, A.; Bayer, I.S. Stretchable Graphene and Carbon Nanofiber Capacitive Touch Sensors for Robotic Skin Applications. Journal of Industrial and Engineering Chemistry 2021. [CrossRef]

- Newcomb, B.A. Processing, Structure, and Properties of Carbon Fibers. Compos Part A Appl Sci Manuf 2016, 91, 262–282. [CrossRef]

- Torris, A.; Badiger, M. V. Polysaccharide Hydrogel Incorporated Carbon Nanofiber Microelectrode for Designing Neural Interfaces. J Bionic Eng 2019, 16, 696–710. [CrossRef]

- Jung, H.; Kwon, D.; Lee, S.A.; Kim, Y.J.; Ahn, J.W. Carbon Nanofiber-Based Wearable Patches for Bio-Potential Monitoring. J Med Biol Eng 2019, 39, 892–900. [CrossRef]

- Wu, H.; Sun, H.; Han, F.; Xie, P.; Zhong, Y.; Quan, B.; Zhao, Y.; Liu, C.; Fan, R.; Guo, Z. Negative Permittivity Behavior in Flexible Carbon Nanofibers-Polydimethylsiloxane Films. Engineered Science 2022, 17, 113–120. [CrossRef]

- Bhawal, P.; Ganguly, S.; Das, T.K.; Mondal, S.; Nayak, L.; Das, N.C. A Comparative Study of Physico-Mechanical and Electrical Properties of Polymer-Carbon Nanofiber in Wet and Melt Mixing Methods. Mater Sci Eng B Solid State Mater Adv Technol 2019, 245, 95–106. [CrossRef]

- Xu, Y.; Higgins, B.; Brittain, W.J. Bottom-up Synthesis of PS–CNF Nanocomposites. Polymer (Guildf) 2005, 46, 799–810. [CrossRef]

- Kumar, S.; Rath, T.; Mahaling, R.N.; Reddy, C.S.; Das, C.K.; Pandey, K.N.; Srivastava, R.B.; Yadaw, S.B. Study on Mechanical, Morphological and Electrical Properties of Carbon Nanofiber/Polyetherimide Composites. Materials Science and Engineering: B 2007, 141, 61–70. [CrossRef]

- Ma, H.; Zeng, J.; Realff, M.L.; Kumar, S.; Schiraldi, D.A. Processing, Structure, and Properties of Fibers from Polyester/Carbon Nanofiber Composites. Compos Sci Technol 2003, 63, 1617–1628. [CrossRef]

- Tibbetts, G.G.; McHugh, J.J. Mechanical Properties of Vapor-Grown Carbon Fiber Composites with Thermoplastic Matrices. J Mater Res 1999, 14, 2871–2880. [CrossRef]

- Cataldi, P.; Dussoni, S.; Ceseracciu, L.; Maggiali, M.; Natale, L.; Metta, G.; Athanassiou, A.; Bayer, I.S. Carbon Nanofiber versus Graphene-Based Stretchable Capacitive Touch Sensors for Artificial Electronic Skin. Advanced Science 2018, 5, 1700587. [CrossRef]

- Cataldi, P.; Steiner, P.; Raine, T.; Lin, K.; Kocabas, C.; Young, R.J.; Bissett, M.; Kinloch, I.A.; Papageorgiou, D.G. Multifunctional Biocomposites Based on Polyhydroxyalkanoate and Graphene/Carbon Nanofiber Hybrids for Electrical and Thermal Applications. ACS Appl Polym Mater 2020, 2, 3525–3534. [CrossRef]

- Guo, Z.; Long, B.; Gao, S.; Luo, J.; Wang, L.; Huang, X.; Wang, D.; Xue, H.; Gao, J. Carbon Nanofiber Based Superhydrophobic Foam Composite for High Performance Oil/Water Separation. J Hazard Mater 2021, 402, 123838. [CrossRef]

- Slipher, G.A.; David Hairston, W.; Cortney Bradford, J.; Bain, E.D.; Mrozek, R.A. Carbon Nanofiber-Filled Conductive Silicone Elastomers as Soft, Dry Bioelectronic Interfaces. PLoS One 2018, 13, e0189415. [CrossRef]

- Rennhofer, H.; Zanghellini, B. Dispersion State and Damage of Carbon Nanotubes and Carbon Nanofibers by Ultrasonic Dispersion: A Review. Nanomaterials 2021, Vol. 11, Page 1469 2021, 11, 1469. [CrossRef]

- Hsu, L.; Weder, C.; Rowan, S.J. Stimuli-Responsive, Mechanically-Adaptive Polymer Nanocomposites. J Mater Chem 2011, 21, 2812–2822. [CrossRef]

- Souri, H.; Bhattacharyya, D. Wearable Strain Sensors Based on Electrically Conductive Natural Fiber Yarns. Mater Des 2018, 154, 217–227. [CrossRef]

- Devaraj, H.; Giffney, T.; Petit, A.; Assadian, M.; Aw, K. The Development of Highly Flexible Stretch Sensors for a Robotic Hand. Robotics 2018, 7. [CrossRef]

- Ying, B.; Chen, R.Z.; Zuo, R.; Li, J.; Liu, X. An Anti-Freezing, Ambient-Stable and Highly Stretchable Ionic Skin with Strong Surface Adhesion for Wearable Sensing and Soft Robotics. Adv Funct Mater 2021, 31, 2104665. [CrossRef]

