1. Introduction

The world’s cotton looks at China, and China’s cotton looks at Xinjiang [

1]. As an inevitable product of cotton production, the annual yield of cotton stalk in Xinjiang is as high as 16.875 million tons. At present, cotton stalks in Xinjiang are mainly returned to the field [

2], resulting in waste of resources and the stalks are not easy to rot, which affects the sowing of the next crop, the cotton yield in the next year is affected by the carrying disease [

3]. Cotton stalk is not only rich in nitrogen, phosphorus, potassium and other trace elements, but also lignocellulose, phloem fiber, crude protein and so on, it has great potential for comprehensive utilization [

4,

5,

6,

7]. Cotton stalk leaving the field is an important measure to deal with agricultural waste and resource recycling, the research on mechanized harvesting technology of cotton stalk has become one of the focuses of the research on the whole mechanization technology of cotton production [

5,

6,

7,

8].

Cotton planting in foreign countries mainly adopts a large single-row standardized model, most of the cotton stalk harvesting machinery is mainly based on the roller type pulling machine, Australia’s MUTI harvester and the United States’ AMADAS harvester are representative machines, which is difficult to adapt to the row spacing of machine cotton picking operations [

9]. The cotton straw harvester that has been developed in China mainly includes chain tooth type [

10], tooth disc type [

11], wallet type [

12], and clamping roller type [

13]; Zhang et al. [

10] developed the chain tooth cotton straw harvester, which is easy to cause cotton straw blockage in the process of pulling cotton straw. Chen et al. [

11,

14] Zhang Jiaxi et al. [

15] designed the toothed disc cotton straw harvester, which is easy to clip or interrupt the cotton straw to increase the breakage rate, and is not suitable for the dense planting mode in Xinjiang. Zhang Jiaxi’s team [

12] designed a clip-type cotton straw harvester, which has high requirements for tensioning ,the insufficient tension of the belt will cause the phenomenon of cotton stalk left behind, and the friction between the flexible materials is seriously heated. Tang et al. [

16] developed the toothed roller cotton straw harvester, which appears to be wound with plastic film during work, causing the machine to be easily stuck, and the performance of the machine is unstable, which increases energy consumption. Xie Jianhua’s [

13] team designed a clamping roller cotton stalk pulling machine, which requires a large bending angle of cotton straw and poor adaptability to cotton straw with low moisture content. There is less precipitation in Xinjiang, agriculture mainly depends on irrigation, and cotton planting has been mechanized, and the tractor has entered and exited the cotton field to carry out operations for many times, which leads to serious soil compaction in the cotton field after the cotton harvest, and if only the above-mentioned pulling mode is adopted, it is easy to cause the cotton stalk to break, resulting in high breaking rate [

9].

In order to solve the above problems, according to the soil conditions and the cotton planting model of one film and six rows in Xinjiang cotton area, the root-soil complex model of cotton plants was established based on discrete element, among them, the soil is discrete element particles, and the root model is formed by bonding the discrete element particles with a suitable contact mechanics model [

17,

18]. The relationship between cotton roots, soil and V-shaped root-cutting knife in the process of shoveling was studied by force analysis and simulation in the root breaking process, and finally the parameters of the V-shaped root-cutting knife were optimized to determine its optimal design value to improve the pull-out rate of cotton straw [

19,

20].

2. Loosening Soil and Root-Cutting Cotton Stalk Pulling the Setting Machine

2.1. The Structure and Working Principle of the Whole Machine

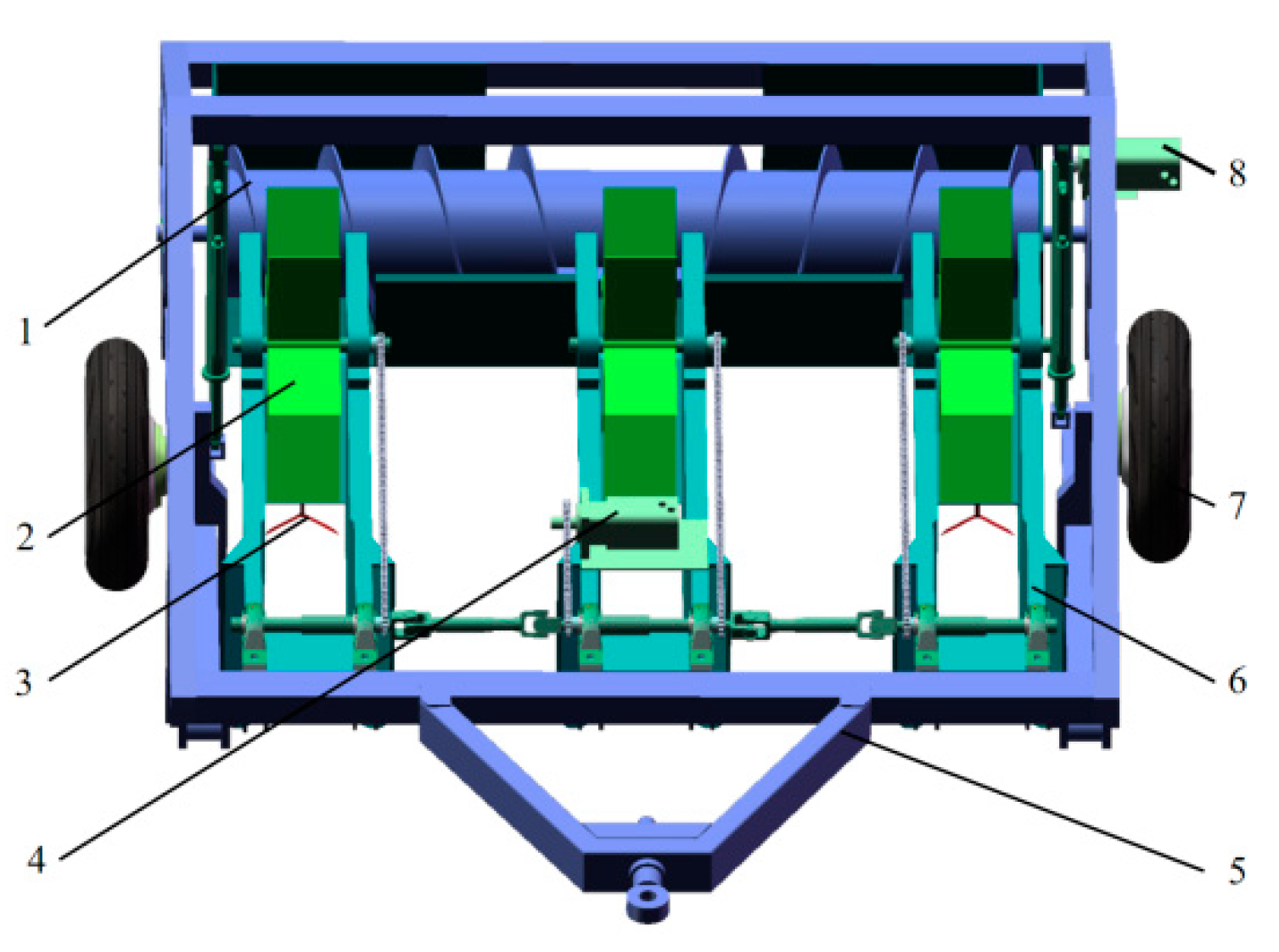

Loosening soil and root-cutting cotton stalk pulling the setting machine is mainly composed of V-shaped root-cutting knife, gathering device, pulling device, strips helicoidis, as shown in

Figure 1. V-shaped root-cutting knife is installed behind the gathering device, the pulling device is located above the gathering device, and the Strips helicoidis located behind the gathering device. Loosening soil and root-cutting cotton stalk pulling the setting machine is pulled by tractor to work. V-shaped root-cutting knife cuts the root-soil complex of the cotton plant, shovels the cotton root and loosens the soil. The hydraulic motor I drives the pulling device to rotate at high speed, and the cotton stalk after the root-cutting is orderly pulled and transported to the strips helicoidis. The hydraulic motor II drives the strips helicoidis to rotate and complete the cotton stalk set-bar operation.

2.2. Technical Parameter

According to the cotton planting pattern in Xinjiang, the main parameters of the loosening soil and root-cutting cotton stalk pulling the setting machine were determined, as shown in

Table 1.

