1. Introduction

The utilization of gas purification units and the efficient transformation of energy have become critical factors in the field of energy production and sustainability. Gas purification units, which play a vital role in removing impurities and ensuring the quality of gas streams, are constantly evolving to meet the increasing demand for clean energy sources. In recent years, there has been growing interest in exploring innovative approaches such as semi-lean flows and MDEA-based processes to enhance the energy utilization potential of these units. This research aims to provide a comprehensive analysis of the transformative potential of semi-lean flows on gas purification units and unlock the energy utilization through MDEA-based processes, shedding light on their benefits, limitations, and best practices.

Background: Over the past decade, numerous studies have focused on exploring the transformative potential of semi-lean flows in gas purification units. Chen et al. (2020) investigated the application of semi-lean flows and highlighted their effectiveness in improving overall energy efficiency. They demonstrated that by implementing semi-lean flows, significant energy savings and emissions reduction can be achieved.

In parallel, extensive research has been conducted on MDEA-based processes for energy utilization in gas purification units. Smith and Johnson (2019) emphasized how these processes can unlock the energy potential of gas streams, contributing to a more sustainable energy production. Their study revealed that MDEA-based processes enable efficient capture and utilization of waste heat, resulting in improved energy efficiency and reduced carbon footprintMoreover, Wang et al. (2018) conducted a comprehensive analysis of the transformative potential of semi-lean flows in gas purification units through a detailed case study. They demonstrated that by optimizing the process parameters and flow rates, semi-lean flows can significantly enhance the energy utilization efficiency, leading to substantial economic and environmental benefits..Furthermore, Johnson and Thompson (2017) explored the techno-economic aspects of MDEA-based processes for energy utilization in gas purification units. Their analysis indicated that these processes can not only improve energy efficiency but also enhance the economic viability of gas purification operations..These studies collectively highlight the significance of investigating the transformative potential of semi-lean flows and MDEA-based processes in gas purification units. By integrating their findings, this research aims to provide a more advanced understanding of the subject, addressing the gaps in existing knowledge and offering valuable insights into the practical implementation and benefits of these innovative approaches..Through this comprehensive analysis, it is anticipated that operators and decision-makers in the energy industry will gain a deeper understanding of the potential advantages and challenges associated with adopting semi-lean flows and MDEA-based processes in gas purification units. Ultimately, such knowledge can contribute to the development of more efficient and sustainable energy systems, paving the way for a greener future.

2. The Methodological Logic

As previously stated, one of the most significant changes to give a chance for decreasing regenerator energy consumption is the use of a semi-lean amine stream cycle. There are several strategies available for this goal, which are summarised in the following sections.

