Submitted:

09 August 2024

Posted:

09 August 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Methodology

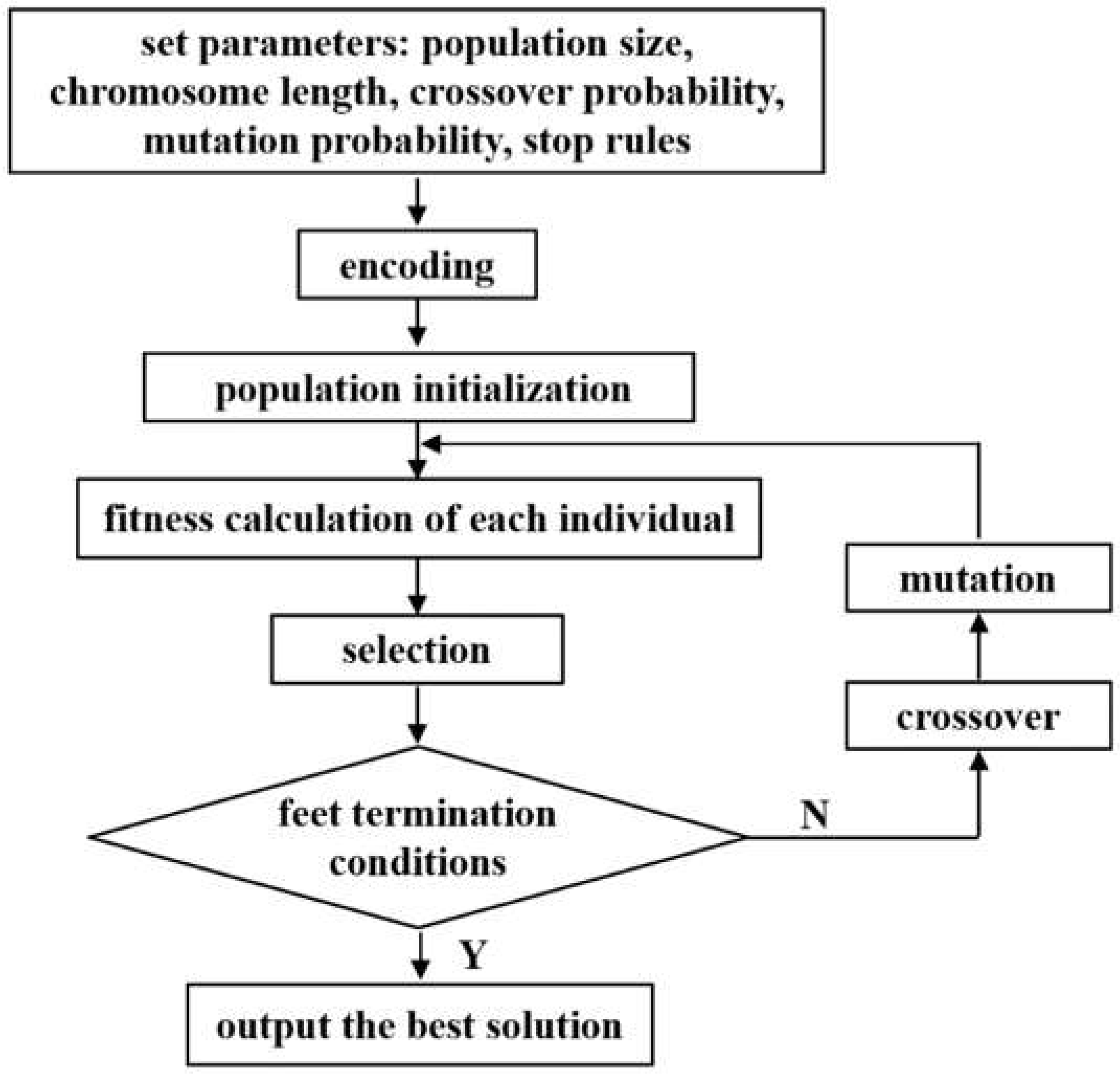

2.1. Genetic Algorithm

2.2. Optimization of Layers Regrouping Scheme with Genetic Algorithm

2.2.1. Parameter Preset

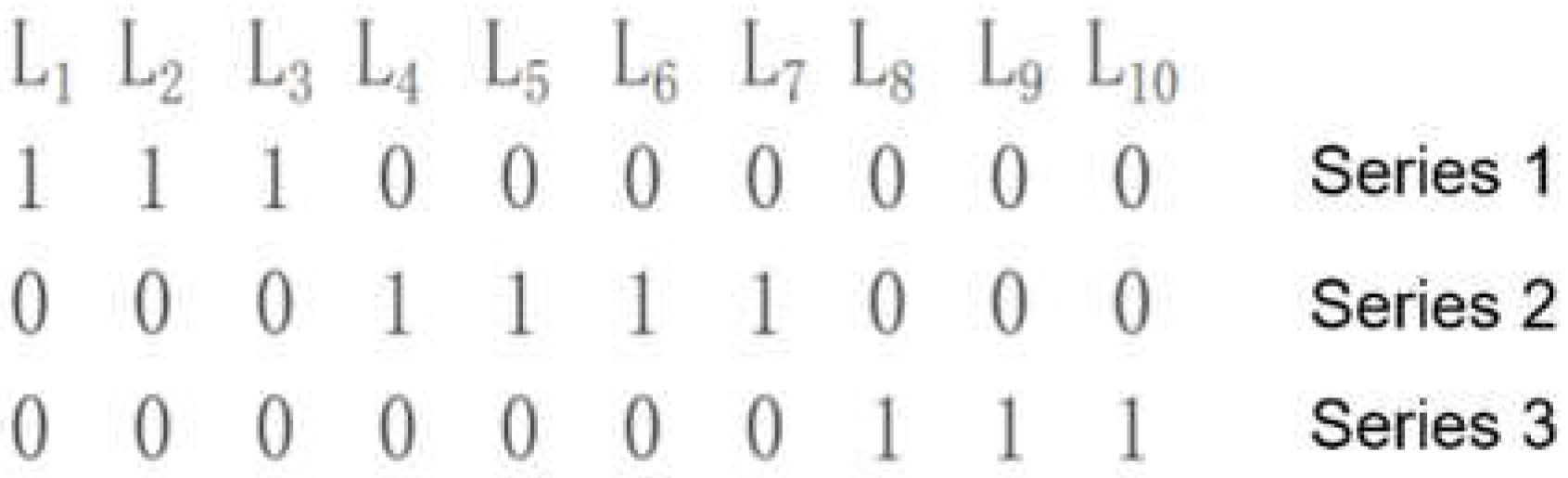

2.2.2. Population Initialization

2.2.3. Calculation of the Fitness Value for Each Regrouping Scheme

2.2.4. Genetic Calculation

3. Case Application

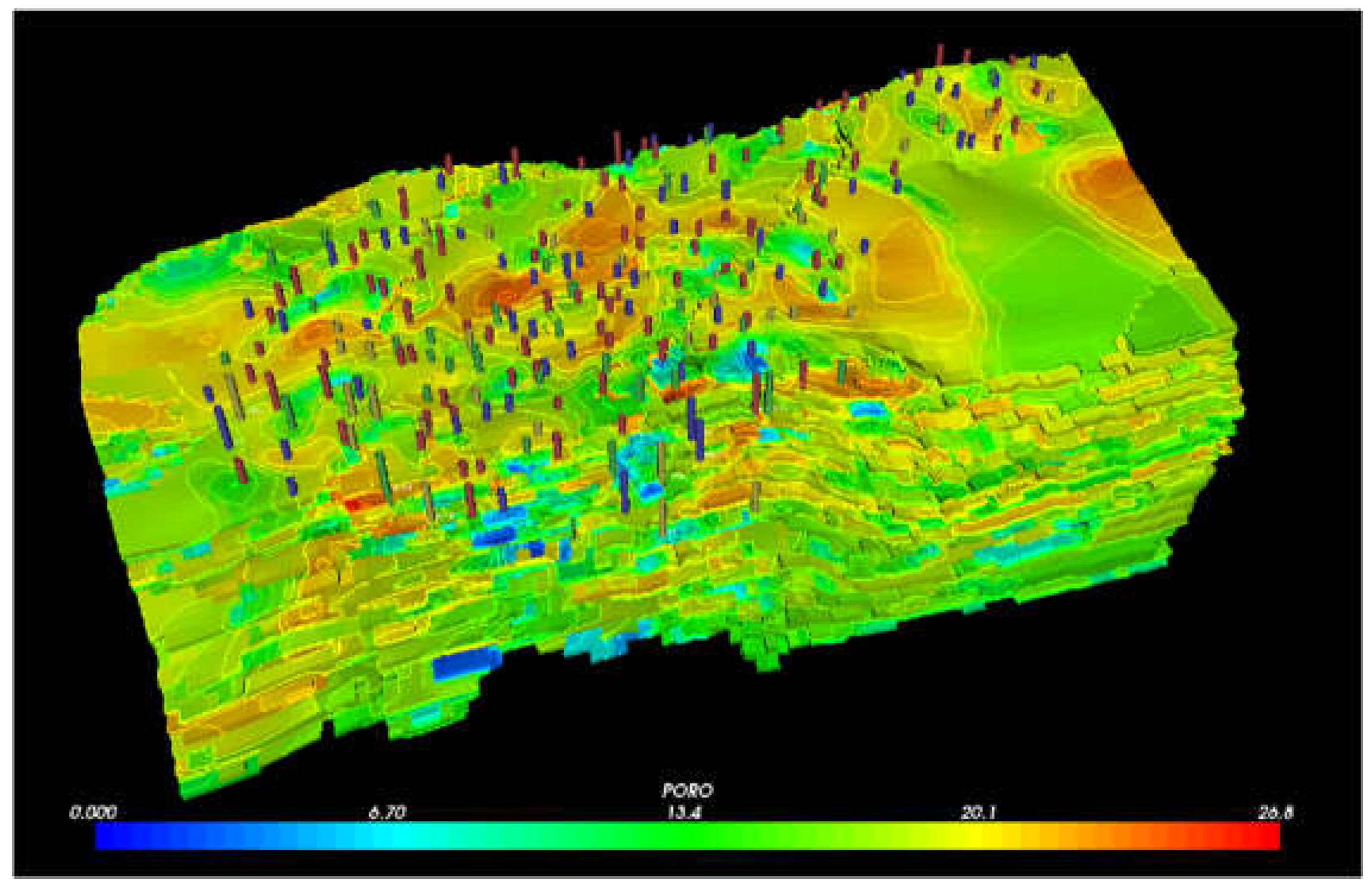

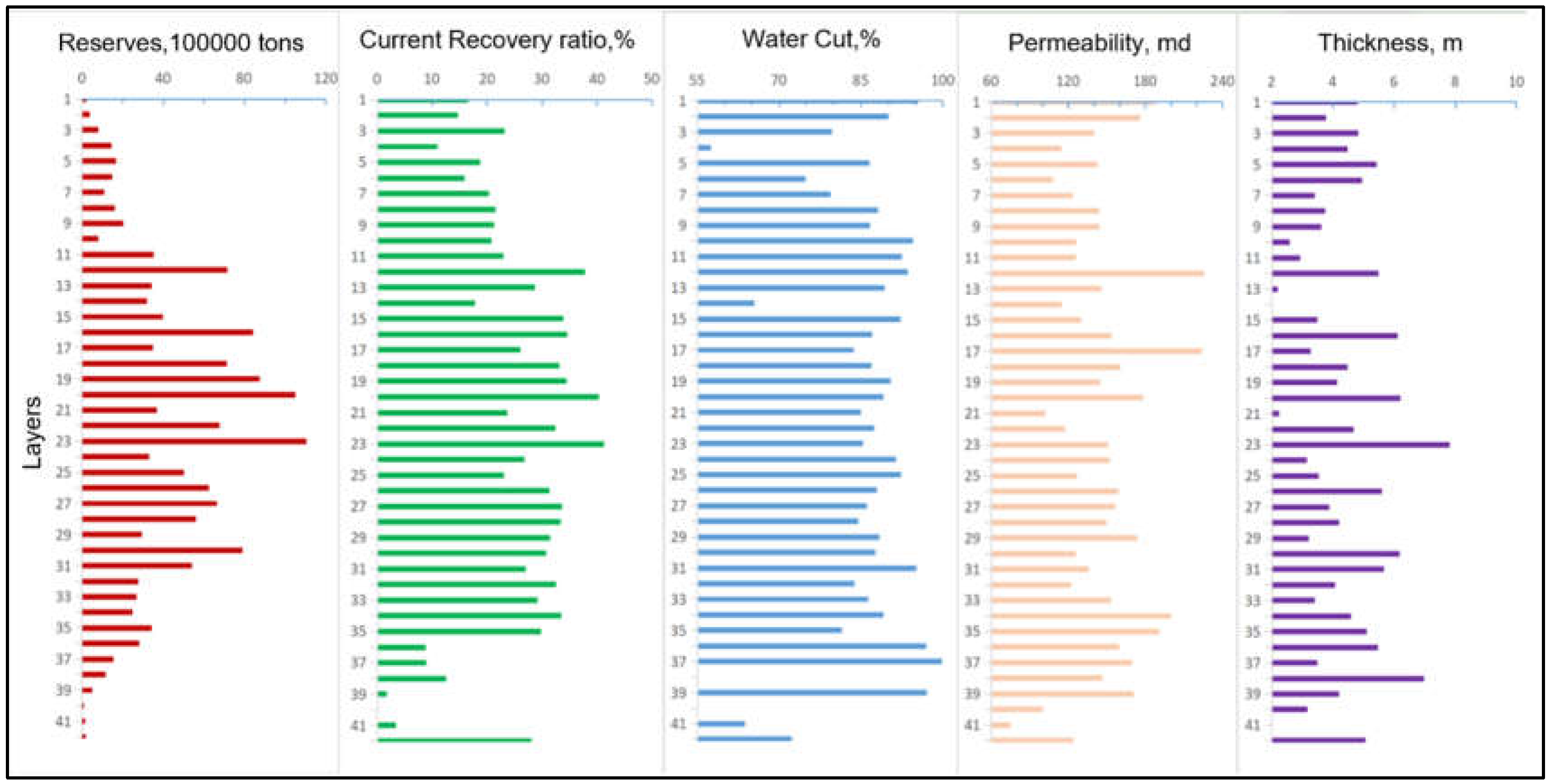

3.1. Overview of the Reservoir