3. Calculation of Key Parameters of V-Shaped Root-Cutting Knife

3.1. Design of Slide Cutting Angle of V-Shaped Root-Cutting Knife

The root breaking operation is to apply the cutting force to the cotton root through the V-shaped root-cutting knife to break the cotton root, and the appropriate cutting force strength is an important guarantee to improve the pull-out rate of the cotton stalk [

21]. The slide cutting method can effectively reduce the cutting resistance and improve the cutting strength. Based on the sliding cutting principle, a sliding cut V-shaped root-cutting knife with a slide cutting angle of

θ was designed to facilitate the sliding cutting effect of the blade on the cotton stalk and soil, and improve the root breaking rate of the cotton stalk [

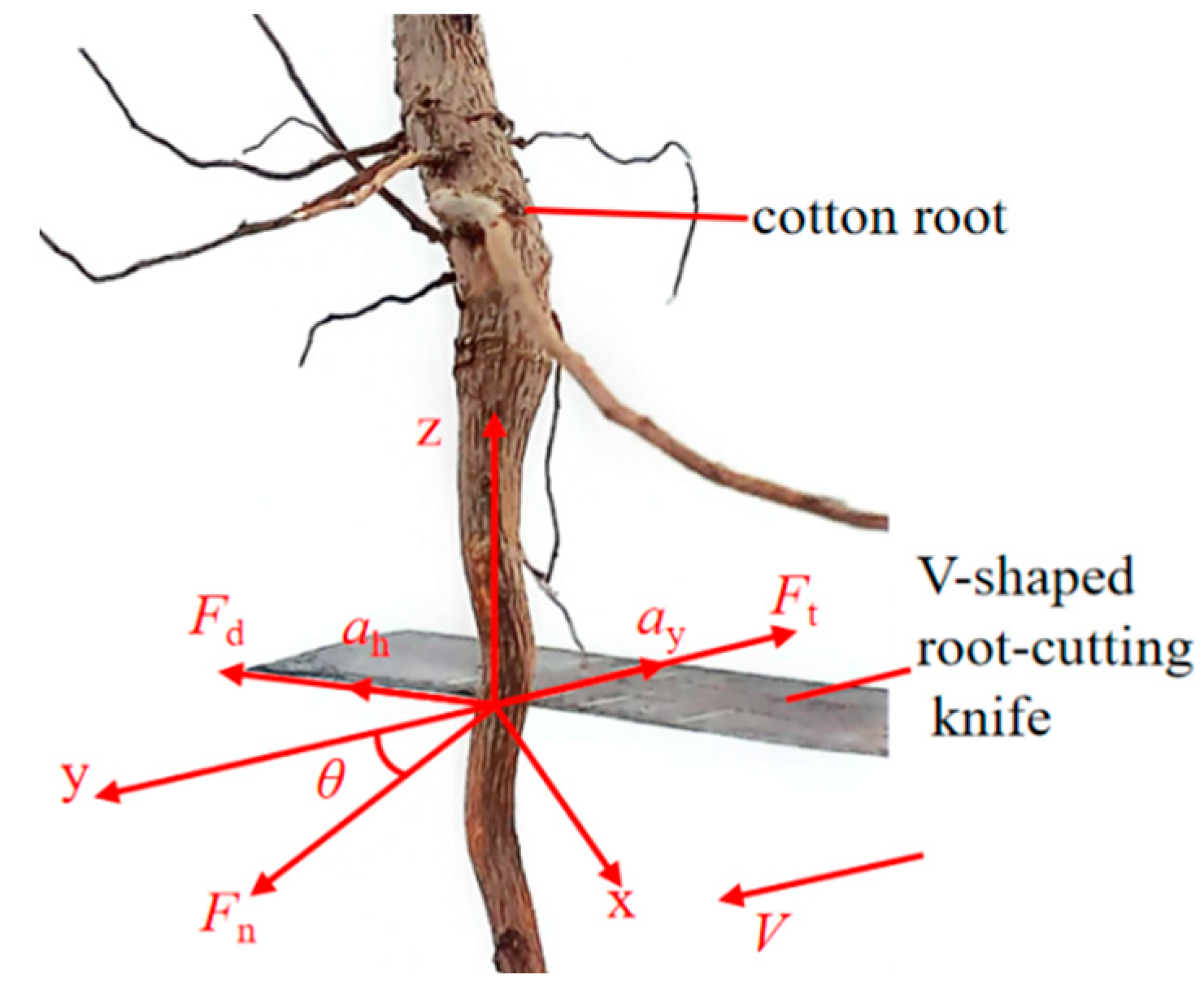

22].

During sliding cutting, the forward speed V of the machine deviates from the normal direction of the blade, and a slide cutting angle

θ is generated with the normal direction, the slide cutting angle

θ reduces the actual wedge angle

Y of the blade cutting into the material. The smaller slide cutting angle

θ makes the sliding cutting effect not obvious, but the larger slide cutting angle

θ will cause the blade to be very long, increase the friction surface between the V-shaped root-cutting knife and the soil, aggravate the wear of the blade and increase the cutting resistance. The slide cutting angle is more suitable in the range of 20° ~ 55° [

22]. Based on this, in order to obtain the ideal slide cutting angle of the V-shaped root-cutting knife, the critical condition of slide cutting is solved by establishing the kinematics and dynamics model of root cutting, taking the forward direction of the tool as the y-axis, the plane rectangular coordinate system is established on the cutting plane of the knife, as shown in

Figure 2. Under the traction of the tractor, the V-shaped root-cutting knife performs root cutting operation along the y-axis direction, the contact point between a cotton root and the blade is regarded as a particle A, the particle dynamics differential equation of the particle A along the tangential direction and the normal direction of the blade is

Where,

Fn is the normal force of the cutting edge of the knife, N;

Ft is the friction force of root-soil complex on sliding particle A along Y axis, N;

θ is the slide cutting angle, °;

m is the quality of sliding cutting particle A, kg;

ay is the transport acceleration along the Y axis direction, m/s

2;

Fd is the friction force of sliding cutting particle along the tangential direction of cutting edge of the knife, N;

ah is the acceleration of sliding cutting particle along the tangential direction of cutting edge of the knife, m/s

2.

The sliding cutting particle A has a tendency to move forward along the positive direction of the Y-axis during the cutting action of cutting edge of the knife, while the root-soil complex has a friction force along the negative direction of the Y-axis, if there is a relative sliding between the knife and the sliding cutting particle A, there must be a relative movement trend between the two, therefore, the friction force F

d of the sliding cutting particle A along the tangential direction of cutting edge of the knife.

Where,

f is the friction factor of sliding cutting particle and cutting edge of the knife;

γ is the friction angle between sliding cutting particle and cutting edge of the knife, °;

(1) (2) Simultaneous simplification is available

When the V-shaped root-cutting knife is used for root-cutting operation, to further reduce the cutting resistance, it is necessary to make the sliding cutting movement between the particle A and the blade, that is, ah > 0, and γ < θ can be obtained from Formula (3). The friction angle between the sliding cutting particle and the blade edge is less than the slide cutting angle, at this time, the cotton root not only bears the positive pressure of the blade, but also bears the lateral force of the blade, and slides along the edge direction during cutting. The friction angle between the cotton root and the steel plate was measured by the slope sliding method, the friction angle between the cotton root and the steel plate was 35.9°, and the designed slide cutting angle θ of the blade should be greater than 35.9°.

3.2. Design of Cutting Edge Angle of V-Shaped Root-Cutting Knife

In order to make the V-shaped root-cutting knife more sharp, optimize the cutting effect, reduce the working resistance and improve the root cutting rate, it is necessary to cutting edge with the V-shaped root-cutting knife. The cutting edge angle refers to the angle between the two cutting edges. The smaller the angle, the sharper the cutting edge, the smaller the resistance during cutting, and it is easier to cut off the cotton root. However, a small cutting edge angle will make the cutting edge cross section too small, and the cutting edge wear will be aggravated. The appropriate cutting edge angle can not only ensure the cutting performance, but also reduce the working resistance, reduce the tool wear and improve the service life of the knife [

23].

