Submitted:

14 May 2024

Posted:

14 May 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

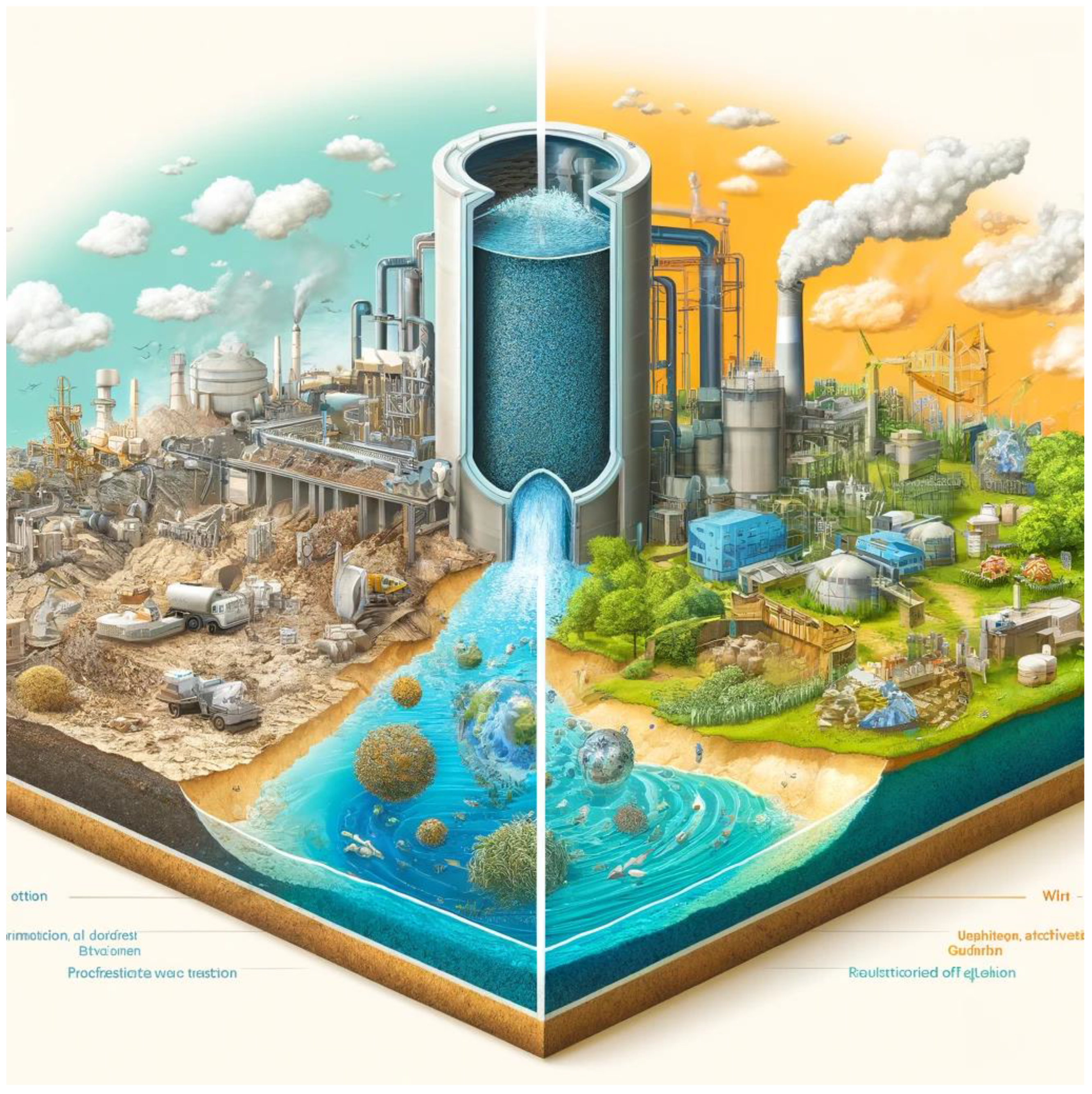

1.1. Water Pollution and the Need for Purification

1.2. Role of Activated Carbon in Water Treatment

- Adsorption Mechanism

- 2.

- Removal of Organic Contaminants

- 3.

- Removal of Inorganic Contaminants

- 4.

- Removal of Emerging Contaminants

- 5.

- Regeneration and Reuse

- 6.

- Synergistic Effects

1.3. Emergence of Biowaste Activated Carbon (BAC)

- Environmental Sustainability The utilization of biowaste for activated carbon production offers several environmental benefits compared to traditional sources such as coal and wood. Biowaste materials are renewable and abundant, reducing the reliance on finite fossil resources and mitigating the environmental impact associated with their extraction and processing [26]. Moreover, converting biowaste into activated carbon can help mitigate greenhouse gas emissions by diverting organic waste from landfills and reducing methane emissions from anaerobic decomposition [27].

- Waste Valorization Biowaste activated carbon represents a form of waste valorization, transforming underutilized biomass residues into high-value products with potential applications in water treatment, air purification, soil remediation, and renewable energy production. By converting biowaste into activated carbon, waste streams that would otherwise be discarded or incinerated can be repurposed into valuable resources, contributing to a circular economy and reducing the environmental burden of waste disposal [28].

- Cost-effectiveness Biowaste materials are often available at low or even negative cost, as they are generated as byproducts of agricultural, forestry, and food processing industries. The utilization of biowaste for activated carbon production can therefore offer cost advantages compared to conventional precursor materials, such as coconut shells or coal, which may incur higher procurement and processing costs [29]. Additionally, the localized availability of biowaste sources can reduce transportation costs and logistical challenges associated with sourcing raw materials.

- Social Impact The production of biowaste activated carbon has the potential to generate socio-economic benefits by creating employment opportunities, particularly in rural and agricultural communities where biowaste materials are abundant. Furthermore, the adoption of sustainable waste management practices, such as biowaste valorization, can contribute to improved public health outcomes by reducing pollution, mitigating environmental contamination, and promoting community resilience [30].

- Technological Innovation The development of innovative processes for the synthesis of biowaste activated carbon has spurred technological advancements in the field of waste-to-resource conversion and sustainable materials engineering [31]. Researchers are exploring novel activation methods, such as pyrolysis, carbonization, and chemical activation, to optimize the production efficiency, adsorption performance, and environmental sustainability of BAC. Additionally, advancements in characterization techniques, such as surface analysis, pore structure characterization, and adsorption kinetics studies, are enhancing our understanding of the physicochemical properties and performance of biowaste-derived activated carbon materials [32].

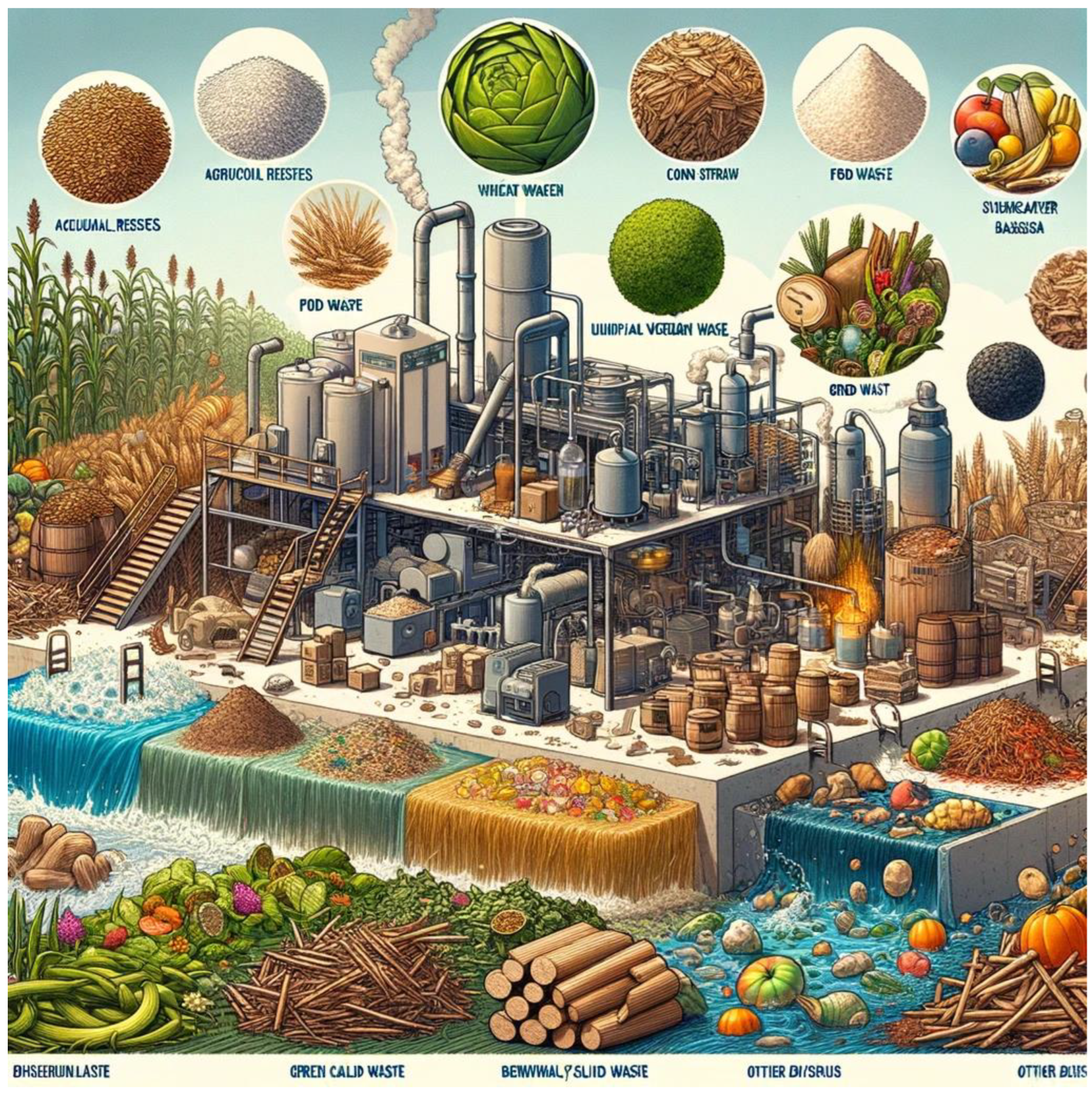

1. Sources of Biowaste for AC Synthesis

- Agricultural Residues

- 2.

- Food Waste

- 3.

- Forestry Residues

- 4.

- Municipal Solid Waste (MSW)

- 5.

