1. Introduction

When analyzing the performance of rock blasting, the geometric (bench characteristics, drill mesh, hole length) and charging (specific charge, position of charges, bottom and column charge, decking) parameters dominate the design and prediction models; on the other hand the study of the influence of timing on rock fragmentation and downstream operations is not fully developed [

1].

Some of the research on the effects of timing on rock fragmentation is based on small-scale tests blasts [

2,

3,

4,

5]. [

2] performed small-scale tests in dolomite benches, using 0 to 45 ms delay intervals, equivalent to 0 to 118 ms/m of burden. Delay intervals of 3 to 56 ms/m of burden obtained the smallest particle sizes; coarse fragmentation resulted from short delays (<3 ms/m). In the short delay configuration, the breakage mechanism was similar to that of pre-splitting: fractures connecting the blast-holes and large blocks in the burden region. Coarse fragmentation also resulted from long delays (>57 ms/m): in this case there was no cooperation between charges and the blastholes broke the rock independently. [

3] considered the role of gas flow between fractures caused by the stress wave induced by the explosive. [

4] performed small-scale blasts in hard Canadian granite: coarse fragmentation results from, but the average fragment size does not change much once small delays are used. [

5] performed drop test to study the material grindability on three granites, comparing specimens blasted and not blasted; in conclusion blasting appears to reduce the work index by 5-11%. [

6] conducted eight experiments on granite bench blasting models employing double holes with delay times ranging from approximately 13 ms to 300 ms, finding an “optimal” inter-hole delay at 200 µs, where to simultaneous detonation, the median size was decreased by about 14.5% for the inter-hole delay of 200 µs; the same authors in [

7] conducted a similar test and found that, compared to short delay times such as 27.36 µs, x50 was improved by approximately 25% at the delay time of 180 µs. The results indicated a notable difference and substantial improvement in fragmentation when the delay times fell within the range of no-shock-wave interaction. [

8] conducted full-scale tests on short-delay blasting using electronic detonators to enhance the tensile effect of the stress wave tail. Field experiments revealed a 45.6% improvement in the mean size of fragments compared to blasts with longer delay times. [

9,

10] proposed an analytical solution for predicting the supersonic detonation of a cylindrically shaped explosive charge, which is suitable for numerical method . To validate the model, the authors conducted tests to investigate stress wave expansion from a detonating borehole and stress wave interactions with geological features such as discontinuities, interfaces, and cracks. Similar outputs were found by [

11]. [

12,

13] conducted tests in an open-pit limestone quarry, confirming that the right selection of delay timing can enhance fragmentation and, consequently, improve subsequent extraction processes. [

14] observed as that energy consumption at the primary crusher is the sum of two components depending by the distribution of the muckpile: the energy used for mechanical crushing and the energy used for winning the inertial resistances. [

15] discusses the limitation of electronic detonators, commenting that the delay time and initiation accuracy are not typical governing factors for blast performances; [

16] indicatively agrees with[

15] interacting stress waves have local impact, insignificant at the scale of the volume of fragmentation, therefore very short delay will not generate significant change in fragmentation. [

16] obtained experimental results, and [

17] numerical results, in agreement with [

15], where showed no significative differences in fragmentation where oibserved when there were shockwave interactions compared to no shockwave interaction.

This research studies through full-scale experimental approach the role of delays and delays density in blasts; the delay time is a constant, being 42ms as explained in the next section. Therefore, this study will not focus on the performance of different delay times nor on the shockwave’s interaction for different timing.

2. Materials and Methods

The research has been conducted at the Experimental Mine of the University of Sao Paulo, Brazil. The research constants are as follows:

The rock and rock mass: dolomitic marble, moderately fractured.

The explosive: emulsion in cartridges, 64 mm in diameter.

The holes diameter: 76 mm.

The initiation system: detonating cord 10 g/m.

The sequencing system: pyrotechnic connectors for det cord with delay of 42 ms.

It must be noted that the scattering of the real time of delays around its nominal time was considered as an unavoidable, systematic experimental error, present during all experiments, therefore analysis such as [

18] was not performed.