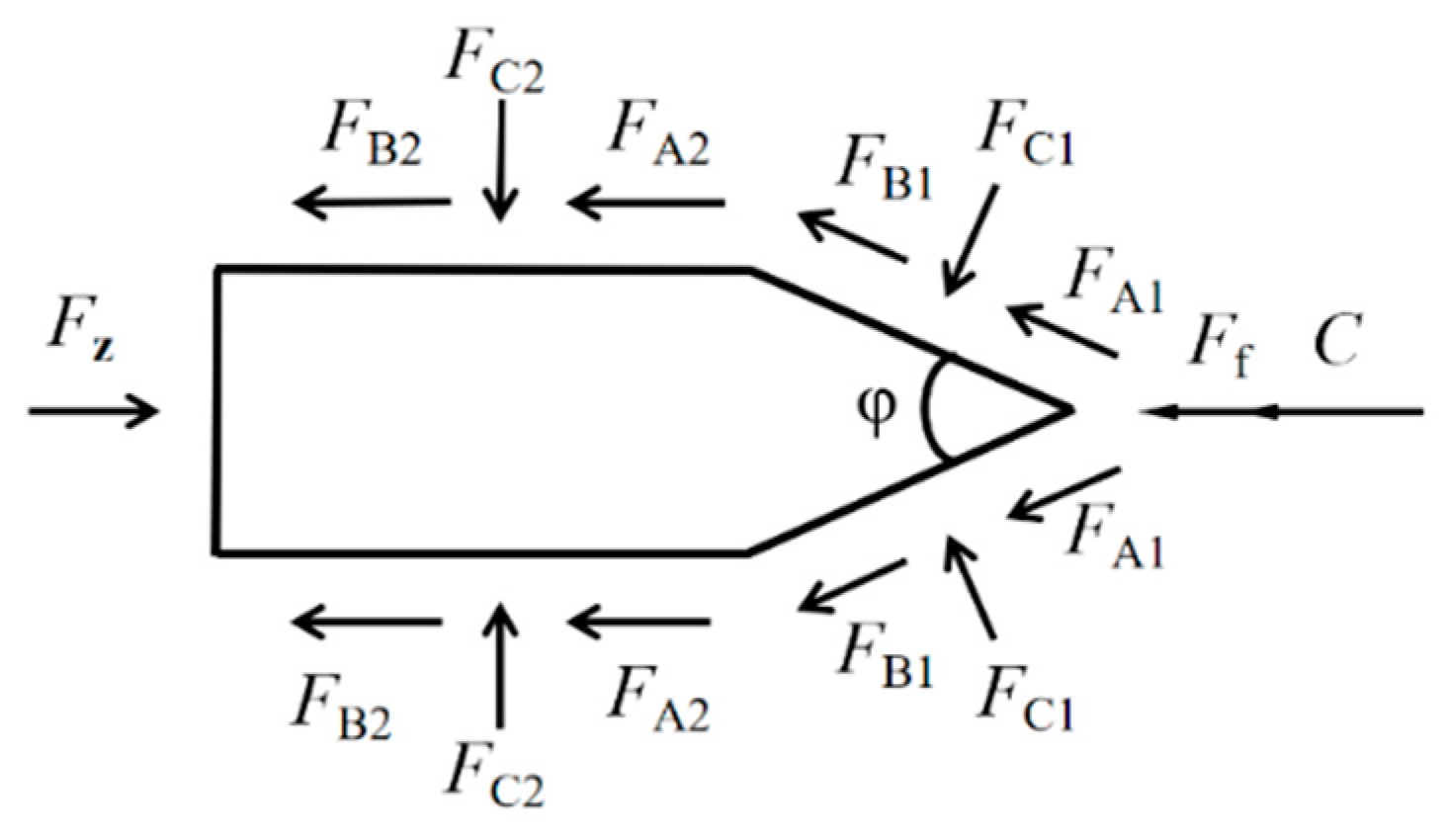

In order to obtain the optimal range of V-shaped root-cutting edge angle, as shown in

Figure 3, the resistance is analyzed, , as shown in Formula (5), (6).

Where,

Fz is the working resistance of V-shaped root-cutting knife, N;

φ is the cutting edge angle of V-shaped root-cutting knife, °;

FA1 is the soil adhesion force of V-shaped root-cutting knife, N;

FA2 is the soil adhesion force of V-shaped root-cutting knife, N;

FB1 is the soil friction of V-shaped root-cutting knife, N;

FB2 is the soil friction of V-shaped root-cutting knife, N;

FC1 is the the normal force of soil on the V-shaped root-cutting knife, N;

FC2 is the the normal force of soil on the V-shaped root-cutting knife, N;

C is the soil cohesion, N;

Ff is the shear resistance of cotton root, N;

μ is the friction factor between soil and V-shaped root-cutting knife;

Pi is the pressure on unit area of V-shaped root-cutting knife, Pa;

Ai is the contact area between the V-shaped root-cutting knife and the soil, m;

From (4) (5), we can obtain

In order to obtain the minimum value of

FZ, the second derivative of (6) can be obtained.

The sliding friction factor of soil and steel was measured by the slope rolling method. The sliding friction factor of soil and steel was 0.192, and the tangential adhesion force of soil was (2.6 ± 1238) N [

19,

22]. Substituting it into the Formula (8) calculate, the optimal range of cutting edge angle

φ is 43.18° ~ 62.53°.

3.3. Design of the Soil Entry Angle of the V-Shaped Root-Cutting Knife

Referring to the classification of tangent, the concept of sliding cutting is elaborated in detail based on the angle between the blade surface of V-shaped root-cutting knife and the cotton root axis direction. The sliding cutting is divided into horizontal sliding cutting and oblique sliding cutting, the horizontal sliding cutting refers to the knife surface is perpendicular to the cotton root axis and parallel to the direction of the knife movement. The oblique sliding cutting is that the knife surface and the cotton root axis and the tool movement direction are skewed. Cellulose fiber is the main component of plant cell wall, which endows cotton root with strength and toughness. The direction of cellulose fiber is approximately parallel to the cotton root axis. Therefore, when the cotton root is cut by two different sliding cutting methods, the angle between the direction of the V-shaped root-cutting knife cutting into the cotton root and the direction of the cotton root’s own fiber is obviously different, and the cutting resistance and the root-cutting effect are also different. The angle between the V-shaped root-cutting blade surface and the normal line of the cotton root during the sliding cutting process is called the soil entry angle

β [

24], when two different sliding cutting methods are used to cut the cotton root, it is found that compared with the transverse sliding cutting, using the oblique sliding cutting has a better axial crushing effect on the cellulose; when the soil entry angle is 13° < β < 79°, the cutting destructive force required for oblique sliding cutting can be reduced by 25.48% ~ 31.76% compared with horizontal sliding cutting, the cutting direction and cutting surface of transverse sliding cutting are perpendicular to the axis of straw, and the anti-cutting strength of cotton root is the largest, so the cutting resistance of transverse sliding cutting is the largest. In order to reduce the area of the contact surface between the V-shaped root-cutting knife and the soil, the soil entry angle of the V-shaped root-cutting knife is designed to be 13°<

β < 45°.

4. Discrete Element Simulation of V-Shaped Root-Cutting Knife

It is difficult to observe the dynamic characteristics of cotton roots and soil particles from the microscopic point of view when studying the interaction between the machinery of the entry and root-soil complex. At present, the combination of experiment and numerical simulation is widely used [

19,

20]. The discrete element method has unique advantages in optimizing the parameters of V-shaped root-cutting knife, the root-soil composite model constructed by discrete element method can simulate the relative displacement, rotation, friction and collision between particles, so as to reflect the interaction between soil particles and cotton roots in the process of root cutting; The simulation results provided by DEM method can be processed and analyzed by visualization software to intuitively explain the source of shoveling resistance and the principle and effect of root cutting [

17,

18,

19]. By simulating the cutting resistance and root cutting effect of different parameter combinations of V-shaped root-cutting knife, the influence of these parameters on the cutting resistance and root cutting effect can be observed and analyzed, using data analysis tools to statistically analyze the simulation results, the optimal combination of V-shaped root-cutting structure parameters can be quickly obtained, which can reduce the number and cost of actual tests and provide a scientific basis for the design of V-shaped root-cutting knife parameters [

18,

22].