- Other Biomass Sources

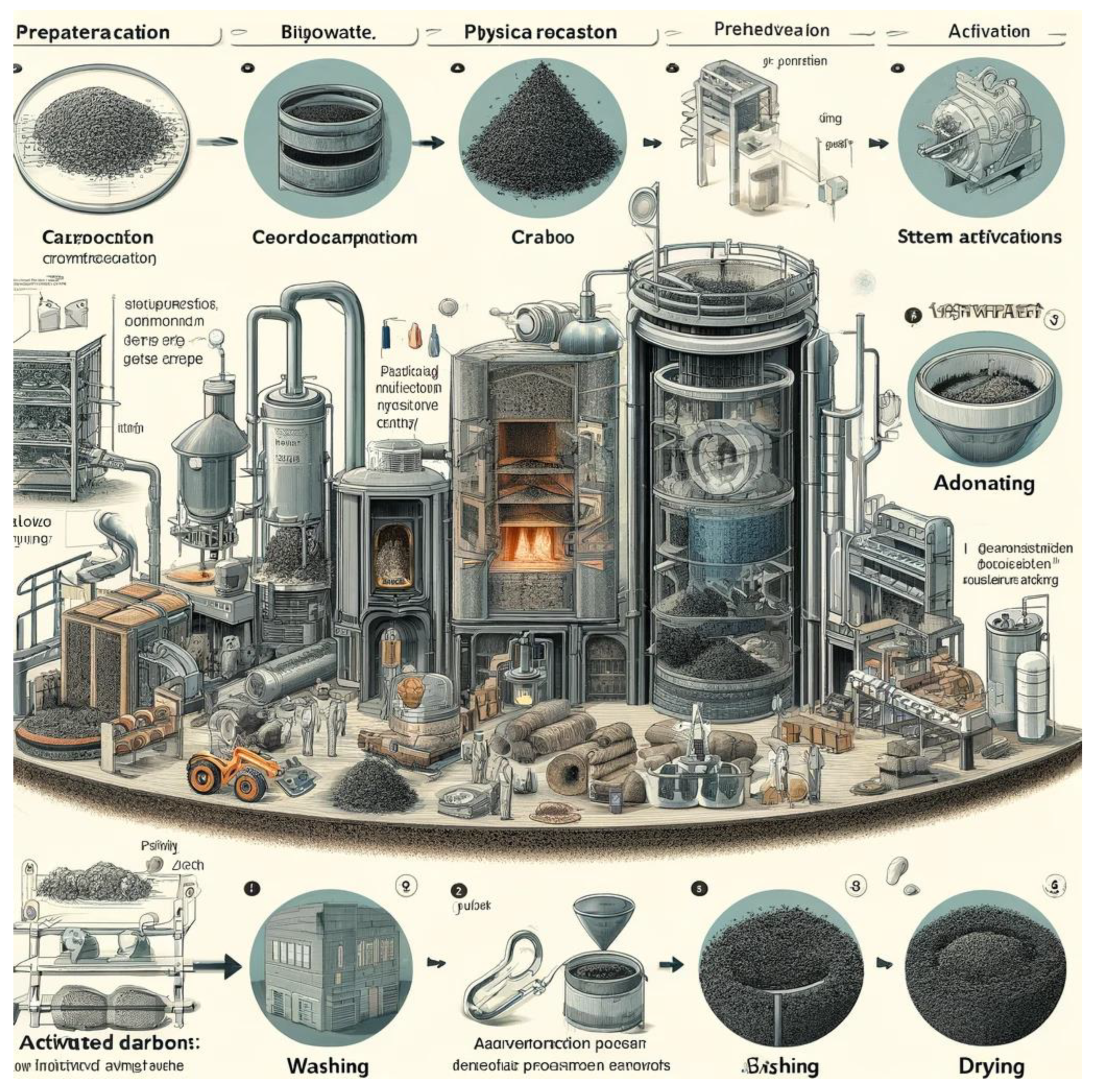

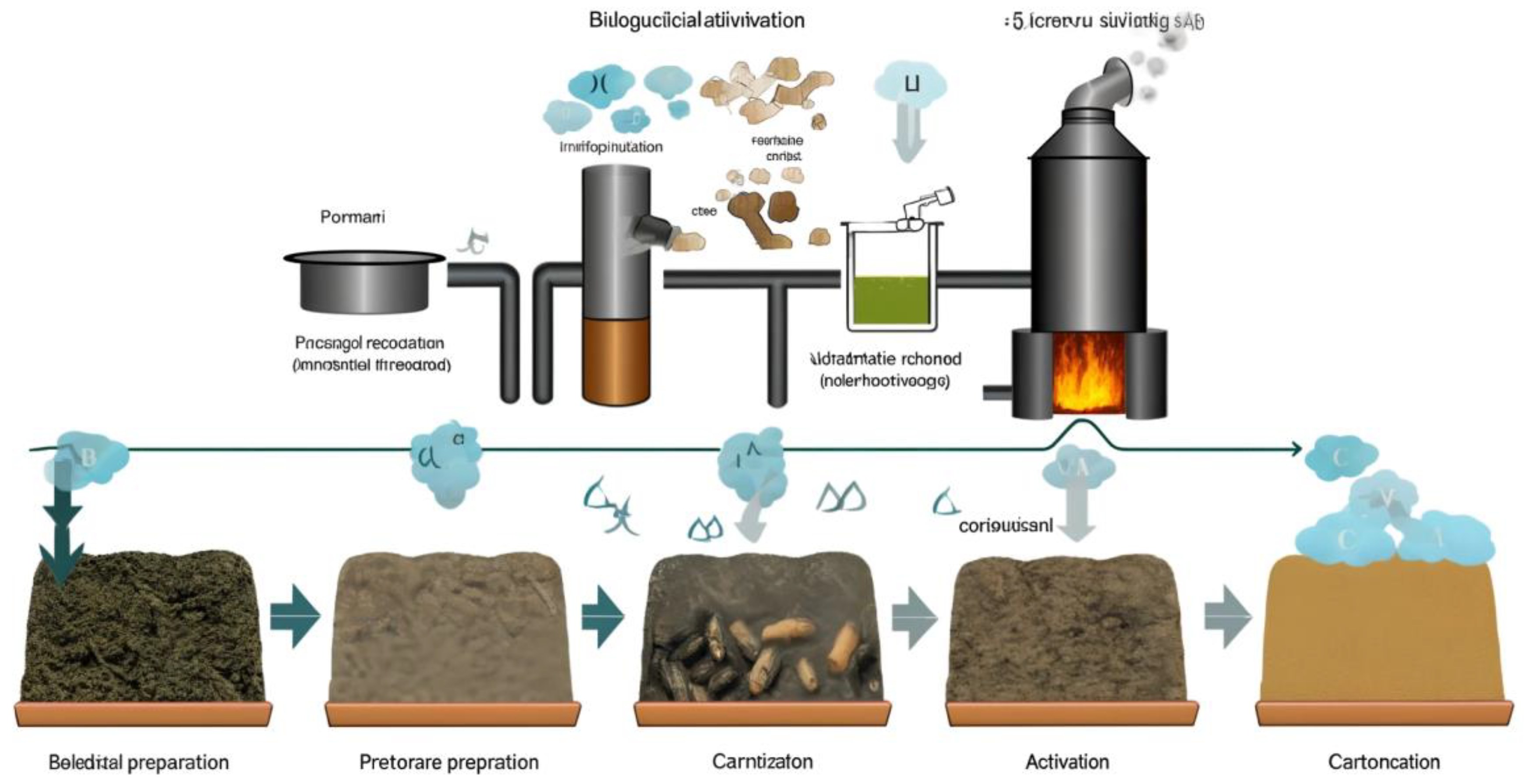

3. Synthesis Methods of BAC

3.1. Physical Activation

- Precursor Preparation

- 2.

- Carbonization

- 3.

- Activation

- 4.

- Washing and Drying

3.2. Chemical Activation

- Precursor Preparation

- 2.

- Carbonization

- 3.

- Impregnation

- 4.

- Activation

- 5.

- Washing and Drying

3.3. Biological Activation

- 1.

- Precursor Preparation

- 2.

- Bioconversion

- 3.

- Carbonization

- 4.

- Activation

- 5.

- Washing and Drying

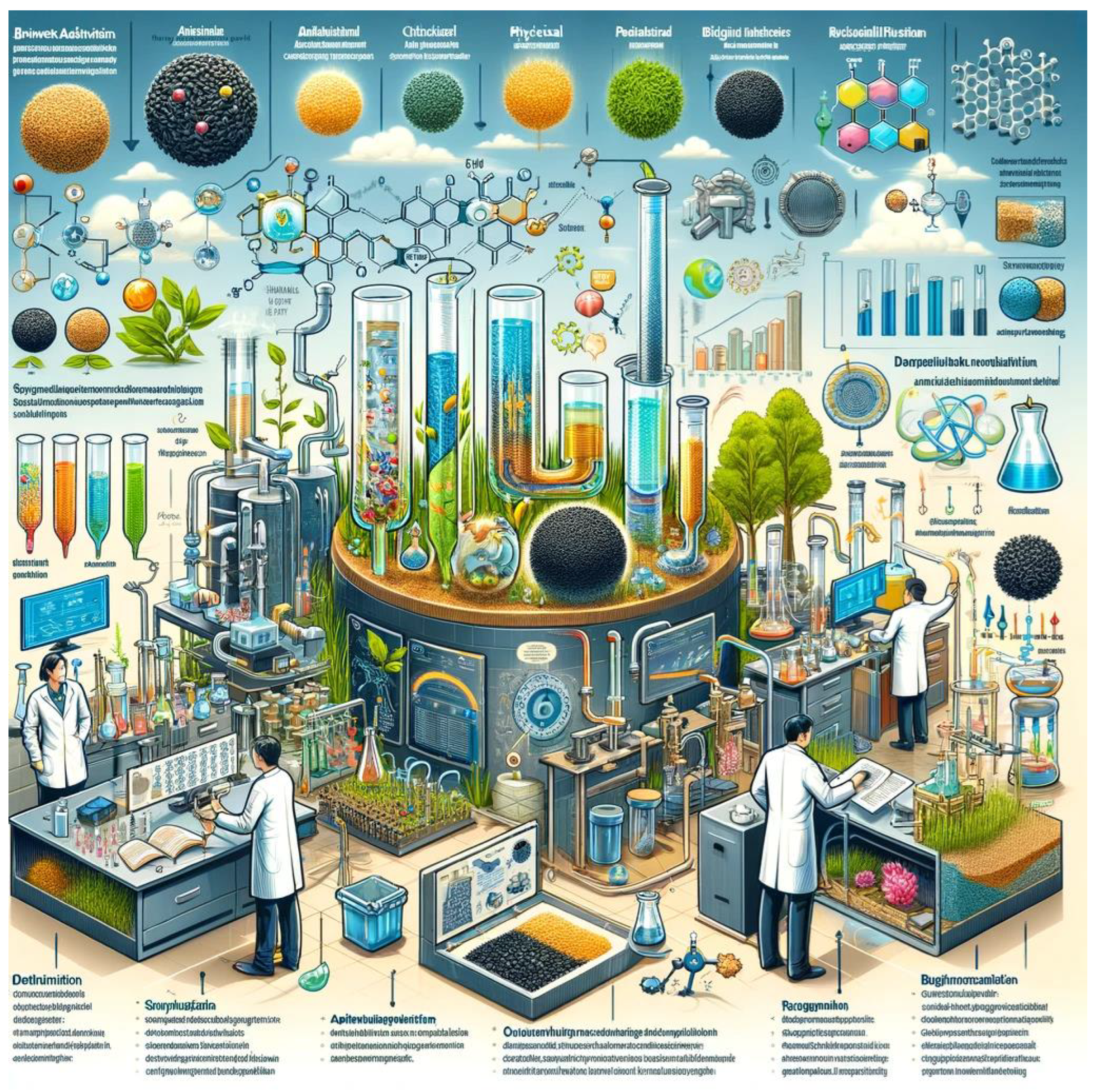

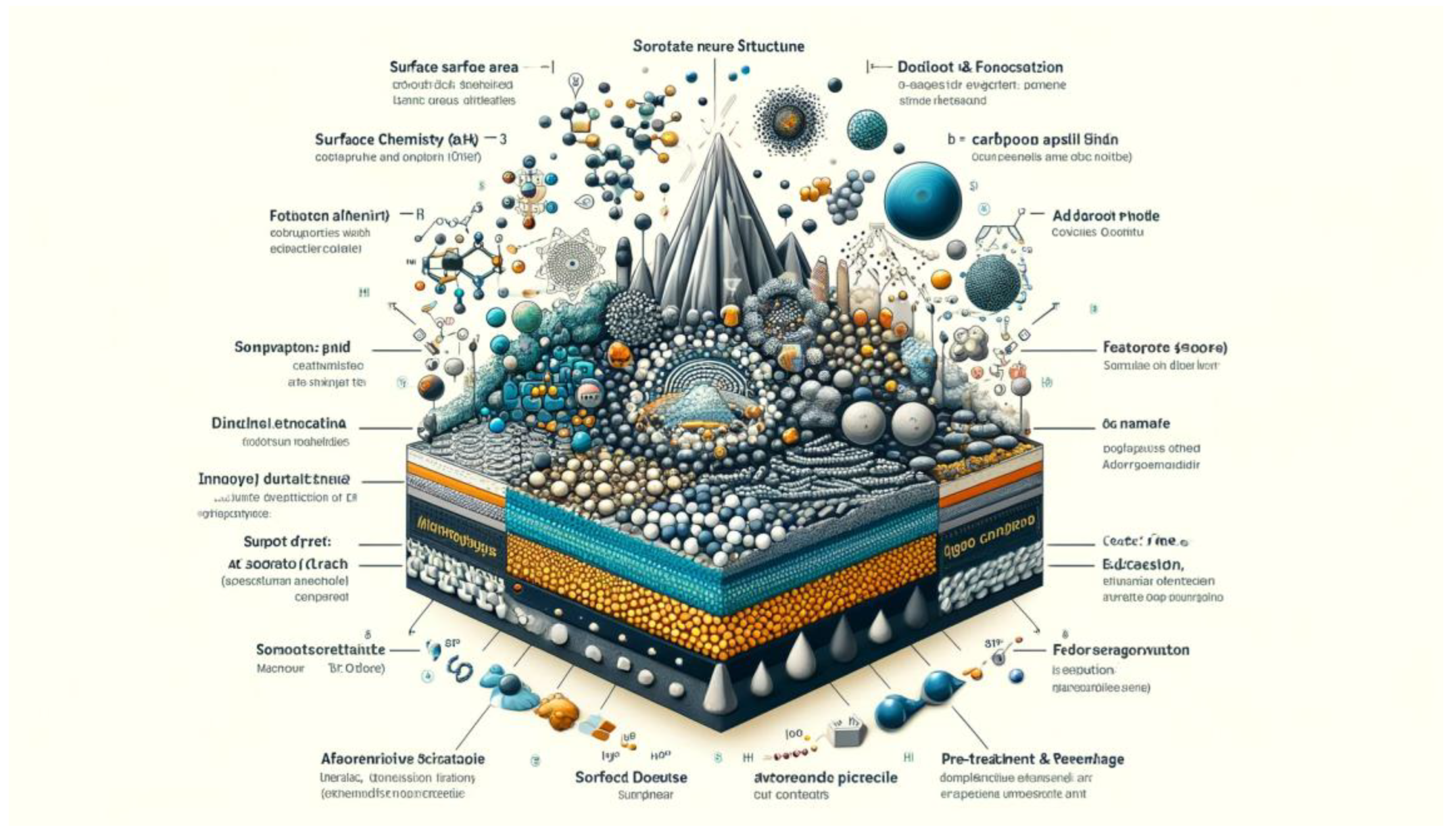

4. Characterization Techniques for BAC

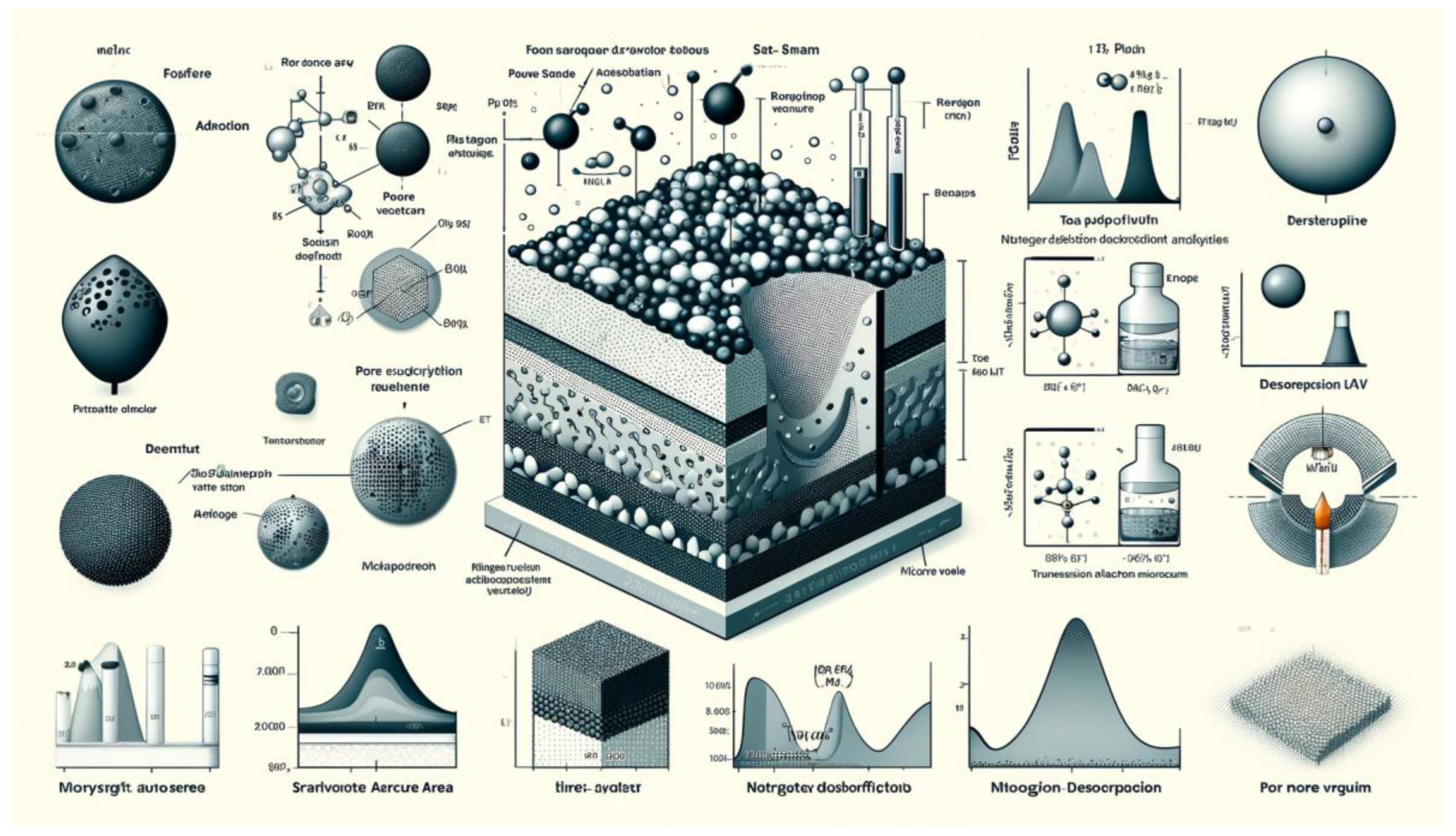

4.1. Surface Area and Pore Structure Analysis

- Brunauer-Emmett-Teller (BET) Surface Area Analysis

- 2.