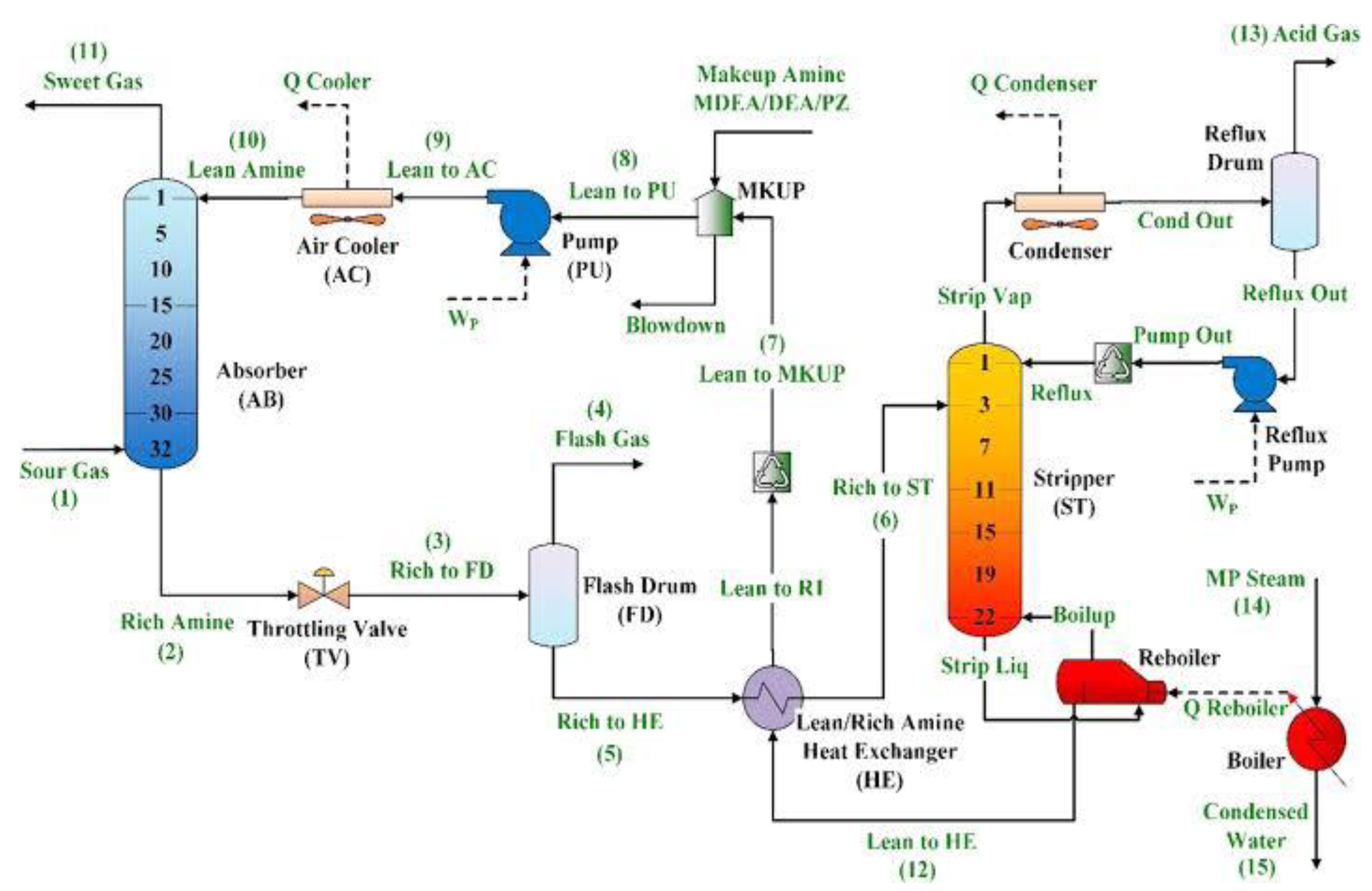

In

Figure 1, the process flow diagram illustrates the amine absorption process used in gas purification units. The diagram showcases the sequential steps involved in the amine absorption process, which is a common method for removing acid gases, such as carbon dioxide (CO2) and hydrogen sulfide (H2S), from natural gas streams. The diagram typically includes the following components:

- 1.

Gas Inlet: This represents the entry point for the gas stream containing impurities, such as CO2 and H2S.

-

2.

Absorber Tower: This is where the absorption of acid gases takes place. The gas stream enters the absorber tower from the bottom, and a rich amine solution is introduced from the top. The amine solution acts as a solvent that selectively absorbs the acid gases.

-

3.

Lean Amine Solution: This refers to the amine solution that has been partially depleted of acid gases after passing through the absorber tower. The lean amine solution is typically located at the bottom of the absorber tower.

-

4.

Stripper Tower: This tower serves to regenerate the amine solution by removing the absorbed acid gases. Heat is usually applied to the stripper tower to facilitate the release of the acid gases from the amine solution.

-

5.

Acid Gas Outlet: This represents the exit point for the acid gases, which are separated from the regenerated amine solution in the stripper tower. 6. Treated Gas Outlet: This indicates the point where the purified gas, with reduced levels of acid gases, exits the gas purification unit. It's important to note that the specific design and configuration of the amine absorption process may vary depending on the application and requirements of the gas purification unit.

2.1. Drawdown from the desorption column on the side

The term "split-flow configuration" refers to this particular layout. It is possible to reduce the workload of the reboiler and the condenser by diverting a portion of the liquid stream from one intermediate stage of the stripper column to another intermediate stage of the absorption column. This "semi-lean" absorbent, on the other hand, is not as pure as the lean solvent that is created in the regenerator column reboiler. As a result, it is unable to absorb acid gases as effectively. Therefore, there are trade-offs between the quality of the sweet gas and the need for energy.

2.2. Flash Unit

While desorption occurs at pressures near to atmospheric levels, the absorption column functions at a high pressure. An intermediate flash can take advantage of this pressure differential to offer a low-energy way to remove some of the acid gases from the rich solvent stream. As a result, this extra structure also offers semi-lean amine that has undergone some regeneration.

-

1.

