1. Introduction

Making decisions in an organization is the most important managerial problem, the answer is not easy to give, but it must be understood that all decisions are economic decisions. This article aims at the analysis of the technical-economic system, the optimization of decisions and strategic policies taken by a company with the help of the economic tool.

A company has to develop its own stimulator of the "body", which is the most risky method, with a small percentage of success due to the perseverance that is lost along the way, but with a high capacity for long-term evolution [

1,

2,

3].

Figure 1 shows the model of the items needed in the development of methods to stimulate the economic organization.

Carbonization and prevention for construction materials, exploring how the production processes of construction materials contribute to carbon emissions and climate change involves a detailed analysis of each step in the production chain and its environmental impact, such as [

4,

5]:

- ⮚

Extraction of raw materials

Mining and extraction, the carbon impact concerning raw materials such as limestone for cement, iron ore for steel, and aggregates for concrete, are often energy-intensive processes, generating significant CO2 emissions.

Extraction processes can lead to deforestation, loss of biodiversity, and water and air pollution, indirectly contributing to climate change.

The potential for meaningful climate impact through low-carbon and carbon-storing materials highlights materials that have the potential to change the climate profile of buildings from a leading driver of climate change to a leading carbon reservoir, reversing it [

1,

6].

- ⮚

Production and manufacturing

Cement production: the process of calcining limestone to produce clinker (the main component of cement) releases CO2. In fact, cement production is responsible for approximately 7-8% of global CO2 emissions.

Energy consumption: cement kilns require significant energy and are often powered by fossil fuels, adding even more carbon emissions.

Steel manufacturing: traditional steel production involves blast furnaces that burn coal to reduce iron ore, a process that generates large amounts of CO2. The process also produces other greenhouse gases, such as carbon monoxide (CO) and methane (CH4), which are additional indirect emissions [

7,

8,

9,

10].

Decarbonization encompasses both the reduction of operational carbon and embodied carbon, which refers to the carbon emissions released during the use phase and over the entire life cycle of a building, respectively. This life cycle encompasses extraction, transport, installation, use and end of life for each material or piece of furniture and is responsible for 11% of global greenhouse gas emissions and 28% of global emissions from the construction sector [

11,

12].

Initiatives such as the Net Zero Carbon Buildings Commitment, launched at the 2018 Global Climate Action Summit, promote global operational carbon reduction by calling for reducing the amount of carbon dioxide emissions released annually to zero or on a negative trend. Other initiatives, such as the US Carbon Leadership Forum, stress the importance of reducing embodied carbon, citing forecasts that global building space will double by 2060 [

13,

14,

15].