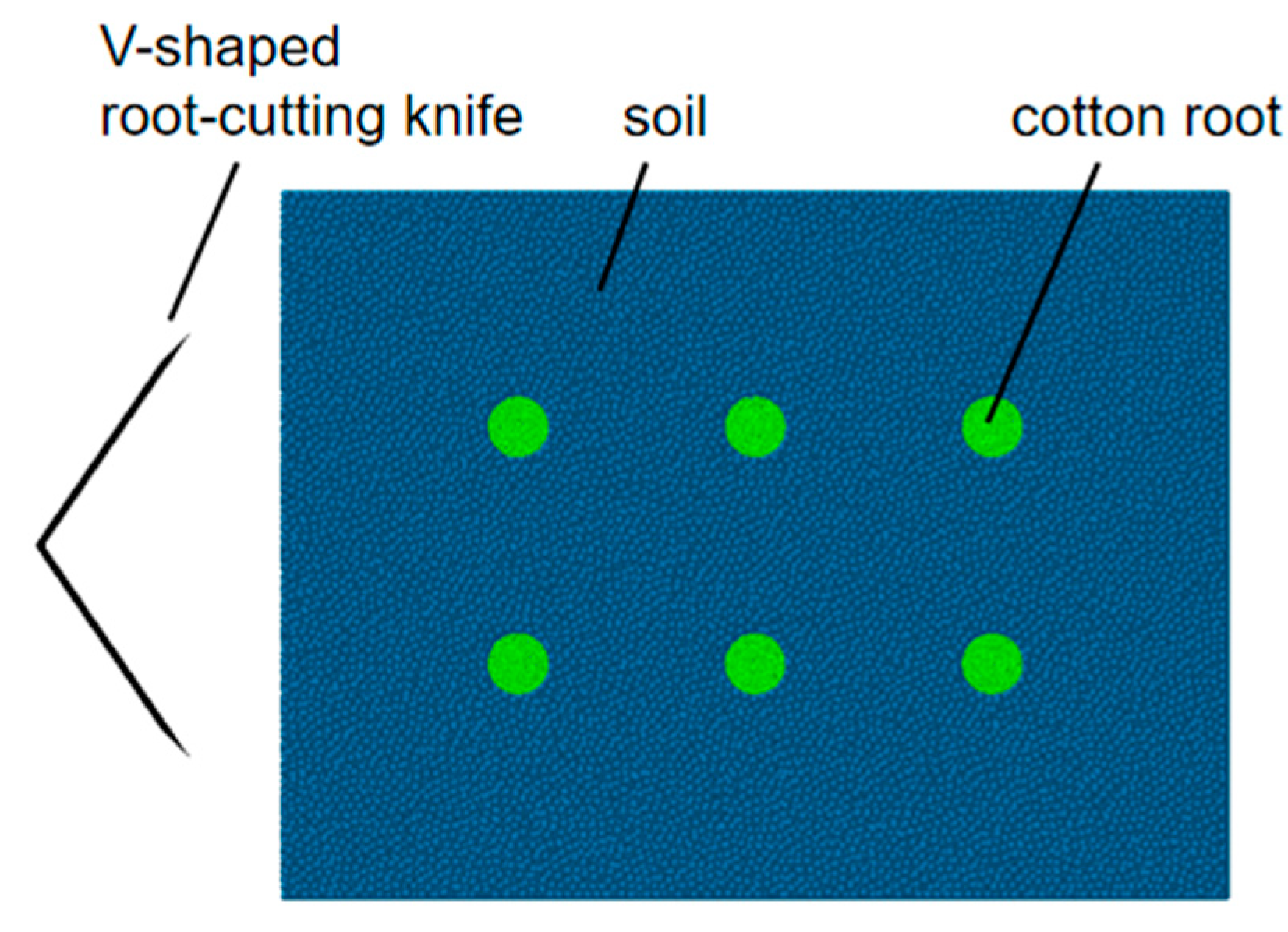

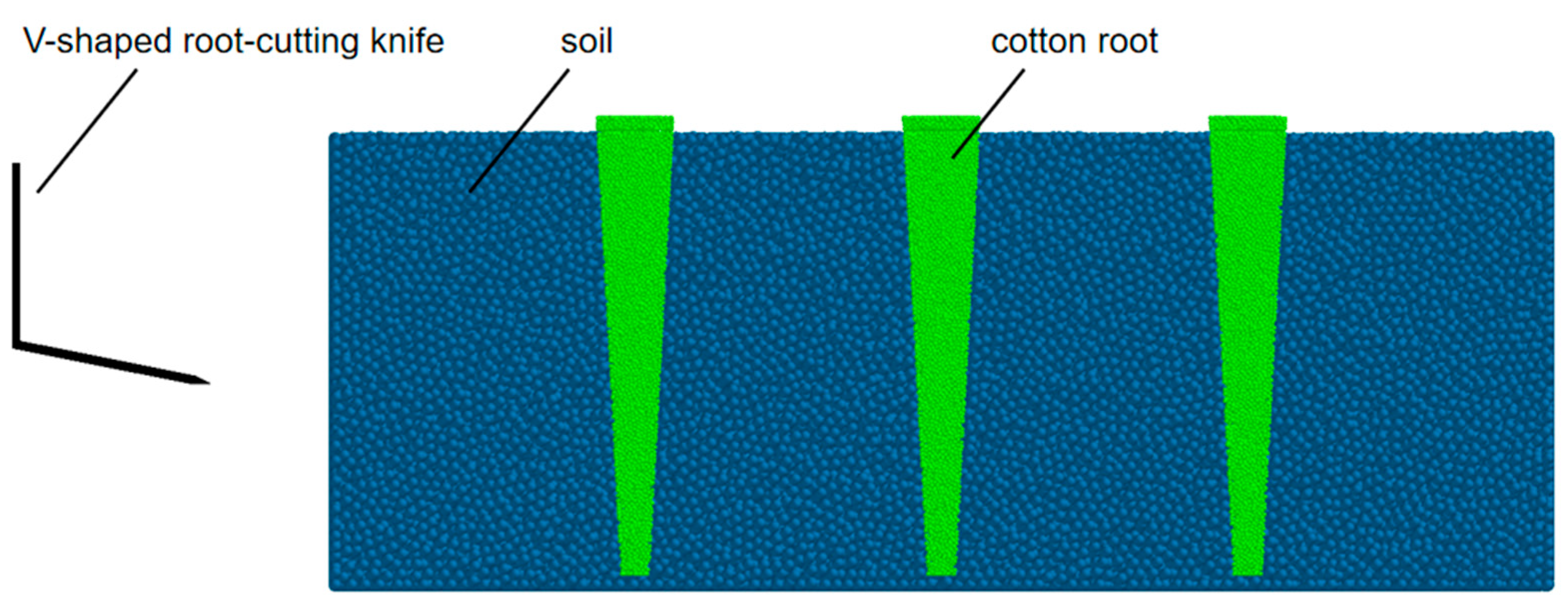

4.1. Establishment of Discrete Element Interaction Model between V-Shaped Root-Cutting Knife and Root-soil Complex

Cotton is a typical Taproot crops, which is mainly composed of a main root deep into the soil, a small amount of lateral roots, main roots and a large number of root hairs on the lateral roots, all roots are inverted cones in the soil, in order to simplify the root-soil composite model and reduce the CPU calculation time to improve the simulation efficiency [

25], the cotton root model was simplified to a round table with an upper diameter of 13.84 mm, a lower diameter of 3.74 mm and a height of 180 mm. In discrete element, a 6 cotton root model was established by rapid filling method with particles with a radius of 0.7 mm [

26]. After completion, the time step was set as the initial time step, and an open-top soil trough with a length, width and height of 400 mm, 300 mm and 200 mm was established. The particle factory was set up to fill with soil particles with a radius of 2 mm, and the filling time was 1 s. The research object selected in this paper is the cotton area of Xinjiang, China. The soil in the cotton field by the cotton picker is seriously hardened after harvesting, the adhesion force between soil and cotton root particles and the adhesion force between soil particles and cotton root are larger, Therefore, the bond contact model (Hertz-Mindlin Bonding V2) is selected as the particle contact model [

27] as shown in

Figure 4 to

Figure 5. The addition time of Bonding V2 is set to 7 s in the Bond Creation Time of the particle factory. Based on the previous research work of the research group and the calibration of the parameters of the root-soil composite model by domestic and foreign scholars [

28,

29,

30], the discrete element simulation parameters used in this paper are shown in

Table 2.