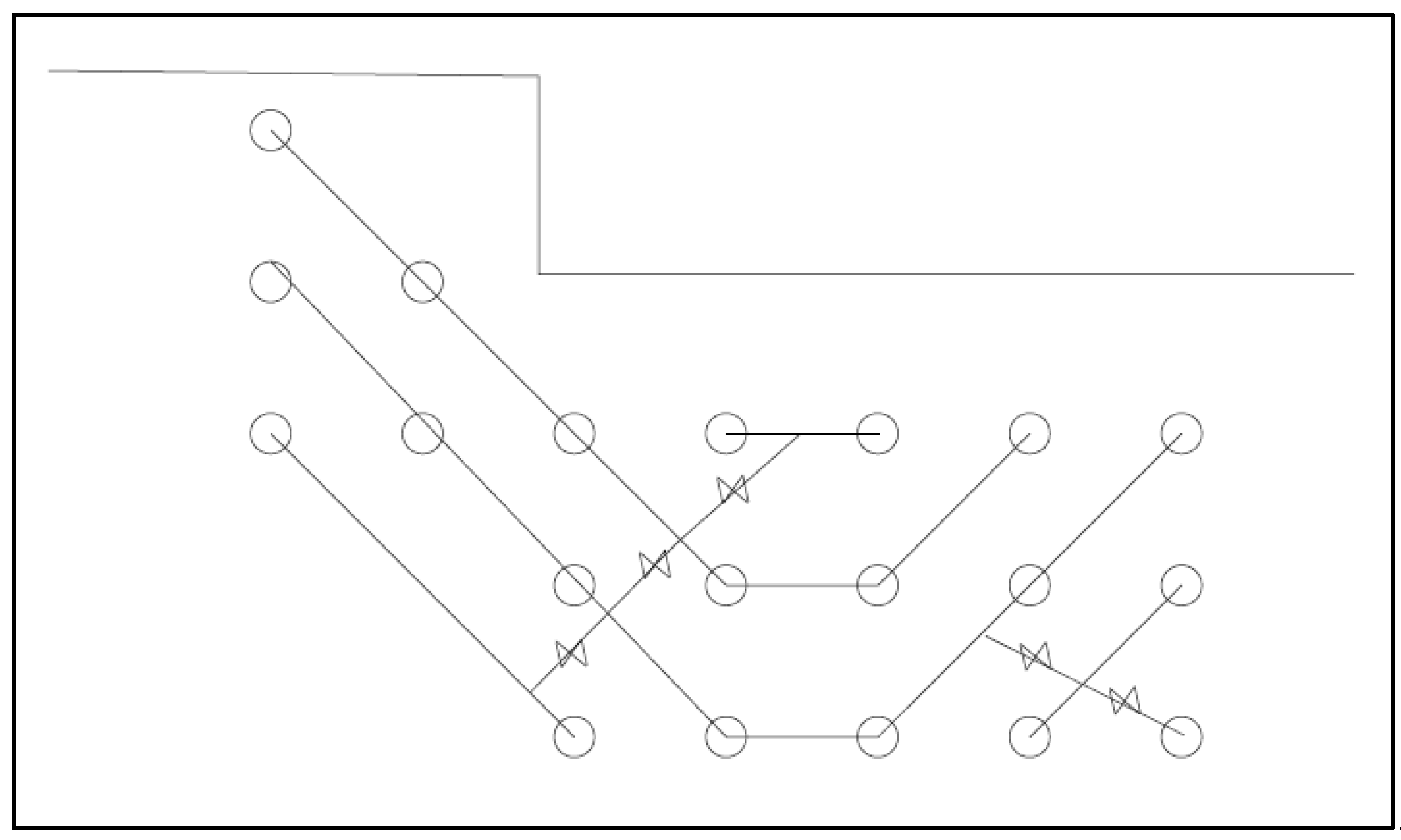

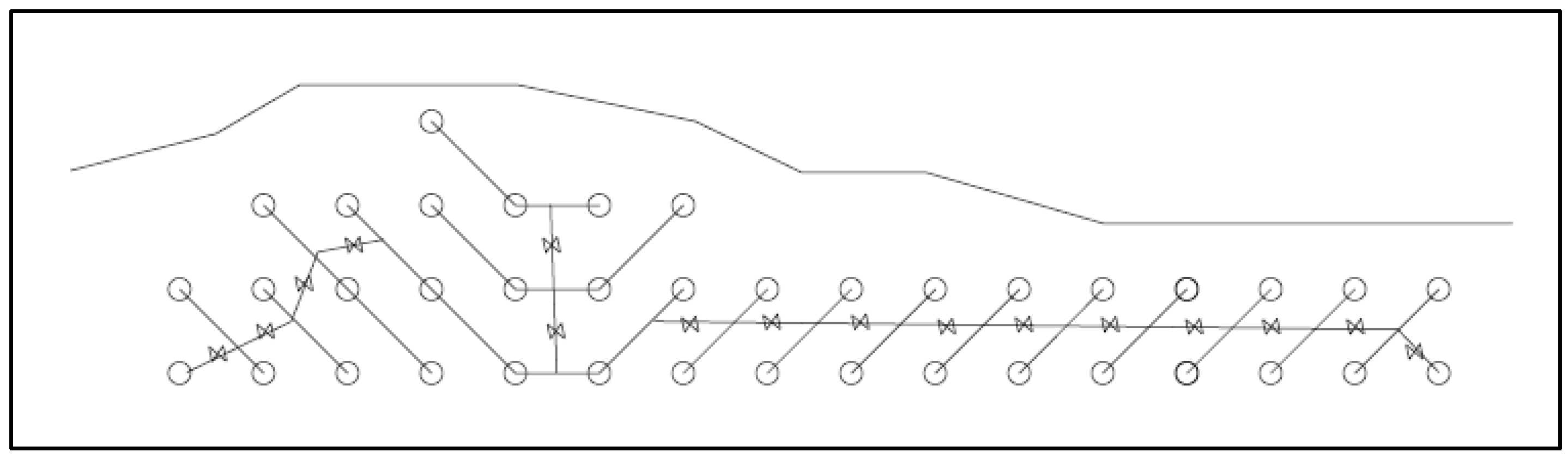

Figure 1 and

Figure 2 show two examples of blast plans with a typical distribution of delays as used during the research. All the experimental blasts took place at the last level of benches above the quarry floor; a panoramic view of this sector of the quarry is shown in

Figure 3.

All the blast tests took place at short distance one from the other, therefore the experimental medium (rock mass) can be considered as a constant. The characteristics of the intact rock are shown in

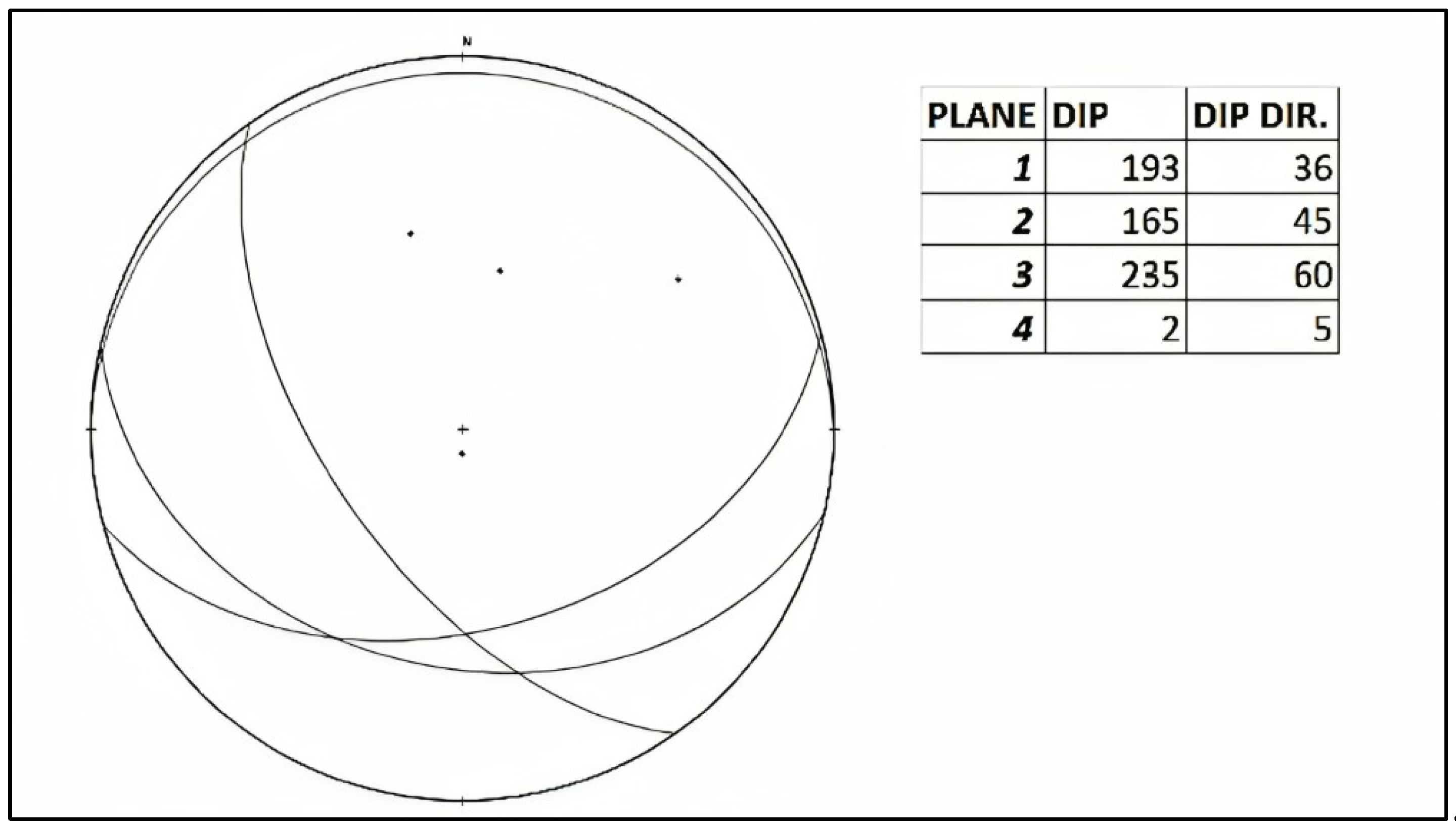

Table 1, in which are reported the ultimate compression strength (UCS), the Schmidt hammer rebound and the corrected point load test value (Is50). The main sets of discontinuities present in the rock mass are shown in

Figure 4.

Figure 4.

– Stereographic representation of the four main sets of discontinuities present in the rock mass where the blasts took place.

Figure 4.

– Stereographic representation of the four main sets of discontinuities present in the rock mass where the blasts took place.

Key Performance Indicators (KPIs) were collected and used to analyze the results. Said KPIs are reported in

Table 2, where their detailes description is given. Similar KPIs are used by Dragano et al., (2019) and Cardu et al., (2015).

3. Results

The results are summarized in charts reported from

Figure 5 to Figure 12. Each chart features a dashed line, not representing linear regression but serving as a visual indicator of the data trend on the scatterplot.

