Submitted:

29 May 2024

Posted:

29 May 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

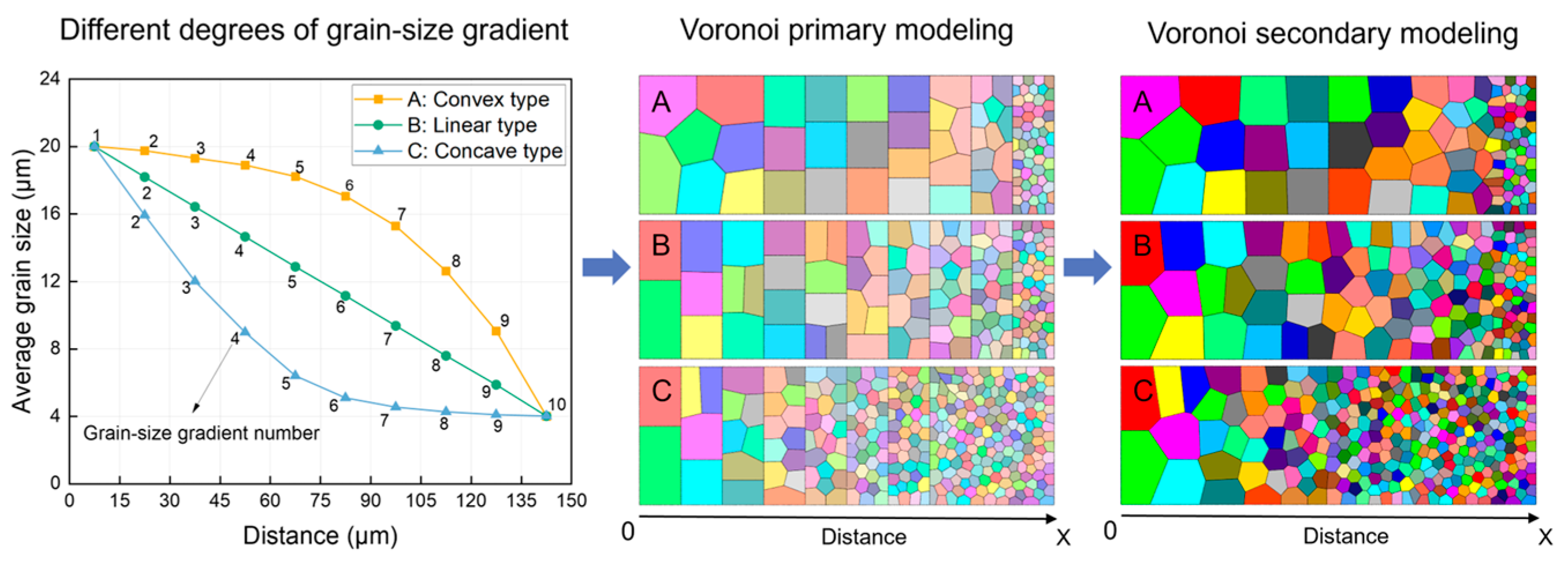

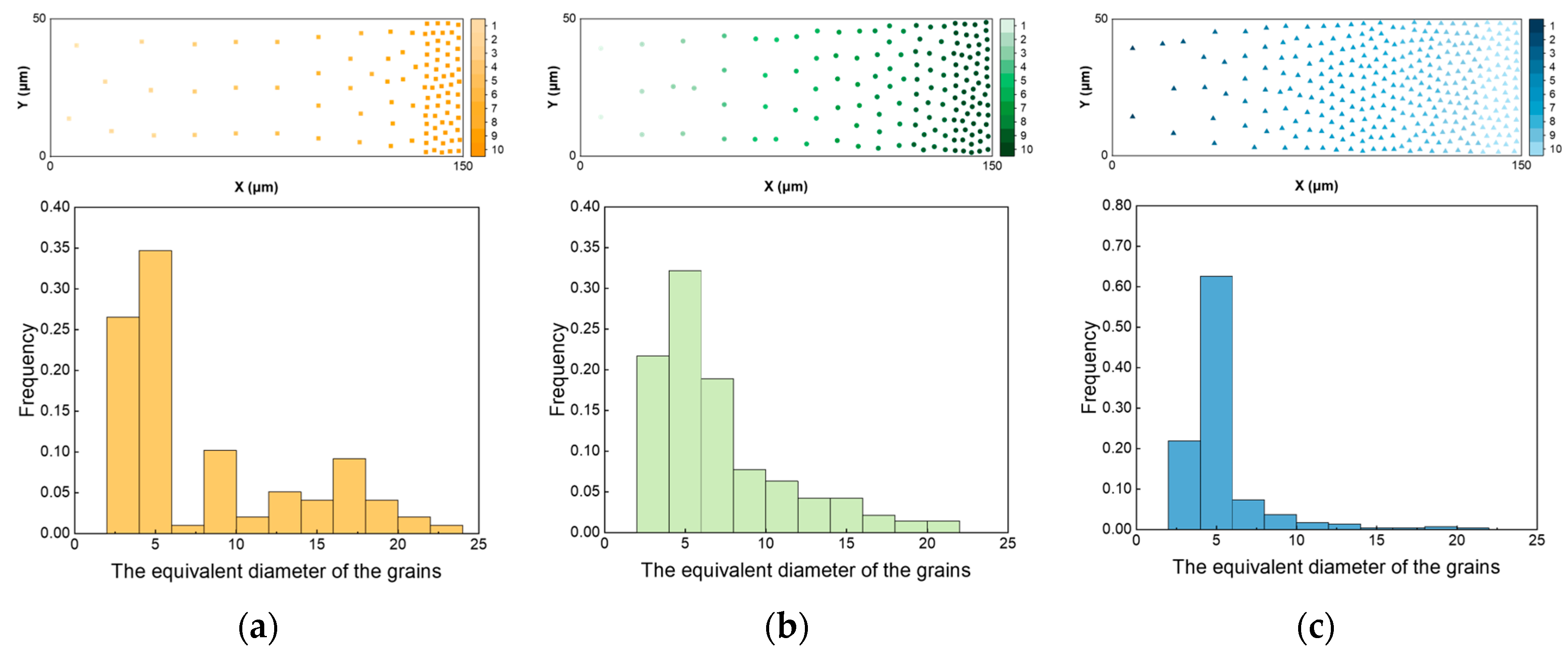

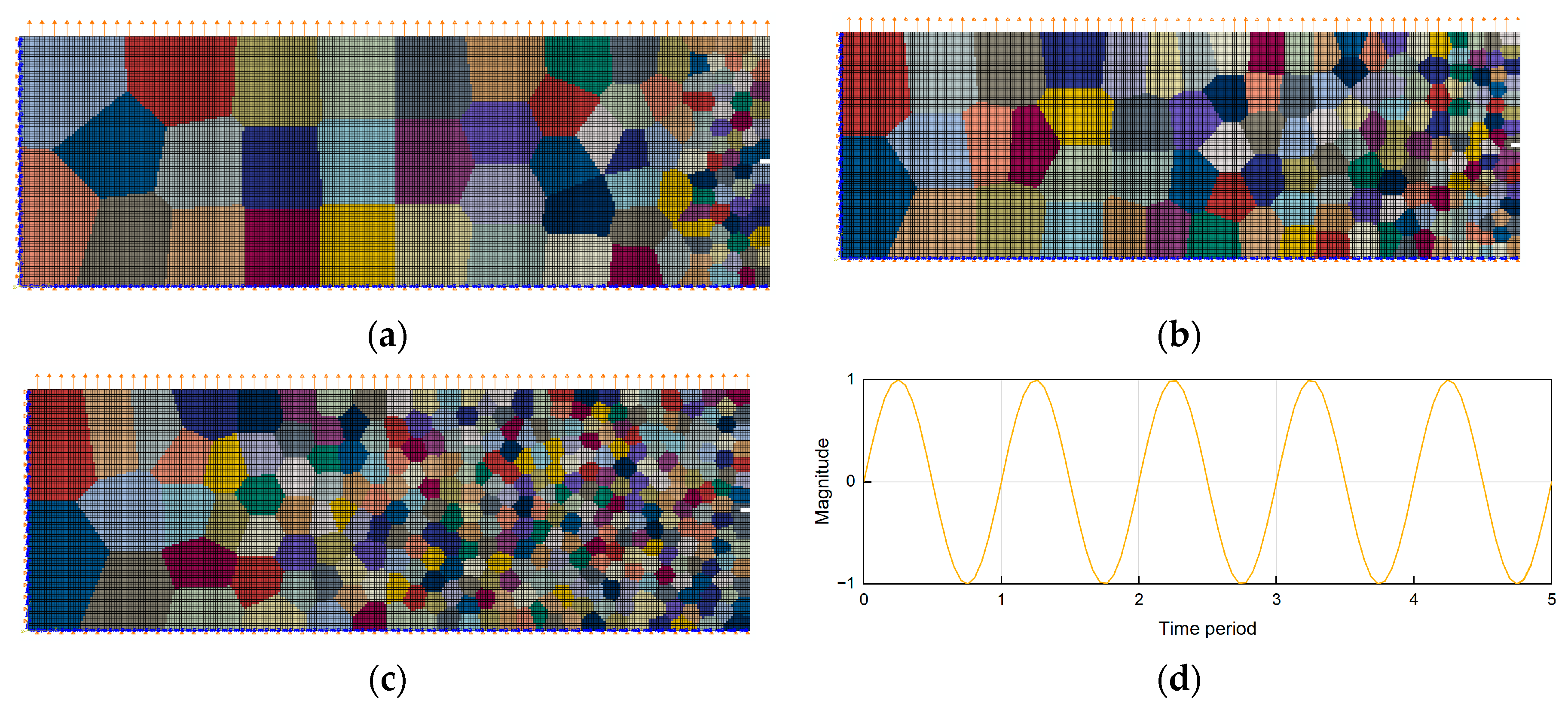

