Submitted:

21 August 2024

Posted:

23 August 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

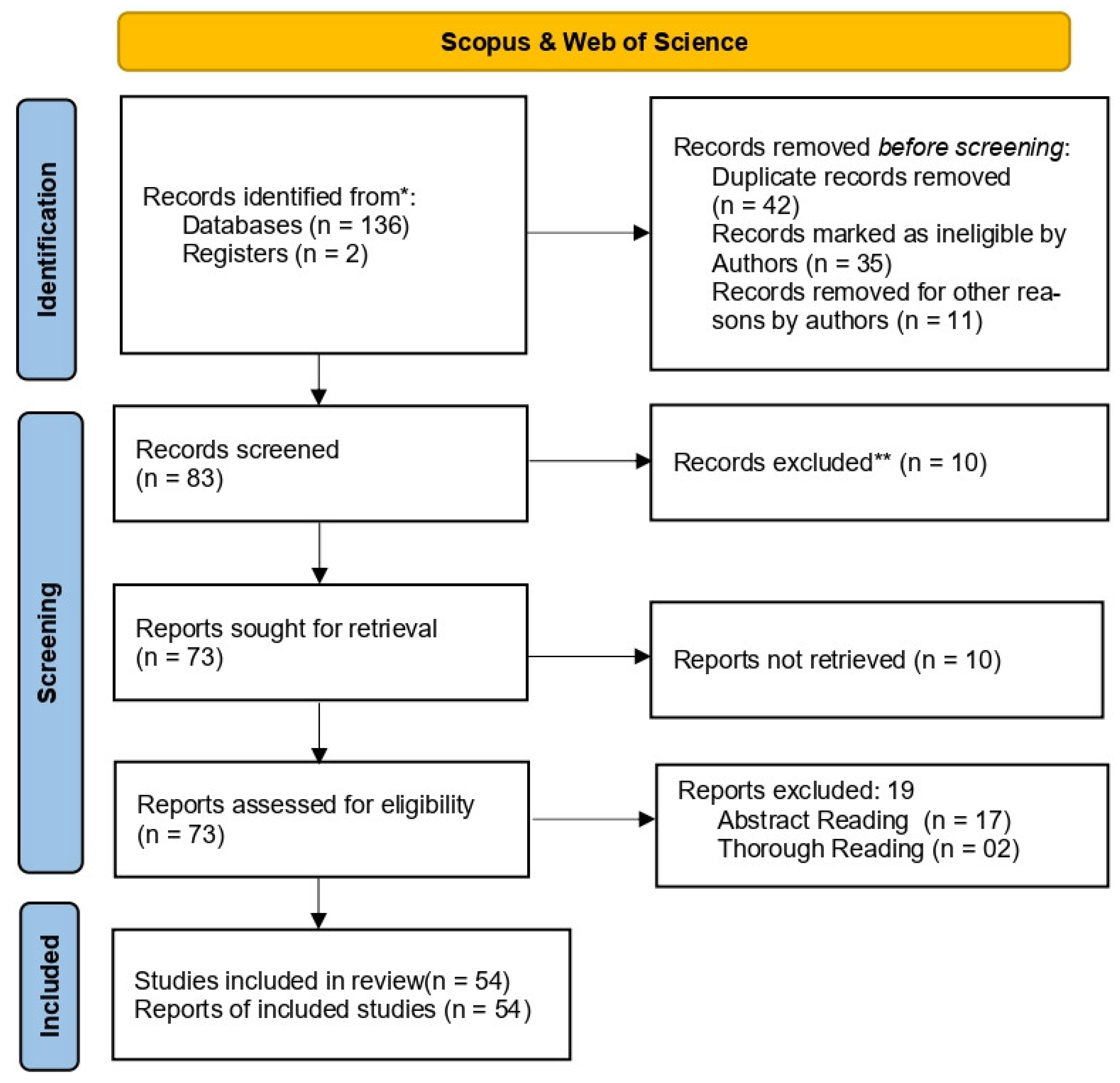

2. Methodology

3. Results

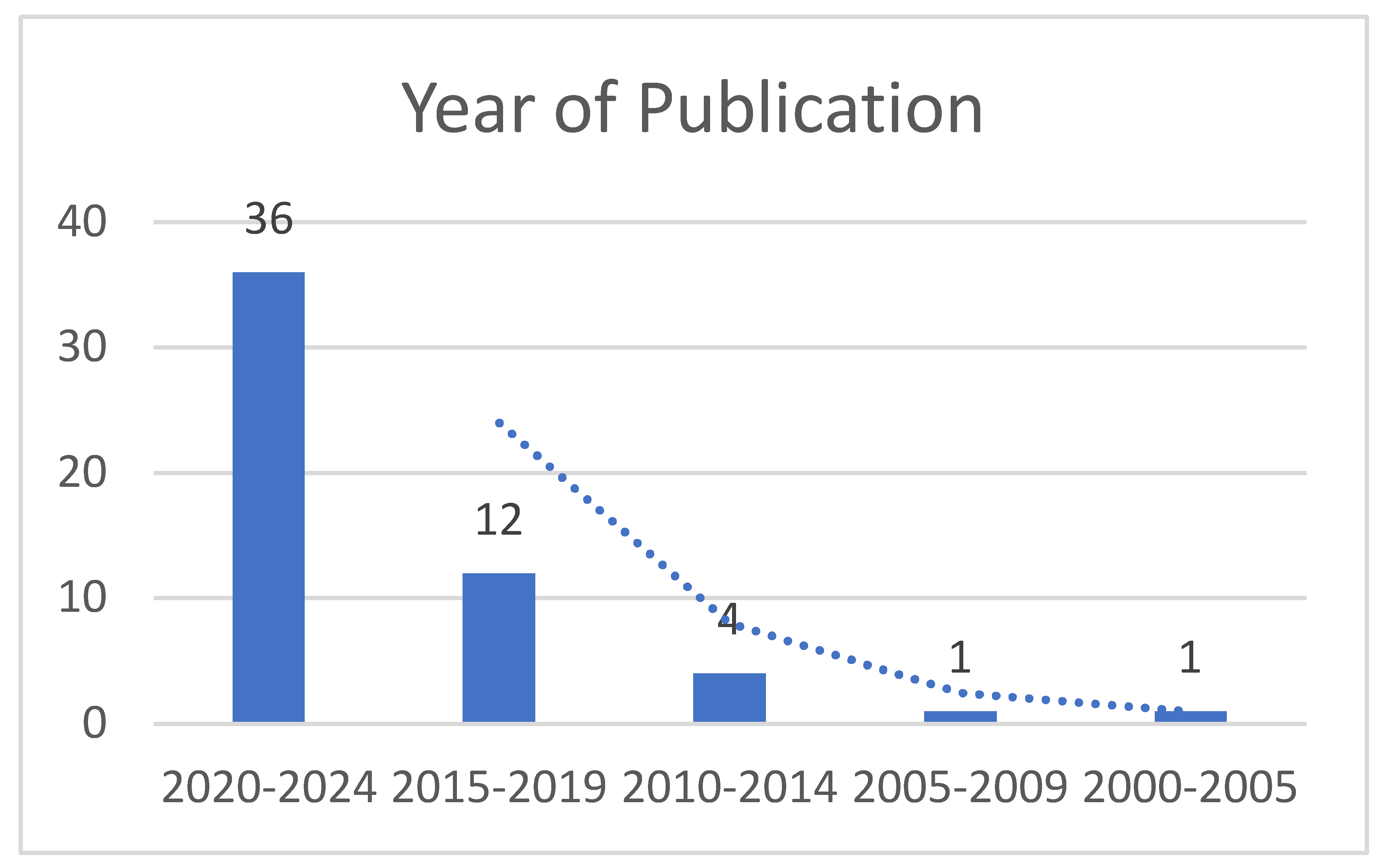

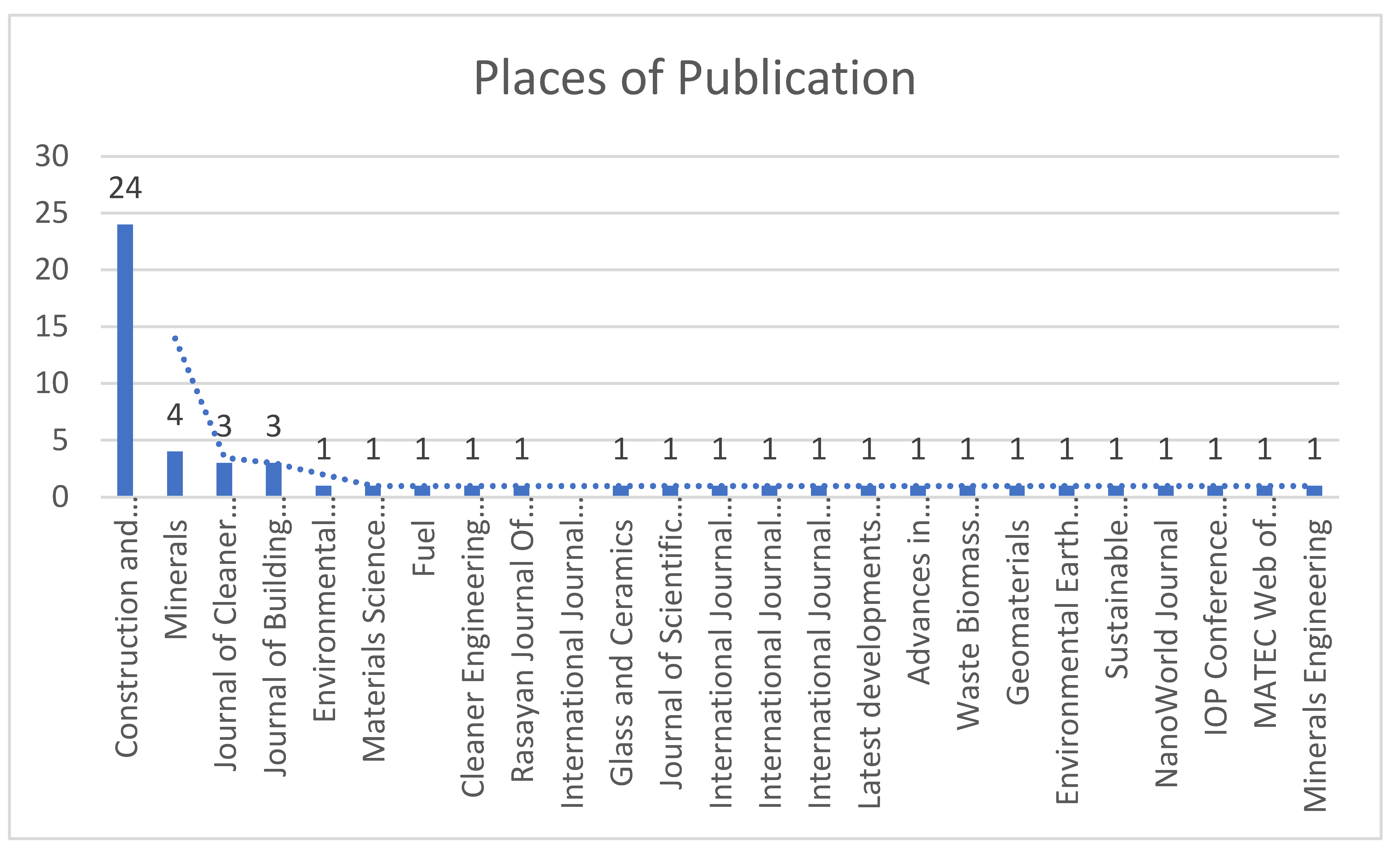

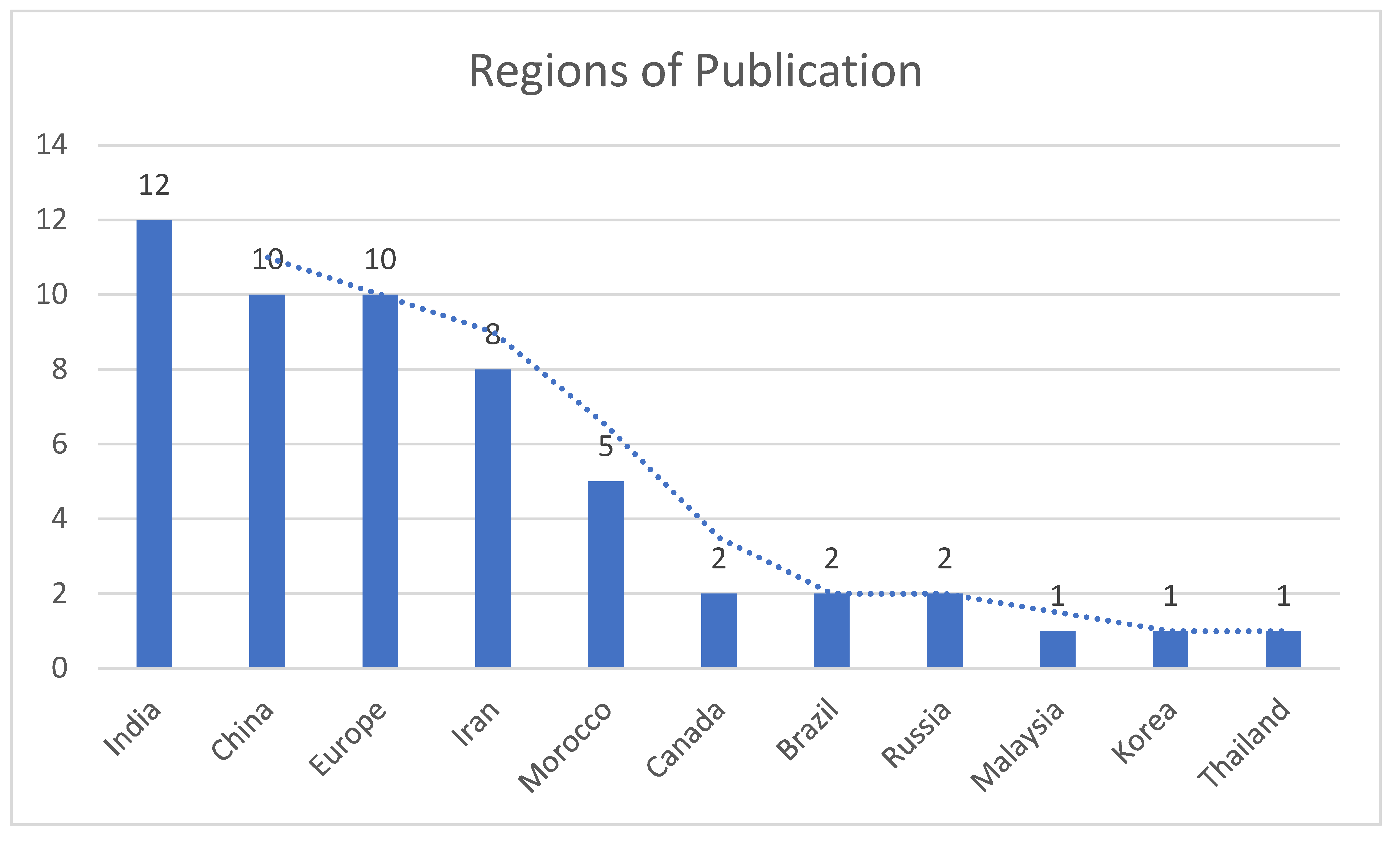

3.1. Descriptive Analysis

3.2. Content Analysis

3.2.1. Bricks

| S. No. | Type of Coal-Mining Waste | Application in Construction | Region | “R principle” integration | References |

| 01 | Coal Mine Overburden Clay | Compressed Stabilized Earth Brick | India | Reduce, Reuse, & Replace | [35] |

| 02 | Coal Gangue Powder from tailings and Shale (overburden) replacing natural clay | Sintered Bricks | China | Recycle, Replace & Reuse | [36] |

| 03 | Coal Mine Overburden | Clay Bricks | Korea | Recycle & Reuse | [39] |

| 04 | Coal Mine Overburden Rocks and waste coals | Ceramic Bricks | Russia | Recycle & Reuse | [21] |

| 05 | Coal Dust Waste at thermal power plants | Bricks | India | Recycle & Reuse | [38] |

| 06 | Coal Mine Overburden Rocks | Bricks | India | Recycle & Reuse | [37] |

| 07 | Coal Mine Waste Rocks and Treated coal mine tailings | Fired Bricks | Canada Morocco | Recycle & Reuse | [18] |

| 08 | Coal Mine Overburden (Rocks and Clay) | Bricks and Pavement Material | India | Recycle & Reuse | [40] |