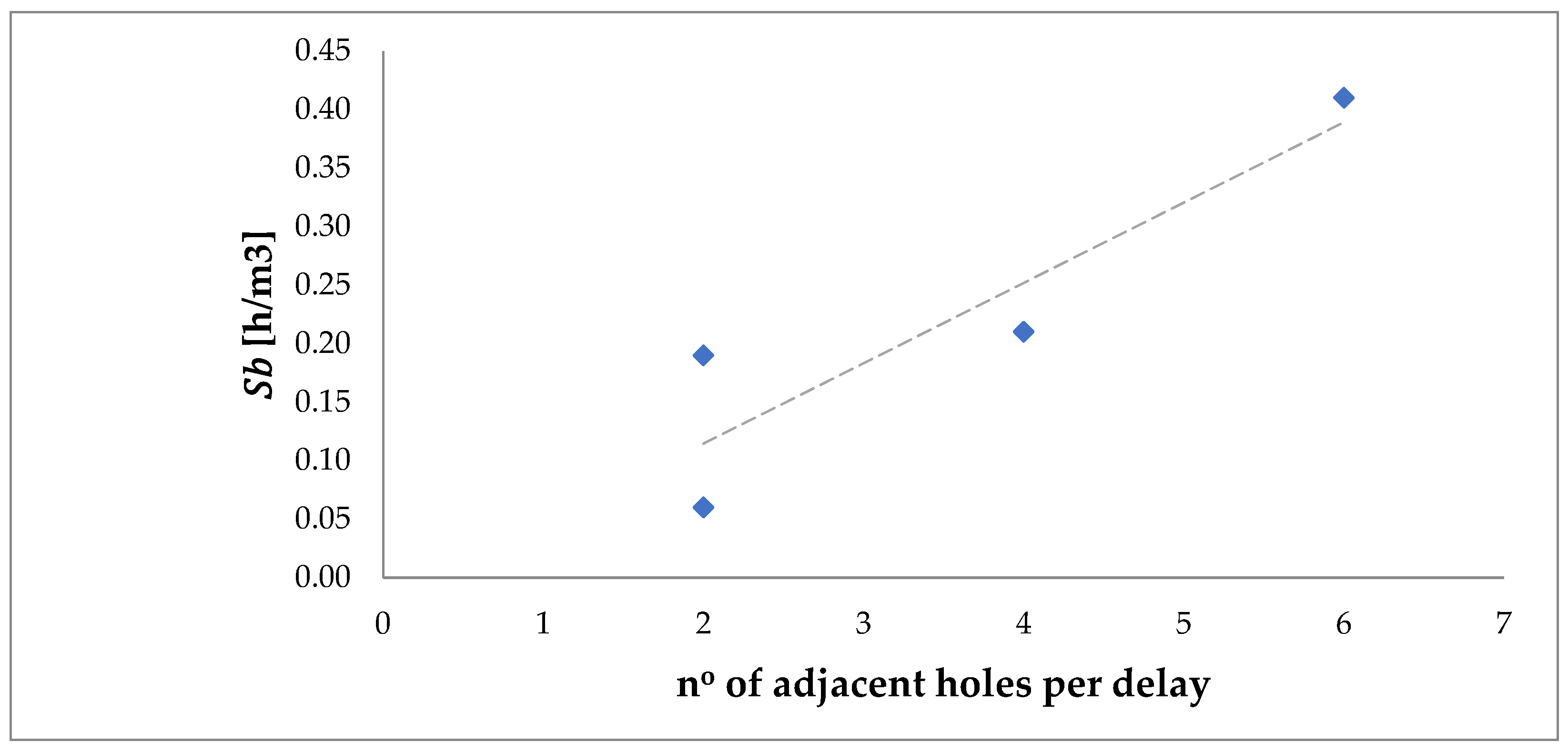

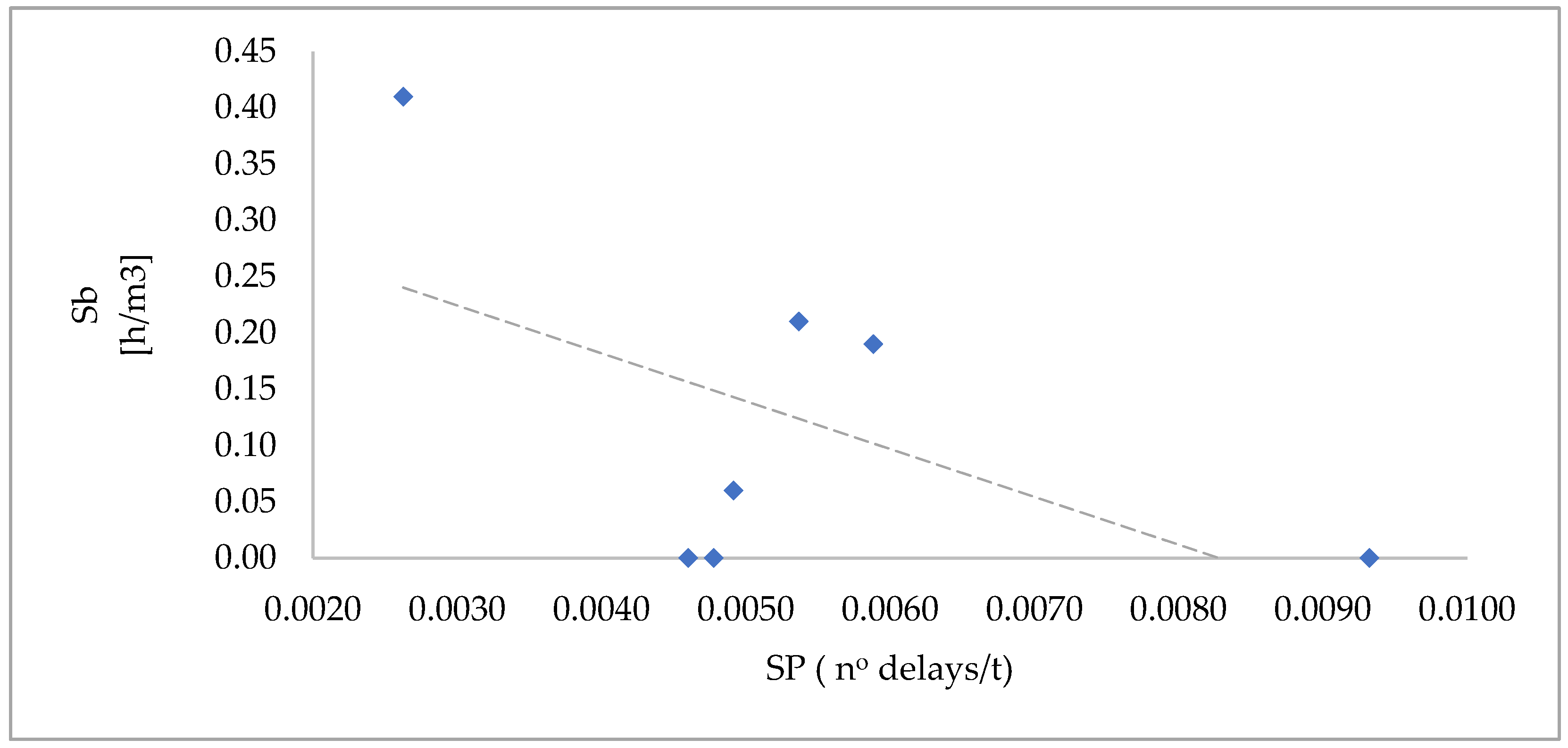

The incidence of the use of a hydraulic secondary breaker, quantified by S

b, is an indicator of the quality of fragmentation: the lower are the hours of operation of the hydraulic hammer per unit of volume of blasted rock, the better the fragmentation.

Figure 5 shows the increase in the use of hydraulic hammer at the increase of the number of adjacent holes blasted with the same delay.

Figure 4.

– The incidence of the use of a hydraulic secondary breaker in function of the number of adjacent holes per delay.

Figure 4.

– The incidence of the use of a hydraulic secondary breaker in function of the number of adjacent holes per delay.