- Pore Size Distribution Analysis

- 3.

- Nitrogen Adsorption-Desorption Isotherms

- 4.

- Micropore Volume and Total Pore Volume

- 5.

- Scanning Electron Microscopy (SEM) and Transmission Electron Microscopy (TEM)

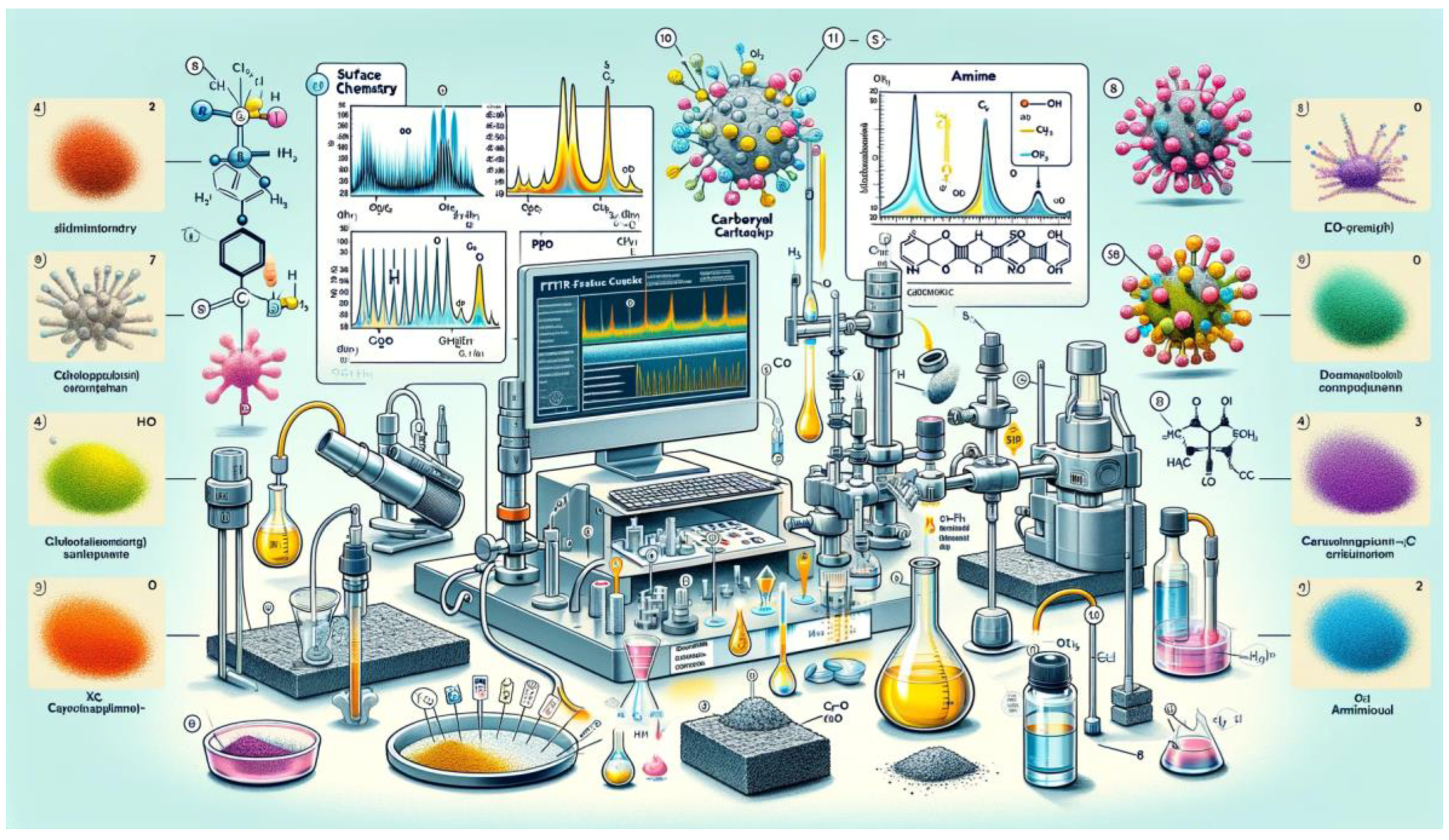

4.2. Surface Chemistry and Functional Groups

- Fourier Transform Infrared Spectroscopy (FTIR)

- 2.

- Boehm Titration

- 3.

- X-ray Photoelectron Spectroscopy (XPS)

- 4.

- Temperature Programmed Desorption (TPD)

- 5.

- Elemental Analysis

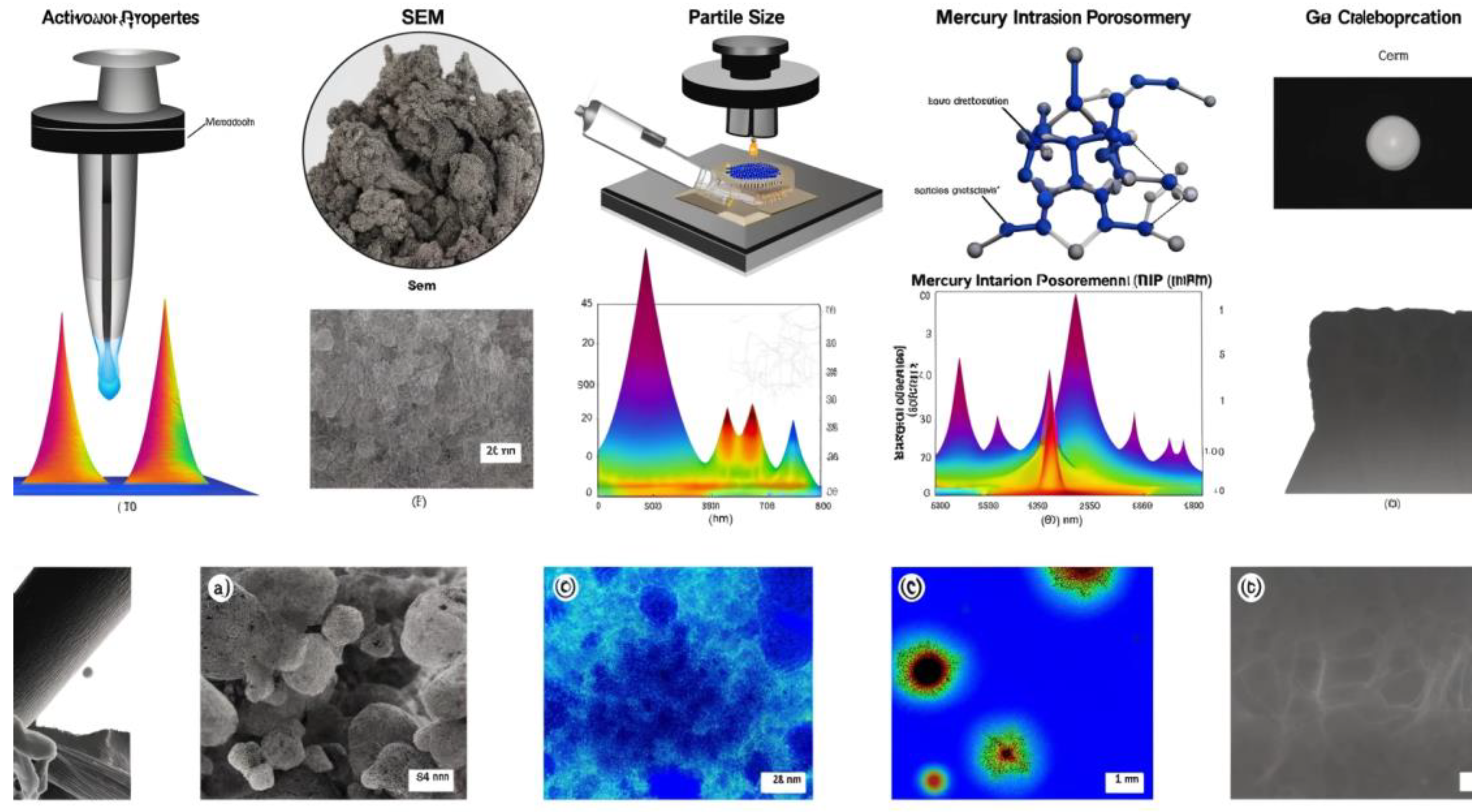

4.3. Morphological Properties

- Scanning Electron Microscopy (SEM)

- 2.

- Transmission Electron Microscopy (TEM)

- 3.

- Particle Size Analysis

- 4.

- Mercury Intrusion Porosimetry (MIP)

- 5.