3.2.2. Aggregates (Fine and Coarse) and Sand

| S. No. | Type of Coal-Mining Waste | Application in Construction | Region | “R principle” integration | References |

| 01 | Coal Mine Overburden Rocks and Clay | Sand, Fine and Coarse Aggregates in Concrete | India (3) | Reduce, Reuse, & Replace | [11,42,45] |

| 02 | Coal Mine Overburden | Fine Aggregates and Sand | India (2), Brazil | Replace & Reuse | [41,43,44] |

| 03 | Coal Mine Overburden Rocks | Fine Aggregates in fly ash-based geopolymer | Italy | Replace & Reuse | [22] |

| 04 | Coal Mining and Processing Waste (Overburden, Tailing, Fly Ash, Bottom Ash) | Secondary aggregates in the base and sub-base layer of pavement | India | Recycle, Replace & Reuse | [2] |

| 05 | Coal Waste Powder (Coal Extraction and Washing Process) | Replacing natural aggregate filler | Iran | Recycle, Replace & Reuse | [8] |

| 06 | Untreated Coal Waste (Raw Coal) | Aggregates in concrete | Iran | Replace & Reuse | [9] |

3.2.3. Cement

| S. No. | Type of Coal-Mining Waste | Application in Construction | Region | “R principle” integration | References |

| 01 | Thermally activated coal mining waste | Replacing Cement | Czech Republic (2), Spain (4), Brazil | Recycle, Replace & Reuse | [46,47,48,49,50,51,53] |

| 02 | Coal Washing Waste Ash | Blended cement | Iran | Recycle, Replace & Reuse | [54] |

| 03 | Coal Mining Wastes from Washery | Cement Clinker Production | Spain | Recycle & Reuse | [55] |

| 04 | Coal Gangue | Alkali-activated binder alternatives | Morocco | Recycle & Reuse | [56] |

| 05 | Coal Bottom Ash | Replacing Cement | Malaysia | Recycle & Reuse | [58] |

| 06 | Coal Fly Ash | Fly ash fibers for fiber-reinforced cement composites | Thailand | Recycle & Reuse | [59] |

| 07 | Coal Waste Powder, Coal Waste Ash, Limestone Powder | Replacing cement in roller-compacted concrete pavement | Iran | Recycle, Replace & Reuse | [60] |

| 08 | Coal Industry by-products and red mud | Cementitious Material | China | Recycle & Reuse | [61] |

| 09 | Coal Mine Waste | Replacing Cement, which helps in soil stabilisation | Iran | Recycle & Reuse | [62] |

3.2.4. Geopolymers

3.2.5. Concrete

| S. No. | Type of Coal-Mining Waste | Application in Construction | Region | “R principle” integration | References |

| 01 | Coal Mine Waste | Geopolymers in light-weight structural and non-structural applications | Poland | Recycle & Reuse | [14] |

| 02 | Aggregates from open-pit mines, GGBS, and coal fly ash | Geopolymers in road construction | China | Recycle & Reuse | [65] |

| 03 | Coal-washing Waste | Replacing cement in geopolymer concrete | Iran | Recycle, Replace & Reuse | [54] |

| 04 | Coal-mining waste | Geo-polymeric materials replacing cement | Morocco | Recycle, Replace & Reuse | [66] |

| 05 | Coal Gangue, Fly ash, Bentonite | Geo-polymer-based grouting material | China | Recycle & Reuse | [67] |

| 06 | Coal Gangue | Replacing Gravel in concrete for farmland drainage | China | Recycle & Reuse | [69] |

| 07 | Coal Mine Waste replacing natural sand | Foam Concrete | United Kingdom | Recycle, Replace & Reuse | [70] |

| 08 | Coal Mine Waste (Coal Washing Plant) | Concrete | Iran | Recycle & Reuse | [71] |

| 09 | Non-activated coal gangue aggregates | Replacing Natural aggregates in concrete | China | Recycle & Reuse | [72] |

3.2.6. Road, Embankments and Backfill

3.2.7. Others

| S. No. | Type of Coal-Mining Waste | Application in Construction | Region | “R principle” integration | References |

| 01 | Coal Mining Waste | Aggregates for Road Embankment | Canada | Recycle & Reuse | [74] |

| 02 | Coal Waste Ash from Washery | As filler in hot mix asphalt used in road and pavement construction | Iran | Recycle & Reuse | [75] |

| 03 | Coal Gangue Waste | As fillers in asphalt replacing limestone | China | Recycle, Replace & Reuse | [76] |

| 04 | Coal Mine Waste Rocks (Weathered Form) | Construction of Embankments | Morocco | Recycle & Reuse | [84] |

| 05 | Coal Mine Waste (Coal Thermal Power Plant), Coal Gangue | Cemented Backfill | China (2) | Recycle & Reuse | [78,79] |

| 06 | Coal Gangue, Coal Bottom Ash, Fly Ash | Stabilized with cement to use as pavement base materials | China | Recycle & Reuse | [80] |

| 07 | Coal Mine Overburden | Sub-ballast in railway tracks | India | Recycle & Reuse | [81] |

| 08 | Coal Mine Waste (Power Plants) | Ceramic Tiles | Russia | Recycle & Reuse | [82] |

| 09 | Coal Fly Ash | Light-weight Gypsum Composites | Morocco | Recycle & Reuse | [83] |

| 10 | Coal Mine Overburden (Soft Shale) | Medium-strength composites | India | Recycle & Reuse | [16] |

4. Discussion and Conclusion

- The studies related to using coal mining wastes in the construction industry in the untreated form are limited. Waste treatment through the “R principle” of recycling or recovery is at a lower hierarchy in the circular economy. Therefore, to achieve the aim of a circular economy of waste elimination and regenerating ecosystems, the study proposes further research into using coal mining wastes in construction in untreated form.