2.1. Three-Types of Gradient Rate Polycrystalline Models

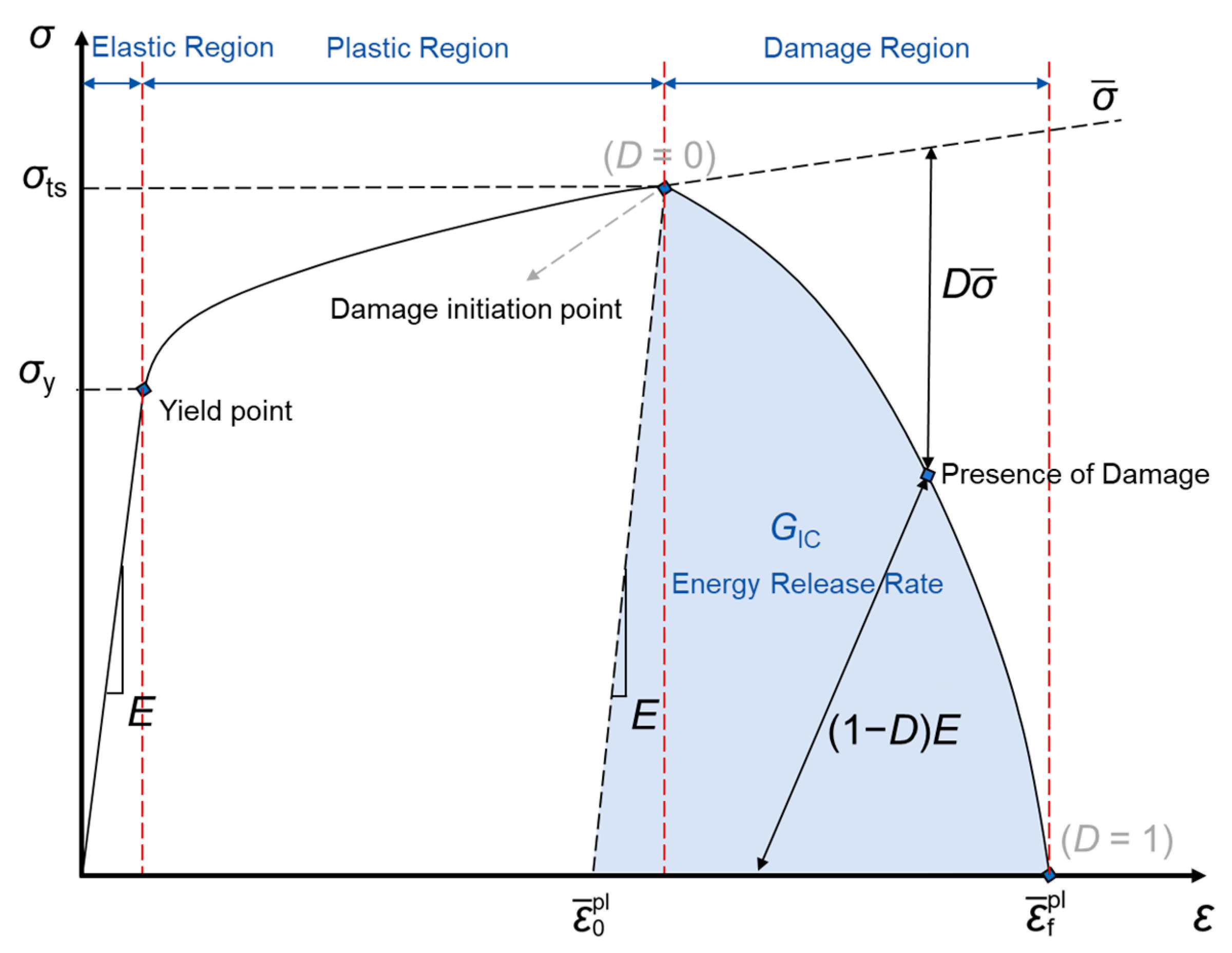

2.2. Elastoplastic and Damage Constitutive Equation

2.3. Pre-Processing and Abaqus/Explicit Calculation Method

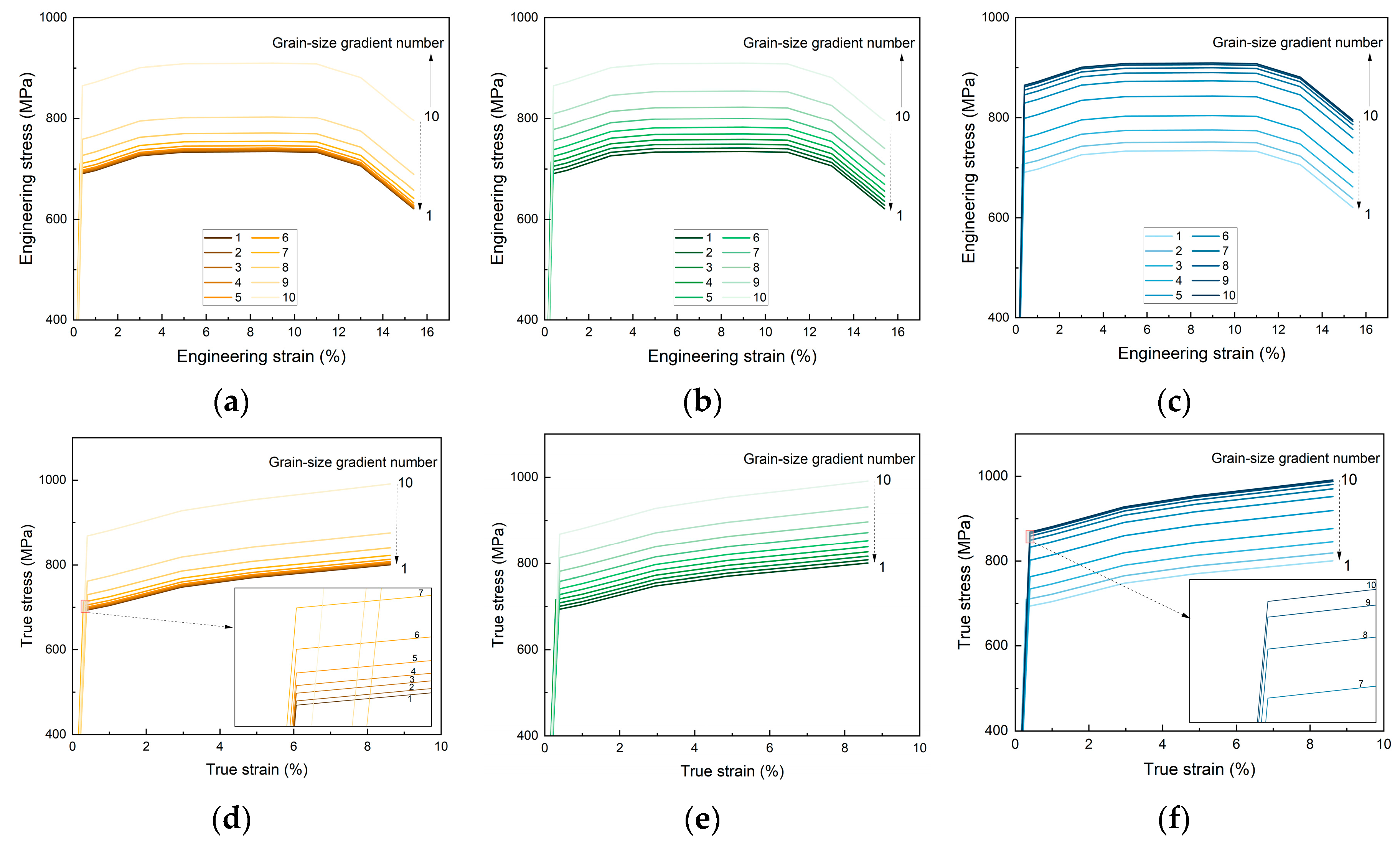