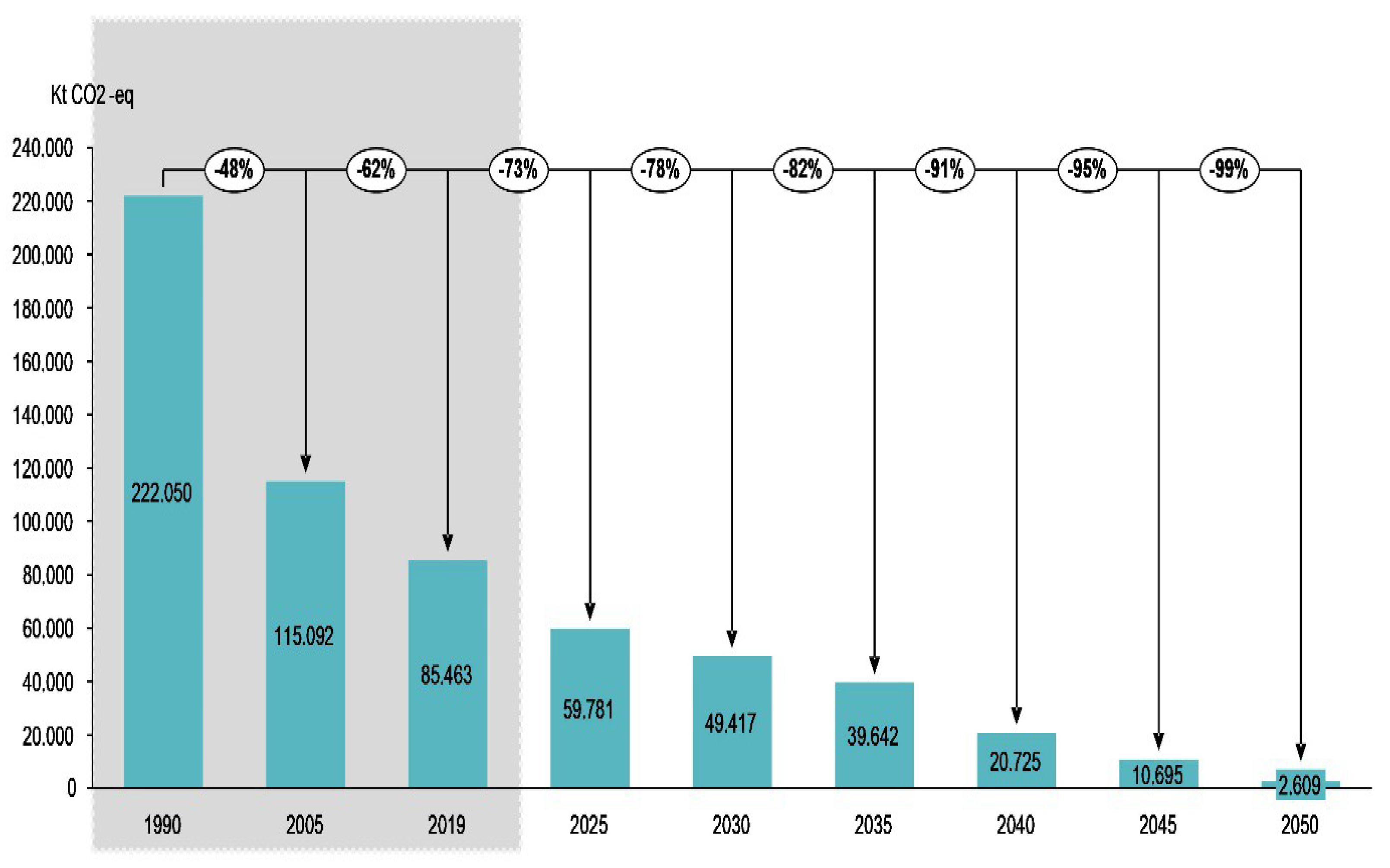

Romania has already started the decarbonization process by reducing emissions by 62% in 2019 compared to the 1990 level (

Figure 2). However, further efforts are needed to achieve climate neutrality in 2050. First, the 2030 milestone of a 78% reduction in net emissions from 1990 levels is needed.

However, further efforts are needed to achieve climate neutrality in 2050. First, the 2030 milestone of a 78% reduction in net emissions compared to 1990 levels is needed. Achieving the targets is only possible through the implementation of policies and appropriate measures for each sector, according to those presented in

Figure 3 and

Figure 4, to achieve the sectoral objectives regarding the reduction of emissions presented in

Figure 2. In the case of some of the sectors, it is first necessary to stop the trend of increasing emissions [

16,

17,

18,

19].

