Submitted:

03 January 2024

Posted:

04 January 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

- Improved Efficiency: The integration of an electric powertrain allows a more precise control of energy usage, optimizing the tractor’s performance during farming operations;

- Fuel Savings: The reduced reliance on fossil fuels by harnessing electric power, leading to significant fuel savings and cost reduction;

- Lower Emissions: The emission of fewer pollutant exhaust and GHG during operations, contributing to a cleaner and more sustainable farming practice;

- Flexibility: The tractor can switch between the ICE and the electric power source, allowing the farmers to adapt their employment to different workloads and working conditions;

- Reduced Noise and Vibrations: The electric motor operates quietly, reducing noise pollution in rural areas and improving the working environment;

- Less Maintenance Costs: The tractor have far lower maintenance requisites than the diesel counterparts because they have fewer mechanical parts, reducing the chance to break down;

- Safety and Stability: These tractors have a center of gravity positioned lower than the diesel counterparts, reducing the likelihood of their toppling or rolling over uneven terrains;

2. Materials and Methods

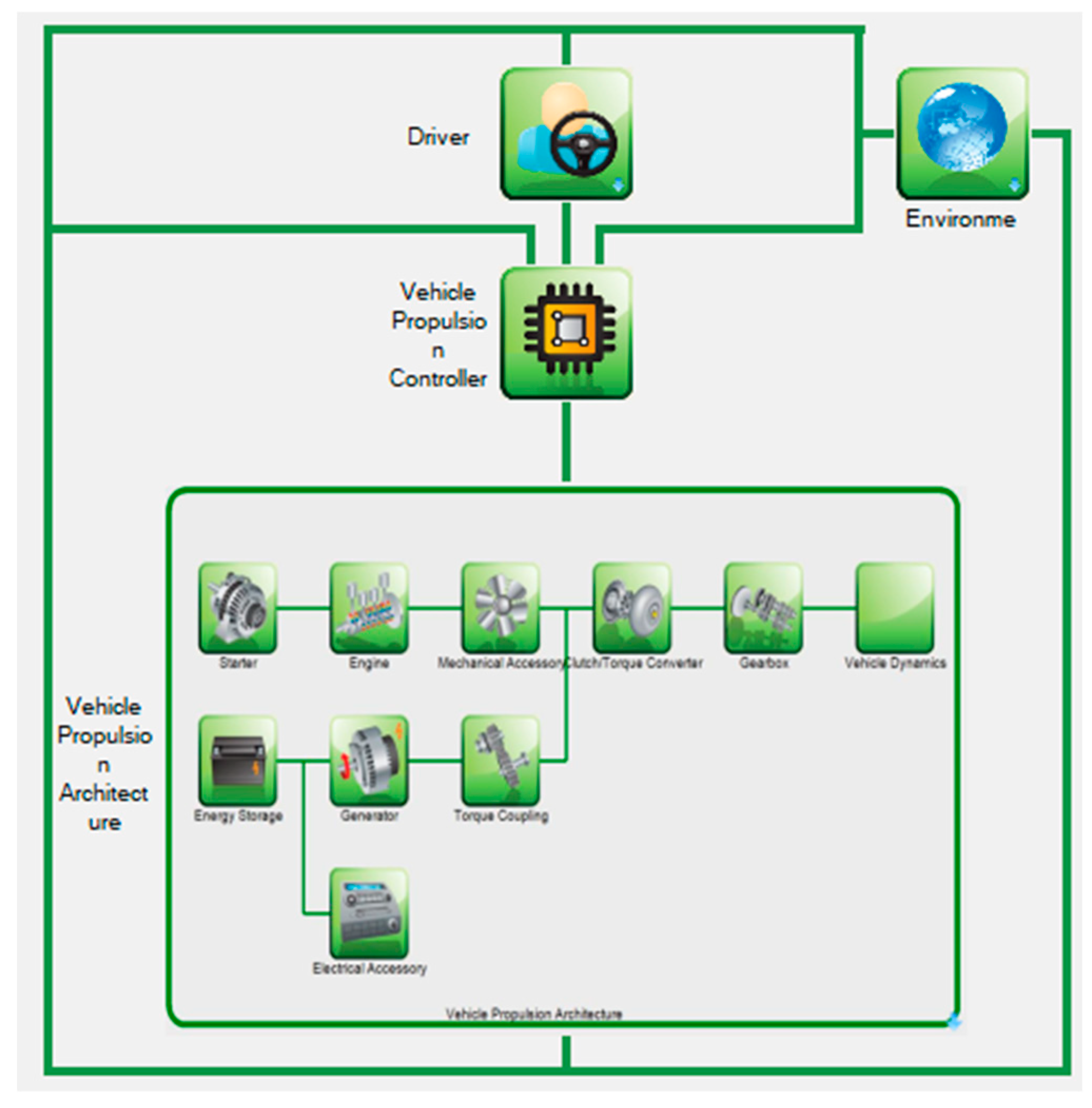

2.1. “ Autonomie” Simulation Software

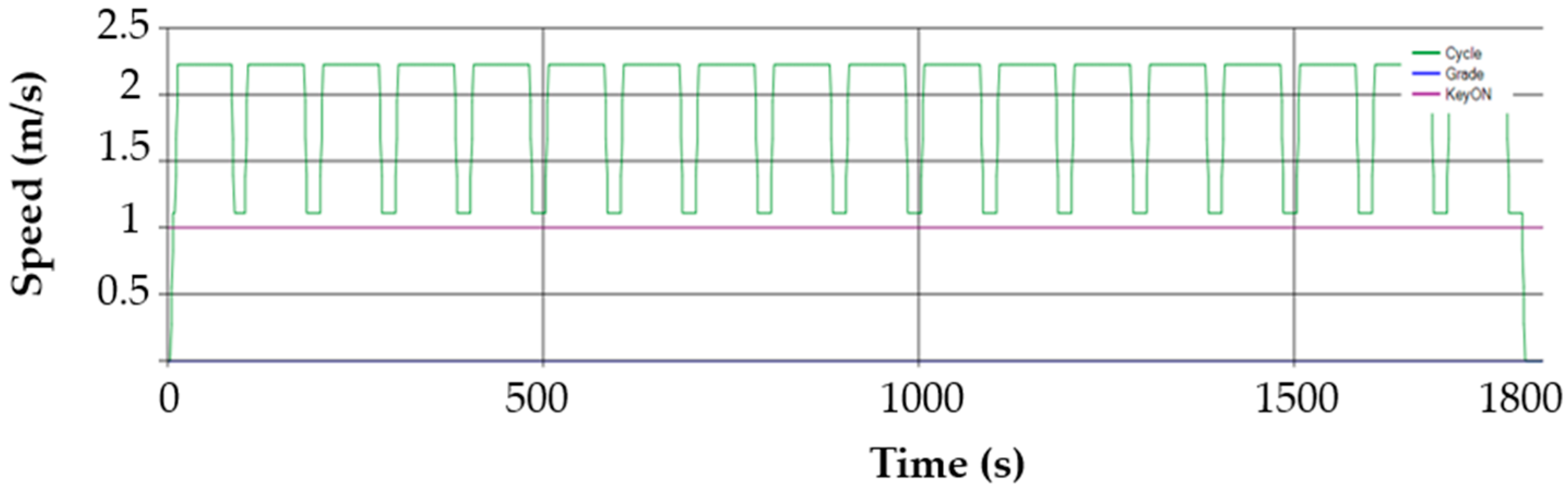

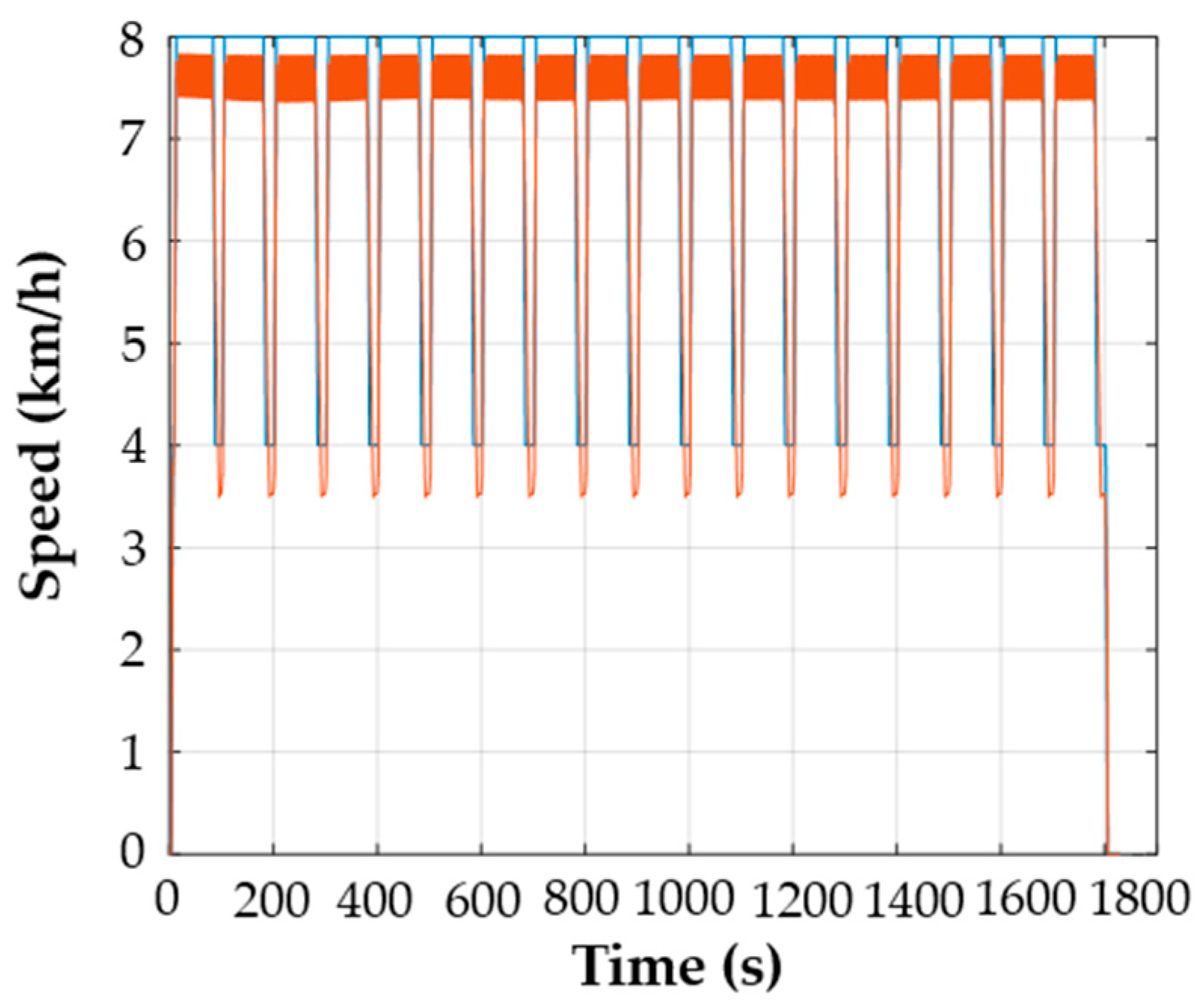

2.2. Working Cycle Definition

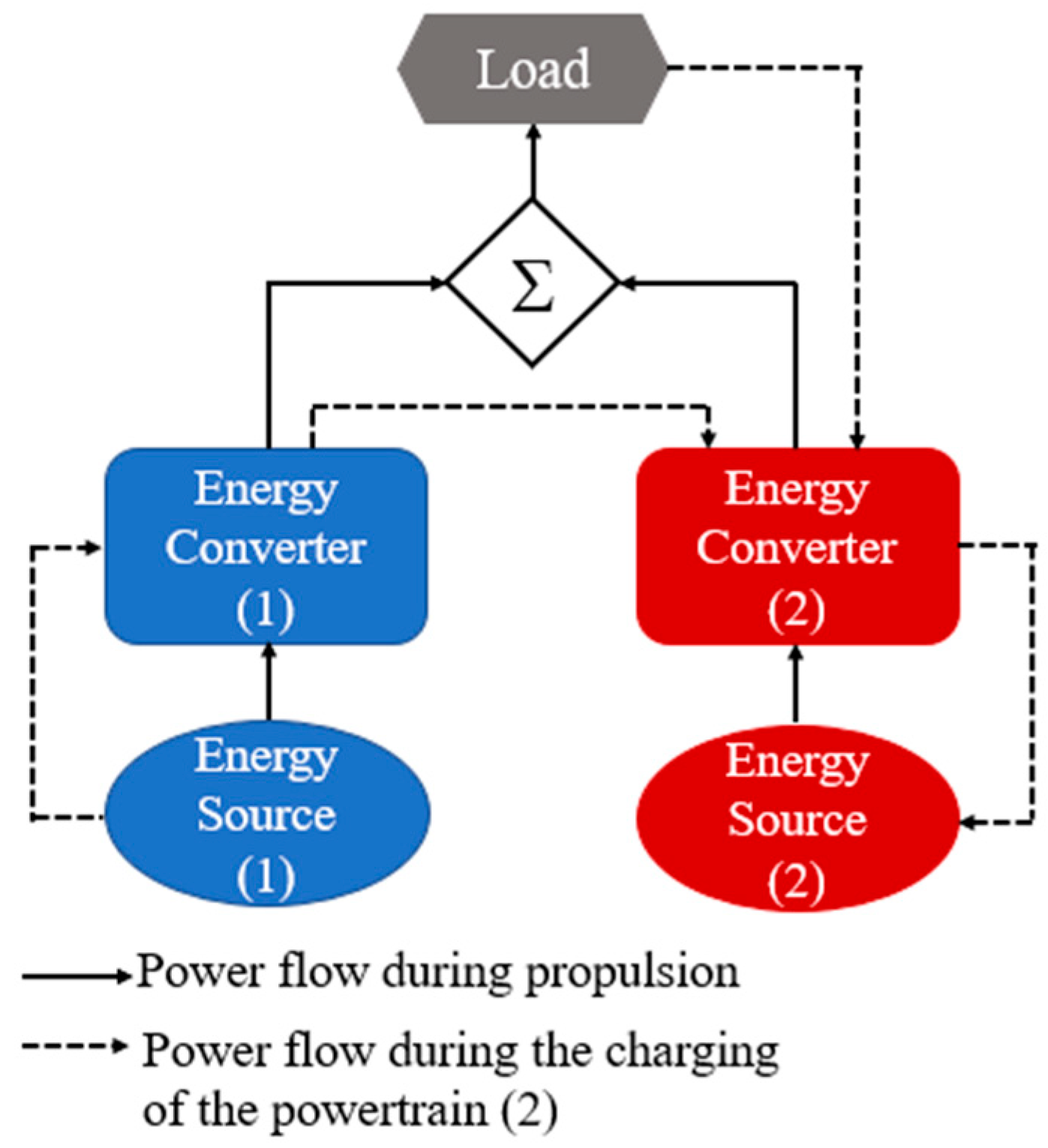

2.3. Hybrid Electric Agricultural Tractor Powertrain

2.4. Simulink Models for parameters calculation

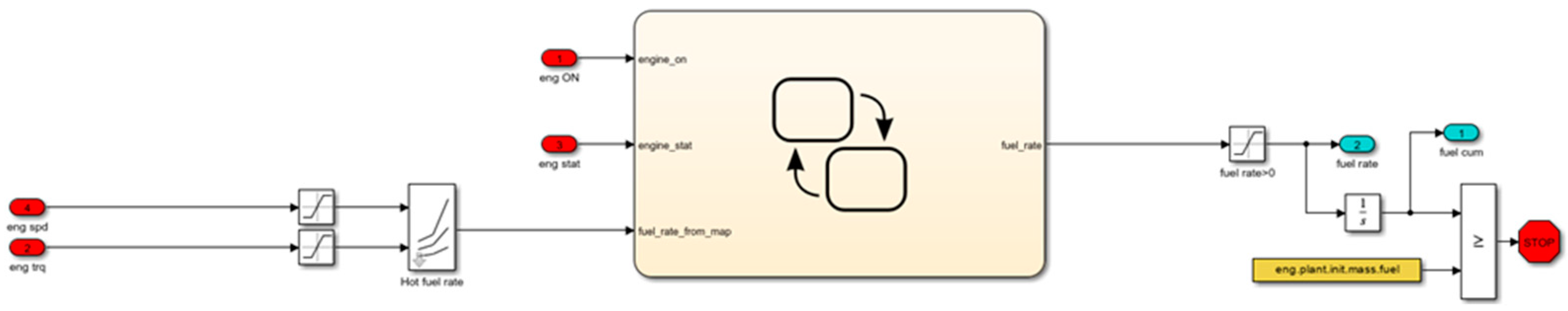

2.4.1. Fuel Consumption Calculation

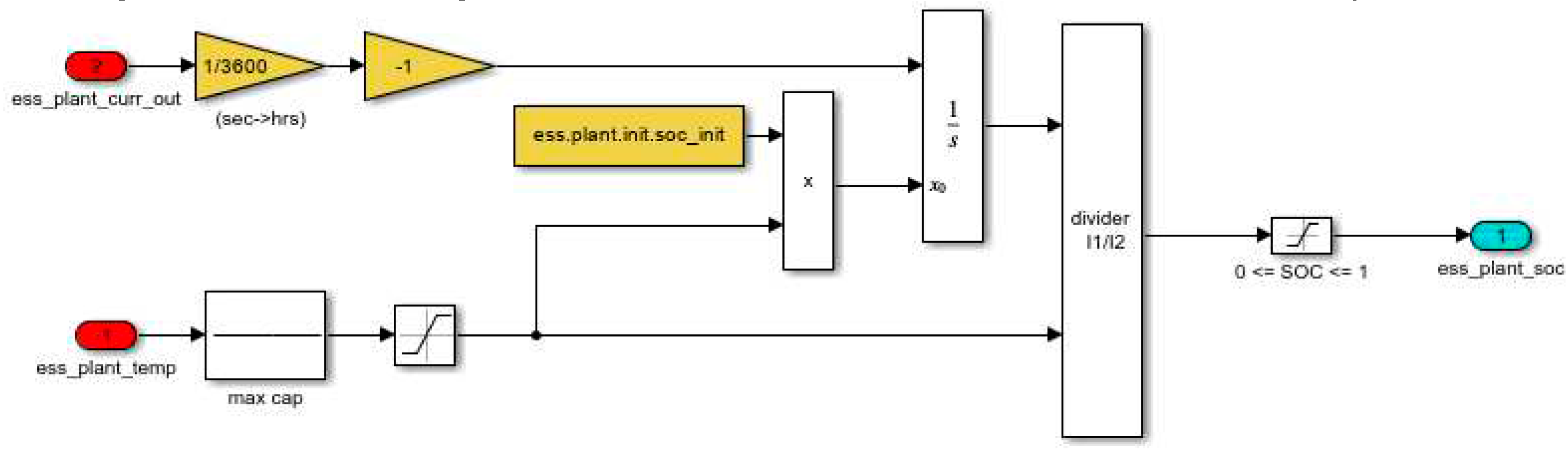

2.4.2. Battery State of Charge Calculation

3. Results

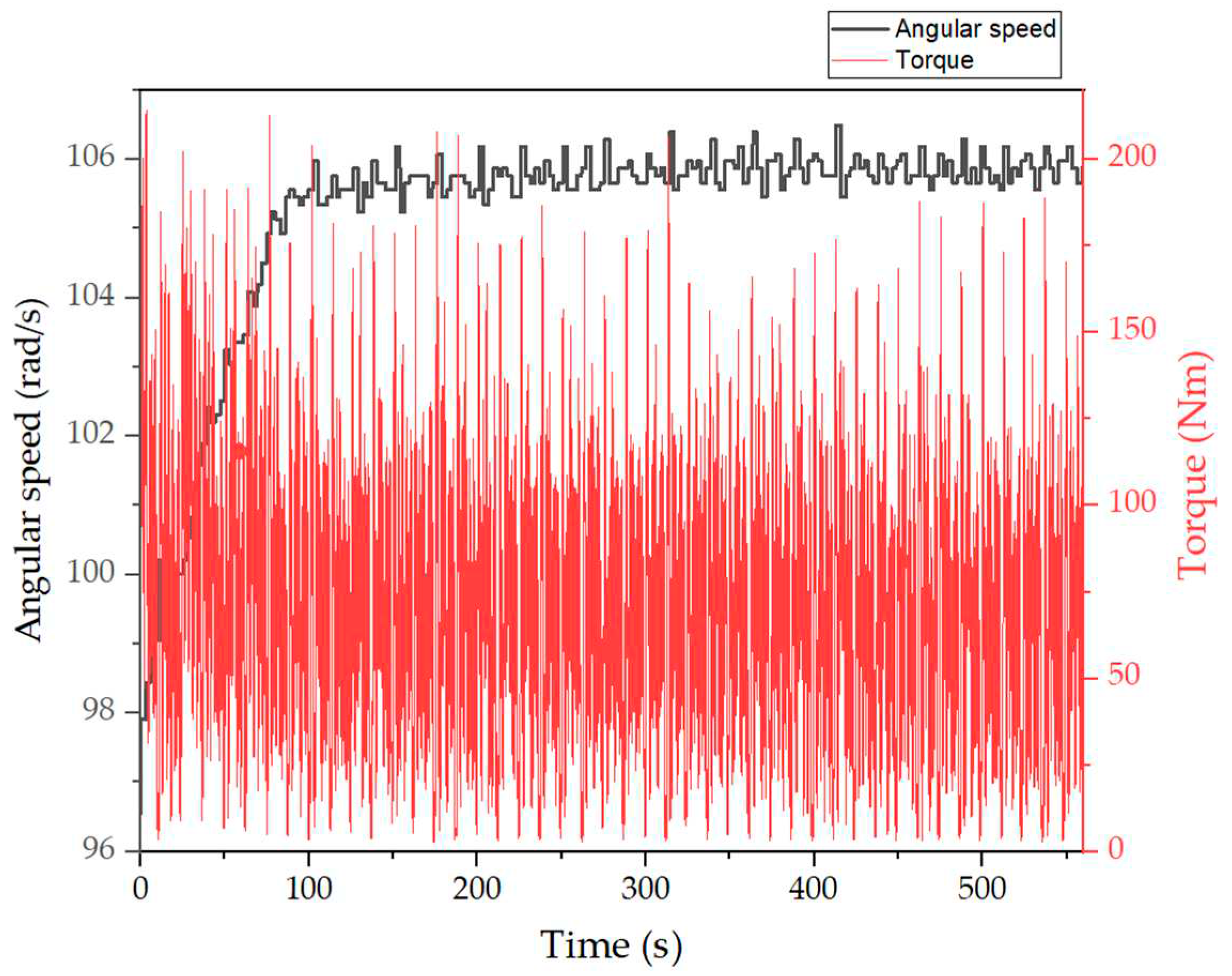

3.1. Measuring the Torque and the PTO angular speed

