Submitted:

08 May 2023

Posted:

08 May 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Material

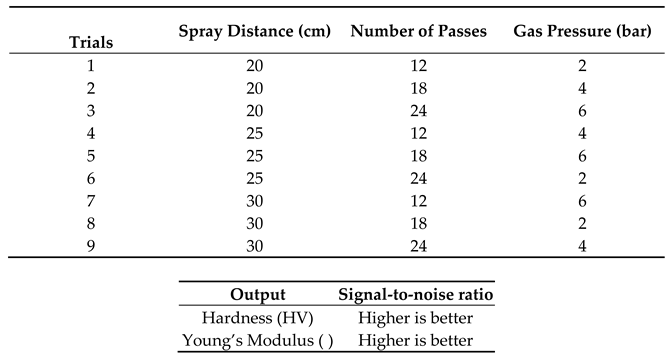

2.2. Process Parameters

| Parameter | Units | Levels |

|---|---|---|

| Spraying Distance | cm | 20, 25, 30 |

| Number of Passes Gas Pressure |

- bar |

12, 18, 24 2, 4, 6 |

2.3. Signal-to-noise ratio (SN ratio)

2.3. Design of Experiment (DOE)

| Trials | Spray Distance (cm) | Number of Passes | Gas Pressure (bar) | Young’s Modulus | Hardness (HV) |

