Submitted:

25 May 2024

Posted:

27 May 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Damage Prediction Model Development

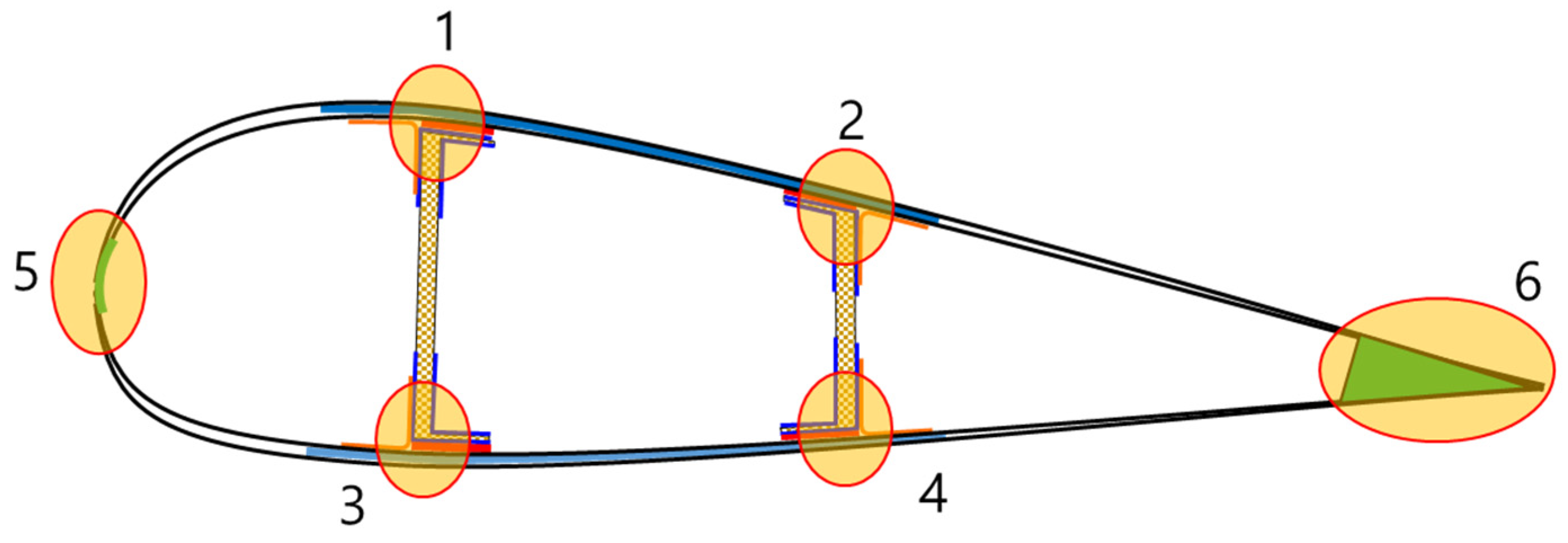

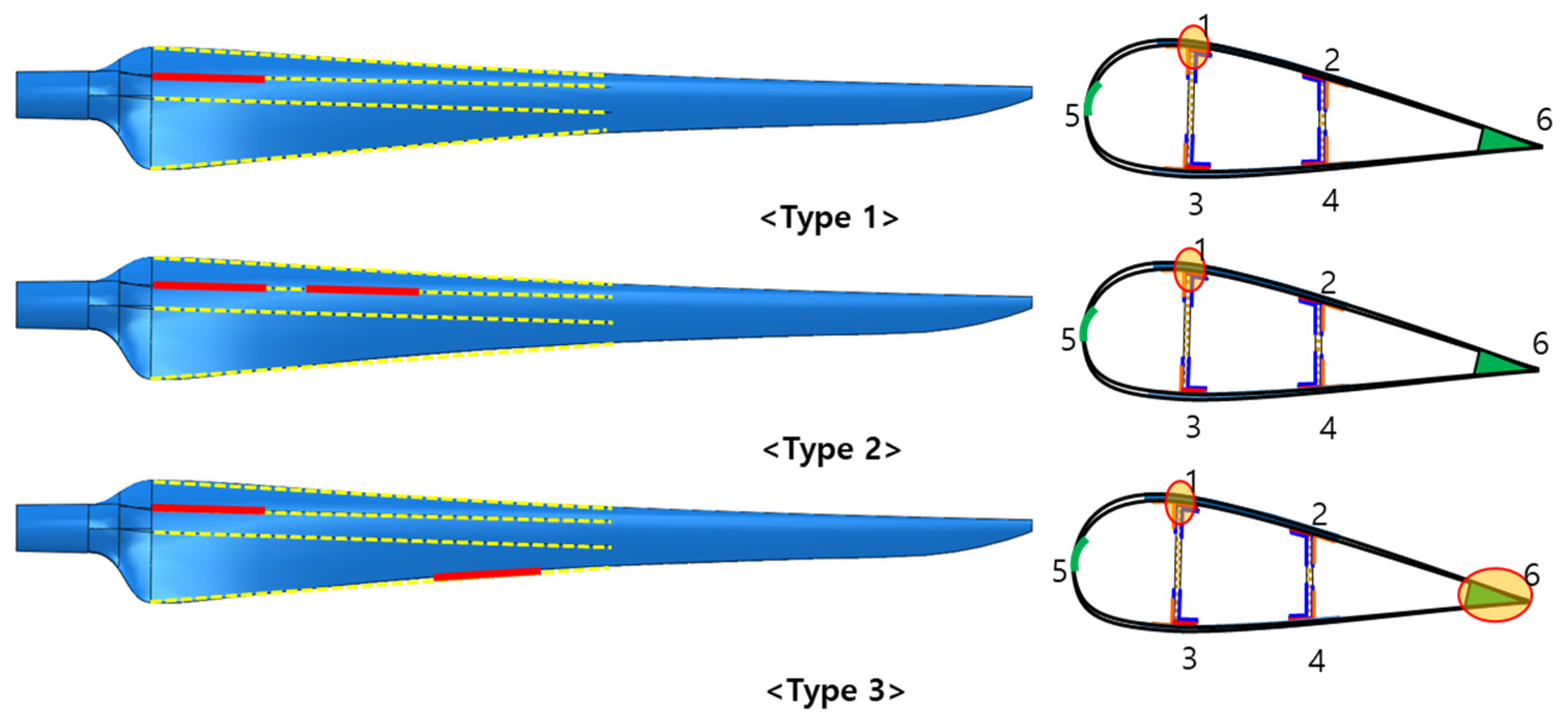

2.1. Damage Selection

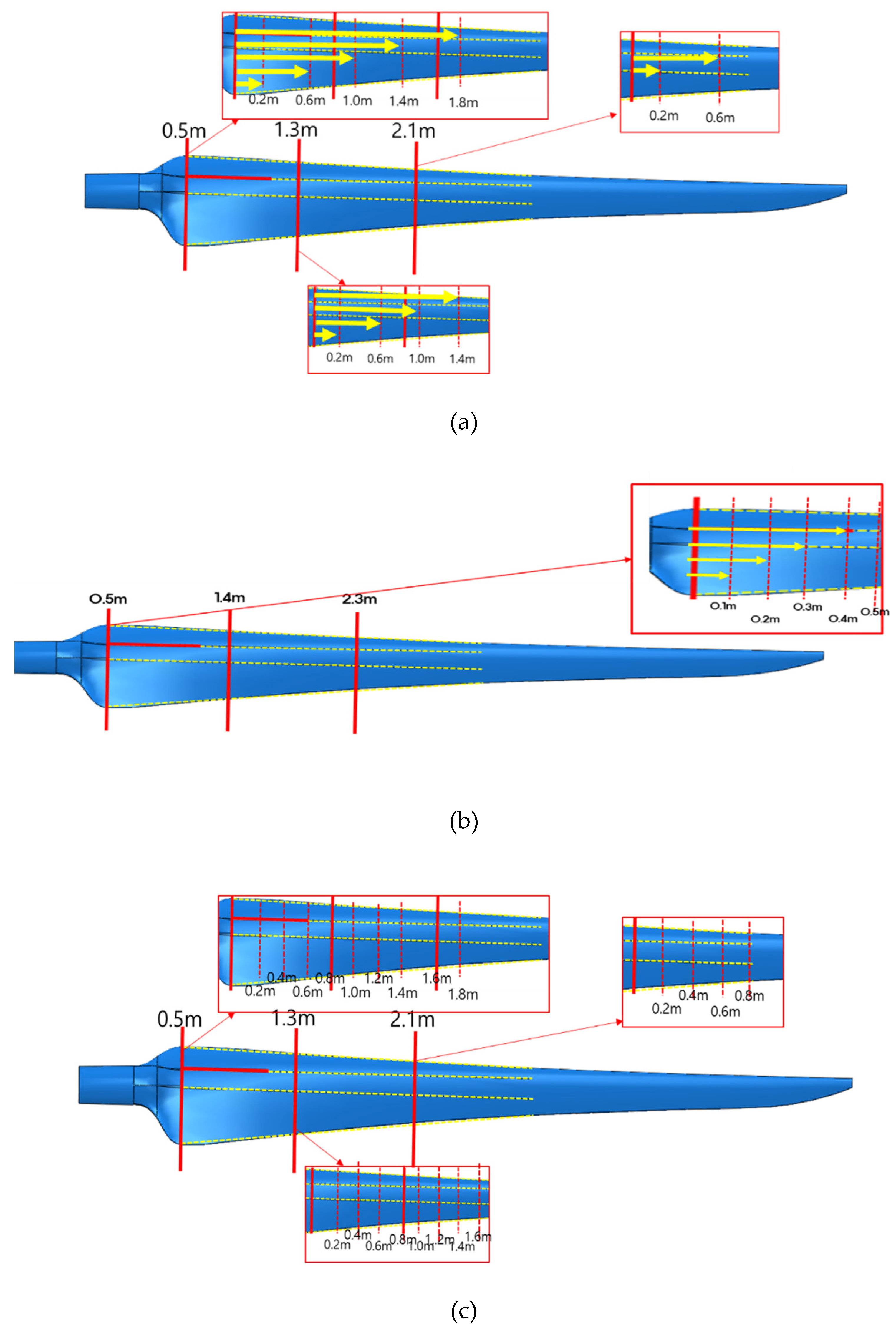

2.2. Acquisition of Unique Characteristics

2.3. Prediction Model Construction

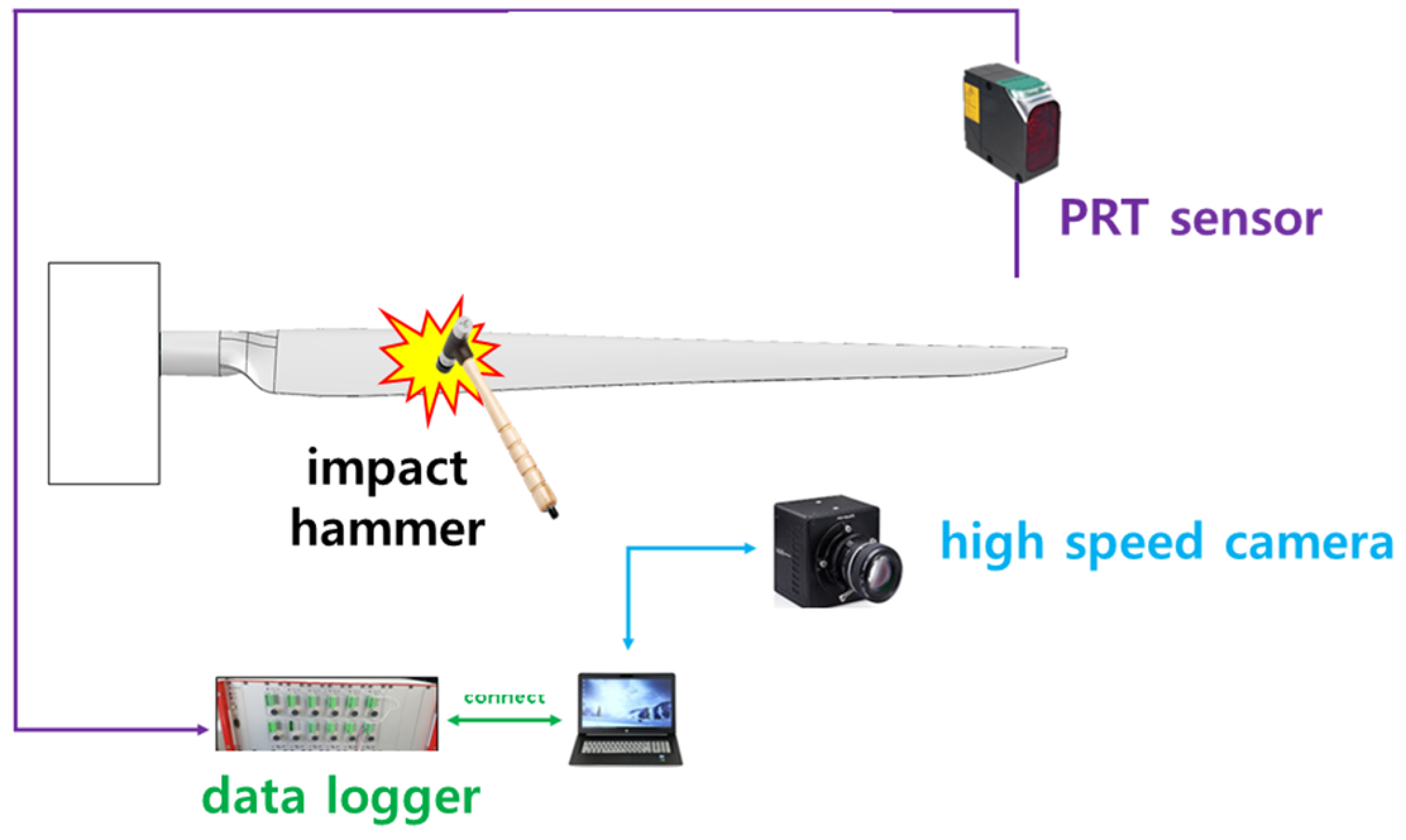

