Submitted:

08 July 2024

Posted:

09 July 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

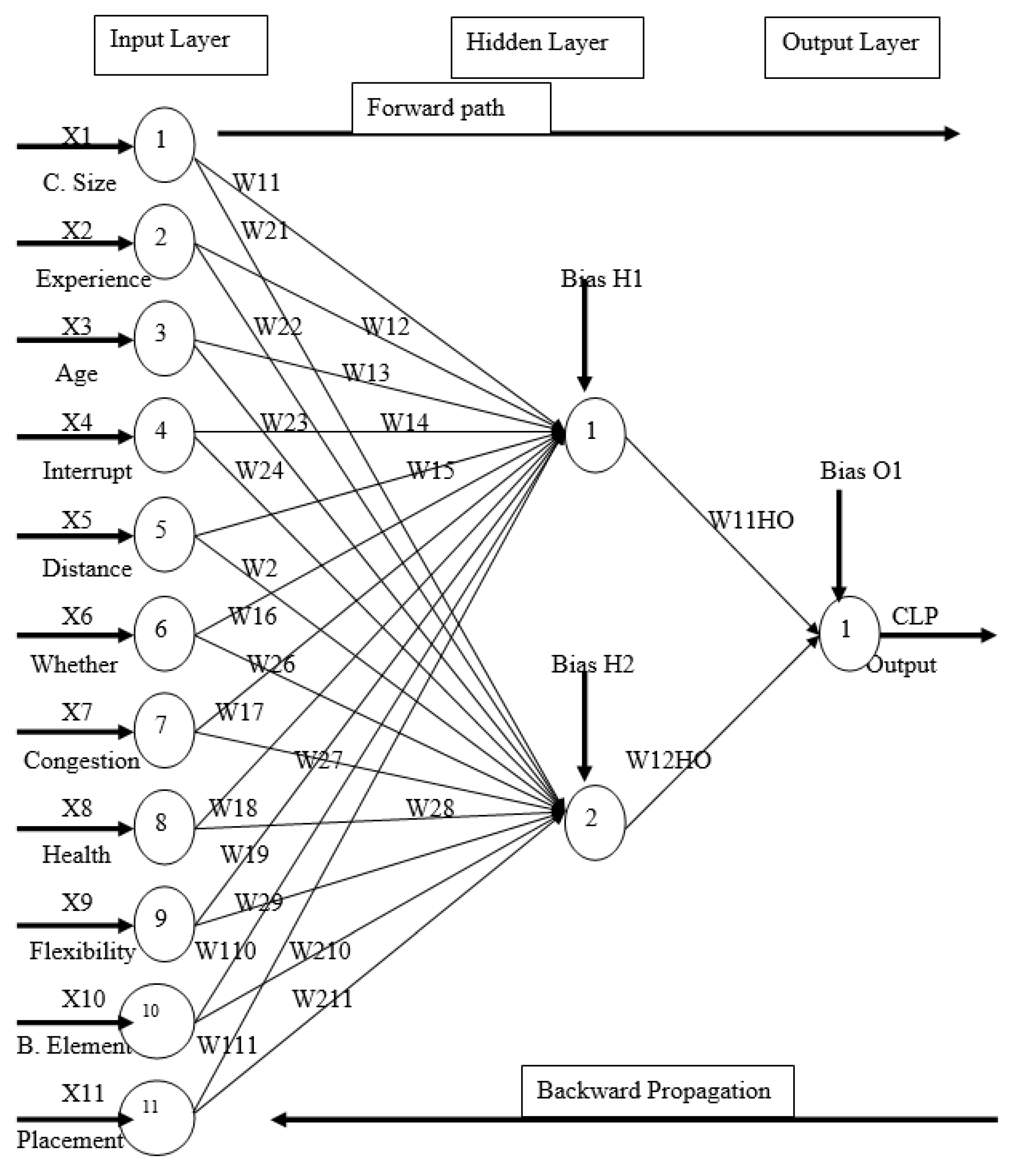

2.1. Model Development

2.2. Mathematical Steps for the Training Algorism into ANN’s

3. Results

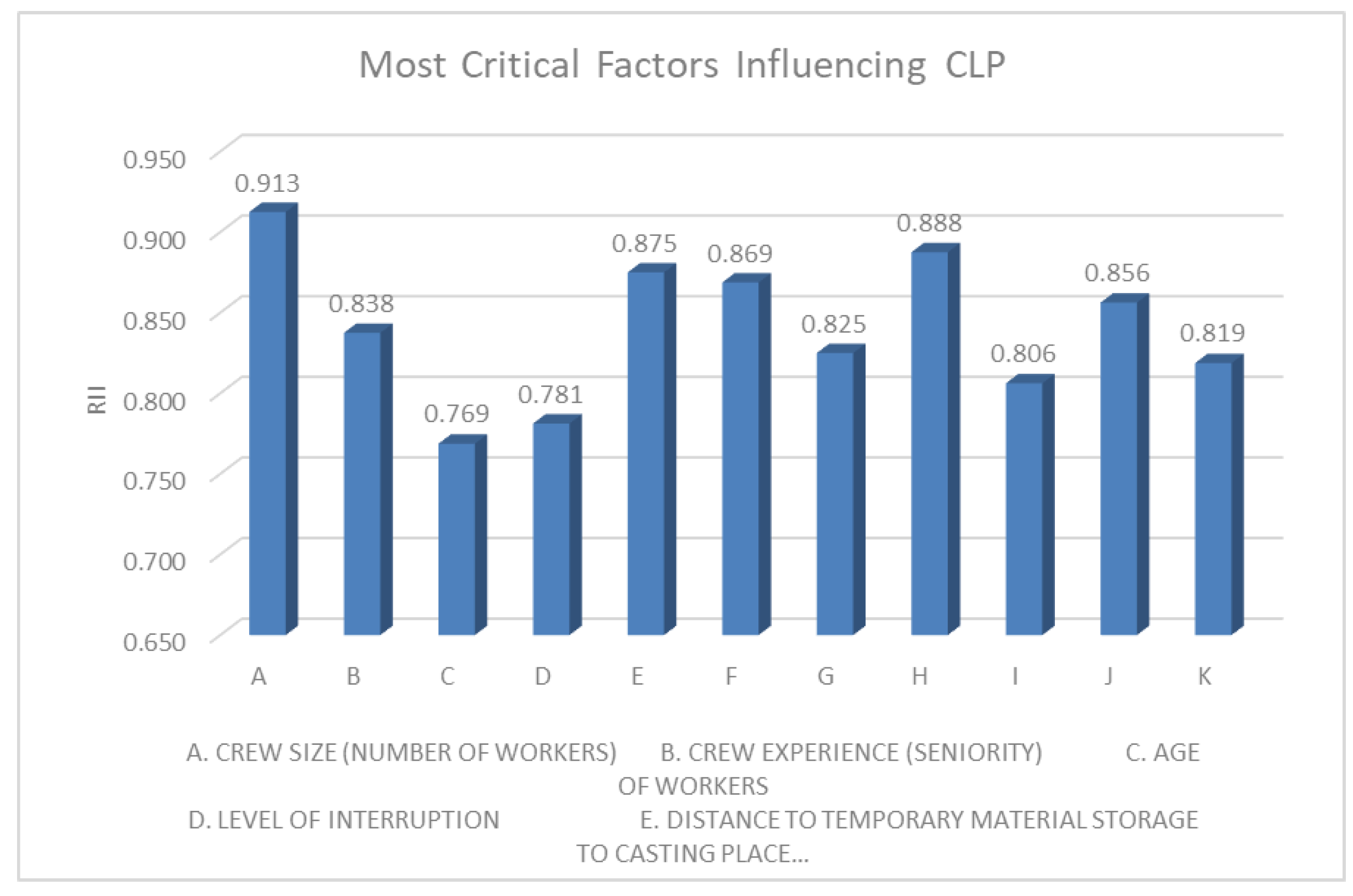

3.1. Identification of input Parameters

3.2. Quantification of Input Parameters

| In put parameters for objective Variables | ||||

|---|---|---|---|---|

| Identification code. | Parameter | Description | Measurement scale (unit) | Data source |

| N | Crew Size (number of workers) | Weather condition (comfort level) | Integer | DC* |

| E | Crew experience (seniority) | The average years of experience of the crew members in concreting activity | Real number | F+CM* |

| A | Age of workers | The average age of workers performing the actual work in years. | Real number | F+CM* |

| I | Level of interruption and disruption | The time lost and delayed events are caused due to several reasons, which may disrupt the crew from performing the assigned tasks. | Integer (total minutes spent) | DC |

| D | Distance from mixing place to final casting and finishing place | The average distance between mixing place to final placing and finishing | Integer | DC |

| In put parameters for subjective variables | ||||

|---|---|---|---|---|

| Identification Code. | Parameter | Description | Measurement scale (unit) | Data source |

| W | Whether condition | The atmospheric weather condition of the site during performing the required task | 1-4 pre-determined rating shown below 1- Sunny 2- Moderately sunny 3- Moderately rainy 4- Rainy |

DC |

| C | Congested work area | Arrangement of falsework and ease of the site to perform the task in question | 1-4 pre-determined rating shown below 1- Completely uncongested 2- Somewhat congested 3- congested 4- completely congested |

DC |

| H | Health status of workers | Health status of workers during the execution of the task | 1-4 pre-determined rating shown below 1- Very good 2- Good 3- Moderate 4- Bad |

CM |

| F | Crew flexibility | Crew willingness in performing other members’ task | 1-4 pre-determined rating shown below 1- Completely willing 2- Willing 3- Somewhat willing 4- Completely unwilling |

DC |

| B | Building element | Beam, column, slab, septic tank | 1-4 pre-determined rating shown below 1- Slab 2- Beam 3- Column 4- Septic tank |

DC |

| P | Placement technique | Pump, winch, bucket, direct chute | 1-4 pre-determined rating are shown below 1- Pump 2- Winch 3- Direct chute 4- Bucket |