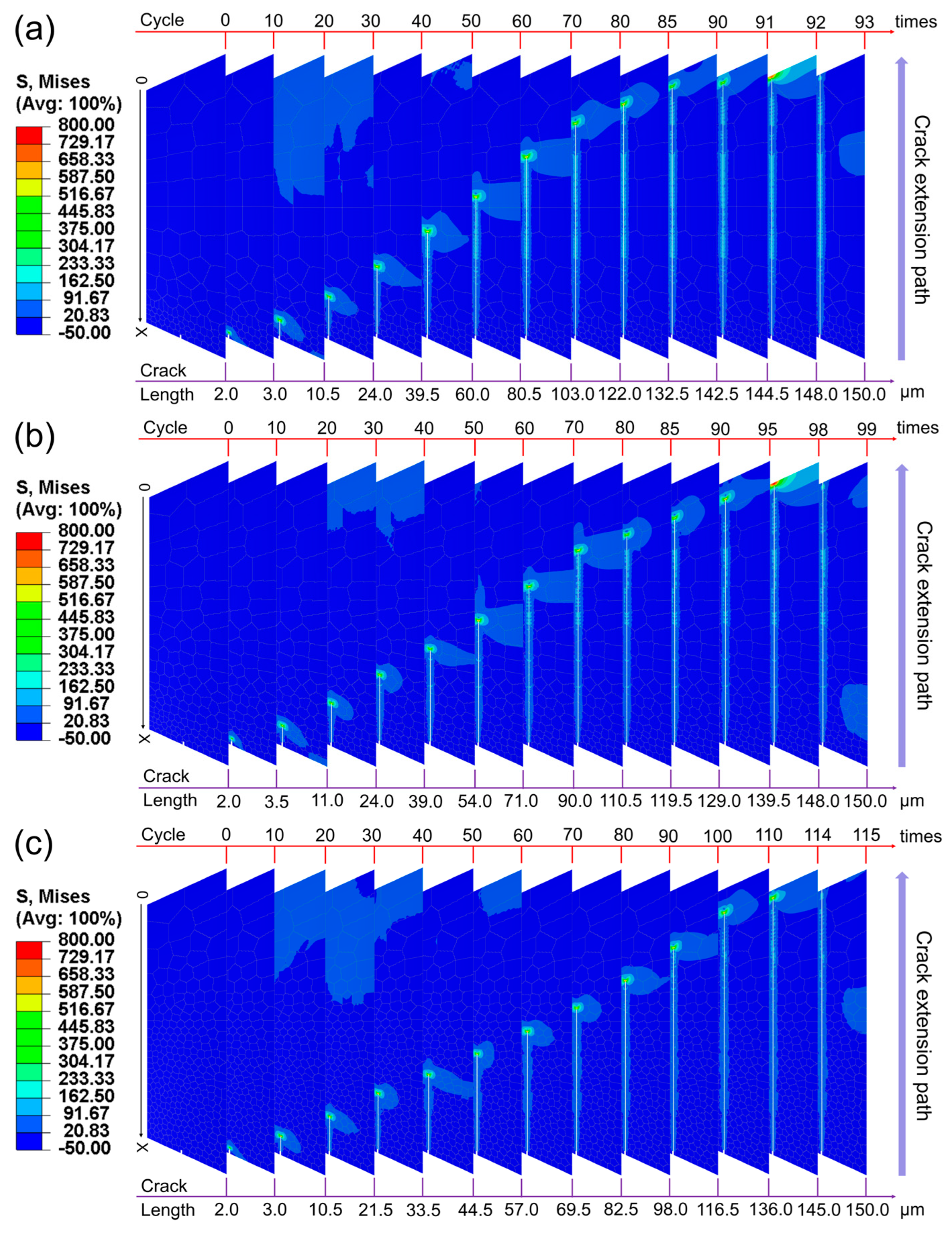

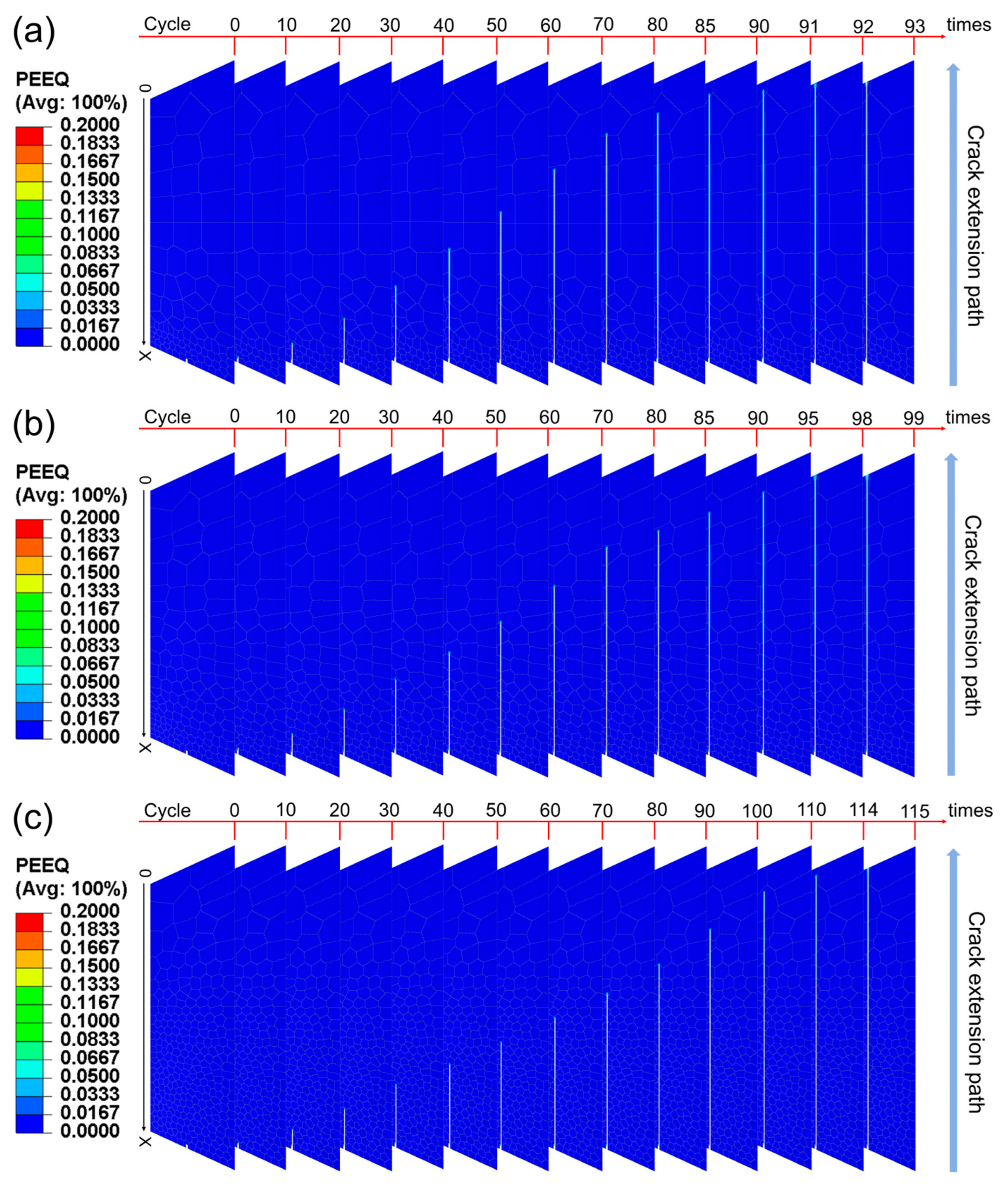

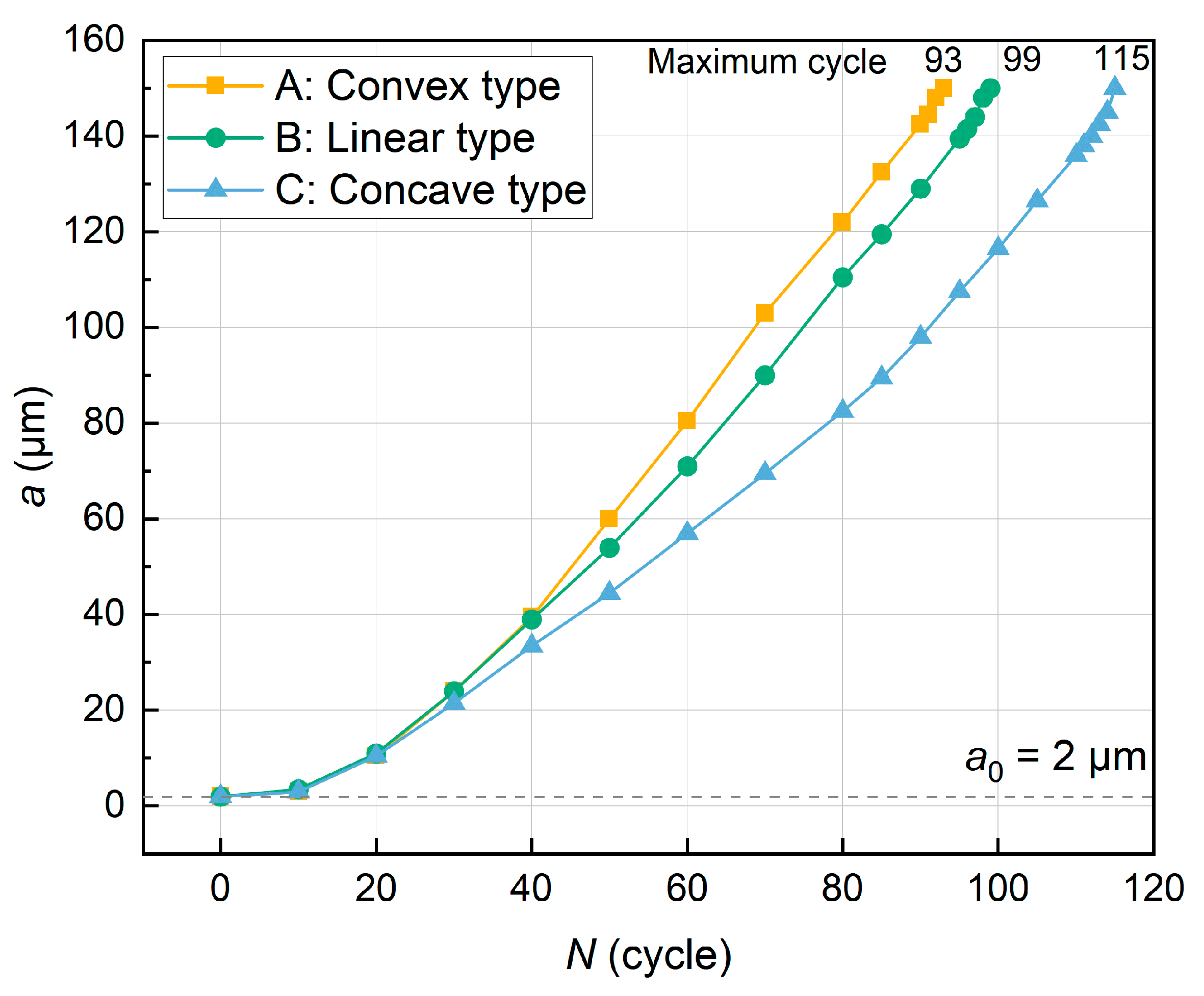

3. Results

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ji, W.M.; Zhou, R.H.; Vivegananthan, P.; Wu, M.S.; Gao, H.J.; Zhou, K. Recent progress in gradient-structured metals and alloys. Prog. Mater Sci. 2023, 140. [CrossRef]

- Wang, X.; Zhang, C.H.; Cui, X.; Zhang, S.; Chen, J.; Zhang, J.B. Novel gradient alloy steel with quasi-continuous ratios fabricated by SLM: Material microstructure and wear mechanism. Mater. Charact. 2021, 174, 111020. [CrossRef]

- Han, J.C.; Xu, L.; Wang, B.L.; Zhang, X.H. Progress and prospects of functional gradient materials. J. Solid. Rocket. Techno. 2004, 27, 207-215.