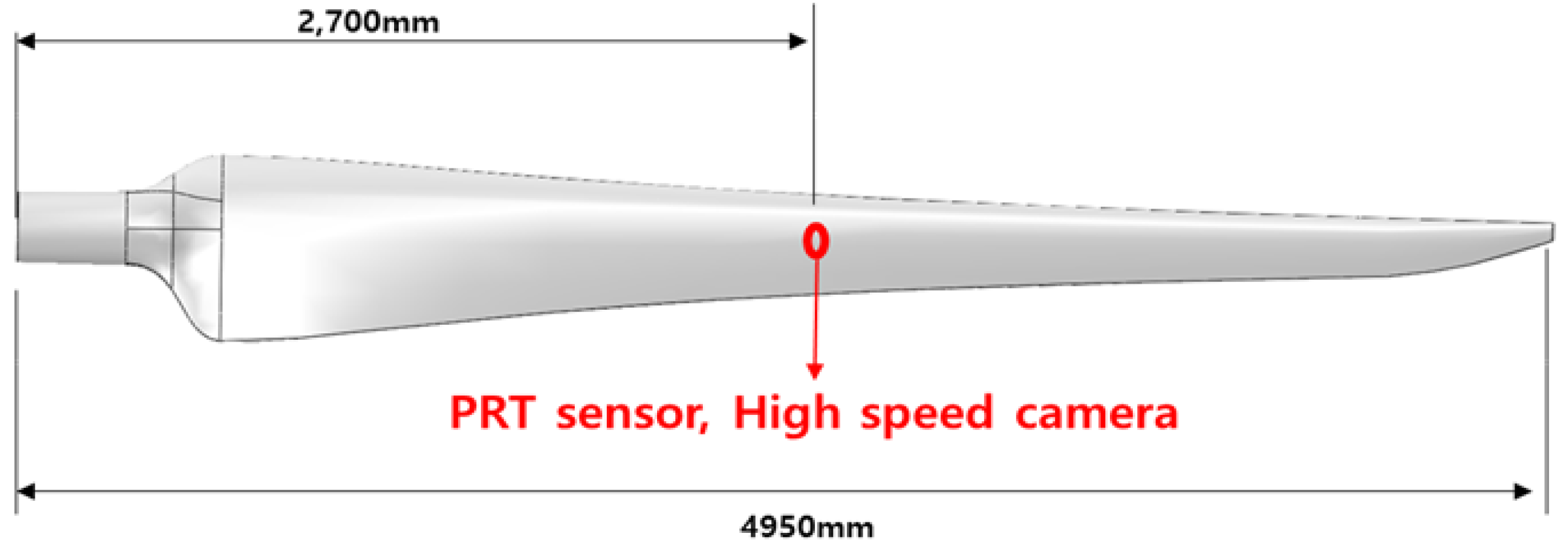

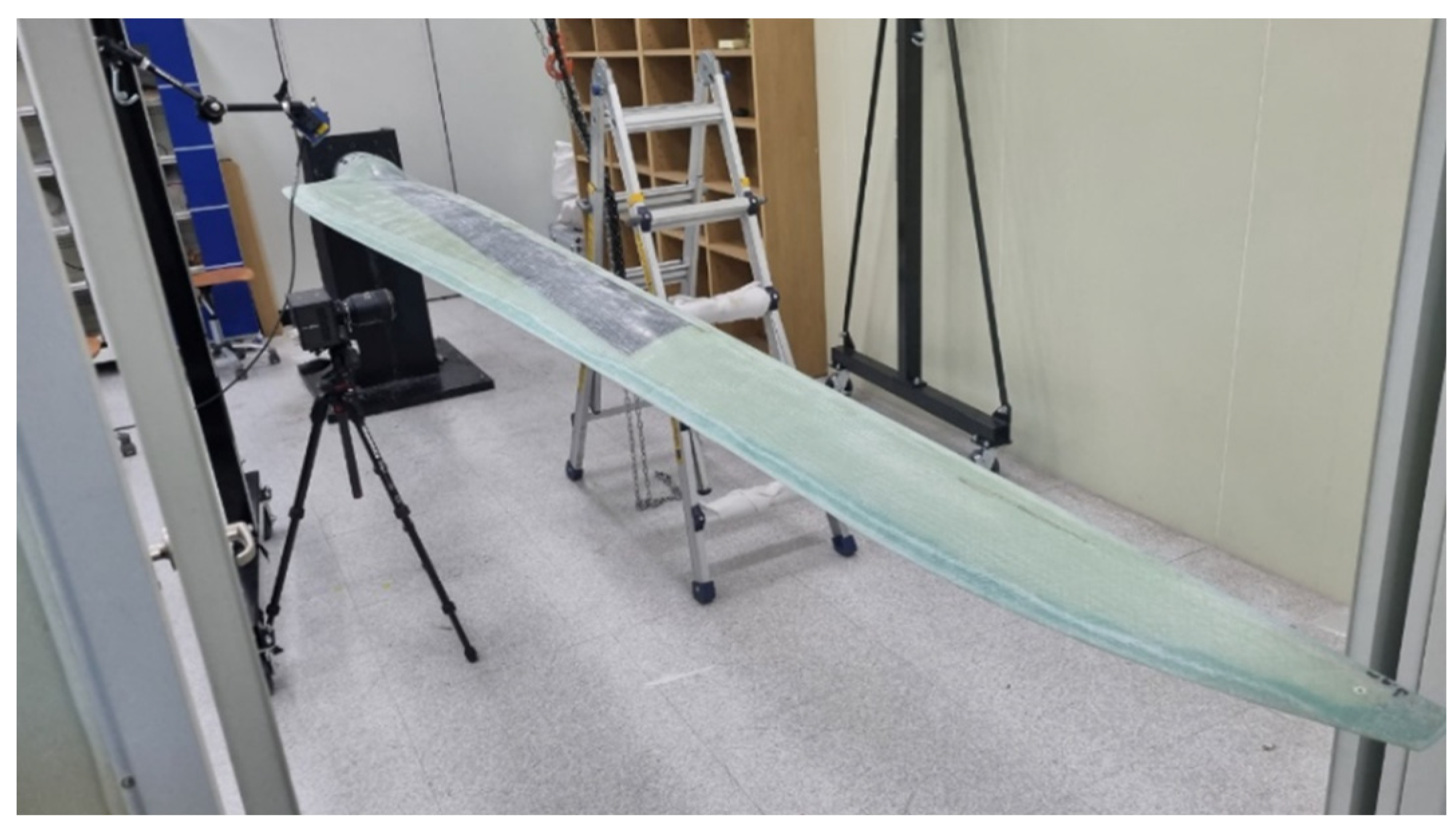

3. Modal Test for Model Synchronization

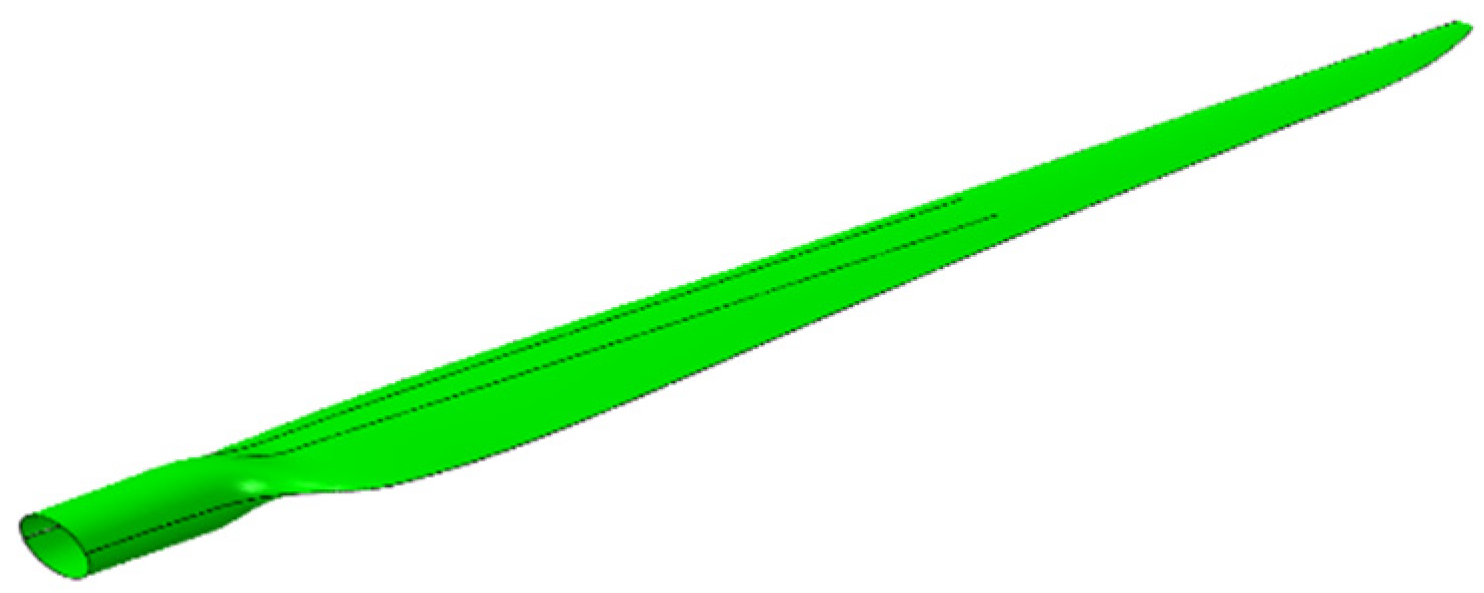

3.1. Blade Manufacturing

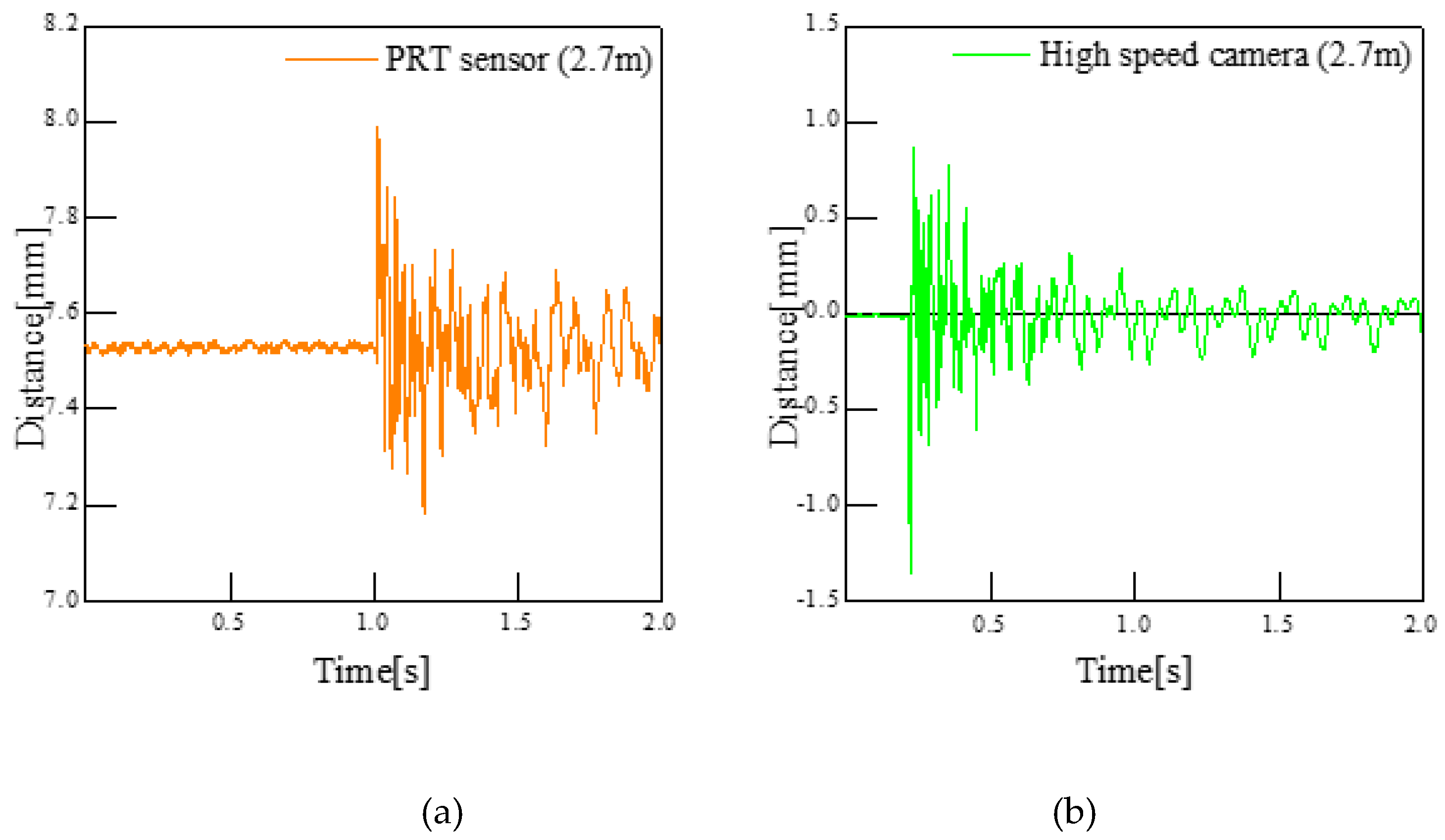

3.3. Modal Test

4. Results and Discussion

4.1. Blade Model Synchronization

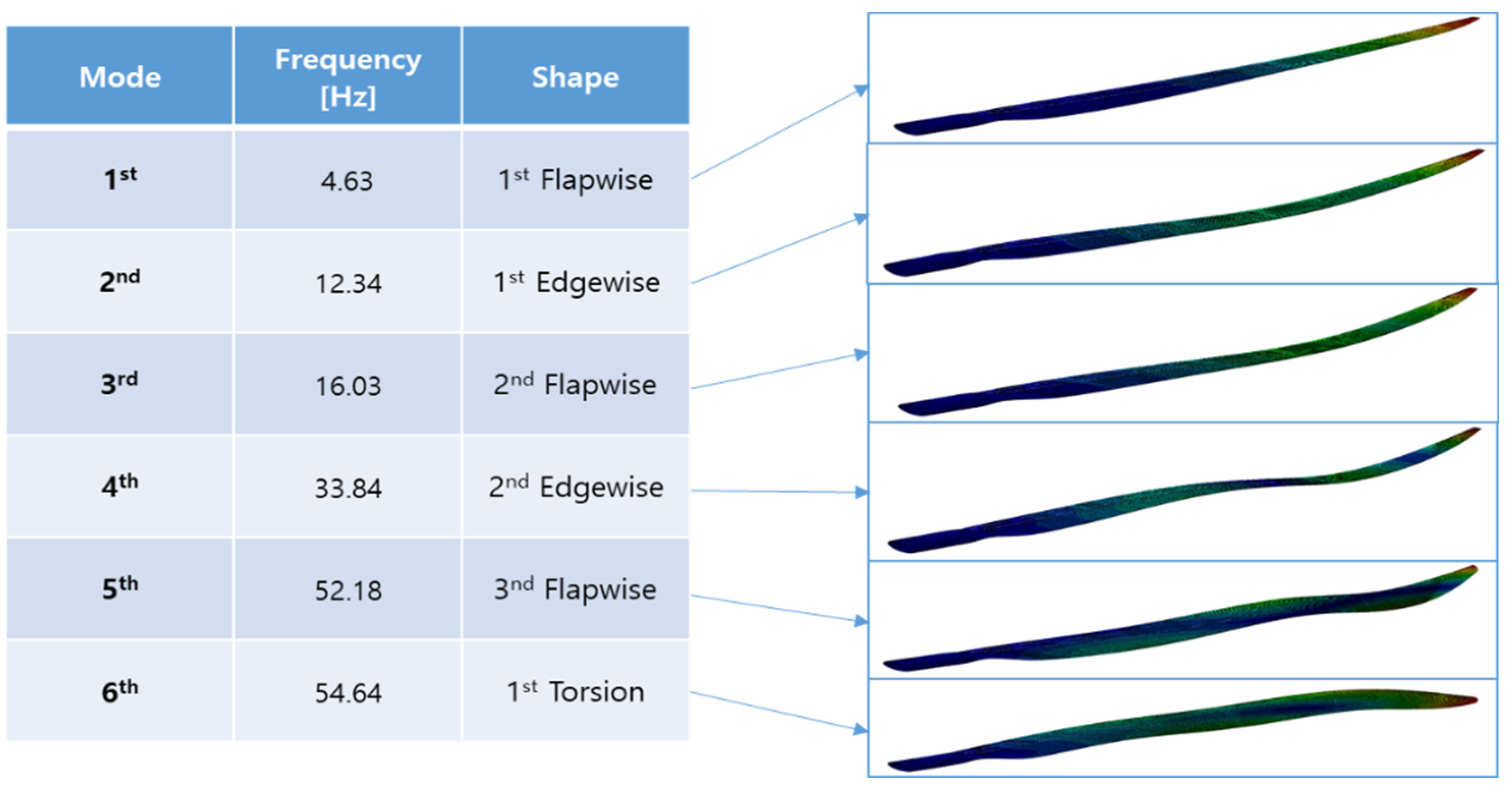

4.2. Natural Frequency Analysis

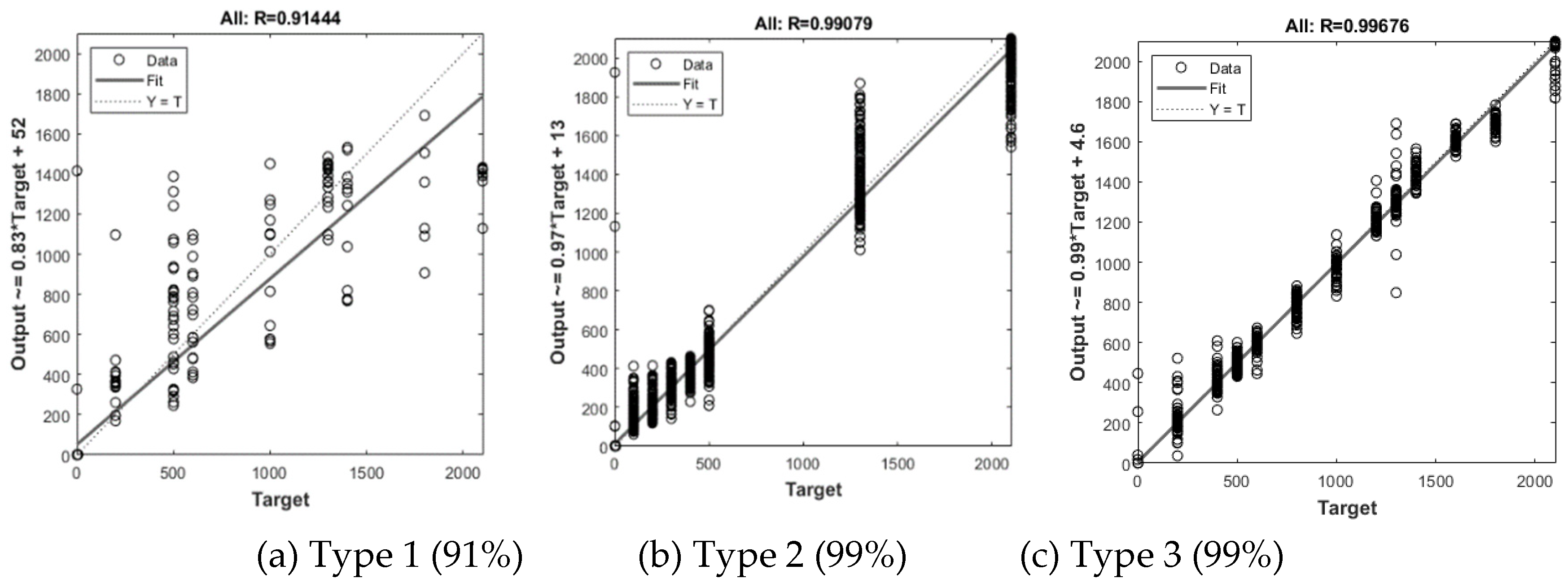