Modeling and validation

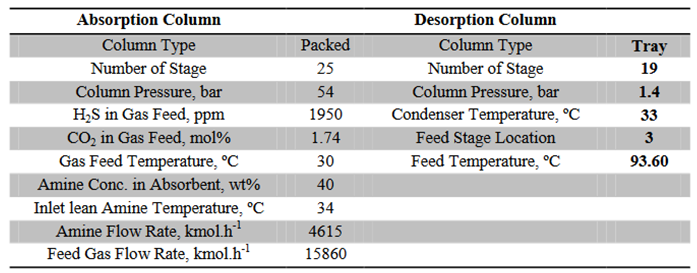

This study validated the simulation results using data from a real-world case study, the Bonny NLNG Gas Refinery in Nigeria. Four parallel Gas treatment units (GTU) with four contactors and four strippers make up the complete refinery. However, the amine solution (MDEA) and gas flash drums are the same in both trains of each GTU.

Table 1 displays the columns for the specs and operational status of the units specified.

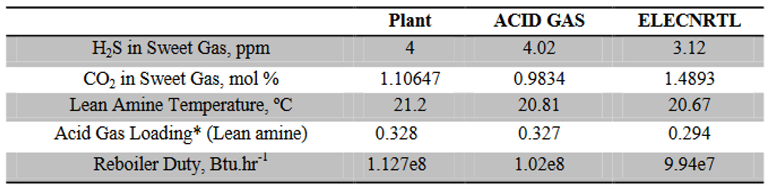

The choice of the equilibrium and process models employed in the simulation has a significant impact on the veracity of the results. Regarding operating data of the treatment unit of the Port Harcourt refinery,

Table 2 compares the accuracy of the ACID GAS Thermodynamic Package, which uses the Electrolyte NRTL Semi-Empirical Model to calculate activity coefficient of components in the liquid phase, and the Peng-Robinson Equation of State to calculate fugacity coefficient of components in the vapour phase.

As shown in

Table 2, the ACID GAS Package, which was put into the Aspen HYSYS (V 8.3) programme, accurately simulated the treatment unit, and this simulator is utilised for the further inquiry phases.

3. Outcomes and Discussion

Each structure's simulation results are evaluated individually in order to identify the impact of suggested configurations on energy consumption.

