Submitted:

23 March 2024

Posted:

26 March 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Experimental Procedure

2.1. Fabrication

2.1.1. Procedure

2.1.2. Fabrication Parameters

2.2. Micro Structure Analysis

2.3. Hardness

2.4. Heat Treatment

2.5. Tensile Test

3. Result and Discussion

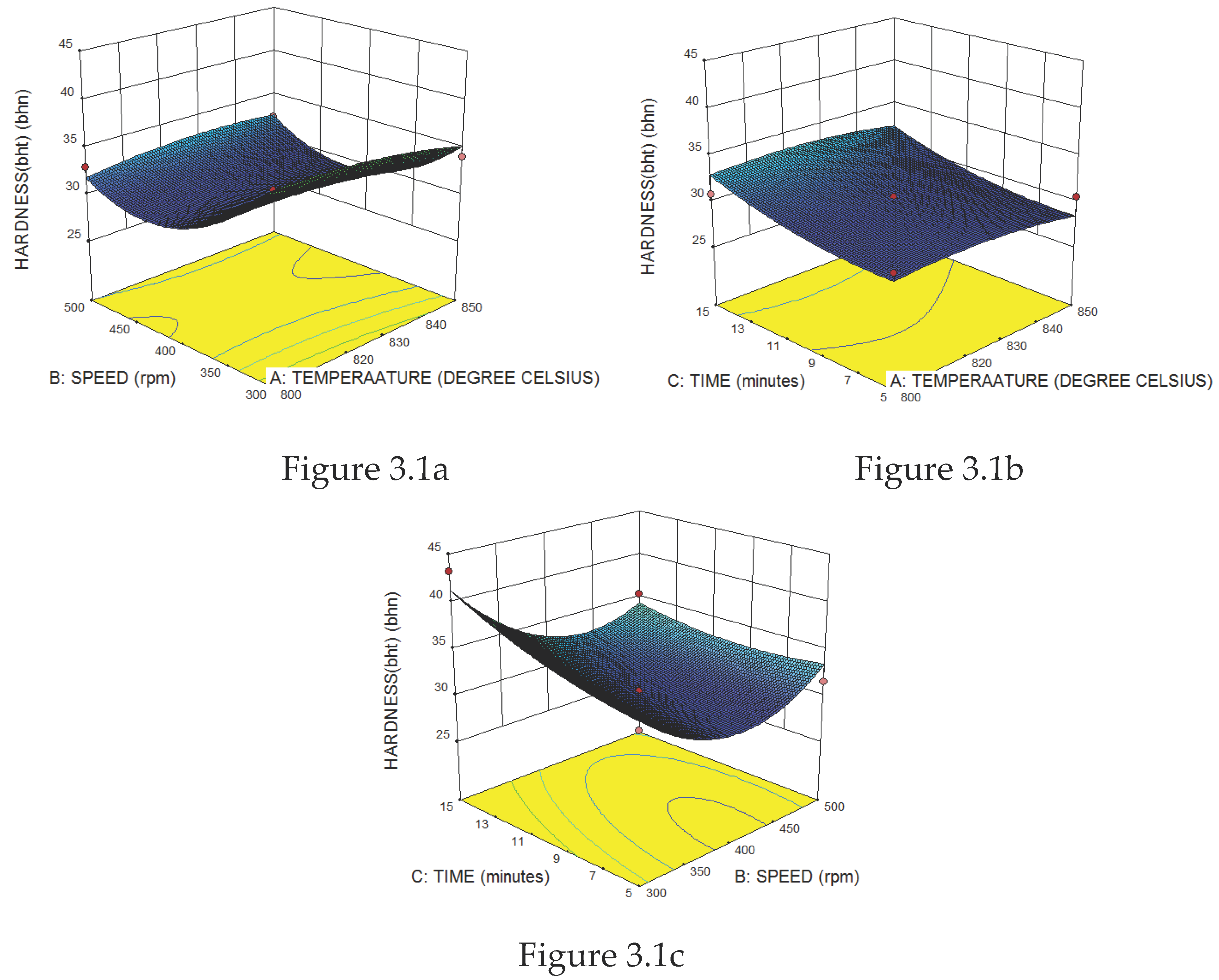

3.1. Hardness (Before Heat Treatment)

Analysis of variance:

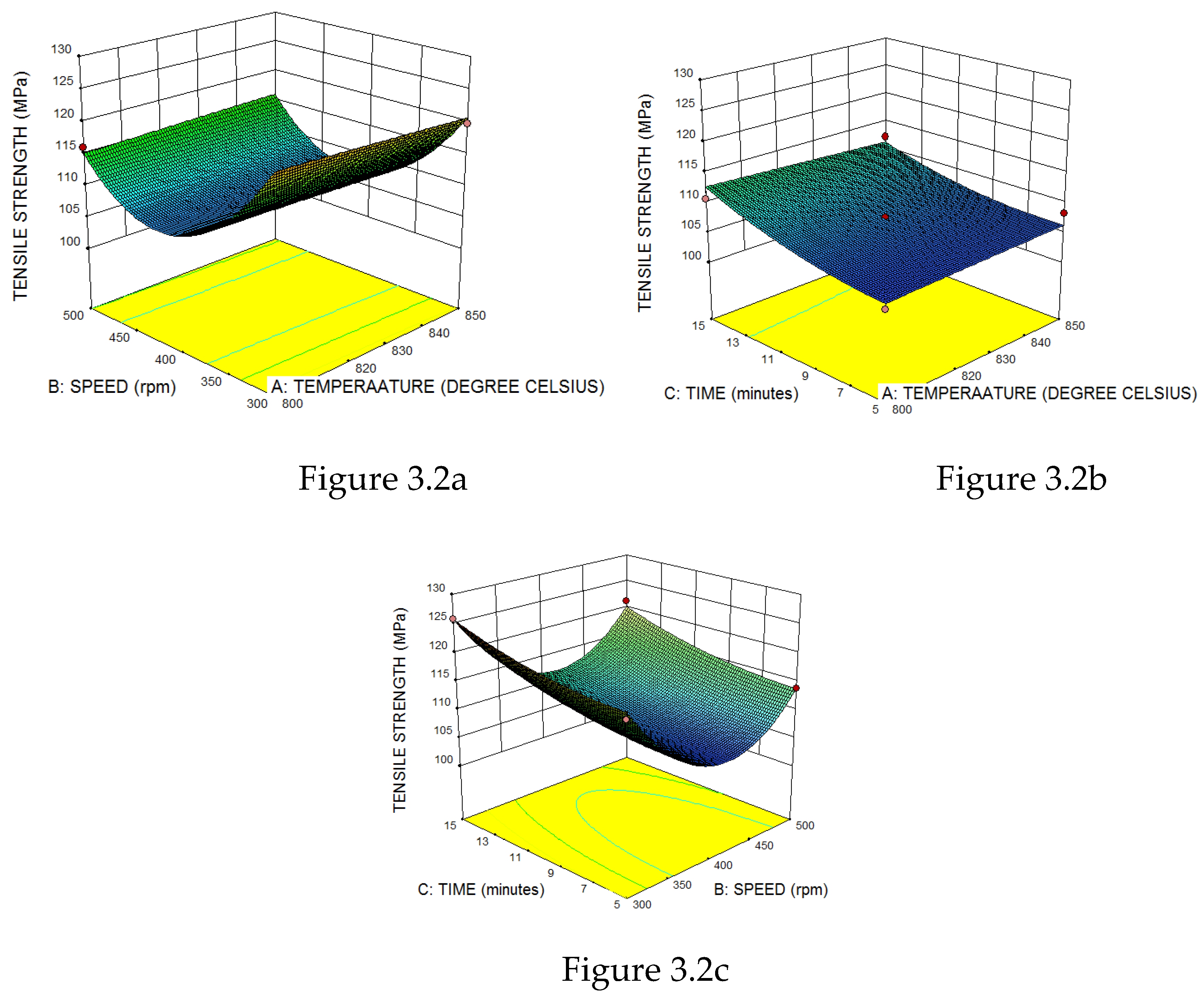

3.2. Tensile Test

Analysis of variance:

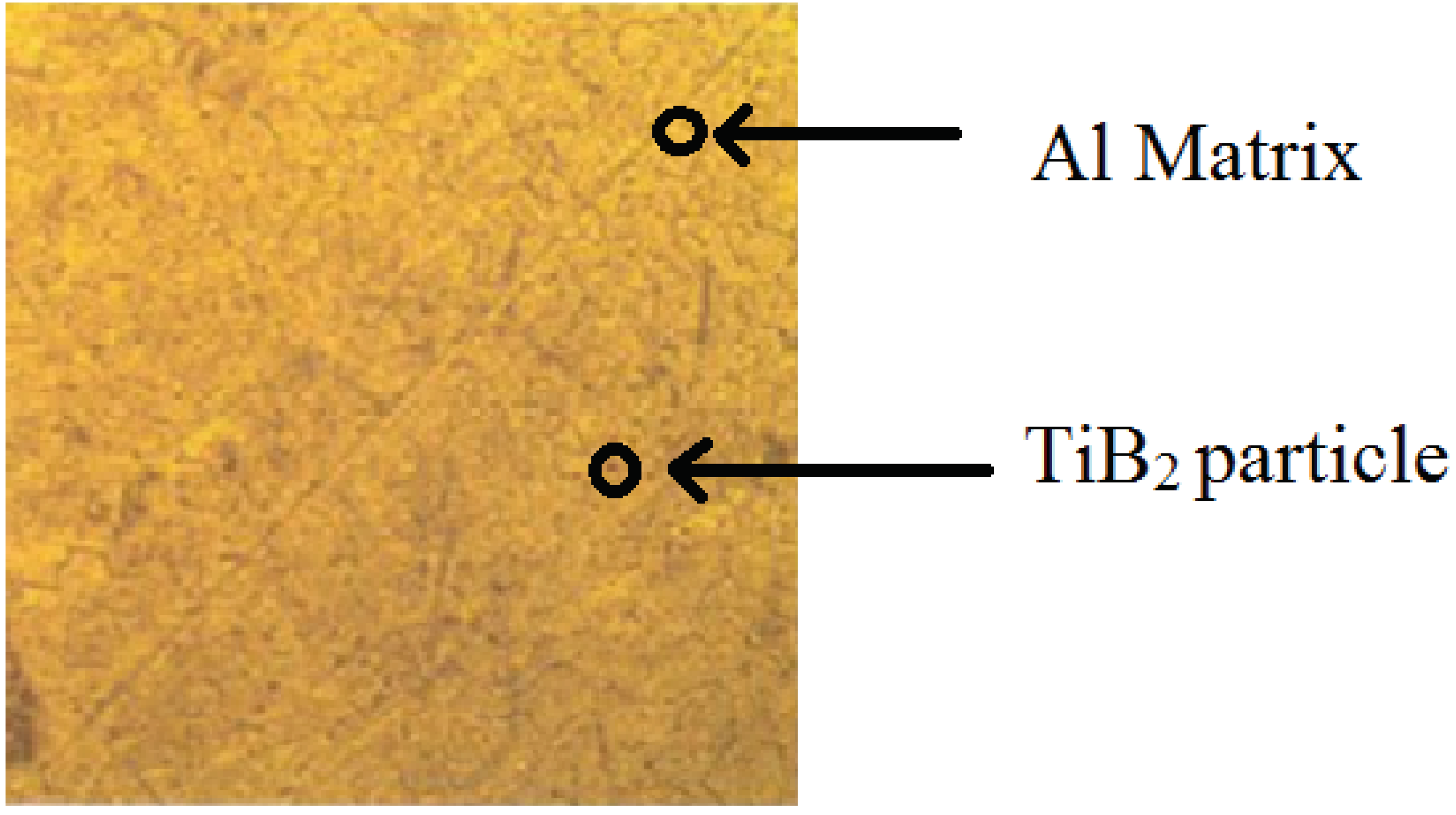

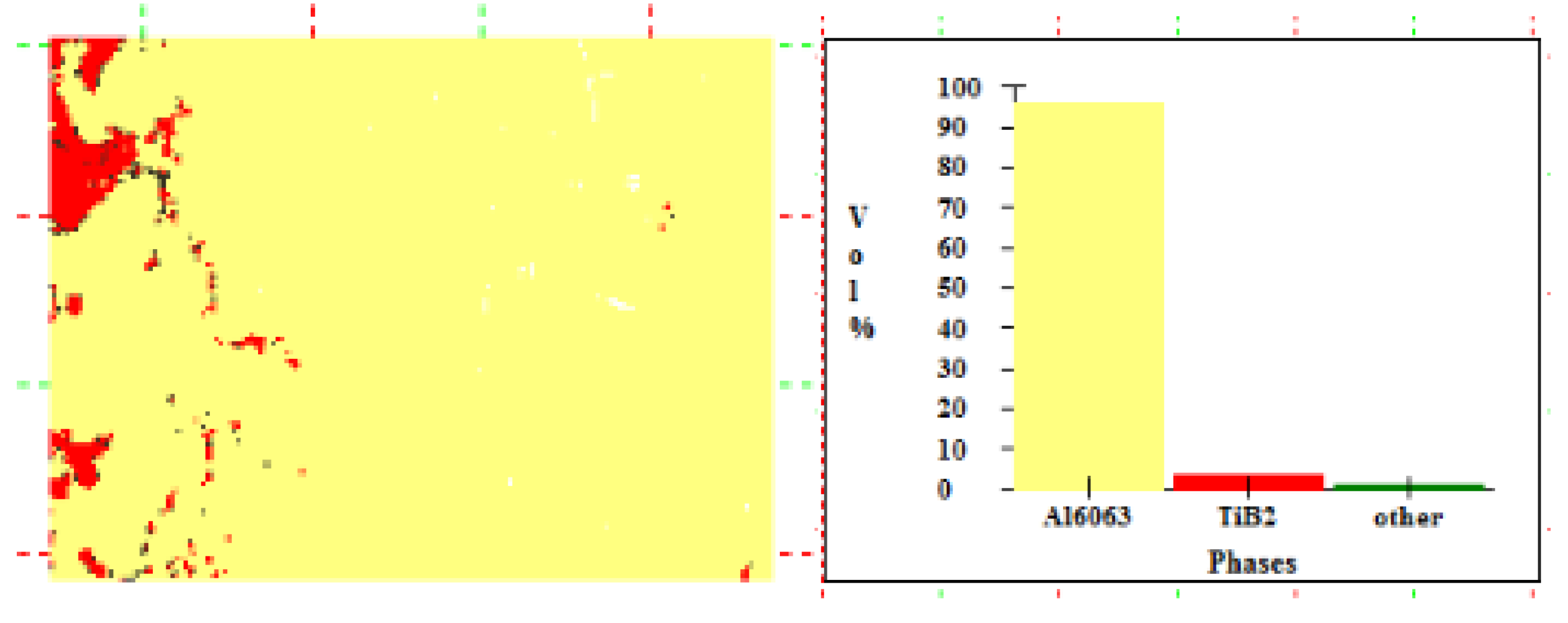

3.3. Optical Micrograph Studies

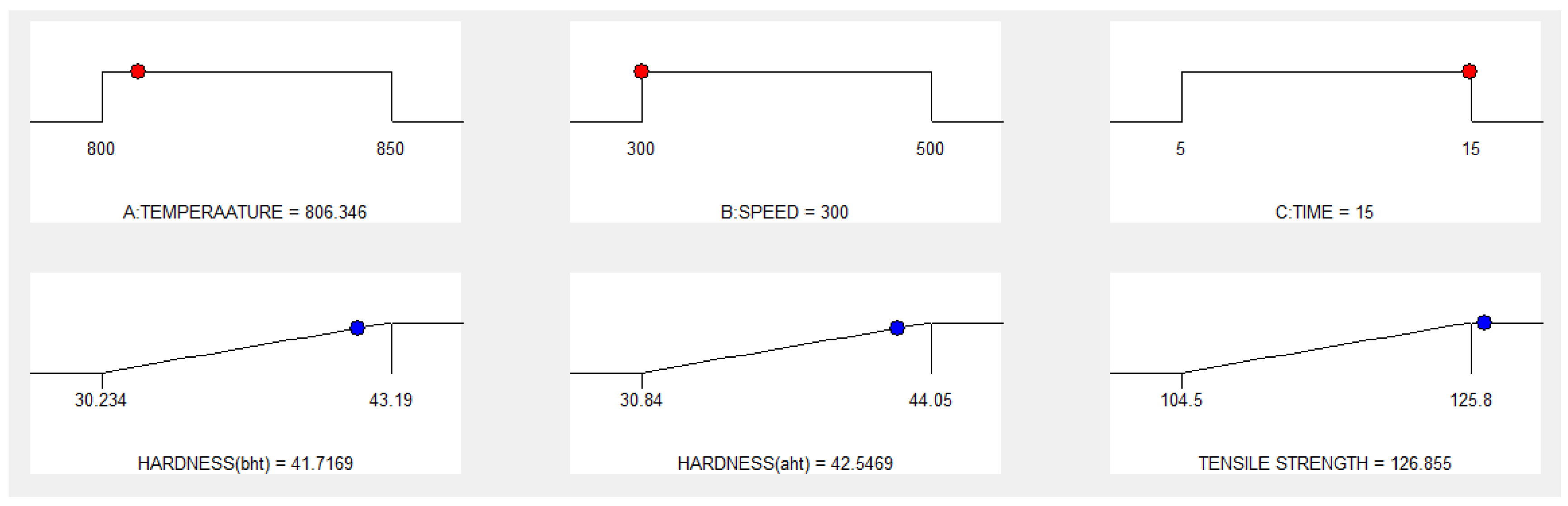

3.4. Optimal Solution

3.5. Confirmation Test

4. Conclusion

References

- Fei chen, Zonging chen, Fen Mao; TiB2 reinforced aluminium based in situ composites fabricated by stir casting. Materials and Engineering A 625 (2015) 357-368. [CrossRef]

- L.LU, M.O.Lai , Y.Su , h.l.Teo , C.F.Feng; In situ TiB2 reinforced Al alloy composites. Scripta materialia 45 (2010) 1017-1023. [CrossRef]

- Dr.S.Periyasamy, M. Dr.S.Periyasamy, M.Aravind, D.vivek, Dr.K.S.Amirthagadeswaran; Optimization of surface grinding process parameters for minimum surface roughness in AISI 1080 using response surface methodology. Advanced materials research vols 984-985(2014) 118-123. [CrossRef]