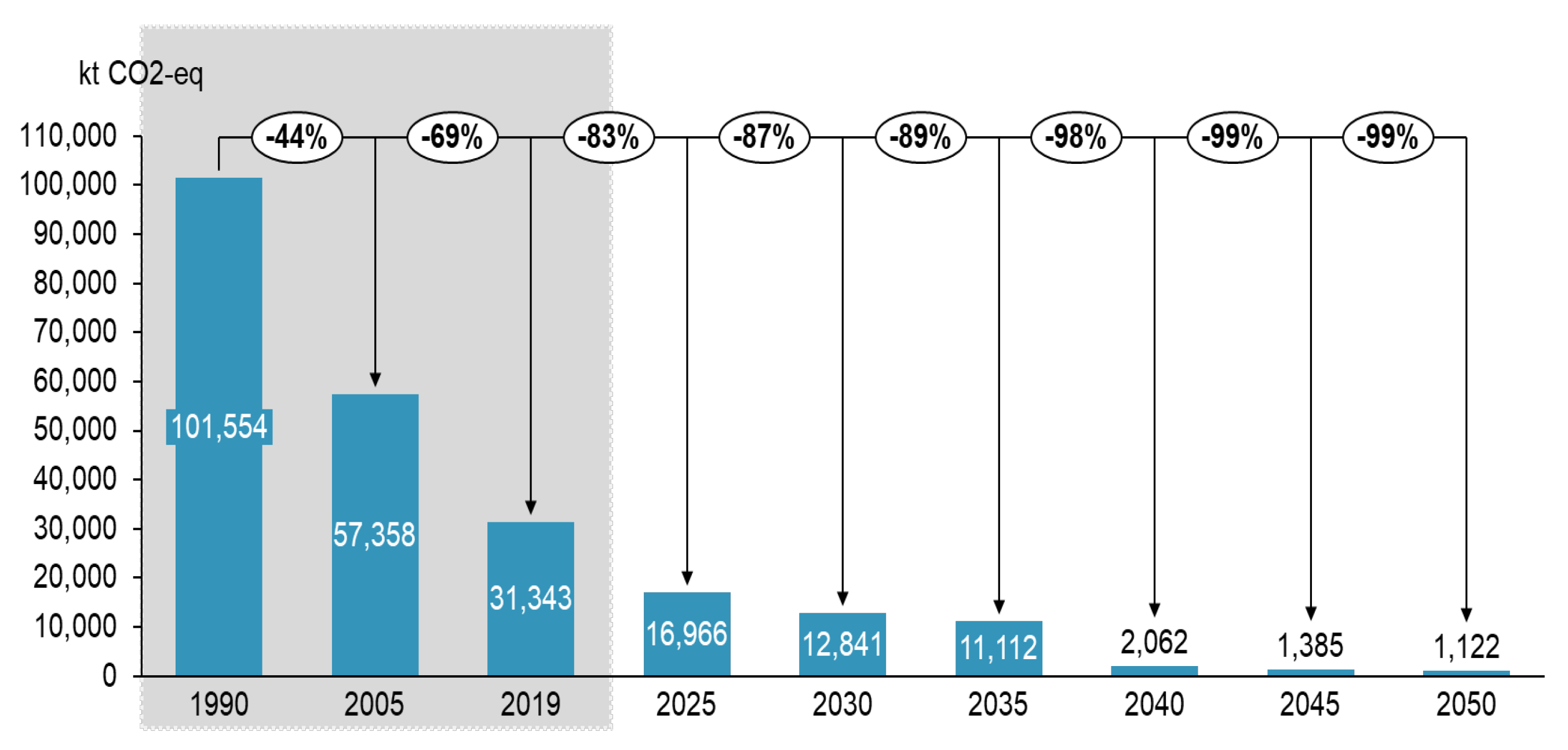

Decarbonisation of the energy sector has already begun. In 2019, 69% of the 2050 emissions reduction target has already been achieved. By 2035, 98% of the goal will have been achieved [

20,

21,

22,

23].

