Submitted:

27 December 2023

Posted:

29 December 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Solid Lubricants: Classification, Types, and Machining Applications

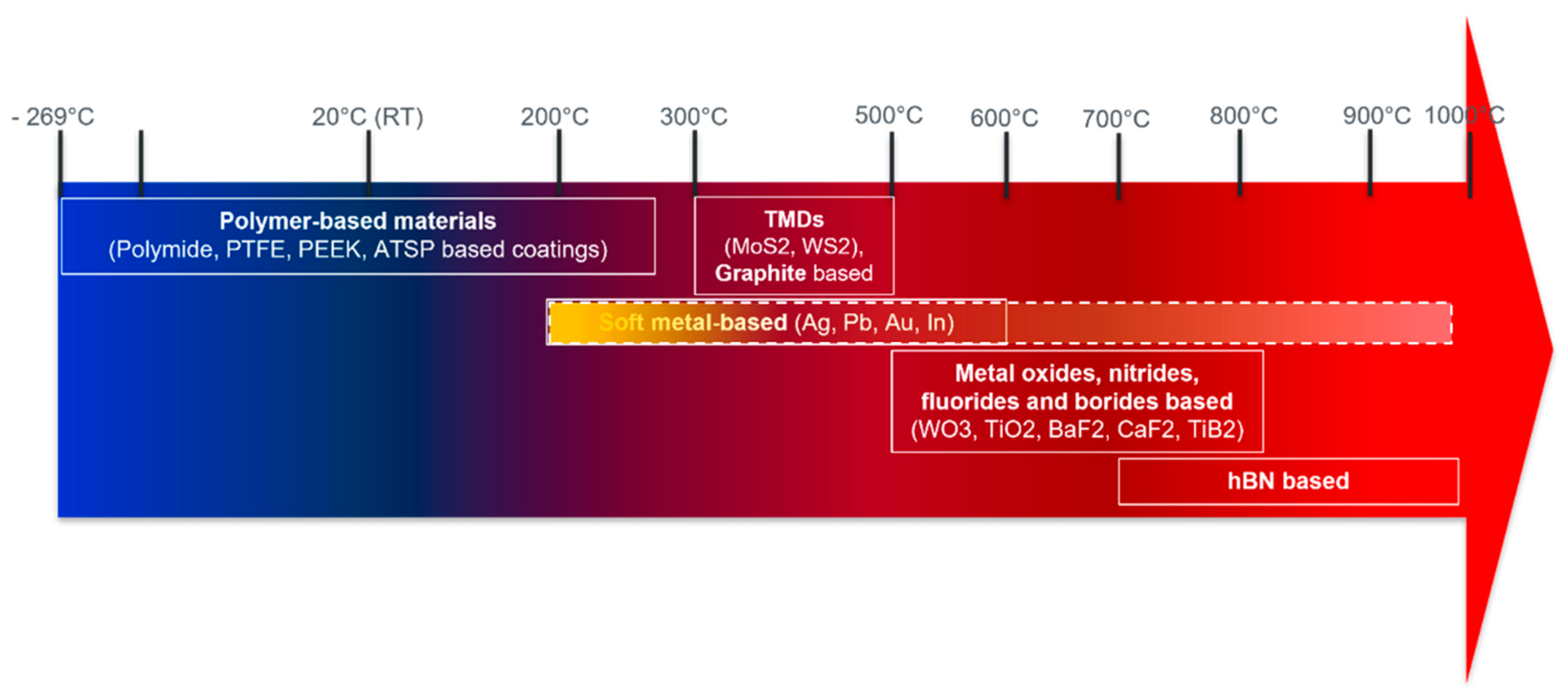

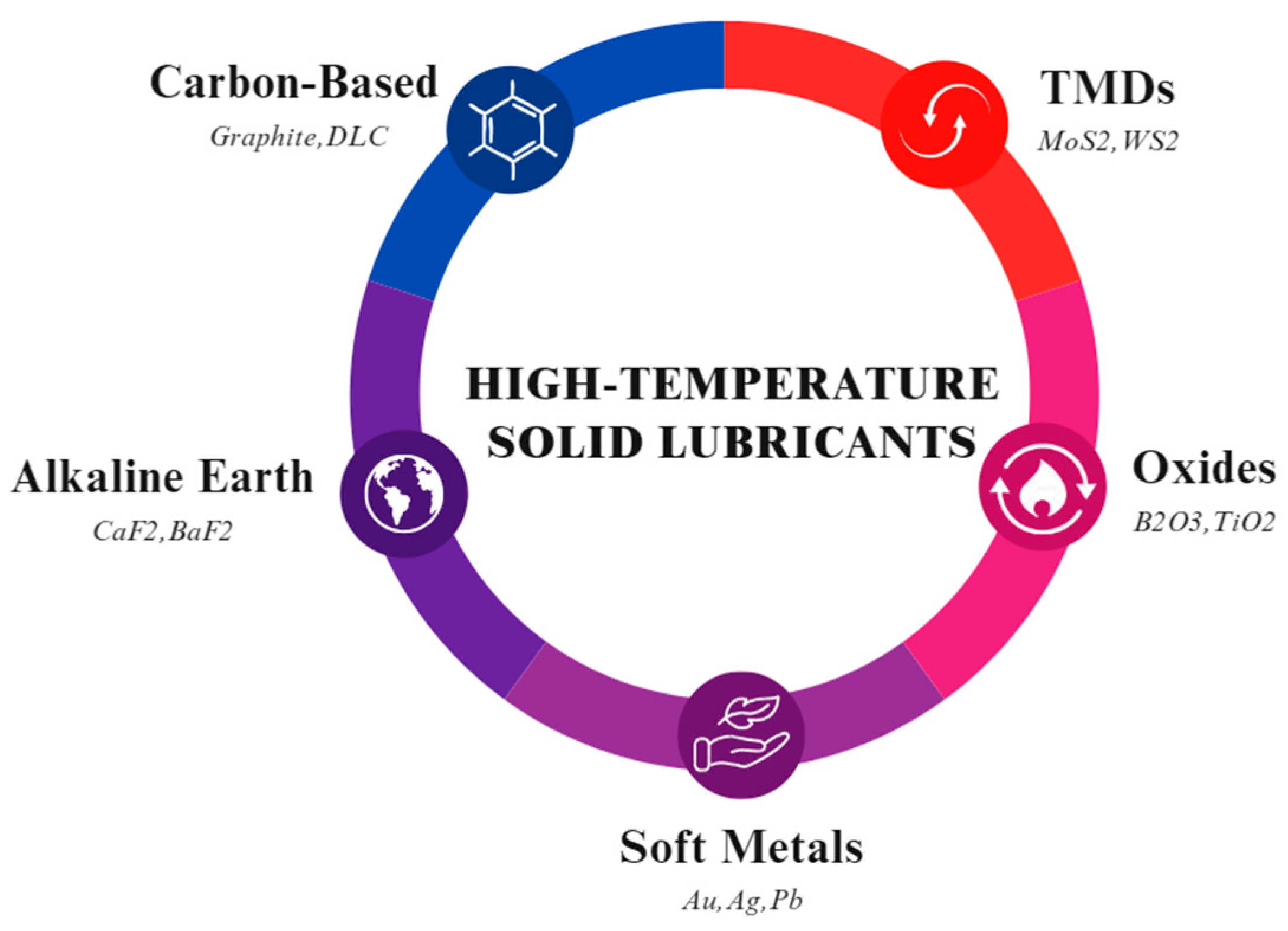

2.1. High-temperature solid lubricants used in machining