- Zhu, Y.T.; Wu, X.L. Heterostructured materials. Prog. Mater Sci. 2023, 131, 101019. [CrossRef]

- Jiang, W.; Xu, P.; Li, Y.; Wang, H.; Cai, Z.; Li, J.; Liang, Y.; Liang, Y. Effect of a gradient structure on the mechanical performance of Inconel 718 Ni-based superalloy at elevated temperatures. J. Mater. Res. Technol. 2023, 23, 2031-2042. [CrossRef]

- Cheng, Z.; Bu, L.; Zhang, Y.; Wu, H.; Zhu, T.; Gao, H.; Lu, L. Unraveling the origin of extra strengthening in gradient nanotwinned metals. Proceedings of the National Academy of Sciences 2022, 119, e2116808119. [CrossRef]

- Lu, K. Making strong nanomaterials ductile with gradients. Science 2014, 345, 1455-1456. [CrossRef]

- Fang, T.H.; Li, W.L.; Tao, N.R.; Lu, K. Revealing Extraordinary Intrinsic Tensile Plasticity in Gradient Nano-Grained Copper. Science 2011, 331, 1587-1590. [CrossRef]

- Ma, Z.W.; Liu, J.B.; Wang, G.; Wang, H.T.; Wei, Y.J.; Gao, H.J. Strength gradient enhances fatigue resistance of steels. Sci. Rep. 2016, 6, 22156. [CrossRef]

- Li, X.; Lu, L.; Li, J.; Zhang, X.; Gao, H. Mechanical properties and deformation mechanisms of gradient nanostructured metals and alloys. Nat. Rev. Mater. 2020, 5, 706-723. [CrossRef]

- Wang, Y. Numerical investigations on strengthening-toughening and failure mechanisms of metallic materials with gradient structure. PhD Dissertation, Beijing Jiaotong University, Beijing, 2019.

- Shuai, L.; Yinlei, G.; Dongdong, L.; Ziyue, L.; Yunli, F.; Fucheng, Z. Unusual grain-size effects on tensile deformation behavior of twinning-induced plasticity steel with low Mn content. J. Mater. Res. Technol. 2023, 24, 586-594. [CrossRef]

- Suresh, S. Fatigue of materials; Cambridge University Press: Cambridge, England, 1998.

- Fujii, T.; Muhamad Azmi, M.S.B.; Tohgo, K.; Shimamura, Y. Influence of Strain Gradient on Fatigue Life of Carbon Steel for Pressure Vessels in Low-Cycle and High-Cycle Fatigue Regimes. Materials 2022, 15, 445. [CrossRef]

- Zerbst, U.; Klinger, C.; Klingbeil, D. Structural assessment of railway axles–A critical review. Eng. Fail. Anal. 2013, 35, 54-65. [CrossRef]

- Liu, Z.P.; Zhang, H.X.; Yan, Z.F.; Dong, P. Enhanced fatigue performance of aluminum alloy through surface strengthening treatment. Mater. Lett. 2022, 306, 130864. [CrossRef]

- Liu, W.; Wu, G.; Zhai, C.; Ding, W.; Korsunsky, A.M. Grain refinement and fatigue strengthening mechanisms in as-extruded Mg–6Zn–0.5 Zr and Mg–10Gd–3Y–0.5 Zr magnesium alloys by shot peening. Int. J. Plast. 2013, 49, 16-35. [CrossRef]

- Pandey, V.; Chattopadhyay, K.; Santhi Srinivas, N.C.; Singh, V. Low Cycle Fatigue behavior of AA7075 with surface gradient structure produced by Ultrasonic Shot Peening. Procedia Struct. Integrity 2016, 2, 3288-3295. [CrossRef]

- Bagheri, S.; Guagliano, M. Review of shot peening processes to obtain nanocrystalline surfaces in metal alloys. Surf. Eng. 2009, 25, 3-14. [CrossRef]

- Li, W.; Tao, N.R.; Lu, K. Fabrication of a gradient nano-micro-structured surface layer on bulk copper by means of a surface mechanical grinding treatment. Scr. Mater. 2008, 59, 546-549. [CrossRef]

- Ke, L.; Jian, L. Surface nanocrystallization (SNC) of metallic materials-presentation of the concept behind a new approach. Journal of Materials Sciences and Technology 1999, 15, 193-197.

- Wei, Y.J.; Li, Y.Q.; Zhu, L.C.; Liu, Y.; Lei, X.Q.; Wang, G.; Wu, Y.X.; Mi, Z.L.; Liu, J.B.; Wang, H.T.; et al. Evading the strength–ductility trade-off dilemma in steel through gradient hierarchical nanotwins. Nat. Commun. 2014, 5, 3580. [CrossRef]

- Lin, Y.; Yu, Q.; Pan, J.; Duan, F.H.; Ritchie, R.O.; Li, Y. On the impact toughness of gradient-structured metals. Acta Mater. 2020, 193, 125-137. [CrossRef]

- Lu, K. Gradient nanostructured materials. Acta Metall Sin 2015, 51, 1-10. [CrossRef]

- Zeng, Z.; Li, X.Y.; Xu, D.S.; Lu, L.; Gao, H.J.; Zhu, T. Gradient plasticity in gradient nano-grained metals. Extreme Mech. Lett. 2016, 8, 213-219. [CrossRef]

- Luo, X.K.; Wang, Y.M.; Dang, N.; Tian, K.; Wang, K.; Zhao, C.L.; Zha, X.H.; Wang, X.; Yu, Y. Gradient microstructure and foreign-object-damaged fatigue properties of Ti6Al4V titanium alloy processed by the laser shock peening and subsequent shot peening. Mater. Sci. Eng., A 2022, 849, 143398. [CrossRef]

- Yang, M.X.; Li, R.G.; Jiang, P.; Yuan, F.P.; Wang, Y.D.; Zhu, Y.T.; Wu, X.L. Residual stress provides significant strengthening and ductility in gradient structured materials. Mater. Res. Lett. 2019, 7, 433-438. [CrossRef]

- Wu, X.L.; Jiang, P.; Chen, L.; Yuan, F.P.; Zhu, Y.T. Extraordinary strain hardening by gradient structure. Proc. Natl. Acad. Sci. U.S.A. 2014, 111, 7197-7201. [CrossRef]

- Ding, J.; Xue, S.; Shang, Z.; Li, J.; Zhang, Y.; Su, R.; Niu, T.; Wang, H.; Zhang, X. Characterization of precipitation in gradient Inconel 718 superalloy. Materials Science and Engineering: A 2021, 804, 140718. [CrossRef]