- Narendra kumar , Rakesh kumar gowtham , Sunil mohan; In-situ Development of ZrB2 particles and their effect on microstructure and mechanical properties of AA5052 metal matrix composites. Materials and Design. [CrossRef]

- R.Keshavamurthy, Sadananda mageri, Ganesh raj, B.Naveen Kumar and K.Vasu; Microstructure and mechanical properties of Al7065-TiB2 In-Situ Composites. Research Journal of Material Sciences. ISSN 2320-6065 Vol 1(10), 6-10, 2013. [CrossRef]

- B.Ravi, B. B.Ravi, B.Balu Naik, J.Udhayapraksh; Characterization of Aluminum matrix composites (AA6061/B4C) fabricated by stir casting technique. Materials Today: Proceedings 2 2015 2984-2990. [CrossRef]

- Pardeep sharma, Satpal sharma, Dinesh Khanduja; Production and characterization of AA6082-(Si3N4 + Gr) stir cast hybrid composite. Particulate Science and Technology. 0272-6356(print) / 1548-0056(online). [CrossRef]

- A.B.Sarmasti, M. A.B.Sarmasti, M.Yazdanirad,M.Nauri Khezrabad,m.Kharbalaie; Effect of alumina particle size and thermal condition of casting on microstructure and mechanical properties of stir cast Al-Al2O3 composites. Materials science and Technology Vol27 No11 1653. [CrossRef]

- Ranjith Bauria and, M.K. Surappa; Processing and properties of Al-Li-SiCp Composites. Science and technology of adanced materials 8 2007 494-502. [CrossRef]

- Ibrahim Ozbek; A study on re solution heat treatment of AA2618 alumnium alloy. Materials characterisation 58 (2007) 312-317. [CrossRef]