2.1.1. Carbon-based lubricants

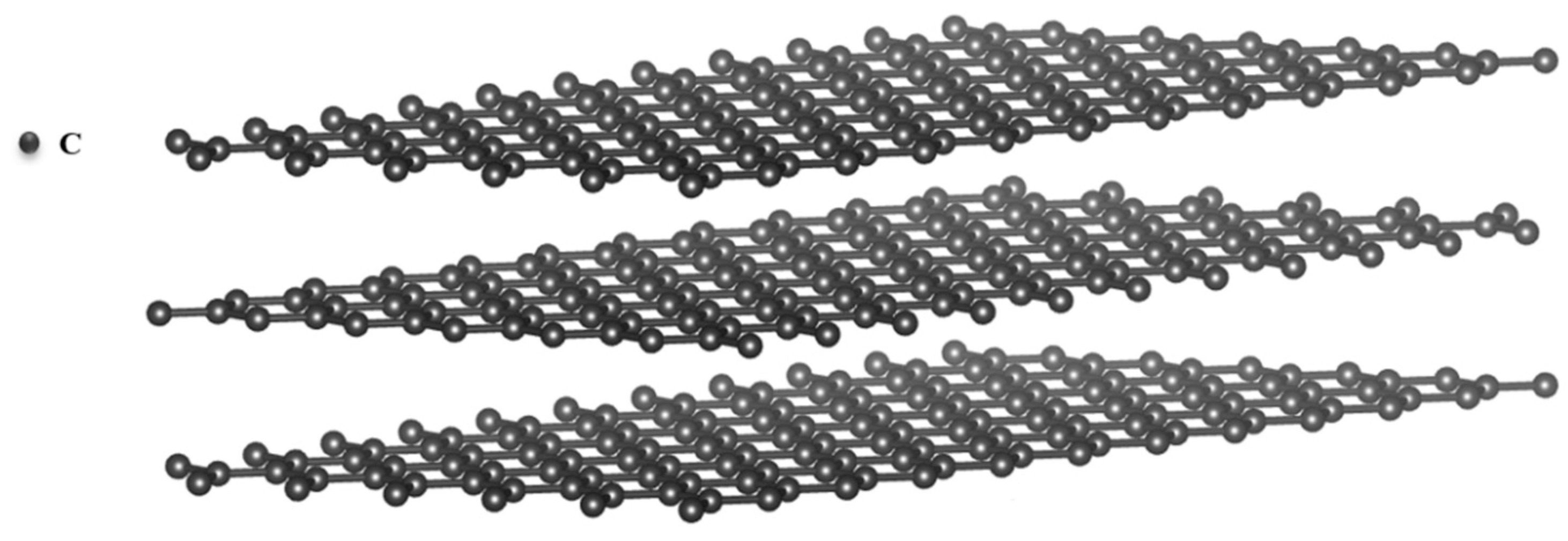

2.1.1.1. Graphite

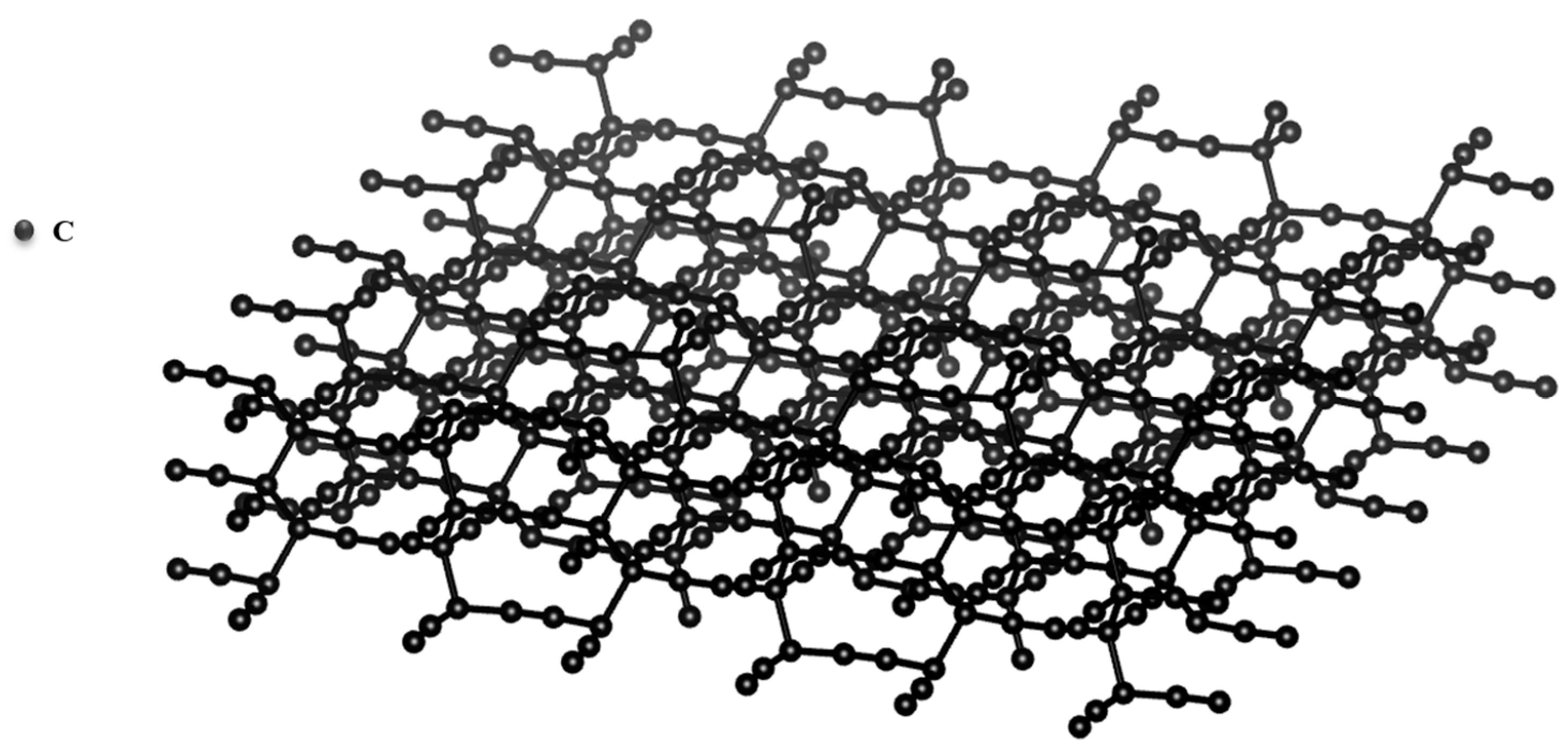

2.1.1.2. Diamond-Like Carbon (DLC)

2.1.2. Transition metal dichalcogenide compounds (TMDs)

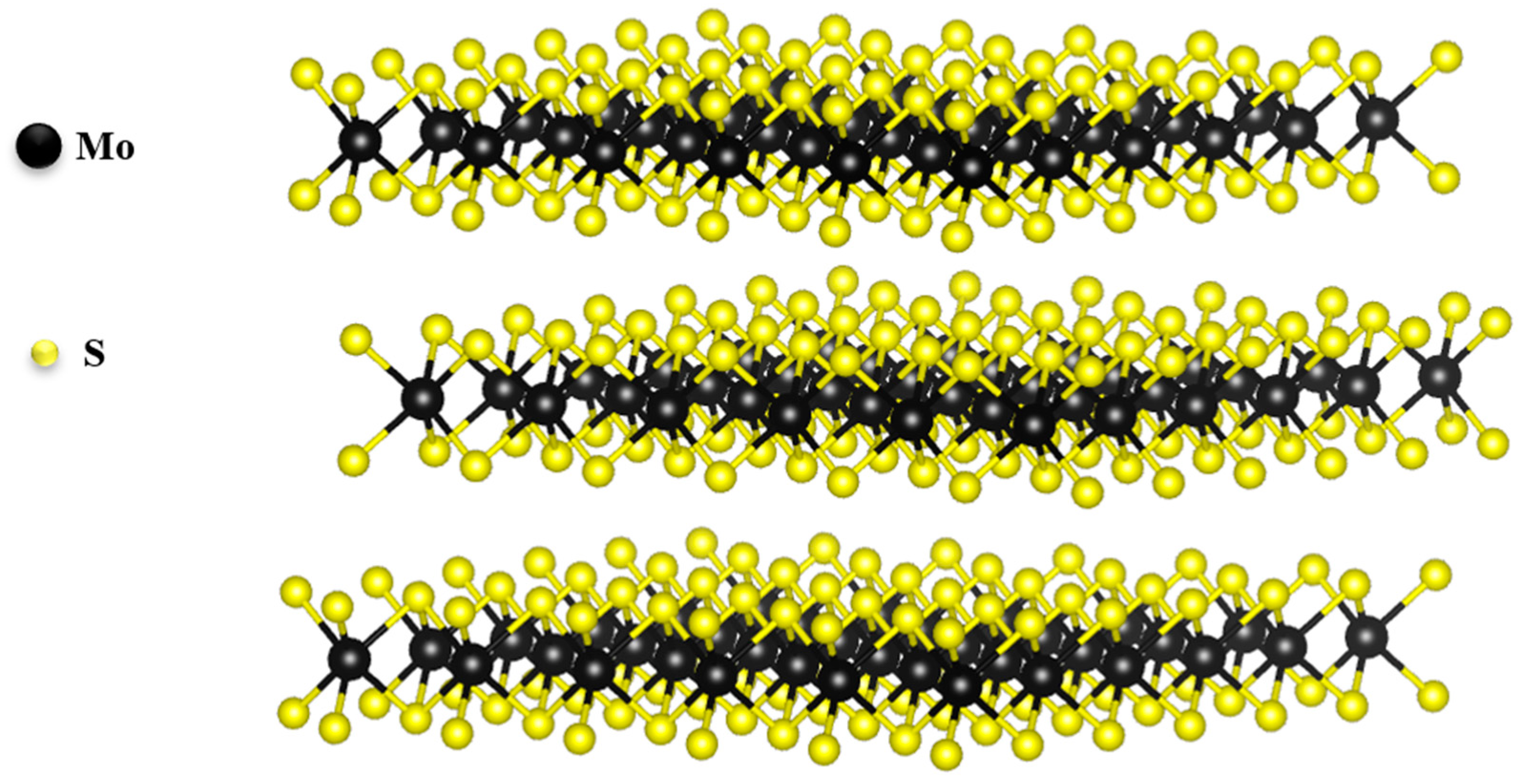

Molybdenum Disulfide (MoS2)

2.1.3. Oxides

Boric Acid (H₃BO₃)

