Submitted:

07 August 2024

Posted:

07 August 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

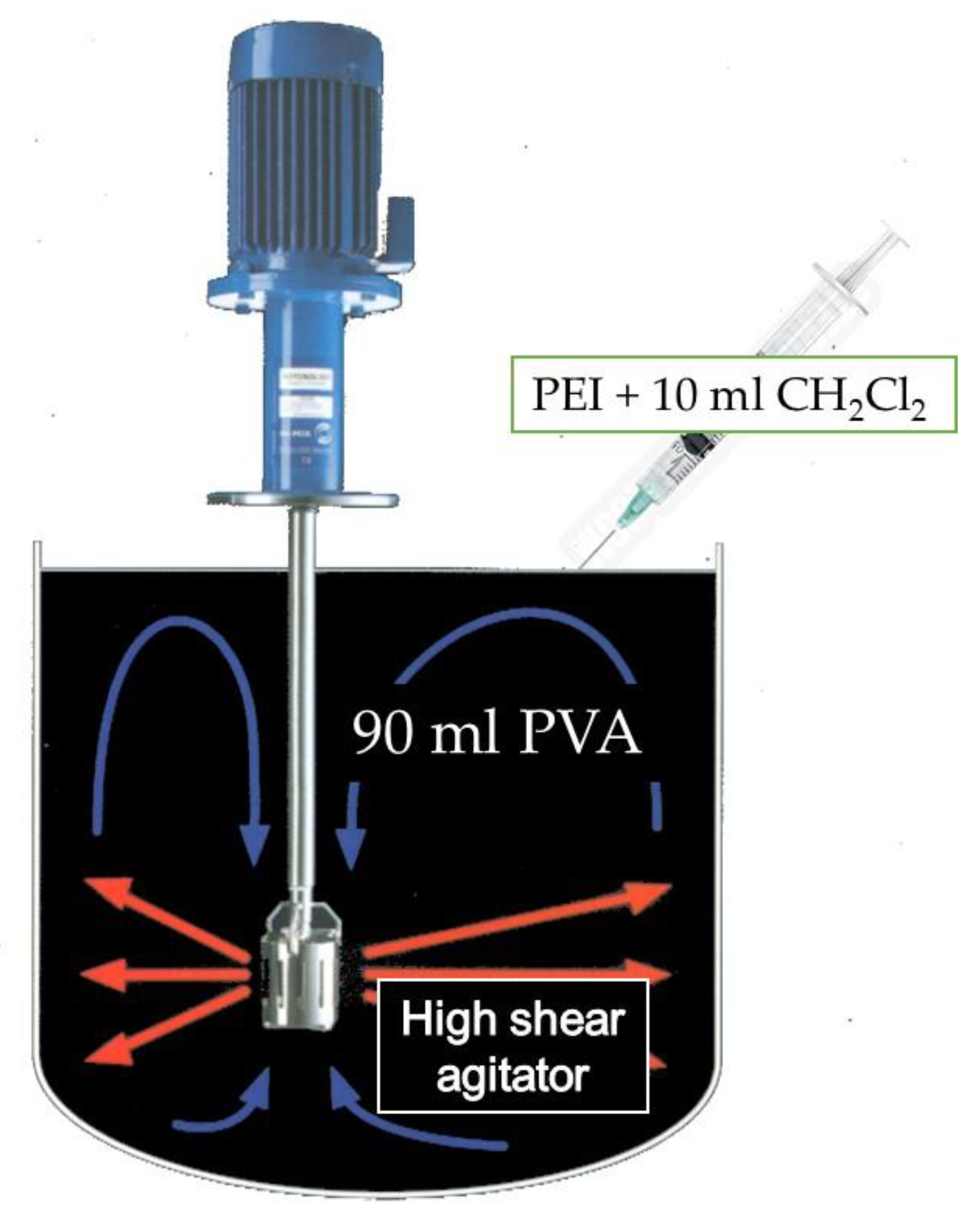

2.1. Experimental Methodology

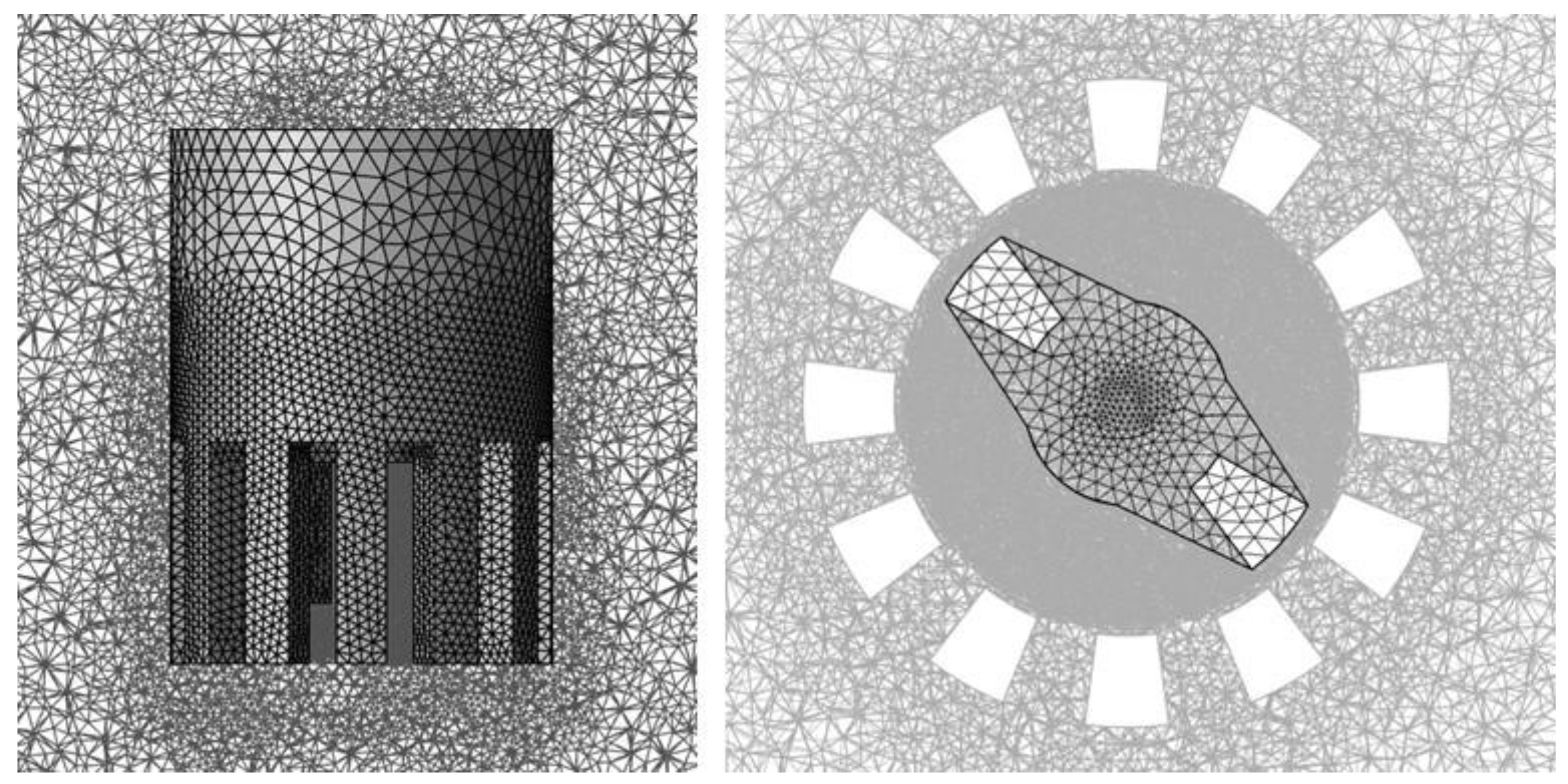

2.2. CFD Simulation Strategy

3. Results and Discussion

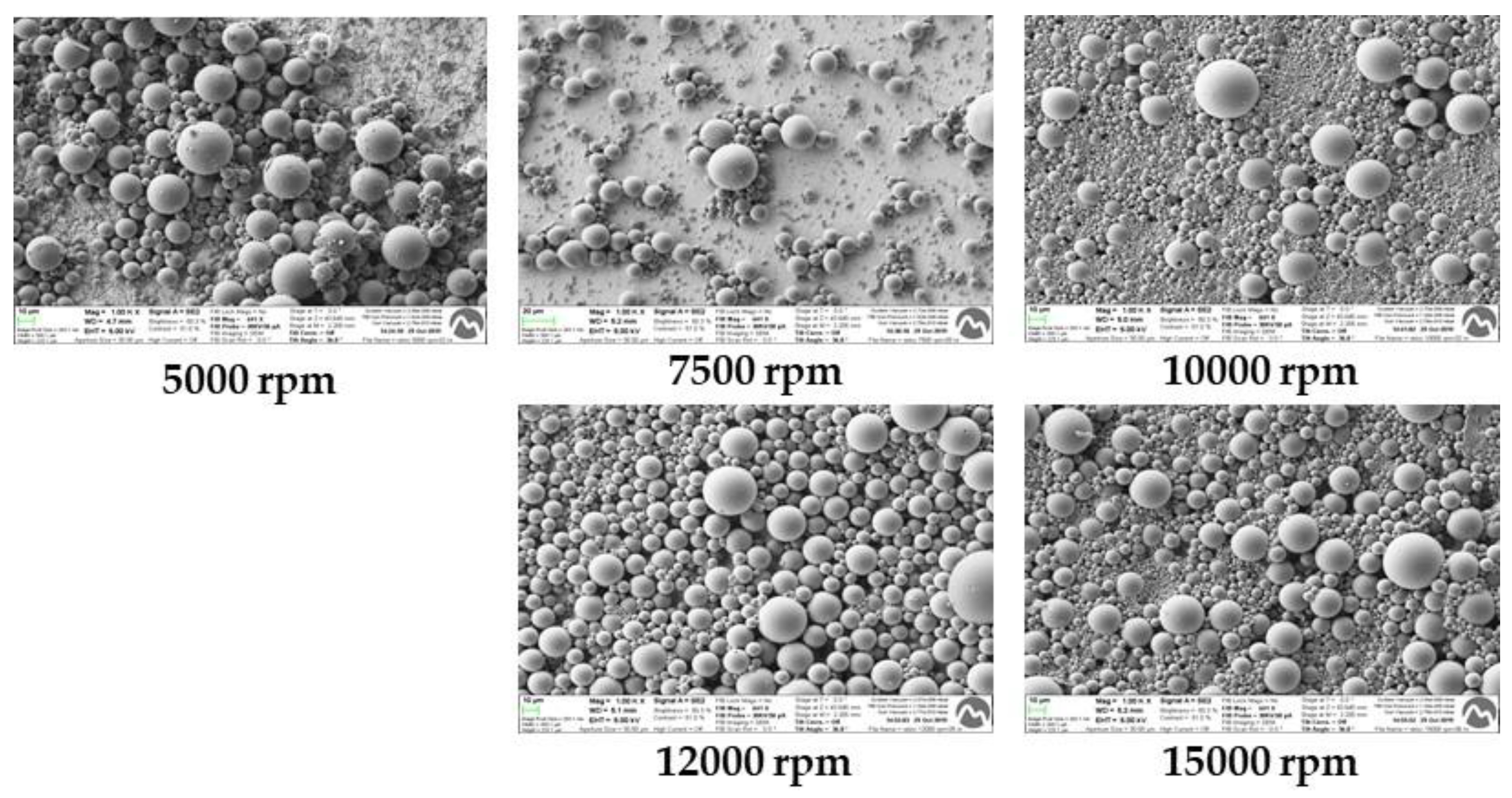

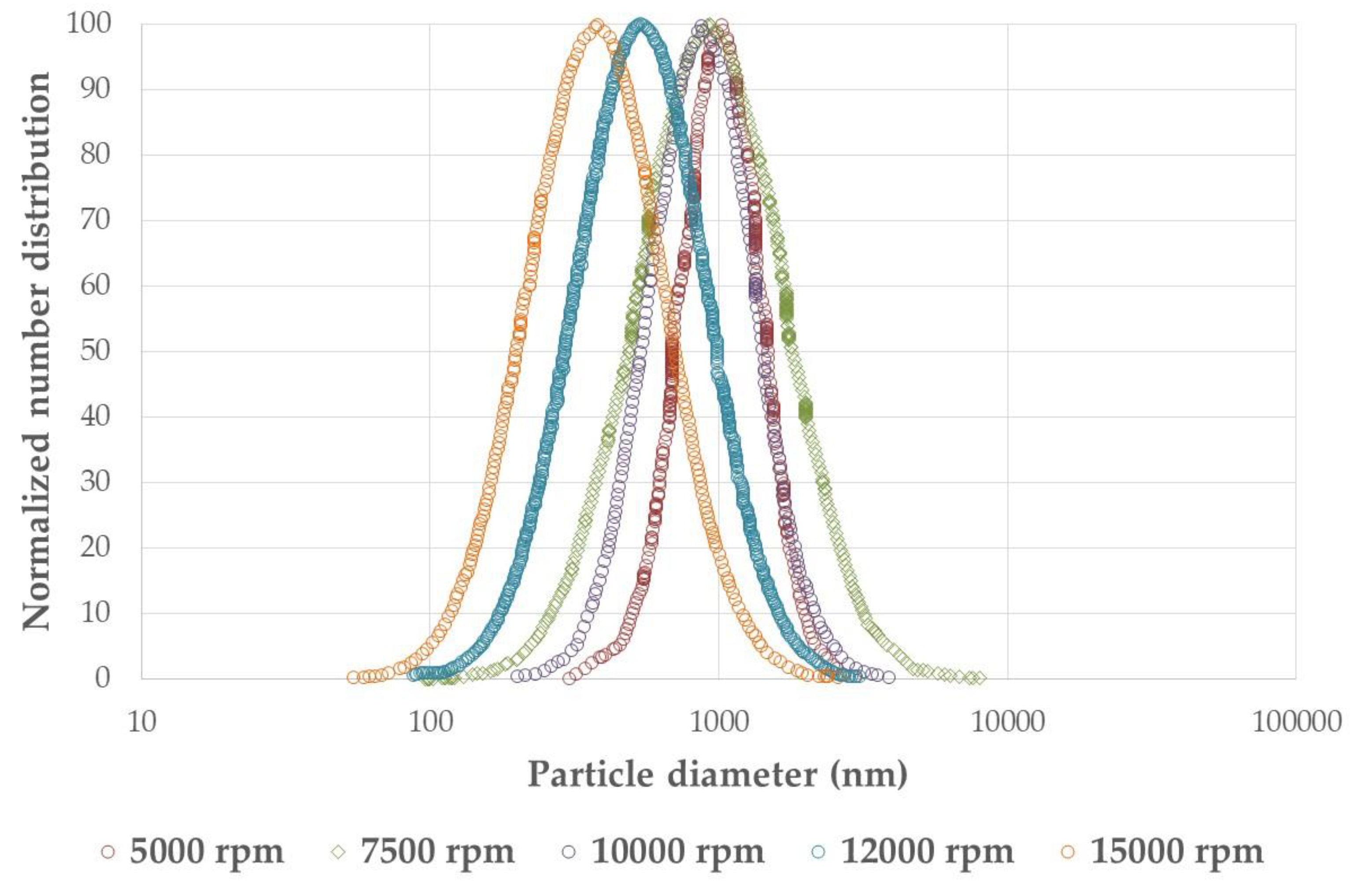

