Submitted:

29 July 2024

Posted:

29 July 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Preparation and Conditioning of Films

2.2.2. Optical Properties

- ΔE = (ΔL*2 + Δa*2 + Δb*2)0.5 (1)

- Op = A600/t (2)

2.2.3. Water Affinities

- WVP = (WVTR x t)/Δp (3)

2.2.4. Mechanical Properties

- σmax = Fmax/A (4)

- E = (ΔL/L) x100 (5)

- EM = (σ2 – σ1 )/(ε2 - ε1) (6)

2.2.5. Statistical Analysis

3. Results and Discussion

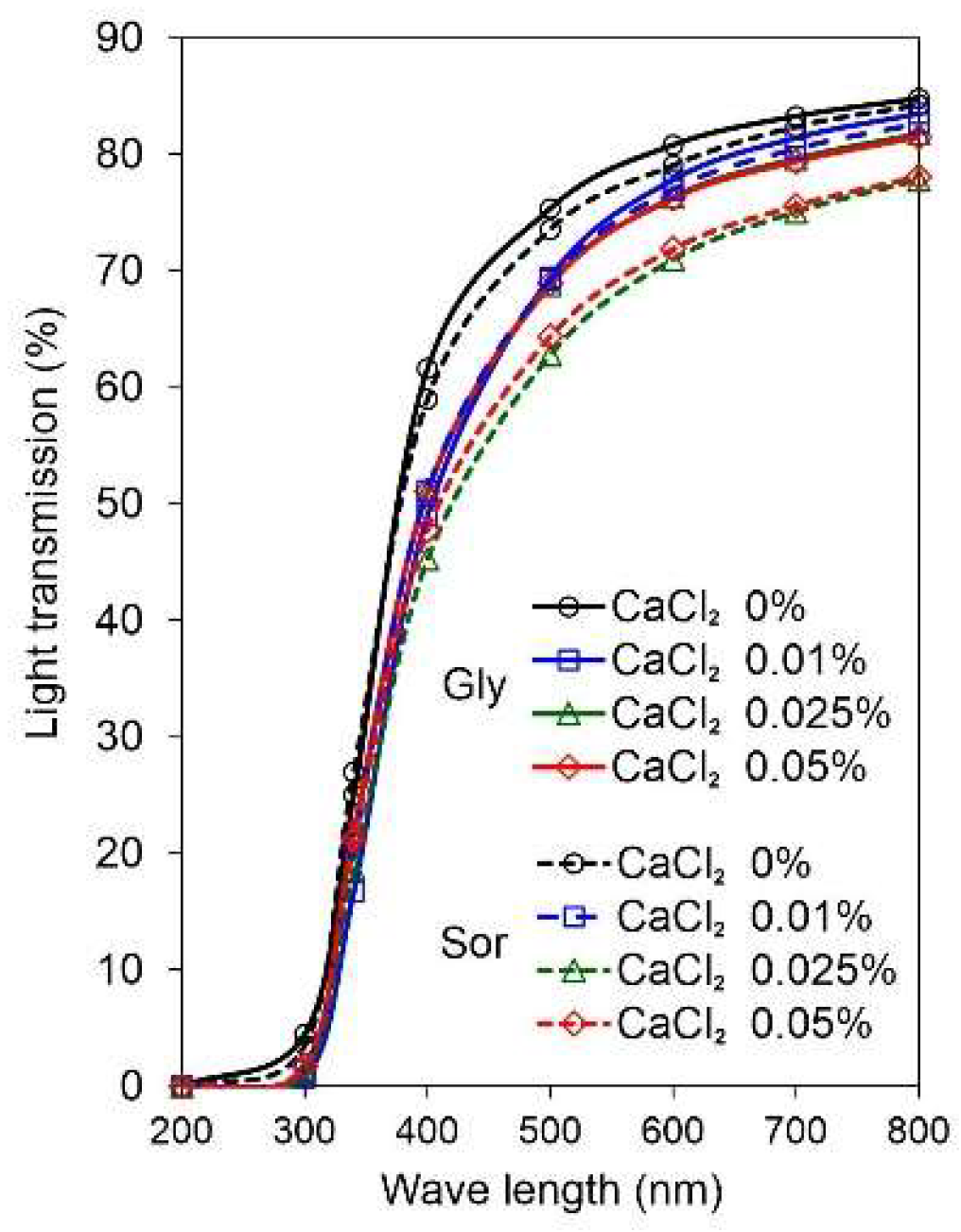

3.1. Optical Properties

3.2. Water Afinities

3.2. Mechanical Properties

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Directive (EU) 2019/904 of the European Parliament and of the Council of 5 June 2019 on the reduction of the impact of certain plastic products on the environment. OJ L 155 2019, 12.6.2019, 1–19, https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:32019L0904.