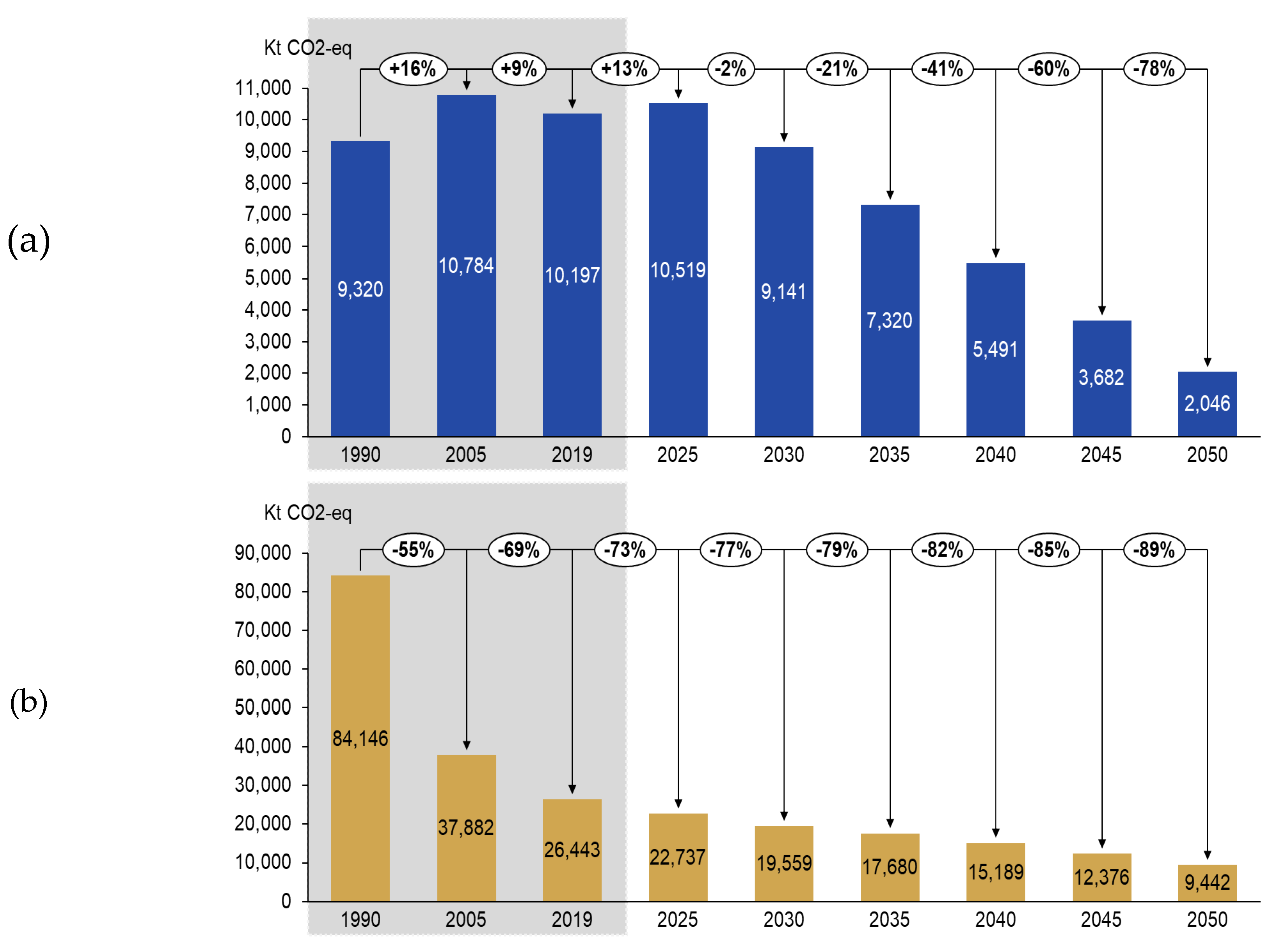

Emissions from the buildings sector (

Figure 4a) increased by 9% by 2019 compared to 1990 and are expected to continue to increase until 2025. After that, emissions will start to decline, and in 2050 they will be 78% lower than of the 1990 level.

In the industry sector (

Figure 4b), net emissions fell by 73% between 1990 and 2019. The ultimate goal is to reduce by 89% in 2050 compared to 1990 levels.

Emissions from the buildings sector (

Figure 4a) increased by 9% by 2019 compared to 1990 and are expected to continue to increase until 2025. After that, emissions will start to decline, and in 2050 they will be 78% lower than of the 1990 level.

In the industry sector (

Figure 4b), net emissions fell by 73% between 1990 and 2019. The ultimate goal is to reduce by 89% in 2050 compared to 1990 levels.

Since different carbon reduction strategies create varying levels of effectiveness and different stages of construction require distinct procedures, the World Resources Institute has presented a list of prioritized strategies that can be transformed into three decarbonization procedures.

The IMR list for reducing operational emissions is as follows: energy efficiency before renewable energy; on-site renewable energy before off-site renewable energy and renewable energy before carbon offset (renewable energy investments). Through this hierarchy of priorities, we can approach the decarbonization of buildings on three different levels:

1. Reduction of operational carbon in existing buildings through energy efficiency;

2. Using renewable energy to meet the remaining low energy demand, ideally on-site or nearby off-site if necessary;

3. Reducing the embodied carbon of new buildings throughout their entire life cycle.

From the point of view of financial efficiency, for the building owner, the most advantageous approach is for the levels to be implemented in the order mentioned above.

Concrete production: mixing cement, aggregates, and water to produce concrete does not directly produce many emissions, but the contribution comes from the production of the component materials.

As [

16] “It is widely known that many kinds of waste may be utilized rather than raw materials in the field of construction materials. However, for the wide use of waste in building construction, it is necessary to ensure that the characteristics of the resulting building materials are appropriate. Recycled glass waste is one of the most attractive waste materials that can be used to create sustainable concrete compounds. Therefore, researchers focus on the production of concrete and cement mortar by utilizing waste glass as an aggregate or as a pozzolanic material. In this article, the literature discussing the use of recycled glass waste in concrete as a partial or complete replacement for aggregates has been reviewed by focusing on the effect of recycled glass waste on the fresh and mechanical properties of concrete.”

As [

17] “Development of sustainable concrete as an alternative to conventional concrete helps in reducing carbon dioxide footprint associated with the use of cement and disposal of waste materials in landfill. One way to achieve that is the use of fly ash (FA) as an alternative to ordinary Portland cement (OPC) because FA is a pozzolanic material and has a high amount of alumina and silica content. Because of its excellent mechanical properties, several studies have been conducted to investigate the use of alkali-activated FA-based concrete as an alternative to conventional concrete. FA, as an industrial by-product, occupies land, thereby causing environmental pollution and health problems.”

Transport and use: emissions are also generated through the transportation of materials and the equipment used for pouring and finishing concrete.

Transporting raw materials from extraction sites to factories involves using heavy vehicles that burn fossil fuels, generating CO2 and other pollutants. Additionally, the import and export of materials over long distances increase the carbon footprint.

- □

Use and maintenance of buildings

Energy efficiency, insulation, and construction materials: energy-efficient materials can reduce emissions over the lifespan of buildings by decreasing the need for heating and cooling.

Durable materials: durable materials require less maintenance and replacement, thus reducing emissions associated with the production of new materials.

Maintenance and repairs: activities related to the maintenance and repairs over the building's lifespan involve energy and material consumption, which can lead to additional emissions.

Reducing the carbon footprint of construction materials requires an integrated approach that involves technological improvements, the use of renewable energy sources, and the adoption of circular economy practices. By implementing these strategies, the construction industry can significantly contribute to global efforts to combat climate change and transition to a sustainable, low-carbon economy.