3.1. Experimental Particle Size Distributions

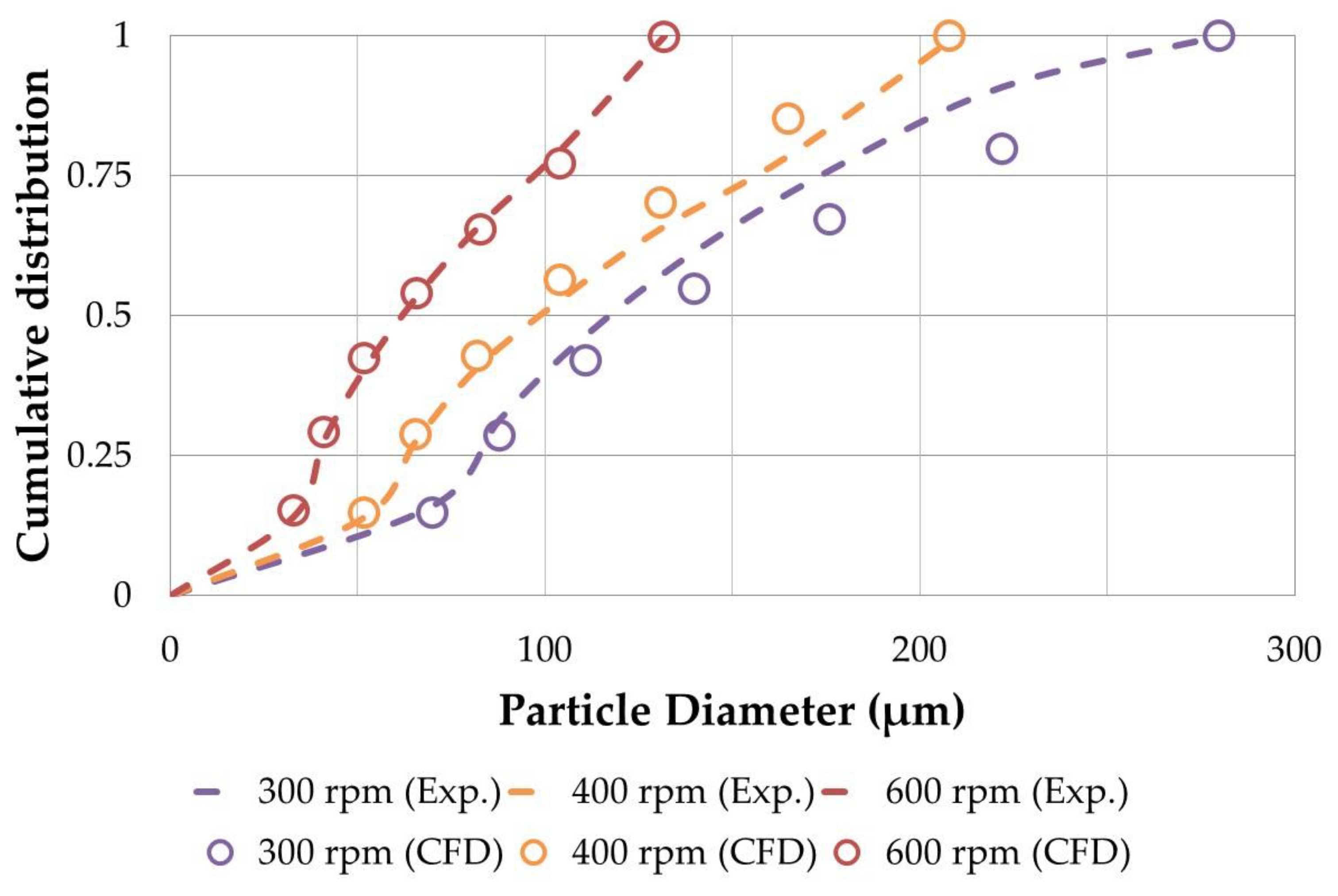

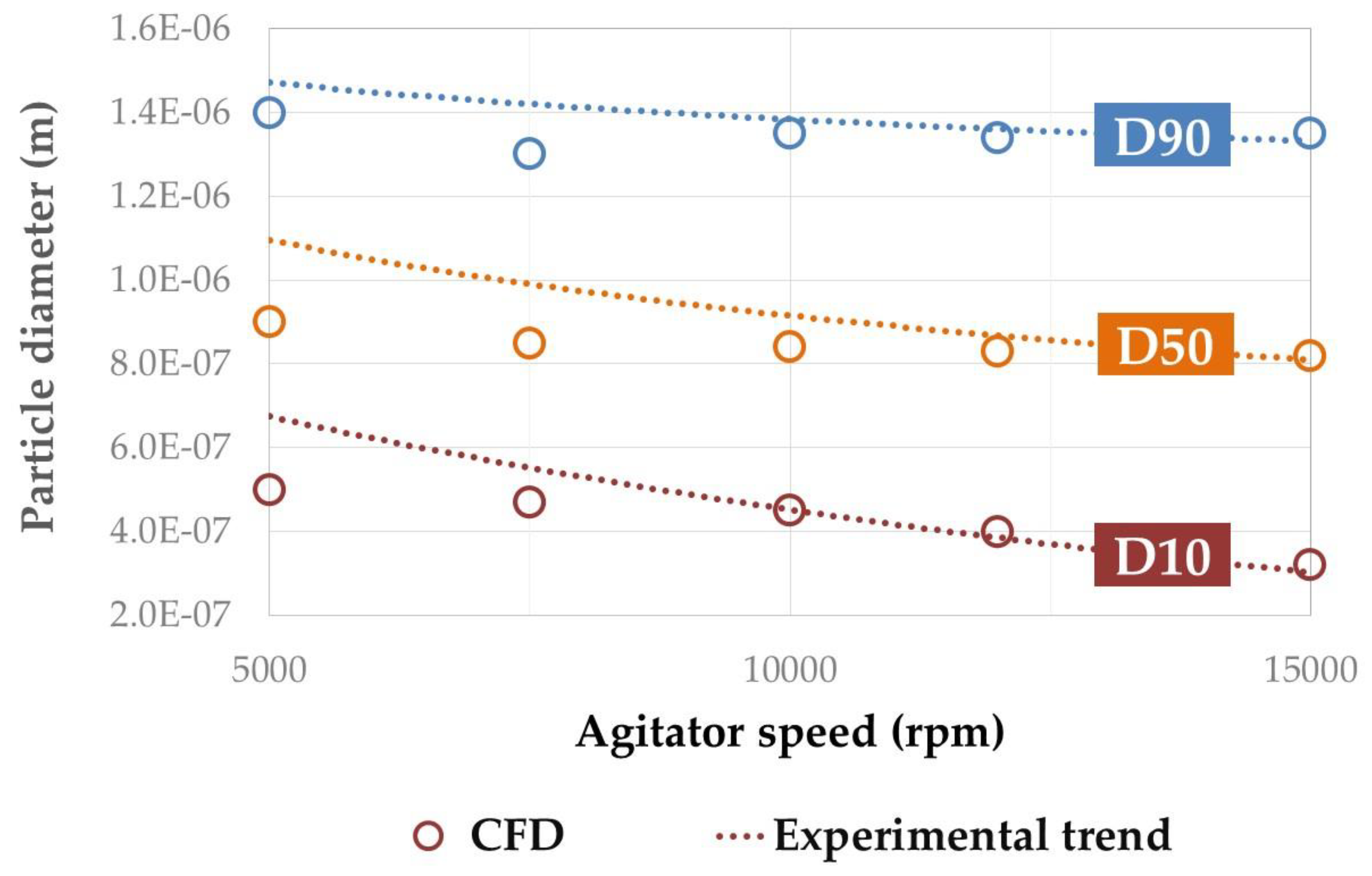

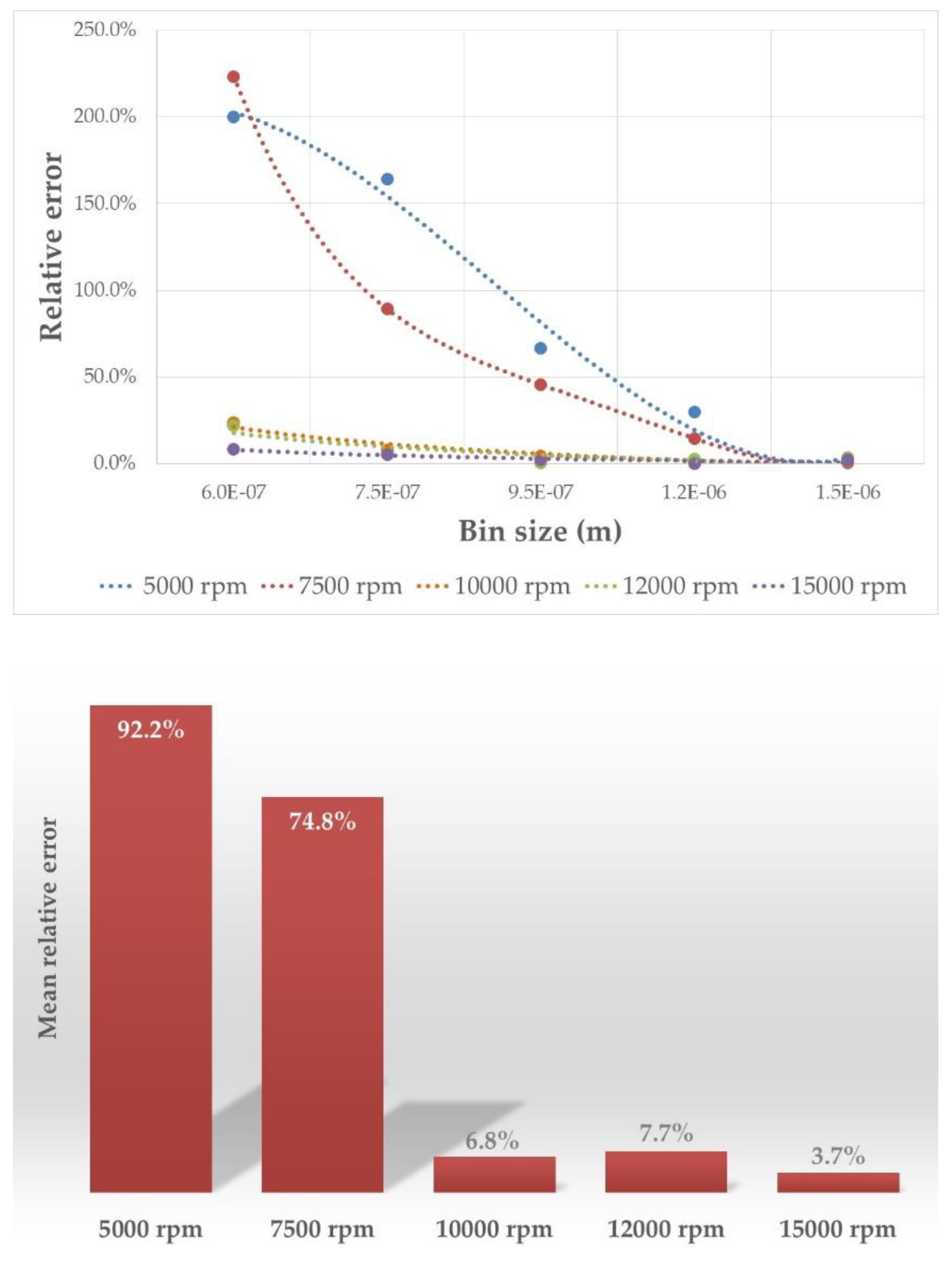

3.2. CFD + PBM Model Performance

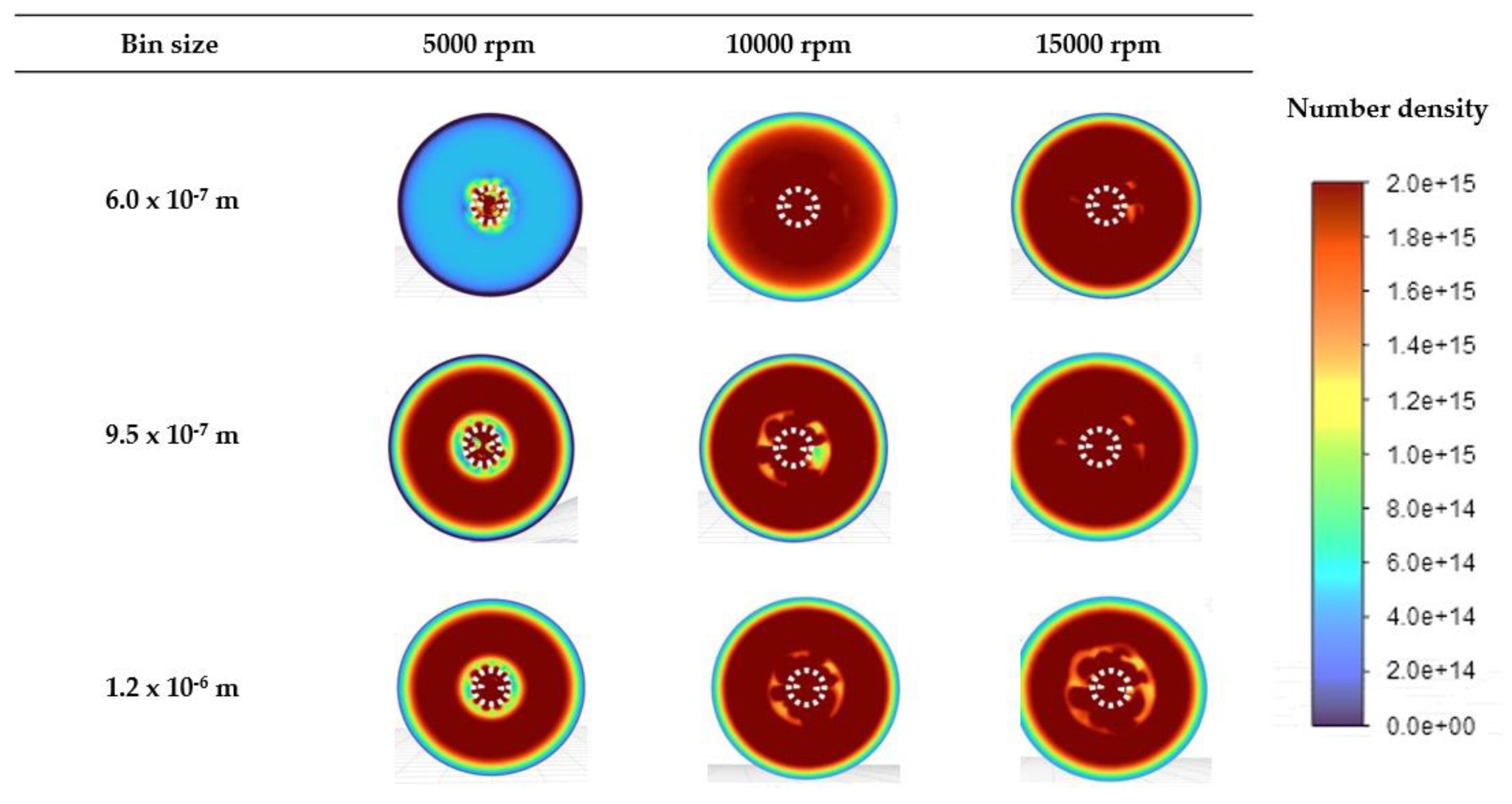

3.2.1. Particle Number Densities

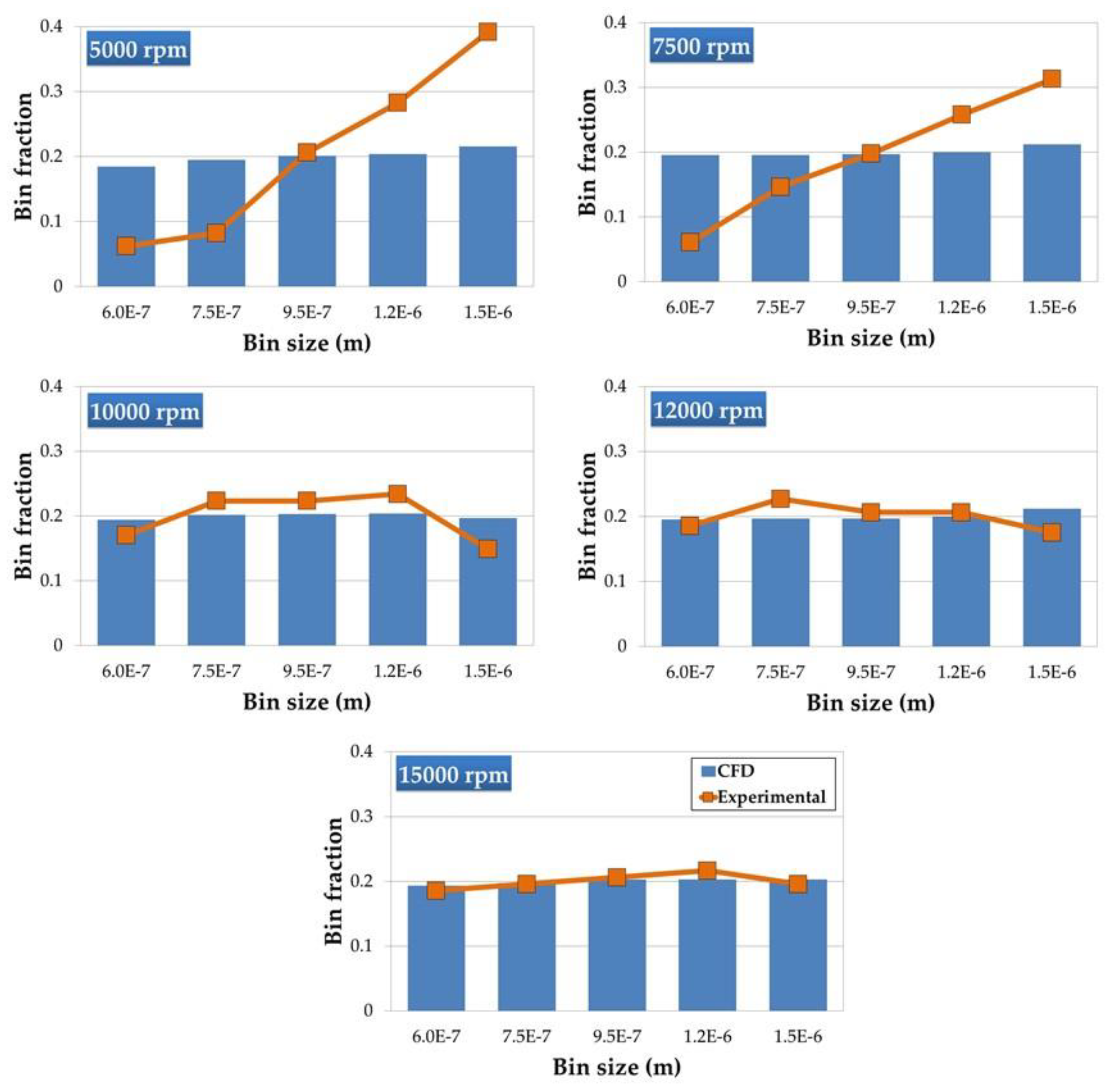

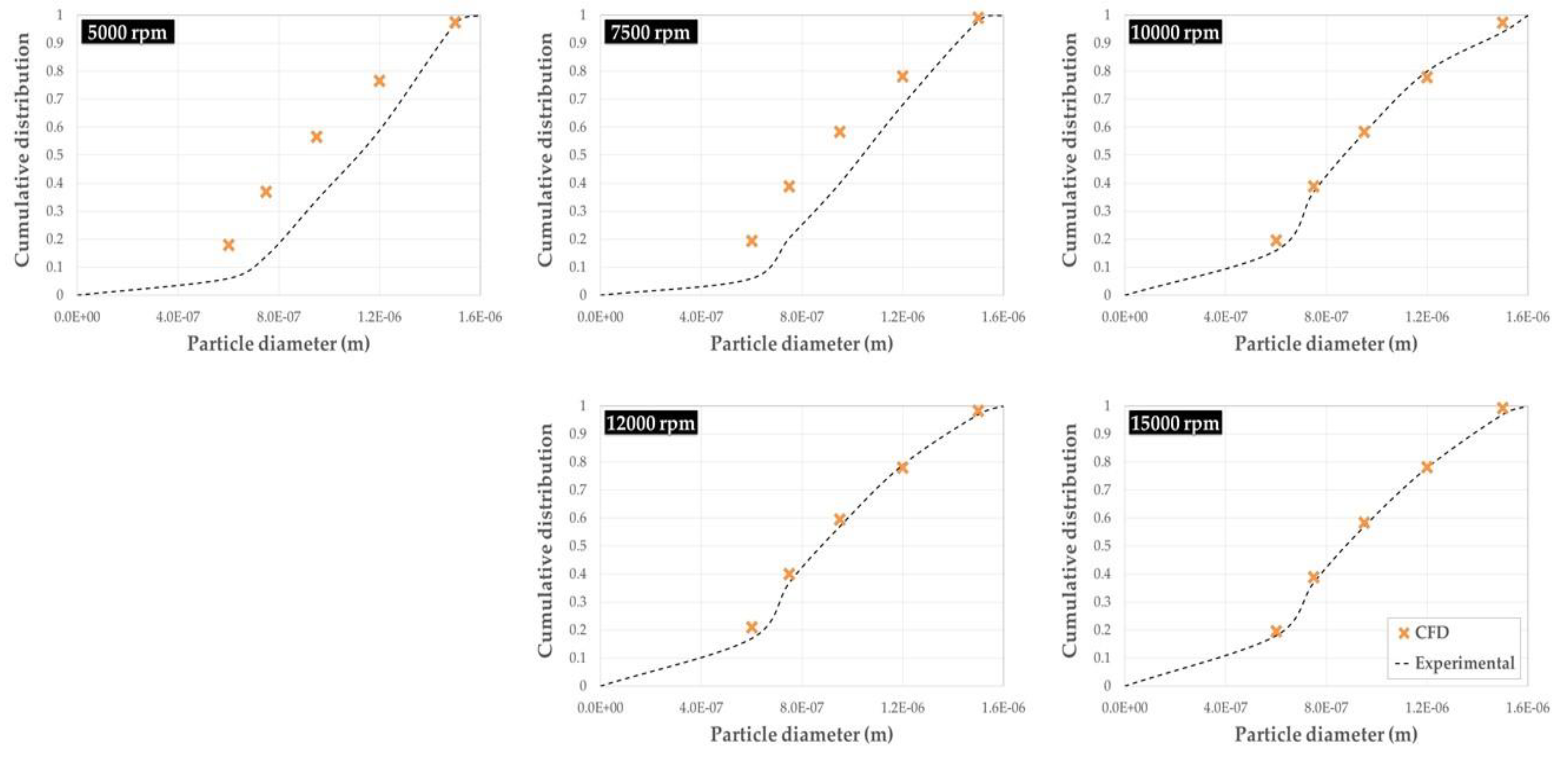