2.1.4. Alkaline Earth

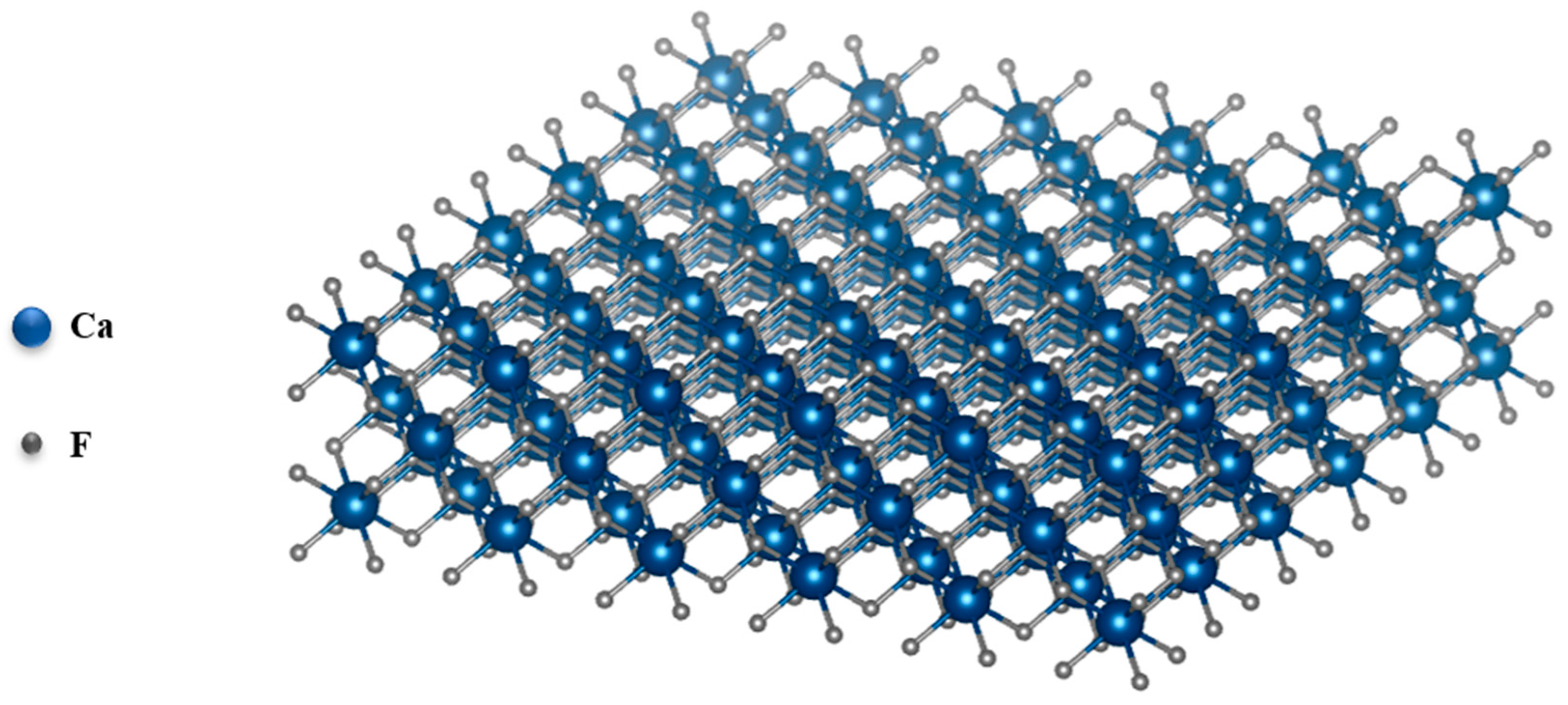

Calcium Fluoride (CaF2)

2.1.5. Soft Metals

3. Exploring Solid Lubricants in Machining

3.1. Turning

3.2. Milling

3.3. Grinding

3.4. Drilling

4. Conclusions

Acknowledgement

References

- Vamsi Krishna, P.; Srikant, R.R.; Nageswara Rao, D. Solid Lubricants in Machining. http://dx.doi.org/10.1177/1350650111398172 2011, 225, 213–227. [CrossRef]

- Sterle, L.; Kalin, M. Performance Evaluation of Solid Lubricants under Machining-like Conditions. In Proceedings of the Procedia CIRP; 2018; Vol. 77.

- Zabel, A.; Saelzer, J.; Elgeti, S.; Alammari, Y.; Berger, S.; Biermann, D. Fundamental Tribological Effects in Lubricated Cutting Processes. CIRP Annals 2023, 72, 37–40. [Google Scholar] [CrossRef]

- Bannister, K.E. Lubrication for Industry; Industrial Press Inc., 1996; ISBN 083113061X.

- Debnath, S.; Reddy, M.M.; Yi, Q.S. Environmental Friendly Cutting Fluids and Cooling Techniques in Machining: A Review. J Clean Prod 2014, 83, 33–47. [CrossRef]

- Abdalla, H.S.; Baines, W.; McIntyre, G.; Slade, C. Development of Novel Sustainable Neat-Oil Metal Working Fluids for Stainless Steel and Titanium Alloy Machining. Part 1. Formulation Development. International Journal of Advanced Manufacturing Technology 2007, 34, 21–33. [CrossRef]

- Ravuri, B.; Goriparthi, B.; … R.R.-T.I.J. of; 2016, undefined Performance Evaluation of Grinding Wheels Impregnated with Graphene Nanoplatelets. SpringerBP Ravuri, BK Goriparthi, RS Revuru, VG AnneThe International Journal of Advanced Manufacturing Technology, 2016•Springer 2016, 85, 2235–2245. [CrossRef]

- Simpson, A.T.; Stear, M.; Groves, J.A.; Piney, M.; Bradley, S.D.; Stagg, S.; Crook, B. Occupational Exposure to Metalworking Fluid Mist and Sump Fluid Contaminants. Ann. occup. Hyg 2003, 47, 17–30. [Google Scholar] [CrossRef]

- Zeman, A.; Sprengel, A.; Niedermeier, D.; Späth, M. Biodegradable Lubricants—Studies on Thermo-Oxidation of Metal-Working and Hydraulic Fluids by Differential Scanning Calorimetry (DSC). Thermochim Acta 1995, 268, 9–15. [Google Scholar] [CrossRef]

- Marques, A.; Paipa Suarez, M.; Falco Sales, W.; Rocha Machado, Á. Turning of Inconel 718 with Whisker-Reinforced Ceramic Tools Applying Vegetable-Based Cutting Fluid Mixed with Solid Lubricants by MQL. J Mater Process Technol 2019, 266, 530–543. [Google Scholar] [CrossRef]

- Byrne, G.; annals, E.S.-C.; 1993, undefined Environmentally Clean Machining Processes—a Strategic Approach. Elsevier.

- Sreejith, P.S.; Ngoi, B.K.A. Dry Machining: Machining of the Future. J Mater Process Technol 2000, 101, 287–291. [Google Scholar] [CrossRef]

- Zhu, S.; Cheng, J.; Qiao, Z.; International, J.Y.-T.; 2019, undefined High Temperature Solid-Lubricating Materials: A Review. Elsevier.

- Wang, Q.; Zheng, F.; Wang, T. Tribological Properties of Polymers PI, PTFE and PEEK at Cryogenic Temperature in Vacuum. Cryogenics (Guildf) 2016, 75, 19–25. [Google Scholar] [CrossRef]

- Reeves, C.J.; Menezes, P.L.; Lovell, M.R.; Jen, T.C. Tribology of Solid Lubricants. Tribology for Scientists and Engineers: From Basics to Advanced Concepts 2013, 9781461419457, 447–494. [CrossRef]

- Aramesh, M. Ultra Soft Cutting Tool Coatings and Coating Method (U.S. Patent No. 16/383,157), U.S. Patent and Trademark Office 2019.

- Akhtar, S.S. A Critical Review on Self-Lubricating Ceramic-Composite Cutting Tools. Ceram Int 2021, 47, 20745–20767. [Google Scholar] [CrossRef]

- Allam, I.M. Solid Lubricants for Applications at Elevated Temperatures: A Review. J Mater Sci 1991, 26. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A. V. Graphene: A New Emerging Lubricant. Materials Today 2014, 17, 31–42. [Google Scholar] [CrossRef]

- Sliney, H.E. Solid Lubricant Materials for High Temperatures—a Review. Tribol Int 1982, 15, 303–315. [Google Scholar] [CrossRef]

- Friction Science and Technology FROM CONCEPTS to APPLICATIONS.

- Donnet, C.; Erdemir, A. Tribology of Diamond-like Carbon Films: Fundamentals and Applications; Springer Science & Business Media, 2007.

- Kalin, M.; Velkavrh, I.; Vižintin, J.; Ožbolt, L. Review of Boundary Lubrication Mechanisms of DLC Coatings Used in Mechanical Applications. Meccanica 2008, 43, 623–637. [Google Scholar] [CrossRef]

- Scharf, T.W.; Prasad, S. V. Solid Lubricants: A Review. J Mater Sci 2013, 48, 511–531. [Google Scholar] [CrossRef] [PubMed]

- Reisel, G.; Steinhäuser, S.; Wielage, B. The Behaviour of DLC under High Mechanical and Thermal Load. Diam Relat Mater 2004, 13, 1516–1520. [Google Scholar] [CrossRef]

- Yang, B.; Zheng, Y.; Zhang, B.; Wei, L.; Zhang, J. The High-Temperature Tribological Properties of Si-DLC Films. Surface and interface analysis 2012, 44, 1601–1605. [Google Scholar] [CrossRef]

- Bhowmick, S.; Shirzadian, S.; Alpas, A.T. High-Temperature Tribological Behavior of Ti Containing Diamond-like Carbon Coatings with Emphasis on Running-in Coefficient of Friction. Surf Coat Technol 2022, 431, 127995. [Google Scholar] [CrossRef]

- Bhowmick, S.; Lou, M.; Khan, M.Z.U.; Banerji, A.; Alpas, A.T. Role of an Oxygen Atmosphere in High Temperature Sliding Behaviour of W Containing Diamond-like Carbon (W-DLC). Surf Coat Technol 2017, 332, 399–407. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Mishchenko, A.; Carvalho, A.; Castro Neto, A.H. 2D Materials and van Der Waals Heterostructures. Science (1979) 2016, 353, aac9439. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; He, X.; Xiao, C.; Kim, S.H. Effect of Humidity on Friction and Wear—A Critical Review. Lubricants 2018, 6. [Google Scholar] [CrossRef]

- Furlan, K.P.; de Mello, J.D.B.; Klein, A.N. Self-Lubricating Composites Containing MoS2: A Review. Tribol Int 2018, 120, 280–298. [Google Scholar] [CrossRef]

- Lancaster, J.K. Anisotropy in the Mechanical Properties of Lamellar Solids and Its Effect on Wear and Transfer. Wear 1966, 9, 169–188. [Google Scholar] [CrossRef]

- Savan, A.; Pflüger, E.; Voumard, P.; Schröer, A.; Simmonds, M. Modern Solid Lubrication: Recent Developments and Applications of MoS2. Lubrication Science 2000, 12, 185–203. [Google Scholar] [CrossRef]

- Damera, N.R.; Pasam, V.K. Performance Profiling of Boric Acid as Lubricant in Machining. Journal of the Brazilian Society of Mechanical Sciences and Engineering 2008, 30, 239–244. [Google Scholar] [CrossRef]

- Scharf, T.W.; Prasad, S. V Solid Lubricants: A Review. J Mater Sci 2013, 48, 511–531. [Google Scholar] [CrossRef]

- Vamsi Krishna, P.; Srikant, R.R.; Nageswara Rao, D. Solid Lubricants in Machining. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology 2011, 225, 213–227. [CrossRef]

- Damera, N.R.; Pasam, V.K. Performance Profiling of Boric Acid as Lubricant in Machining. Journal of the Brazilian Society of Mechanical Sciences and Engineering 2008, 30, 239–244. [Google Scholar] [CrossRef]

- Sliney, H.E. Solid Lubricants. 1991.