- Shao, C.W.; Zhang, X.Q.; Zhao, S.; Zhu, Y.K.; Yang, H.J.; Tian, Y.Z.; Zhang, Z.Z.; Zhang, P.; An, X.H.; Zhang, Z.F. Fatigue-resistant design in low-cycle regime by regulating the micro-structural gradient in a TWIP steel: Modelling and experiment. Int. J. Plast. 2022, 159, 103471. [CrossRef]

- Tilbrook, M.T.; Moon, R.J.; Hoffman, M. Finite element simulations of crack propagation in functionally graded materials under flexural loading. Eng. Fract. Mech. 2005, 72, 2444-2467. [CrossRef]

- Wang, Y.; Yang, G.; Wang, W.; Wang, X.; Li, Q.; Wei, Y. Optimal stress and deformation partition in gradient materials for better strength and tensile ductility: A numerical investigation. Sci. Rep. 2017, 7, 10954. [CrossRef]

- Li, J.; Soh, A.K. Modeling of the plastic deformation of nanostructured materials with grain size gradient. Int. J. Plast. 2012, 39, 88-102. [CrossRef]

- Lin, Y.; Pan, J.; Zhou, H.F.; Gao, H.J.; Li, Y. Mechanical properties and optimal grain size distribution profile of gradient grained nickel. Acta Mater. 2018, 153, 279-289. [CrossRef]

- Zhang, H.; Wu, S.; Ao, N.; Zhang, J.; Li, H.; Zhou, L.; Xu, P.; Su, Y. Fatigue crack non-propagation behavior of a gradient steel structure from induction hardened railway axles. Int. J. Fatigue 2023, 166, 107296. [CrossRef]

- Zhang, S.J.; Xie, J.J.; Jiang, Q.Q.; Zhang, X.L.; Sun, C.Q.; Hong, Y.S. Fatigue crack growth behavior in gradient microstructure of hardened surface layer for an axle steel. Mater. Sci. Eng., A 2017, 700, 66-74. [CrossRef]

- Du, Y.; Schmid-Fetzer, R.; Wang, J.C.; Liu, S.H.; Wang, J.C.; Jin, Z.P. Computational Design of Engineering Materials: Fundamentals and Case Studies; Cambridge University Press: Cambridge, England, 2023. [CrossRef]

- Wang, X.; Xiang, Y.X.; Zhu, W.J.; Ding, T.T.; Li, H.Y. Damage assessment in Q690 high strength structural steel using nonlinear Lamb waves. Constr. Build. Mater. 2020, 234, 117384. [CrossRef]

- Quey, R.; Kasemer, M. The Neper/FEPX Project: Free/Open-source Polycrystal Generation, Deformation Simulation, and Post-processing. IOP Conf. Ser.: Mater. Sci. Eng. 2022, 1249, 012021. [CrossRef]

- Bedford, A.; Liechti, K.M. Mechanics of materials; Springer Nature: Cham, Switzerland, 2019. [CrossRef]

- Seok, M.Y.; Choi, I.C.; Moon, J.; Kim, S.; Ramamurty, U.; Jang, J.-i. Estimation of the Hall–Petch strengthening coefficient of steels through nanoindentation. Scr. Mater. 2014, 87, 49-52. [CrossRef]

- Wagner, R. ABAQUS Tutorial: Damage for Ductile Metals–Material Model Explained–Ductile Damage. Available online: https://www.researchgate.net/publication/350124892 (accessed on 17 March 2021).

- Hanlon, T.; Kwon, Y.N.; Suresh, S. Grain size effects on the fatigue response of nanocrystalline metals. Scr. Mater. 2003, 49, 675-680. [CrossRef]

- Paris, P.C.; Marines-Garcia, I.; Hertzberg, R.; Donald, J.K. The relationship of effective stress intensity, elastic modulus and Burgers-vector on fatigue crack growth as associated with “fish eye” gigacycle fatigue phenomena. Proceedings of VHCF-3, Kyoto, Japan 2004, 1-13.

- Li, Y. Research Progress on Gradient Metallic Materials. Materials China 2016, 35, 658-665.

- Huang, H.W.; Wang, Z.B.; Lu, J.; Lu, K. Fatigue behaviors of AISI 316L stainless steel with a gradient nanostructured surface layer. Acta Mater. 2015, 87, 150-160. [CrossRef]

- Wang, Y.; Yuan, L.C.; Zhang, S.J.; Sun, C.Q.; Wang, W.J.; Yang, G.X.; Li, Q.; Wei, Y.J. The influence of combined gradient structure with residual stress on crack-growth behavior in medium carbon steel. Eng. Fract. Mech. 2019, 209, 369-381. [CrossRef]

| Point | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|

| Strain | 0.10 | 0.20 | 0.30 | 0.50 | 0.70 | 0.90 | 0.11 | 0.13 | 0.15 |

| Stress (MPa) | 697.35 | 711.81 | 725.91 | 733.34 | 733.85 | 734.45 | 732.95 | 706.23 | 620.81 |