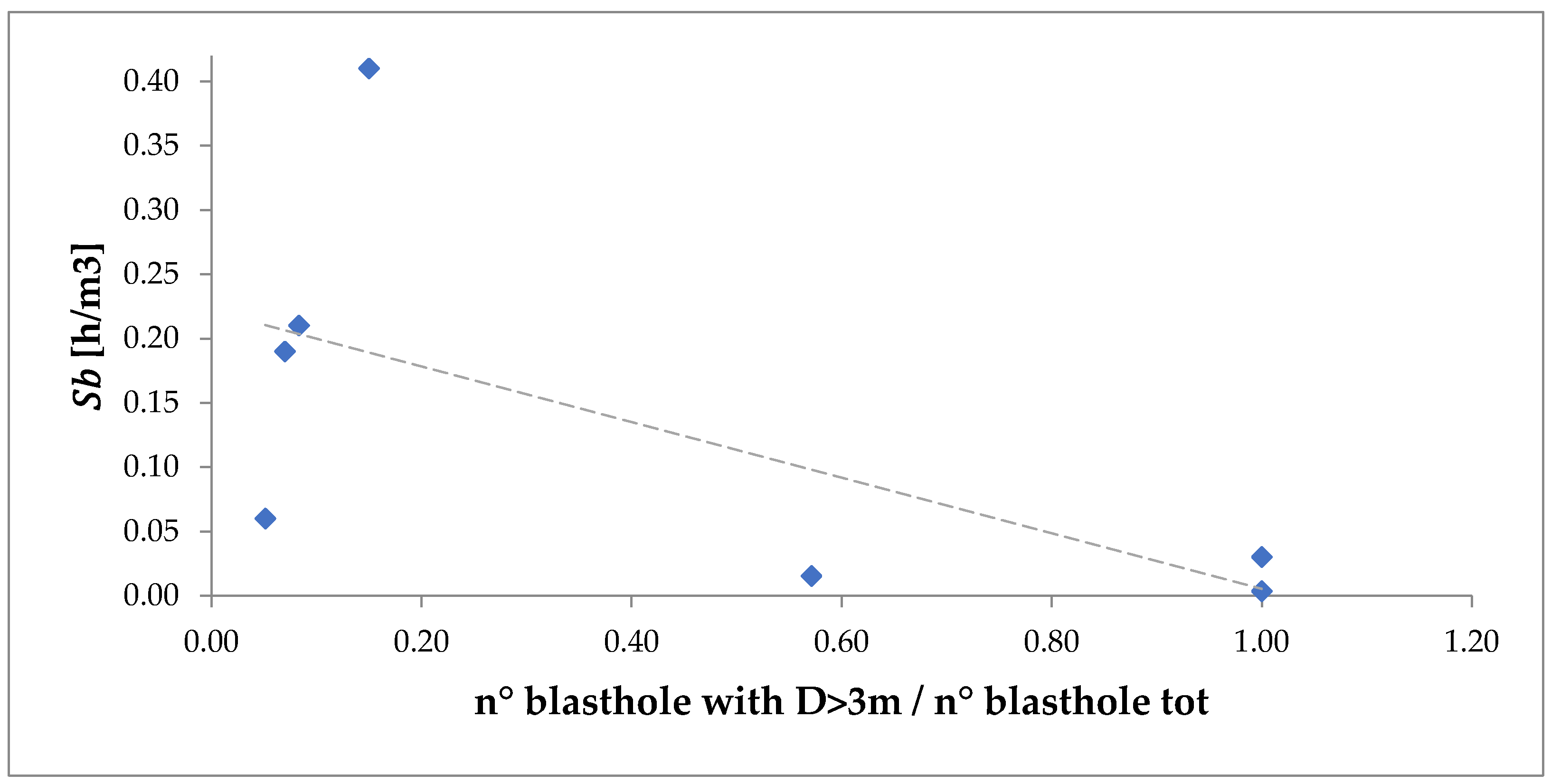

The experimental points reported in

Figure 6 show that increasing the blasthole density with D larger than 3 m (number of blasthole with D>3m normalized respect the total number of blasthole tends to 1), the value of S

b decrease considerably obtaining some experimental points close to 0.

Figure 5.

– The incidence of the use of a hydraulic secondary breaker in function of the number of adjacent holes per delay.

Figure 5.

– The incidence of the use of a hydraulic secondary breaker in function of the number of adjacent holes per delay.