- Nair, S.S.; Trafiałek, J.; Kolanowski, W. Edible Packaging: A Technological Update for the Sustainable Future of the Food Industry. Appl. Sci. 2023, 13, 8234. [Google Scholar] [CrossRef]

- Bar-On, Y.M.; Phillips, R.; Milo, R. The biomass distribution on Earth. Proc. Natl. Acad. Sci. USA 2018, 115, 6506–6511. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Lan, Y. A comparative study on carbon footprints between plant- and animal-based foods in China. J. Clean. Prod. 2016, 112, 2581–2592. [Google Scholar] [CrossRef]

- Linares-Castañeda, A.; Sánchez-Chino, X.M.; Yolanda de las Mercedes Gómez y Gómez; Jiménez-Martínez, C.; Martínez Herrera, J.; Cid-Gallegos, M.S.; Corzo-Ríos, L.J. Cereal and Legume Protein Edible Films: A Sustainable Alternative to Conventional Food Packaging. Int J Food Prop 2023, 26, 3197–3213. [Google Scholar] [CrossRef]

- Lu, Z.X.; He, J.F.; Zhang, Y.C.; Bing, D.J. Composition, physicochemical properties of pea protein and its application in functional foods. Crit. Rev. Food Sci. Nutr. 2019, 60, 2593–2605. [Google Scholar] [CrossRef] [PubMed]

- Shanthakumar, P.; Klepacka, J.; Bains, A.; Chawla, P.; Dhull, S.B.; Najda, A. The Current Situation of Pea Protein and Its Application in the Food Industry. Molecules 2022, 27, 5354. [Google Scholar] [CrossRef]

- Regulation (EU) No 1169/2011 of the European Parliament and of the Council of 25 October 2011 on the provision of food information to consumers, amending Regulations (EC) No 1924/2006 and (EC) No 1925/2006 of the European Parliament and of the Council, and repealing Commission Directive 87/250/EEC, Council Directive 90/496/EEC, Commission Directive 1999/10/EC, Directive 2000/13/EC of the European Parliament and of the Council, Commission Directives 2002/67/EC and 2008/5/EC and Commission Regulation (EC) No 608/2004 Text with EEA relevance. OJ L 304 2011, 22.11.2011, 18–63, https://eur-lex.europa.eu/eli/reg/2011/1169/oj.

- Kowalczyk, D.; Baraniak, B. Effects of plasticizers, pH and heating of film-forming solution on the properties of pea protein isolate films. J. Food Eng. 2011, 105, 295–305. [Google Scholar] [CrossRef]

- Kowalczyk, D.; Gustaw, W.; Świeca, M.; Baraniak, B. A Study on the Mechanical Properties of Pea Protein Isolate Films. J. Food Process. Preserv. 2013, 38, 1726–1736. [Google Scholar] [CrossRef]

- Kowalczyk, D.; Baraniak, B. EFFECT OF SELECTED POLYSACCHARIDES ON PHYSICOCHEMICAL PROPETRTIES OF EDIBLE FILMS PRODUCED ON THE BASIS OF PEA PROTEINS. Zywnosc.Nauka.Technologia.Jakosc/Food.Science.Technology.Quality 2012. [Google Scholar] [CrossRef]

- Kowalczyk, D.; Gustaw, W.; Zięba, E.; Lisiecki, S.; Stadnik, J.; Baraniak, B. Microstructure and functional properties of sorbitol-plasticized pea protein isolate emulsion films: Effect of lipid type and concentration. Food Hydrocoll. 2016, 60, 353–363. [Google Scholar] [CrossRef]

- Kowalczyk, D.; Stryjecka M., Baraniak, B. The Comparition of Effect of Acetylation on Functional Properties of Protein Hydrolysates Obtained from Legume Seeds. Food. Science Technology. Quality 2006, 4, 90–100. [Google Scholar]