- Chen, H.; Wang, F.; Chen, H.; Fang, H. Da; Feng, W.; Wei, Y.; Wang, F.F.; Su, H.L.; Mi, Y.D.; Zhou, M.; et al. Specific Biotests to Assess Eco-Toxicity of Biodegradable Polymer Materials in Soil. J Environ Sci (China) 2021, 105, 150–162. [CrossRef]

- Rosa, D.S.; Grillo, D.; Bardi, M.A.G.; Calil, M.R.; Guedes, C.G.F.; Ramires, E.C.; Frollini, E. Mechanical, Thermal and Morphological Characterization of Polypropylene/Biodegradable Polyester Blends with Additives. Polym Test 2009, 28, 836–842. [CrossRef]

- Witt, U.; Einig, T.; Yamamoto, M.; Kleeberg, I.; Deckwer, W.D.; Müller, R.J. Biodegradation of Aliphatic–Aromatic Copolyesters: Evaluation of the Final Biodegradability and Ecotoxicological Impact of Degradation Intermediates. Chemosphere 2001, 44, 289–299. [CrossRef]

- Han, F.; Li, M.; Ye, H.; Zhang, G. Materials, Electrical Performance, Mechanisms, Applications, and Manufacturing Approaches for Flexible Strain Sensors. Nanomaterials 2021, 11.

- Amjadi, M.; Kyung, K.-U.; Park, I.; Sitti, M.; Amjadi, M.; Sitti, M.; Kyung, K.; Park, I. Stretchable, Skin-Mountable, and Wearable Strain Sensors and Their Potential Applications: A Review. Adv Funct Mater 2016, 26, 1678–1698. [CrossRef]

- Han, S.T.; Peng, H.; Sun, Q.; Venkatesh, S.; Chung, K.S.; Lau, S.C.; Zhou, Y.; Roy, V.A.L. An Overview of the Development of Flexible Sensors. Advanced Materials 2017, 29, 1700375. [CrossRef]

- Maiolino, P.; Maggiali, M.; Cannata, G.; Metta, G.; Natale, L. A Flexible and Robust Large Scale Capacitive Tactile System for Robots. IEEE Sens J 2013, 13, 3910–3917. [CrossRef]

- Araby, S.; Meng, Q.; Zhang, L.; Kang, H.; Majewski, P.; Tang, Y.; Ma, J. Electrically and Thermally Conductive Elastomer/Graphene Nanocomposites by Solution Mixing. Polymer (Guildf) 2014, 55, 201–210.

- Saidina, D.S.; Eawwiboonthanakit, N.; Mariatti, M.; Fontana, S.; Hérold, C. Recent Development of Graphene-Based Ink and Other Conductive Material-Based Inks for Flexible Electronics. Journal of Electronic Materials 2019 48:6 2019, 48, 3428–3450. [CrossRef]

- Rickaby, S.R.; Scott, N.H. Cyclic Stress-Softening Model for the Mullins Effect in Compression. Int J Non Linear Mech 2013, 49, 152–158. [CrossRef]

- Mullins, L. Effect of Stretching on the Properties of Rubber. Rubber Chemistry and Technology 1948, 21, 281–300. [CrossRef]

- Mullins, L. Softening of Rubber by Deformation. Rubber Chemistry and Technology 1969, 42, 339–362. [CrossRef]

- Dorfmann, A.; Ogden, R.W. A Constitutive Model for the Mullins Effect with Permanent Set in Particle-Reinforced Rubber. Int J Solids Struct 2004, 41, 1855–1878. [CrossRef]

- Laffranchi, M.; Boccardo, N.; Traverso, S.; Lombardi, L.; Canepa, M.; Lince, A.; Semprini, M.; Saglia, J.A.; Naceri, A.; Sacchetti, R.; et al. The Hannes Hand Prosthesis Replicates the Key Biological Properties of the Human Hand. Sci Robot 2020, 5. [CrossRef]

- Caserta, G.; Boccardo, N.; Freddolini, M.; Barresi, G.; Marinelli, A.; Canepa, M.; Stedman, S.; Lombardi, L.; Laffranchi, M.; Gruppioni, E.; et al. Benefits of the Cybathlon 2020 Experience for a Prosthetic Hand User: A Case Study on the Hannes System. J Neuroeng Rehabil 2022, 19, 1–15. [CrossRef]

- Marinelli, A.; Boccardo, N.; Tessari, F.; Di Domenico, D.; Caserta, G.; Canepa, M.; Gini, G.; Barresi, G.; Laffranchi, M.; De Michieli, L.; et al. Active Upper Limb Prostheses: A Review on Current State and Upcoming Breakthroughs. Progress in Biomedical Engineering 2023, 5, 012001. [CrossRef]

- Jamali, N.; Maggiali, M.; Giovannini, F.; Metta, G.; Natale, L. A New Design of a Fingertip for the ICub Hand. IEEE International Conference on Intelligent Robots and Systems 2015, 2015-December, 2705–2710. [CrossRef]

| Wave Number (ink) (cm-1) |

Wave Number (PVAc-VL) (cm-1) |

Groups Associated |

|---|---|---|

| 1103 | 1109 | C-O stretching vibration |

| 1221 | 1227 | C-O asymmetric stretching |

| 1364 | 1371 | CH3 symmetric bending |

| 1728 | 1731 | C=O stretching |

| 2850 | 2852 | C-H symmetric stretching |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).