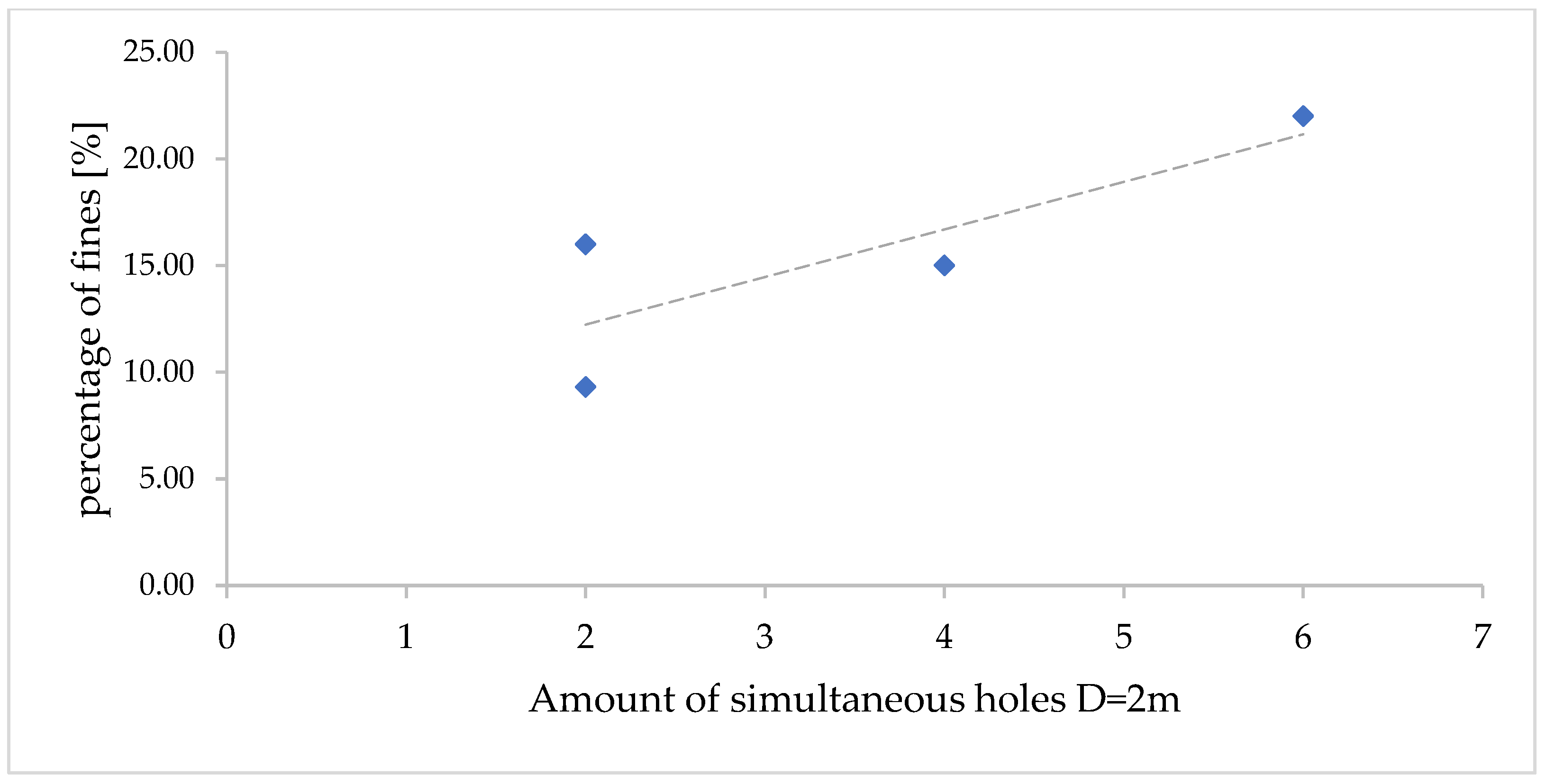

On the other hand,

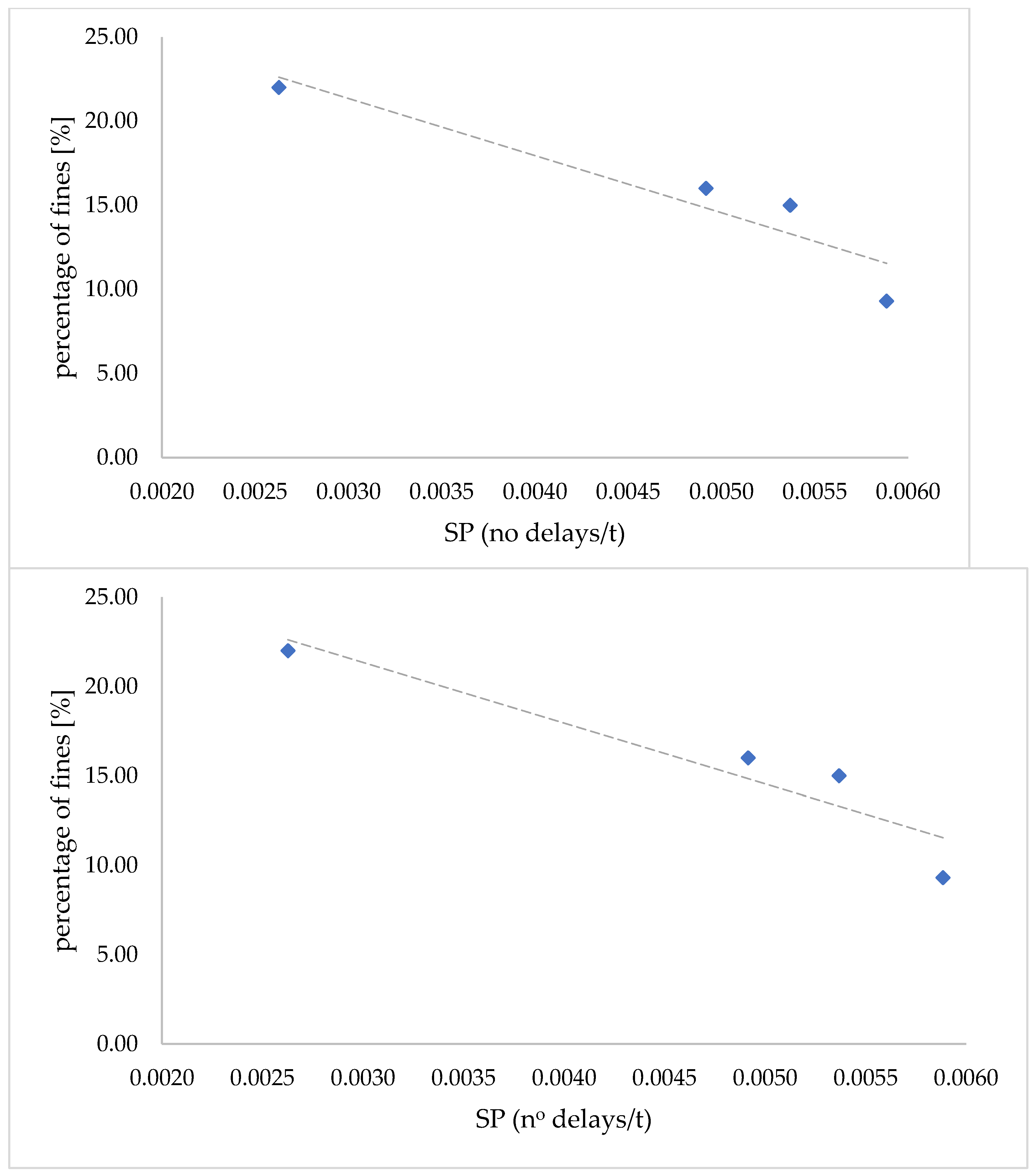

Figure 7 shows that increasing the density of blasthole with D=2 m increase in an approximately proportional way the quantity of fines produced; in other words, increasing the distance between simultaneous holes, it induces a better distribution of the explosive energy achieving more homogeneous fragmentation and lower value of fines.

Figure 6.

– The influence of the number of blast holes with D= 2m on the percentage of fines in the muckpile.

Figure 6.

– The influence of the number of blast holes with D= 2m on the percentage of fines in the muckpile.

These two combined results suggest that managing a better decomposition of the blast by increasing the distance between simultaneous holes can induce the explosive to work along the burden towards the free surface instead of along the spacing between holes, obtaining a more homogeneous fragmentation that reduces the production for coarser material and at the same time avoids the excess of fines.