DC |

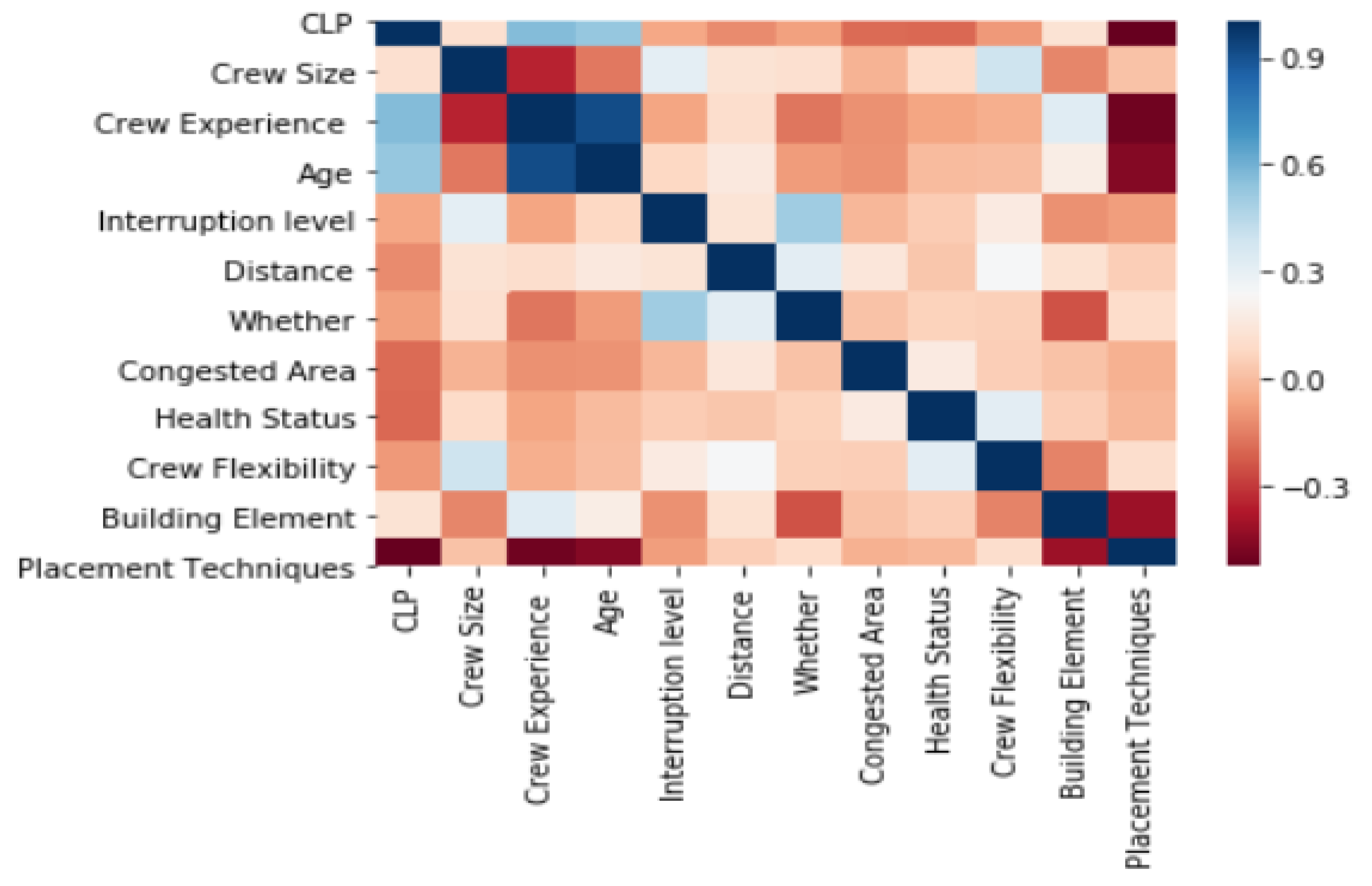

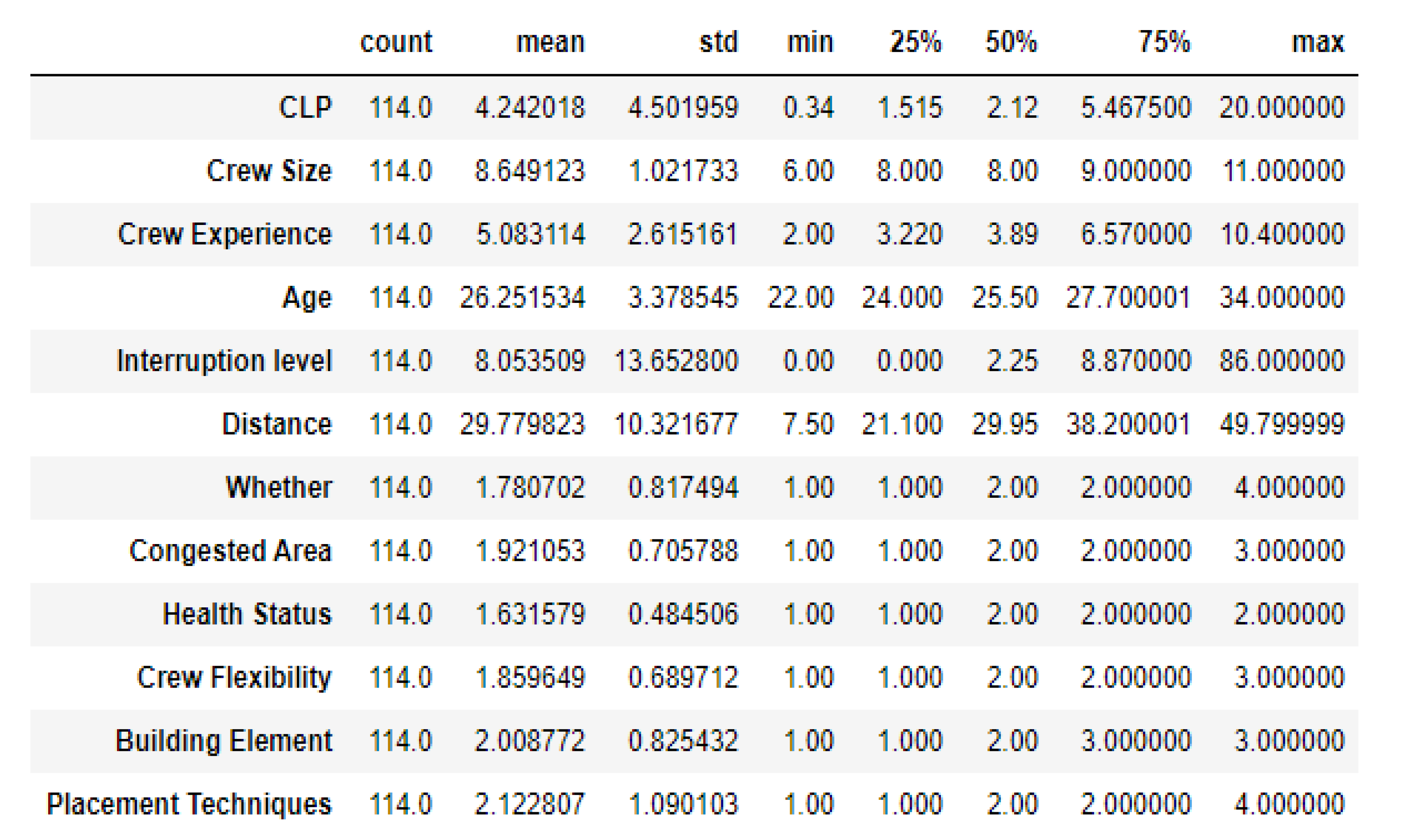

3.3. Data Analysis

3.4. Optimal Data Division

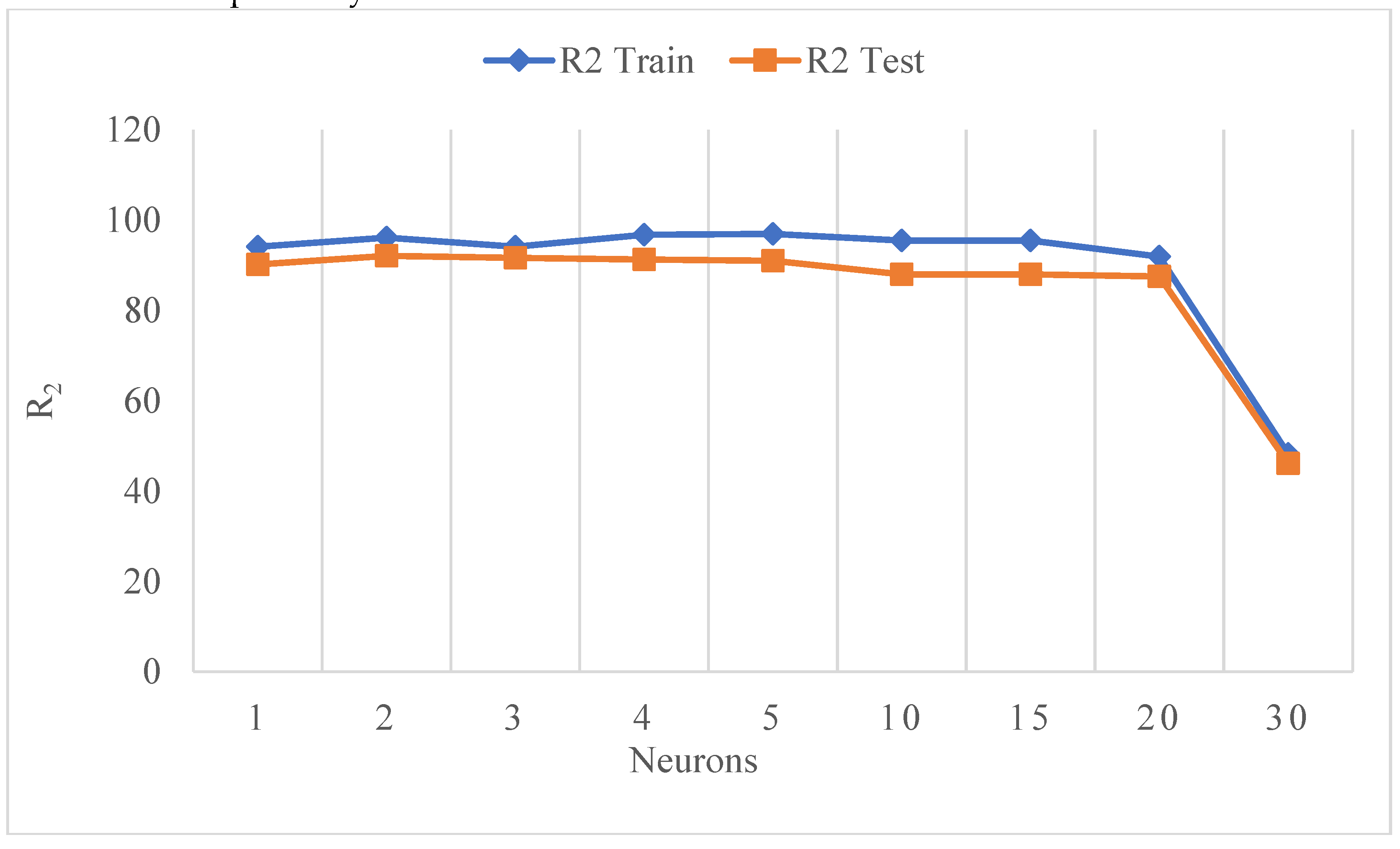

3.5. ANN Optimal Parameters

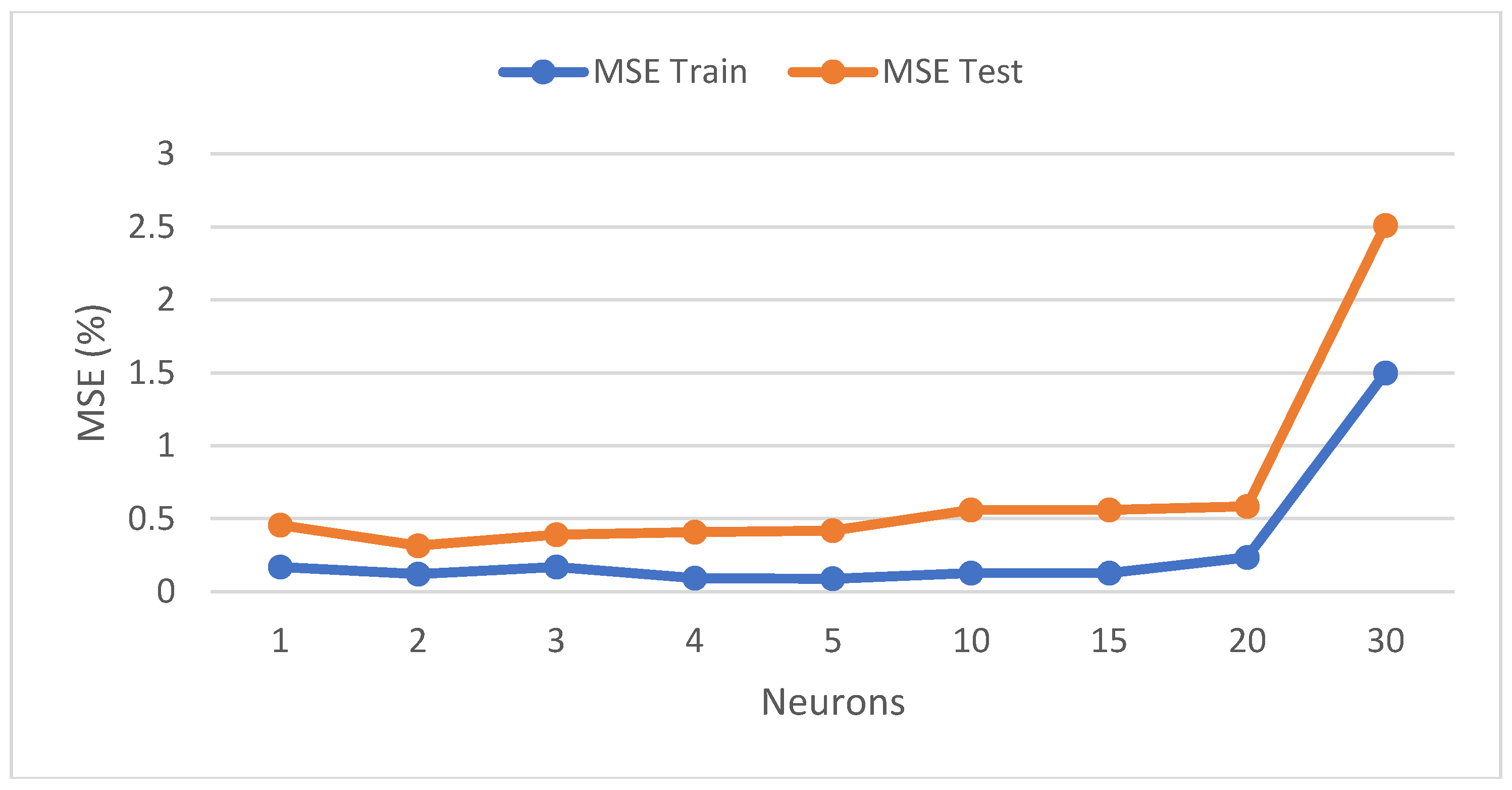

3.5.1. Effects of Hidden Nodes on Performance of NN’s

3.5.2. Equation of the ANN model

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Golnaraghi, S.; Zangenehmadar, Z.; Moselhi, O.; Alkass, S. Application of Artificial Neural Network (s) in Predicting Formwork Labour Productivity. Adv. Civ. Eng. 2019, 2019, 1–11. [Google Scholar] [CrossRef]

- Muqeem, S.; Khamidi, M.F.; Idrus, A.; Zakaria, S. Bin Development of Construction Labor Productivity Estimation Model Using Artificial Neural Network. In Proceedings of the 2011 National Postgraduate Conference; IEEE; 2011; pp. 1–6. [Google Scholar]