2. Materials and Methods

2.1. Carbon Reduction Technologies in Construction

An analysis of new technologies and practices aimed at reducing the carbon footprint of construction materials, including durable and recyclable materials.

Use of alternative cements: utilizing alternative cements such as composite Portland cement, which includes waste materials like blast furnace slag or fly ash, and CO2 mineralized technology through carbon capture and storage (CCS) directly in concrete through mineralization processes.

Low-carbon steel: low-carbon footprint steel is recycled steel made using a high percentage of recycled scrap iron. Efficient production processes utilize direct reduced iron (DRI) technologies with hydrogen instead of coal to reduce emissions.

Implementing new technologies and practices for reducing the carbon footprint of construction materials is essential for the sustainable development of the construction industry. Durable and recyclable materials, along with innovative technologies and efficient strategies, can significantly contribute to reducing carbon emissions, conserving resources, and protecting the environment. Adopting these solutions not only supports the transition to a low-carbon economy but also improves the long-term economic performance of the construction sector.

2.2. Innovations in Carbon-Neutral Construction Materials

Introduction of innovative materials with a near-zero or negative carbon footprint, such as renewable materials and those produced with renewable energy.

Examples of innovative materials and manufacturing methods:

CLT is a construction material made from layers of wood glued perpendicularly. It is sustainable because it comes from responsibly managed forests and has a much lower carbon footprint than concrete or steel. In some cases, CLT can have a negative carbon footprint if the forests used to supply the wood are reforested.

The T3 Building in Minneapolis, USA, is one of the largest commercial buildings made of CLT, demonstrating its viability for commercial construction.

Traditional Portland cement production is one of the largest sources of CO2 emissions. Alternatives, such as low-clinker concrete or the use of ground granulated blast furnace slag, can significantly reduce carbon emissions. Another innovation is "green" concrete that uses captured carbon dioxide in the curing process.

The Innovation Tower in Hong Kong uses green concrete in its structure, reducing the carbon emissions associated with its construction.

Bricks made from biocomposite materials, such as hemp or other natural fibers mixed with lime, have a very low carbon footprint and are biodegradable. These bricks not only reduce emissions during production but also have the ability to absorb CO2 from the atmosphere.

Flat House in Cambridgeshire, UK, uses hemp in its construction, reducing carbon emissions and demonstrating the efficiency of biocomposite materials.

Panels made from seaweed offer a sustainable and renewable solution. The production of these panels is not only carbon-neutral but can also be negative, as algae absorb CO2 during growth.

The Bio Intelligent Quotient (BIQ) House in Hamburg, Germany, uses bioreactor facades with algae to produce energy and reduce carbon emissions.

Producing construction materials in factories powered by solar energy can significantly reduce their carbon footprint. For example, solar panels manufactured in a solar-powered facility have a much lower carbon footprint than those produced conventionally.

Tesla Gigafactory in Nevada, USA, is largely powered by solar energy and produces batteries and other components used in construction with a reduced carbon footprint [

8].

Cement and steel factories powered by wind energy can reduce the carbon emissions associated with these essential construction materials.

Orascom construction in Egypt has begun using wind energy for cement production, reducing CO2 emissions.

Implementing innovative materials and using renewable energy in their production are crucial steps toward carbon neutrality in the construction industry. The mentioned building examples demonstrate that these technologies are not only viable but also bring significant benefits in terms of reducing carbon emissions and increasing the sustainability of construction projects.

2.3. Impact of Climate Change on the Construction Industry

Analysis of the effects of climate change on construction materials and how the industry can respond to mitigate these impacts.

Exposure to extreme weather conditions: construction materials like concrete, steel, and wood can suffer significant damage from storms, floods, and extreme temperatures.

These conditions can lead to various issues: concrete can crack and deteriorate more rapidly due to repeated freeze-thaw cycles and exposure to saltwater.

Submersible materials such as hydraulic concretes and composites are becoming essential. Moisture barriers and waterproof insulations are increasingly necessary to protect structures against water infiltration [

13].

Steel may corrode faster in high humidity conditions.

Wood can rot or warp in excessive moisture or fluctuating temperatures.

Rising average temperatures can cause problems by increasing global average temperatures, which affect the thermal performance of construction materials and can lead to increased energy demand for cooling buildings.

Insulating materials may become less efficient under extreme temperatures, necessitating the use of ceramics and other thermoresistant materials to improve building energy performance.

Higher humidity levels and flooding:

Problems: rising sea levels and increased flood frequency put pressure on construction materials, increasing the risk of degradation.

Developing durable and climate-resistant materials:

Durable concrete: producing concrete using pozzolanic additives or carbon capture technologies to reduce emissions and increase durability.