- Azeredo, H.M.; Waldron, K.W. Crosslinking in polysaccharide and protein films and coatings for food contact – A review. Trends Food Sci. Technol. 2016, 52, 109–122. [Google Scholar] [CrossRef]

- Ma, T.; Xiong, Y.L.; Jiang, J. Calcium-aided fabrication of pea protein hydrogels with filler emulsion particles coated by pH12-shifting and ultrasound treated protein. Food Hydrocoll. 2021, 125, 107396. [Google Scholar] [CrossRef]

- Mezgheni, E.; D'Aprano, G.; Lacroix, M. Formation of Sterilized Edible Films Based on Caseinates: Effects of Calcium and Plasticizers. J. Agric. Food Chem. 1998, 46, 318–324. [Google Scholar] [CrossRef]

- Avena-Bustillos, R.; Krochta, J. Water Vapor Permeability of Caseinate-Based Edible Films as Affected by pH, Calcium Crosslinking and Lipid Content. J. Food Sci. 1993, 58, 904–907. [Google Scholar] [CrossRef]

- Fabra, M.J.; Talens, P.; Chiralt, A. Influence of calcium on tensile, optical and water vapour permeability properties of sodium caseinate edible films. J. Food Eng. 2010, 96, 356–364. [Google Scholar] [CrossRef]

- Park, S.K.; Rhee, C.O.; Bae, D.H.; Hettiarachchy, N.S. Mechanical Properties and Water-Vapor Permeability of Soy-Protein Films Affected by Calcium Salts and Glucono-δ-lactone. J. Agric. Food Chem. 2001, 49, 2308–2312. [Google Scholar] [CrossRef] [PubMed]

- Fang, Y.; Tung, M.; Britt, I.; Yada, S.; Dalgleish, D. Tensile and Barrier Properties of Edible Films Made from Whey Proteins. J. Food Sci. 2002, 67, 188–193. [Google Scholar] [CrossRef]

- Chai, Z.; Shang, J.; Jiang, Y.; Ren, F.; Leng, X. Effects of the free and pre-encapsulated calcium ions on the physical properties of whey protein edible film. Int. J. Food Sci. Technol. 2010, 45, 1532–1538. [Google Scholar] [CrossRef]

- PN-ISO 2528:2000 - Sheet Materials - Determination of Water Vapour Transmission Rate - Gravimetric (Dish) Method.

- Xiao, Y.; Kang, S.; Liu, Y.; Guo, X.; Li, M.; Xu, H. Effect and mechanism of calcium ions on the gelation properties of cellulose nanocrystals-whey protein isolate composite gels. Food Hydrocoll. 2020, 111, 106401. [Google Scholar] [CrossRef]

- Edelenbos, M.; Christensen, L.P.; Grevsen, K. HPLC Determination of Chlorophyll and Carotenoid Pigments in Processed Green Pea Cultivars (Pisum sativum L.). J. Agric. Food Chem. 2001, 49, 4768–4774. [Google Scholar] [CrossRef] [PubMed]

- Kapoor, R.; Karabulut, G.; Mundada, V.; Feng, H. Unraveling the potential of non-thermal ultrasonic contact drying for enhanced functional and structural attributes of pea protein isolates: A comparative study with spray and freeze-drying methods. Food Chem. 2023, 439, 138137. [Google Scholar] [CrossRef] [PubMed]

- Mokrzycki Cardinal Stefan, W.; Tatol, M. Color Difference Delta E-A Survey Colour Difference ∆E-A Survey.

- Jonauskaite, D.; Mohr, C.; Antonietti, J.-P.; Spiers, P.M.; Althaus, B.; Anil, S.; Dael, N. Most and Least Preferred Colours Differ According to Object Context: New Insights from an Unrestricted Colour Range. PLOS ONE 2016, 11, e0152194–e0152194. [Google Scholar] [CrossRef] [PubMed]

- Ruiz-Gutiérrez, M.G.; Quintero-Ramos, A.; Meléndez-Pizarro, C.O.; Talamás-Abbud, R.; Barnard, J.; Márquez-Meléndez, R.; Lardizábal-Gutiérrez, D. NIXTAMALIZATION IN TWO STEPS WITH DIFFERENT CALCIUM SALTS AND THE RELATIONSHIP WITH CHEMICAL, TEXTURE AND THERMAL PROPERTIES IN MASA AND TORTILLA. J. Food Process. Eng. 2011, 35, 772–783. [Google Scholar] [CrossRef]

- García A.S.A. Method for the Nixtamalization of Whole Corn for the Production of Nixtamalized Corn Flour. Patent WO2017082715A1 2017.