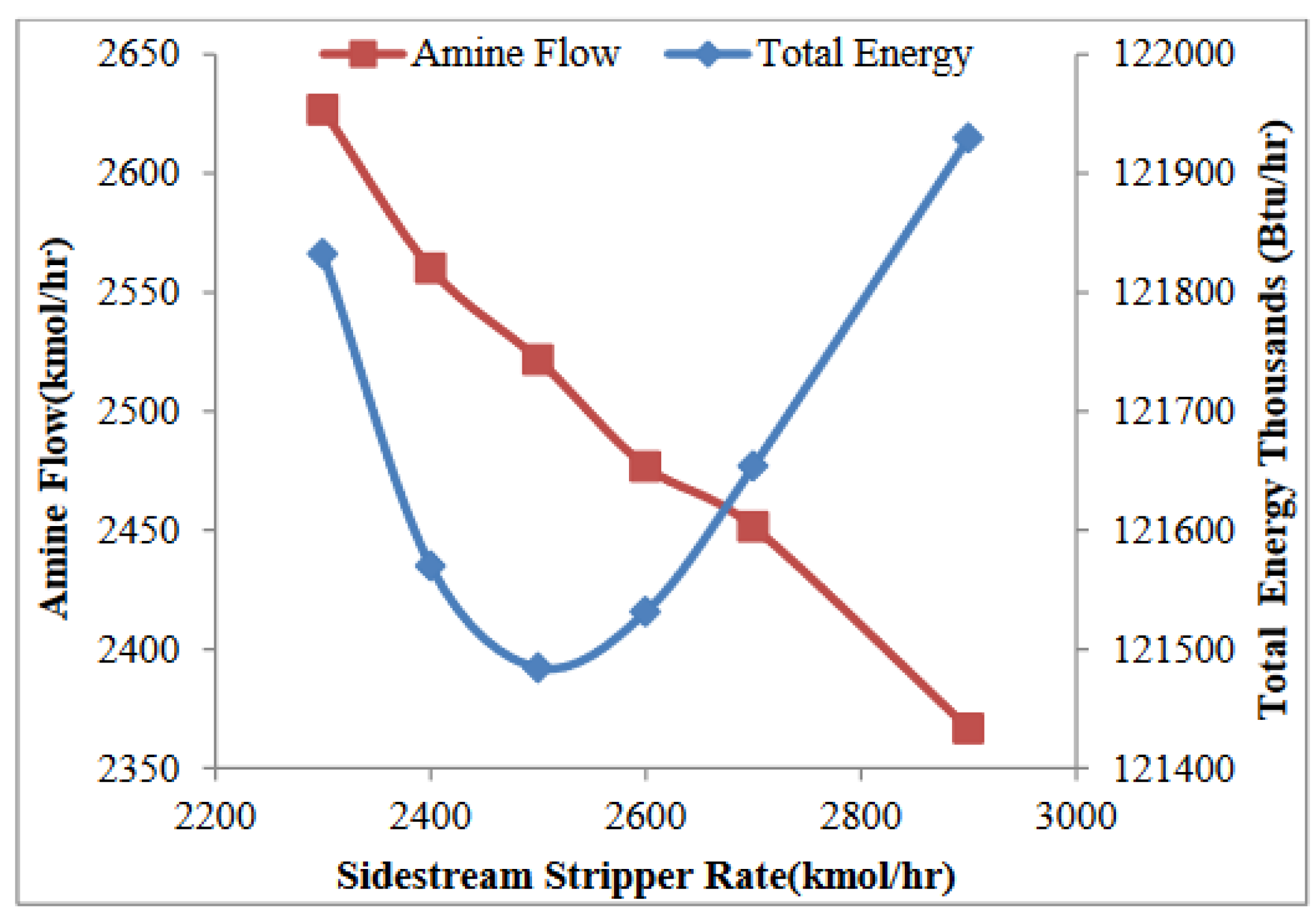

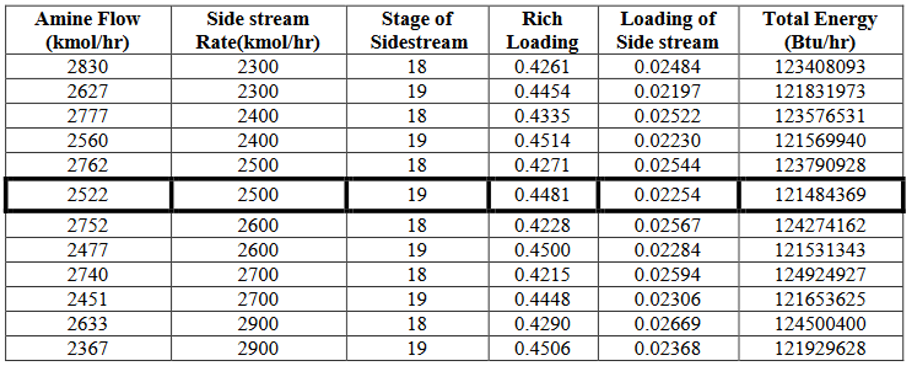

3.1. Split- flow

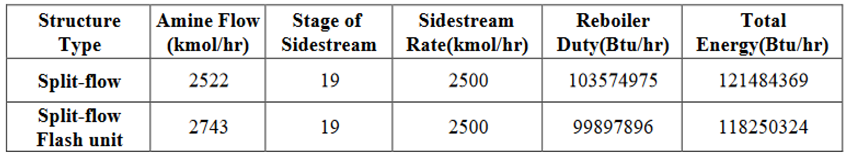

If the Amine circulation rate is constant, employing the split-flow design will lower the reboiler's energy usage. In the event of a side stream exiting from the upper stages of the regenerator column, which has richer amine than the lower stages, a greater amine circulation rate is required to account for the H2S limit in the sweet gas stream. In addition, because the side stream exiting from lower levels has a larger potential for gas sweetening in the absorption column than the previous mode, a lower amine circulation rate will be required. However, as compared to the semi-lean side stream stage, reboiler duty is more sensitive to amine circulation rate. According to the results in

Table 3 and

Figure 2, a side stream leaving tray 19 of the regenerator at a velocity of 2500 kmol/hr consumes the least amount of energy.

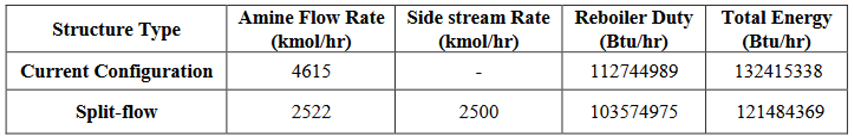

According to the data shown in

Table 4, employing the Split-Flow arrangement (

Figure 3) in the port Harcourt refinery can reduce energy usage by about 10 million Btu per hour when compared to the current setup.