- Gas Adsorption Techniques

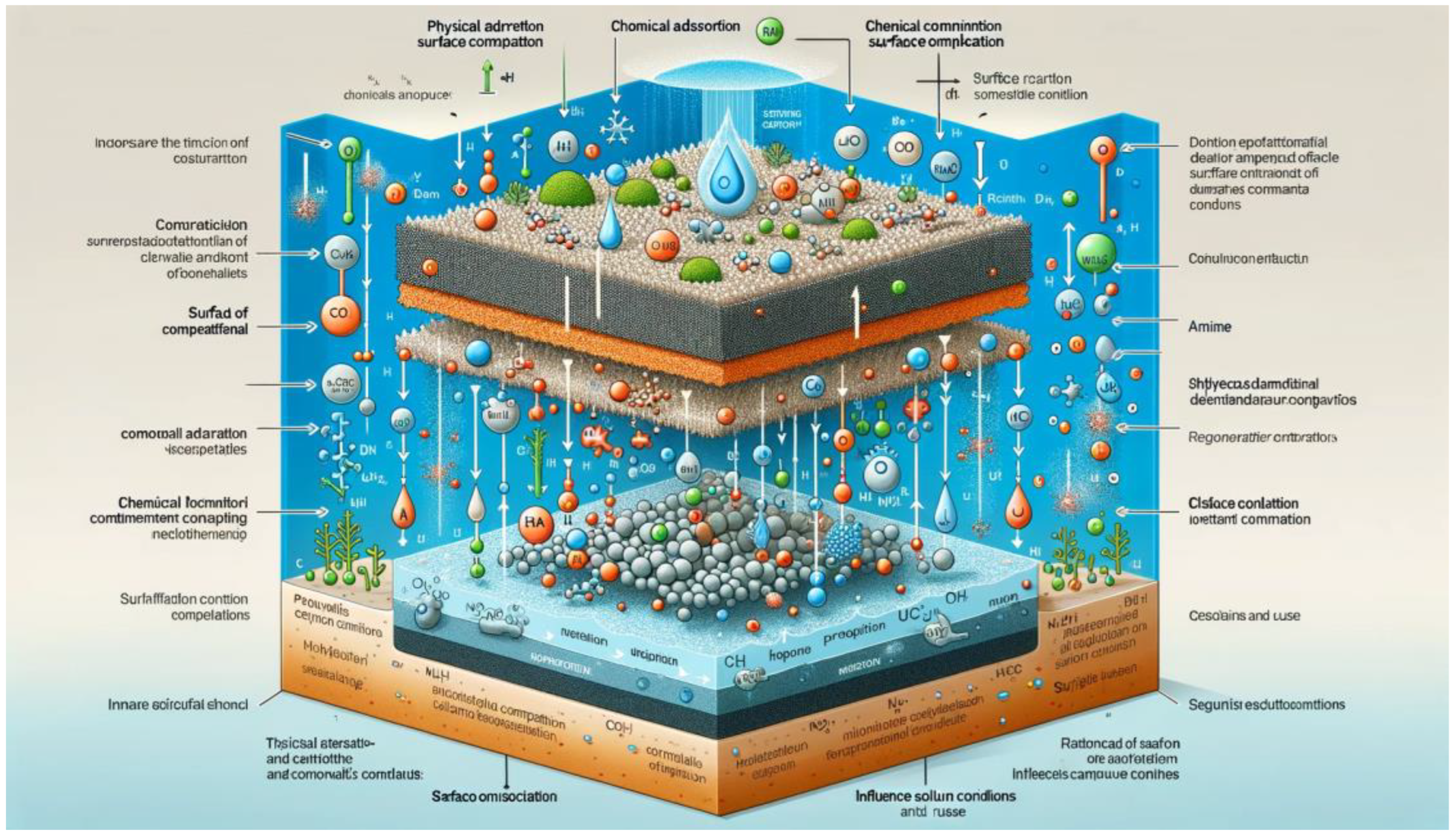

5. Adsorption Mechanisms and Performance Factors

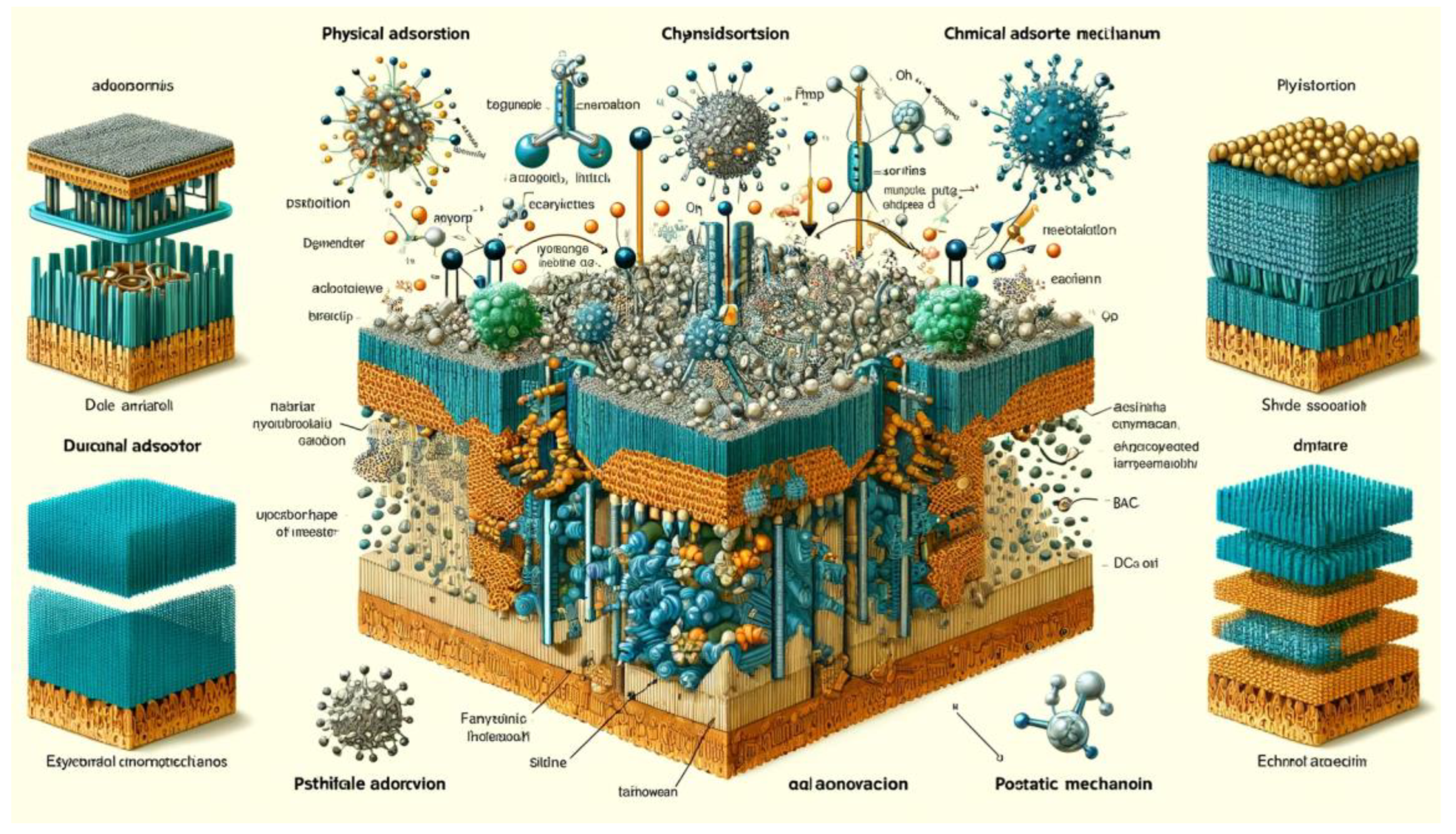

5.1. Mechanisms of Adsorption on BAC

- Physical Adsorption (Physisorption)

- 2.

- Chemical Adsorption (Chemisorption)

- 3.

- Pore-Filling Mechanism

- 4.

- Electrostatic Interactions

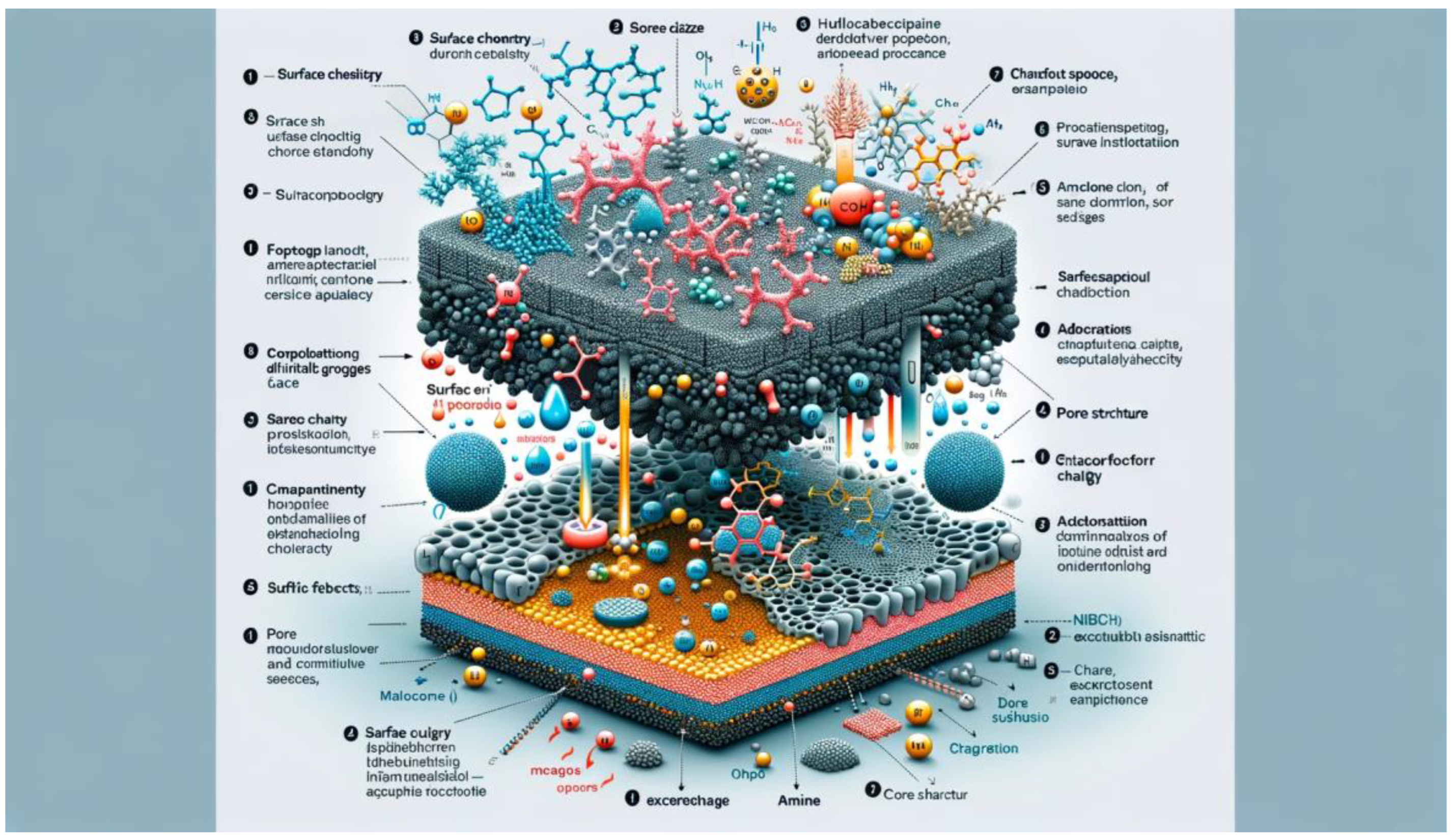

5.2. Influence of Surface Chemistry and Pore Structure

- Surface Chemistry

- 2.

- Pore Structure

- 3.

- Synergistic Effects

5.3. Factors Affecting Adsorption Performance

- Surface Area and Pore Structure

- 2.

- Surface Chemistry and Functional Groups

- 3.

- Adsorbate Characteristics

- 4.

- Solution Conditions

- 5.

- Contact Time and Agitation

- 6.

- Adsorbent Dosage and Particle Size

- 7.

- Pre-treatment and Regeneration

6. Applications of BAC in Water Purification

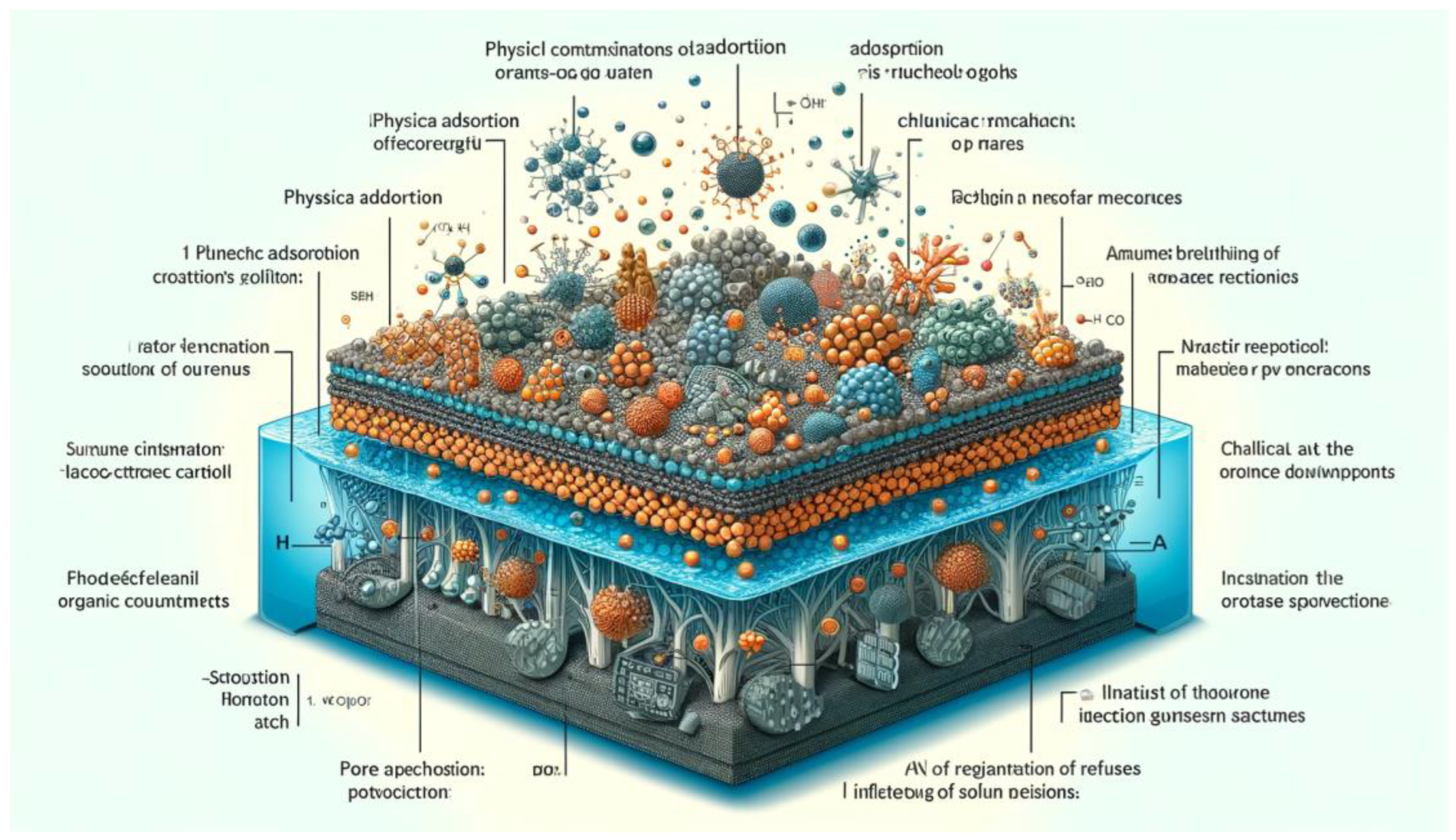

6.1. Removal of Organic Contaminants

- Physical Adsorption

- 2.

- Chemical Adsorption

- 3.

- Pore-Filling Mechanism

- 4.

- Influence of Solution Conditions

- 5.

- Regeneration and Reuse

6.2. Removal of Inorganic Contaminants

- Physical Adsorption

- 2.

- Chemical Adsorption and Surface Complexation

- 3.

- Ion Exchange

- 4.

- Influence of Solution Conditions

- 5.