3.2.2. Particle Size Distribution

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kolhe, P.; Randhe, G.; Shingote, V.; Thorat, S. A Review: Microencapsulation. International Research Journal of Modernization in Engineering Technology and Science 2024, 06, 149–156. [Google Scholar]

- Ibraheem, U.; Rehman, A.; Ahmed, N. Microencapsulation: Methodologies and Applications. Novel Formulations and Future Trends: Recent and Future Trends in Pharmaceutics, Volume 3 2024, 3, 31–60. [Google Scholar] [CrossRef]

- Elkalla, E.; Khizar, S.; Tarhini, M.; Lebaz, N.; Zine, N.; Jaffrezic-Renault, N.; Errachid, A.; Elaissari, A. Core-Shell Micro/Nanocapsules: From Encapsulation to Applications. J Microencapsul 2023, 40, 125–156. [Google Scholar] [CrossRef] [PubMed]

- Luo, H.; Svendsen, H.F. Theoretical Model for Drop and Bubble Breakup in Turbulent Dispersions. AIChE Journal 1996, 42, 1225–1233. [Google Scholar] [CrossRef]

- Thakur, N.; Murthy, H. Simulation Study of Droplet Formation in Inkjet Printing Using ANSYS FLUENT. J Phys Conf Ser 2022, 2161, 012026. [Google Scholar] [CrossRef]

- Niamah, A.K.; Gddoa Al-Sahlany, S.T.; Ibrahim, S.A.; Verma, D.K.; Thakur, M.; Singh, S.; Patel, A.R.; Aguilar, C.N.; Utama, G.L. Electro-Hydrodynamic Processing for Encapsulation of Probiotics: A Review on Recent Trends, Technological Development, Challenges and Future Prospect. Food Biosci 2021, 44, 101458. [Google Scholar] [CrossRef]