- Sukumaran, S.; Francis Xavier, L.; Deepanraj, B. A Review on the Scope of Using Calcium Fluoride as a Multiphase Coating and Reinforcement Material for Wear Resistant Applications. Mater Today Proc 2023, 77, 478–489. [Google Scholar] [CrossRef]

- Mittal, D.; Singh, D.; Kumar Sharma, S. Thermal Characteristics and Tribological Performances of Solid Lubricants: A Mini Review. In Advanced Rheology and Its Applications [Working Title]; 2023.

- Wan, S.H. Solid Lubricant: Soft Metal. Encyclopedia of Tribology 2013, 3152–3159. [Google Scholar] [CrossRef] [PubMed]

- Imai, M.; Rabinowicz, E.; Imaji, M.; Rabi, E. Lubrication by Low-Melting-Point Metals at Elevated Temperatures. ASLE TRANSACTIONS 1963, 6, 286–294. [Google Scholar] [CrossRef]

- Aramesh, M.; Montazeri, S.; Veldhuis, S.C. A Novel Treatment for Cutting Tools for Reducing the Chipping and Improving Tool Life during Machining of Inconel 718. Wear 2018, 414–415. [Google Scholar] [CrossRef]

- Montazeri, S.; Aramesh, M.; Veldhuis, S.C. Novel Application of Ultra-Soft and Lubricious Materials for Cutting Tool Protection and Enhancement of Machining Induced Surface Integrity of Inconel 718. J Manuf Process 2020, 57. [Google Scholar] [CrossRef]

- Sharma, V.S.; Dogra, M.; Suri, N.M. Cooling Techniques for Improved Productivity in Turning. 2009. [Google Scholar] [CrossRef]

- Vedha Hari, B.N.; Sathiya Narayanan, N.; Baskar, N.; Sriraman, N.; Suraj Nanduru, V.S.P. Performance of Ceramic Cutting Tool with Groove and Cross-Chevron Surface Textures Filled with Semi-Solid Lubricants. Mater Today Proc 2022, 63, 504–509. [Google Scholar] [CrossRef]

- Chary Nalband, S.; Pamidimukkala, K.; Gunda, R.K.; Reddy Paturi, U.M. Effect of Minimum Quantity Solid Lubrication (MQSL) Parameters on Cutting Force and Temperature during Turning of EN31 Steel. Mater Today Proc 2021, 38, 3314–3319. [Google Scholar] [CrossRef]

- Sarıkaya, M.; Şirin, Ş.; Yıldırım, Ç.V.; Kıvak, T.; Gupta, M.K. Performance Evaluation of Whisker-Reinforced Ceramic Tools under Nano-Sized Solid Lubricants Assisted MQL Turning of Co-Based Haynes 25 Superalloy. Ceram Int 2021, 47, 15542–15560. [Google Scholar] [CrossRef]

- Dilbag, S.; Rao, P. V. Performance Improvement of Hard Turning with Solid Lubricants. International Journal of Advanced Manufacturing Technology 2008, 38, 529–535. [Google Scholar] [CrossRef]

- Marques, A.; Guimarães, C.; da Silva, R.B.; da Penha Cindra Fonseca, M.; Sales, W.F.; Machado, Á.R. Surface Integrity Analysis of Inconel 718 after Turning with Different Solid Lubricants Dispersed in Neat Oil Delivered by MQL. Procedia Manuf 2016, 5, 609–620. [Google Scholar] [CrossRef]

- Vamsi Krishna, P.; Rao, D.N. Performance Evaluation of Solid Lubricants in Terms of Machining Parameters in Turning. Int J Mach Tools Manuf 2008, 48, 1131–1137. [Google Scholar] [CrossRef]

- Makhesana, M.A.; Patel, K.M.; Mawandiya, B.K. Environmentally Conscious Machining of Inconel 718 with Solid Lubricant Assisted Minimum Quantity Lubrication. Metal Powder Report 2021, 76, S24–S29. [Google Scholar] [CrossRef]

- Song, W.; Wang, Z.; Wang, S.; Zhou, K.; Guo, Z. Experimental Study on the Cutting Temperature of Textured Carbide Tool Embedded with Graphite. International Journal of Advanced Manufacturing Technology 2017, 93, 3419–3427. [Google Scholar] [CrossRef]

- Makhesana, M.A.; Patel, K.M.; Krolczyk, G.M.; Danish, M.; Singla, A.K.; Khanna, N. Influence of MoS2 and Graphite-Reinforced Nanofluid-MQL on Surface Roughness, Tool Wear, Cutting Temperature and Microhardness in Machining of Inconel 625. CIRP J Manuf Sci Technol 2023, 41. [Google Scholar] [CrossRef]

- Performance Evaluation of Nano Graphite Inclusion in Cutting Fluids with MQL Technique in Turning of AISI 1040 Steel | Request PDF Available online:. Available online: https://www.researchgate.net/publication/285329660_Performance_evaluation_of_nano_graphite_inclusion_in_cutting_fluids_with_MQL_technique_in_turning_of_AISI_1040_steel (accessed on 13 September 2023).

- Sivalingam, V.; Zan, Z.; Sun, J.; Selvam, B.; Gupta, M.K.; Jamil, M.; Mia, M. Wear Behaviour of Whisker-Reinforced Ceramic Tools in the Turning of Inconel 718 Assisted by an Atomized Spray of Solid Lubricants. Tribol Int 2020, 148. [Google Scholar] [CrossRef]

- Mawandiya, B.K.; Makhesana, M.A.; Suthar, V.J.; Mahida, N.G.; Patel, K.M. Experimental Investigations on Eco-Friendly Lubrication Techniques for Improving Machining Performance. Lecture Notes in Mechanical Engineering 2023, 331–338. [Google Scholar] [CrossRef]

- Uddin Siddiqui, T.; Kumar Singh, S. Design, Fabrication and Characterization of a Self-Lubricated Textured Tool in Dry Machining. Mater Today Proc 2021, 41, 863–869. [Google Scholar] [CrossRef]

- Divya, C.; Suvarna Raju, L.; Singaravel, B. Experimental Investigation of Different Cutting Conditions in Turning of Inconel 718. IOP Conf Ser Mater Sci Eng 2021, 1057, 012070. [Google Scholar] [CrossRef]

- Khani, S.; Shahabi Haghighi, S.; Razfar, M.R.; Farahnakian, M. Improvement of Thread Turning Process Using Micro-Hole Textured Solid-Lubricant Embedded Tools. Proc Inst Mech Eng B J Eng Manuf 2021, 235, 1727–1738. [Google Scholar] [CrossRef]

- Gunda, R.K.; Narala, S.K.R. Electrostatic High-Velocity Solid Lubricant Machining System for Performance Improvement of Turning Ti–6Al–4V Alloy. Proc Inst Mech Eng B J Eng Manuf 2019, 233, 118–131. [Google Scholar] [CrossRef]

- Orra, K.; Choudhury, S.K. Tribological Aspects of Various Geometrically Shaped Micro-Textures on Cutting Insert to Improve Tool Life in Hard Turning Process. J Manuf Process 2018, 31, 502–513. [Google Scholar] [CrossRef]

- Kumar, C.S.; Patel, S.K.; Fernandes, F. Performance of Al2O3/TiC Mixed Ceramic Inserts Coated with TiAlSiN, WC/C and DLC Thin Solid Films during Hard Turning of AISI 52100 Steel. Journal of Materials Research and Technology 2022, 19, 3380–3393. [Google Scholar] [CrossRef]

- Parida, A.K.; Rao, P.V.; Ghosh, S. Machinability Study of Ti-6Al-4V Alloy Using Solid Lubricant. Sadhana - Academy Proceedings in Engineering Sciences 2020, 45, 1–8. [Google Scholar] [CrossRef]

- Suarez, M.P.; Marques, A.; Boing, D.; Amorim, F.L.; Machado, Á.R. MoS2 Solid Lubricant Application in Turning of AISI D6 Hardened Steel with PCBN Tools. J Manuf Process 2019, 47, 337–346. [Google Scholar] [CrossRef]

- Patel, A.S.; Makhesana, M.A.; Patel, K.M. Investigative Study of Temperature Produced During Turning Operation Using MQL and Solid Lubricants. Lecture Notes on Multidisciplinary Industrial Engineering 2019, Part F162, 539–549. [Google Scholar] [CrossRef]

- Darshan, C.; Jain, S.; Dogra, M.; Gupta, M.K.; Mia, M.; Haque, R. Influence of Dry and Solid Lubricant-Assisted MQL Cooling Conditions on the Machinability of Inconel 718 Alloy with Textured Tool. International Journal of Advanced Manufacturing Technology 2019, 105, 1835–1849. [Google Scholar] [CrossRef]

- Gajrani, K.K.; Sankar, M.R.; Dixit, U.S. Environmentally Friendly Machining with MoS2-Filled Mechanically Microtextured Cutting Tools. Journal of Mechanical Science and Technology 2018, 32, 3797–3805. [Google Scholar] [CrossRef]

- Arulkirubakaran, D.; Senthilkumar, V.; Dinesh, S.; Velmurugan, C.; Manikandan, N.; Raju, R. Effect of Textured Tools on Machining of Ti-6Al-4V Alloy under Lubricant Condition. Mater Today Proc 2018, 5, 14230–14236. [Google Scholar] [CrossRef]