4.2. Simulation Optimization of V-Shaped Root-Cutting Knife Parameters

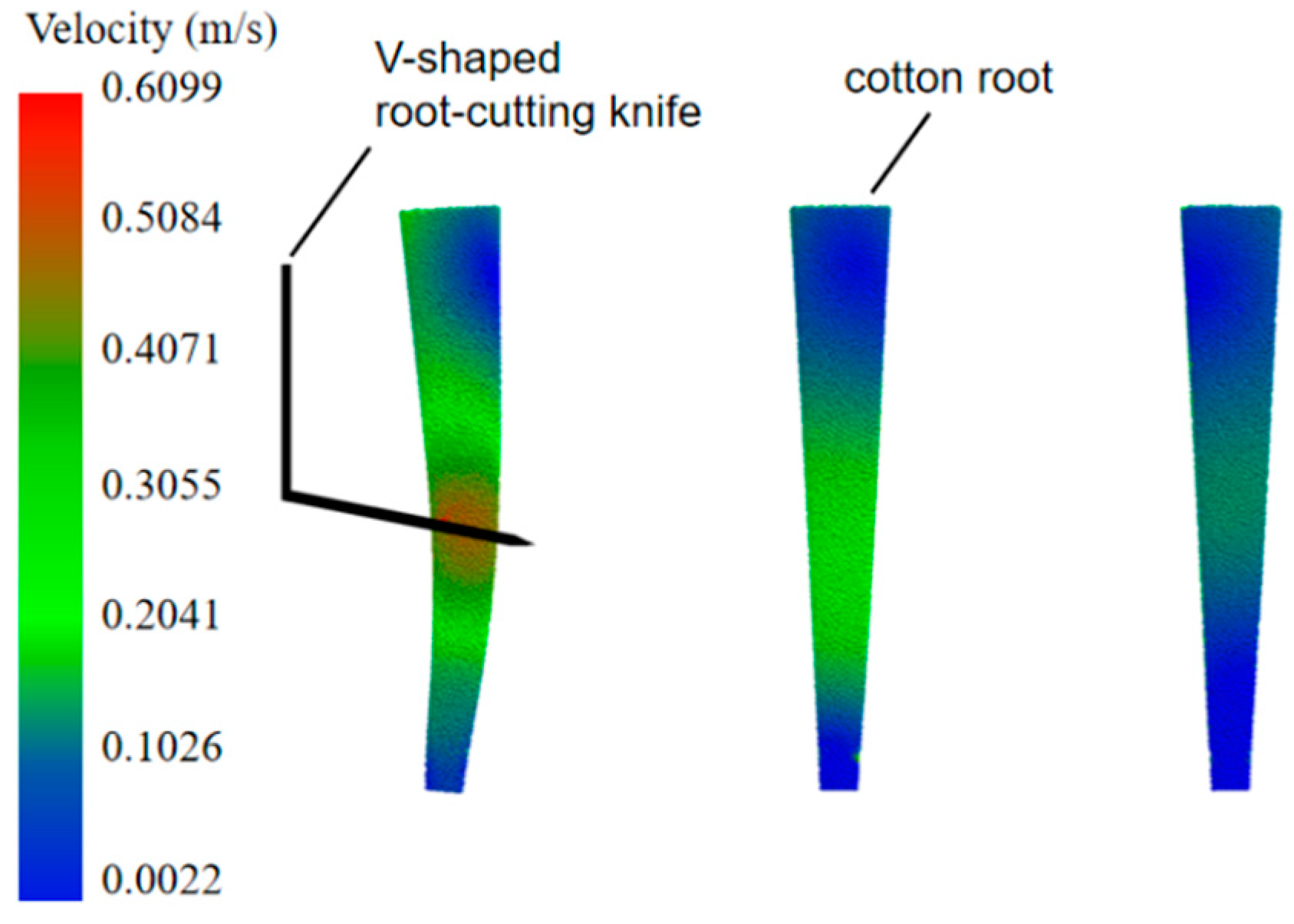

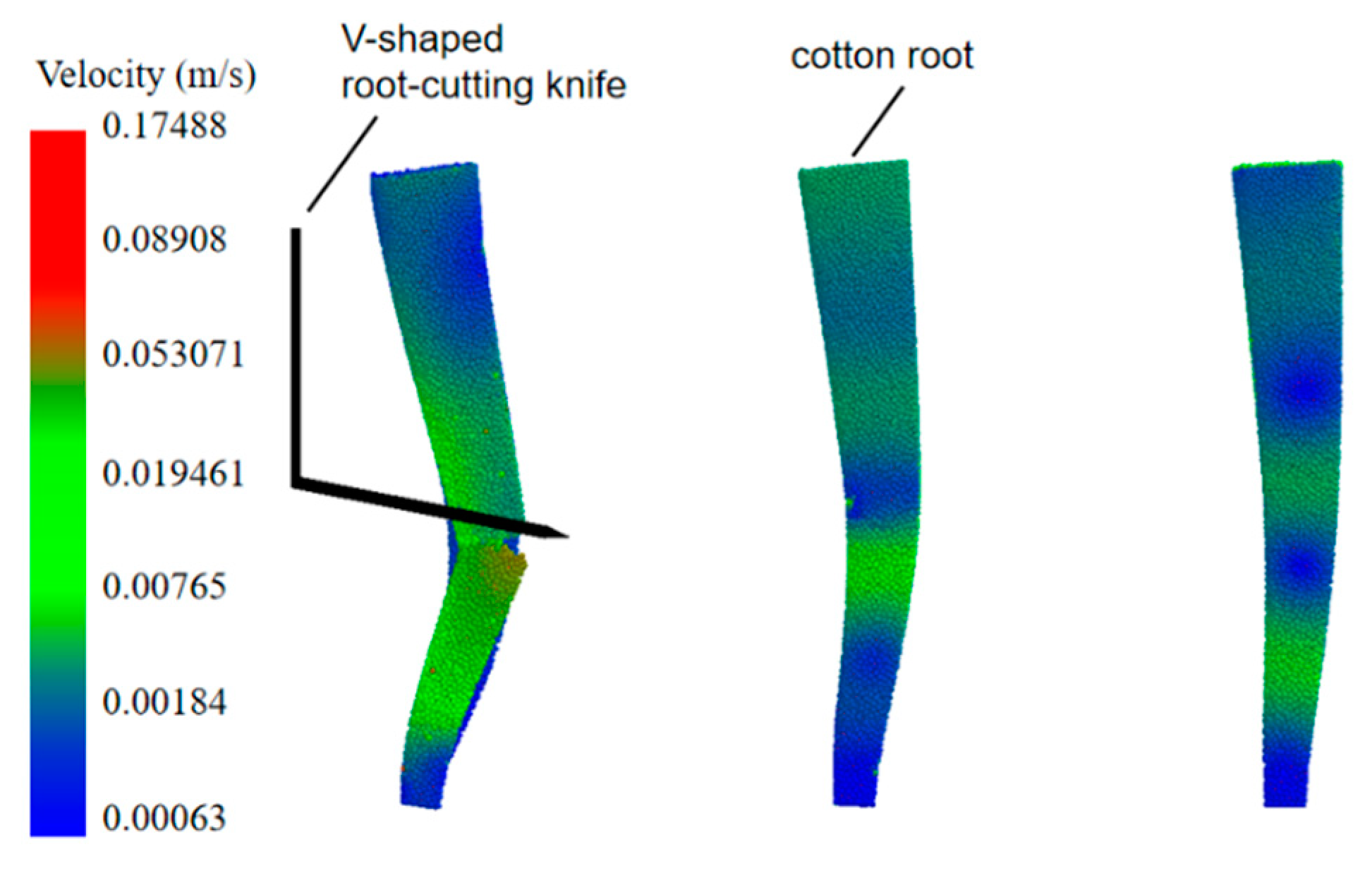

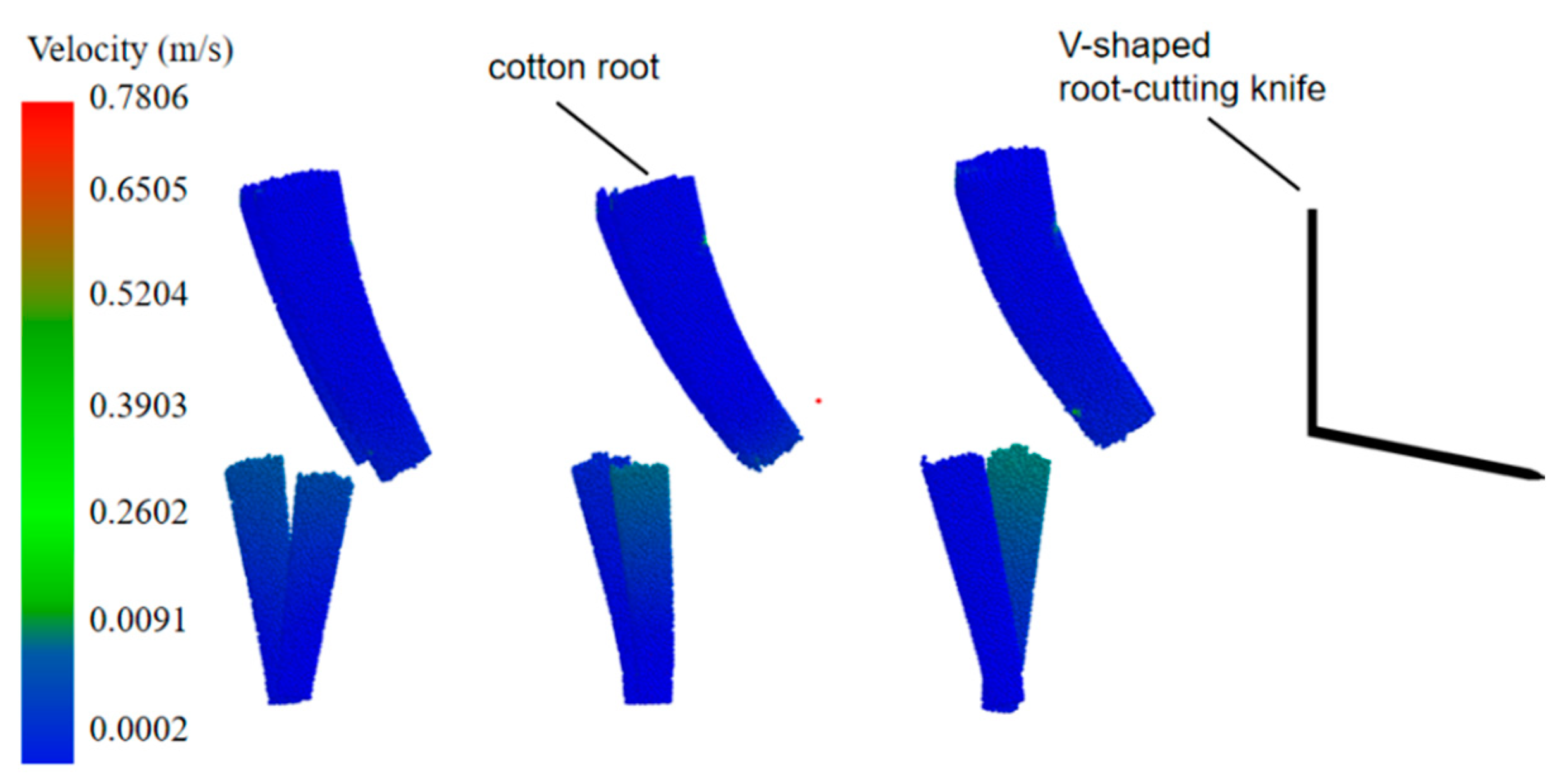

4.2.1. Simulated Test

Through the above theory and simulation test, it is found that different slide cutting angle