- Alotaibi, H.; Abeykoon, C.; Soutis, C.; Jabbari, M. A Numerical Thermo-Chemo-Flow Analysis of Thermoset Resin Impregnation in LCM Processes. Polymers (Basel) 2023, 15, 1572. [Google Scholar] [CrossRef] [PubMed]

- Yuile, A.; Schulz, A.; Wiss, E.; Müller, J.; Wiese, S. The Simulated Effect of Adding Solder Layers on Reactive Multilayer Films Used for Joining Processes. Applied Sciences 2022, 12, 2397. [Google Scholar] [CrossRef]

- Ma, G. Microencapsulation of Protein Drugs for Drug Delivery: Strategy, Preparation, and Applications. Journal of Controlled Release 2014, 193, 324–340. [Google Scholar] [CrossRef] [PubMed]

- Khandbahale, S. V. Microencapsulation-A Novel Approach in Drug Delivery: A Review. Asian Journal of Research in Pharmaceutical Science 2020, 10, 39. [Google Scholar] [CrossRef]

- Zhu, J.; He, J.; Zhou, J.; Yang, Z.; Li, X.; Li, Y.; You, Z. Recent Progress in Microencapsulation Technology and Its Applications in Petroleum Industry. J Mol Liq 2024, 407, 125162. [Google Scholar] [CrossRef]

- Desai, K.G.H.; Jin Park, H. Recent Developments in Microencapsulation of Food Ingredients. Drying Technology 2005, 23, 1361–1394. [Google Scholar] [CrossRef]

- Calderón-Oliver, M.; Ponce-Alquicira, E. The Role of Microencapsulation in Food Application. Molecules 2022, 27, 1499. [Google Scholar] [CrossRef] [PubMed]

- Carvalho, I.T.; Estevinho, B.N.; Santos, L. Application of Microencapsulated Essential Oils in Cosmetic and Personal Healthcare Products – a Review. Int J Cosmet Sci 2016, 38, 109–119. [Google Scholar] [CrossRef] [PubMed]

- Martins, I.M.; Barreiro, M.F.; Coelho, M.; Rodrigues, A.E. Microencapsulation of Essential Oils with Biodegradable Polymeric Carriers for Cosmetic Applications. Chemical Engineering Journal 2014, 245, 191–200. [Google Scholar] [CrossRef]

- Randolph, A.D.; Larson, M.A. Theory of Particulate Processes; Elsevier, 1971; ISBN 9780125796507.

- Hounslow, M.J.; Ryall, R.L.; Marshall, V.R. A Discretized Population Balance for Nucleation, Growth, and Aggregation. AIChE Journal 1988, 34, 1821–1832. [Google Scholar] [CrossRef]

- Heath, A.R.; Koh, P.T.L. Combined Population Balance and CFD Modeling of Particle and Aggregation by Polymeric Flocculant. In Proceedings of the Third International Conference on CFD in the Minerals and Porcess Industries; Melbourne, Australia; 2003; pp. 339–344. [Google Scholar]

- Agterof, W.G.M.; Vaessen, G.E.J.; Haagh, G.A.A.V.; Klahn, J.K.; Janssen, J.J.M. Prediction of Emulsion Particle Sizes Using a Computational Fluid Dynamics Approach. Colloids Surf B Biointerfaces 2003, 31, 141–148. [Google Scholar] [CrossRef]

- Kerdouss, F.; Bannari, A.; Proulx, P.; Bannari, R.; Skrga, M.; Labrecque, Y. Two-Phase Mass Transfer Coefficient Prediction in Stirred Vessel with a CFD Model. Comput Chem Eng 2008, 32, 1943–1955. [Google Scholar] [CrossRef]

- Bayraktar, E.; Mierka, O.; Platte, F.; Kuzmin, D.; Turek, S. Numerical Aspects and Implementation of Population Balance Equations Coupled with Turbulent Fluid Dynamics. Comput Chem Eng 2011, 35, 2204–2217. [Google Scholar] [CrossRef]

- Lehr, F.; Millies, M.; Mewes, D. Bubble-Size Distributions and Flow Fields in Bubble Columns. AIChE Journal 2002, 48, 2426–2443. [Google Scholar] [CrossRef]

- Schütz, S.; Gorbach, G.; Piesche, M. Modeling Fluid Behavior and Droplet Interactions during Liquid–Liquid Separation in Hydrocyclones. Chem Eng Sci 2009, 64, 3935–3952. [Google Scholar] [CrossRef]

- Silva, L.F.L.R.; Lage, P.L.C. Development and Implementation of a Polydispersed Multiphase Flow Model in OpenFOAM. Comput Chem Eng 2011, 35, 2653–2666. [Google Scholar] [CrossRef]

- Silva, L.F.L.R.; Damian, R.B.; Lage, P.L.C. Implementation and Analysis of Numerical Solution of the Population Balance Equation in CFD Packages. Comput Chem Eng 2008, 32, 2933–2945. [Google Scholar] [CrossRef]

- Silva, L.F.L.R.; Rodrigues, R.C.; Mitre, J.F.; Lage, P.L.C. Comparison of the Accuracy and Performance of Quadrature-Based Methods for Population Balance Problems with Simultaneous Breakage and Aggregation. Comput Chem Eng 2010, 34, 286–297. [Google Scholar] [CrossRef]

- Vladisavljević, G.T.; Kobayashi, I.; Nakajima, M. Effect of Dispersed Phase Viscosity on Maximum Droplet Generation Frequency in Microchannel Emulsification Using Asymmetric Straight-through Channels. Microfluid Nanofluidics 2011, 10, 1199–1209. [Google Scholar] [CrossRef]

- Liao, Y.; Lucas, D. A Literature Review of Theoretical Models for Drop and Bubble Breakup in Turbulent Dispersions. Chem Eng Sci 2009, 64, 3389–3406. [Google Scholar] [CrossRef]

- Hinze, J.O. Fundamentals of the Hydrodynamic Mechanism of Splitting in Dispersion Processes. AIChE Journal 1955, 1, 289–295. [Google Scholar] [CrossRef]

- Lebaz, N.; Azizi, F.; Sheibat-Othman, N. Modeling Droplet Breakage in Continuous Emulsification Using Static Mixers in the Framework of the Entire Spectrum of Turbulent Energy. Ind Eng Chem Res 2022, 61, 541–553. [Google Scholar] [CrossRef]

- Andersson, R.; Andersson, B. Modeling the Breakup of Fluid Particles in Turbulent Flows. AIChE Journal 2006, 52, 2031–2038. [Google Scholar] [CrossRef]

- Rommel, W.; Meon, W.; Blass, E. Hydrodynamic Modeling of Droplet Coalescence at Liquid-Liquid Interfaces. Sep Sci Technol 1992, 27, 129–159. [Google Scholar] [CrossRef]