| S.No | Parameters | Level 1 | Level 2 | Level 3 |

| 1 | Stirring temperature | 750 | 800 | 850 |

| 2 | Stirring Time | 5 | 10 | 15 |

| 3 | Stirring Speed | 300 | 400 | 500 |

| Factor 1 | Factor 2 | Factor 3 | |

|---|---|---|---|

| Run | Temperature °C |

Speed rpm |

Time sec |

| 1 | 825 | 300 | 5 |

| 2 | 850 | 500 | 10 |

| 3 | 825 | 400 | 10 |

| 4 | 800 | 500 | 10 |

| 5 | 800 | 400 | 15 |

| 6 | 825 | 500 | 15 |

| 7 | 850 | 400 | 15 |

| 8 | 850 | 300 | 10 |

| 9 | 800 | 300 | 10 |

| 10 | 825 | 300 | 15 |

| 11 | 825 | 500 | 5 |

| 12 | 850 | 400 | 5 |

| 13 | 800 | 400 | 5 |

| Parameters | Value |

|---|---|

| Stirring speed | 300-500 rpm |

| Stirring temperature | 800-8500C |

| Reinforcement preheat temperature | 2000C |

| Stirring time | 5-15 minutes |

| Inert gas | Argon |

| Preheat temperature of mould | 4000C |

| Factor 1 | Factor 2 | Factor 3 | Output Responses | |||

|---|---|---|---|---|---|---|

| Run | Temperature °c |

Speed rpm |

Time sec |

Hardness (BHT) |

Hardness (AHT) |

Tensile Strength (MPa) |

| 1 | 825 | 300 | 5 | 33.79 | 34.47 | 118.9 |

| 2 | 850 | 500 | 10 | 32.79 | 33.04 | 114.0 |

| 3 | 825 | 400 | 10 | 30.49 | 31.10 | 107.6 |

| 4 | 800 | 500 | 10 | 32.96 | 33.62 | 116.1 |

| 5 | 800 | 400 | 15 | 30.83 | 31.45 | 110.7 |

| 6 | 825 | 500 | 15 | 35.31 | 36.02 | 121.3 |

| 7 | 850 | 400 | 15 | 31.49 | 32.12 | 112.2 |

| 8 | 850 | 300 | 10 | 34.11 | 34.79 | 119.8 |

| 9 | 800 | 300 | 10 | 37.74 | 38.49 | 124.4 |

| 10 | 825 | 300 | 15 | 43.19 | 44.05 | 125.8 |

| 11 | 825 | 500 | 5 | 31.59 | 32.22 | 113.9 |

| 12 | 850 | 400 | 5 | 30.56 | 31.17 | 108.3 |

| 13 | 800 | 400 | 5 | 30.23 | 30.84 | 104.5 |

| Source | Sum of Squares | df | Mean Square |

F-Value | Prob > F |

|---|---|---|---|---|---|

| Model | 165.08 | 9 | 18.34 | 5.90 | 0.0144 |

| A-SPEED | 34.35 | 1 | 34.35 | 11.05 | 0.0127 |

| B-TEMPERATURE | 1.30 | 1 | 1.30 | 0.42 | 0.5392 |

| C-TIME | 26.82 | 1 | 26.82 | 8.63 | 0.0218 |

| AB | 2.34 | 1 | 2.34 | 0.75 | 0.4140 |

| AC | 8.07 | 1 | 8.07 | 2.59 | 0.1512 |

| BC | 0.028 | 1 | 0.03 | 0.01 | 0.9265 |

| A2 | 85.30 | 1 | 85.30 | 27.44 | 0.0012 |

| B2 | 2.01 | 1 | 2.01 | 0.65 | 0.4475 |

| C2 | 4.04 | 1 | 4.04 | 1.30 | 0.2920 |

| Residual | 21.76 | 7 | 3.11 | ||

| Lack of Fit | 21.76 | 3 | 7.25 | ||

| Pure Error | 0.000 | 4 | 0.00 | ||

| Cor Total | 186.84 | 16 |

| Source | Sum of Squares | Df | Mean Square |

F-Value | Prob > F |

|---|---|---|---|---|---|

| Model | 675.58 | 9 | 75.06 | 23.0 | 0.0002 |

| A-TEMPERATURE | 0.25 | 1 | 0.25 | 0.08 | 0.7920 |

| B-SPEED | 69.62 | 1 | 69.62 | 21.33 | 0.0024 |

| C-TIME | 74.42 | 1 | 74.42 | 22.8 | 0.0020 |

| AB | 1.56 | 1 | 1.56 | 0.48 | 0.5113 |

| AC | 1.32 | 1 | 1.32 | 0.41 | 0.5447 |

| BC | 0.063 | 1 | 0.06 | 0.02 | 0.8938 |

| A2 | 0.005921 | 1 | 0.01 | 0.02 | 0.9672 |

| B2 | 510.63 | 1 | 510.63 | 156.43 | 0.0001 |

| C2 | 7.82 | 1 | 7.82 | 2.39 | 0.1651 |

| Residual | 22.85 | 7 | 3.26 | ||

| Lack of Fit | 22.85 | 3 | |||

| Cor Total | 698.43 | 16 |

| Calculated value | Experimental value | |

| Hardness | 41.7169 | 39.85 |

| Tensile strength | 126.902 | 124 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).