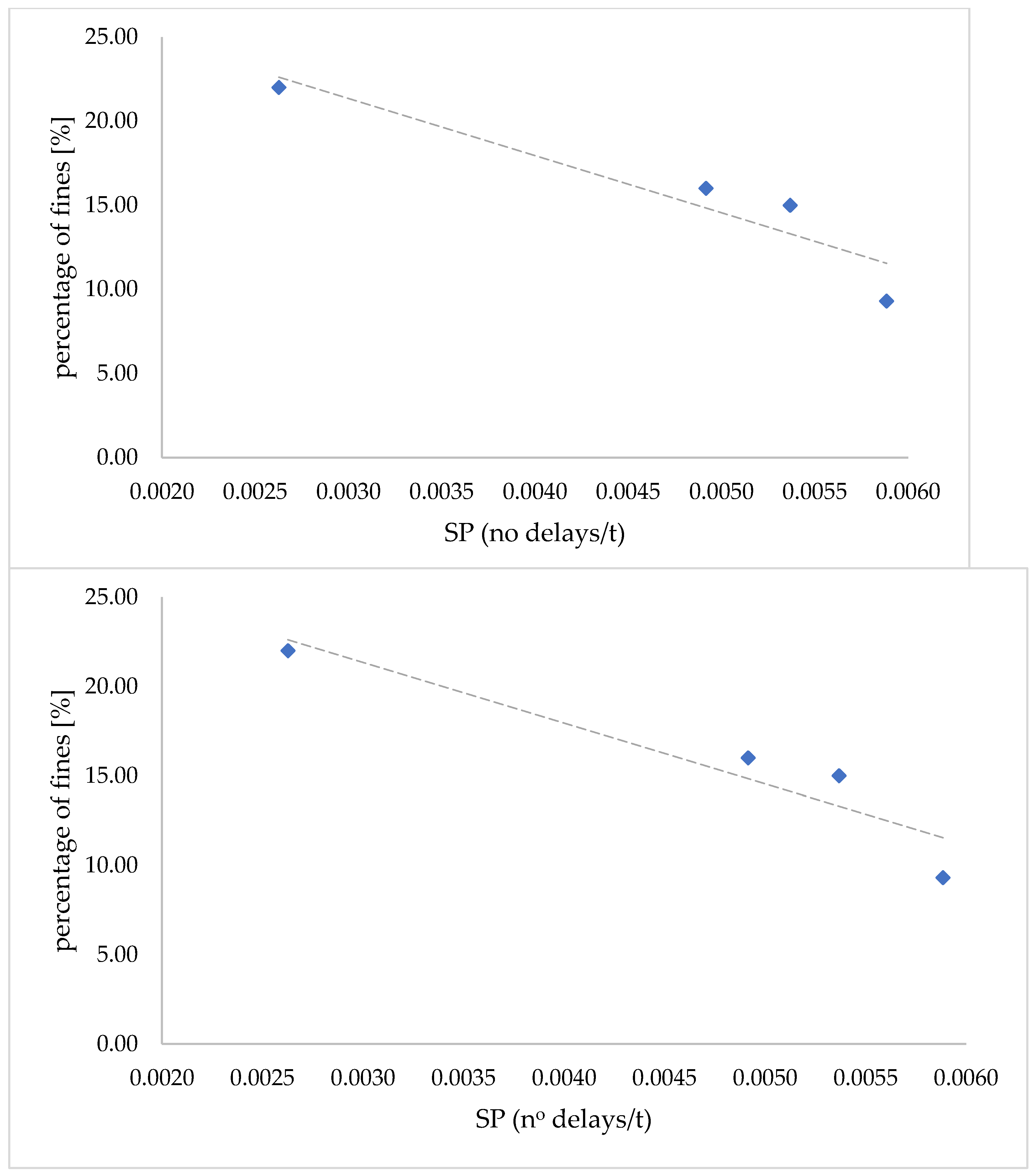

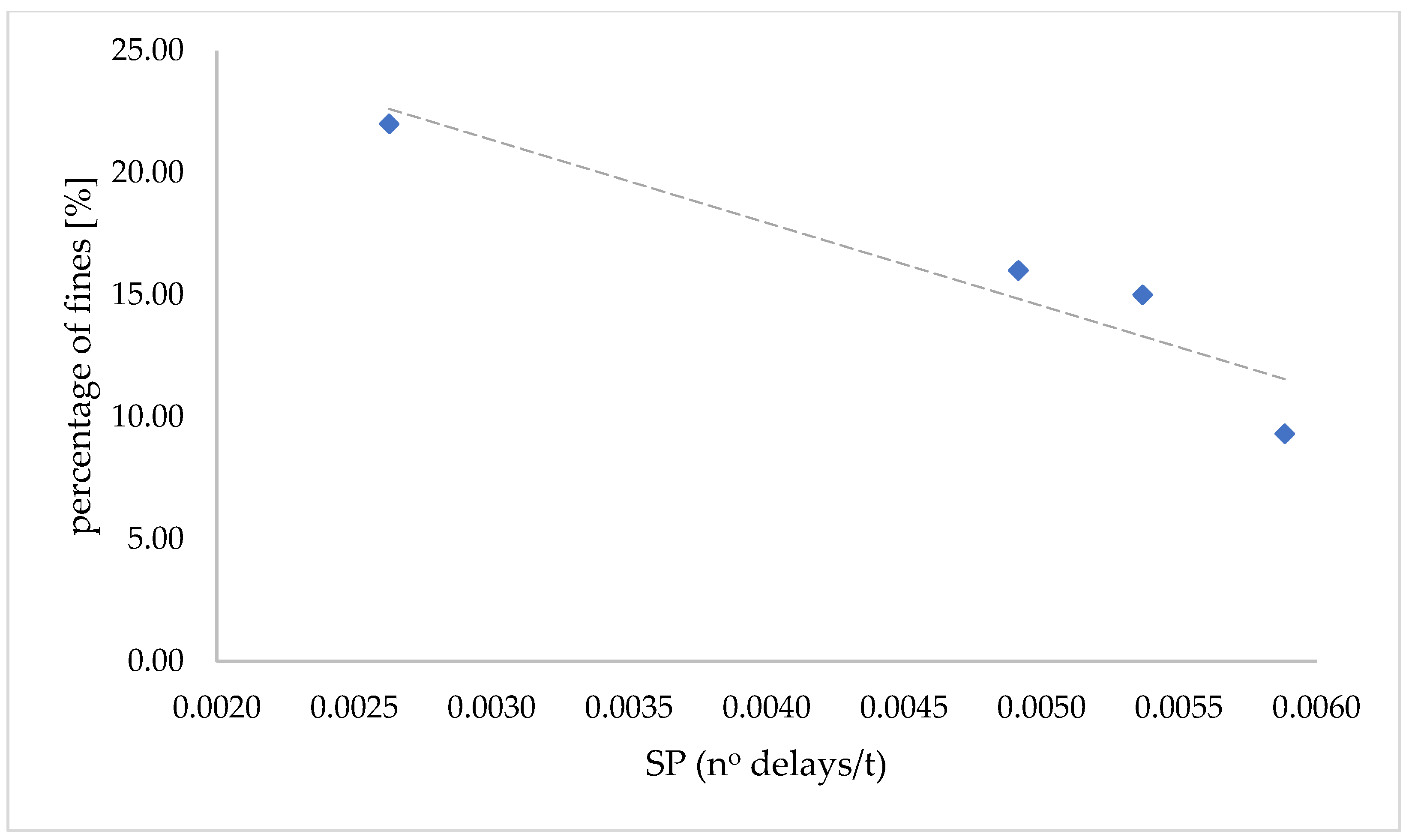

Figure 7 shows a decreasing in the percentage of fines at the increase of the density of delay. Under the same condition, increasing of SP dramatically decreases the particle size, in the preset study quantified through P80, as seen in the trend of

Figure 8.

Figure 7.

– When more delays are used per unit of blasted rock, less fines result from the blast. Definition of “fines”: material passing a mesh of 5mm.

Figure 7.

– When more delays are used per unit of blasted rock, less fines result from the blast. Definition of “fines”: material passing a mesh of 5mm.

Figure 8.

– Increasing the specific priming (number of delays per ton of blasted rock) dramatically decreases the particle size.

Figure 8.

– Increasing the specific priming (number of delays per ton of blasted rock) dramatically decreases the particle size.

These two combined results indicate the same behavior as discussed above: managing a better decomposition of the blast by increasing the distance between simultaneous holes can induce the explosive to work along the burden towards the free surface instead along the spacing between holes, obtaining a more homogeneous fragmentation that reduces the production for coarser material and at the same time avoids the excess of fines. On the other hand, simultaneous holes at close distance can create a cooperation of charges along the line connecting the two holes axes: this that may induce the explosive energy to work along the surface between the holes with shear effect instead of producing fragmentation. Increasing the distance between simultaneous holes reduces the possibility of creating a shear effect, inducing the explosive energy to work on the line of least energy (the burden) to produce fragmentation.

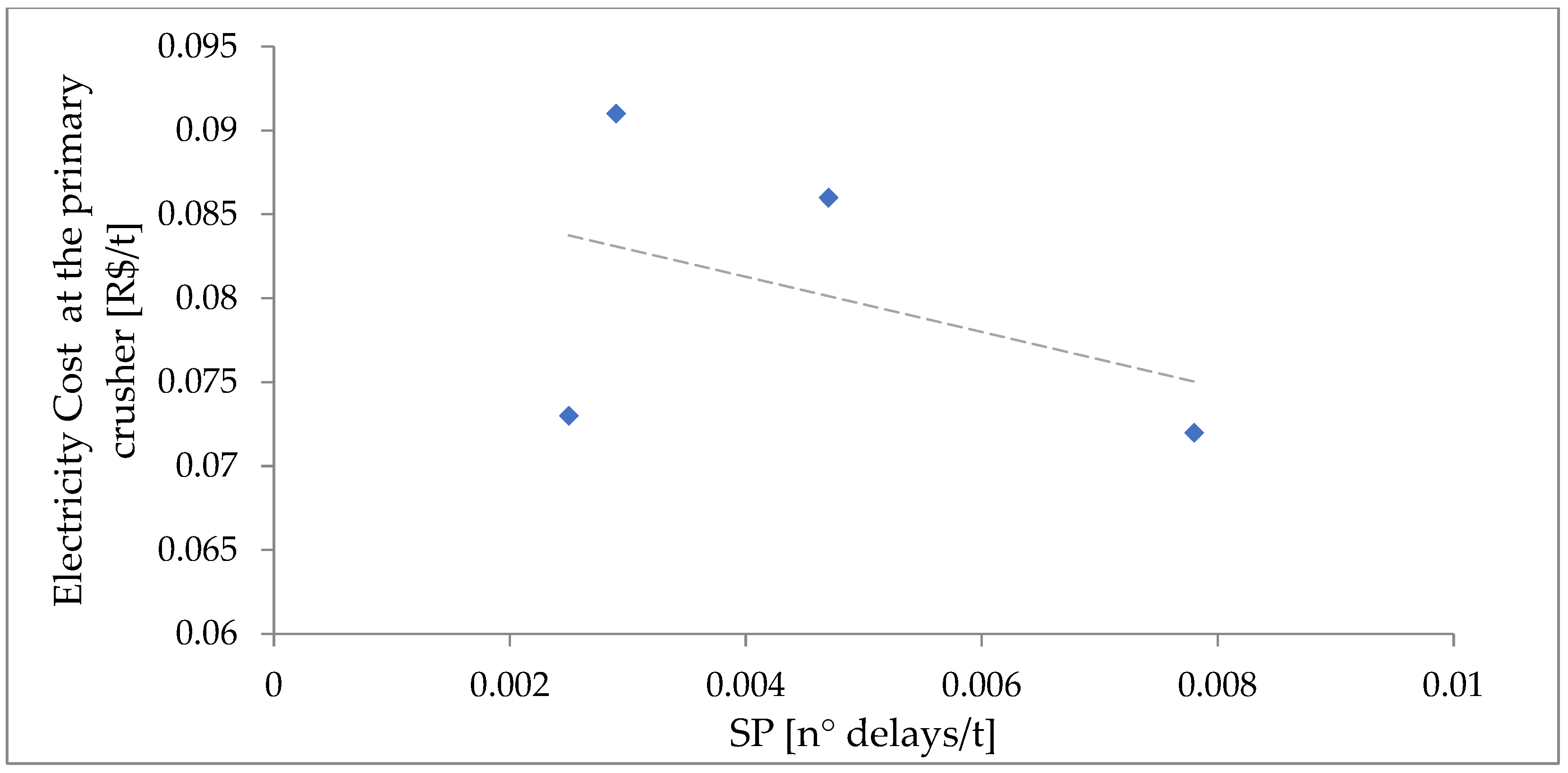

Considering the downstream processes, as said before, the incidence of the use of a hydraulic secondary breaker is an indicator of the quality of fragmentation and, according to the experimental points of

Figure 9, higher SP reduces the use of secondary breaking by hydraulic hammer. This last result agrees with the trend observed in graph

Figure 10: the higher the specific priming, the lower the particle size, therefore the lower the electricity costs at the primary crusher.