- Frising, T.; Noïk, C.; Dalmazzone, C. The Liquid/Liquid Sedimentation Process: From Droplet Coalescence to Technologically Enhanced Water/Oil Emulsion Gravity Separators: A Review. J Dispers Sci Technol 2006, 27, 1035–1057. [Google Scholar] [CrossRef]

- Kamp, J.; Villwock, J.; Kraume, M. Drop Coalescence in Technical Liquid/Liquid Applications: A Review on Experimental Techniques and Modeling Approaches. Reviews in Chemical Engineering 2017, 33, 1–47. [Google Scholar] [CrossRef]

- Liao, Y.; Lucas, D. A Literature Review on Mechanisms and Models for the Coalescence Process of Fluid Particles. Chem Eng Sci 2010, 65, 2851–2864. [Google Scholar] [CrossRef]

- Fathi Roudsari, S.; Turcotte, G.; Dhib, R.; Ein-Mozaffari, F. CFD Modeling of the Mixing of Water in Oil Emulsions. Comput Chem Eng 2012, 45, 124–136. [Google Scholar] [CrossRef]

- Fathi Roudsari, S.; Ein-Mozaffari, F.; Dhib, R. Use of CFD in Modeling MMA Solution Polymerization in a CSTR. Chemical Engineering Journal 2013, 219, 429–442. [Google Scholar] [CrossRef]

- Roudsari, S.F. Experimental and CFD Investigation of the Mixing of MMA Emulsion Polymerization in a Stirred Tank Reactor. Ph.D. Thesis, Toronto Metropolitan University, 2015.

- Patil, A. V.; Johansen, S.T. Computaional and Experimental Study of Oil-Water Emulsion Flow and Stability in Stirred Tanks. In Proceedings of the The 11th International Conference on CFD in the Minerals and Process Industries; Solnordal, C.B., Liovic, P., Delaney, G.W., Cummins, S.J., Schwarz, M.P., Witt, P.J., Eds.; Melbourne, Australia, 2015; pp. 1–7.

- Zhang, J.; Xu, S.; Li, W. High Shear Mixers: A Review of Typical Applications and Studies on Power Draw, Flow Pattern, Energy Dissipation and Transfer Properties. Chemical Engineering and Processing: Process Intensification 2012, 57–58, 25–41. [Google Scholar] [CrossRef]

- Cardoso, F.A.R.; Rezende, R.V.P.; Almeida, R.A.; Mezzomo, N.; Ferreira, S.R.S.; Meier, H.F.; Cardozo-Filho, L. CFD-Based Modeling of Precipitation by Supercritical Anti-Solvent Process of Microparticles from Grape Pomace Extract with Population Balance Approach. J Supercrit Fluids 2018, 133, 519–527. [Google Scholar] [CrossRef]

- Cheng, J.C.; Fox, R.O. Kinetic Modeling of Nanoprecipitation Using CFD Coupled with a Population Balance. Ind Eng Chem Res 2010, 49, 10651–10662. [Google Scholar] [CrossRef]

- Lavino, A.D.; Ferrari, M.; Barresi, A.A.; Marchisio, D. Effect of Different Good Solvents in Flash Nano-Precipitation via Multi-Scale Population Balance Modeling-CFD Coupling Approach. Chem Eng Sci 2021, 245, 116833. [Google Scholar] [CrossRef]

- Gobert, S.R.L.; Kuhn, S.; Teixeira, R.F.A.; Braeken, L.; Thomassen, L.C.J. Scale-up of Continuous Microcapsule Production. Chemical Engineering and Processing - Process Intensification 2020, 153, 107989. [Google Scholar] [CrossRef]

- IKA-Werke GmbH % Co S 18N-19G Dispersing Tool Available online:. Available online: https://www.ika.com/en/Products-LabEq/Dispersers-pg177/S-18-N-19-G-Dispersing-tool-L004640/ (accessed on 18 July 2024).

- Telstar LyoQuest Basic Research Freeze Dryer Available online:. Available online: https://www.telstar.com/en/laboratory-equipment/laboratory-freeze-dryers/basic-research-benchtop-freeze-dryer/ (accessed on 18 July 2024).

- Parra Mondejar, A. Simulació Fluidodinàmica (CFD) de Formació de Nanoparticules a Escala Industrial. B.Sc. Thesis, Universitat Politècnica de Catalunya, 2016.

- Ansys Inc. Ansys Fluent 2020.

- Vankova, N.; Tcholakova, S.; Denkov, N.D.; Ivanov, I.B.; Vulchev, V.D.; Danner, T. Emulsification in Turbulent Flow: 1. Mean and Maximum Drop Diameters in Inertial and Viscous Regimes. J Colloid Interface Sci 2007, 312, 363–380. [Google Scholar] [CrossRef] [PubMed]

- Sajjadi, S. Nanoemulsion Formation by Phase Inversion Emulsification: On the Nature of Inversion. Langmuir 2006, 22, 5597–5603. [Google Scholar] [CrossRef] [PubMed]

- Boxall, J.A.; Koh, C.A.; Sloan, E.D.; Sum, A.K.; Wu, D.T. Measurement and Calibration of Droplet Size Distributions in Water-in-Oil Emulsions by Particle Video Microscope and a Focused Beam Reflectance Method. Ind Eng Chem Res 2010, 49, 1412–1418. [Google Scholar] [CrossRef]

- Guardo, A.; Coussirat, M.; Larrayoz, M.A.; Recasens, F.; Egusquiza, E. Influence of the Turbulence Model in CFD Modeling of Wall-to-Fluid Heat Transfer in Packed Beds. Chem Eng Sci 2005, 60, 1733–1742. [Google Scholar] [CrossRef]

| Material | Density (kg/m3) | Viscosity (Pa·s) |

|---|---|---|

| PEI | 1332.7 | 3.21 x 10-1 |

| PVA | 998.00 | 1.02 x10-3 |

| Parameter | Value |

|---|---|

| Solver | Pressure based, double precision |

| Viscous model | |

| Multiphase model | Eulerian implicit |

| Population balance model | Discrete |

| Pressure-velocity coupling algorithm | SIMPLE |

| Discretization methods | |

| Pressure | Standard |

| Momentum; Turbulence; Phases | First order upwind |

| Under-relaxation factors | |

| Pressure | 0.3 |

| Momentum; PEI bins | 0.5 |

| Turbulence kinetic energy | 0.8 |

| Turbulence dissipation rate | 0.7 |

| Residuals convergence criteria | < 0.001 |

| 5000 rpm | 7500 rpm | 10000 rpm | 12500 rpm | 15000 rpm | |

|---|---|---|---|---|---|

| Particle diameter | 990.7 | 972.0 | 944.0 | 552.5 | 455.0 |

| Standard deviation | 68.13 | 76.21 | 126.4 | 81.72 | 129.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).