|---|---|---|---|---|---|

| 1 | 20 | 12 | 2 | 24.2 | 225 |

| 2 | 20 | 18 | 4 | 18.259 | 220 |

| 3 | 20 | 24 | 6 | 10.904 | 260 |

| 4 | 25 | 12 | 4 | 18.008 | 233 |

| 5 | 25 | 18 | 6 | 26.152 | 200 |

| 6 | 25 | 24 | 2 | 23.27 | 243 |

| 7 | 30 | 12 | 6 | 21.2295 | 212 |

| 8 | 30 | 18 | 2 | 14.456 | 223 |

| 9 | 30 | 24 | 4 | 24.711 | 243 |

2.4. Experiment Procedures

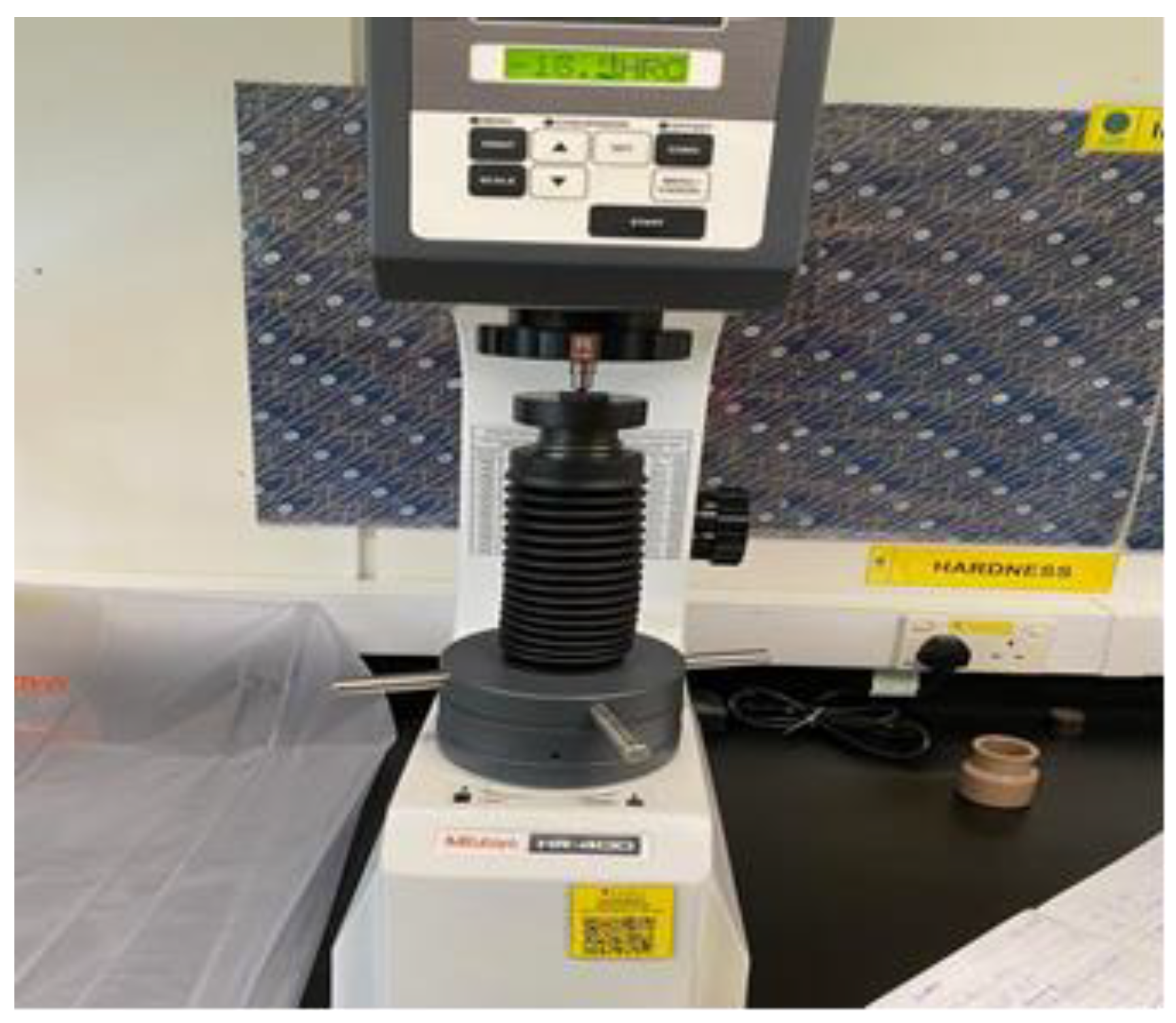

2.4.1. Hardness testing

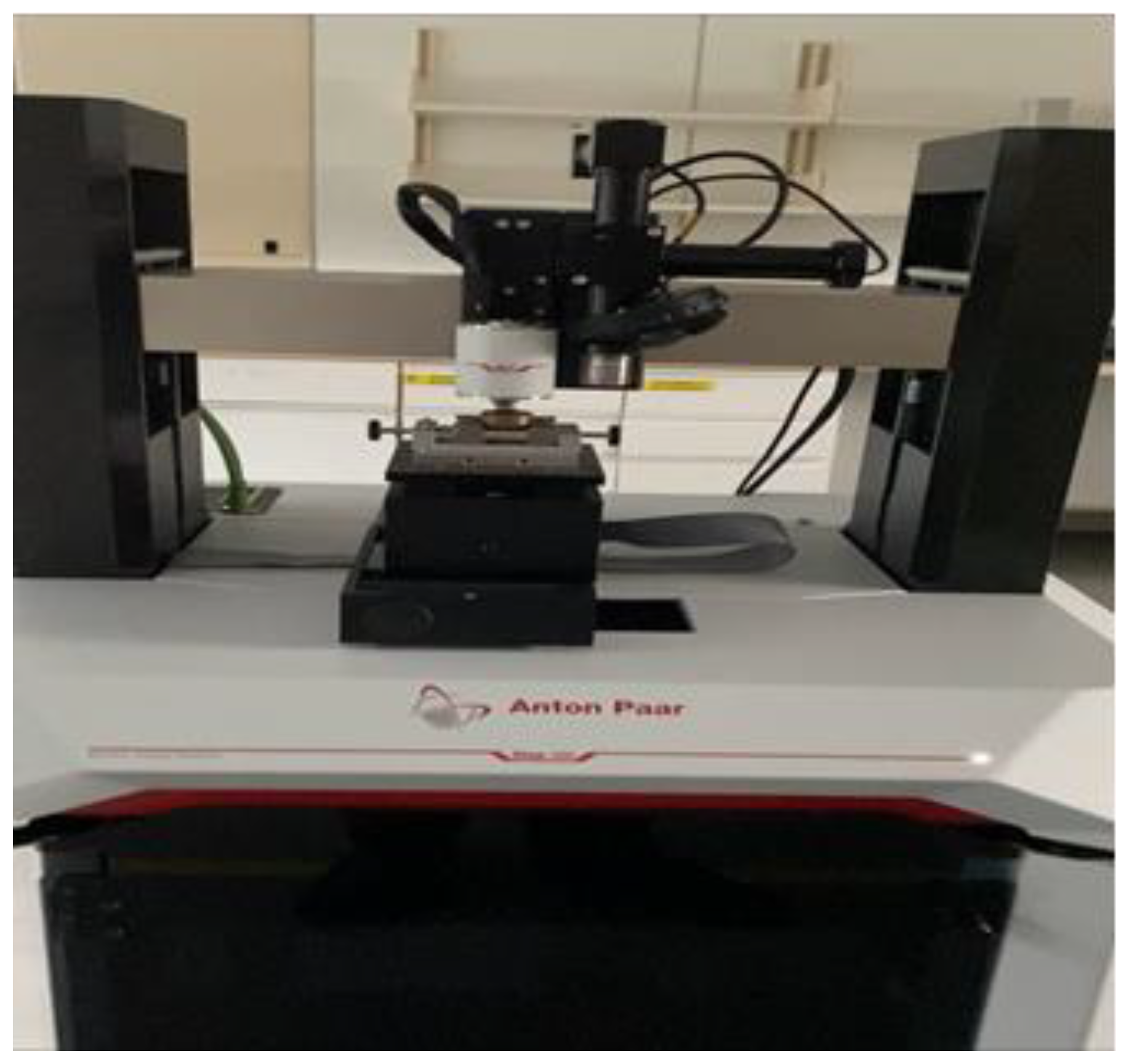

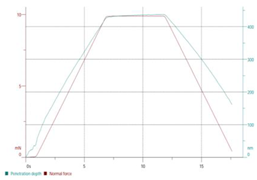

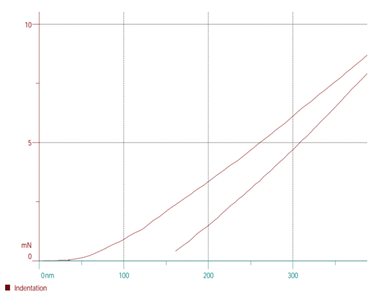

2.4.2. Nanoindentation testing

| Acquisition rate | 20 Hz |

|---|---|

| Max load | 10 mN |

| Loading rate | 100 mN/min |

| Approach distance | 2000 nm |

| Approach speed | 4000 nm |

| Stiffness threshold | 500 µN/µm |

|

|

3. Results

3.1. Taguchi Method

| Trials | Spray Distance (cm) | Number of Passes | Gas Pressure (bar) | Young’s Modulus | Hardness (HV) |