θ, cutting edge angle

φ and different soil entry angle

β have significant effects on root cutting effect and shovel cutting resistance. Therefore, the slide cutting angle

θ, the cutting edge angle

φ and the soil entry angle

β are selected as the test factors, and the three-factor three-level orthogonal simulation test is carried out with the force required to cut the cotton root (hereinafter referred to as root-breaking force)

Y1 and mean value of the cutting resistance

Y2 as the test indexes. In the simulation process, the operating speed of the V-shaped root-cutting knife is 1 m/s, and the operating depth is 100 mm as shown in

Figure 6,

Figure 7 and

Figure 8. The factor coding for the response surface test is presented in

Table 3.

4.2.2. Test Result

According to the principle of Box-Behnken experimental design, 17 sets of simulation experiments were carried out by using three-factor and three-level response surface analysis method, including 12 analysis factor experiments and 5 error experiments of zero point estimation. The design and results of the response surface test are shown in

Table 4.

The Design-Expert 13.0 software was used to analyze the variance properties of the regression equation, the variance analysis results of root-breaking force and mean value of the cutting resistance of the V-shaped root-cutting knife are obtained as shown in

Table 5 and

Table 6.

According to the analysis results of

Table 5 and

Table 6, the

P values of the

Y1 regression model of root-breaking force of the V-shaped root-cutting knife and the

Y2 regression model of mean value of the cutting resistance are less than 0.0001, which indicates that the regression model is significant. The loss of fit term L was greater than 0.05 (L

Y1 = 0.4267, L

Y2 = 0.1579, respectively), indicating that the regression equation had a high degree of fitting. The determination coefficient

R2 of the equation is 0.9845 and 0.9923, indicating that this model can be used to explain more than 95% of the evaluation indexes. This model can be used to analyze and predict root-breaking force

Y1 and mean value of the cutting resistance

Y2 of the V-shaped root-cutting knife. It can be seen from

Table 5 and

Table 6 that the slide cutting angle

X1 and the soil entry angle

X3 have a very significant effect on

Y1 and

Y2 (

P < 0.01), and the cutting edge angle

X2 has a very significant effect on

Y1 (

P < 0.01). The significant of influencing factors on the root-breaking force are in a descending order as: slide cutting angle

θ, cutting edge angle

φ, soil entry angle

β; the degree of influence on the mean value of the cutting re-sistance are as follows: slide cutting angle

θ, soil entry angle

β, cutting edge angle

φ.

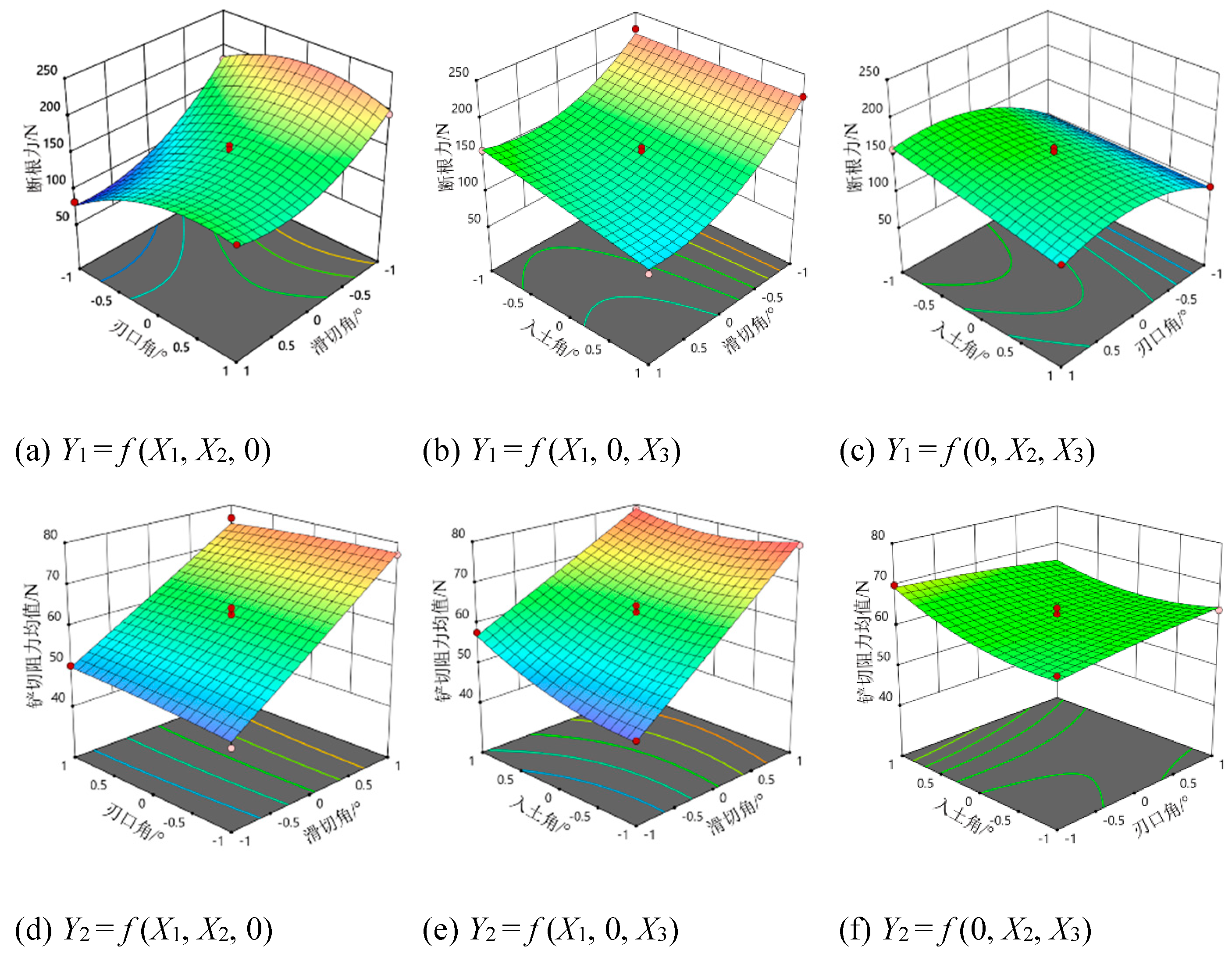

The response surface image can analyze the interaction effect of slide cutting angle

θ, the cutting edge angle

φ, and the soil entry angle

β on the response value. Using the response surface software and combining the regression equation analysis results, the response surface image is obtained as shown in

Figure 9. The interaction between slide cutting angle

θ and cutting edge angle

φ (

X1 X2), the interaction between slide cutting angle

θ and soil entry angle

β (

X1 X3), the interaction between cutting edge angle

φ and soil entry angle

β (

X2 X3) had a significant effect on root-breaking force

Y1 (

P < 0.05), the interaction of slide cutting angle

θ and soil entry angle

β (

X1 X3) had a very significant effect on

Y2 (

P < 0.01), and the interaction of cutting edge angle

φ and soil entry angle

β (

X2 X3) had a significant effect on the mean value of cutting resistance

Y2 (

P < 0.05).

The regression model equations for the effect of each factor on the root breaking force

Y1 and the mean value of cutting resistance

Y2 of the V-shaped root-cutting knife, after excluding insignificant factors, are shown in Equation (11).