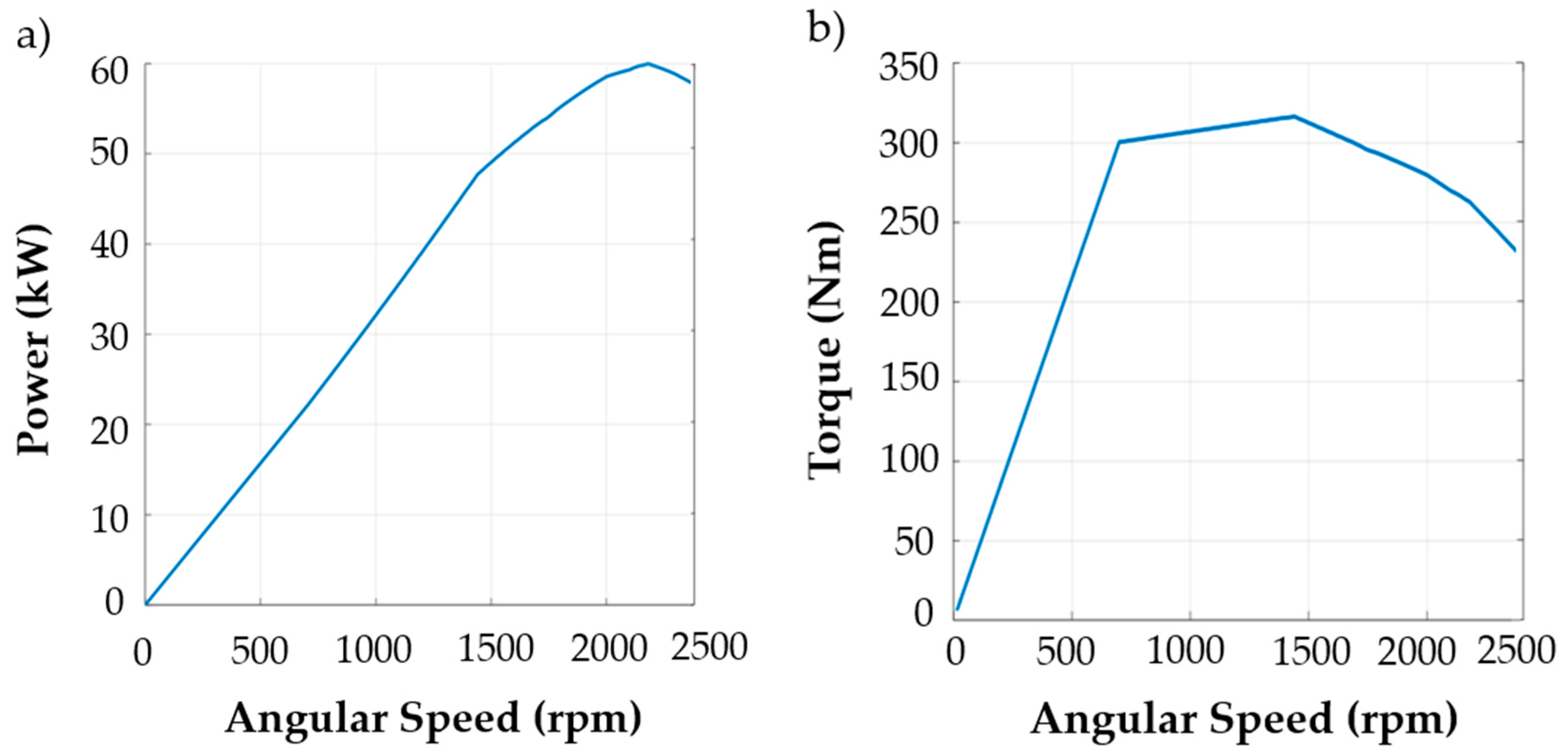

3.2. Parameters of the models

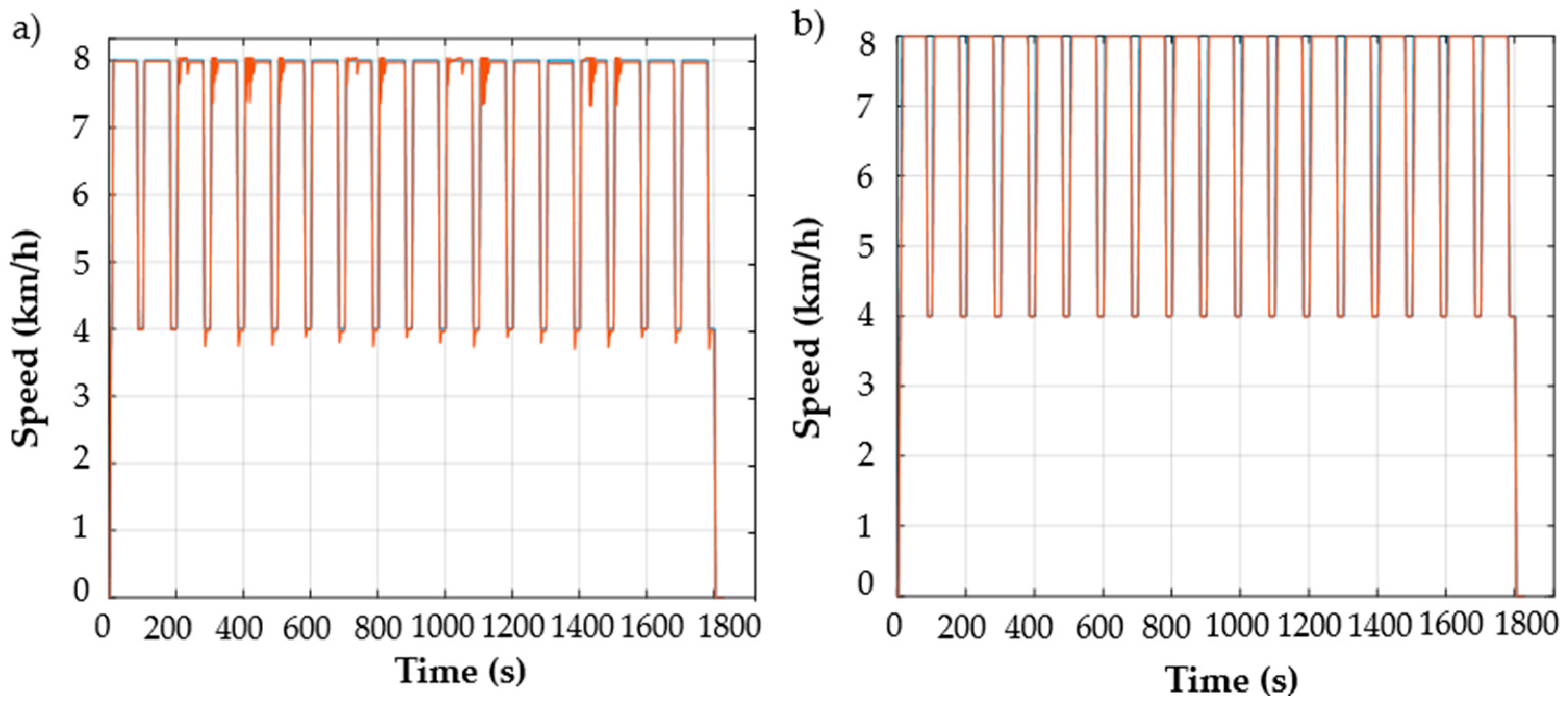

3.3. Models’ Simulations

3.3.1. Conventional Agricultural Tractor

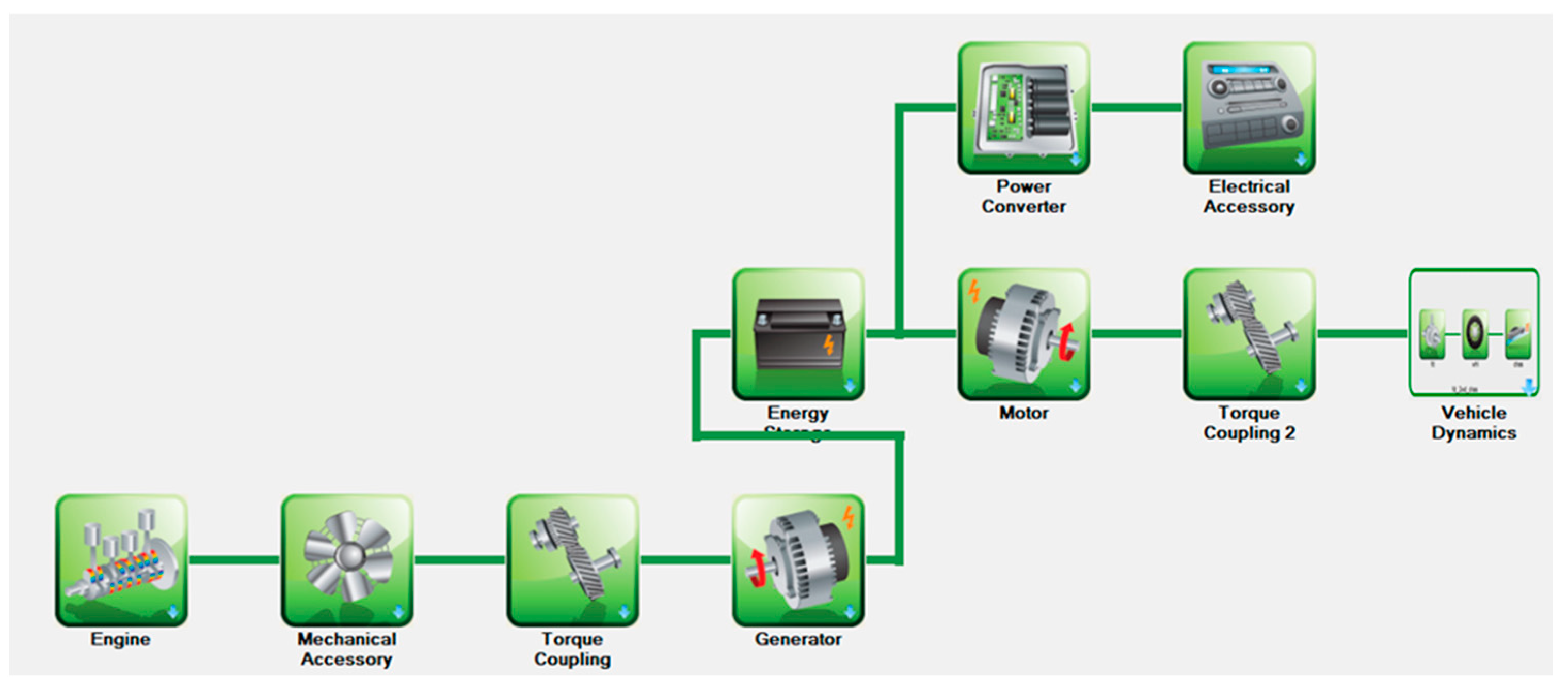

3.3.2. Series Electric Hybrid Agricultural Tractor

- Tractor 1 (60 kW)

- Tractor 2 (90 kW)

- Tractor 3 (160 kW)

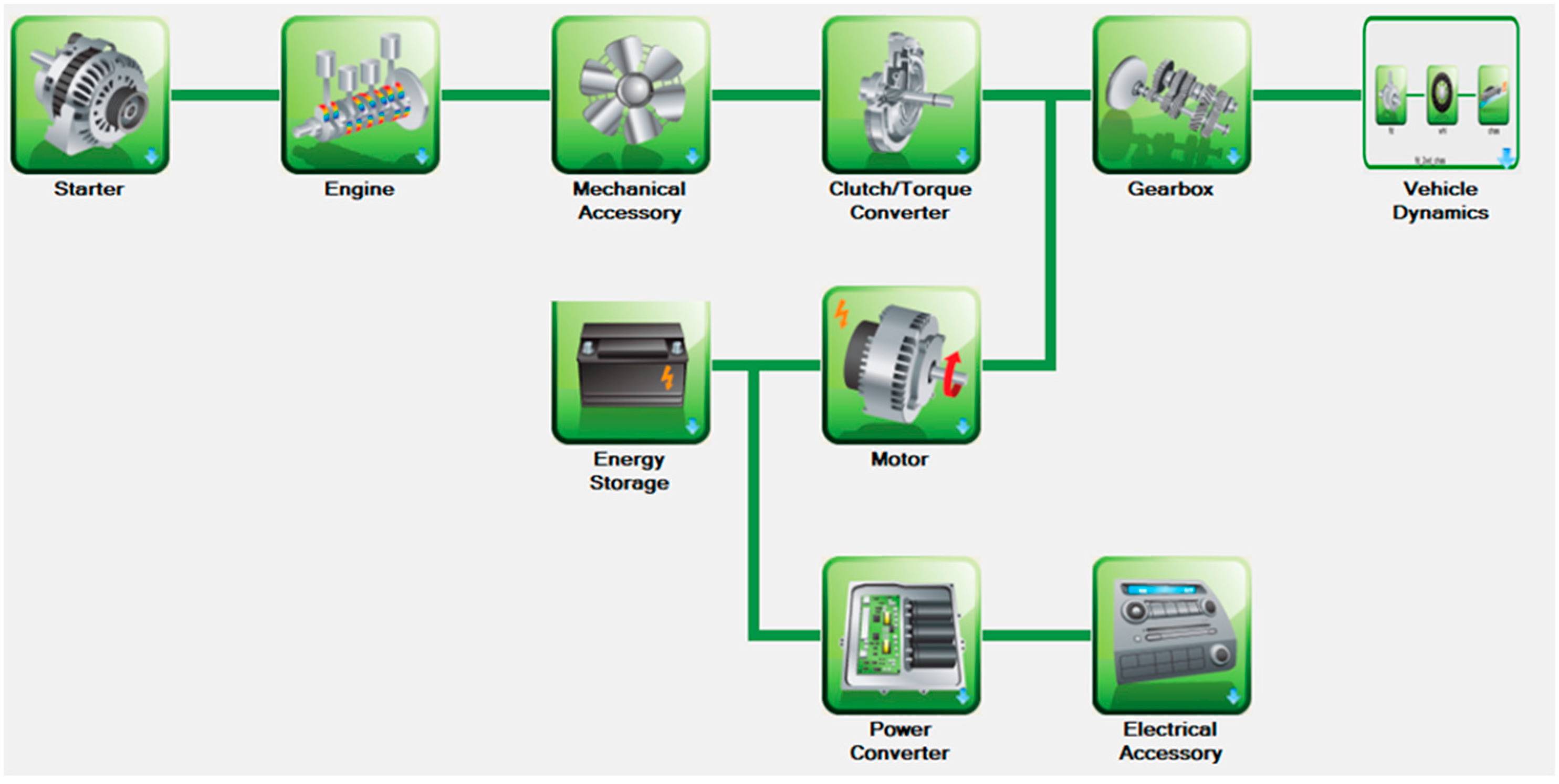

3.3.3. Parallel Electric Hybrid Agricultural Tractor

- Tractor 1 (60 kW)

- Tractor 2 (90 kW)

- Tractor 3 (160 kW)

4. Discussion

4.1. Conventional powertrain

4.2. Series Electric Hybrid Powertrain

4.3. Parallel Electric Hybrid