- Johari, S.; Jha, K.N. Impact of Work Motivation on Construction Labor Productivity. J. Manag. Eng. 2020, 36, 4020052. [Google Scholar] [CrossRef]

- Girma, S.; Chimdi, J.; Mosisa, A. CHALLENGES OF USING PREFABRICATION TECHNOLOGY IN OROMIA REGIONAL STATE. J. Civ. Eng. Sci. Technol. 2020, 11, 22–27. [Google Scholar] [CrossRef]

- Zenebe, E.; Quezon, E.T.; Mosisa, A. Contract Claim Analysis on Building Construction Project in Addis Ababa: A Case Study at Yeka Sub City. Int. J. Sci. Eng. Res 2016, 7, 1154–1160. [Google Scholar]

- Sheikh, N.A.; Ullah, F.; Ayub, B.; Thaheem, M.J. Labor Productivity Assessment Using Activity Analysis on Semi High-Rise Building Projects in Pakistan. Eng. J. 2017, 21, 273–286. [Google Scholar] [CrossRef]

- Assefa Tsehayae, A.; Robinson Fayek, A. Developing and Optimizing Context-Specific Fuzzy Inference System-Based Construction Labor Productivity Models. J. Constr. Eng. Manag. 2016, 142, 4016017. [Google Scholar] [CrossRef]

- Khan, Z.U. Modeling and Parameter Ranking of Construction Labor Productivity, Concordia University, 2005.

- Chimdi, J.; Girma, S.; Mosisa, A.; Mitiku, D. ASSESSMENT OF FACTORS AFFECTING ACCURACY OF COST ESTIMATION IN PUBLIC BUILDING CONSTRUCTION PROJECTS IN WESTERN OROMIA REGION, ETHIOPIA. J. Civ. Eng. Sci. Technol. 2020, 11, 111–124. [Google Scholar] [CrossRef]

- Mekonen, H.; Legesse, A.M.; Ameya, F.M. Investigation of Price Escalation and Its Mitigation Mechanisms on Selected Building Construction Projects of Jimma University. Jordan J. Civ. Eng. 2023, 17, 194–202. [Google Scholar] [CrossRef]

- Harmon, K.M.; Cole, B. Loss of Productivity Studies–Current Uses and Misuses. Constr. Briefings 2006, 8, 1–19. [Google Scholar]

- Tsehayae, A.A. Developing and Optimizing Context-Specific and Universal Construction Labour Productivity Models, University of Alberta, 2015.