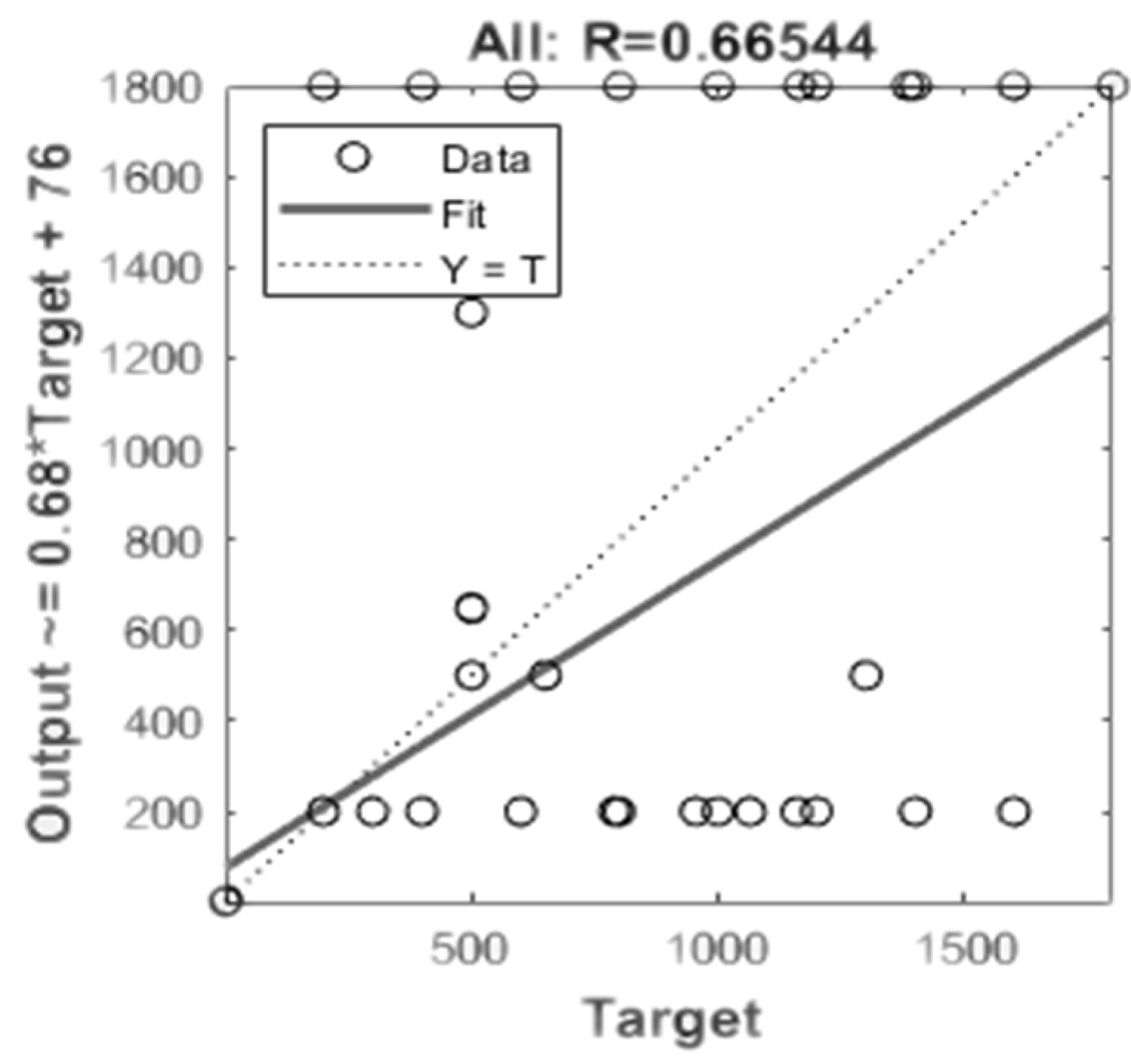

4.3. Damage Prediction Model Results

4.4. Learning Model Improvement for Higher Accuracy

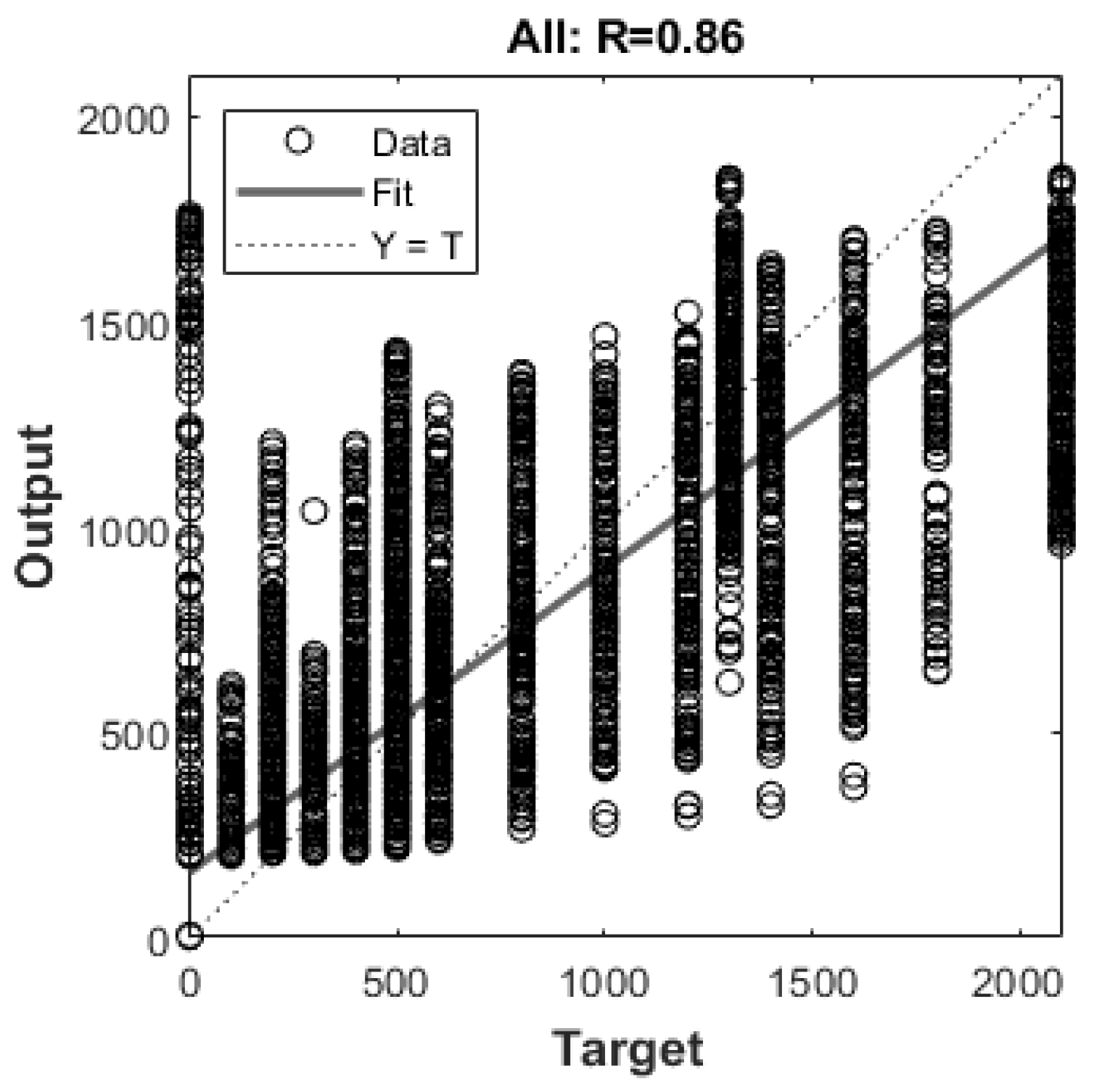

4.5. Composite Blade Damage Detection Performance Verification

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Hong-Kwan, K.; Tae-Seong, K.; Jang-Ho, L.; Byung-Young, M.; Ki-Weon, K. “Full Scale Structural Testing of Small