Submitted:

10 September 2024

Posted:

11 September 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

- Extrusion and Casting:

- Foaming:

- Nanoparticles integration:

2.1. Implementation in Construction

- Insulation for Walls and Rooves:

- Insulation for Windows and Doors

- Chemical Foaming

- Physical Foaming

- Foaming with Biopolymers

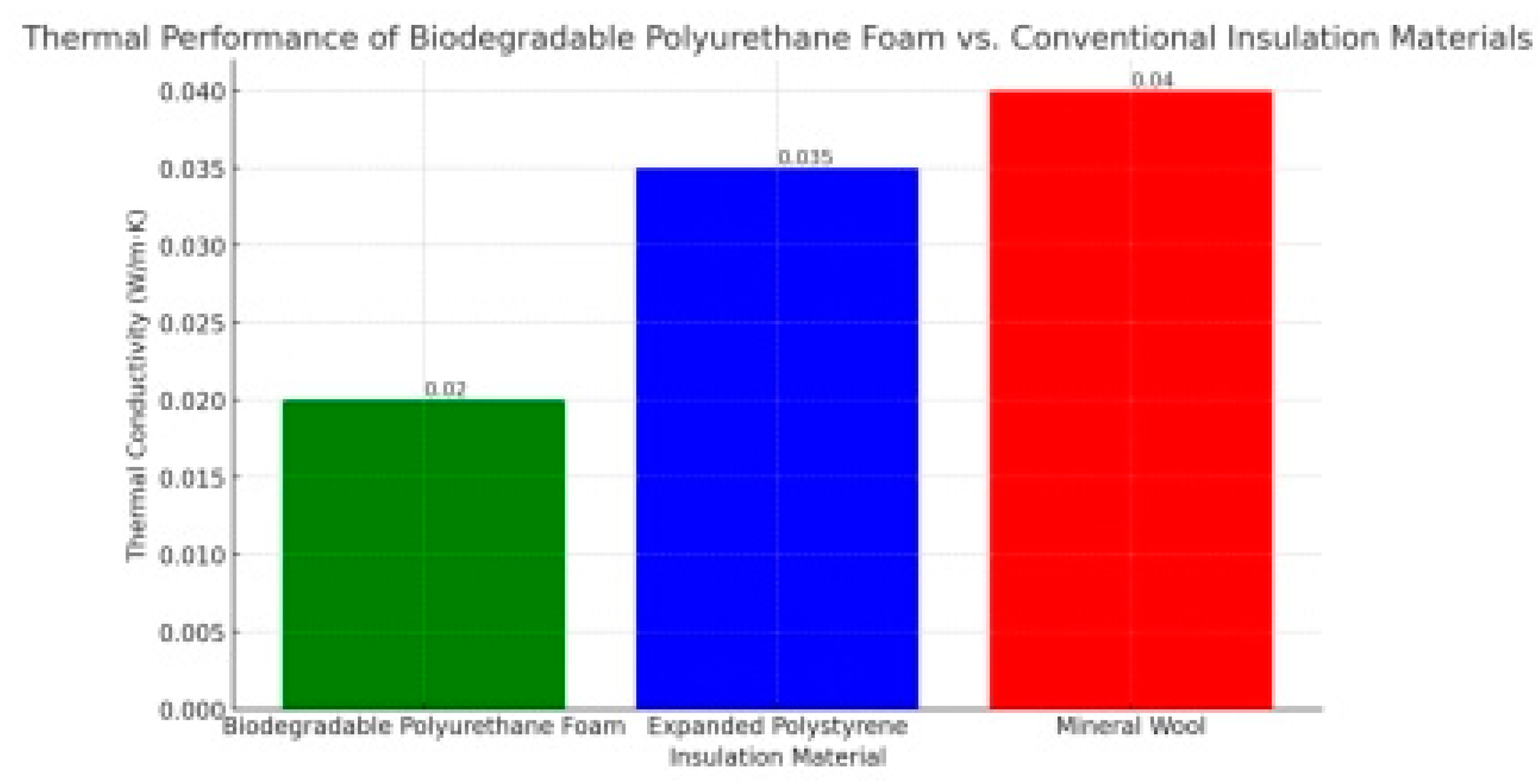

| Material | Thermal conductivity (λ) [W/(m·K)] |

|---|---|

| Foamed Polyurethane | 0.020-0.025 |

| Mineral WoolExpanded Polystyrene | 0.035-0.0450.030-0.040 |

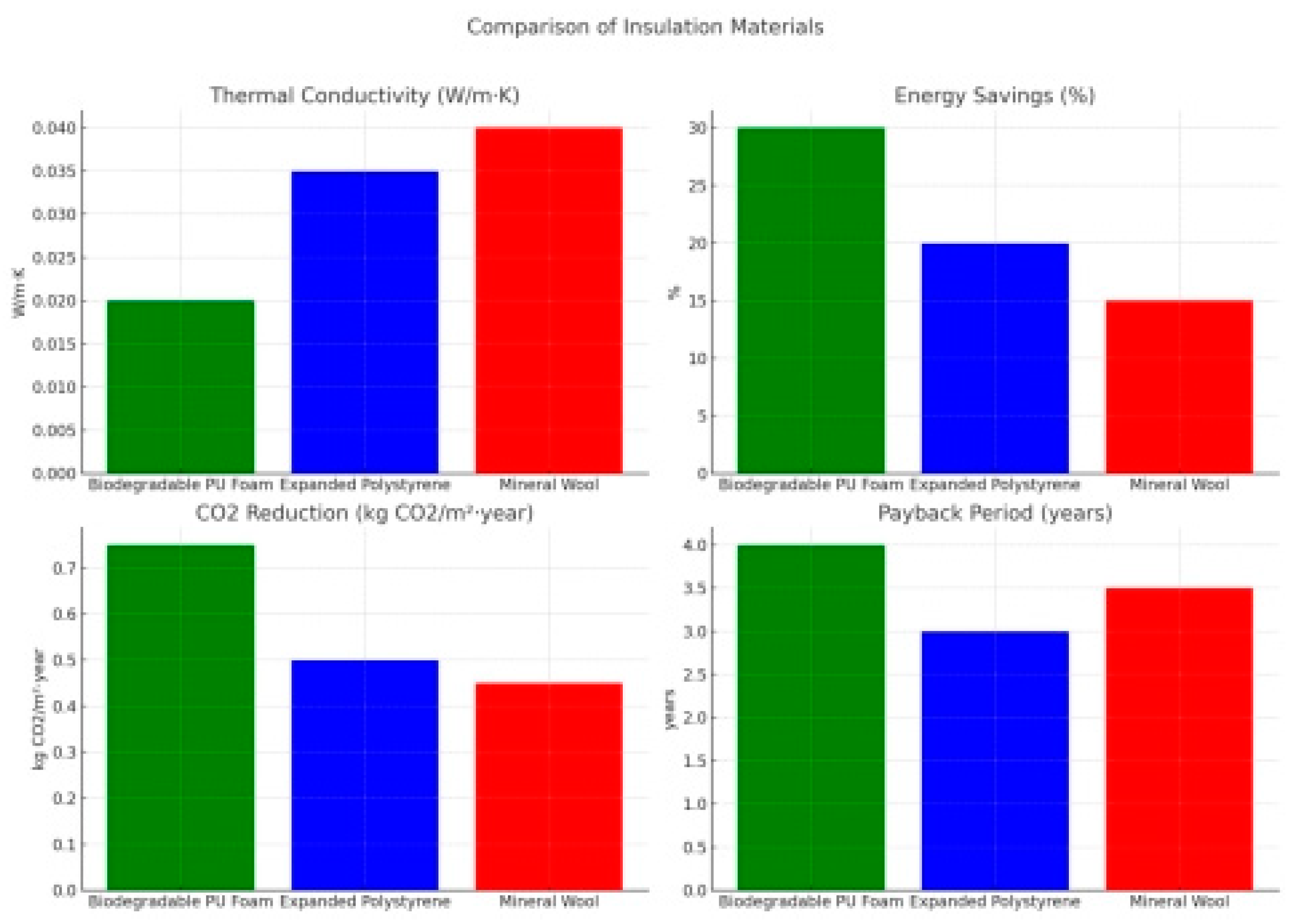

| Material | Percentage of enrgy savings [%] |

|---|---|

| Foamed Polyurethane | 30 |

| Mineral Wool Expanded Polystyrene |

15 20 |

| Material | CO2 Emissions Reduction [kg CO2/m2·year] |

|---|---|

| Foamed Polyurethane | 0.75 |

| Mineral Wool Expanded Polystyrene |

0.45k 0.50k |

| Material | Payback period [years] |

|---|---|

| Foamed Polyurethane | 4 |

| Mineral Wool Expanded Polystyrene |

3.5 3 |

3. Results

- Thermal Conductivity

- Energy Savings

- CO2 Emissions Reduction

- Investment Payback Period

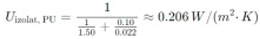

- Thermal Conductivity

- Thermal conductivity of biodegradable foamed polyurethane (λ): 0.022 W/(m·K)