- Dai, M.; Zhou, K.; Yuan, Z.; Ding, Q.; Fu, Z. The Cutting Performance of Diamond and DLC-Coated Cutting Tools. Diam Relat Mater 2000, 9, 1753–1757. [Google Scholar] [CrossRef]

- dos Santos, G.R.; da Costa, D.D.; Amorim, F.L.; Torres, R.D. Characterization of DLC Thin Film and Evaluation of Machining Forces Using Coated Inserts in Turning of Al–Si Alloys. Surf Coat Technol 2007, 202, 1029–1033. [Google Scholar] [CrossRef]

- Grigoriev, S.; Volosova, M.; Fyodorov, S.; Lyakhovetskiy, M.; Seleznev, A. DLC-Coating Application to Improve the Durability of Ceramic Tools. J Mater Eng Perform 2019, 28, 4415–4426. [Google Scholar] [CrossRef]

- Wenlong, S.; Jianxin, D.; Hui, Z.; Pei, Y.; Jun, Z.; Xing, A. Performance of a Cemented Carbide Self-Lubricating Tool Embedded with MoS2 Solid Lubricants in Dry Machining. J Manuf Process 2011, 13, 8–15. [Google Scholar] [CrossRef]

- Gajrani, K.K.; Suvin, P.S.; Kailas, S.V.; Mamilla, R.S. Thermal, Rheological, Wettability and Hard Machining Performance of MoS2 and CaF2 Based Minimum Quantity Hybrid Nano-Green Cutting Fluids. J Mater Process Technol 2019, 266, 125–139. [Google Scholar] [CrossRef]

- Makhesana, M.A.; Patel, K.M.; Patel, A.S. Applicability of CaF2 Solid Lubricant-Assisted Minimum Quantity Lubrication in Turning for Sustainable Manufacturing. Lecture Notes on Multidisciplinary Industrial Engineering 2019, Part F162, 229–238. [Google Scholar] [CrossRef]

- Makhesana, M.A.; Patel, K.M. Performance Assessment of CaF2 Solid Lubricant Assisted Minimum Quantity Lubrication in Turning. Procedia Manuf 2019, 33, 43–50. [Google Scholar] [CrossRef]

- Zhang, S.; Xiao, G.; Chen, Z.; Xu, C.; Yi, M.; Li, Q.; Zhang, J. Influence of CaF2@Al2O3 on Cutting Performance and Wear Mechanism of Al2O3/Ti(C,N)/CaF2@Al2O3 Self-Lubricating Ceramic Tools in Turning. Materials 2020, Vol. 13, Page 2922 2020, 13, 2922. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, S.; Guo, R.; Ji, L.; Guo, N.; Li, Q.; Xu, C. Preparation of Al2O3/Ti(C,N)/ZrO2/CaF2@Al(OH)3 Ceramic Tools and Cutting Performance in Turning. Materials 2019, Vol. 12, Page 3820 2019, 12, 3820. [Google Scholar] [CrossRef] [PubMed]

- Bade, V.S.; Srinivasa Rao, Y.; Yegireddi, S.; Eshete, G. Influence of Nano Boric Acid Material in Bio-Diesel Blends to Enhance the Surface Quality with Minimum Quality Lubrication. Advances in Materials Science and Engineering 2022, 2022. [Google Scholar] [CrossRef]

- Penta, S.R.; Rao, P.M.; Avvari, R.K. Tribological Behavior of the Boric Acid and Titanium Dioxide Based Nanofluid in Machining of EN24 Steel. Tribologia 2020, 37, 46–52. [Google Scholar] [CrossRef]

- Venkata Vishnu, A.; Venkata Ramana, M.; Tilak, K.B.G. Experimental Investigations of Process Parameters Influence on Surface Roughness in Turning of EN-353 Alloy Steel under Different Machining Environments. Mater Today Proc 2018, 5, 4192–4200. [Google Scholar] [CrossRef]

- Aramesh, M.; Montazeri, S.; Veldhuis, S.C. A Novel Treatment for Cutting Tools for Reducing the Chipping and Improving Tool Life during Machining of Inconel 718. Wear 2018, 414–415, 79–88. [CrossRef]

- Montazeri, S.; Aramesh, M.; Fazal, A.; Arif, M.; Veldhuis, S.C. Tribological Behavior of Differently Deposited Al-Si Layer in the Improvement of Inconel 718 Machinability. [CrossRef]

- Paturi, U.M.R.; B., V.D.; Reddy, N.S. Progress of Machinability on the Machining of Inconel 718: A Comprehensive Review on the Perception of Cleaner Machining. Clean Eng Technol 2021, 5, 100323. [CrossRef]

- Kurimoto, T.; Barrow, G.; Davies, B.J. The Influence of Aqueous Fluids on the Wear Characteristics and Life of Carbide Cutting Tools. CIRP Annals 1982, 31, 19–23. [Google Scholar] [CrossRef]

- Muaz, M.; Choudhury, S.K. Experimental Investigations and Multi-Objective Optimization of MQL-Assisted Milling Process for Finishing of AISI 4340 Steel. Measurement 2019, 138, 557–569. [Google Scholar] [CrossRef]

- Muaz, M.; Kumar, R.; Choudhury, S.K. Enhancing Tribo-Rheological Performance of Solid Lubricants Mixed Bio-Based Emulsions Applied through Minimum Quantity Cooling Lubrication Technique. Sadhana - Academy Proceedings in Engineering Sciences 2022, 47, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Suresh Kumar Reddy, N.; Venkateswara Rao, P. Experimental Investigation to Study the Effect of Solid Lubricants on Cutting Forces and Surface Quality in End Milling. Int J Mach Tools Manuf 2006, 46, 189–198. [Google Scholar] [CrossRef]

- Sterle, L.; Mallipeddi, D.; Krajnik, P.; Pušavec, F. The Influence of Single-Channel Liquid CO2 and MQL Delivery on Surface Integrity in Machining of Inconel 718. Procedia CIRP 2020, 87, 164–169. [Google Scholar] [CrossRef]

- Marcon, A.; Melkote, S.; Kalaitzidou, K.; annals, D.D.-C.; 2010, undefined An Experimental Evaluation of Graphite Nanoplatelet Based Lubricant in Micro-Milling. Elsevier.

- Nguyen, T.; Nguyen, D.; Howes, P.; Kwon, P.; Park, K.-H. Minimum Quantity Lubrication (MQL) Using Vegetable Oil With Nano-Platelet Solid Lubricant in Milling Titanium Alloy 2015.

- Rahmati, B.; Sarhan, A.A.D.; Sayuti, M. Morphology of Surface Generated by End Milling AL6061-T6 Using Molybdenum Disulfide (MoS2) Nanolubrication in End Milling Machining. J Clean Prod 2014, 66, 685–691. [Google Scholar] [CrossRef]

- Uysal, A.; Demiren, F.; Altan, E. Applying Minimum Quantity Lubrication (MQL) Method on Milling of Martensitic Stainless Steel by Using Nano Mos2 Reinforced Vegetable Cutting Fluid. Procedia Soc Behav Sci 2015, 195, 2742–2747. [Google Scholar] [CrossRef]

- Campos Rubio, J.C.; Guasca González, A.G.; Barcelos, D.J.; Câmara, M.A.; Mata Cabrera, F.; de Oliveira Leite, W. Tribological Analysis and Performance of a DLC Coating on Tungsten Carbide Micro-Tools to Use at Tantalum Precision Machining. International Journal of Advanced Manufacturing Technology 2021, 116, 719–732. [Google Scholar] [CrossRef]

- Ucun, I.; Aslantas, K.; Bedir, F. The Performance Of DLC-Coated and Uncoated Ultra-Fine Carbide Tools in Micromilling of Inconel 718. Precis Eng 2015, 41, 135–144. [Google Scholar] [CrossRef]

- Brzezinka, T.L.; Rao, J.; Paiva, J.M.; Kohlscheen, J.; Fox-Rabinovich, G.S.; Veldhuis, S.C.; Endrino, J.L. DLC and DLC-WS2 Coatings for Machining of Aluminium Alloys. Coatings 2019, 9. [Google Scholar] [CrossRef]

- Ucun, irfan; Aslantas, K.; Bedir, F. An Experimental Investigation of the Effect of Coating Material on Tool Wear in Micro Milling of Inconel 718 Super Alloy. Wear 2013, 300, 8–19. [CrossRef]

- Kursuncu, B.; Yaras, A. Assessment of the Effect of Borax and Boric Acid Additives in Cutting Fluids on Milling of AISI O2 Using MQL System. International Journal of Advanced Manufacturing Technology 2018, 95, 2005–2013. [Google Scholar] [CrossRef]

- Shaji, S.; Radhakrishnan, V. An Investigation on Surface Grinding Using Graphite as Lubricant. Int J Mach Tools Manuf 2002, 42, 733–740. [Google Scholar] [CrossRef]

- Benedicto, E.; Carou, D.; Rubio, E.M. Technical, Economic and Environmental Review of the Lubrication/Cooling Systems Used in Machining Processes. In Proceedings of the Procedia Engineering; 2017; Vol. 184.