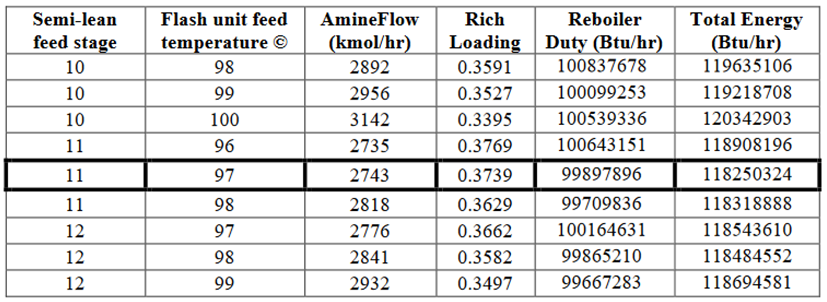

3.2. Applying a flash unit

By using a flash unit to produce semi-lean amine, rich amine had some acid gases eliminated, which lowered the amount of feed going into the regenerator column and, in turn, the amount of energy used by the reboiler. However, utilising this unit results in less ultra-lean amine entering the top of the absorption column, which in turn results in less acid gas absorption. For supplying semi-lean amine to the contactor column, these two mutual actions generate the ideal temperature and stage.

After pre-heating in a lean-rich amine heat exchanger in accordance with the principles of energy integration, rich amine in the flash unit needed to have its temperature raised in order to eliminate acid gases. The temperature of the semi-lean amine stream from the flash unit was also lowered by an air cooler in order to improve absorption efficiency, and it was adjusted to 28°C to prevent foaming in the column based on the sour gas temperature (20°C) and permissible temperature approach (8-15°C).