- Tsehayae, A.A.; Robinson Fayek, A. Identification and Comparative Analysis of Key Parameters Influencing Construction Labour Productivity in Building and Industrial Projects. Can. J. Civ. Eng. 2014, 41, 878–891. [Google Scholar] [CrossRef]

- Sarihi, M.; Shahhosseini, V.; Banki, M.T. Development and Comparative Analysis of the Fuzzy Inference System-Based Construction Labor Productivity Models. Int. J. Constr. Manag. 2021, 1–18. [Google Scholar] [CrossRef]

- Yi, W.; Chan, A.P.C. Critical Review of Labor Productivity Research in Construction Journals. J. Manag. Eng. 2014, 30, 214–225. [Google Scholar] [CrossRef]

- Elfaki, A.O.; Alatawi, S.; Abushandi, E. Using Intelligent Techniques in Construction Project Cost Estimation: 10-Year Survey. Adv. Civ. Eng. 2014, 2014, 1–11. [Google Scholar] [CrossRef]

- Oduba, A.O. Predicting Industrial Construction Productivity Using Fuzzy Expert Systems, University of Alberta, 2002.

- Gurmu, A.T.; Ongkowijoyo, C.S. Stochastic-Based Model for Setting Formwork-Productivity Baseline. J. Constr. Eng. Manag. 2020, 146, 4020099. [Google Scholar] [CrossRef]

- Mohammadfam, I.; Soltanzadeh, A.; Moghimbeigi, A.; Savareh, B.A. Use of Artificial Neural Networks (ANNs) for the Analysis and Modeling of Factors That Affect Occupational Injuries in Large Construction Industries. Electron. physician 2015, 7, 1515–1522. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.-R.; Gibson Jr, G.E. A Study of Preproject Planning and Project Success Using ANNs and Regression Models. Autom. Constr. 2010, 19, 341–346. [Google Scholar] [CrossRef]

- Tam, C.M.; Tong, T.K.L. GA-ANN Model for Optimizing the Locations of Tower Crane and Supply Points for High-Rise Public Housing Construction. Constr. Manag. Econ. 2003, 21, 257–266. [Google Scholar] [CrossRef]

- Yousefi, S.; Hegazy, T.; Capuruço, R.A.; Attalla, M. System of Multiple ANNs for Online Planning of Numerous Building Improvements. J. Constr. Eng. Manag. 2008, 134, 342–351. [Google Scholar] [CrossRef]

- Heravi, G.; Eslamdoost, E. Applying Artificial Neural Networks for Measuring and Predicting Construction-Labor Productivity. J. Constr. Eng. Manag. 2015, 141, 1–11. [Google Scholar] [CrossRef]

- Nasirzadeh, F.; Kabir, H.M.D.; Akbari, M.; Khosravi, A.; Nahavandi, S.; Carmichael, D.G. ANN-Based Prediction Intervals to Forecast Labour Productivity. Eng. Constr. Archit. Manag. 2020, 27, 2335–2351. [Google Scholar] [CrossRef]

- Goodarzizad, P.; Mohammadi Golafshani, E.; Arashpour, M. Predicting the Construction Labour Productivity Using Artificial Neural Network and Grasshopper Optimisation Algorithm. Int. J. Constr. Manag. 2021, 1–17. [Google Scholar] [CrossRef]

- Negnevitsky, M. Artificial Intelligence: A Guide to Intelligent Systems; Second.; Pearson education, 2005; ISBN 0321204662.

- Haykin, S. Neural Networks: A Comprehensive Foundation Prentice-Hall Upper Saddle River; 2nd ed. 1999. [Google Scholar]

- Beale, M.H.; Hagan, M.T.; Demuth, H.B. Neural Network Toolbox. User’s Guid. MathWorks 2010, 2, 77–81. [Google Scholar]

- Aswed, G.K. Productivity Estimation Model for Bracklayer in Construction Projects Using Neural Network. Al-Qadisiyah J. Eng. Sci. 2016, 9, 183–199. [Google Scholar]

- Al-Zwainy, F.M.S.; Abdulmajeed, M.H.; Aljumaily, H.S.M. Using Multivariable Linear Regression Technique for Modeling Productivity Construction in Iraq. 2013, 3, 128–135. [CrossRef]

- Idrus, A.; Muqeem, S.; Khamidi, M.F.; Zakariya, M.S. Bin Estimating Construction Labor Productivity for Concreting Activity Using Artificial Neural Network. In Proceedings of the International Conference on Computer and Computational Intelligence; American Society of Mechanical Engineers; 2011; pp. 507–511. [Google Scholar]

- Sonmez, R.; Rowings, J.E. Construction Labor Productivity Modeling with Neural Networks. J. Constr. Eng. Manag. 1998, 124, 498–504. [Google Scholar] [CrossRef]

| S.No. | Objective (Quantitative) factors | Subjective (Qualitative) factors |

|---|---|---|

| 1 | Crew Size (number of workers) | Weather condition (comfort level) |

| 2 | Crew experience (seniority) | Location of project |

| 3 | Age of workers | Comfortability of materials storage for work |

| 4 | Average wind speed | Scaffold requirement |

| 5 | Number of consecutive days worked | Skill level of labor |

| 6 | Number of languages spoken | Congested work area (arrangement of falsework) |

| 7 | Number of craftsperson technical training | Communication problems with workers |

| 8 | Level of overtime | Alcoholism |

| 9 | Level of interruption and disruption | Disruption of power/water supplies |

| 10 | Foreman experience | Health status of workers |

| 11 | Distance to temporary material storage to casting place | Extent and quality of supervision |