- Gopal, A.V.; Venkateswara Rao, P. Performance Improvement of Grinding of SiC Using Graphite as a Solid Lubricant. Materials and Manufacturing Processes 2004, 19, 177–186. [Google Scholar] [CrossRef]

- Shaji, S.; Radhakrishnan, V. Application of Solid Lubricants in Grinding: Investigations on Graphite Sandwiched Grinding Wheels. Machining Science and Technology 2003, 7, 137–155. [Google Scholar] [CrossRef]

- Zhao, J.; Zhao, B.; Ding, W.; Wu, B.; Han, M.; Xu, J.; Liu, G. Grinding Characteristics of MoS2-Coated Brazed CBN Grinding Wheels in Dry Grinding of Titanium Alloy. Chinese Journal of Mechanical Engineering 2023, 36, 1–13. [Google Scholar] [CrossRef]

- Alberts, M.; Kalaitzidou, K.; Melkote, S. An Investigation of Graphite Nanoplatelets as Lubricant in Grinding. Int J Mach Tools Manuf 2009, 49, 966–970. [Google Scholar] [CrossRef]

- Singh, H.; Sharma, V.S.; Singh, S.; Dogra, M. Nanofluids Assisted Environmental Friendly Lubricating Strategies for the Surface Grinding of Titanium Alloy: Ti6Al4V-ELI. J Manuf Process 2019, 39, 241–249. [Google Scholar] [CrossRef]

- Rais, M.R.H.; Ali, M.Y.; Ramesh, S.; Ya’akub, S.R.; Ibrahim, Z. Performance of Graphite Based Nanofluid in MQL Grinding of Mild Steel. Lecture Notes in Mechanical Engineering 2023, 351–357. [Google Scholar] [CrossRef]

- Wojtewicz, M.; Nadolny, K.; Kapłonek, W.; Rokosz, K.; Matýsek, D.; Ungureanu, M. Experimental Studies Using Minimum Quantity Cooling (MQC) with Molybdenum Disulfide and Graphite-Based Microfluids in Grinding of Inconel® Alloy 718. International Journal of Advanced Manufacturing Technology 2019, 101, 637–661. [Google Scholar] [CrossRef]

- Azami, A.; Salahshournejad, Z.; Shakouri, E.; Sharifi, A.R.; Saraeian, P. Influence of Nano-Minimum Quantity Lubrication with MoS2 and CuO Nanoparticles on Cutting Forces and Surface Roughness during Grinding of AISI D2 Steel. J Manuf Process 2023, 87. [Google Scholar] [CrossRef]

- Sui, M.; Li, C.; Wu, W.; Yang, M.; Ali, H.M.; Zhang, Y.; Jia, D.; Hou, Y.; Li, R.; Cao, H. Temperature of Grinding Carbide with Castor Oil-Based MoS2 Nanofluid Minimum Quantity Lubrication. J Therm Sci Eng Appl 2021, 13. [Google Scholar] [CrossRef]

- Pal, A.; Chatha, S.S.; Singh, K. Performance Evaluation of Minimum Quantity Lubrication Technique in Grinding of AISI 202 Stainless Steel Using Nano-MoS2 with Vegetable-Based Cutting Fluid. International Journal of Advanced Manufacturing Technology 2020, 110, 125–137. [Google Scholar] [CrossRef]

- Kumar, A.; Ghosh, S.; Aravindan, S. Experimental Investigations on Surface Grinding of Silicon Nitride Subjected to Mono and Hybrid Nanofluids. Ceram Int 2019, 45. [Google Scholar] [CrossRef]

- Ezugwu, E.O.; Lai, C.J. Failure Modes and Wear Mechanisms of M35 High-Speed Steel Drills When Machining Inconel 901. J Mater Process Technol 1995, 49, 295–312. [Google Scholar] [CrossRef]

- Sharman, A.R.C.; Amarasinghe, A.; Ridgway, K. Tool Life and Surface Integrity Aspects When Drilling and Hole Making in Inconel 718. J Mater Process Technol 2008, 200, 424–432. [Google Scholar] [CrossRef]

- Heinemann, R.; Hinduja, S.; Barrow, G.; Petuelli, G. Effect of MQL on the Tool Life of Small Twist Drills in Deep-Hole Drilling. Int J Mach Tools Manuf 2006, 46, 1–6. [Google Scholar] [CrossRef]

- Mathew, N.T.; Vijayaraghavan, L. Environmentally Friendly Drilling of Intermetallic Titanium Aluminide at Different Aspect Ratio. J Clean Prod 2017, 141, 439–452. [Google Scholar] [CrossRef]

- Velmurugan, V.; Manimaran, G. H-MoS2 Solid Lubricant Performance on Inconel 718 in Drilling Operations. Arab J Sci Eng 2023, 48, 12015–12028. [Google Scholar] [CrossRef]

- Velmurugan, V.; Manimaran, G.; Ross, K.N.S. Impact of MoS2 Solid Lubricant on Surface Integrity of Ti-6Al-4V with PVD-TiN Coated Tool in Drilling. Journal of the Brazilian Society of Mechanical Sciences and Engineering 2021, 43, 1–13. [Google Scholar] [CrossRef]

- Sandeep Reddy, A. V.; Ajay Kumar, S.; Jagadesh, T. The Influence of Graphite, MOS2 and Blasocut Lubricant on Hole and Chip Geometry during Peck Drilling of Aerospace Alloy. Mater Today Proc 2020, 24, 690–697. [Google Scholar] [CrossRef]

- Mosleh, M.; Shirvani, K.A.; Smith, S.T.; Belk, J.H.; Lipczynski, G. A Study of Minimum Quantity Lubrication (MQL) by Nanofluids in Orbital Drilling and Tribological Testing. Journal of Manufacturing and Materials Processing 2019, 3. [Google Scholar] [CrossRef]

- Lishchenko, N.; Larshin, V.; Marchuk, I. Solid Lubricants Used in Small Diameter Drilling BT - Advanced Manufacturing Processes II.; Tonkonogyi, V., Ivanov, V., Trojanowska, J., Oborskyi, G., Grabchenko, A., Pavlenko, I., Edl, M., Kuric, I., Dasic, P., Eds.; Springer International Publishing: Cham, 2021; pp. 402–411.

- Silva, W.M.; Jesus, L.M.; Carneiro, J.R.; Souza, P.S.; Martins, P.S.; Trava-Airoldi, V.J. Performance of Carbide Tools Coated with DLC in the Drilling of SAE 323 Aluminum Alloy. Surf Coat Technol 2015, 284, 404–409. [Google Scholar] [CrossRef]

- Heinemann, R.K.; Hinduja, S. Investigating the Feasibility of DLC-Coated Twist Drills in Deep-Hole Drilling. International Journal of Advanced Manufacturing Technology 2009, 44, 862–869. [Google Scholar] [CrossRef]

- Bhowmick, S.; Alpas, A.T. The Role of Diamond-like Carbon Coated Drills on Minimum Quantity Lubrication Drilling of Magnesium Alloys. Surf Coat Technol 2011, 205, 5302–5311. [Google Scholar] [CrossRef]

- Dheeraj, N.; Sanjay, S.; Kiran Bhargav, K.; Jagadesh, T. Investigations into Solid Lubricant Filled Textured Tools on Hole Geometry and Surface Integrity during Drilling of Aluminium Alloy. In Proceedings of the Materials Today: Proceedings; 2019; Vol. 26.

- Velmurugan, V.; Manimaran, G. Effect of MoS2 Solid Lubricant on the Tribological Aspects of Ti-6Al-4V Alloy in Drilling Operations. Mater Today Proc 2022, 62. [Google Scholar] [CrossRef]

- Hassan, S.R.A.; Mativenga, P.T.; Cooke, K.; Sun, H.; Field, S.; Walker, M.; Chodynicki, J.; Sharples, C.; Jensen, B.; Mortensgaard, M.F. Effectiveness of Lubricating Coatings in Dry Drilling of Aluminium Alloys. Journal of the Brazilian Society of Mechanical Sciences and Engineering 2022, 44. [Google Scholar] [CrossRef]

| Tool/workpiece | Solid Lubricant | Method of Application | Most Significant Findings | Ref |

| Ceramic tools (Al2O3)Gray Cast Iron (ASTM A48) | Graphite;MoS2(mixed) | A textured tool with grooves filled with graphite and MoS2, and SAE 40 oil mixture | Reduced cutting forces and coefficient of friction when using solid lubricant with textured tool. | [46] |

| Coated carbide toolEN31 Steel | Graphite;MoS2(mixed) | Minimum Quantity Solid Lubrication (MQSL) system with the mixture of solid lubricants and SAE 40 oil | Decreased cutting forces and improved surface integrity when using solid lubricants with the MQSL method compared to MQL and Wet conditions. | [47] |

| Whisker-reinforced ceramic toolCo-based Haynes 25 | Graphite;MoS2;hBN(separately) | Nanofluid-MQL system, solid lubricants and vegetable-based oil mixture | Reduced surface roughness, graphite outperformed other solid lubricants.Decreased cutting temperature for all types of solid lubricants compared to the base fluid-MQL system and dry.hBN outperformed MoS2 and graphite in terms of reducing nose wear.The base material’s micro-hardness improvement was not significant. | [48] |

| Ceramic toolsAISI 52100 | Graphite;MoS2(separately) | Solid lubricants with an average particle size of 2 µm sprayed on the machining region | Lower surface roughness and cutting force were obtained by using the solid lubricants compared to the dry condition.MoS2 outperformed graphite in terms of surface roughness and cutting forces. | [49] |

| Ceramic tool (whisker-reinforced)IN718 | Graphite; MoS2(separately) | MQL system,Solid lubricants and vegetable-based oil mixture (LB2000) | Increased tool life by MoS2+MQL compared to graphite+MQL, MQL and dry conditions.Decreased cutting force by using graphite+MQL and MoS2+MQL.Lower surface micro-hardness with MoS2+MQL. | [11] |

| Cemented carbide tool (PVD-coated)IN718 | Graphite;MoS2(separately) | MQL system,Solid lubricants and vegetable-based oil mixture (LB2000) | Improved tool life and surface roughness by using graphite+MQL compared to MoS2+MQL, MQL and dry.No presence of tensile residual stress when using graphite+MQL. | [50] |

| Uncoated cemented carbide toolEN8 Steel | Graphite;Boric acid(separately) | Directly injected by atmospheric pressure,Solid lubricants mixed with SAE 40 oil | Improved tool life, surface roughness and cutting forces when using 20% boric acid+SAE 40 oil compared to graphite with the same concentration in SAE 40 oil, Wet and dry conditions. | [51] |