Treatable steel: utilizing treated steel to resist corrosion and exposure to aggressive environments.

Modified wood: implementing thermally treated wood or laminated wood for increased resistance to moisture and pests.

The Edge, Amsterdam: one of the most sustainable office buildings in the world, The Edge utilizes advanced insulation technologies, solar panels, and water management systems to reduce climate impact.

Benefits: achieving net-zero energy consumption and reducing associated carbon emissions.

One Central Park, Sydney: this innovative building uses a combination of vertical gardens, solar panels, and water recycling systems to create a sustainable urban microclimate.

Benefits: improving air quality and reducing the carbon footprint.

The effects of climate change on construction materials are significant, but the industry can respond by developing durable materials, using low-emission production technologies, and adopting sustainable practices. Case studies show that implementing these strategies not only reduces climate impact but can also improve the performance and value of buildings in the long term [

3].

2.4. Regulations and Standards for Sustainable Construction Materials

An examination of government policies and industry standards that encourage the use of low-carbon construction materials and promote sustainability in construction.

Research is ongoing for the development of carbon prevention and absorption technologies in construction materials, such as using materials that absorb CO2 during the manufacturing or usage process.

Calculating the carbon footprint involves assessing the total amount of greenhouse gases (GHGs) emitted directly or indirectly by an individual, organization, or product over a specific time period, typically measured in tons of carbon dioxide equivalent (CO2e).

A simplified method for calculating the carbon footprint:

Identify and categorize emissions: first, you need to identify the main sources of greenhouse gas emissions associated with the activity or entity you are analysing.

These may include direct emissions, such as those from vehicle fuel consumption or utilities, as well as indirect emissions, such as those associated with the production and transportation of goods and services used by the entity.

Data Collection

Accurate data on energy consumption, such as electricity and gas bills, vehicle mileage, fuel consumption, water usage, and other relevant data, must be collected.

Collecting data on the carbon emissions of a construction project can be done through a systematic process involving identifying and quantifying sources of GHG emissions. Here are some common methods for collecting this data:

Energy and carbon audit: an energy and carbon audit involves a detailed assessment of energy consumption and carbon emissions associated with all aspects of the construction and its operations. This may include analysing electricity, gas, heating fuel consumption, and transportation, as well as evaluating indirect emissions associated with the production and transportation of construction materials.

Energy consumption monitoring: installing energy consumption monitoring equipment can provide precise and real-time data on how a construction project uses electricity, gas, and other energy sources. This data can be used to estimate carbon emissions associated with the construction's energy consumption.

Construction materials assessment: construction materials can represent a significant source of carbon emissions, either during the manufacturing process or during their use in construction. Collecting data on the materials used in construction, including their manufacturing process, transportation, and installation, can provide important insights into their environmental impact.

Life cycle analysis: life cycle analysis can be used to assess the environmental impact of a construction project over its entire life cycle, from raw material extraction to demolition and disposal. This may involve evaluating carbon emissions associated with each stage of the life cycle and identifying opportunities for reducing them [

4].

Use of publicly available data: Some organizations or authorities may provide public data or reports on the carbon emissions of constructions in a particular region or sector. This information can be used to gain a better understanding of trends and factors influencing construction carbon emissions [

5].

It is important to carefully collect data and use reliable methods and data sources to ensure the accuracy and relevance of the collected information.

Conversion of data into CO2 emissions

After collecting the data, you need to convert it into CO2e emissions using standardized conversion factors. These conversion factors reflect the relative impact of each type of emission on climate change and are expressed in CO2e units.

Calculating the total

Add up all emissions converted into CO2e to obtain the total carbon footprint.

Reporting and Monitoring

Once you have calculated the carbon footprint, it is important to report and monitor the results over time to assess progress and identify opportunities for emission reduction.

It is important to note that calculating the carbon footprint can be complex and may vary depending on the specific context and methods used. Therefore, it is sometimes helpful to consult experts or use specialized tools to perform these calculations accurately and comprehensively.

3. Results

3.1. Modernization of an Old Hotel Using Sustainable Materials and Efficient Technologies

Context and need

The Old Bucharest Hotel (fictional name), a symbol of Bucharest's architecture, was built in 1931 and is one of the most recognized buildings. However, given its age and the technologies used in its initial construction, the building needed major upgrades to become more energy-efficient and reduce its environmental impact.

The modernization of the Old Bucharest Hotel involved significant investments in various energy-efficient technologies and materials. In this analysis, we will detail the main components of the technical costs associated with the modernization, based on real data and price estimates from the market.

Objectives of modernization:

- □

Reduce energy consumption and carbon emissions.

- □

Improve comfort and working conditions for tenants.

- □

Increase the value and attractiveness of the building.