| 12 | Space of casting (volume of work) | Safety requirements |

| 13 | quality requirements | |

| 14 | Crew flexibility (crew willingness in performing other members task) | |

| 15 | Building element (footing, grade beam, column, slab…) | |

| 16 | Cover from weather effect | |

| 17 | The working condition (noise) | |

| 18 | Placement technique (Pump, Crane, bucket, direct chute…) |

| Influencing Factors | Correlation(R) |

|---|---|

| Crew Size | 0.1160 |

| Crew Experience | 0.5681 |

| Age | 0.5349 |

| Interruption level | -0.0573 |

| Distance | -0.1201 |

| Whether | -0.0748 |

| Congested Area | -0.1944 |

| Health Status | -0.1984 |

| Crew Flexibility | -0.0912 |

| Building Element | 0.1266 |

| Placement Techniques | -0.5227 |

| Type of Dataset | Number of Data Instances | Percentage (%) |

|---|---|---|

| Training | 74 | 65 |

| Validation | 17 | 15 |

| Testing | 23 | 20 |

| Total | 144 | 100 |

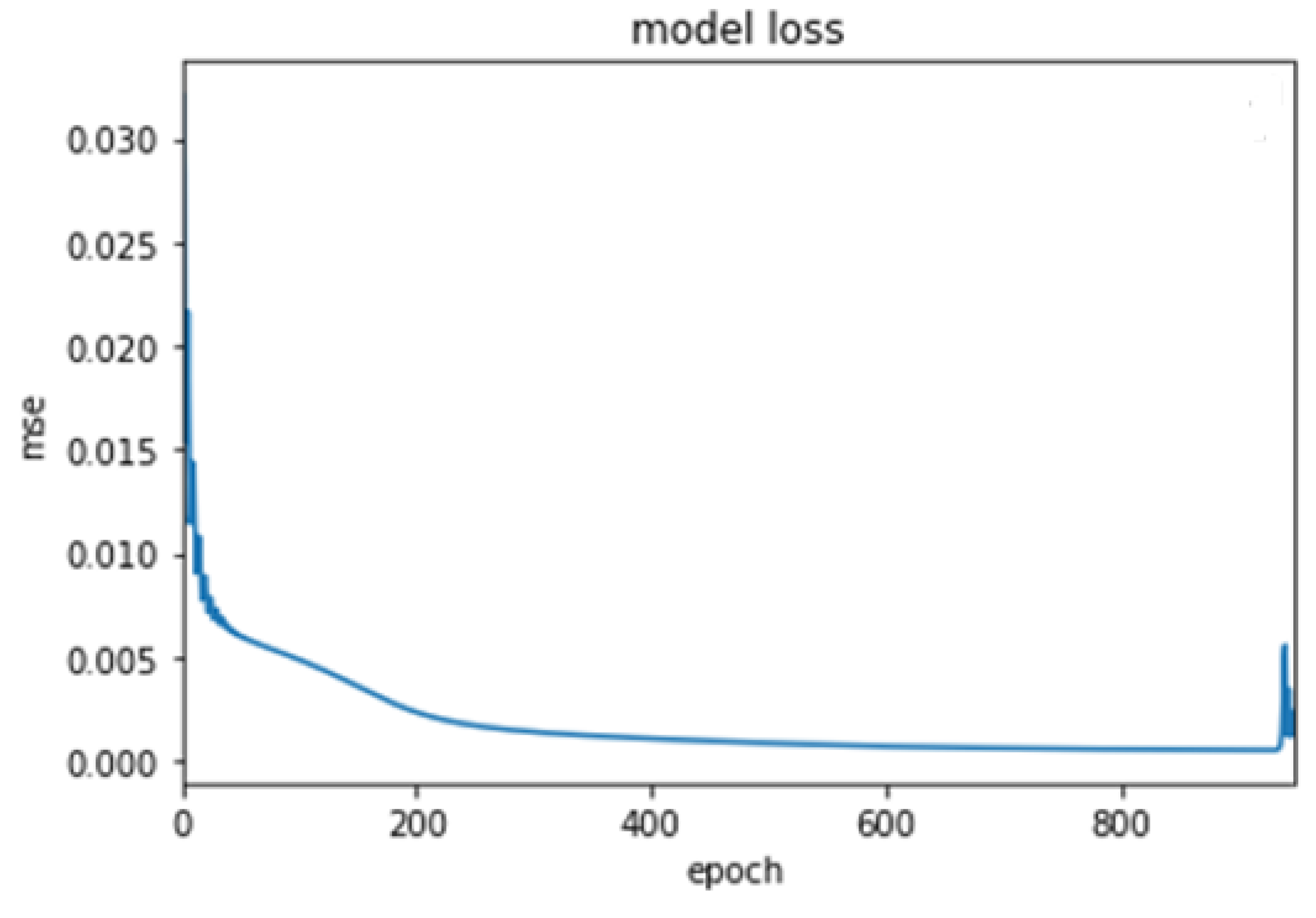

| Document String Type | Description |

|---|---|

| Hidden layer size | Number of layers and neurons are introduced (1 hidden layer and 2 hidden nods) |