The root-breaking force Y1 and mean value of the cutting resistance Y2 of the V-shaped root-cutting knife are important indexes to evaluate the working effect of the loosening soil and root-cutting cotton stalk pulling the setting machine. In order to find the best combination of working parameters of loosening soil and root-cutting cotton stalk pulling the setting machine and reduce the pulling rate and energy consumption of the machine, Design-Expert was used to optimize root-breaking force and mean value of the cutting resistance of the V-shaped root-cutting knife. The optimization range of the slide cutting angle of the V-shaped root-cutting knife is set between 36° ~ 55°, the optimization range of the cutting edge angle is between 43.2° ~ 63.5°, and the optimization range of the soil entry angle is between 13° ~ 45°. The optimization objective is set to be the minimum root-breaking force Y1 and the minimum mean value of the cutting resistance Y2 of the V-shaped root-cutting knife. The second optimization objective is equal weight ( + + + ), and the optimization is carried out by means of experimental analysis software. According to the constraint conditions, the parameter combination optimization model is established, as shown in equation (11).

The optimal test parameters are as follows: the slide cutting angle of the V-shaped root-cutting knife is 48.3°, the cutting edge angle is 43.4°, and the soil entry angle is 26.2°. At this time, the predicted root-breaking force of the V-shaped root-cutting knife is 87.15 N, and the predicted mean value of the cutting resistance is 63.39 N.

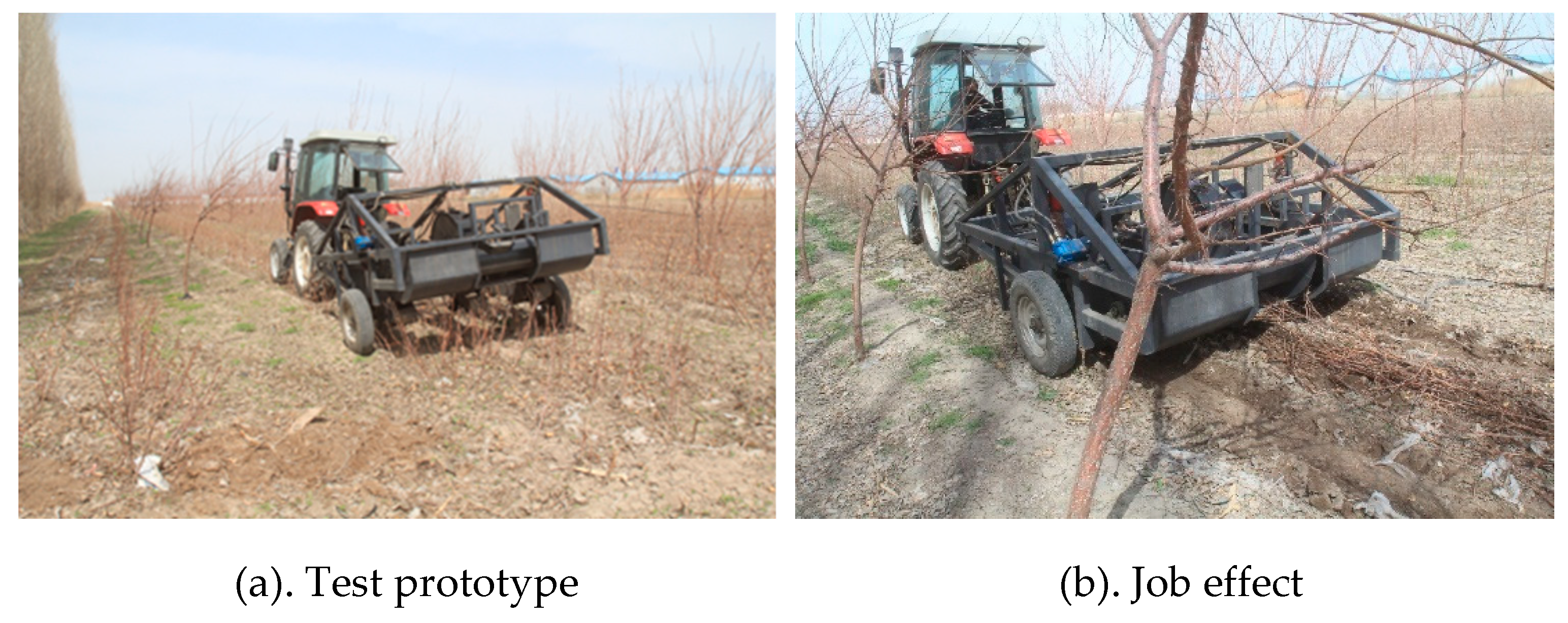

5. Filed Test

To validate the optimization results to obtain the best test coefficients, the V-shaped root-cutting knife was used with a slide cutting angle of 48.3°, a cutting edge angle of 43.4° and a soil entry angle of 26.2°. On March 22, 2024, the verification test was carried out in the 3-consecutive test site of the 145 th Regiment in Shihezi City, Xinjiang. The soil firmness was 63.43 kPa, the soil moisture content was 10.46%, the operating speed of the loosening soil and root-cutting cotton stalk pulling the setting machineis 1 m/s, and the operating depth was 100 mm. The main equipment used in the field test is as follows: Kohl KE704B tractor (70 hp), loosening soil and root-cutting cotton stalk pulling the setting machine, soil firmness machine, soil moisture meter, ruler, tape, stopwatch, etc.

The test was carried out with reference to GB/T 8097-2008 ‘Harvester Combine Test Method’. In order to ensure the stable operation of the tractor and reduce the error, there was a 20 m stable area before the tractor enters the cotton stalk area to adjust the working condition of the tractor. The length of the test area was 30 m, and the test was repeated three times, and the test results were averaged. The test results are shown in

Figure 10, the average pass rate of root breakage was 94.8%, and the average pull-out rate of the cotton stalk was 93.2%.

6. Conlusion

In order to solve the problems of low reliability, high breakage rate and high leakage rate of the existing pull-out device, a loosening soil and root-cutting cotton stalk pulling the setting machine was designed. Through the kinematics and dynamics analysis of the root cutting process, the main structural parameter range of the V-shaped root-cutting knife is obtained.

Develop a simulation model of V-shaped root-cutting knife root-soil complex interaction, taking the side cutting angle θ, the cutting edge angle φ and the soil entry angle β of the V-shaped root-cutting knife as the test factors, the root-breaking force and the mean value of the cutting resistance are taken as the test indexes to carry out the simulation test. The test results show that the influence of each factor on the root-breaking force is in the order of the slide cutting angle θ, the cutting edge angle φ, the soil entry angle β. The test results show that the influence of each factor on the mean value of the cutting resistance is in the order of slide cutting angle θ, the soil entry angle β, and the cutting edge angle φ.

The established linear regression model was optimized, and the optimal combination of factors was obtained as follows: the slide cutting angle of the V-shaped root-cutting knife was 48.3°, the cutting edge angle was 43.4°, and the soil entry angle was 26.2°. The field experiment was carried out with the forward speed of the machine 1 m/s: the average pass rate of root breakage was 94.8%, and the average pull-out rate of the cotton stalk was 93.2%, which proved the reliability of the optimization design of V-shaped root-cutting knife. This study can provide theoretical support for the design of root-breaking cotton stalk pulling machine.

Author Contributions

resources, S.C.; data curation, Y.L.; writing—original draft preparation, H.L.; Software, H.L.; writing—review and editing, S.C. and H.M.; visualization, D.H.; supervision, S.C. and H.M.; project administration, S.C. and H.M.; Formal analysis, L.H.; Investigation, S.W.; Validation, J.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the the National Key Research and Development Program of China (2022YFD2002400), the Autonomous Region Key research and development task special project of Xinjiang, China (2022B02033-2), the Xinjiang Corps Financial Science and Technology Program Projects (2023AB014), the Innovation Team of Xinjiang Academy of Agricultural and Reclamation Sciences (NCG202302) and Seventh Division - Shihezi University Science and Technology Innovation Special Project (QS2023006).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding authors.