4.4. General Evaluation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Lovarelli, D.; Bacenetti, J. Exhaust gases emissions from agricultural tractors: State of the art and future perspectives for machinery operators. Biosystems Engineering 2019, 186, 204–213. [Google Scholar] [CrossRef]

- Gołasa, P.; Wysokiński, M.; Bieńkowska-Gołasa, W.; Gradziuk, P.; Golonko, M.; Gradziuk, B.; Siedlecka, A.; Gromada, A. Sources of Greenhouse Gas Emissions in Agriculture, with Particular Emphasis on Emissions from Energy Used. Energies 2021, 14, 3784. [Google Scholar] [CrossRef]

- Murawska, A.; Goryńska-Goldmann, E. Greenhouse Gas Emissions in the Agricultural and Industrial Sectors—Change Trends, Economic Conditions, and CountryD Classification: Evidence from the European Union. Agriculture 2023, 13, 1354. [Google Scholar] [CrossRef]

- Pérez-Martínez, PJ. Energy consumption and emissions from the road transport in Spain: a conceptual approach. Transport 2012, 27, 383–396. [Google Scholar] [CrossRef]

- Renius, K. T. Fundamentals of tractor design; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Hoy, R.; Rohrer, R.; Liska, A.; Luck, J.; Isom, L.; Keshwani, D. (2014). Agricultural Industry Advanced Vehicle Technology: Benchmark Study for Reduction in Petroleum Use. Adam Liska Papers 2014, 19.