|---|---|---|---|---|---|

| 1 | 20 | 12 | 2 | 24.2 | 225 |

| 2 | 20 | 18 | 4 | 18.259 | 220 |

| 3 | 20 | 24 | 6 | 10.904 | 260 |

| 4 | 25 | 12 | 4 | 18.008 | 233 |

| 5 | 25 | 18 | 6 | 26.152 | 200 |

| 6 | 25 | 24 | 2 | 23.27 | 243 |

| 7 | 30 | 12 | 6 | 21.2295 | 212 |

| 8 | 30 | 18 | 2 | 14.456 | 223 |

| 9 | 30 | 24 | 4 | 24.711 | 243 |

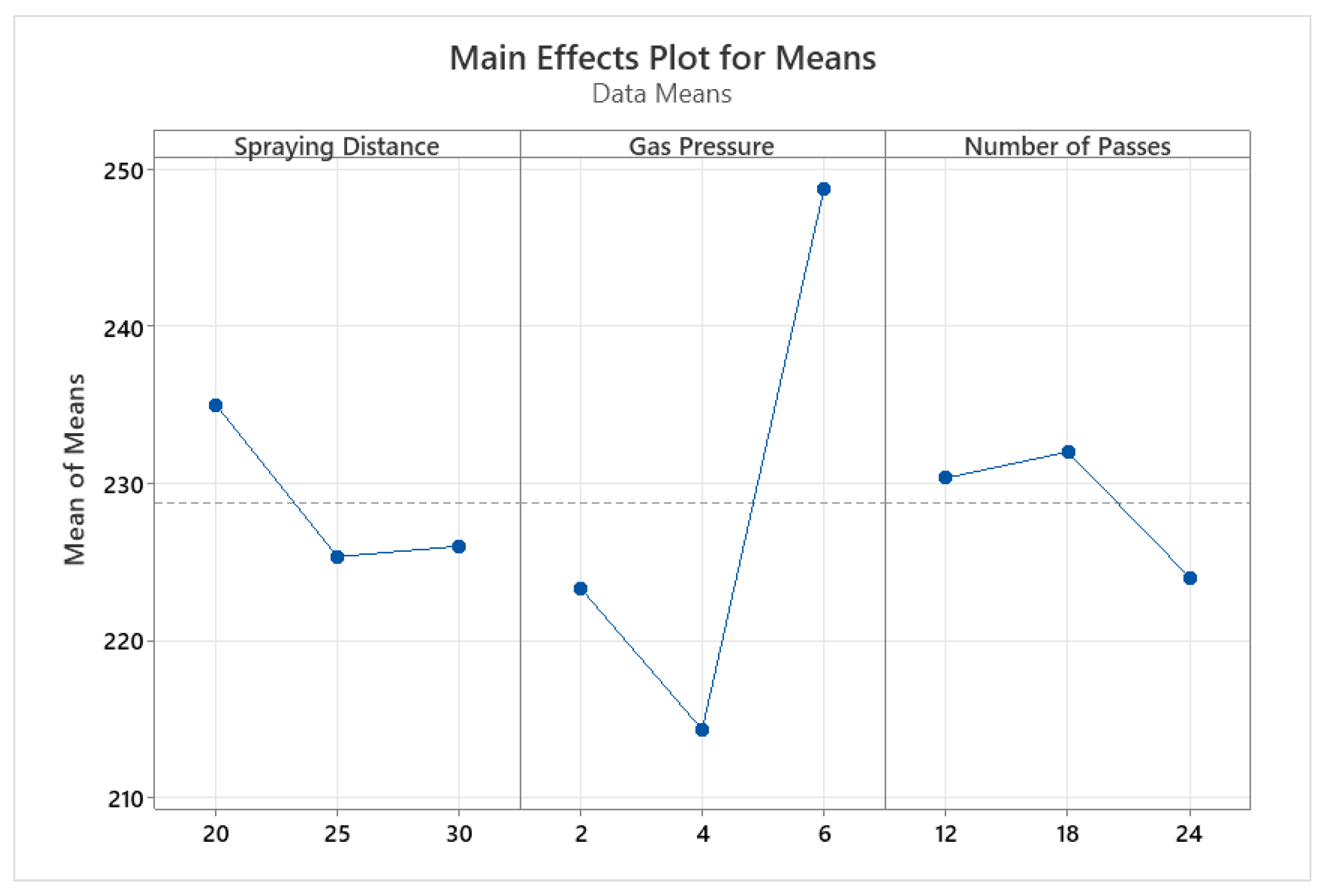

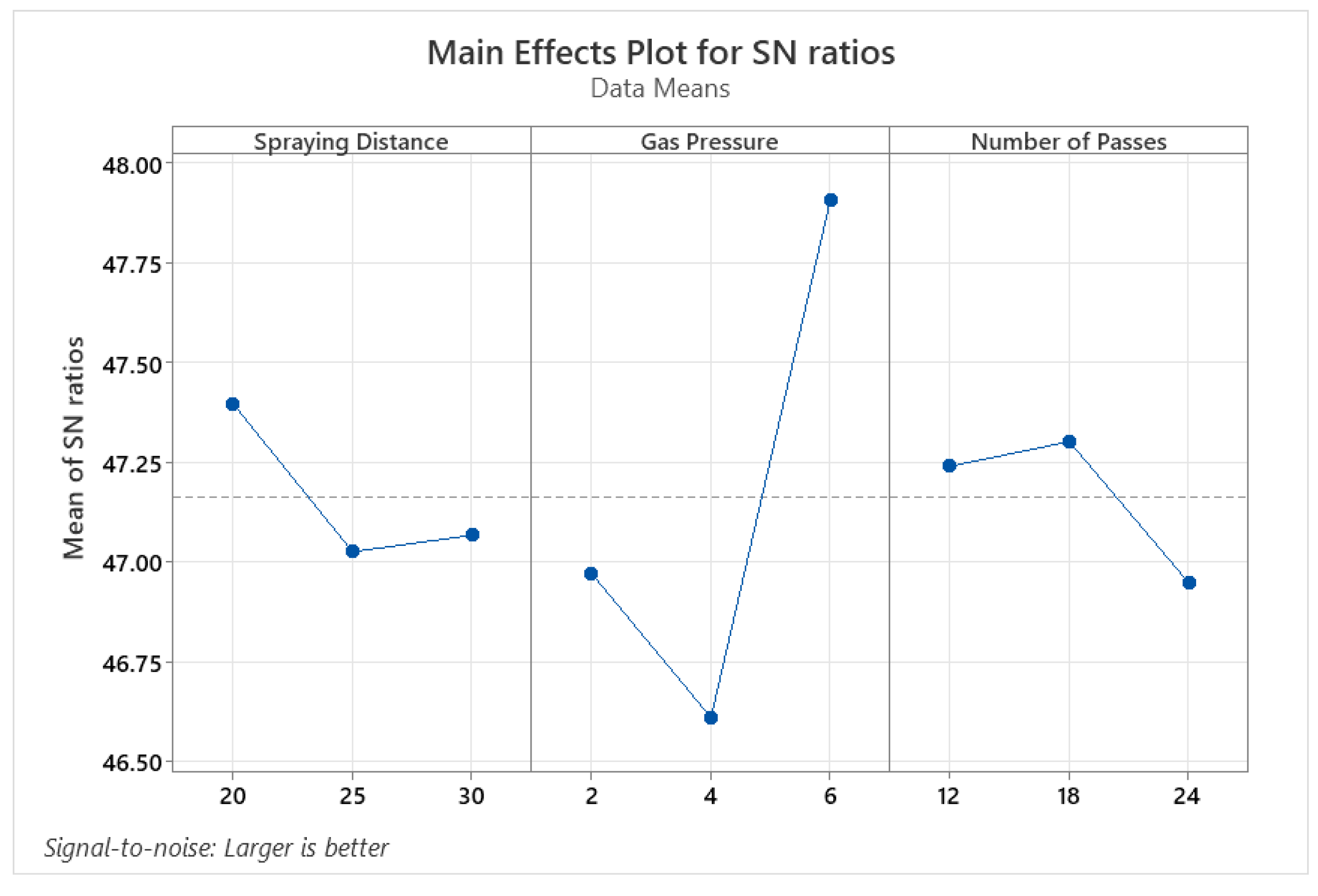

| Level | Spraying Distance | Gas Pressure | Number of Passes |

|---|---|---|---|

| 1 | 47.40 | 46.97 | 47.24 |

| 2 | 47.03 | 46.61 | 47.30 |

| 3 | 47.07 | 47.91 | 46.95 |

| Delta | 0.37 | 1.30 | 0.35 |

| Rank | 2 | 1 | 3 |

| Level | Spraying Distance | Gas Pressure | Number of Passes |

|---|---|---|---|

| 1 | 235.0 | 223.3 | 230.3 |

| 2 | 225.3 | 214.3 | 232.0 |

| 3 | 226.0 | 248.7 | 224.0 |

| Delta | 9.7 | 34.3 | 8.0 |

| Rank | 2 | 1 | 3 |

3.2. Optimization of parameters via Taguchi method