- With extensive studies in the area, implementing the same in the construction industry is challenging. This requires a ready digital database of the amount and properties of the coal mining waste, which can help the construction stakeholders use them in the industry as applicable.

- One of the prime concerns on the coal mining site (open cast and underground) is overburden disposal because of the high stripping ratio. Although the literature suggests the usage of coal mine overburden in construction, a large amount of the same lie on the site. Further, more studies can be conducted using coal mine overburden directly into the construction industry, aiming towards zero waste on the coal mining site.

- Coal mining waste in the end products/ application areas mainly focuses on non-structural components. The use of the same in high-performance concrete and structural concrete is where further studies can be conducted.

- Several studies above demonstrate coal mine waste’s pozzolanic properties in its raw, heat-treated, or thermally activated form. This is mainly due to iron, silica, alumina, and calcium oxides. Therefore, further research can be conducted on elements of high performance and binding, such as nano silica from coal mine waste, which can be used in concrete with healing and high durability properties.

- While there is strong evidence of coal mine wastes replacing sand and fine aggregates in concrete and mortar, the evidence of using the same replacing coarse aggregates in concrete products is limited.

- Using the latest tools, such as life cycle analysis, material flow analysis, and material passport (details of the end-product), can help derive better results and a more significant impact in the construction and coal mining industry.

- Another gap highlighted by [2] is the method for decreasing the high-water absorption properties of coal mining waste to make it more suitable for the construction industry.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgements

Conflicts of Interest

References

- I. Energy Agency, “World Energy Outlook 2020,” 2020. [Online]. Available: www.iea.org/weo.

- M. Mohanty, D. R. Biswal, and S. S. Mohapatra, “A systematic review exploring the utilization of coal mining and processing wastes as secondary aggregate in sub-base and base layers of pavement,” Mar. 03, 2023, Elsevier Ltd. [CrossRef]

- T. B. Johansson et al., “Global Energy Assessment Toward a Sustainable Future.”.

- A. N. Ally, M. M. Blanche, U. J. P. Nana, M. M. Grâce, N. François, and C. Pettang, “Recovery of Mining Wastes in Building Materials: A Review,” Open Journal of Civil Engineering, vol. 11, no. 04, pp. 379–397, 2021. [CrossRef]

- J. Weiler, B. A. Firpo, and I. A. H. Schneider, “Coal waste derived soil-like substrate: An opportunity for coal waste in a sustainable mineral scenario,” J Clean Prod, vol. 174, pp. 739–745, Jan. 2018. [CrossRef]

- I. A. Straupnik, “An overview of the environmental impact of coal industry waste,” in IOP Conference Series: Earth and Environmental Science, Institute of Physics, 2022. [CrossRef]

- A. Sokratidou, C. Roumpos, N. Paraskevis, A. Servou, and F. Pavloudakis, “Extractive Waste Management in Coal Surface Mining Projects—A Circular Economy Approach,” MDPI AG, Oct. 2023, p. 13. [CrossRef]

- H. Ziari, M. Zalnezhad, M. Ali Ziari, and E. Nasiri Amiri, “Substitution of the natural aggregate filler by coal waste powder (CWP) in microsurfacing surface treatment: Mix design and performance evaluation,” Constr Build Mater, vol. 354, Nov. 2022. [CrossRef]

- M. Karimaei, F. Dabbaghi, A. Sadeghi-Nik, and M. Dehestani, “Mechanical performance of green concrete produced with untreated coal waste aggregates,” Constr Build Mater, vol. 233, Feb. 2020. [CrossRef]

- “PROVISIONAL COAL STATISTICS 2022-23 GOVERNMENT OF INDIA MINISTRY OF COAL COAL CONTROLLER’S ORGANISATION DELHI.”.

- A. S. Rathore, M. Pradhan, and S. V Deo, “Assessment of Coal Mine Overburden Sand for Use in Concrete Making as Fine Aggregate,” International Journal of Advanced Research in Engineering and Technology, vol. 11, no. 9, pp. 368–379, 2020. [CrossRef]

- B. Indraratna, C. Rujikiatkamjorn, and G. Chiaro, “Characterization of compacted coal wash as structural fill material,” 2012.

- T. Liem Vo et al., “Coal mining wastes valorisation as raw geomaterials in construction: A review with new perspectives 2 3.”.