- Rincón-Aguirre, A.; Figueroa-Cárdenas, J.d.D.; Ramírez-Wong, B.; Arámbula-Villa, G.; Jiménez-Sandoval, S.J.; Martinez-Flores, H.E.; Pérez-Robles, J.F. Effect of nixtamalization with Ca(OH)2, CaCl2, and CaCO3 on the protein secondary structure, rheological, and textural properties of soft wheat flour doughs. J. Cereal Sci. 2021, 101, 103271. [Google Scholar] [CrossRef]

- Demchenko, P.D.A.P. Spectroscopic Properties of Protein Chromophores. In Ultraviolet Spectroscopy of Proteins; Springer: Berlin/Heidelberg, Germany, 1986; pp. 5–26. [Google Scholar] [CrossRef]

- Kowalczyk, D.; Szymanowska, U.; Skrzypek, T.; Basiura-Cembala, M.; Bartkowiak, A.; Łupina, K. A Comprehensive Study on Gelatin- and Whey Protein Isolate-Based Edible Films as Carriers of Fireweed (Epilobium angustifolium L.) Extract. Food Bioprocess Technol. 2022, 15, 2547–2561. [Google Scholar] [CrossRef]

- Kowalczyk, D.; Kordowska-Wiater, M.; Nowak, J.; Baraniak, B. Characterization of films based on chitosan lactate and its blends with oxidized starch and gelatin. Int. J. Biol. Macromol. 2015, 77, 350–359. [Google Scholar] [CrossRef] [PubMed]

- Kowalczyk, D.; Baraniak, B. Effect of candelilla wax on functional properties of biopolymer emulsion films – A comparative study. Food Hydrocoll. 2014, 41, 195–209. [Google Scholar] [CrossRef]

- Takahashi, M.; Yamada, M.; Machida, Y.; Tsuda, Y. A New Method to Evaluate the Softening Effect of Cosmetic Ingredients on the Skin. 1984.

- Yan, J.; Yin, L.; Qu, Y.; Yan, W.; Zhang, M.; Su, J.; Jia, X. Effect of calcium ions concentration on the properties and microstructures of doubly induced sorghum arabinoxylan/soy protein isolate mixed gels. Food Hydrocoll. 2022, 133. [Google Scholar] [CrossRef]

- Zhang, J.; Jiang, L.; Yang, J.; Chen, X.; Shen, M.; Yu, Q.; Chen, Y.; Xie, J. Effect of calcium chloride on heat-induced Mesona chinensis polysaccharide-whey protein isolation gels: Gel properties and interactions. LWT 2021, 155, 112907. [Google Scholar] [CrossRef]

- Arabestani, A.; Kadivar, M.; Shahedi, M.; Goli, S.A.H.; Porta, R. Properties of a new protein film from bitter vetch (Vicia ervilia) and effect of CaCl2 on its hydrophobicity. Int. J. Biol. Macromol. 2013, 57, 118–123. [Google Scholar] [CrossRef] [PubMed]

- Galietta, G.; Di Gioia, L.; Guilbert, S.; Cuq, B. Mechanical and Thermomechanical Properties of Films Based on Whey Proteins as Affected by Plasticizer and Crosslinking Agents. J. Dairy Sci. 1998, 81, 3123–3130. [Google Scholar] [CrossRef]

- Valdivia-López, M.A.; Tecante, A.; Granados-Navarrete, S.; Martínez-García, C. Preparation of Modified Films with Protein from Grouper Fish. Int. J. Food Sci. 2016, 2016, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Gorissen, S.H.M.; Crombag, J.J.R.; Senden, J.M.G.; Waterval, W.A.H.; Bierau, J.; Verdijk, L.B.; van Loon, L.J.C. Protein content and amino acid composition of commercially available plant-based protein isolates. Amino Acids 2018, 50, 1685–1695. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

| Plasticizer | CaCl2 (%) | L* | a* | b* | h (°) | C* | ΔE |

|---|---|---|---|---|---|---|---|

| Gly | 0 | 41.39 ± 0.01 cd | -0.21 ± 0.03 c | 2.13 ± 0.07 cd | 95.77 ± 0.39 a | 2.14 ±0.07 bc | - |