Figure 9.

– As said before, the incidence of the use of a hydraulic secondary breaker is an indicator of the quality of fragmentation: higher specific priming reduces the use of secondary breaking by hydraulic hammer.

Figure 9.

– As said before, the incidence of the use of a hydraulic secondary breaker is an indicator of the quality of fragmentation: higher specific priming reduces the use of secondary breaking by hydraulic hammer.

Figure 10.

– The higher the specific priming, the lower the particle size, therefore the lower the electricity costs at the primary crusher.

Figure 10.

– The higher the specific priming, the lower the particle size, therefore the lower the electricity costs at the primary crusher.

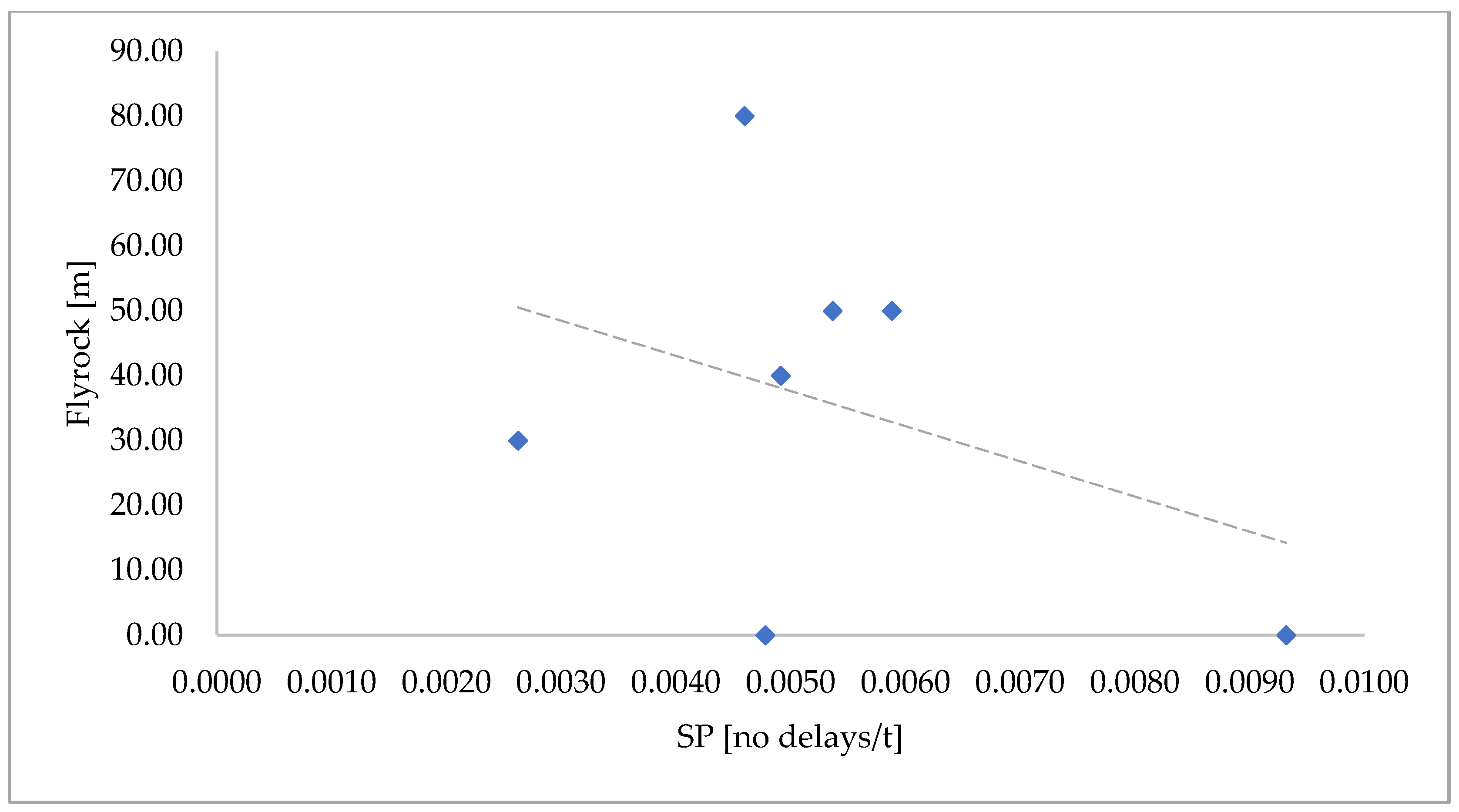

Finaly, observing the dangerous phenomenon of flyrock: decreasing the holes detonating with the same delay or short delays between them distribute the explosive energy in time in a better way allowing burden relief, therefore leading, as shown in

Figure 11, to less fly rock during the detonation.

Figure 11.

– Less holes detonating with the same delay or short delays between them distribute the explosive energy in time in a better way: less flyrock results.

Figure 11.

– Less holes detonating with the same delay or short delays between them distribute the explosive energy in time in a better way: less flyrock results.

3. Discussion

The results of the experimental campaign have been analyzed observing operational KPIs. One of the most important parameters is the specific priming (SP), i.e. the density of delay per unit of blasted rock. SP was related to parameters associated with the quality of fragmentation resulting from the detonation.

Recent research addresses the topic of delays in blasting. [

19,

20] consider crack growth: they state that delayed initiation provides enough timing for preconditioning the surrounding rock for the neighboring blasthole. [

21] considered the initiation sequence of a row of holes: one-directional initiation vs. initiating the row from the extremities towards the center: the order of ignition of blast holes is from the center to both ends of the row of blast holes can produce a more uniform size of fragmented rocks. Also [

22] discuss fracture creation, considering also rock mass joints: for simultaneous holes they state that cracks propagate along the lines between boreholes with larger filled joint strengths. [

23]Yin et al., (2021) study crack formation and damage to the surrounding rock could considering shaped charge form and short time delay blasting scheme. [

24] study no-delay (simultaneous blasting): their work indicates that the number of simultaneous blast-holes has a much smaller influence vivrations than site constants.

The present study suggests that simultaneous holes detonating at close distances, despite not being contour charges, still behave with a cooperative effect along the line connecting the axes of the two holes. This cooperation causes the explosive energy to exert a shear effect along the surface between the holes, creating fines and coarse fragments instead of fragmenting effectively. Increasing the distance between simultaneous holes diminishes the likelihood of creating a shear effect, directing therefore the explosive energy to work along the line of least resistance (the burden) and promoting effective fragmentation. An increase in the density of simultaneous blastholes spaced more than 3 m results in better fragmentation, significantly reducing the work of second breaking by the hydraulic hammer, bringing it close to zero. Transitioning from 2 to 6 simultaneous holes at 2 m distance leads to a doubling of the fines produced, increasing from approximately 10% to about 20%.

In general, increasing the specific priming enhances the quality of fragmentation, reflected in lower values of fines, a smaller P80, and lower impact of secondary breaking, along with a reduction in costs at the primary crusher. Notably, P80 proves to be the most sensitive KPI, decreasing 25% (from around 450 mm to approximately 360 mm) doubling the specific priming (+ 220% from 0.0025 to 0.008).