| PVD-Coated (TiAlN/TiN) and CVD-coated (TiCN/Al2O3) cemented carbide toolsIN718 | Graphite;MoS2(separately) | MQSL system, Solid lubricants mixed with cutting fluid | Improved surface finish with the use of MoS2+MQSL compared to graphite+MQSL, MQL, Wet and dry conditions.Reduced cutting temperature when using MQSL and MQL.Longer tool life was achieved by using PVD-coated tool with MQSL and MQL conditions. | [52] |

| Cemented carbide toolAISI 1045 steel | Graphite | Textured tool with 150 µm diameter micro-holes filled with graphite | Decreased cutting temperature by reducing the CoF at the tool/chip interface compared to the tool without texture.Improved tool life when using the textured tool. | [53] |

| PVD-coated (TiAlN) carbide toolInconel 625 | Graphite;MoS2(separately) | Nanofluid-MQL systems, Solid lubricants mixed with vegetable oil | Decreased surface roughness significantly when using MoS2+nMQL compared to the graphite+nMQL, MQL, and dry.Improved tool life due to less abrasion wear on the cutting tool, the best is MoS2+nMQL compared to MQL and graphite+nMQL.Cutting temperature is most reduced by MoS2+nMQL. | [54] |

| HSS and uncoated cemented carbide toolsAISI 1040 steel | Graphite | MQL system,Graphite nano-particles mixed with water-soluble oil | Reduced surface roughness and cutting force when using graphite nano-particles compared to conventional methods. | [55] |

| Ceramic tool(Al2O3 + SiC)IN718 | Graphite;MoS2(mixed) | Atomization-based cutting fluid (ACF),Solid lubricants mixed withacetone and vegetable oil | 38% reduction in flank wear through the application of ACF compared with dry machining.21% to 39% improvements in surface roughness using ACF compared with dry machining. | [56] |

| Coated carbide toolSteel AISI 4340 | MoS2 | MQL system, Solid lubricant mixed with castor oil or SAE40 oil | Lower surface roughness when using MoS2 with SAE40 oil compared to the MoS2 castor oil. | [57] |

| Cemented carbide toolAl6061-T6 | MoS2 | Textured tools filled with solid lubricant in powder form | Reduced cutting tool temperature and decreased flank wear when using this technique compared to the conventional method. | [58] |

| Uncoated carbide toolIN718 | MoS2;WS2(separately) | Textured tools with different patterns filled with solid lubricants and coconut oil mixture | Reduced coefficient of friction.Lower surface roughness when using WS2 compared to MoS2.Texture patterns may affect solid lubricant delivery. | [59] |

| Cemented carbide toolAluminum 7075-T6 | MoS2;Carbon nanotube (CNT)(separately) | Textured tool with micro-holes filled with solid lubricants | Reduced cutting forces when using CNT textured tool compared to other conditions. | [60] |

| Coated carbide toolTi-6Al-4V | MoS2 | Electrostatic high-velocity solid lubricants (EHVSL) and MQSL system, Solid lubricant mixed with SAE 40 oil | Reduced cutting force and tool wear by using the EHVSL method compared to the MQSL condition.Improved surface roughness with the EHVSL method.EHVSL method outperformed MQSL. | [61] |

| Ceramic (Al2O3/TiC)toolAISI 4340 steel | MoS2 | Textured tools with different patterns filled with solid lubricant | Reduced cutting forces and tool wear.Decreased coefficient of friction in tool/chip interface compared to conventional methods.Texture patterns may affect machining performance | [62] |

| Ceramic (Al2O3/TiC)ToolAISI 52100 steel | DLC coating | Direct current reactive magnetron sputtering (DCRMS) | Reduced cutting forces when using DLC coating compared to uncoated and ceramic tools.Decreased coefficient of friction at the cutting zone in cutting speeds up to 200 m/min for DLC-coated tools. | [63] |

| Coated carbide toolTi-6Al-4V | MoS2 | Solid lubricant with an average particle size of 2 µm sprayed on the machining region | Increased shear angle and chip reduction coefficient when using MoS2 compared to dry condition.Reduced tool wear and chip/tool contact length when using MoS2 compared to dry condition. | [64] |

| PCBN, ceramic (TiCN+Al2O3), coated carbide toolsAISI D6 hardened steel | MoS2 | Minimum Quantity Fluid (MQF) system, vegetable-based oil LB2000 mixture by solid lubricant | Claimed to be a viable alternative to tackle most machining challenges. | [65] |

| Coated carbide toolAISI 4140 steel | Graphite;MoS2(separately) | MQL system, Solid lubricants mixed with SAE 40 oil | Reduced cutting temperature when using MoS2+MQL compared to graphite+MQL.Results were validated by simulation (ANSYS). | [66] |

| Uncoated carbide toolIN718 | MoS2 | Textured tools with dimple patterns assisted with MQL system, solid lubricant mixed with canola oil | Improved tool wear by 20-30% when using MoS2+MQL compared to dry.Decreased cutting forces, surface roughness and cutting temperature with this method compared to dry. | [67] |

| HSS toolAISI 1040 steel | MoS2 | Textured tools filled with solid lubricant and graphite-based grease mixture | Reduced cutting temperature.Improved surface roughness.Decreased coefficient of friction and chip thickness. | [68] |

| Uncoated carbide toolTi-6Al-4V | MoS2 | Textured tools filled with solid lubricant, SAE 40 oil mixture | Reduced machining forces and power consumption when using MoS2 with textured tool compared to dry condition. | [69] |

| Cemented carbide toolAluminum silicon alloy;Aluminum bronze alloy | DLC coating;Diamond coating | Vacuum cathode multi-arc deposition and DC plasma jet coating method | Improved cutting tool life when using DLC-coated tool compared to uncoated tool (7 times longer for aluminum bronze workpieces). | [70] |

| Tungsten carbide toolAluminum silicon alloy | DLC coating | Plasma Enhanced Chemical Vapour Deposition (PECVD) coating method | Decreased cutting forces when using DLC-coated tool compared to uncoated tool. | [71] |

| Ceramic tool (Al2O3+TiC)Hardened steel 102Cr6 | DLC coating | Arc-PVD and Plasma Assisted Chemical Vapour Deposition (PACVD) coating methods | Improved tool life for both conditions compared to uncoated ceramic tools.Lower CoF for both conditions compared to uncoated tools. | [72] |

| Cemented carbide toolHardened steel | MoS2 | Drill micro-holes on the tool faces (flank and rake) filled with a solid lubricant | Decreased cutting forces for all tool conditions compared to conventional tools.Improved tool life when drilling micro-holes on the flank face. | [73] |

| Tungsten carbide toolHardened AISI H13 steel | MoS2 nanoplatelets;CaF2 nanoparticles(separately) | Minimum quantity cutting fluids (MQCF); used hybrid-nano green cutting fluids (HN-GCFs) with different concentrations | 0.3% concentration of HN-GCFs for CaF2 was optimized for thermal conductivity, specific heat, and viscosity.Less tool wear and workpiece adhesion with HN-GCF-0.3 of CaF2. | [74] |

| Coated carbide toolAISI 1040 steel | CaF2 | MQSL machining with 10% and 20% CaF2 concentration mixed with SAE 40 oil | Improved tool life and surface finish by CaF2+MQSL method compared to MQL, wet and dry conditions.10% CaF2 concentration showed better machining performance. | [75] |

| Coated carbide toolEN31 steel | CaF2 | MQSL machining with 10%, 15% and 20% CaF2 concentration mixed with SAE 40 oil | Improved tool life, surface quality and cutting temperature reduction were achieved by 15% CaF2 concentration. compared to Wet and dry conditions. | [76] |

| Ceramic tool (Al2O3+TiC)40Cr | CaF2 | Added CaF2 and CaF2@Al2O3 to the ceramic tool by hot pressing (HP) method with different concentration | Improved flank wear and surface roughness when using all CaF2@Al2O3 concentrations compared to the ceramic tool.Decreased cutting force and temperature when using vol 10% of CaF2@Al2O3. | [77] |

| Ceramic tool (Al2O3/Ti(C,N))40Cr | CaF2 | Added CaF2@Al(OH)3 to the ceramic tool by heterogeneous nucleation method | Decreased cutting temperature and surface roughness with this method compared to the ceramic tool.Improved tool life by increasing wear resistance properties of ceramic tools. | [78] |

| HSS toolMild steel | Boric acid | MQL system, Solid lubricant mixed with coconut oil | Decreased surface roughness by 40% compared with dry and 18% with wet machining. | [79] |

| Carbide toolEN24 steel | Boric acid | MQL system, Solid lubricant mixed with SAE 40 oil and/or TiO2 | Reduced cutting forces, cutting temperature and surface roughness by Boric acid+ TiO2+SAE 40 oil compared to when mixed separately with oil, only oil and dry conditions. | [80] |

| Uncoated carbide tool, CVD, PVDEN353 | Boric acid | Dry, SAE 40 oil,Boric acid + SAE 40 oil all applied by coolant nozzle | Better cutting conditions when using SAE 40 oil.Improved surface roughness with SAE 40 oil and CVD tool. | [81] |

| Uncoated carbide toolIN718 | Soft metal coating | In situ coating (pre-machining) process prior to the main machining process | Improved tool life by 300% compared with untreated tools.Decreased cutting forces by 40-50%.Reduced work-hardening in machined workpieces by 45%. | [82] |

| Uncoated carbide toolIN718 | Soft metal coating | PVD coating | A threefold increase in lifespan compared with uncoated tools.Decreased cutting forces significantly.Reduced by 25% in work hardened surface layer | [83] |

| Tool/workpiece | Solid Lubricant | Method of Application | Most Significant Findings | Ref |

| TiCN/Al2O3/TiN CVD coated tungsten carbide toolAISI 4340 steel | Graphite;Boric acid(separately and mixed) | MQL system used an emulsion oil mixture with graphite and/or boric acid | MQL 10%wt Boric acid mixture with emulsion oil showed better machining performance compared to when both solid lubricants are mixed together. | [86] |