| 0.01 | 37.60 ± 3.37 b | -0.69 ± 0.13 b | 2.50 ± 0.16 d | 106.41 ± 7.70 a | 2.60 ± 0.18 d | 3.97 ± 3.15 a | |

| 0.025 | 30.87 ± 1.24 a | -1.00 ± 0.09 a | 1.79 ± 0.51 bc | 126.01 ±17.71 c | 2.06 ± 0.49 bc | 10.56 ± 1.23 b | |

| 0.05 | 29.80 ± 0.40 a | -1.04 ± 0.02a | 1.44 ± 0.20 ab | 126.17 ± 4.42 c | 1.78 ± 0.15 ab | 11.64 ± 0.40 b | |

| Sor | 0 | 41.72 ± 0.04 d | -0.28 ± 0.02 c | 2.30 ± 0.06 d | 96.85 ± 0.32 a | 2.32 ± 0.06 cd | - |

| 0.01 | 38.46 ± 3.23 bc | -0.77 ± 0.24 b | 2.27 ±0.48 d | 108.40 ± 10.89 ab | 2.42 ± 0.39 cd | 3.36 ± 3.19 a | |

| 0.025 | 30.16 ± 0.62 a | -1.04 ± 0.08 a | 1.80 ± 0.11 bc | 126.69 ± 7.96 c | 2.08 ± 0.05 bc | 11.60 ± 0.61 b | |

| 0.05 | 30.03 ± 0.44 a | -0.97 ± 0.08 a | 1.25 ± 0.06 a | 122.31 ± 7.80 bc | 1.58 ± 0.06 a | 11.76 ± 0.45 b |

| Plasticizer | CaCl2 (%) | Op (A600/mm) | MC (%) | WVP (*) | So (%) |

|---|---|---|---|---|---|

| Gly | 0 | 0.90 ± 0.02 a | 29.46 ± 1.14 d | 18.60 ± 0.88 c | 100.00 ± 0.00 a |

| 0.01 | 1.09 ± 0.05 bc | 26.88 ± 1.42 c | 14.91 ± 0.77 b | 100.00 ± 0.00 a | |

| 0.025 | 1.19 ± 0.06 d | 27.63 ± 1.32 c | 14.43 ± 0.98 b | 100.00 ± 0.00 a | |

| 0.05 | 1.19 ± 0.05 d | 27.34 ± 1.50 c | 15.51 ± 1.93 b | 100.00 ± 0.00 a | |

| Sor | 0 | 1.02 ± 0.08 b | 11.50 ± 0.44 b | 1.40 ± 0.04 a | 100.00 ± 0.00 a |

| 0.01 | 1.13 ± 0.06 cd | 6.71 ± 0.12 a | 0.81 ± 0.20 a | 100.00 ± 0.00 a | |

| 0.025 | 1.40 ± 0.08 e | 6.62 ± 0.42 a | 1.19 ± 0.16 a | 100.00 ± 0.00 a | |

| 0.05 | 1.43 ± 0.01 e | 6.69 ± 0.57 a | 1.43 ± 0.07 a | 100.00 ± 0.00 a |

| Plasticizer | CaCl2 (%) | σmax (MPa) | EM (MPa) | εb (%) |

|---|---|---|---|---|

| Gly | 0 | 1.70 ± 0.17 b | 51.03 ± 3.35 b | 73.79 ± 4.58 d |

| 0.01 | 1.43 ± 0.18 a | 44.14 ± 8.00 ab | 60.80 ± 4.89 c | |

| 0.025 | 1.42 ± 0.16 a | 42.52 ± 7.22 ab | 57.52 ± 3.90 c | |

| 0.05 | 1.41 ± 0.20 a | 39.49 ± 4.00 a | 59.49 ± 4.00 c | |

| Sor | 0 | 6.31 ± 0.24 e | 219.15 ± 12.36 e | 37.01 ± 3.70 a |

| 0.01 | 5.40 ± 0.27 d | 193.52 ± 14.36 d | 32.67 ± 2.72 a | |

| 0.025 | 3.99 ± 0.26 c | 129.23 ± 7.46 c | 55.23 ± 3.06 c | |

| 0.05 | 4.14 ± 0.25 c | 133.39 ± 10.62 c | 46.14 ± 8.88 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).