Acknowledgments

The authors are grateful to anonymous reviewers for their comments.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Cheng, Y. Study on Fluctuation and Influencing Factors of Cotton Production in Xinjiang. Ph.D. Thesis, Shihezi University, Xinjiang, China, 2022. (in Chinese). [Google Scholar]

- Sun, Z.Y. Research on the adoption and effectiveness evaluation of agricultural socialized services in Xinjiang cotton region. Ph.D. Thesis, Shihezi University, Xinjiang, China, 2023. (in Chinese). [Google Scholar]

- Suraj, P.; Radha; Kanika, S.; Sangram, D.; Marisennayya, S.; Vishal, P.D.; Sunil, K.; Madhu.; T, A.; V, B.; Ravi, P.; Manoj, K. Unlocking the potential of cottonstalk as a renewable source ofcellulose: A review on advancementsand emerging applications. J. InternationalJournal of BiologicaL Macromolecules International journal of Biological Macromolecules. 2024, 261, 129456. [Google Scholar]

- Ding, X.H.; Yan, L.H.; Guo, C.; Jia, D.Z.; Guo, N.N.; Wang, L.X. Synergistic Effects between Lignin, Cellulose and Coal in the Co-Pyrolysis Process of coal and Cotton Stalk. J. Molecules. 2023, 28, 5708. [Google Scholar] [CrossRef] [PubMed]

- Narendra, R.; Yang, Y.Q. Properties and potential applications of natural cellulose fibers from the bark of cotton stalks. J. Bioresource Technology. 2009, 100, 3563–3569. [Google Scholar]

- Cai, C.G.; Wang, Z.B.; Ma, L.; Xu, Z.X.; Yu, J.M.; Li, F.G. Cotton stalk valorization towards bio-based materials, chemicals, and biofuels: A review. J. Renewable and Sustainable EnergyReviews. 2024, 202, 114651. [Google Scholar] [CrossRef]

- Dong, Z.; Hou, X.L.; Ian, H.; Yang, Y.Q. Preparation and properties of cotton stalk bark fibers and their cotton blended yarns and fabrics. J. Journal of Cleaner Production. 2016, 139, 267–276. [Google Scholar] [CrossRef]

- Li, H.; Zhao, C.S.; Han, W.J.; Jiang, Y.F.; Wang, S. Preparation and Research of Environment-friendly Degradable Paper Mulching Film of Cotton Stalk Fiber. J. IOP Conference Series: Earth and Environmental Science. 2018, 199, 042052. [Google Scholar] [CrossRef]

- Shen, C.J.; Guo, H.J.; Dai, Y.M.; Li, F.; Cao, S.L.; Jin, X.W.; Shen, L.; Deng, Y. Situation and strategies of mechanization in recycling of cotton stalk in Xinjiang. J. Journal of Huazhong Agricultural University. 2023, 42, 53–63. (in Chinese). [Google Scholar]

- Zhang, J.X.; Wang, T.Y.; Chen, M.J.; Zhao, W.S.; Wang, Z.W.; Yeerbolatl, T.M.E.; Wang, Y.C.; Liu, X.; Liu, A.P. Design of toothed disc cotton stalk harvester. J. Transactions of the Chinese Society of Agricultural Engineering. 2019, 35, 1–8. (in Chinese). [Google Scholar]

- Chen, M.J.; Zhao, W.S.; Wang, Z.W.; Liu, K.K.; Chen, Y.S.; Hu, Z.C. Operation Process Analysis and Parameter Optimization of Dentate Disc Cotton-stalk Uprooting Mechanism. J. Transactions of the Chinese Society for Agricultural Machinery. 2019, 50, 109–120. (in Chinese). [Google Scholar]

- Zhang, J.X.; Rui, Z.Y.; Cai, J.L.; Wang, Y.C.; Yeerbolatl, T.M.E.; Gao, Z.M. Design and Test of Front Mounted Belt Clamping and Conveying Cotton-stalk Pulling Device. J. Transactions of the Chinese Society for Agricultural Machinery. 2021, 52, 77–84. (in Chinese). [Google Scholar]

- Xie, J.H.; Wu, S.H.; Cao, S.L.; Zhang, Y.; Zhao, W.S.; Zhou, J.B. Design and Experiment of Clamping Roller Cotton Stalk Extraction Device. J. Transactions of the Chinese Society for Agricultural Machinery. 2023, 54, 101–111. (in Chinese). [Google Scholar]

- Chen, M.J. Research on the Key Technology of Dentate Disc Cotton-stalk Uprooting Machine. Ph.D. Thesis, Chinese Academy of Agricultural Sciences, Beijing, China, 2022. (in Chinese). [Google Scholar]

- Zhang, J.X.; Yang, R.; Wang, Z.W.; Hou, C.F.; Wang, Y.C.; Cai, J.L.; Yasenjiang, B.K.L.; Guo, G. Design and test of the cottonstalk pulling equipment with toothed plate. J. Transactions of the Chinese Society of Agricultural Engineering. 2024, 40, 41–50. (in Chinese). [Google Scholar]

- Tang, Z.F.; Han, Z.D.; Gan, B.X.; Bao, C.L.; Hao, F.P. Design and Experient on Cotton Stalk Pullng Head with Regardless of Row. J. Transactions of the Chinese Society of Agricultural Engineering, 2010; 41, 80–85. (in Chinese) [Google Scholar]

- Chen, W.X.; Ren, J.B.; Huang, W.L.; Chen, L.B.; Weng, W.X.; Chen, C.C.; Zheng, S.H. Design and Parameter Optimization of a Dual-Disc Trenching Device for Ecological Tea Plantations. J. Agriculture, 2024, 14, 704. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, J.; Zhu, Y.Y. Improved Design and Simulation of an Integrated Ridge-Breaking Earth Cultivator for Ratoon Sugarcane Fields. J. Agriculture, 2024, 14, 1013. [Google Scholar] [CrossRef]

- Awuah, E.; Zhou, J.; Liang, Z.; Aikins, K.A.; Gbenontin, B.V.; Mecha, P.; Makange, N.R. Parametric analysis and numerical optimisation of Jerusalem artichoke vibrating digging shovel using discrete element method. J. Soil Tillage Res. 2022, 219, 105344. [Google Scholar] [CrossRef]

- Zhou, W.Q.; Ni, X.; Song, K.; Wen, N.; Wang, J.W.; Fu, Q.; Na, M.J.; Tang, H.; Wang, Q. Bionic Optimization Design and Discrete Element Experimental Design of Carrot Combine Harvester Ripping Shovel. J. Processes 2023, 11, 1526. [Google Scholar] [CrossRef]

- Huang, W.T.; Zhao, D.; Liu, C.; Meng, X.J.; Kong, L.H.; Du, W.H. Optimization of garlic digging shovel parameters based on EDEM and quadratic regression orthogonal rotation combination design. C. 2020 3rd World Conference on Mechanical Engineering and Intelligent Manufacturing (WCMEIM), Shanghai, China, 2020; 707–711. [Google Scholar]

- Zou, L.L.; Yan, D.W.; Niu, Z.R.; Yuan, J.; Cheng, H.; Zheng, H. Parametric analysis and numericaloptimisation ofspinach root vibration shovel cutting using discreteelement method. J. Computers and Electronics in Agriculture. 2023, 212, 108138. [Google Scholar] [CrossRef]

- Liu, S.H.; Weng, S.J.; Liao, Y.L.; Zhu, D.Y. Structural Bionic Design for Digging Shovel of cassava Harvester Considering Soil Mechanics. J. Applied Bionics and Biomechanics. 2014, 11, 1–2. [Google Scholar] [CrossRef]

- Gao, J.M.; Jin, Z.P.; Ai, A.J. The Optimized Design of Soil-Touching Parts of a Greenhouse Humanoid Weeding Shovel Based on Strain Sensing and DEM-ADAMS Coupling simulation. J. Sensors 2024, 24, 868. [Google Scholar] [CrossRef]

- Zhu, L.Y. Study on Cotton Root and Shoot Morphological and Physiological Characteristies and Root Transcriptome under Low Nitrogen Conditions. Ph.D. Thesis, Hebei Agricultural University, Hebei, China, 2022. (in Chinese). [Google Scholar]

- Coetzee, C.J.; Lombard C J Coetzee, S.G.; Lombard, S.G. The destemming of grapes: experiments and discrete element modelling. J. Biosyst. Eng. 2013, 114, 232–248. [Google Scholar] [CrossRef]

- Luo, Q.; Huang, X.P.; Wu, J.F.; Mou, X.B.; Li, S.Y.; Ma, G.J.; Wan, F.X.; Peng, L.Z. Simulation Analysis and Parameter Optimization of Seed-Flesh Separation Process of Seed Melon Crushing and Seed Extraction Separator Based on DEM. J. Agriculture, 2024, 14, 1008. [Google Scholar] [CrossRef]

- Li, J.L.; Lu, Y.T.; Peng, X.B.; Jiang, P.; Zhang, B.C.; Zhang, L.Y.; Meng, H.W.; Kan, Z.; Wang, X.Z. Discrete element method for simulation and calibration of cotton stalk contact parameters. J. BioResources. 2022, 18, 400–416. [Google Scholar] [CrossRef]

- Zhang, J.X.; Zang, P.; Zhang, H.; Tan, C.L.; Wan, W.Y.; Wang, Y.C. Calibration of Simulation Parameters of Xinjiang Cotton Straw Based on Discrete Element Method. J. Transactions of the Chinese Society for Agricultural Machinery. 2023, 55, 11–16. (in Chinese). [Google Scholar]

- Jiang, D.L.; Chen, X.G.; Yan, L.M.; Gou, H.X.; Yang, J.C.; Li, Y. Parameter Calibration of Discrete Element Model for Cotton Rootstalk–Soil Mixture at Harvest Stage in Xinjiang Cotton Field. J. Agriculture. 2023, 13, 1344. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).