3.2. Optimization of Layers Regrouping Scheme with Genetic Algorithm

3.3. Optimization Results

3.4. Reliability Analysis of Optimization Results

4. Deficiencies

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Han, D. Discussions on Concepts, Countermeasures and Technical Routes for the Redevelopment of High Water-cut Oilfields. Pet. Explor. Dev. 2010, 37, 583–591. [Google Scholar]

- Yu, H.; Wang, Y. Remaining oil distribution characteristics in an oil reservoir with ultra-high water-cut. Energy Geoscience 2022, 6, 004. [Google Scholar] [CrossRef]

- Mikael, H.; Tang, X. Development Journey and Outlook of Chinese Giant Oilfields. Pet. Explor. Dev. 2010, 37, 237–249. [Google Scholar]

- Song, X.; Qu, D. Low Cost Development Strategy for Oilfields in China. Pet. Explor. Dev. 2021, 48, 1007–1018. [Google Scholar] [CrossRef]

- Wang, W. Secondary Development Method of Lamadian Oilfield. Pet. Geol. Oilfield Dev. Daqing 2015, 34, 69–73. [Google Scholar]

- Hu, W. Necessity and Feasibility of PetroChina Mature Field Redevelopment. Pet. Explor. Dev. 2008, 35, 1–5. [Google Scholar] [CrossRef]

- Xue, L.; Liu, P. Status and Prospect of Improved Oil Recovery Technology of High Water Cut Reservoirs. Water 2023, 15, 1342. [Google Scholar] [CrossRef]

- Jin, Y. Optimization Technology of Stratigraphic Series Combination and Well Pattern in X Block During the Extra High Water Cut Period and Its Application. Pet. Geol. Oilfield Dev. Daqing 2020, 39, 86–93. [Google Scholar]

- Huang, X.; Zhang, X. Development by Layer Series Subdivision in Wendong Oil Field. Pet. Explor. Dev. 2003, 30, 84–87. [Google Scholar]

- Li, R.; Zhang, J. The Research of Layer System Subdivision and Adjustment Methods in YSL Block of the Low Permeability Reservoirs. Mech. Eng., Mater. Sci. Civ. Eng. 2013, 274, 153. [Google Scholar] [CrossRef]