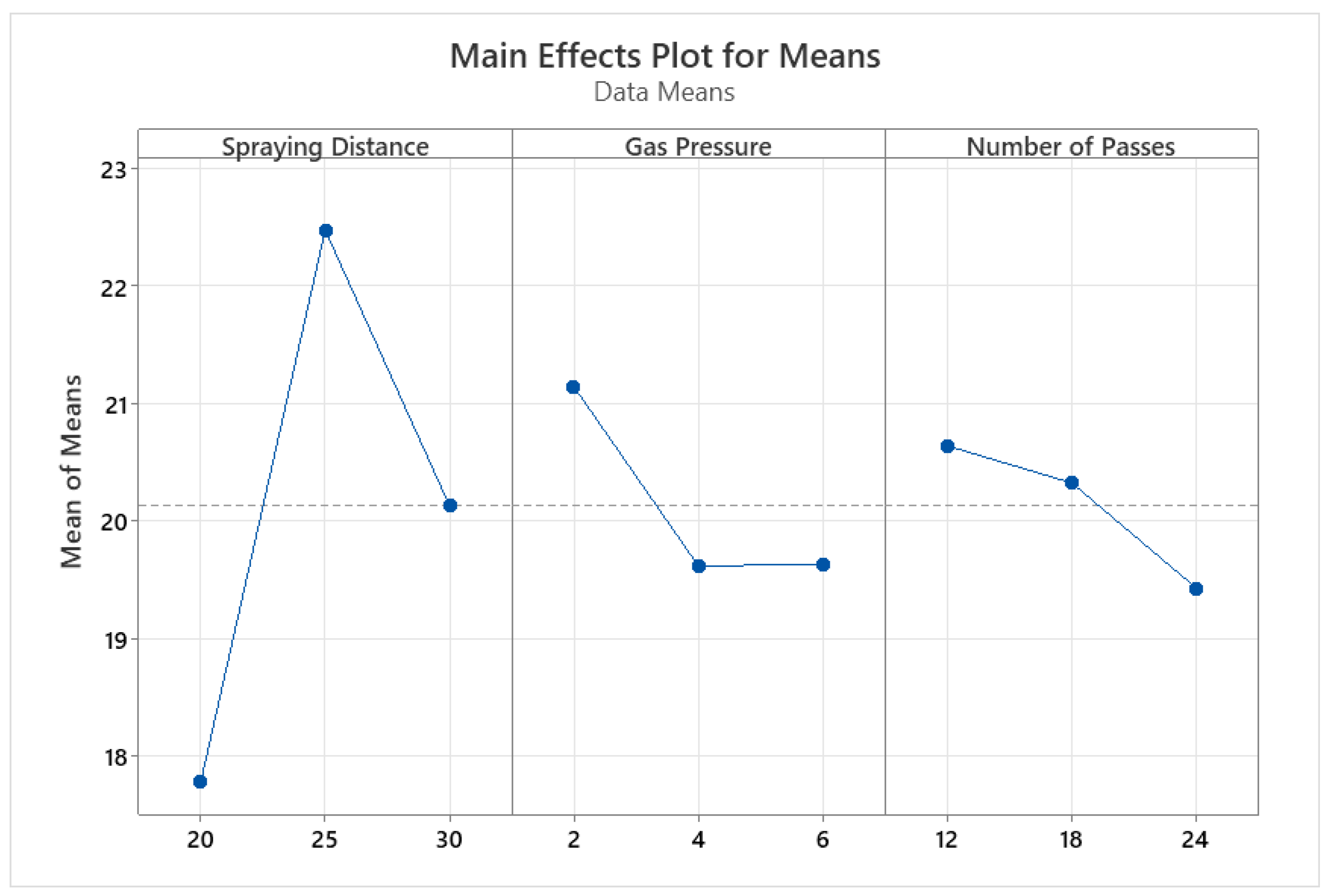

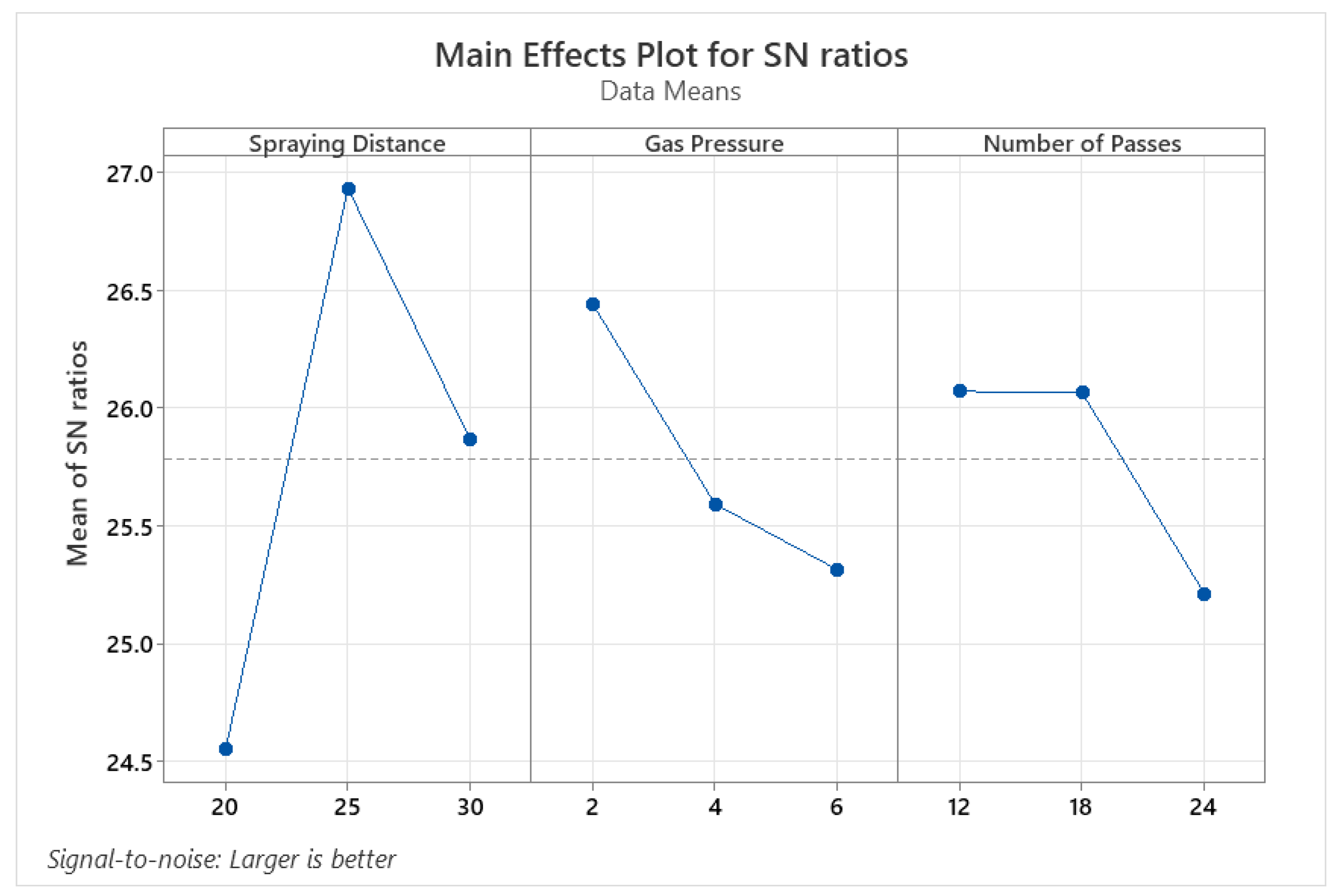

| Level | Spraying Distance | Gas Pressure | Number of Passes |

|---|---|---|---|

| 1 | 24.55 | 26.44 | 26.07 |

| 2 | 26.93 | 25.59 | 26.07 |

| 3 | 25.87 | 25.32 | 25.21 |

| Delta | 2.38 | 1.13 | 0.86 |

| Rank | 1 | 2 | 3 |

| Level | Spraying Distance | Gas Pressure | Number of Passes |

|---|---|---|---|

| 1 | 17.79 | 21.15 | 20.64 |

| 2 | 22.48 | 19.62 | 20.33 |

| 3 | 20.13 | 19.63 | 19.43 |

| Delta | 4.69 | 1.52 | 1.21 |

| Rank | 1 | 2 | 3 |

4. Conclusion

Author Contributions

Funding

References

- Dinh VC: Nguyen TP, Doan TH, Bui VK. Optimizating Spray Parameters of High Velocity Oxy Fuel (HVOF) for Cr3C2 - NiCr Coating. Appl Mech Mater 2019;889:168–76. [CrossRef]

- Kout A, Müller H. Parameter optimization for spray coating. Adv Eng Softw 2009;40:1078–86. [CrossRef]