| Activation | Activation used in the hidden layer (Logistic) |

| Maximum iterations | Number of epoch (2000) |

| Solver (Optimizer) | For weight optimization (Adam) |

| Initial learning rate | Controls weights and bias update (0.1) |

| Momentum | For gradient decent update(0.9) |

| Early stopping | Stops training when loss stops decreasing (True) |

| Validation fraction | Set aside data for validation (15%) |

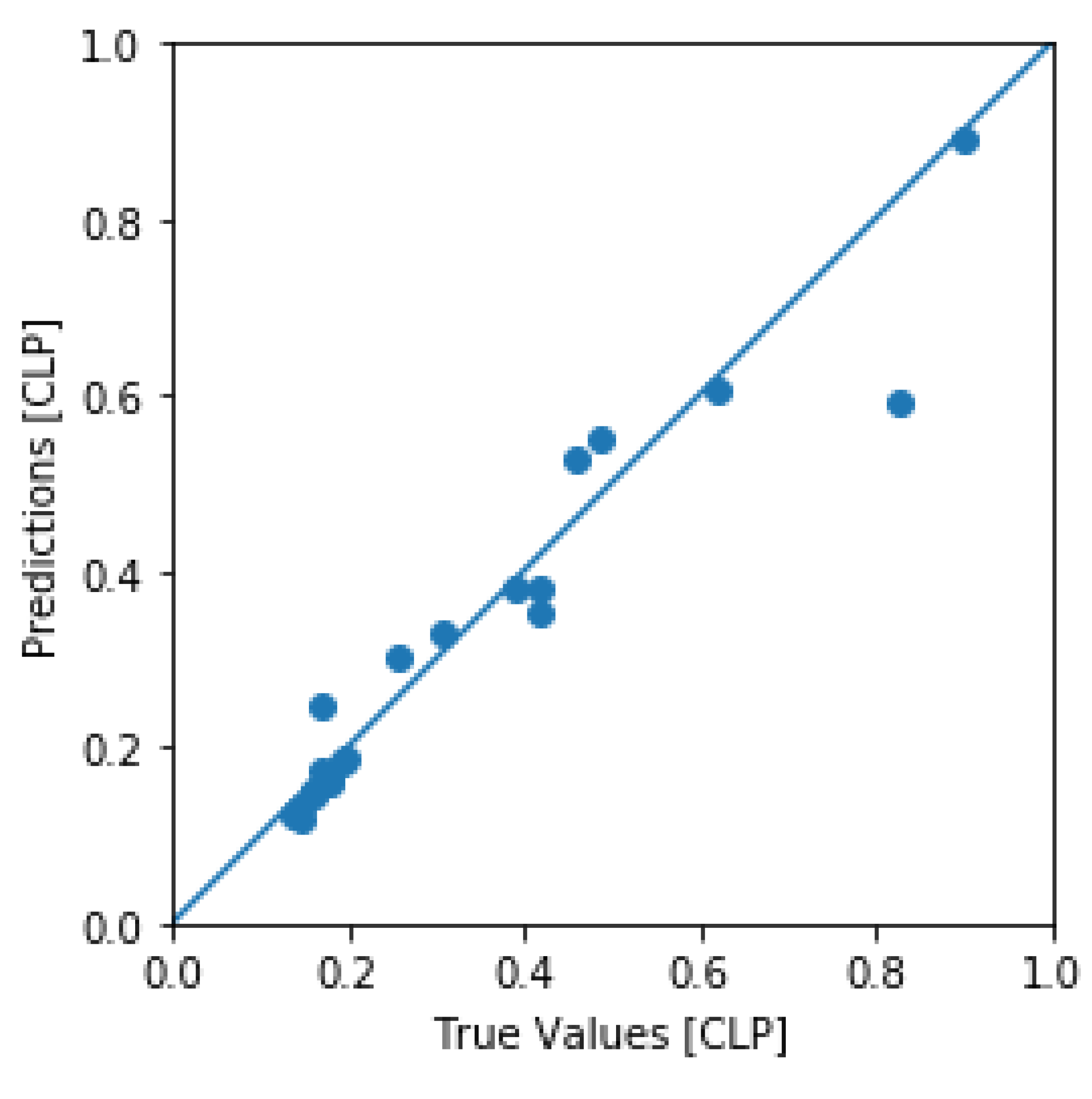

| MAE Train | MSE Train | R2 Train | |||

|---|---|---|---|---|---|

| Train | Test | Train | Test | Train | Test |

| 0.03253 | 0.04141 | 0.00170 | 0.00457 | 0.94080 | 0.90182 |

| 0.02051 | 0.03060 | 0.00121 | 0.00316 | 0.96110 | 0.92065 |

| 0.02962 | 0.03561 | 0.00170 | 0.00391 | 0.94105 | 0.91596 |

| 0.02136 | 0.03395 | 0.00094 | 0.00407 | 0.96739 | 0.91253 |

| 0.02016 | 0.03621 | 0.00088 | 0.00420 | 0.96924 | 0.90972 |

| 0.02652 | 0.04498 | 0.00129 | 0.00562 | 0.95500 | 0.87939 |

| 0.02652 | 0.04498 | 0.00129 | 0.00562 | 0.95500 | 0.87939 |

| 0.03276 | 0.04400 | 0.00234 | 0.00583 | 0.91867 | 0.87482 |

| 0.08388 | 0.11183 | 0.01497 | 0.02511 | 0.48165 | 0.46114 |

| Weights between input nodes and hidden node 1 | Weights between input nodes and hidden node 2 | Hidden Biases | Hidden to output weights | Output bias |

|---|---|---|---|---|

| W11= -0.80771825 | W21= -1.29754431 | BH1 = 0.358 34581 BH2 = -1.508 88807 |

W11HO= -0.6679519 W12HO= -1.62451474 |

B01= 1.955 71816 |

| W12= 0.145702103 | W22= -2.42387211 | |||

| W13= -0.528524606 | W23= 2.26612486 | |||

| W14= 0.201301486 | W24= 2.74387717 | |||

| W15= 0.132271702 | W25= -0.026419671 | |||

| W16= 0.0334985595 | W26= -0.00353481671 | |||

| W17= -0.0949299372 | W27= 0.00908773745 | |||

| W18= -0.282357359 | W28= 0.336306823 | |||

| W19= 0.103049981 | W29= 0.588741942 | |||

| W110= -0.214612051 | W210= 2.39695108 | |||

| W111= -1.21460908 | W211= 10.5258561 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).