- N. Paszek and M. Górski, “Defining the optimal mixture composition of geopolymers based on the coal mine waste and the shale.,” MATEC Web of Conferences, vol. 274, p. 01002, 2019. [CrossRef]

- N. Adibee, M. Osanloo, and M. Rahmanpour, “Adverse effects of coal mine waste dumps on the environment and their management,” Environ Earth Sci, vol. 70, no. 4, pp. 1581–1592, Oct. 2013. [CrossRef]

- S. K. Das, M. Mahamaya, and K. R. Reddy, “Coal mine overburden soft shale as a controlled low strength material,” Int J Min Reclam Environ, vol. 34, no. 10, pp. 725–747, Nov. 2020. [CrossRef]

- Y. Taha, A. Elghali, M. Derhy, M. Amrani, R. Hakkou, and M. Benzaazoua, “Towards an integrated approach for zero coal mine waste storage: solutions based on materials circularity and sustainable resource governance,” Mineral Processing and Extractive Metallurgy Review, vol. 44, no. 6, pp. 375–388, 2023. [CrossRef]

- Y. Taha, M. Benzaazoua, R. Hakkou, and M. Mansori, “Coal mine wastes recycling for coal recovery and eco-friendly bricks production,” Miner Eng, vol. 107, pp. 123–138, Jun. 2017. [CrossRef]

- L. Haibin and L. Zhenling, “Recycling utilization patterns of coal mining waste in China,” Resour Conserv Recycl, vol. 54, no. 12, pp. 1331–1340, 2010. [CrossRef]

- U. Nazarbek, P. Abdurazova, S. Nazarbekova, M. Kambatyrov, and Y. Raiymbekov, “Coal mining waste is a valuable secondary raw material,” Rasayan Journal of Chemistry, vol. 14, no. 4, pp. 2171–2176, 2021. [CrossRef]

- A. Y. Stolboushkin, A. I. Ivanov, G. I. Storozhenko, V. A. Syromyasov, and D. V. Akst, “Use of overburden rocks from open-pit coal mines and waste coals of Western Siberia for ceramic brick production with a defect-free structure,” in IOP Conference Series: Earth and Environmental Science, Institute of Physics Publishing, Sep. 2017. [CrossRef]

- I. Capasso et al., “Reuse of mining waste as aggregates in fly ash-based geopolymers,” J Clean Prod, vol. 220, pp. 65–73, May 2019. [CrossRef]

- R. Kazmi and M. Chakraborty, “Identification of parameters and indicators for implementing circularity in the construction industry,” Dec. 01, 2023, Institute for Ionics. [CrossRef]

- R. Kazmi and M. Chakraborty, “Status and probable direction of circular economy in the construction industry in India through a systematic literature review,” 2024.

- “Founding Partners of the Ellen MacArthur Foundation 2013 CIRCULAR ECONOMY TOWARDS THE Economic and business rationale for an accelerated transition.”.

- M. P. Hekkert and E. Worrell, “The effects of incubation on the networks and performance of clean-tech startups View project LICCER View project José Potting.” [Online]. Available: https://www.researchgate.net/publication/319314335.

- Ö. Çimen, “Construction and built environment in circular economy: A comprehensive literature review,” Jul. 10, 2021, Elsevier Ltd. [CrossRef]

- D. Kazmi, M. Serati, D. J. Williams, S. Qasim, and Y. P. Cheng, “The potential use of crushed waste glass as a sustainable alternative to natural and manufactured sand in geotechnical applications,” J Clean Prod, vol. 284, Feb. 2021. [CrossRef]

- M. Smol, J. Kulczycka, A. Henclik, K. Gorazda, and Z. Wzorek, “The possible use of sewage sludge ash (SSA) in the construction industry as a way towards a circular economy,” May 15, 2015, Elsevier Ltd. [CrossRef]

- S. K. Kaliyavaradhan, T. C. Ling, and K. H. Mo, “Valorization of waste powders from cement-concrete life cycle: A pathway to circular future,” Sep. 20, 2020, Elsevier Ltd. [CrossRef]

- K. Pactwa, J. Woźniak, and M. Dudek, “Coal mining waste in Poland in reference to circular economy principles,” Fuel, vol. 270, Jun. 2020. [CrossRef]

- G. L. F. Benachio, M. do C. D. Freitas, and S. F. Tavares, “Circular economy in the construction industry: A systematic literature review,” Jul. 01, 2020, Elsevier Ltd. [CrossRef]

- Y. Xiao and M. Watson, “Guidance on Conducting a Systematic Literature Review,” Mar. 01, 2019, SAGE Publications Inc. [CrossRef]

- R. B. Briner and D. Denyer, “Systematic Review and Evidence Synthesis as a Practice and Scholarship Tool,” in The Oxford Handbook of Evidence-Based Management, Oxford University Press, 2012. [CrossRef]

- A. S. Rathore, M. Pradhan, S. V. Deo, and A. K. Dash, “Coal Mine Overburden As Resource Material For Making Brick,” International Journal of Engineering Trends and Technology, vol. 70, no. 1, pp. 118–125, Jan. 2022. [CrossRef]

- L. Luo, K. Li, F. Weng, C. Liu, and S. Yang, “Preparation, characteristics and mechanisms of the composite sintered bricks produced from shale, sewage sludge, coal gangue powder and iron ore tailings,” Constr Build Mater, vol. 232, Jan. 2020. [CrossRef]

- S. K. Singh, “Manufacturing of Bricks From Coal Mine Overburden Dump of Korba, Chhattisgarh, India,” 2020. [CrossRef]

- R. Agrawal, D. Garg, and P. Gour, “Springer Professional Utilization of Coal Dust Waste in Bricks an Experimental Approach Highlight text sections to discover more relevant content with AI-assisted Search.”.

- J. W. Yoo, J. H. Jung, and H. T. Kim, “Synthesis and Characterization of Clay Brick Using Coal Wastes,” Materials Science Forum, vol. 486–487, pp. 403–406, Jun. 2005. [CrossRef]

- A. Jamal and S. Sidharth, “Value added constructional bricks from overburden of opencast coalmines,” 2008.