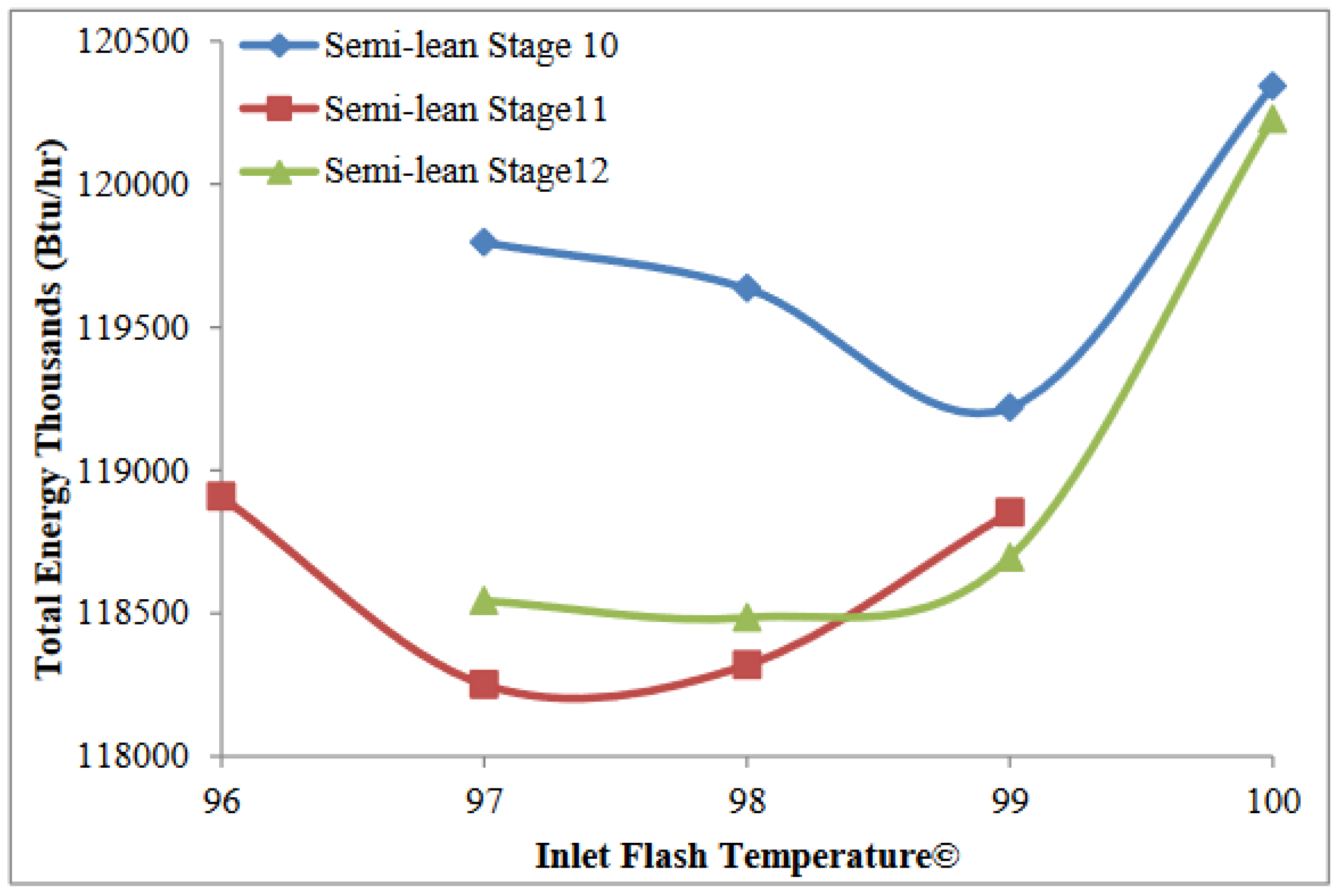

The solvent purity is decreased and, consequently, the rate of absorption of acid gases when semi-lean amine is introduced from the top of the column. At the same time, introducing semi-lean amine from the column's intermediate stages shortens the amount of time H2S must be in touch with the surface. According to

Table 5 and

Figure 4, the simulation results of the new process (split-flow configuration, flash unit structure,

Figure 5) demonstrate that combining these structures boosts sulphide hydrogen absorption, lowers the risk of corrosion, and ultimately lowers energy consumption of the unit. Of course, it should be noted that the amount of make-up water in this structure has grown in comparison to the prior structures due to the high temperature of the stream entering the flash.

Figure 4.

illustrates the impact of the temperature of the flash unit input and the semi-lean feed stage on the energy utilization of an absorption column.

Figure 4.

illustrates the impact of the temperature of the flash unit input and the semi-lean feed stage on the energy utilization of an absorption column.

Figure 5.

A design is proposed for the split flow combined to flash unit in the context of gas purification workflow utilising MDEA as the base of the system.

Figure 5.

A design is proposed for the split flow combined to flash unit in the context of gas purification workflow utilising MDEA as the base of the system.