- Regeneration and Reuse

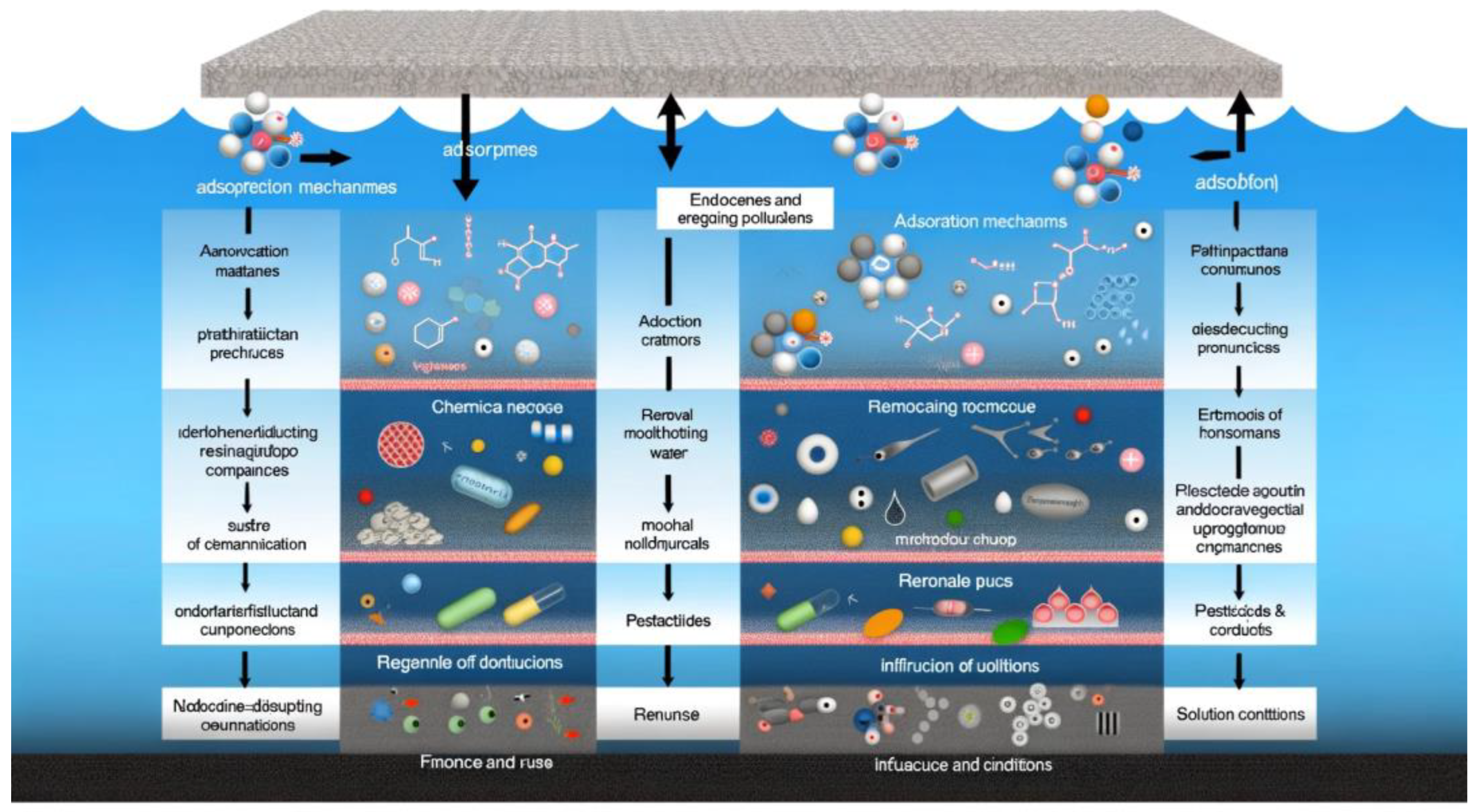

6.3. Removal of Emerging Pollutants

- Adsorption Mechanisms

- 2.

- Removal of Pharmaceuticals and Personal Care Products (PPCPs)

- 3.

- Removal of Endocrine-Disrupting Compounds (EDCs)

- 4.

- Removal of Pesticides and Agrochemicals

- 5.

- Removal of Microplastics

- 6.

- Influence of Solution Conditions

- 7.

- Regeneration and Reuse

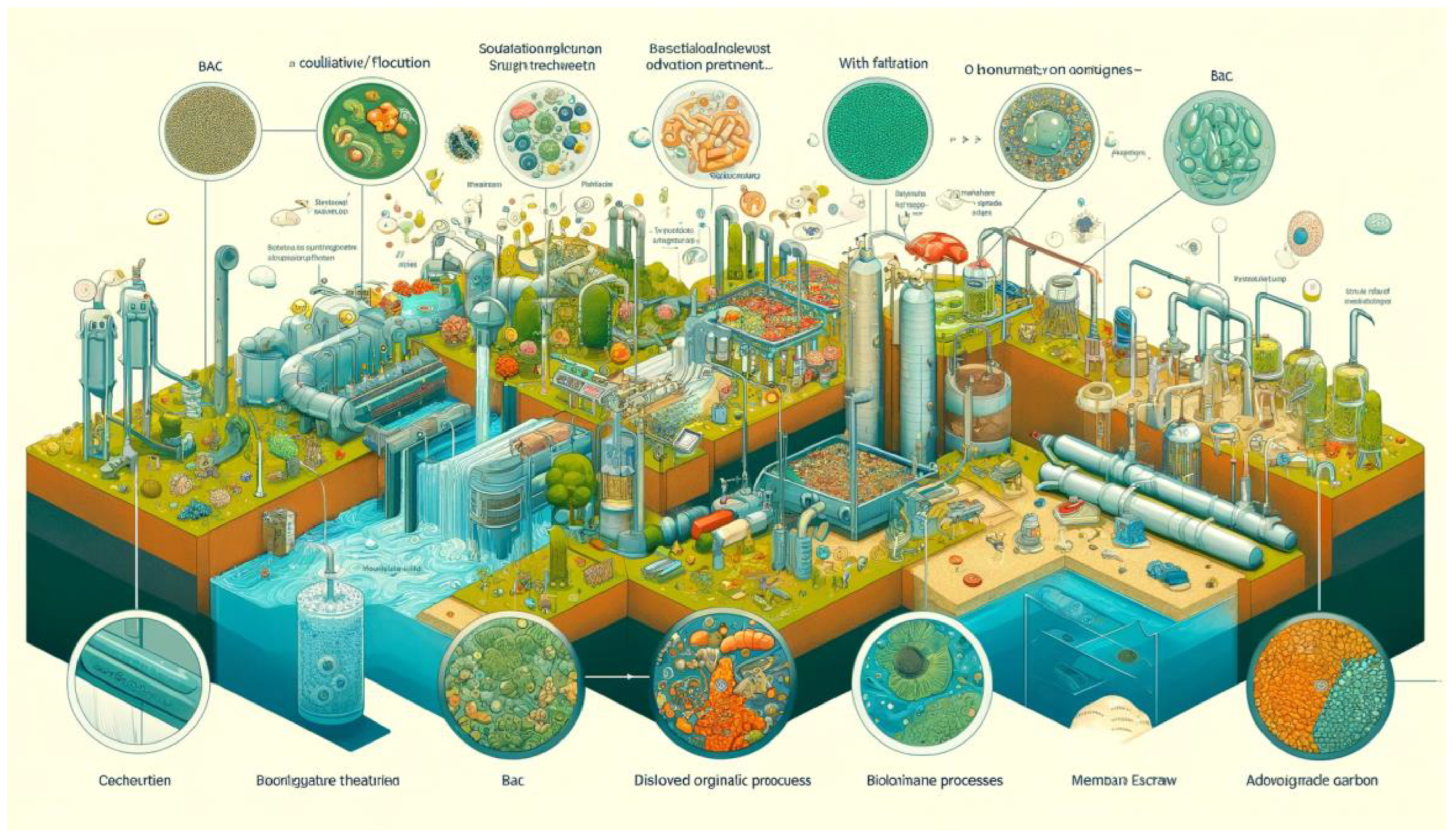

6.4. BAC in Combination with Other Treatment Methods

- BAC with Coagulation/Flocculation:

- 2.

- BAC with Filtration

- 3.

- BAC with Oxidation Processes

- 4.

- BAC with Biological Treatment

- 5.

- BAC with Ion Exchange

- 6.

- BAC with Membrane Processes

- 7.

- BAC with Advanced Treatment Technologies

7. Regeneration and Reuse of BAC

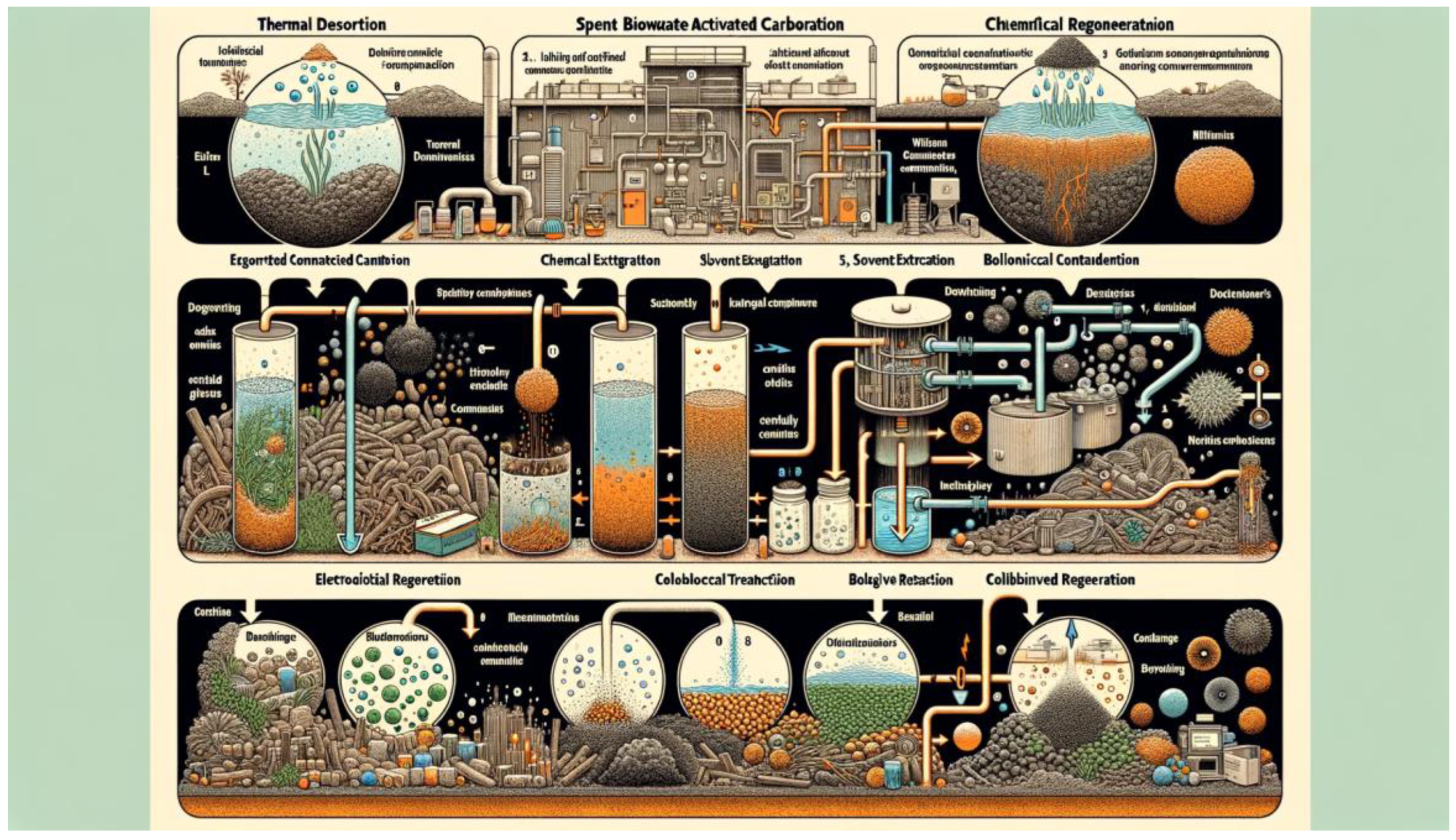

7.1. Regeneration Techniques

- Thermal Desorption:

- 2.

- Chemical Regeneration

- 3.

- Solvent Extraction

- 4.

- Biological Treatment

- 5.

- Electrochemical Regeneration

- 6.

- Combined Regeneration Techniques

7.2. Challenges and Considerations

- Contaminant Specificity: BAC may exhibit variations in adsorption efficiency and selectivity depending on the type and characteristics of the contaminants present in water [163]. Tailoring BAC properties to specific contaminants and understanding their adsorption mechanisms are crucial for achieving optimal removal efficiency.

- Regeneration Efficiency: The regeneration of spent BAC can be energy-intensive, costly, and may not always fully restore its adsorption capacity. Developing efficient and sustainable regeneration techniques while minimizing environmental impacts and operational costs is essential for the long-term viability of BAC-based water treatment systems [112].

- Water Matrix Interference: The presence of co-existing ions, natural organic matter (NOM), and other dissolved substances in water may compete with target contaminants for adsorption sites on BAC, leading to reduced removal efficiency and breakthrough [164]. Understanding the interactions between BAC and the water matrix is essential for optimizing treatment performance under real-world conditions.

- Long-Term Performance: Assessing the long-term stability and performance of BAC materials under continuous operation is critical for ensuring reliable and sustainable water treatment. Factors such as fouling, aging, pore blockage, and microbial growth on BAC surfaces may affect its adsorption capacity and require periodic monitoring and maintenance [165].

- Scale-Up and Implementation: Scaling up BAC-based water treatment systems from laboratory-scale studies to full-scale applications presents engineering and logistical challenges, including reactor design, flow dynamics, media regeneration, and operational management. Developing scalable and cost-effective treatment solutions that meet regulatory requirements and address site-specific needs is essential for successful implementation [166].

- Environmental Impact: The production, use, and disposal of BAC materials may have environmental implications, including energy consumption, carbon emissions, waste generation, and potential leaching of contaminants. Considering the life cycle impacts of BAC-based water treatment systems and adopting sustainable practices, such as using renewable feedstocks, minimizing waste generation, and promoting recycling and reuse, can mitigate environmental concerns.

- Emerging Contaminants: BAC’s effectiveness in removing emerging contaminants, such as pharmaceuticals, personal care products, microplastics, and nanomaterials, requires further investigation due to their complex physicochemical properties and potential health risks. Monitoring and addressing emerging contaminants in water sources necessitate ongoing research, regulatory updates, and technological advancements to ensure public health and environmental protection [167].

- Technological Advancements: Continual research and development efforts are needed to advance BAC synthesis, activation, modification, and regeneration techniques, as well as to explore novel applications, such as hybrid treatment systems, smart materials, and advanced characterization methods. Leveraging emerging technologies, such as nanotechnology, artificial intelligence, and biotechnology, can enhance the performance, efficiency, and sustainability of BAC-based water treatment solutions.

8. Environmental and Economic Considerations

8.1. Sustainability of BAC Production

- Feedstock Selection: Utilizing biowaste materials, such as agricultural residues, food waste, forestry by-products, and wastewater sludge, as feedstock for BAC production reduces reliance on virgin resources, minimizes waste generation, and promotes circular economy principles. Selecting locally sourced, abundant, and renewable feedstocks that have low environmental impact and are readily available can enhance the sustainability of BAC production.