- Mihoob MM, Mohammed HG, Albarody TMB, Ahmad F, Alnarabiji MS. Optimal Process Parameters for a Thermal-Sprayed Molybdenum-Reinforced Zirconium Diboride Composite on a Dummy Substrate. Energies 2022;15. [CrossRef]

- Sharma A, Bandari V, Ito K, Kohama K, Ramji RM, Himasekhar HS. A new process for design and manufacture of tailor-made functionally graded composites through friction stir additive manufacturing. J Manuf Process 2017;26:122–30. [CrossRef]

- Mihoob MM, Mohammed HG, Mohammed T, Albarody B, Ahmad F. Optimal Process Parameters for Thermal-Sprayed Molyb- denum Reinforced Zirconium diboride Composite on A Dummy Substrate 2022:1–15.

- Odhiambo JG, Li WG, Zhao YT, Li CL. Porosity and its significance in plasma-sprayed coatings. Coatings 2019;9:1–19. [CrossRef]

- Wu C, Tang Y, Mao B, Zhao K, Cao S, Wu Z. Rapid apatite induction of polarized hydrophilic HA/PVDF bio-piezoelectric coating on titanium surface. Surf Coatings Technol 2021;405:126510. [CrossRef]

- Rammah YS, Somaily HH, Alrowaili ZA, Al-Baradi AM, Olarinoye IO, Al-Buriahi MS. High density binary TeO2–Bi2O3 glasses: strong potential as a nontoxic and environmentally friendly glass shields for photons/charged particles. J Mater Res Technol 2022;17:1311–8. [CrossRef]

- Podra P, Andersson S. Simulating sliding wear with finite element method. Tribol Int 1999;32:71–81. [CrossRef]

- Babu MV, Kumar RK, Prabhakar O, Shankar NG. Simultaneous optimization of flame spraying process parameters for high quality molybdenum coatings using Taguchi methods. Surf Coatings Technol 1996;79:276–88. [CrossRef]

- Oksa M, Turunen E, Suhonen T, Varis T, Hannula SP. Optimization and characterization of high velocity oxy-fuel sprayed coatings: Techniques, materials, and applications. Coatings 2011;1:17–52. [CrossRef]

- Huang B, Zhang C, Zhang G, Liao H. Wear and corrosion resistant performance of thermal-sprayed Fe-based amorphous coatings: A review. Surf Coatings Technol 2019;377:124896. [CrossRef]