- Sendzikiene, E.; Makareviciene, V.; Kalenska, S. Exhaust emissions from the engine running on multi-component fuel. Transport 2012, 27, 111–117. [Google Scholar] [CrossRef]

- Labeckas, G.; Slavinskas, S. Performance and emission charakteristics of a direct injection diesel engine operating on KDV synthetic diesel fuel. Energy Convers Manage 2013, 66, 173–88. [Google Scholar] [CrossRef]

- Rakopoulos, D.C.; Rakopoulos, C.D.; Kakaras, E.C; Giakoumis, E.G. Effects of ethanol diesel fuel blends on the performance and exhaust emissions of heavy duty DI diesel engine. Energy Convers Manage 2008, 49, 3155–3162. [Google Scholar] [CrossRef]

- Tomic, M.; Savin, L.; Micic, R.; Simikić, M.; Furman, T. Effects of fossil diesel and biodiesel blends on the performances and emissions of agricultural tractor engines. Thermal Science 2013, 17. [Google Scholar] [CrossRef]

- Guo, X.; Wu, H.; Chen, D.; Ye Z Shen, Y.; Liu, J.; Cheng, S. Estimation and prediction of pollutant emissions from agricultural and construction diesel machinery in the Beijing-Tianjin-Hebei (BTH) region, China☆. Environ Pollut 2020, 260, 113973. [Google Scholar] [CrossRef]

- Lindgren, M.; Arrhenius, K.; Larsson, G.; Bäfver, L.; Arvidsson, H.; Wetterberg, C. Analysis of unregulated emissions from an off-road diesel engine during realistic work operations. Atmos Environ 2011, 45, 5394–5398. [Google Scholar] [CrossRef]

- Li, Y.X.; McLaughlin, N.B.; Patterson, B.S.; Burtt, S.D. Fuel efficiency and exhaust emissions for biodiesel blends in an agricultural tractor. Can Biosyst Eng 2006, 48, 15–22. [Google Scholar]

- Lindgren, M.; Larsson, G.; Hansson, P.A. Evaluation of factors influencing emissions from tractors and construction equipment during realistic work operations using diesel fuel and bio-fuels as substitute. Biosyst Eng 2010, 107, 123–30. [Google Scholar] [CrossRef]

- Algirdas Janulevičius, Antanas Juostas, Gediminas Pupinis, Tractor’s engine performance and emission characteristics in the process of ploughing, Energy Conversion and Management, Volume 75, 2013, Pages 498-508. [CrossRef]

- Lovarelli, D.; Fiala, M.; Larsson, G. Fuel consumption and exhaust emissions during on-field tractor activity: A possible improving strategy for the environmental load of agricultural mechanization. Computers and Electronics in Agriculture 2018, 151. [Google Scholar] [CrossRef]

- Janulevicius, A.; Juostas, A.; Pupinis, G. Engine performance during tractor operational period. Energy Convers Manage 2013, 68, 9–11. [Google Scholar] [CrossRef]

- Hansson, P.A.; Lindgren, M.; Norén, O. A comparison between different methods of calculating average engine emissions for agricultural tractors. J Agric Eng Res 2001, 80, 37–43. [Google Scholar] [CrossRef]

- Bulgakov, V.; Pascuzzi, S.; Adamchuk, V.; Kuvachov, V.; Nozdrovicky, L. Theoretical study of transverse offsets of wide span tractor working implements and their influence on damage to row crops. Agriculture 2019, 9, 144. [Google Scholar] [CrossRef]

- An, H.; Yang, W.M.; Maghbouli, A.; Li, J.; Chou, S.K.; Chua, K.J. Performance, combustion and emission characteristics of biodiesel derived from waste cooking oils. Appl Energy 2013, 112, 493–499. [Google Scholar] [CrossRef]

- Martini, V.; Mocera, F.; Somà, A. Numerical Investigation of a Fuel Cell-Powered Agricultural Tractor. Energies 2022, 15, 8818. [Google Scholar] [CrossRef]

- Mocera, F.; Martini, V.; Soma, A. Comparative Analysis of Hybrid Electric Architectures for Specialized Agricultural Tractors. Energies 2022, 15, 1944. [Google Scholar] [CrossRef]

- Mocera, F.; Somà, A. Analysis of a Parallel Hybrid Electric Tractor for Agricultural Applications. Energies 2020, 13, 3055. [Google Scholar] [CrossRef]

- Dalboni, M.; Santarelli, P.; Patroncini, P.; Soldati, A.; Concari, C.; Lusignani, D. Electrification of a Compact Agricultural Tractor: A Successful Case Study. In Proceedings of the IEEE Transportation Electrification Conference and Expo (ITEC), Detroit, MI, USA; 2019. [Google Scholar] [CrossRef]

- Mocera, F.; Somà, A.; Martelli, S.; Martini, V. Trends and Future Perspective of Electrification in Agricultural Tractor-Implement Applications. Energies 2023, 16, 6601. [Google Scholar] [CrossRef]

- Gray, N.; O'Shea, R.; Wall, D.; Smyth, B.; Lens, P.N.L; Murphy, J. Batteries, fuel cells, or engines? A probabilistic economic and environmental assessment of electricity and electrofuels for heavy goods vehicles. Advances in Applied Energy 2022, 8. [Google Scholar] [CrossRef]

- Scolaro, E.; Beligoj, M.; Perez Estevez, M.; Alberti, L.; Renzi, M.; Mattetti, M. Electrification of Agricultural Machinery A Review. IEEE Access 2021, 9, 164520–164541. [Google Scholar] [CrossRef]

- Eftekhari, A. Energy efficiency: a critically important but neglected factor in battery research. Sustainable Energy & Fuels, 2017; 1.10, 2053–2060. [Google Scholar] [CrossRef]