- Production Processes: Implementing environmentally friendly and energy-efficient production processes for BAC synthesis, activation, and modification reduces greenhouse gas emissions, energy consumption, and resource depletion [168]. Adopting sustainable manufacturing practices, such as biomass pyrolysis, carbonization, and activation using renewable energy sources, bio-based catalysts, and green solvents, minimizes environmental footprint and enhances process sustainability.

- Waste Management: Proper management of by-products, residues, and emissions generated during BAC production is essential for minimizing environmental pollution and resource depletion [169]. Implementing waste reduction, reuse, recycling, and treatment measures, such as capturing and recycling process gases, recovering valuable by-products, and treating wastewater and solid residues, ensures responsible waste management and reduces environmental impact.

- Life Cycle Assessment (LCA): Conducting life cycle assessments to evaluate the environmental, economic, and social impacts of BAC production from cradle to grave provides insights into its sustainability performance and identifies opportunities for improvement [170]. Considering factors such as raw material sourcing, manufacturing processes, transportation, use phase, and end-of-life disposal enables informed decision-making and promotes sustainable practices throughout the product life cycle.

- Environmental Regulations and Standards: Complying with environmental regulations, standards, and certifications, such as ISO 14001, EMAS, and eco-labeling schemes, ensures regulatory compliance, stakeholder confidence, and market competitiveness [171]. Adhering to environmental best practices, pollution prevention measures, and sustainable development goals fosters accountability, transparency, and continuous improvement in BAC production.

- Social Responsibility: Promoting social responsibility and ethical practices in BAC production involves safeguarding human health, worker safety, and community well-being, as well as respecting indigenous rights, cultural heritage, and local livelihoods [172]. Engaging with stakeholders, fostering partnerships, and investing in social initiatives, such as education, training, and capacity building, fosters inclusive and sustainable development that benefits society as a whole.

- Economic Viability: Ensuring the economic viability and competitiveness of BAC production involves optimizing resource utilization, minimizing production costs, and maximizing value creation. Investing in research and innovation, process optimization, and market diversification enhances product performance, efficiency, and marketability, driving economic growth and long-term sustainability.

8.2. Cost-Effectiveness and Scalability

- Feedstock Optimization: Selecting low-cost and abundant biowaste feedstocks, such as agricultural residues, forestry by-products, and food processing waste, can reduce raw material expenses and minimize production costs [173]. Identifying locally available feedstock sources and establishing strategic partnerships with suppliers enable reliable and cost-efficient feedstock procurement.

- Process Efficiency: Optimizing production processes, including carbonization, activation, impregnation, and post-treatment, improves energy efficiency, resource utilization, and product yield. Implementing process optimization techniques, such as process intensification, heat integration, and automation, reduces production time, energy consumption, and labor costs, enhancing overall process efficiency and cost-effectiveness.

- Scale-Up Strategies: Developing scalable production technologies and manufacturing processes enables efficient production scale-up from laboratory-scale to pilot-scale and commercial-scale operations. Investing in equipment upgrades, production facilities, and infrastructure development facilitates economies of scale, reduces unit costs, and improves production efficiency, making BAC production more cost-effective and scalable [174].

- By-Product Valorization: Exploring opportunities for valorizing by-products, residues, and waste streams generated during BAC production, such as biochar, syngas, bio-oil, and bio-based chemicals, creates additional revenue streams and enhances overall process economics [175]. Implementing by-product recovery, recycling, and utilization strategies maximizes resource efficiency, minimizes waste generation, and improves the sustainability and cost-effectiveness of BAC production.

- Technological Innovation: Investing in research and development (R&D) initiatives to advance BAC synthesis, activation, modification, and regeneration technologies drives technological innovation and process optimization. Leveraging emerging technologies, such as microwave pyrolysis, hydrothermal carbonization, and 3D printing, enhances production efficiency, product quality, and cost competitiveness, positioning BAC as a cost-effective and scalable solution for water treatment [176].

- Market Diversification: Expanding market opportunities and diversifying product applications beyond water treatment, such as air purification, soil remediation, energy storage, and advanced materials, increases demand and revenue potential for BAC products. Identifying niche markets, addressing unmet needs, and developing tailored solutions for specific industries and applications enhance market competitiveness and scalability of BAC production.

- Cost-Benefit Analysis: Conducting comprehensive cost-benefit analyses to evaluate the economic viability and financial feasibility of BAC production projects provides insights into investment returns, payback periods, and profitability metrics [177]. Considering factors such as capital investment, operating costs, revenue generation, and market risks enables informed decision-making and strategic planning for cost-effective and scalable BAC production.

9. Future Directions and Emerging Trends

9.1. Advances in BAC Synthesis Techniques

- Hydrothermal Carbonization (HTC): Hydrothermal carbonization is a promising technique for converting biowaste feedstocks, such as agricultural residues, food waste, and wastewater sludge, into biochar precursor materials through controlled heating in an aqueous environment under elevated temperature and pressure conditions. HTC offers several advantages, including high carbon yield, rapid reaction kinetics, and low energy consumption, making it an efficient and sustainable method for BAC synthesis.

- Microwave Pyrolysis: Microwave pyrolysis is an emerging technique for producing BAC from biowaste feedstocks using microwave irradiation to heat and decompose organic materials into biochar in the absence of oxygen. Microwave heating enables rapid and uniform heating of feedstock particles, leading to shorter processing times, higher carbonization efficiency, and improved product quality compared to conventional pyrolysis methods. Microwave pyrolysis also offers greater control over process parameters, such as temperature, heating rate, and residence time, allowing for the production of BAC with tailored properties and enhanced adsorption performance.

- Solvent-Free Activation: Solvent-free activation methods, such as steam activation and carbon dioxide activation, have gained attention as environmentally friendly alternatives to conventional chemical activation processes for producing BAC. Steam activation involves treating biochar precursor materials with steam at high temperatures to create a highly porous structure with a large surface area, while carbon dioxide activation utilizes carbon dioxide gas as an activating agent to enhance micropore development and surface reactivity. Solvent-free activation methods offer several advantages, including reduced environmental impact, simplified process operation, and improved adsorption properties of BAC products.

- Biomass Blending and Co-Pyrolysis: Biomass blending and co-pyrolysis involve combining multiple biowaste feedstocks with complementary properties to optimize BAC synthesis and product performance. By blending different types of biomass materials, such as agricultural residues, woody biomass, and organic waste, researchers can tailor the chemical composition, pore structure, and surface chemistry of BAC to enhance its adsorption capacity, selectivity, and regeneration efficiency. Co-pyrolysis of biomass blends allows for synergistic interactions between feedstock components, leading to the formation of BAC with unique properties and improved performance for water treatment applications.

- Activation with Sustainable Catalysts: Activation with sustainable catalysts, such as alkali metal salts, phosphoric acid, and bio-derived catalysts, offers an environmentally friendly approach to enhancing the adsorption properties of BAC while minimizing the use of hazardous chemicals. Sustainable catalysts promote the activation of biochar precursor materials by facilitating pore formation, surface functionalization, and chemical activation reactions, resulting in BAC products with enhanced surface area, pore volume, and adsorption capacity. Activation with sustainable catalysts also reduces the environmental footprint of BAC production and contributes to the development of greener and more sustainable water treatment technologies.

- Integration of Additive Manufacturing Technologies: The integration of additive manufacturing technologies, such as 3D printing and extrusion, with BAC synthesis processes enables the precise control of material structure, morphology, and porosity, leading to the production of BAC with custom-designed architectures and optimized performance characteristics. Additive manufacturing allows for the fabrication of complex BAC structures, including hierarchical pore networks, interconnected channels, and functionalized surfaces, which enhance mass transfer, adsorption kinetics, and regeneration efficiency. By leveraging additive manufacturing techniques, researchers can overcome limitations associated with traditional BAC synthesis methods and develop innovative materials with tailored properties for specific water treatment applications.

9.2. Integration of BAC with Novel Purification Technologies

- Membrane-BAC Hybrid Systems

- 2.

- Advanced Oxidation-BAC Hybrid Systems

- 3.

- Electrochemical-BAC Hybrid Systems

- 4.

- Biochar-BAC Composite Materials

- 5.

- Hybrid Adsorbent-BAC Systems

- 6.

- Smart Materials-BAC Systems

- 7.

- Hierarchical Structured-BAC Materials

9.3. Application in Wastewater Treatment and Resource Recovery

- Removal of Organic Contaminants

- 2.

- Reduction of Nutrient Pollution

- 3.

- Recovery of Metals and Nutrients

- 4.

- Treatment of Industrial Wastewaters

- 5.

- Microbial Contaminant Removal

- 6.

- Odor and Taste Removal

- 7.

- Generation of Value-Added Products

10. Conclusions

References

- Kılıç, Z., The importance of water and conscious use of water. International Journal of Hydrology, 2020. 4(5): p. 239-241.

- Sonone, S.S., et al., Water contamination by heavy metals and their toxic effect on aquaculture and human health through food Chain. Lett. Appl. NanoBioScience, 2020. 10(2): p. 2148-2166.

- Sweetman, M.J., et al., Activated carbon, carbon nanotubes and graphene: materials and composites for advanced water purification. C, 2017. 3(2): p. 18.

- Fazal-ur-Rehman, M., Methodological trends in preparation of activated carbon from local sources and their impacts on production-a review. Curr Trends chem Eng Process Technol: CTCEPT-101. DOI, 2018. 10.

- Ng, H.S., et al., Recent advances on the sustainable approaches for conversion and reutilization of food wastes to valuable bioproducts. Bioresource technology, 2020. 302: p. 122889.

- Oladoye, P.O., et al., Advancements in adsorption and photodegradation technologies for rhodamine B dye wastewater treatment: Fundamentals, applications, and future directions. Green Chemical Engineering, 2023.

- Bolisetty, S., M. Peydayesh, and R. Mezzenga, Sustainable technologies for water purification from heavy metals: review and analysis. Chemical Society Reviews, 2019. 48(2): p. 463-487.

- Akhtar, N., et al., Various natural and anthropogenic factors responsible for water quality degradation: A review. Water, 2021. 13(19): p. 2660.

- Morin-Crini, N., et al., Emerging contaminants: analysis, aquatic compartments and water pollution. Emerging Contaminants Vol. 1: Occurrence and Impact, 2021: p. 1-111.

- Rahman, Z. and V.P. Singh, The relative impact of toxic heavy metals (THMs)(arsenic (As), cadmium (Cd), chromium (Cr)(VI), mercury (Hg), and lead (Pb)) on the total environment: an overview. Environmental monitoring and assessment, 2019. 191: p. 1-21.

- Islam, M.S. and M. Tanaka, Impacts of pollution on coastal and marine ecosystems including coastal and marine fisheries and approach for management: a review and synthesis. Marine pollution bulletin, 2004. 48(7-8): p. 624-649.

- Rashmi, I., et al., Organic and inorganic fertilizer contaminants in agriculture: Impact on soil and water resources. Contaminants in Agriculture: Sources, Impacts and Management, 2020: p. 3-41.

- Rodić, L. and D.C. Wilson, Resolving governance issues to achieve priority sustainable development goals related to solid waste management in developing countries. Sustainability, 2017. 9(3): p. 404.

- Bashir, I., et al., Concerns and threats of contamination on aquatic ecosystems. Bioremediation and biotechnology: sustainable approaches to pollution degradation, 2020: p. 1-26.

- Reza, M.S., et al., Preparation of activated carbon from biomass and its’ applications in water and gas purification, a review. Arab Journal of Basic and Applied Sciences, 2020. 27(1): p. 208-238.

- Nguyen, D.T., et al., Adsorption process and mechanism of acetaminophen onto commercial activated carbon. Journal of Environmental Chemical Engineering, 2020. 8(6): p. 104408.

- Jawad, A.H., S.H. Mallah, and M.S. Mastuli, Adsorption behavior of methylene blue on acid-treated rubber (Hevea brasiliensis) leaf. Desalin. Water Treat, 2018. 124: p. 297-307.

- Pignatello, J.J., Adsorption of dissolved organic compounds by black carbon. Molecular environmental soil science, 2013: p. 359-385.

- Jadhav, S.V., et al., Arsenic and fluoride contaminated groundwaters: a review of current technologies for contaminants removal. Journal of environmental management, 2015. 162: p. 306-325.

- Yang, X., et al., Surface functional groups of carbon-based adsorbents and their roles in the removal of heavy metals from aqueous solutions: a critical review. Chemical Engineering Journal, 2019. 366: p. 608-621.

- Almeida-Naranjo, C.E., V.H. Guerrero, and C.A. Villamar-Ayala, Emerging contaminants and their removal from aqueous media using conventional/non-conventional adsorbents: a glance at the relationship between materials, processes, and technologies. Water, 2023. 15(8): p. 1626.

- Alipoori, S., et al., Polymer-based devices and remediation strategies for emerging contaminants in water. ACS Applied Polymer Materials, 2021. 3(2): p. 549-577.

- El Gamal, M., et al., Bio-regeneration of activated carbon: A comprehensive review. Separation and Purification Technology, 2018. 197: p. 345-359.

- Chowdhury, Z.K., Activated carbon: solutions for improving water quality. 2013: American Water Works Association.

- Karić, N., et al., Bio-waste valorisation: Agricultural wastes as biosorbents for removal of (in) organic pollutants in wastewater treatment. Chemical Engineering Journal Advances, 2022. 9: p. 100239.

- Igbokwe, V.C., et al., Biochemical biorefinery: A low-cost and non-waste concept for promoting sustainable circular bioeconomy. Journal of Environmental Management, 2022. 305: p. 114333.

- Sánchez, A., et al., Greenhouse gas emissions from organic waste composting. Environmental chemistry letters, 2015. 13: p. 223-238.

- Emenike, E.C., et al., Advancing the circular economy through the thermochemical conversion of waste to biochar: a review on sawdust waste-derived fuel. Biofuels, 2024. 15(4): p. 433-447.

- Shah, H.H., et al., Overview of environmental and economic viability of activated carbons derived from waste biomass for adsorptive water treatment applications. Environmental Science and Pollution Research, 2023: p. 1-26.