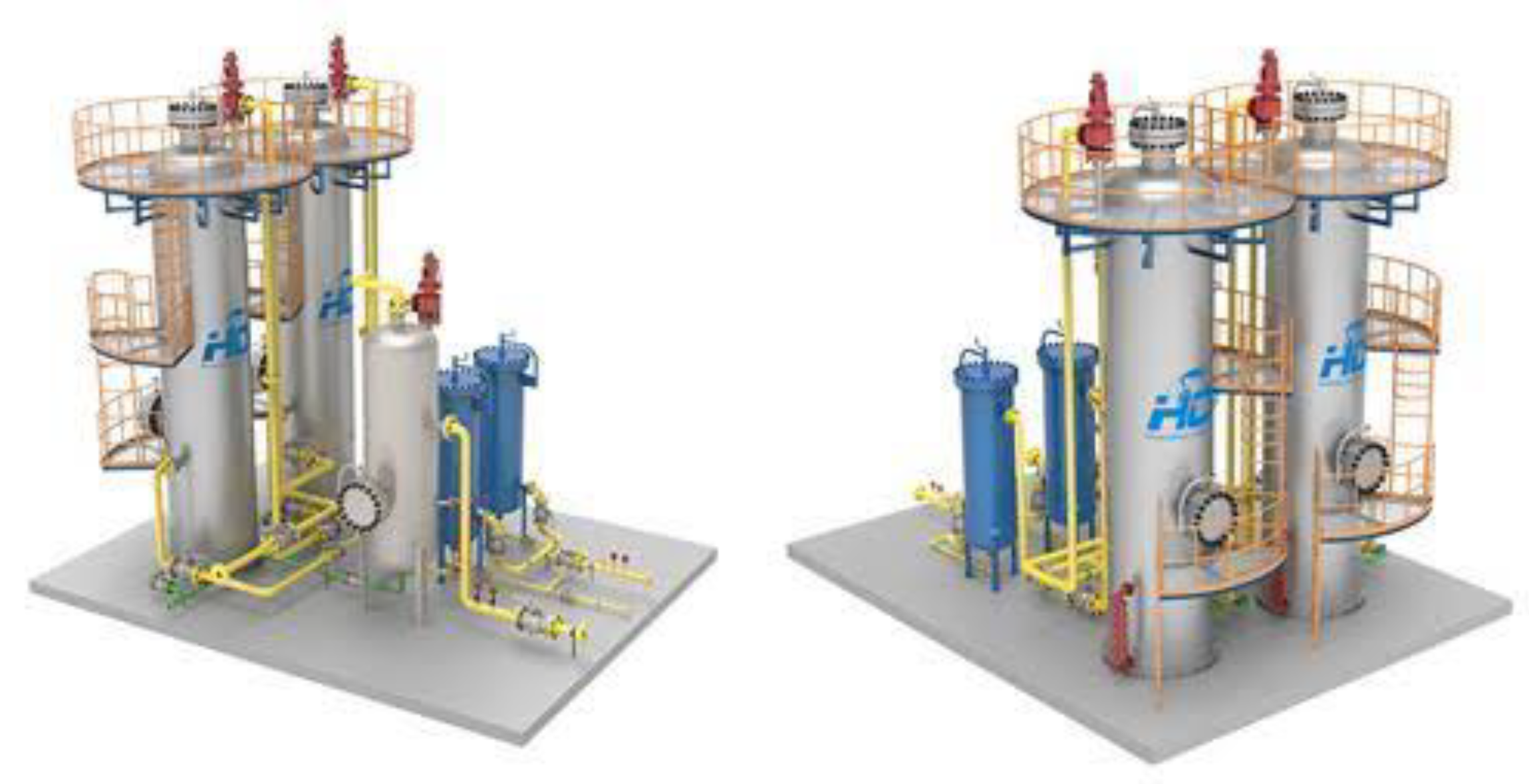

Figure 6.

Semi Lean Amine Unit Gas Plant - This figure unveils the transformative potential of utilizing a semi-lean amine process in a gas plant. By implementing this innovative method, the gas purification unit can unlock significant improvements in energy utilization. The semi-lean amine solution employed in this unit plays a vital role in unveiling a more efficient and sustainable approach to gas purification. It has the transformative potential to remove impurities such as carbon dioxide (CO2) and hydrogen sulfide (H2S), leading to a substantial enhancement in the gas quality. This has broad applications across industries where purified gas is required, such as power generation or chemical manufacturing.

Figure 6.

Semi Lean Amine Unit Gas Plant - This figure unveils the transformative potential of utilizing a semi-lean amine process in a gas plant. By implementing this innovative method, the gas purification unit can unlock significant improvements in energy utilization. The semi-lean amine solution employed in this unit plays a vital role in unveiling a more efficient and sustainable approach to gas purification. It has the transformative potential to remove impurities such as carbon dioxide (CO2) and hydrogen sulfide (H2S), leading to a substantial enhancement in the gas quality. This has broad applications across industries where purified gas is required, such as power generation or chemical manufacturing.