Wind Turbine Composite Blade,”. Trans. Korean Soc. Mech. Eng. A, 2011, 35, 1407–1413. [Google Scholar]

- Sun-Ho, P.; Kyung-Seop, H. “Structural Analysis and Proof Test of Composite Rotor Blades for Wind Turbine,” New & Renewable Energy, 2008, 4(3), pp. 45–50.

- Choong-hun, L.; Jin-Moo, P.; Tae-Wook, K.; Ji-Sang, P. “Structural design and analysis of a composite wind turbine blade.”, Trans. Korean Soc. Mech. Eng. 2002, pp. 558–562.

- Dae-jhoong, Y.; Hee-Chang, L. “Study of the Damage Monitoring System on Wind Turbine Blades.”, The 2013 World Congress on Advances in Structural Engineering and Mechanics(ASEM13). 2013, pp. 3549–3565.

- Chia, C.C.; Jung-Ryul, L.; Hyung-Joon, B. “Structural health monitoring for a wind turbine system: a review of damage detection methods”, Mead. Sci. Technol. 2008, 19(121001), p. 20.

- Rafiee, R.; Hashemi-Taheri, M.R. “Failure analysis of a composite wind turbine blade at the adhesive joint of the trailing edge”, Engineering Failure Analysis 2021, 121, p. 105148.

- Yang, J.; Peng, C.; Xiao, J.; Zeng, J.; Xing, S.; Jing, J.; Deng, H. “Structural investigation of composite wind turbine blade considering structural collapse in full-scale static tests”, Composite Structures 2013, 97, pp. 15–29.

- Kang, B.W.; Nam, M.H.; Lim, I.S. “A Study on Reliability Validation by Infrared Thermography of Composite Material Blade for Wind Turbine Generator”, Journal of Applied Reliability 2016, 14(3), pp. 176–181.

- Xiao, C. “Fractographic analysis of sandwich panels in a composite wind turbine blade using optical microscopy and X-ray computed tomography”, Engineering Failure Analysis 2020, 111, 104475.