- Lajunen, A. Simulation of energy efficiency and performance of electrified powertrains in agricultural tractors. In Proceedings of the 2022 IEEE Vehicle Power and Propulsion Conference (VPPC), Merced, CA, USA; 2022. [Google Scholar] [CrossRef]

- Mohsen, A.; Bilge G., C. ; Digital Twin: Benefits, use cases, challenges, and opportunities. Decision Analytics Journal 2023, 6, 100165. [Google Scholar] [CrossRef]

- Guerrieri, A. S.; Anifantis, A.; Santoro, F.; Pascuzzi, S. Study of a Large Square Baler with Innovative Technological Systems that Optimize the Baling Effectiveness. Agriculture 2019, 9, 86. [Google Scholar] [CrossRef]

- Karbowski, D.; Pagerit, S. “Autonomie”, a plug-and-play software architecture. In Proceedings of the Vehicle Power and Propulsion Conference, Lille, France; 2010. [Google Scholar]

- Vijayagopal, R.; Rousseau, A. System Analysis of Multiple Expert Tools. SAE Technical Paper-01-0754 2011,1-11. [CrossRef]

- Halbach, S.; Sharer, P.; Pagerit, S.; Rousseau, A.; et al. Model Architecture, Methods, and Interfaces for Efficient Math-Based Design and Simulation of Automotive Control Systems. SAE Technical Paper 2010. [Google Scholar] [CrossRef]

- Lajunen, A.; Lipman, T. Lifecycle cost assessment and carbon dioxide emissions of diesel, natural gas, hybrid electric, fuel cell hybrid and electric transit buses. Energy, 2016; 106, 329–342. [Google Scholar] [CrossRef]

- Rahman, S.M.A.; Fattah, I.M.R.; Ong, H.C.; Ashik, F.R.; Hassan, M.M.; Murshed, M.T.; Imran, M.A.; Rahman, M.H.; Rahman, M.A.; Hasan, M.A.M.; et al. State-of-the-Art of Establishing Test Procedures for Real Driving Gaseous Emissions from Light- and Heavy-Duty Vehicles. Energies 2021, 14, 4195. [Google Scholar] [CrossRef]

- Bulgakov, V.; Pascuzzi, S.; Beloev, H.; Ivanovs, S. Theoretical investigations of the headland turning agility of a trailed asymmetric implement-and-tractor aggregate. Agriculture 2019, 9, 224. [Google Scholar] [CrossRef]

- Crolla, D.A. Torsional Vibration Analysis of tractor and machine PTO drivelines. J. Agric. Eng. Res. 1978, 23, 259–272. [Google Scholar] [CrossRef]

- Crolla, D.A. Theoretical analysis of inertia torque overloads when starting up PTO driven machinery. J. Agric. Eng. Res. 1977, 22, 197. [Google Scholar] [CrossRef]

- Park, Y.J.; Kim, S.C.; Kim, J.G. Analysis and verification of power transmission characteristics of the hydromechanical transmission for agricultural tractors. J. Mech Sci Technol 2016, 30, 5063–5072. [Google Scholar] [CrossRef]

- Gomez, K.A.; Gomez, A.A. Statistical Procedures for Agricultural Research, 2nd ed.; Wiley-Interscience: New York, NY, USA, 1984. [Google Scholar]

- Karner, J.; Baldinger, M.; Reichl, B. Prospects of Hybrid Systems on Agricultural Machinery. GSTF Journal on Agricultural Engineering 2014, 1. [Google Scholar] [CrossRef] [PubMed]

- Lovarelli, D.; Fiala, M.; Larsson, G. Fuel consumption and exhaust emissions during on-field tractor activity: A possible improving strategy for the environmental load of agricultural mechanisation. Computers and Electronics in Agriculture 2018, 151, 238–248. [Google Scholar] [CrossRef]

- Kim, S. C.; Kim, K. U.; Kim, D. C. Prediction of fuel consumption of agricultural tractors. Applied Engineering in Agriculture 2011, 27, 705–709. [Google Scholar] [CrossRef]

- Khatawkkar, D.; Shaji, P.; Dhalin, D. Modern trends in farm machinery-electric drives: A review. Int.J.Curr.Microbiol.App.Sci 2019, 8, 83–98. [Google Scholar] [CrossRef]

- Kolator, B.A. Modeling of Tractor Fuel Consumption. Energies 2021, 14, 2300. [Google Scholar] [CrossRef]

- Piller, S.; Perrin, M.; Jossen, A. Methods for state-of-charge determination and their applications. Journal of power sources 2001, 96, 113–120. [Google Scholar] [CrossRef]

| Min | Max | Average | Standard Deviation | |

| PTO (rad/s) | 96.55 | 106.50 | 105.21 | 1.63 |

| Torque (Nm) | 2.64 | 214.41 | 69.25 | 40.94 |

| Parameter | Tractor 1 | Tractor 2 | Tractor 3 |

|---|---|---|---|

| ICE Maximum Power @ 2200 rpm [kW] |

60 kW | 90 kW | 160 kW |

| Maximum Torque @ 1400 rpm [Nm] |

315 | 475 | 845 |

| Mass [kg] | 2050 | 5000 | 8000 |

| Wheel Radius [m] | 0.3 | 0.38 | 0.42 |

| Parameter | Conventional Tractor | ||

|---|---|---|---|

| Tractor 1 (60 kW) | Tractor 2 (90 kW) | Tractor 3 (160 kW) | |

| CO2 Emission [kg/h] | 13 | 11 | 11.8 |

| Fuel consumption [L/h] | 5 | 4.7 | 5.8 |

| Parameter | Series Electric Hybrid Tractor | ||

|

Tractor 1 (60 kW) Config. A Config. B |

Tractor 2 (90 kW) Config. A Config. B |

Tractor 3 (160 kW) Config. A Config. B |

|

| CO2 emission [kg/h] | 1.1 0.7 | 3 2.5 | 4.6 3.7 |

| Fuel Consumption [L/h] | 0.5 0.4 | 1.4 1.2 | 2.2 1.8 |

| Δ SOC [%] | -22.5 -24.5 | -25.1 -26.6 | -27.1 -27.7 |

| Parameter | Parallel Electric Hybrid Tractor | ||

|

Tractor 1 (60 kW) Config. A Config. B |

Tractor 2 (90 kW) Config. A Config. B |

Tractor 3 (160 kW) Config. A Config. B |

|

| CO2 emission [kg/h] | 2.3 1.6 | 4.5 4.2 | 7.7 6.3 |

| Fuel Consumption [L/h] | 1.1 0.8 | 2.1 2 | 3.5 3 |

| Δ SOC [%] | -3.3 -5 | -5.5 -6.4 | -7 -7.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).