4. Conclusions

The present research aimed to study and understand the effect of initiation delays on the result of bench blasting at real scale. To do so, field tests were conducted with all other variables than the number of delays being constant, including the rock mass due to the proximity of all the blasts. Operational KPIs were used to quantify the result of the blast.

The parameters that mostly characterized the results obtained during this research have been the distance between simultaneous holes and the specific priming, defined as the density of delays per unit of blasted rock.

The analysis of results shows that increasing the number of delays in the initiation sequence per unit of blasted rock leads to finer fragmentation, reduces the amount of fines and reduces secondary breaking to the point of eliminating it.

The analysis suggests that production holes behave like contour holes if detonated simultaneously in proximity: it is induced a cooperation of charges that creates a shear effect, directing the explosive energy to work along the inter-axis line between the holes, producing fines along the shear surface and coarse fragmentation in the rest of the blasted volume. Higher distance between simultaneous holes favors instead the breakage along line of least resistance (the burden), leading to smaller fragments instead of producing shear, therefore also reducing the amount of fines. The proximity of simultaneous holes results in a form of dust-and-boulder behavior. From the point of view of safety, avoiding the cooperation of charges also reduces flyrock.

Author Contributions

“Conceptualization, J.S.; methodology, J.S. and M.C..; software, J.S.; validation, J.S., S.V.,T.M.,M.C.; J.S.; investigation, J.S., T.M.,M.C.; resources, , J.S., T.M.,M.C.; data curation, J.S., A.V.; writing—original draft preparation, J.S., S.V.; writing—review and editing, J.S., S.V.; visualization, J.S,. S.V.; supervision, J.S.; project administration,T.M.; funding acquisition, J.S., T.M.,M.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by CNPQ, grant number 400417/2014-6 and MSCA-RISE grant number: 823948

Institutional Review Board Statement

Not applicable: the study did not involve humans or animals.

Acknowledgments

Sociedade Extrativa Dolomia Ltda., Taubaté, Brazil allowed all the field work.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Seccatore, J., Cardu, M., & Bettencourt, J. (2015). The music of blasting. SUSTAINABLE INDUSTRIAL PROCESSING SUMMIT, 4.

- Stagg M.S. (1987). Influence of blast delay time on rock fragmentation: One-tenth scale tests. International Journal of Surface Mining, Reclamation and Environment. Vol. 1, Issue 4, pp. 215-222. [CrossRef]

- Cho S.H., Kaneko K. (2004) Rock fragmentation control in blasting materials. The Mining and Materials Processing Institute of Japan. v. 45, n. 5, p. 1722 -1730.

- Katsabanis, P.D., Tawadrous, A., Braun, C., Kennedy, C. (2006). Timing effects on the fragmentation of small scale blocks of granodiorite. Int J Blast Frag, 10 (2006), pp. 83-93. [CrossRef]

- KIM S.J. (2010). Experimental investigation of the effect of blasting on the impact breakage of rocks. Kingston, Ontario, Canada: The Robert M. Buchan Department of Mining, Queen’s University, 2010. (Master Thesis).

- Tang, H.L., Liu, X., Yang, J. and Yu, Q., 2022. Experimental study on the influence of delay time on rock fragmentation in bench blasting. Applied Sciences, 13(1), p.85. [CrossRef]

- Tang, H.L., Yang, J. and Yu, Q., (2023). Experimental Investigation of the Effect of Delay Time on Rock Fragmentation in Multi-Hole Bench Blasting. Applied Sciences, 13(12), p.7329. [CrossRef]

- Vanbrabant F., Espinosa A. (2006). Impact of short delays sequence on fragmentation by means of electronic detonators: theoretical concepts and field validation. In: Proceedings of the 8th International Symposium on Rock Fragmentation by Blasting. Santiago; 7–11 May 2006:326–331.

- Rossmanith, H.P. (2002) The use of Lagrange diagrams in precise initiation blasting. Part I: two interacting blastholes. Int J Blast Frag, 6 (2002), pp. 104-136.

- Rossmanith, H.P., Kouzniak, N. (2004). Supersonic detonation in rock mass: particle displacements and velocity fields for single and multiple non-delayed and delayed detonating blastholes. Int J Blast Frag, 8, pp. 95-117. [CrossRef]

- Johansson, D., Ouchterlony, F. (2013). Shock wave interactions in rock blasting-the use of short delays to improve fragmentation in model-scale. Rock Mech Rock Eng, 46, pp. 1-18. [CrossRef]

- Cardu, M., Seccatore, J., Vaudagna, A., Rezende, A., Galvão, F., Bettencourt, J., De Tomi, G. (2015a). "Evidences of the influence of the detonation sequence in rock fragmentation by blasting – Part I". Submitted to: REM- Revista Escola de Minas, Ouro Preto.

- Cardu, M., Seccatore, J., Vaudagna, A., Rezende, A., Galvão, F., Bettencourt, J., De Tomi, G. (2015b). "Evidences of the influence of the detonation sequence in rock fragmentation by blasting – Part II". Submitted to: REM- Revista Escola de Minas, Ouro Preto. [CrossRef]

- Dragano, M.A., Seccatore, J., Cardu, M., Marin, T., Bettencourt, J. (2019). Influence of blasting charges and delays on the energy consumption of mechanical crushing. REM: Rev. Esc. Minas. REM, Int. Eng. J., Ouro Preto, 72(2), 345-352, apr. Jun. [CrossRef]

- Blair, D.P. (2009) Limitations of electronic delays for the control of blast vibration and fragmentation. In: Proceedings of the 9th International Symposium on Rock Fragmentation by Blasting. Granada; 13–17 August 2009:171–184.

- Schill M., Sjöberg J. (2012) Finite element simulations of blasting and fragmentation with precise initiation. In: Proceedings of the 12th International LS-DYNA User Conference. Dearborn; 3–5 June 2012:1–10.

- Yi, C.P., Johansson, D., Nyberg, U., Beyglou, A. (2016). Stress wave interaction between two adjacent blast holes. Rock Mech Rock Eng, 49 (2016), pp. 1803-1812. [CrossRef]

- Agrawal, H., Mishra, A.K. (2021) An Analytical Approach to Measure the Probable Overlapping of Holes Due to Scattering in Initiation System and Its Effect on Blast-Induced Ground Vibration in Surface Mines. Mining, Metallurgy & Exploration 38, 485–495. [CrossRef]

- Ding, X., Yang, Y., Zhou, W., An, W., Li, J., & Ebelia, M. (2022). The law of blast stress wave propagation and fracture development in soft and hard composite rock. Scientific Reports, 12(1), 17120. [CrossRef]

- Saadatmand Hashemi, A. and Katsabanis, P., (2020). The effect of stress wave interaction and delay timing on blast-induced rock damage and fragmentation. Rock mechanics and rock engineering, 53(5), pp.2327-2346. [CrossRef]

- Sasaoka, T., Takahashi, Y., Hamanaka, A., Wahyudi, S. and Shimada, H., (2020). Effect of delay time and firing patterns on the size of fragmented rocks by bench blasting. In Proceedings of the 28th International Symposium on Mine Planning and Equipment Selection-MPES 2019 28 (pp. 449-456). Springer International Publishing.

- Huang, J., Zhang, G., Luo, Y., Li, X., Song, K. and Liu, T., (2021). Study on timing sequence control fracture blasting excavation of deep rock masses with filled joints. Scientific Reports, 11(1), p.21056. [CrossRef]

- Yin, Y., Sun, Q., Zou, B. and Mu, Q., (2021). Numerical study on an innovative shaped charge approach of rock blasting and the timing sequence effect in microsecond magnitude. Rock Mechanics and Rock Engineering, 54(9), pp.4523-4542. [CrossRef]

- Yue, H.Z., Yu, C., Li, H.B., Zhou, C.B., Chen, S.H. and Shao, Z.S., (2022). The effect of blast-hole arrangement, delay time, and decoupling charge on rock damage and vibration attenuation in multihole blasting. Shock and Vibration, 2022, pp.1-18. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).