- Yao, B.; Zhao, Q. A Successful Test with Subdivision of Oil Layers and Adjustment of Water Flooding in Gaotaizi Oil Zone, Daqing Oilfield. Pet. Explor. Dev. 2008, 35, 220–224. [Google Scholar] [CrossRef]

- Lin, L. Study on Optimization of Combined Parameters of Subdivision Water Injection Layer Sections in Ultra-high Water Cut Stage. In Proceedings of the 3rd International Conference on Advances in Energy and Environment Research (ICAEER 2018), Guilin, China, Agu10-12, 2018. E3S Web of Conferences 2018, 53, 01020. [Google Scholar]

- Wang, H. Research on Improvement of Water Flooding by Subdivision of Extra-High Water Cut Period. In Proceedings of the 4th International Conference on Energy Science and Applied Technology, Chongqing, China, 2018. AIP Conference Proceedings 2066, 020033(2019)., Dec29-30. [CrossRef]

- Wang, S.; Niu, S. Layer Subdivision in The Late High Water Cut Stage in The Complex Fault Block Reservoirs, Dongxin Oilfield. Pet. Explor. Dev. 2004, 31, 116–118. [Google Scholar]

- Li, L. Technical Limits of Layer Recombination and Well Pattern Reconfiguration in B2 Oil Region. Spr. Ser. Geomech. Geoeng. 2020, 1560–1568. [Google Scholar]

- Zhang, C.; Teng, S. Optimization of CO2 flooding layer combination in multi thin and ultra-low permeability beach bar sand reservoirs. Petroleum Geology and Recovery Efficiency, 2021, 28, 119–125. [Google Scholar]

- Li, Q.; Zhang, J. Grey Decision-making Theory in the Optimization of Strata Series Recombination Programs of High water-cut Oilfields. Pet. Explor. Dev. 2011, 38, 463–468. [Google Scholar] [CrossRef]

- Shen, A.; Gao, L. Application of Grey Correlation and Cluster Analysis Method in Optimization and Reorganization of Oil Layer Series. Math. Prac. Theor. 2019, 5, 130–137. [Google Scholar]

- Wu, Y. Optimization of Production Layers Subdivision and Prediction of Oil Displacement Effect in Multi-layer Water Drive Reservoirs. Chem. Enterp. Manage. 2021, 11, 197–198. [Google Scholar]

- Hu, Q.; Wang, X. The Mathematical Method and Application of Strata Series Recombination in the Middle-late Stages of Multi-layer Sandstone Reservoir Development. Spr. Ser. Geomech. Geoeng. 2023, 4063–4078. [Google Scholar]

- Wu, Z.; Cui, C. Layer Regrouping Optimization for Multilayer Heterogeneous Reservoirs at a High Water Cut Stage. Arabian Journal of Geosciences. 2019, 12, 458. [Google Scholar] [CrossRef]

- Cui, C.; Jian, P. Layer Regrouping for Water-flooded Commingled Reservoirs at a High Water-cut Stage. Petroleum Science. 2016, 13, 272–279. [Google Scholar] [CrossRef]

- Holland, J. Adaptation in Natural and Artificial Systems. University of Michigan Press: Michigan, USA; 1975; 211-247.

- Yan, X. Genetic Algorithm and Its Applications. China University of Geosciences Press: Beijing, China, 2018; 2-51.

- Zheng, S. Industrial Intelligence Technology and Applications. Shanghai Science & Technology Publishers: Shanghai, China, 2019; 250-251.

| Schemes | Division standard |

|---|---|

| Initial 1 | 3 series with reserves of 150000 tons and 500000 tons as thresholds |

| Initial 2 | 3 series with remaining reserves of 100000 tones and 400000 tons as thresholds |

| Initial 3 | 3 series with current recovery ratio of 0.15 and 0.25 as thresholds |

| Initial 4 | 3 series with comprehensive water cut of 0.75 and 0.9 as thresholds |