- Sharma, H.B., et al., Circular economy approach in solid waste management system to achieve UN-SDGs: Solutions for post-COVID recovery. Science of the Total Environment, 2021. 800: p. 149605.

- Zaman, K., et al., Environmental effects of bio-waste recycling on industrial circular economy and eco-sustainability. Recycling, 2022. 7(4): p. 60.

- Wong, S., et al., Recent advances in applications of activated carbon from biowaste for wastewater treatment: a short review. Journal of Cleaner Production, 2018. 175: p. 361-375.

- Contescu, C.I., et al., Activated carbons derived from high-temperature pyrolysis of lignocellulosic biomass. C, 2018. 4(3): p. 51.

- Zou, R., et al., Biochar: From by-products of agro-industrial lignocellulosic waste to tailored carbon-based catalysts for biomass thermochemical conversions. Chemical Engineering Journal, 2022. 441: p. 135972.

- Patra, B.R., Slow pyrolysis of agro-food waste to produce biochar and activated carbon for adsorption of pollutants from model wastewater. 2021, University of Saskatchewan.

- Umego, E.C. and C. Barry-Ryan, Review of the valorization initiatives of brewing and distilling by-products. Critical Reviews in Food Science and Nutrition, 2023: p. 1-17.

- del Rosario Moreno-Virgen, M., et al., Applications of activated carbons obtained from lignocellulosic materials for the wastewater treatment. Lignocellulosic Precursors Used in the Synthesis of Activated Carbon, 2012: p. 57.

- He, C., et al., Wet torrefaction of biomass for high quality solid fuel production: A review. Renewable and Sustainable Energy Reviews, 2018. 91: p. 259-271.

- Gunarathne, V., et al., Municipal waste biochar for energy and pollution remediation. Green Adsorbents for Pollutant Removal: Innovative materials, 2018: p. 227-252.

- Mu’azu, N.D., et al., Removal of phenolic compounds from water using sewage sludge-based activated carbon adsorption: a review. International journal of environmental research and public health, 2017. 14(10): p. 1094.

- Tsarpali, M., et al., Lipid-extracted algae as a source of biomaterials for algae biorefineries. Algal Research, 2021. 57: p. 102354.

- Mahboubi, A., et al., Waste-derived volatile fatty acids for sustainable ruminant feed supplementation, in Biomass, Biofuels, Biochemicals. 2022, Elsevier. p. 407-430.

- Yahya, M.A., Z. Al-Qodah, and C.Z. Ngah, Agricultural bio-waste materials as potential sustainable precursors used for activated carbon production: A review. Renewable and sustainable energy reviews, 2015. 46: p. 218-235.

- Heidarinejad, Z., et al., Methods for preparation and activation of activated carbon: a review. Environmental Chemistry Letters, 2020. 18: p. 393-415.

- Harish, V., et al., Cutting-edge advances in tailoring size, shape, and functionality of nanoparticles and nanostructures: A review. Journal of the Taiwan Institute of Chemical Engineers, 2023. 149: p. 105010.

- Yap, Y.W., et al., Recent advances in synthesis of graphite from agricultural bio-waste material: A review. Materials, 2023. 16(9): p. 3601.

- Seow, Y.X., et al., A review on biochar production from different biomass wastes by recent carbonization technologies and its sustainable applications. Journal of Environmental Chemical Engineering, 2022. 10(1): p. 107017.

- Gupta, G.K., et al., Excellent supercapacitive performance of graphene quantum dots derived from a bio-waste marigold flower (Tagetes erecta). International Journal of Hydrogen Energy, 2021. 46(77): p. 38416-38424.

- Zhu, R., et al., Analysis of factors influencing pore structure development of agricultural and forestry waste-derived activated carbon for adsorption application in gas and liquid phases: A review. Journal of Environmental Chemical Engineering, 2021. 9(5): p. 105905.

- Muniandy, L., et al., The synthesis and characterization of high purity mixed microporous/mesoporous activated carbon from rice husk using chemical activation with NaOH and KOH. Microporous and Mesoporous Materials, 2014. 197: p. 316-323.

- Gupta, G.K., et al., In situ fabrication of activated carbon from a bio-waste desmostachya bipinnata for the improved supercapacitor performance. Nanoscale research letters, 2021. 16(1): p. 85.

- Gao, Y., et al., Insight into activated carbon from different kinds of chemical activating agents: A review. Science of the Total Environment, 2020. 746: p. 141094.

- Sagar, P., et al., Tagetes erecta as an organic precursor: synthesis of highly fluorescent CQDs for the micromolar tracing of ferric ions in human blood serum. RSC advances, 2021. 11(32): p. 19924-19934.

- Gupta, G.K., et al., Hierarchical NiMn Double Layered/Graphene with Excellent Energy Density for Highly Capacitive Supercapacitors. 2021.

- Gupta, G.K., Development of grapheme Ni Mn layered nanosheets for ultra highSupercapacitance and its performance.

- Feng, J., et al., Polyarylacetylene as a novel graphitizable precursor for fabricating high-density C/C composite via ultra-high pressure impregnation and carbonization. Journal of Materials Science & Technology, 2024. 182: p. 198-209.

- Zhang, Y., et al., Ultra-high surface area and nitrogen-rich porous carbons prepared by a low-temperature activation method with superior gas selective adsorption and outstanding supercapacitance performance. Chemical Engineering Journal, 2019. 355: p. 309-319.

- Wu, F.-c., R.-L. Tseng, and C.-C. Hu, Comparisons of pore properties and adsorption performance of KOH-activated and steam-activated carbons. Microporous and Mesoporous Materials, 2005. 80(1-3): p. 95-106.

- Jha, M.K., et al., Surface modified activated carbons: Sustainable bio-based materials for environmental remediation. Nanomaterials, 2021. 11(11): p. 3140.

- Panahi, H.K.S., et al., A comprehensive review of engineered biochar: production, characteristics, and environmental applications. Journal of cleaner production, 2020. 270: p. 122462.

- Sodhi, A.S., et al., Insights on sustainable approaches for production and applications of value added products. Chemosphere, 2022. 286: p. 131623.

- Ngo, T.C.Q., et al., An insight on Vietnamese bio-waste materials as activated carbon precursors for multiple applications in environmental protection. Open Chemistry, 2022. 20(1): p. 618-626.

- Swetha, T.A., et al., A comprehensive review on techniques used in conversion of biomass into bioeconomy. Sustainable Energy Technologies and Assessments, 2022. 53: p. 102682.

- Sharma, M., P. Dangi, and M. Choudhary, Actinomycetes: source, identification, and their applications. International Journal of Current Microbiology and Applied Sciences, 2014. 3(2): p. 801-832.

- Jjagwe, J., et al., Synthesis and application of granular activated carbon from biomass waste materials for water treatment: A review. Journal of Bioresources and Bioproducts, 2021. 6(4): p. 292-322.

- Li, L., P.A. Quinlivan, and D.R. Knappe, Effects of activated carbon surface chemistry and pore structure on the adsorption of organic contaminants from aqueous solution. Carbon, 2002. 40(12): p. 2085-2100.

- Sudibandriyo, M., et al., Adsorption of methane, nitrogen, carbon dioxide, and their binary mixtures on dry activated carbon at 318.2 K and pressures up to 13.6 MPa. Langmuir, 2003. 19(13): p. 5323-5331.

- Bouchelkia, N., et al., Jujube stones based highly efficient activated carbon for methylene blue adsorption: Kinetics and isotherms modeling, thermodynamics and mechanism study, optimization via response surface methodology and machine learning approaches. Process Safety and Environmental Protection, 2023. 170: p. 513-535.

- Choma, J., J. Jagiello, and M. Jaroniec, Assessing the contribution of micropores and mesopores from nitrogen adsorption on nanoporous carbons: Application to pore size analysis. Carbon, 2021. 183: p. 150-157.

- Pelekani, C. and V.L. Snoeyink, A kinetic and equilibrium study of competitive adsorption between atrazine and Congo red dye on activated carbon: the importance of pore size distribution. Carbon, 2001. 39(1): p. 25-37.

- Shi, K., E.E. Santiso, and K.E. Gubbins, Current advances in characterization of nano-porous materials: Pore size distribution and surface area. Porous Materials: Theory and Its Application for Environmental Remediation, 2021: p. 315-340.

- Nishi, Y. and M. Inagaki, Gas adsorption/desorption isotherm for pore structure characterization, in Materials Science and Engineering of Carbon. 2016, Elsevier. p. 227-247.

- Chen, J.H., et al., Adsorption and desorption of carbon dioxide onto and from activated carbon at high pressures. Industrial & engineering chemistry research, 1997. 36(7): p. 2808-2815.

- Sing, K.S., Adsorption methods for the characterization of porous materials. Advances in colloid and interface science, 1998. 76: p. 3-11.

- Kruk, M., M. Jaroniec, and J. Choma, Comparative analysis of simple and advanced sorption methods for assessment of microporosity in activated carbons. Carbon, 1998. 36(10): p. 1447-1458.

- Stoeckli, F., et al., The comparison of experimental and calculated pore size distributions of activated carbons. Carbon, 2002. 40(3): p. 383-388.

- Far, H.M., et al., Advanced pore characterization and adsorption of light gases over aerogel-derived activated carbon. Microporous and Mesoporous Materials, 2021. 313: p. 110833.

- Liu, X. and Y. Wang, Activated carbon supported nanoscale zero-valent iron composite: aspects of surface structure and composition. Materials Chemistry and Physics, 2019. 222: p. 369-376.

- Alvarez, A., N. Passé-Coutrin, and S. Gaspard, Determination of the textural characteristics of carbon samples using scanning electronic microscopy images: Comparison with mercury porosimetry data. Adsorption, 2013. 19(2): p. 841-850.

- Pereira, M.F.R., et al., Adsorption of dyes on activated carbons: influence of surface chemical groups. Carbon, 2003. 41(4): p. 811-821.

- Dastgheib, S.A., T. Karanfil, and W. Cheng, Tailoring activated carbons for enhanced removal of natural organic matter from natural waters. Carbon, 2004. 42(3): p. 547-557.

- Gómez-Serrano, V., et al., Oxidation of activated carbon by hydrogen peroxide. Study of surface functional groups by FT-ir. Fuel, 1994. 73(3): p. 387-395.

- Fuente, E., et al., Infrared spectroscopy of carbon materials: a quantum chemical study of model compounds. The Journal of physical chemistry B, 2003. 107(26): p. 6350-6359.

- Dandekar, A., R. Baker, and M. Vannice, Characterization of activated carbon, graphitized carbon fibers and synthetic diamond powder using TPD and DRIFTS. Carbon, 1998. 36(12): p. 1821-1831.

- Chen, J.P. and S. Wu, Acid/base-treated activated carbons: characterization of functional groups and metal adsorptive properties. Langmuir, 2004. 20(6): p. 2233-2242.

- Sandler, S.R. and W. Karo, Organic functional group preparations. 2013.

- Park, S.H., et al., Surface and bulk measurements of metals deposited on activated carbon. Chemistry of materials, 1997. 9(1): p. 176-183.

- Biniak, S., et al., The characterization of activated carbons with oxygen and nitrogen surface groups. Carbon, 1997. 35(12): p. 1799-1810.

- Figueiredo, J.L., et al., Modification of the surface chemistry of activated carbons. carbon, 1999. 37(9): p. 1379-1389.

- Liu, S., et al., Oxygen functional groups in graphitic carbon nitride for enhanced photocatalysis. Journal of colloid and interface science, 2016. 468: p. 176-182.

- Hakim, A., et al., Temperature programmed desorption of carbon dioxide for activated carbon supported nickel oxide: The adsorption and desorption studies. Advanced Materials Research, 2015. 1087: p. 45-49.

- Ataman, E., et al., Functional group adsorption on calcite: I. Oxygen containing and nonpolar organic molecules. The Journal of Physical Chemistry C, 2016. 120(30): p. 16586-16596.

- López, D., et al., Low-temperature catalytic adsorption of NO on activated carbon materials. Langmuir, 2007. 23(24): p. 12131-12137.

- Qiu, C., et al., Effects of oxygen-containing functional groups on carbon materials in supercapacitors: A review. Materials & Design, 2023: p. 111952.

- Dittmann, D., et al., Characterization of activated carbons for water treatment using TGA-FTIR for analysis of oxygen-containing functional groups. Applied Water Science, 2022. 12(8): p. 203.

- Carabineiro, S.A., et al., Surface chemistry of activated carbons. Chemical Physics Research Journal, 2011. 4(3/4): p. 291.

- Sun, W., et al., High-performance activated carbons for electrochemical double layer capacitors: Effects of morphology and porous structures. International Journal of Energy Research, 2020. 44(3): p. 1930-1950.

- MiarAlipour, S., et al., TiO2/porous adsorbents: Recent advances and novel applications. Journal of hazardous materials, 2018. 341: p. 404-423.

- Achaw, O.-W., A study of the porosity of activated carbons using the scanning electron microscope, in Scanning electron microscopy. 2012, IntechOpen.

- Ismail, I.M. and P. Pfeifer, Fractal analysis and surface roughness of nonporous carbon fibers and carbon blacks. Langmuir, 1994. 10(5): p. 1532-1538.

- Jurkiewicz, K., M. Pawlyta, and A. Burian, Structure of carbon materials explored by local transmission electron microscopy and global powder diffraction probes. C, 2018. 4(4): p. 68.

- Teimouri, Z., et al., Application of computational fluid dynamics for modeling of Fischer-Tropsch synthesis as a sustainable energy resource in different reactor configurations: A review. Renewable and Sustainable Energy Reviews, 2022. 160: p. 112287.

- Punyapalakul, P., et al., Effects of surface functional groups and porous structures on adsorption and recovery of perfluorinated compounds by inorganic porous silicas. Separation Science and Technology, 2013. 48(5): p. 775-788.

- Feiqiang, G., et al., Characteristics and toxic dye adsorption of magnetic activated carbon prepared from biomass waste by modified one-step synthesis. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2018. 555: p. 43-54.

- Tautz, F., Structure and bonding of large aromatic molecules on noble metal surfaces: The example of PTCDA. Progress in Surface Science, 2007. 82(9-12): p. 479-520.

- Li, X., et al., Adsorption materials for volatile organic compounds (VOCs) and the key factors for VOCs adsorption process: A review. Separation and Purification Technology, 2020. 235: p. 116213.