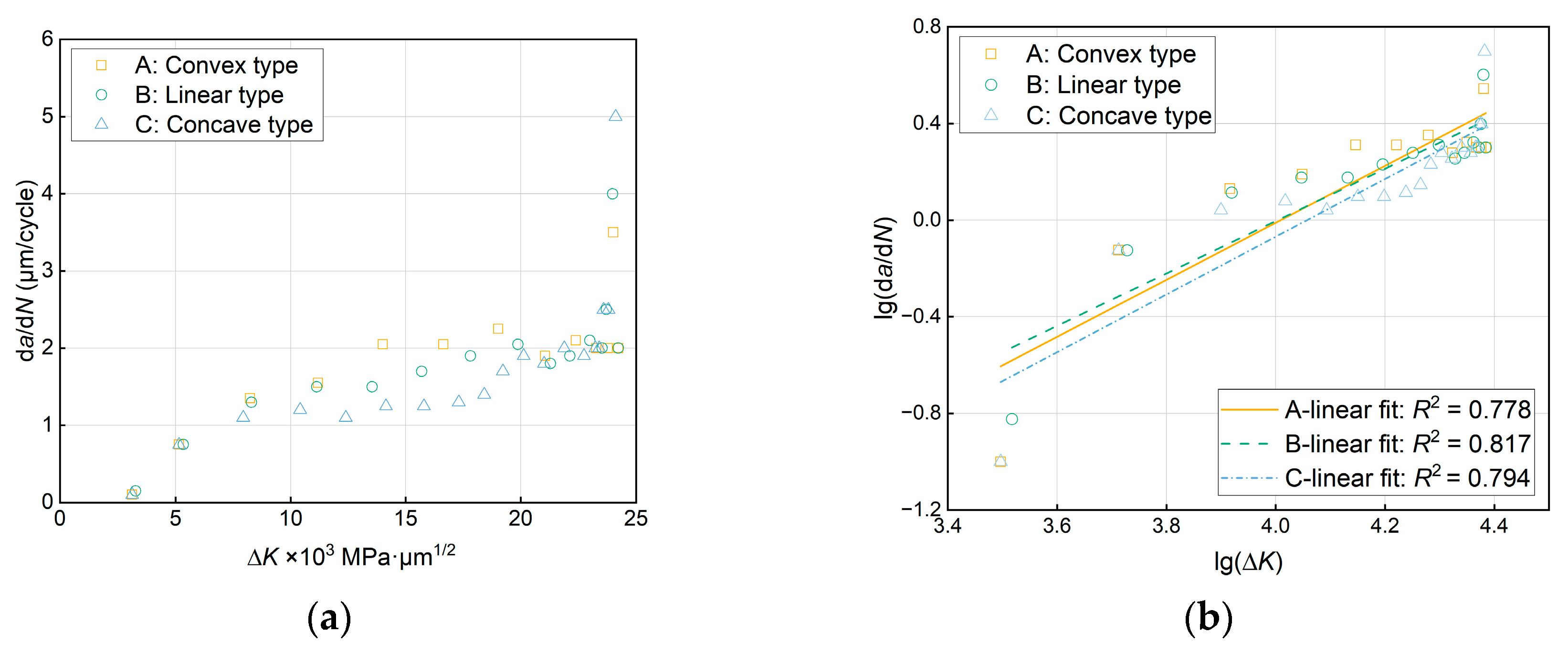

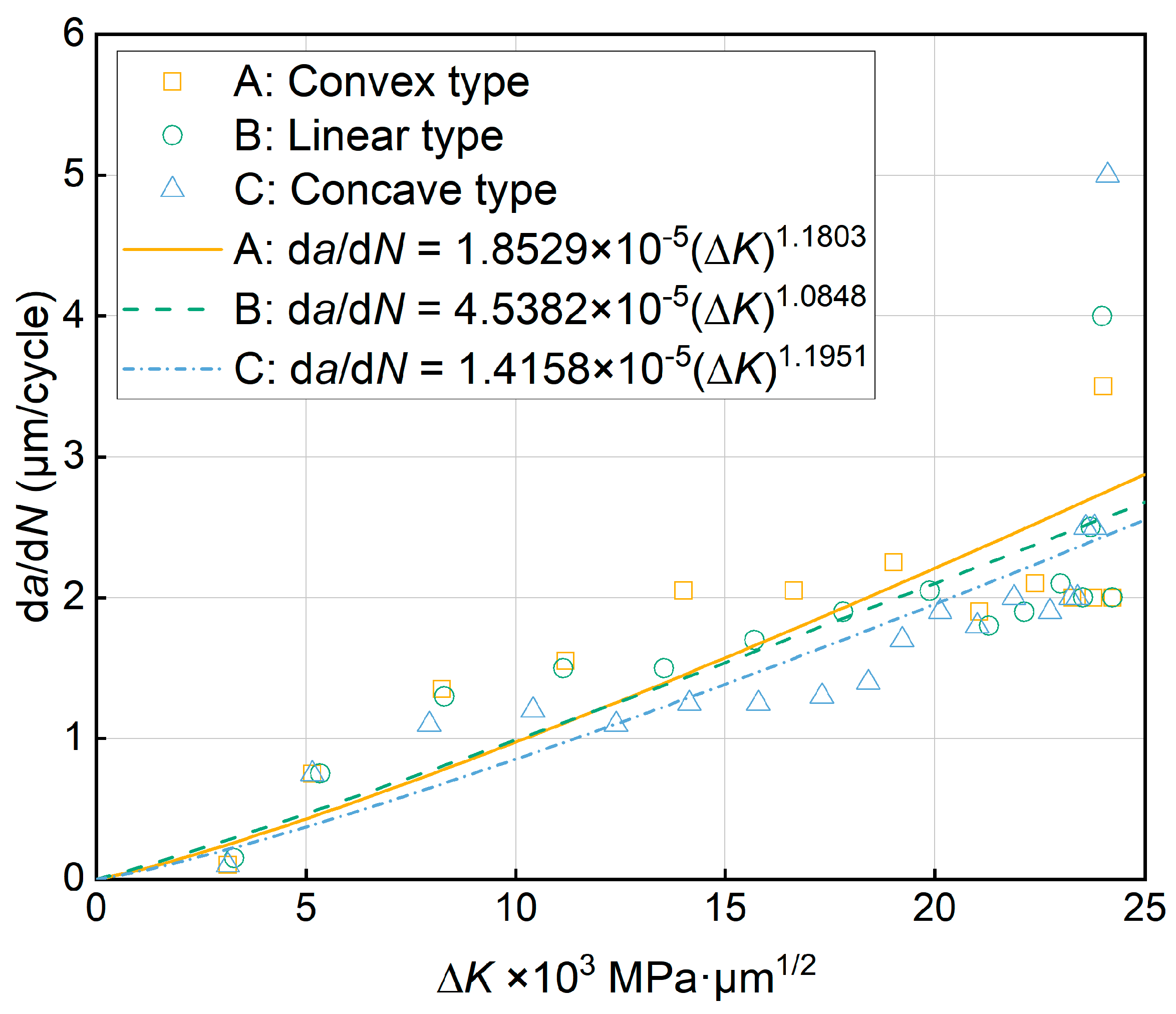

| Model | m | lgC | C | R2 |

|---|---|---|---|---|

| A | 1.1803 | -4.7322 | 1.8529×10-5 | 0.778 |

| B | 1.0848 | -4.3431 | 4.5382×10-5 | 0.817 |

| C | 1.1951 | -4.8490 | 1.4158×10-5 | 0.794 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).