- Christopher, N,; Peter, A.; Julie, C. “Inspection and monitoring of wind turbine blade-embedded wave defects during fatigue testing”, Struct. Health Monit. 2014, 13(6), pp. 1–15.

- Chi, S.C.; Cho, B.J.; Nam, M.H.; Lim, S. “Delamination Detection in Composite Wind Blade by Phased Array Ultrasonic Technology”, J. Korean Soc. Nondestruc. Test. 2017, 37, 183–191. [Google Scholar] [CrossRef]

- Du, Y. et al., “Damage Detection Techniques for Wind Turbine Blades: A Review.”, Mechanical Systems and Signal Processing 2020, 141.

- Kim, B.J. et al. “Motion Estimation and Machine Learning-based Wind Turbine Monitoring System”, The Transactions of the Korean Institute of Electrical Engineers 2017, 66, 1516–1522.

- Hak-Geun, K. “Evaluation of Frequency Response Characteristics according to the Debonding Damage of Composite Blade for Wind Turbine.”, Master Thesis, Graduate School of Kunsan National University 2018.

- Joshuva, A. et al. “A Lazy Learning Approach for Condition Monitoring of Wind Turbine Blade using Vibration Signals and Histogram Features. ”, Measurement 2021, 152. [CrossRef]

- Awadallah, M. et al. “Effect and Detection of Cracks on Small Wind Turbine Blade Vibration using Special Kriging Analysis of Spectral Shifts”, Measurement, 2020, 151. [CrossRef]

- Jong-Su, K.; Chan-Kyu, C.; Hong-Gee, Y. “Application of Excitation Moment for Enhancing Fault Diagnosis Probability of Rotating Blade”, Trans. Korean Soc. Mech. Eng. A 2014, 38, 205–210. [Google Scholar]

- Adrian, S.; Fateme, D.; Xingyu, Z.; Valentin, R.; David, F.; Mike, B.; Hohn, K.; Goran, N. “Machine learning methods for wind turbine condition monitoring: A review”, Renewable Energy, 2019, 133, 620–635. [Google Scholar]

- Yun-Jung, J.; Hyeong-Jin, K.; Hak-Geun, K.; Ki-Weon, K. “Identification of Debonding Damage at Spar Cap-Shear Web Joints by Artificial Neural Network Using Natural Frequency Relevant Key Features of Composite Wind Turbine Blades”, Appl. Sci. 2021, 11, 5327. [Google Scholar] [CrossRef]

- ABAQUS CAE 2022, Dassault Systems Simulia, Inc. 2022.

- MATLAB 2020a, MathWorks, Inc. 2020.

- Sang-Kyun, K.; Sung-Soo, P.; Sang-Il, L.; Jang-Ho, L. “An Analysis of the Drag Effect on the Thrust and Rotational Torque of Wind Turbine Blades with Original Airfoil KA2.”, Journal of Wind Energy, 2021, 12(1), pp.19~25.

| Rated Power | 20 kW |

| Cut-in wind speed | 3 m/s |

| Rated wind speed | 11 m/s |

| Number of blade | 3 |

| Blade length | 4.95 m |

| Properties | GFRP | CFRP | |||

| UD | DB | Tri-axial | UD | DB | |

| Long. Elastic modulus [GPa] | 40,100 | 12,000 | 30,500 | 133,000 | 82,000 |

| Trans. Elastic modulus [GPa] | 12,300 | 12,000 | 15,100 | 9,000 | 80,500 |

| Shear modulus [GPa] | 3,400 | 11,000 | 7,100 | 4,400 | 80,500 |

| Long. Poisson’s ratio | 0.26 | 0.55 | 0.43 | 0.34 | 0.4 |

| Layer Thickness [mm] | 0.91 | 0.59 | 0.91 | 0.1 | 0.91 |

| Properties | PRT sensor | high speed camera | Data logger |

| Model | ILD 1700-100 | Photron Fastcam Mini | GTDL-360 |

| Maximum measurement rate [Hz] |

100 kHz | 2 kHz | 1 kHz |

| Mode | Frequency(PRT) | Frequency(camera) |

| 1 | 4.81 | 4.82 |

| 2 | 11.76 | 11.76 |

| 3 | 16.41 | 16.40 |

| 4 | 32.91 | 32.9 |

| 5 | 50.53 | 50.5 |

| 6 | 56.3 | 56.28 |

| Input data |

Natural frequency (Hz) | ||||||

| No. | 1st | 2nd | 3rd | 4th | 5th | 6th | |

| 1 | 4.63 | 12.34 | 16.03 | 33.84 | 52.18 | 54.64 | |

| 2 | 4.57 | 12 | 15.84 | 33.58 | 52.06 | 54.33 | |

| 3 | 4.54 | 11.95 | 15.78 | 33.45 | 52 | 54.16 | |

| 4 | 4.53 | 11.93 | 15.77 | 33.33 | 51.94 | 54.09 | |

| ⋮ | ⋮ | ⋮ | ⋮ | ⋮ | ⋮ | ⋮ | |

| 7,129 | 4.63 | 12.31 | 15.98 | 33.74 | 51.65 | 54.43 | |

| 7,130 | 4.62 | 12.30 | 15.96 | 33.73 | 51.54 | 54.42 | |

| 7,131 | 4.62 | 12.28 | 15.93 | 33.67 | 51.39 | 54.42 | |

| 7,132 | 4.62 | 12.27 | 15.90 | 33.53 | 51.09 | 54.33 | |

| Target data |

No. | joint 1 | location 1 (mm) |

length 1 (mm) |

joint 2 | location 2 (mm) |

length 2 (mm) |

| 1 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 2 | 1 | 500 | 200 | 0 | 0 | 0 | |

| 3 | 1 | 500 | 600 | 0 | 0 | 0 | |

| 4 | 1 | 500 | 1,000 | 0 | 0 | 0 | |

| ⋮ | ⋮ | ⋮ | ⋮ | ⋮ | ⋮ | ⋮ | |

| 7,129 | 5 | 2,100 | 800 | 6 | 2,100 | 200 | |

| 7,130 | 5 | 2,100 | 800 | 6 | 2,100 | 400 | |

| 7,131 | 5 | 2,100 | 800 | 6 | 2,100 | 600 | |

| 7,132 | 5 | 2,100 | 800 | 6 | 2,100 | 800 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).