Strategies and implemented technologies

- □

Rehabilitation of window system

Issue: the original windows of the building did not provide efficient thermal insulation, leading to significant energy losses.

Solution: modernizing windows by adding a third layer of glass and using inert gas between layers to improve thermal and sound insulation. This led to a significant reduction in heat loss and cooling needs.

Replacement of 6,514 windows with energy-efficient units, including a third layer of glass and the use of inert gases.

Cost: approximately 13 million euros.

Impact: reducing heat losses and improving indoor comfort.

- □

Efficient lighting system:

Issue: traditional lighting consumed a lot of energy and had a short lifespan.

Solution: replacing incandescent bulbs with energy-efficient LEDs, which consume much less energy and have a longer lifespan.

Cost: approximately 4 million euros.

Impact: reducing electricity consumption for lighting and increasing equipment lifespan.

- □

Energy management system:

Issue: lack of an integrated system for monitoring and managing energy consumption.

Solution: implementation of an energy management system that monitors and optimizes energy consumption in real-time. This includes sensors and advanced software that automatically adjusts heating, ventilation, and air conditioning (HVAC) systems based on space occupancy and usage.

Cost: approximately 6 million euros.

Impact: optimizing energy use and identifying savings opportunities.

- □

Thermal insulation and facade systems:

Issue: energy losses through exterior walls and roof.

Solution: adding additional thermal insulation to walls and roofs to reduce heat losses. The building facade was also modernized to improve energy performance without compromising the historic appearance.

Cost: approximately 5 million euros.

Impact: reducing heat losses and improving the overall energy efficiency of the building.

- □

Renewable energy systems:

Issue: dependence on conventional energy sources with high carbon emissions.

Solution: Installation of solar panels on the roof and the use of wind energy to generate green energy. This contributed to reducing carbon emissions and increasing the proportion of renewable energy used by the building.

Results and Benefits:

Improved energy efficiency: the modernization project resulted in a more than 38% reduction in annual energy consumption, saving millions of dollars in operating costs.

Carbon emissions reduction: due to the implemented measures, the building managed to reduce carbon emissions by approximately 105,000 metric tons per year.

Improved tenant comfort: tenants reported more comfortable working conditions due to the improved heating and cooling systems and the reduction of external noise.

Increased economic value: the building became more attractive to potential tenants due to the ecological improvements and operational cost savings. This increased the value and occupancy rate of the building.

The modernization of the Old Bucharest Hotel demonstrates how a historic building can be adapted to meet modern standards of energy efficiency and sustainability. By using durable materials and advanced technologies, it not only preserved a historic monument but also transformed it into a model of energy efficiency and environmental responsibility. This initiative can serve as an example for other existing building modernization projects, showing that sustainability and heritage conservation can coexist harmoniously.

3.2. Challenges and Solutions Encountered in the Renovation Process of Hotel Old Bucharest

Challenge: one of the biggest challenges was modernizing the building without compromising its integrity and historic appearance, protected by strict legislation.

Solution: the project team closely collaborated with heritage conservation specialists to develop solutions that respect the original look of the building. For instance, windows were modernized by adding a third layer of glass and using inert gas for insulation while preserving the original exterior design.

Challenge: limited space and the existing structure of the building imposed restrictions on the types of technologies and materials that could be used.

Solution: solutions included the use of compact and energy-efficient equipment and the implementation of an energy management system to optimize consumption without major structural modifications. Advanced insulation materials offering superior performance in a confined space were also utilized.

Challenge: integrating modern technologies such as energy management systems and renewable energy sources into a nearly century-old building.

Solution: the installation of solar panels and other renewable technologies was carefully carried out to not affect the structure or appearance of the building. Modern HVAC and lighting systems were integrated using customized solutions to fit the available space and aesthetic requirements.

Challenge: ensuring the comfort and continuous operation for existing tenants during renovation works.

Solution: works were planned and implemented in a phased manner to minimize discomfort and disruptions to the daily activities of tenants. For example, window modernization was phased so that only certain sections of the building were affected at any given time.

Challenge: securing the necessary financing for such a large-scale project, considering the high initial costs of energy-efficient renovations.

Solution: financing was obtained through a mix of sources, including green loans and investments from building owners. The economic argument was supported by projections of significant long-term savings and increased property value, attracting financial support.

Challenge: ensuring compliance with strict environmental regulations and requirements for historic buildings.

Solution: the project involved a detailed analysis of existing regulations and close collaboration with environmental and heritage conservation authorities to ensure that all proposed changes comply with the law. Additionally, environmentally certified materials and technologies were used to meet the required standards.

The renovation process of Hotel Old Bucharest faced multiple challenges related to the preservation of historic appearance, spatial limitations, integration of modern technologies, tenant comfort, financing, and compliance with environmental regulations. Through innovative solutions and close collaboration with experts from various fields, these challenges have been successfully overcome, transforming the building into an example of sustainability and energy efficiency.