| CVD-coated tungsten carbide end mill toolAISI 4340 steel | Graphite;Boric acid(separately and mixed) | Minimum quantity cooling lubrication technique (MQCL) system used coconut oil mixture | Improved Ra when using boric acid mixture with coconut oil compared to other conditions.Higher thermal conductivity and lower viscosity were found in boric acid mixture with coconut oil. | [87] |

| Coated carbide end millAISI 1045 steel | Graphite;MoS2(separately) | Directly applied by the motor-driven feeder | MoS2 outperformed graphite and Wet conditions in terms of surface roughness, cutting forces and specific energy | [88] |

| TiAlN-coated carbide end millIN718 | MoS2 | MQL system used a liquid CO2 mixture with solid lubricant. | Improved surface roughness and lower cutting temperature when using the MQL system with liquid CO2 and MoS2 compared to conventional lubrication methods. | [89] |

| Uncoated carbide toolAISI H13 tool steel | Graphite nanoplatelets | Solid lubricant dispersed in distilled water, applied directly by a nozzle for near-dry machining | Reduction in tangential cutting force (due to the presence of graphite) had a negative impact on dimensional accuracy and caused burnishing of the machined surface. | [90] |

| TiAlN-coated carbide toolTi-6Al-4V | Graphitenanoplatelets | MQL system, Solid lubricant mixed withvegetable oil | Decreased tool flank wear and chipping 1% graphite+MQL compared to other concentrations, MQL and dry conditions. | [91] |

| Tungsten carbide toolAluminum alloy (A6061-T6) | MoS2 nanoparticles | MQL system, Solid lubricant mixed withmineral oil | Improved the quality of the machined surface when using 0.5% concentration of MoS2 compared to other concentrations and MQL. | [92] |

| Uncoated tungsten carbide toolAISI 420 | MoS2 nanoparticles | MQL system, Solid lubricant mixed with vegetable oil | Decreased tool wear and surface roughness when using MoS2+MQL with the flow rate of 40ml/h compared to other flow rates, MQL and dry. | [93] |

| Tungsten carbide micro-toolAISI 52100 steel | DLC coating | PVD coating method | Lower cutting force for DLC-coated tool compared to uncoated tool.Reduced CoF in DLC-coated tool compared to uncoated tool. | [94] |

| Ultra-fine-grained carbide toolIN718 | DLC coating | PECVD method | Reduced tool flank wear and cutting forces when using DLC-coated tool compared to uncoated tool. | [95] |

| TiB2 PVD-coated toolAluminum silicon alloy | Monolayer DLC coating;Multilayer DLC and WS2 coating | PVD coating method | The best machining performance was reported to be for two layers of DLC-WS2 compared to other coatings. | [96] |

| WC coated toolIN718 | DLC coating | PVD coating method | Decreased tool wear and built-up edge (BUE) formation when using DLC-coated tool compared to uncoated tool. | [97] |

| Coated (TiN) carbide toolAISI O2 cold work steel | Boric acid | MQL system, Solid lubricants mixed with ethylene glycol and borax decahydrate | Borax additive when mixed with boric acid improved surface roughness compared to conditions with only borax decahydrate is used.In terms of tool life, borax decahydrate showed better results. | [98] |

| Tool/workpiece | Solid Lubricant | Method of Application | Most Significant Findings | Ref |

| Al2O3-grade wheelAISI 1030 steel;AISI 52100 steel | Graphite | Directly injected, Solid lubricant mixed with water-soluble oil | Reduced specific energy when using graphite mixed with oil compared to dry condition. | [99] |

| Diamond wheelSiC | Graphite | Directly injected via funnel pipe | Reduced tangential force and specific grinding energy, and improved surface finish when using graphite compared to dry condition. | [101] |

| Al2O3 grade wheelEN2;EN31 | Graphite | The solid lubricant was sandwiched on the wheel | Reduced surface roughness when using graphite compared to Wet and dry conditions. | [102] |

| Brazed CBN on the wheelTi6-Al-4V | MoS2 | Applied solid lubricant coating by an organic bonding method | Reduced grinding force andExtended grinding wheel service life by using MoS2 coating compared to uncoated CBN tool. | [103] |

| Al2O3 grade wheelHardened D2 tool steel | Graphite nano-platelets | MQL system, solid lubricant mixed with isopropyl alcohol was directly sprayed on the workpiece-wheel interface and the workpiece surface pre-grinding | Reduced cutting forces and specific energy and surface finish improvement when using 15ⴜm graphite nano-platelets compared to smaller diameters of graphite nano-platelets, MQL and dry conditions. | [104] |

| CBN wheelTi-6Al-4V | Graphite;Graphene;MoS2(separately) | MQL system, solid lubricants mixed with vegetable oils | The best performance was reported for graphene compared to graphite and then MoS2 in terms of surface roughness, cutting forces, coefficient of friction and grinding energy. | [105] |

| The tool was not mentioned.Mild steel | Graphite | MQL system,Solid lubricant mixed with LB-3000 lubricant | Improved surface roughness when using graphite+MQL compared to Wet and dry conditions. | [106] |

| Flat cylindrical grinding wheel, Microcrystalline sintered corundum,IN718 | Graphite;MoS2(separately) | Minimum quantity cooling (MQC) system, solid lubricant mixed with water and Syntilo RHS oil | Reduced surface roughness when using graphite+MQC and MoS2+MQC compared to other tested conditions.Lowest surface clogging percentage by using graphite+MQC and MoS2+MQC compared to other conditions. | [107] |

| Aluminum oxide grinding wheelAISI D2 steel | MoS2;CuO(separately and mixed) | MQL system, solid lubricants mixed with soybean base and/or colza oils | Best surface roughness result was obtained by using CuO+MQL colza base oil compared to other tested conditions. | [108] |

| CBN grinding wheelCemented carbide (YG8) | MoS2 | Nano-MQL (NMQL) system, solid lubricant mixed with castor oil | Decreased cutting forces ratio and improved surface quality by using MoS2+NMQL and MQL compared to Wet and dry conditions. | [109] |

| Aluminum oxide grinding wheelAISI 202 stainless steel | MoS2 | Nano Fluid-MQL (NFMQL) system, solid lubricant mixed with vegetable oil-based | Reduced cutting forces and cutting temperature, and improved surface roughness when using MoS2+NFMQL compared to MQL, Wet and dry conditions | [110] |

| Diamond grinding wheelSilicon nitride | MoS2;WS2;hBN;(separately and mixed) | Nanoparticle jet MQL (NJMQL) system,Solid lubricants mixed with de-ionized water | Hybrid MoS2 with WS2 or hBN nanofluids resulted in lower grinding forces, surface roughness, specific grinding energy, surface/sub-surface damages and better surface morphology. | [111] |

| Tool/workpiece | Solid Lubricant | Method of Application | Most Significant Findings | Ref |

| TiN-PVD coated toolIN718 | H-MoS2 | MQSL system, Solid lubricant mixed witholive oiland direct delivery method | Significant surface roughness improvement, flank wear reduction and less cutting temperature when MoS2 is directly applied compared to MQSL and dry conditions. | [116] |

| TiN-PVD coated toolTi-6Al-4V | MoS2 | MQSL system, Solid lubricant mixed with olive oiland direct delivery method | Significant surface roughness improvement, flank wear reduction and less cutting temperature when MoS2 is directly applied compared to MQSL and dry conditions. | [117] |

| Uncoated carbide tool Aluminum alloy | Graphite;MoS2(separately) | Coating - | Reduction in BUE formation, minimum circularity error and no burr formation when using solid lubricant coatings compared to blasocut coolant and conditions. | [118] |

| Tungsten carbide (WC)Ti-6Al-4V | MoS2;hBN nanoparticles(separately) | MQL system, Solid lubricants mixed with Boelube (alcohol-based) fluid | Decreased tool wear and frictional force for both MoS2+MQL and hBN+MQL compared to MQL. | [119] |

| HSS drill toolSteel 35 | MoS2 | The workpiece floated in sulfur and serpentinite with industrial oil and oleic acid mixture by special lab stand | Increased the operation time of the drill tool when using this method compared to Wet and dry conditions | [120] |

| Cemented carbide toolAluminum alloy (SA-323) | DLC coating | PECVD method | Improved the hole quality (roundness curves, radial deviation, and roughness) when using DLC-coated tools compared to uncoated tools.Increased productivity by drilling at high speeds with DLC-coated tools. | [121] |

| HSS tool;Cobalt-alloyed HSS toolAISI 1045 steel | DLC coating;MoS2 coating(separately) | PACVD method | Improved chip evacuation capabilities and decreased drilling torque when using DLC-coated tools compared to MoS2-coated tools and uncoated tools.Tool life reduction was reported for DLC-coated tools. | [122] |

| HSS toolMagnesium alloy(AZ91) | Non-hydrogenated DLC coating | Closed Field Unbalanced Magnetron Sputter Ion Plating (CFUBMSIP) Coating method | Prolonged tool life, less drilling torque and cutting temperature when using DLC-coated tools with the assistance of the H2O-MQL system compared to uncoated HSS tools. | [123] |

| Tungsten carbide toolAluminum alloy | Graphite;MoS2(separately and mixed) | Textured tool filled with solid lubricants, | Improved the dimensional accuracy and decreased surface roughness when using the textured tool filled by graphite and a mixture of graphite and MoS2 compared to other conditions.Increased tool life using graphite coating. | [124] |

| Coated carbide toolsTi-6Al-4V | MoS2 | MQL system, solid lubricant mixed with cottonseed oil | Decreased cutting temperature, improved surface quality, increased tool life and enhanced subsurface hardness when using MoS2+MQL with 20% concentration compared to other conditions. | [125] |

| Tungsten carbide toolAluminum alloys (2024 /7150) | DLC;MoS2(separately) | CFUBMSIP coating method | Improved standard deviation of hole diameter and reduced surface roughness when using DLC-coated and MoS2-coated tools compared to the uncoated tool. | [126] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).