- B. Jena, N. P. Zade, P. Sarkar, and S. K. Karak, “Sustainable integration of coal mine overburden as a substitute for natural sand in concrete to enhance its mechanical and durability properties,” Constr Build Mater, vol. 411, Jan. 2024. [CrossRef]

- K. R. Chandar, B. C. Gayana, and V. Sainath, “Experimental investigation for partial replacement of fine aggregates in concrete with sandstone,” Advances in concrete construction, vol. 4, no. 4, pp. 243–261, Dec. 2016. [CrossRef]

- C. R. dos Santos, J. R. do A. Filho, R. M. C. Tubino, and I. A. H. Schneider, “Use of Coal Waste as Fine Aggregates in Concrete Paving Blocks,” Geomaterials, vol. 03, no. 02, pp. 54–59, 2013. [CrossRef]

- A. Mishra, S. K. Das, and K. R. Reddy, “Life cycle assessment of processing alternate sands for sustainable construction: Coal mine overburden sand versus manufactured sand,” Journal of Building Engineering, vol. 75, Sep. 2023. [CrossRef]

- A. Mishra, S. K. Das, and K. R. Reddy, “Valorization of Coalmine Overburden Waste Rock as Fine and Coarse Aggregate of Mortar and Concrete: Corrosion Resistance Evaluation,” Waste Biomass Valorization, 2023. [CrossRef]

- Z. Pavlík et al., “Utilization of extracted carbonaceous shale waste in eco-friendly cementitious blends,” Constr Build Mater, vol. 394, Aug. 2023. [CrossRef]

- I. Vegas, M. Cano, I. Arribas, M. Frías, and O. Rodríguez, “Physical-mechanical behavior of binary cements blended with thermally activated coal mining waste,” Constr Build Mater, vol. 99, pp. 169–174, Nov. 2015. [CrossRef]

- J. Eduardo Mejia-Ballesteros, L. Rodier, R. Filomeno, H. Savastano, J. Fiorelli, and M. Frias Rojas, “Effect of activated coal waste and treated Pinus fibers on the physico-mechanical properties and durability of fibercement composites,” Constr Build Mater, vol. 392, Aug. 2023. [CrossRef]

- M. Záleská et al., “Thermally treated coal mining waste as a supplementary cementitious material – Case study from Bogdanka mine, Poland,” Journal of Building Engineering, vol. 68, Jun. 2023. [CrossRef]

- L. Caneda-Martínez, M. Frías, C. Medina, M. I. S. de Rojas, N. Rebolledo, and J. Sánchez, “Evaluation of chloride transport in blended cement mortars containing coal mining waste,” Constr Build Mater, vol. 190, pp. 200–210, Nov. 2018. [CrossRef]

- S. Yagüe, I. Sánchez, R. V. De La Villa, R. García-Giménez, A. Zapardiel, and M. Frías, “Coal-mining tailings as a pozzolanic material in cements industry,” Minerals, vol. 8, no. 2, Feb. 2018. [CrossRef]

- R. García Giménez, R. Vigil de la Villa, and M. Frías, “From coal-mining waste to construction material: a study of its mineral phases,” Environ Earth Sci, vol. 75, no. 6, Mar. 2016. [CrossRef]

- R. García-Giménez, M. Frías, I. Arribas, I. Vegas, R. V. de la Villa, and V. Rubio, “Freeze-thaw effect on the durability of binary cements containing activated coal-mining waste,” Constr Build Mater, vol. 190, pp. 140–149, Nov. 2018. [CrossRef]

- A. B. Moradikhou, M. Safehian, and E. M. Golafshani, “High-strength geopolymer concrete based on coal washing waste,” Constr Build Mater, vol. 362, Jan. 2023. [CrossRef]

- B. Malagón, G. Fernández, J. M. De Luis, and R. Rodríguez, “Feasibility study on the utilization of coal mining waste for Portland clinker production,” Environmental Science and Pollution Research, vol. 27, no. 1, pp. 21–32, Jan. 2020. [CrossRef]

- “Effect of Alkali-activation on Elaboration of a Binder Based on Ground Coal Gangue,” NanoWorld J, vol. 9, Sep. 2023. [CrossRef]

- S. Maruthupandian, A. Chaliasou, and A. Kanellopoulos, “Recycling mine tailings as precursors for cementitious binders – Methods, challenges and future outlook,” Dec. 20, 2021, Elsevier Ltd. [CrossRef]

- M. I. Al Biajawi, R. Embong, K. Muthusamy, N. Ismail, and I. I. Obianyo, “Recycled coal bottom ash as sustainable materials for cement replacement in cementitious Composites: A review,” Jul. 04, 2022, Elsevier Ltd. [CrossRef]

- P. Chakartnarodom et al., “Upcycling low-grade coal fly ash for the production of fly ash fibers and their applications in fiber-reinforced cement composites,” Constr Build Mater, vol. 414, Feb. 2024. [CrossRef]

- S. Hesami, A. Modarres, M. Soltaninejad, and H. Madani, “Mechanical properties of roller compacted concrete pavement containing coal waste and limestone powder as partial replacements of cement,” Constr Build Mater, vol. 111, pp. 625–636, May 2016. [CrossRef]

- Y. Yao, Y. Li, X. Liu, S. Jiang, C. Feng, and E. Rafanan, “Characterization on a cementitious material composed of red mud and coal industry byproducts,” Constr Build Mater, vol. 47, pp. 496–501, 2013. [CrossRef]

- M. Taslimi Paein Afrakoti, A. Janalizadeh Choobbasti, M. Ghadakpour, and S. Soleimani Kutanaei, “Investigation of the effect of the coal wastes on the mechanical properties of the cement-treated sandy soil,” Constr Build Mater, vol. 239, Apr. 2020. [CrossRef]

- M. Nawaz, A. Heitor, and M. Sivakumar, “Geopolymers in construction - recent developments,” Nov. 10, 2020, Elsevier Ltd. [CrossRef]

- K. Korniejenko, P. Bazan, B. Figiela, B. Kozub, and M. Łach, “CHARACTERIZATION OF MINE TAILINGS AS RAW MATERIALS FOR GEOPOLYMER SYNTHESIS-MINERALOGICAL COMPOSITION.” [Online]. Available: https://paginas.fe.up.pt/~m2d/proceedings_m2d2022/-1081-.