3.3. Discussion on the Technical and Economic Challenges Encountered in Using Innovative Materials and the Strategies Adopted to Overcome Them

Technical challenges regarding compatibility with the existing structure.

Implementing innovative materials, such as advanced insulation and high-performance windows, in an old building like Hotel Old Bucharest, can be challenging due to structural and design constraints.

The team conducted detailed assessments of the existing structure to identify compatible solutions. Materials that could be integrated without compromising the structural or aesthetic integrity of the building were used. For example, the windows were modernized by adding a third layer of glass and using inert gases to improve insulation while maintaining the original design.

The complexity of installing modern technologies in an old building structure can be complicated and requires customized solutions.

Phased implementation and the use of compact and modular equipment allowed for the adaptation of modern technologies to the available space. Energy-efficient HVAC and lighting systems were installed using methods that minimized structural interventions.

Interference with current activities, ensuring that modernizations do not significantly interfere with the daily activities of the tenants.

The works were planned and carried out in a phased manner, affecting only specific sections of the building at any given time. Effective communication with tenants and detailed planning were essential for minimizing discomfort and maintaining the normal operation of the building.

Amortization of investments, ensuring a sufficiently rapid return on investment to satisfy investors and owners.

Cost-benefit analyses demonstrated substantial savings on energy bills and increased property value. These savings and benefits were used to calculate attractive payback periods, which encouraged investments.

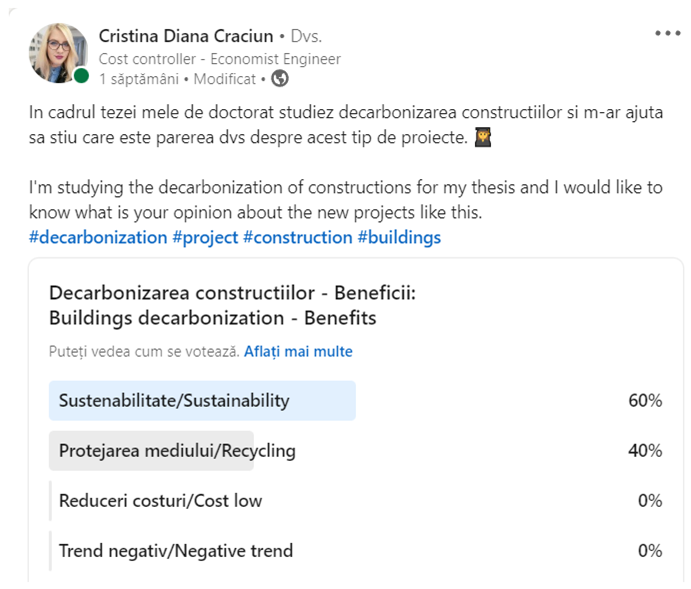

Following the research and updating of up-to-date information about everything new in the market, how the decarbonization of construction is implemented in the technical-economic system, we conducted an opinion survey addressed to specialists in the field (

Table 1).

Managing unexpected costs, the emergence of unforeseen costs during implementation can destabilize the project budget.

Detailed planning and risk assessment allowed for the anticipation of possible additional costs. A contingency budget and flexibility in planning helped efficiently manage unexpected costs.

4. Conclusions

The investment of approximately 65 million euros in modernization was justified by improving energy efficiency and reducing carbon emissions, serving as a model for other buildings and projects. It highlights the importance of detailed planning and the use of innovative technologies to achieve sustainability and energy efficiency goals.

Economic challenges, initial high costs, initial investments in innovative materials and energy-efficient technologies can be substantial, representing a major barrier.

The project benefited from funding through a mix of sources, including green loans and private investments. Strong economic arguments, based on significant energy savings and long-term operational cost reduction, were used to justify and attract the necessary funding.

Total technical cost approximately 65 million euros, economic and energy benefits:

Although the initial investment was significant, the modernization generated considerable energy savings and reduced carbon emissions, increasing property value and reducing long-term operating costs. Cost-benefit analyses demonstrated that these investments pay off over time, due to savings on energy bills and reduced maintenance expenses.

The modernization of Hotel Old Bucharest with innovative materials and energy-efficient technologies encountered multiple technical and economic challenges. Through careful planning, detailed evaluation of the existing structure, phased implementation, and efficient cost management, the project team managed to overcome these challenges, transforming the building into a model of sustainability and energy efficiency. This example serves as a model for other projects and regions, demonstrating that, although there are challenges, innovative and strategic solutions can lead to success.

These case studies and practical examples could illustrate how carbon neutrality strategies are implemented in practice in the construction industry and provide inspiration and guidance for other industries and regions seeking to reduce carbon emissions and promote sustainable development.