- Thermal conductivity of expanded polystyrene (EPS): 0.035 W/(m·K)

- Insulation thickness: 0.10 m (10 cm)

- Insulated area: 100 m2

- Insulation lifespan: 25 years

- Energy cost: 0.12 €/kWh

- Heat transfer coefficient for uninsulated wall (U): 1.50 W/(m2·K)

- Average indoor temperature: 20°C

- Average outdoor temperature: 5°C

- Heating season duration: 200 days/year

- CO2 emissions for energy production: 0.20 kg CO2/kWh

3.1. Calculations

- For biodegradable foamed polyurethane:

- For expanded polystyrene (EPS):

- For biodegradable foamed polyurethane:

- For expanded polystyrene (EPS):

- For biodegradable foamed polyurethane:

- For expanded polystyrene (EPS):

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhao, X., Li, J., Su, S. and Jiang, N., Prediction Models of Mechanical Properties of Jute/PLA Composite Based on X-ray Computed Tomography, Polymers 2024, 16(1), 160.

- 2Cheng, P., Zheng, C., Zhang, Z., Li, Y., Huang, K., Yu, D. and Ji, Y., Preparation and Performance of Bitumen Modified by Melt-Blown Fabric of Waste Mask Based on Grey Relational and Radar Chart Analysis, Polymers 2024, 16(1), 153.

- International Energy Agency (IEA). (2020). Energy Efficiency 2020. Retrieved from https://www.iea.org/reports/energy-efficiency-2020.

- European Commission. (2019). The European Green Deal. Retrieved from https://ec.europa.eu/info/strategy/priorities-2019-2024/european-green-deal_en.

- Smith, L., & Jones, P. (2018). Biodegradable Polymers in the Construction Industry. Journal of Sustainable Building Materials and Technologies, 7(4), 212-225. [CrossRef]

- American Society of Civil Engineers (ASCE). (2017). Sustainability Guidelines for the Construction Industry. Retrieved from https://www.asce.org/sustainability-guidelines.

- United Nations Environment Programme (UNEP). (2019). Emissions Gap Report 2019. Retrieved from https://www.unep.org/resources/emissions-gap-report-2019.

- Wang, Y., & Zhang, X. (2021). Thermal Insulation Properties of Biodegradable Polyurethane Foams. Construction and Building Materials, 275, 122143. [CrossRef]

- Kumar, S., & Gupta, A. (2020). Cost-Benefit Analysis of Biodegradable Insulation Materials. Energy and Buildings, 223, 110024. [CrossRef]

- Global Alliance for Building and Construction (GlobalABC). (2020). The Global Status Report for Buildings and Construction. Retrieved from https://globalabc.org/resources/publications/global-status-report-buildings-and-construction-2020.

- Papadopoulos, A. M. (2005). State of the art in thermal insulation materials and aims for future developments. Energy and Buildings, 37(1), 77-86.

- Asif, M., Muneer, T., & Kelley, R. (2007). Life cycle assessment: A case study of a dwelling home in Scotland. Building and Environment, 42(3), 1391-1394.

- Jelle, B. P., Hynd, A., Gustavsen, A., Arasteh, D., Goudey, H., & Hart, R. (2012). Fenestration of today and tomorrow: A state-of-the-art review and future research opportunities. Solar Energy Materials and Solar Cells, 96, 1-28.

- I. Sabree, J. E. Gough, B. Derby, Ceram. Int. 2015, 41, 8425.

- N. S. Nik, M. R. Rad, P. Nazeman, A. Khojasteh, in Biomaterials for Oral and Dental Tissue Engineering (Eds: L. Tayebi, K. Moharamzadeh), 2017, p. 29.

- A. L. Sisson, D. Ekinci, A. Lendlein, Polymer 2013, 54, 4333.

- F.-L. Jin, M. Zhao, M. Park, S.-J. Park, Polymers 2019, 11, 953, 2.

- S. Ruijtenberg, S. V. Heuvel, Cell Cycle 2016, 2, 207.

- Rezwan K, Chen QZ, Blaker JJ, et al. Biodegradable and bioactive porous polymer/inorganic composite scaffolds for bone tissue engineering. Biomaterials 2006; 27: 3413–3431.

- Crăciunescu, C. M., „Materiale compozite”, Ed. Sedona, Timişoara, 1998.

- Stephen, R. S., “Introduction to design and analysis with advanced composite materials”, Prentice-Hall, 1997.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).