- X. Lu et al., “Innovate geopolymer synthesis for green mine road construction: Analysis of efflorescence behavior and strength analysis,” Constr Build Mater, vol. 401, Oct. 2023. [CrossRef]

- S. Mabroum, S. Moukannaa, A. El Machi, Y. Taha, M. Benzaazoua, and R. Hakkou, “Mine wastes based geopolymers: A critical review,” Dec. 01, 2020, Elsevier Ltd. [CrossRef]

- Y. Guo et al., “Preparation of the geopolymer grouting material by coal-based solid wastes for the aquiclude key strata and its application,” Constr Build Mater, vol. 408, Dec. 2023. [CrossRef]

- L. Haibin and L. Zhenling, “Recycling utilization patterns of coal mining waste in China,” Resour Conserv Recycl, vol. 54, no. 12, pp. 1331–1340, 2010. [CrossRef]

- J. Wang, Q. Qin, S. Hu, and K. Wu, “A concrete material with waste coal gangue and fly ash used for farmland drainage in high groundwater level areas,” J Clean Prod, vol. 112, pp. 631–638, Jan. 2016. [CrossRef]

- E. J. Foghi, T. Vo, M. Rezania, M. Mousavi Nezhad, and L. Ferrara, “Early age hydration behaviour of foam concrete containing a coal mining waste: novel experimental procedures and effects of capillary pressure,” Constr Build Mater, vol. 414, Feb. 2024. [CrossRef]

- H. Amiri, S. Azadi, M. Karimaei, H. Sadeghi, and Farshad Dabbaghi, “Multi-objective optimization of coal waste recycling in concrete using response surface methodology,” Journal of Building Engineering, vol. 45, Jan. 2022. [CrossRef]

- M. Xiao, F. Ju, and Z. quan He, “Research on shotcrete in mine using non-activated waste coal gangue aggregate,” J Clean Prod, vol. 259, Jun. 2020. [CrossRef]

- B. Indraratna, I. Gasson, and R. N. Chowdhury, “Utilization of compacted coal tailings as a struct6i+al fih.” [Online]. Available: www.nrcresearchpress.com.

- P. Segui, A. el M. Safhi, M. Amrani, and M. Benzaazoua, “Mining Wastes as Road Construction Material: A Review,” Jan. 01, 2023, MDPI. [CrossRef]

- A. Modarres and M. Rahmanzadeh, “Application of coal waste powder as filler in hot mix asphalt,” Constr Build Mater, vol. 66, pp. 476–483, Sep. 2014. [CrossRef]

- F. Li, X. Zhao, and X. Zhang, “Utilizing original and activated coal gangue wastes as alternative mineral fillers in asphalt binder: Perspectives of rheological properties and asphalt-filler interaction ability,” Constr Build Mater, vol. 365, Feb. 2023. [CrossRef]

- M. Amrani, Y. Taha, Y. El Haloui, M. Benzaazoua, and R. Hakkou, “Sustainable reuse of coal mine waste: Experimental and economic assessments for embankments and pavement layer applications in morocco,” Minerals, vol. 10, no. 10, pp. 1–17, Oct. 2020. [CrossRef]

- J. Zhang et al., “Study on mechanical properties and damage characteristics of coal-based solid waste cemented backfill,” Constr Build Mater, vol. 368, Mar. 2023. [CrossRef]

- Z. Qin et al., “Insights into mechanical property and damage evaluation of a novel waste-based coal gangue-filled backfill,” Constr Build Mater, vol. 389, Jul. 2023. [CrossRef]

- P. Yan, Z. Ma, H. Li, P. Gong, M. Xu, and T. Chen, “Laboratory tests, field application and carbon footprint assessment of cement-stabilized pure coal solid wastes as pavement base materials,” Constr Build Mater, vol. 366, Feb. 2023. [CrossRef]

- L. Banerjee, S. Chawla, and S. Kumar Dash, “Application of geocell reinforced coal mine overburden waste as subballast in railway tracks on weak subgrade,” Constr Build Mater, vol. 265, Dec. 2020. [CrossRef]

- V. G. Lemeshev, I. K. Gubin, Y. A. Savel’ev, D. V Tumanov, and D. O. Lemeshev, “UTILIZTION OF WASTE UTILIZATION OF COAL-MINING WASTE IN THE PRODUCTION OF BUILDING CERAMIC MATERIALS,” 2004.

- M. Charai et al., “Lightweight waste-based gypsum composites for building temperature and moisture control using coal fly ash and plant fibers,” Constr Build Mater, vol. 393, Aug. 2023. [CrossRef]

- M. Amrani, Y. Taha, Y. El Haloui, M. Benzaazoua, and R. Hakkou, “Sustainable reuse of coal mine waste: Experimental and economic assessments for embankments and pavement layer applications in morocco,” Minerals, vol. 10, no. 10, pp. 1–17, Oct. 2020. [CrossRef]

- E. S. Rentier and L. H. Cammeraat, “The environmental impacts of river sand mining,” Sep. 10, 2022, Elsevier B.V. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).