- Sing, K., The use of nitrogen adsorption for the characterisation of porous materials. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2001. 187: p. 3-9.

- Ahmad, S.Z.N., et al., Adsorptive removal of heavy metal ions using graphene-based nanomaterials: Toxicity, roles of functional groups and mechanisms. Chemosphere, 2020. 248: p. 126008.

- Awad, R., et al., Synthesis and characterization of electrospun PAN-based activated carbon nanofibers reinforced with cellulose nanocrystals for adsorption of VOCs. Chemical Engineering Journal, 2021. 410: p. 128412.

- Sirotkin, A.S., L.Y. Koshkina, and K.G. Ippolitov, The BAC-process for treatment of waste water containing non-ionogenic synthetic surfactants. Water Research, 2001. 35(13): p. 3265-3271.

- Wong, K.J., et al., Shining light on carbon aerogel photocatalysts: unlocking the potentials in the quest for revolutionizing solar-to-chemical conversion and environmental remediation. Advanced Functional Materials, 2023. 33(50): p. 2306014.

- Gopalan, J., A. Buthiyappan, and A.A.A. Raman, Insight into metal-impregnated biomass based activated carbon for enhanced carbon dioxide adsorption: A review. Journal of Industrial and Engineering Chemistry, 2022. 113: p. 72-95.

- Aktaş, Ö. and F. Çeçen, Bioregeneration of activated carbon: a review. International Biodeterioration & Biodegradation, 2007. 59(4): p. 257-272.

- Dong, L., et al., Preparation, characterization, and application of macroporous activated carbon (MAC) suitable for the BAC water treatment process. Science of the total environment, 2019. 647: p. 1359-1367.

- Wang, Y., et al., Precise preparation of biomass-based porous carbon with pore structure-dependent VOCs adsorption/desorption performance by bacterial pretreatment and its forming process. Environmental Pollution, 2023. 322: p. 121134.

- Javanbakht, V., S.A. Alavi, and H. Zilouei, Mechanisms of heavy metal removal using microorganisms as biosorbent. Water Science and Technology, 2014. 69(9): p. 1775-1787.

- Jang, M.-H., et al., Elucidating Adsorption Mechanisms of Benzalkonium Chlorides (BACs) on Polypropylene and Polyethylene Terephthalate Microplastics (MPs): Effects of BACs Alkyl Chain Length and MPs Characteristics. Journal of Hazardous Materials, 2024: p. 133765.

- Tefera, D.T., et al., Modeling competitive adsorption of mixtures of volatile organic compounds in a fixed-bed of beaded activated carbon. Environmental science & technology, 2014. 48(9): p. 5108-5117.

- Bayramoglu, G., B. Altintas, and M.Y. Arica, Adsorption kinetics and thermodynamic parameters of cationic dyes from aqueous solutions by using a new strong cation-exchange resin. Chemical Engineering Journal, 2009. 152(2-3): p. 339-346.

- Zhang, Y., et al., Effects of ionic strength on removal of toxic pollutants from aqueous media with multifarious adsorbents: A review. Science of the Total Environment, 2019. 646: p. 265-279.

- Bhatnagar, A., et al., An overview of the modification methods of activated carbon for its water treatment applications. Chemical Engineering Journal, 2013. 219: p. 499-511.

- Rathi, B.S. and P.S. Kumar, Application of adsorption process for effective removal of emerging contaminants from water and wastewater. Environmental Pollution, 2021. 280: p. 116995.

- Peng, X., et al., Amine-functionalized magnetic bamboo-based activated carbon adsorptive removal of ciprofloxacin and norfloxacin: A batch and fixed-bed column study. Bioresource technology, 2018. 249: p. 924-934.

- Korotta-Gamage, S.M. and A. Sathasivan, A review: Potential and challenges of biologically activated carbon to remove natural organic matter in drinking water purification process. Chemosphere, 2017. 167: p. 120-138.

- Moyo, F., et al., Sorption of hydrophobic organic compounds on natural sorbents and organoclays from aqueous and non-aqueous solutions: a mini-review. International Journal of Environmental Research and Public Health, 2014. 11(5): p. 5020-5048.

- Ewis, D., et al., Adsorption of organic water pollutants by clays and clay minerals composites: A comprehensive review. Applied Clay Science, 2022. 229: p. 106686.

- Ayati, A., et al., Insight into the adsorptive removal of ibuprofen using porous carbonaceous materials: A review. Chemosphere, 2023. 323: p. 138241.

- Yang, H., et al., The approaches and prospects for natural organic matter-derived disinfection byproducts control by carbon-based materials in water disinfection progresses. Journal of Cleaner Production, 2021. 311: p. 127799.

- Dong, L., et al., A new function of spent activated carbon in BAC process: Removing heavy metals by ion exchange mechanism. Journal of hazardous materials, 2018. 359: p. 76-84.

- Yaashikaa, P.R., et al., Advances in biosorbents for removal of environmental pollutants: a review on pretreatment, removal mechanism and future outlook. Journal of Hazardous Materials, 2021. 420: p. 126596.

- Zhou, Y.-F. and R.J. Haynes, Sorption of heavy metals by inorganic and organic components of solid wastes: significance to use of wastes as low-cost adsorbents and immobilizing agents. Critical Reviews in Environmental Science and Technology, 2010. 40(11): p. 909-977.

- Gupta, K., et al., Recent advances in adsorptive removal of heavy metal and metalloid ions by metal oxide-based nanomaterials. Coordination Chemistry Reviews, 2021. 445: p. 214100.

- Kumar, S. and S. Jain, History, introduction, and kinetics of ion exchange materials. Journal of chemistry, 2013. 2013.

- Luo, T., S. Abdu, and M. Wessling, Selectivity of ion exchange membranes: A review. Journal of membrane science, 2018. 555: p. 429-454.

- Kim, S., et al., Removal of contaminants of emerging concern by membranes in water and wastewater: A review. Chemical Engineering Journal, 2018. 335: p. 896-914.

- Cukierman, A.L., G.V. Nunell, and P.R. Bonelli, Removal of emerging pollutants from water through adsorption onto carbon-based materials, in Emerging and nanomaterial contaminants in wastewater. 2019, Elsevier. p. 159-213.

- Ahmed, S., et al., Recent developments in physical, biological, chemical, and hybrid treatment techniques for removing emerging contaminants from wastewater. Journal of hazardous materials, 2021. 416: p. 125912.

- Loganathan, P., et al., Treatment trends and combined methods in removing pharmaceuticals and personal care products from wastewater—A review. Membranes, 2023. 13(2): p. 158.

- Reyes, N.J.D., et al., Pharmaceutical and personal care products in different matrices: occurrence, pathways, and treatment processes. Water, 2021. 13(9): p. 1159.

- Gao, X., et al., Environment-friendly removal methods for endocrine disrupting chemicals. Sustainability, 2020. 12(18): p. 7615.

- Wang, S., et al., A review of advances in EDCs and PhACs removal by nanofiltration: Mechanisms, impact factors and the influence of organic matter. Chemical Engineering Journal, 2021. 406: p. 126722.

- Zamri, M.F.M.A., et al., Treatment strategies for enhancing the removal of endocrine-disrupting chemicals in water and wastewater systems. Journal of Water Process Engineering, 2021. 41: p. 102017.

- Yuan, Z., R. Nag, and E. Cummins, Human health concerns regarding microplastics in the aquatic environment-From marine to food systems. Science of The Total Environment, 2022. 823: p. 153730.

- El Batouti, M., N.F. Alharby, and M.M. Elewa, Review of new approaches for fouling mitigation in membrane separation processes in water treatment applications. Separations, 2021. 9(1): p. 1.

- Joseph, L., et al., Removal of contaminants of emerging concern by metal-organic framework nanoadsorbents: A review. Chemical Engineering Journal, 2019. 369: p. 928-946.

- Iwuozor, K.O., Prospects and challenges of using coagulation-flocculation method in the treatment of effluents. Advanced Journal of Chemistry-Section A, 2019. 2(2): p. 105-127.

- Zahrim, A., C. Tizaoui, and N. Hilal, Coagulation with polymers for nanofiltration pre-treatment of highly concentrated dyes: a review. Desalination, 2011. 266(1-3): p. 1-16.

- Mayer, B.K. and D.R. Ryan, Impact on disinfection byproducts using advanced oxidation processes for drinking water treatment. Applications of advanced oxidation processes (AOPs) in drinking water treatment, 2019: p. 345-386.

- Deng, L., et al., Recent advances in attached growth membrane bioreactor systems for wastewater treatment. Science of The Total Environment, 2022. 808: p. 152123.

- Singh, G., et al., A review on the synthesis and applications of nanoporous carbons for the removal of complex chemical contaminants. Bulletin of the Chemical Society of Japan, 2021. 94(4): p. 1232-1257.

- Charcosset, C., Ultrafiltration, microfiltration, nanofiltration and reverse osmosis in integrated membrane processes. Integrated membrane systems and processes, 2016: p. 1-22.

- Das, P.P., M. Sharma, and M.K. Purkait, Recent progress on electrocoagulation process for wastewater treatment: A review. Separation and Purification Technology, 2022. 292: p. 121058.

- He, M., et al., Waste-derived biochar for water pollution control and sustainable development. Nature Reviews Earth & Environment, 2022. 3(7): p. 444-460.

- Liu, C., et al., Comparison of two typical regeneration methods to the spent biological activated carbon in drinking water. Environmental Science and Pollution Research, 2020. 27: p. 16404-16414.

- Ossai, I.C., et al., Remediation of soil and water contaminated with petroleum hydrocarbon: A review. Environmental Technology & Innovation, 2020. 17: p. 100526.

- Larasati, A., G.D. Fowler, and N.J. Graham, Insights into chemical regeneration of activated carbon for water treatment. Journal of Environmental Chemical Engineering, 2021. 9(4): p. 105555.

- Wells, M.J., Principles of extraction and the extraction of semivolatile organics from liquids. Sample preparation techniques in analytical chemistry, 2003. 162: p. 37-138.

- Płotka-Wasylka, J., et al., Extraction with environmentally friendly solvents. TrAC Trends in Analytical Chemistry, 2017. 91: p. 12-25.

- Biswal, B.K. and R. Balasubramanian, Constructed wetlands for reclamation and reuse of wastewater and urban stormwater: A review. Frontiers in Environmental Science, 2022. 10: p. 836289.

- Yakamercan, E., et al., Comprehensive understanding of electrochemical treatment systems combined with biological processes for wastewater remediation. Environmental Pollution, 2023: p. 121680.

- Radjenovic, J. and D.L. Sedlak, Challenges and opportunities for electrochemical processes as next-generation technologies for the treatment of contaminated water. Environmental science & technology, 2015. 49(19): p. 11292-11302.

- Bao, J., et al., Sonoactivated Nanomaterials: A potent armament for wastewater treatment. Ultrasonics Sonochemistry, 2023. 99: p. 106569.

- Cigeroglu, Z., et al., Clay-based nanomaterials and their adsorptive removal efficiency for dyes and antibiotics: a review. Materials Today Sustainability, 2024: p. 100735.

- Loganathan, P., et al., Ozonation/adsorption hybrid treatment system for improved removal of natural organic matter and organic micropollutants from water–A mini review and future perspectives. Chemosphere, 2022. 296: p. 133961.

- Gkotsis, P.K., et al., Fouling issues in membrane bioreactors (MBRs) for wastewater treatment: major mechanisms, prevention and control strategies. Processes, 2014. 2(4): p. 795-866.

- Lord, A.S., P.H. Kobos, and D.J. Borns, Geologic storage of hydrogen: Scaling up to meet city transportation demands. International journal of hydrogen energy, 2014. 39(28): p. 15570-15582.

- Gavrilescu, M., et al., Emerging pollutants in the environment: present and future challenges in biomonitoring, ecological risks and bioremediation. New biotechnology, 2015. 32(1): p. 147-156.

- Adeleye, A.T., et al., Efficient synthesis of bio-based activated carbon (AC) for catalytic systems: A green and sustainable approach. Journal of Industrial and Engineering Chemistry, 2021. 96: p. 59-75.

- Nidheesh, P. and M.S. Kumar, An overview of environmental sustainability in cement and steel production. Journal of cleaner production, 2019. 231: p. 856-871.

- Soares, N., et al., A review on current advances in the energy and environmental performance of buildings towards a more sustainable built environment. Renewable and Sustainable Energy Reviews, 2017. 77: p. 845-860.

- Gbedemah, F.S., Environmental management system (ISO 14001) certification in manufacturing companies in Ghana: prospects and challenges. 2004. Available online: http://www.lumes.lu.se/database/alumni/03.04/theses/gbedemah_francis.pdf.

- Gibson-Graham, J.-K., J. Cameron, and S. Healy, Take back the economy: An ethical guide for transforming our communities. 2013: U of Minnesota Press.

- Lee, J.-Y., S.-E. Lee, and D.-W. Lee, Current status and future prospects of biological routes to bio-based products using raw materials, wastes, and residues as renewable resources. Critical Reviews in Environmental Science and Technology, 2022. 52(14): p. 2453-2509.

- Kosamia, N.M., et al., Perspectives for scale up of biorefineries using biochemical conversion pathways: Technology status, techno-economic, and sustainable approaches. Fuel, 2022. 324: p. 124532.

- Kumar, V., et al., Valorization of Pulp and Paper Industry Waste Streams into Bioenergy and Value-added Products: An Integrated Biorefinery Approach. Renewable Energy, 2024: p. 120566.

- Andrews, R., Carbon Forward: Advanced Markets for Value-Added Products from Coal. 2021.

- Bottero, M., G. Cavana, and F. Dell’Anna, Feasibility analysis of the application of building automation and control system and their interaction with occupant behavior. Energy Efficiency, 2023. 16(8): p. 83.

- Chaukura, N., et al., Biosorbents for the removal of synthetic organics and emerging pollutants: opportunities and challenges for developing countries. Environmental Development, 2016. 19: p. 84-89.

- Maurya, A., M.K. Singh, and S. Kumar, Biofiltration technique for removal of waterborne pathogens, in Waterborne pathogens. 2020, Elsevier. p. 123-141.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).