- Selvam JDR, Dinaharan I, Rai RS. Matrix and Reinforcement Materials for Metal Matrix Composites. Encycl Mater Compos 2021;2:615–39. [CrossRef]

- Dontsov Y V., Panin S V., Buslovich DG, Berto F. Taguchi optimization of parameters for feedstock fabrication and FDM manufacturing of wear-resistant UHMWPE-based composites. Materials (Basel) 2020;13:1–26. [CrossRef]

- Muhammed OS, Saleh HR, Alwan HL. Using of Taguchi method to optimize the casting of Al–Si/Al2O3 composites. Eng Technol J 2009;27:1143–50. [CrossRef]

- Mehat NM, Kamaruddin S. Quality control and design optimisation of plastic product using Taguchi method: a comprehensive review. Int J Plast Technol 2012;16:194–209. [CrossRef]

- Kiilakoski J, Trache R, Björklund S, Joshi S, Vuoristo P. Process parameter impact on suspension-HVOF-sprayed Cr2O3 coatings. J Therm Spray Technol 2019;28:1933–44.

- Gujba AK, Mahdipoor MS, Medraj M. Water droplet impingement erosion performance of WC-based coating sprayed by HVAF and HVOF. Wear 2021;484:203904. [CrossRef]

- Hanson TC, Settles GS. Particle temperature and velocity effects on the porosity and oxidation of an HVOF corrosion-control coating. J Therm Spray Technol 2003;12:403–15. [CrossRef]

- Prasad R V, Rajesh R, Thirumalaikumarasamy D, Vignesh S, Sreesabari S. Sensitivity analysis and optimisation of HVOF process inputs to reduce porosity and maximise hardness of WC-10Co-4Cr coatings. Sādhanā 2021;46:1–23. [CrossRef]

- Hunter CE, Gardner TP, Zakrajsek CE. Simultaneous Optimization of Diesel Engine Parameters for Low Emissions Using Taguchi Methods. SAE Trans 1990;99:2068–78.

- Opeka MM, Talmy IG, Wuchina EJ, Zaykoski JA, Causey SJ. Mechanical, Thermal, and Oxidation Properties of Refractory Hafnium and zirconium Compounds. J Eur Ceram Soc 1999;19:2405–14. [CrossRef]

- Kuwabara K, Sakamoto S, Kida O, Ishino T, Kodama T, Nakajima H, et al. CORROSION RESISTANCE AND ELECTRICAL RESISTIVITY OF ZrB 2 MONOLITHIC REFRACTORY. Refractories(Tokyo) 2004;56:116.

- Chamberlain AL, Fahrenholtz WG, Hilmas GE, Ellerby DT. High-strength zirconium diboride-based ceramics. J Am Ceram Soc 2004;87:1170–2.

- Rani APDAMA. The undersigned certify that they have read, and recommend to The Postgraduate Studies Programme for acceptance this thesis for the fulfillment ofthe requirements n.d.

- Murata Y. Cutting tool tips and ceramics containing hafnium nitride and zirconium diboride 1970.

- Sung J, Goedde DM, Girolami GS, Abelson JR. Remote-plasma chemical vapor deposition of conformal ZrB 2 films at low temperature: A promising diffusion barrier for ultralarge scale integrated electronics. J Appl Phys 2002;91:3904–11. [CrossRef]

- Zhang H, Hu Y, Hou G, An Y, Liu G. The effect of high-velocity oxy-fuel spraying parameters on microstructure, corrosion and wear resistance of Fe-based metallic glass coatings. J Non Cryst Solids 2014;406:37–44. [CrossRef]

- Cai Z, Deng S, Liao H, Zeng C, Montavon G. The effect of spray distance and scanning step on the coating thickness uniformity in cold spray process. J Therm Spray Technol 2014;23:354–62. [CrossRef]

- ASTM A. ASTM E18-03: Standard test methods for rockwell hardness and rockwell superficial hardness of metallic materials. Annu B ASTM Stand 2003.

- Wilson VH, Udayakumar. Optimization of diesel engine parameters using Taguchi method and design of evolution. J Brazilian Soc Mech Sci Eng 2012;34:423–8. [CrossRef]

- Asiltürk I, Akkuş H. Determining the effect of cutting parameters on surface roughness in hard turning using the Taguchi method. Measurement 2011;44:1697–704. [CrossRef]

- Balak Z, Azizieh M, Kafashan H, Asl MS, Ahmadi Z. Optimization of effective parameters on thermal shock resistance of ZrB2-SiC-based composites prepared by SPS: using Taguchi design. Mater Chem Phys 2017;196:333–40.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).