| Initial 5 | 3 series with permeabilities of 100 md and 150 md as thresholds |

| Initial 6 | 3 series with thicknesses of 3 meters and 5 meters as thresholds |

|

| Layer groups | Layers |

|---|---|

| Group 1 | 1,2,3,4,5,6,7,8,9,10,14,38,39,40,41,42 |

| Group 2 | 11,13,15,17,21,24,29,32,33,34,35,36,37 |

| Group 3 | 12,16,18,19,20,22,23,25,26,27,28,30,31 |

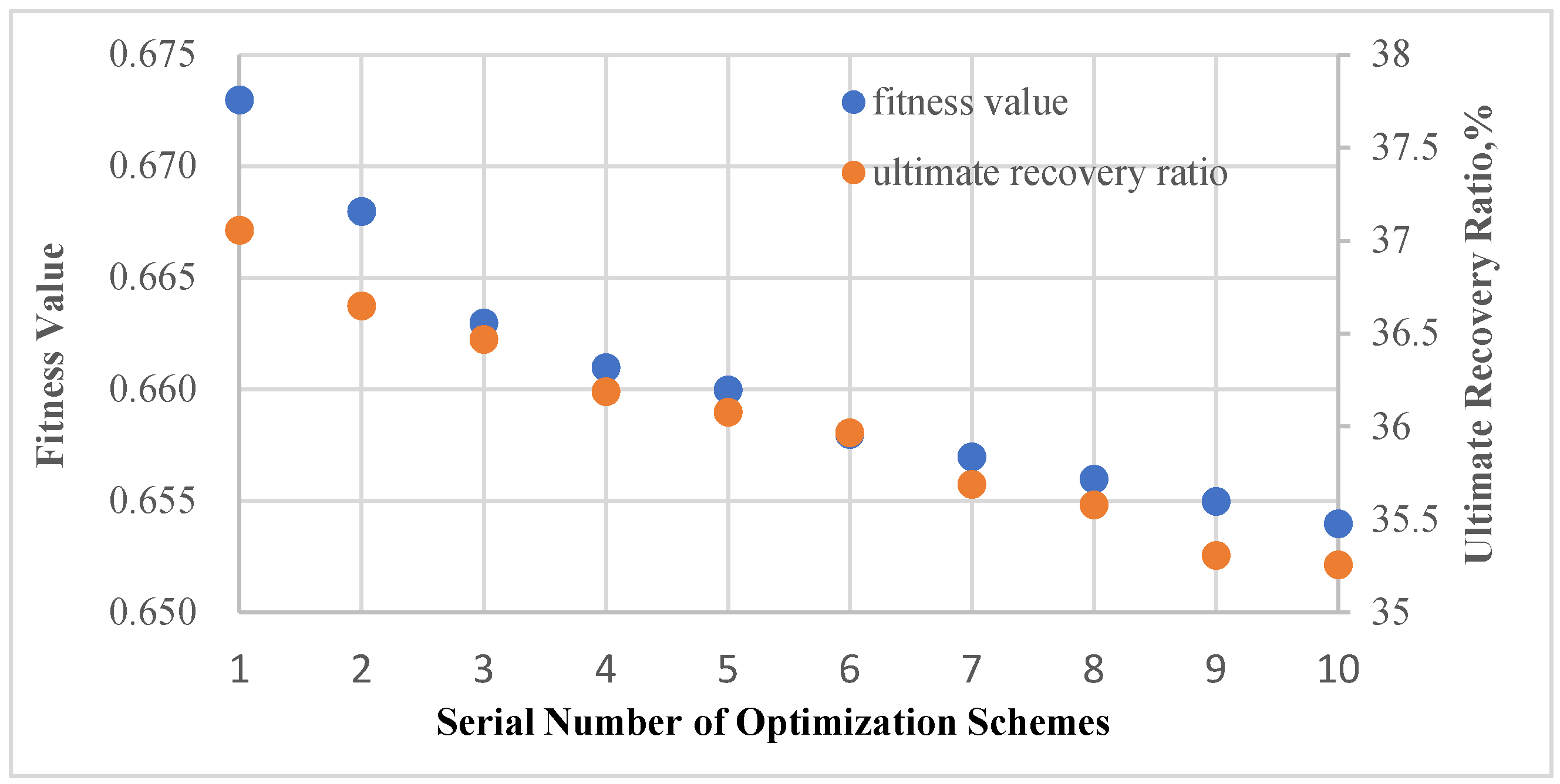

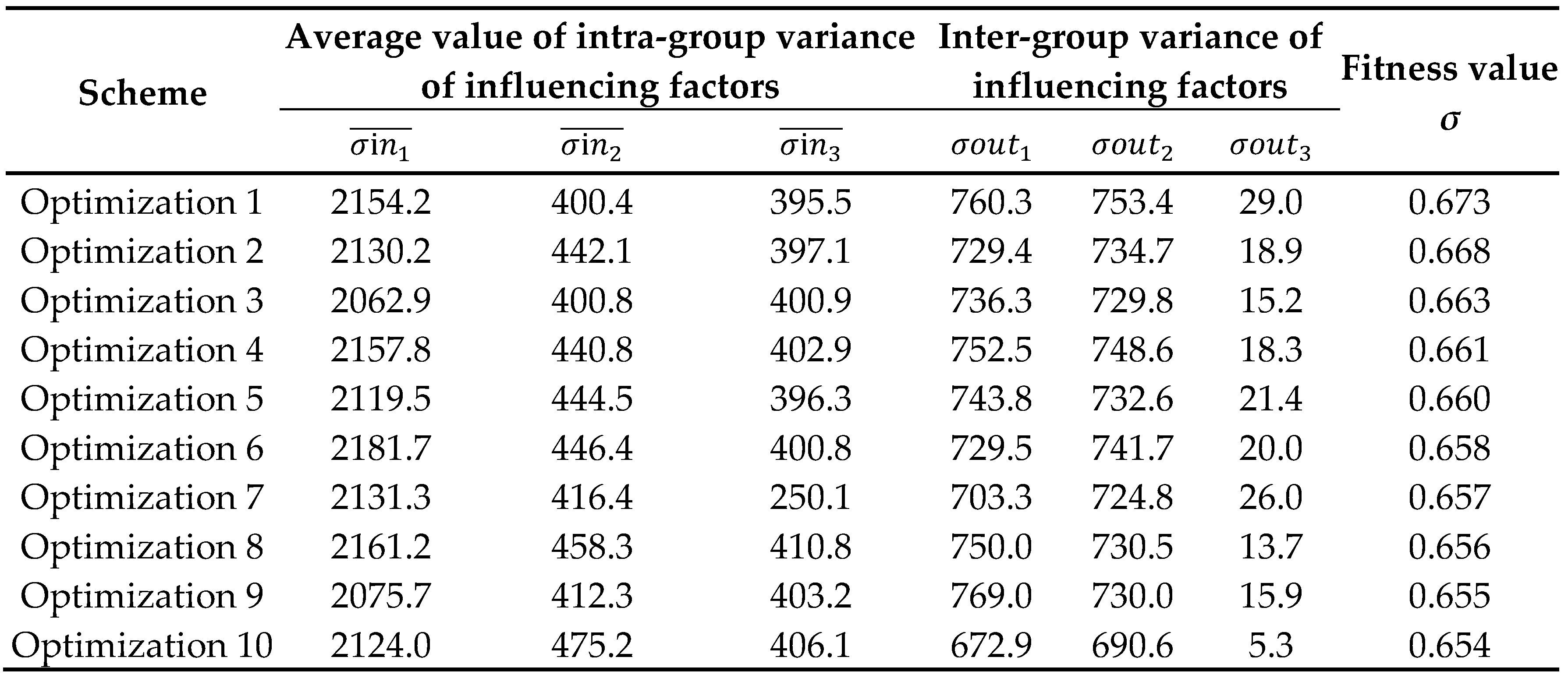

| Scheme | Fitness value | Ultimate recovery rate calculated 刘by numerical simulation, % |

|---|---|---|

| Optimization 1 | 0.673 | 37.06 |

| Optimization 2 | 0.668 | 36.65 |

| Optimization 3 | 0.663 | 36.47 |

| Optimization 4 | 0.661 | 36.19 |

| Optimization 5 | 0.660 | 36.08 |

| Optimization 6 | 0.658 | 35.97 |

| Optimization 7 | 0.657 | 35.69 |

| Optimization 8 | 0.656 | 35.58 |

| Optimization 9 | 0.655 | 35.31 |

| Optimization 10 | 0.654 | 35.26 |

| Non-optimization scheme | 32.72 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).