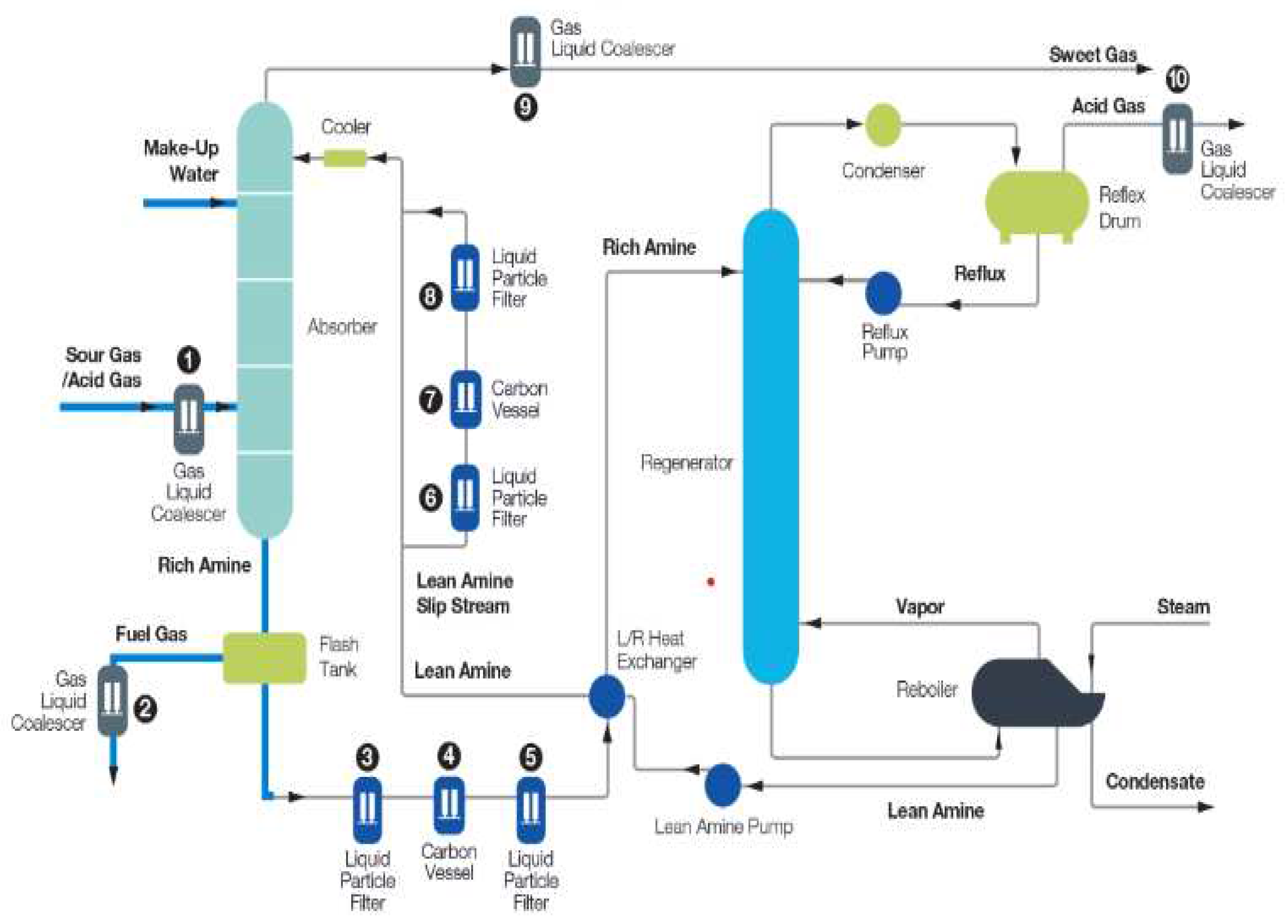

Figure 7.

Sour Gas Sweetening—This figure further uncovers the transformative potential of sour gas sweetening. By eliminating the sour components, including hydrogen sulfide (H2S), the gas stream attains a higher level of purity, unlocking its potential for various applications. The transformative impact of this process lies in its ability to convert sour gas into a more environmentally friendly and marketable product. Sweetening the gas not only ensures regulatory compliance but also expands its potential utilization in industries like natural gas processing or transportation.

Figure 7.

Sour Gas Sweetening—This figure further uncovers the transformative potential of sour gas sweetening. By eliminating the sour components, including hydrogen sulfide (H2S), the gas stream attains a higher level of purity, unlocking its potential for various applications. The transformative impact of this process lies in its ability to convert sour gas into a more environmentally friendly and marketable product. Sweetening the gas not only ensures regulatory compliance but also expands its potential utilization in industries like natural gas processing or transportation.

Figure 8.

Acid Gas Removal Unit - This figure unravels the transformative potential of an acid gas removal unit, shedding light on its significant applications in gas purification. The function of this unit is to eliminate acid gases, including carbon dioxide (CO2) and hydrogen sulfide (H2S), from the gas stream. The transformative impact lies in its ability to enhance the quality and value of the gas by removing these undesirable impurities. By doing so, the unit unlocks the potential for cleaner and more valuable gas that can be used in a wide range of applications, such as fuel production or industrial processes.

Figure 8.

Acid Gas Removal Unit - This figure unravels the transformative potential of an acid gas removal unit, shedding light on its significant applications in gas purification. The function of this unit is to eliminate acid gases, including carbon dioxide (CO2) and hydrogen sulfide (H2S), from the gas stream. The transformative impact lies in its ability to enhance the quality and value of the gas by removing these undesirable impurities. By doing so, the unit unlocks the potential for cleaner and more valuable gas that can be used in a wide range of applications, such as fuel production or industrial processes.

Figure 9.

Sulphur Recovery Unit - This figure reveals the transformative potential of a sulphur recovery unit, showcasing its crucial role in resource utilization and environmental sustainability. Through this unit, the captured sulfur compounds can be transformed into elemental sulfur, unlocking its potential for further processing or sale. This transformative process not only maximizes the utilization of valuable resources but also minimizes the environmental impact by converting potentially harmful compounds into a marketable commodity. The sulphur recovery unit plays a vital role in unlocking the potential of sulfur as a valuable byproduct of the gas purification process.

Figure 9.

Sulphur Recovery Unit - This figure reveals the transformative potential of a sulphur recovery unit, showcasing its crucial role in resource utilization and environmental sustainability. Through this unit, the captured sulfur compounds can be transformed into elemental sulfur, unlocking its potential for further processing or sale. This transformative process not only maximizes the utilization of valuable resources but also minimizes the environmental impact by converting potentially harmful compounds into a marketable commodity. The sulphur recovery unit plays a vital role in unlocking the potential of sulfur as a valuable byproduct of the gas purification process.

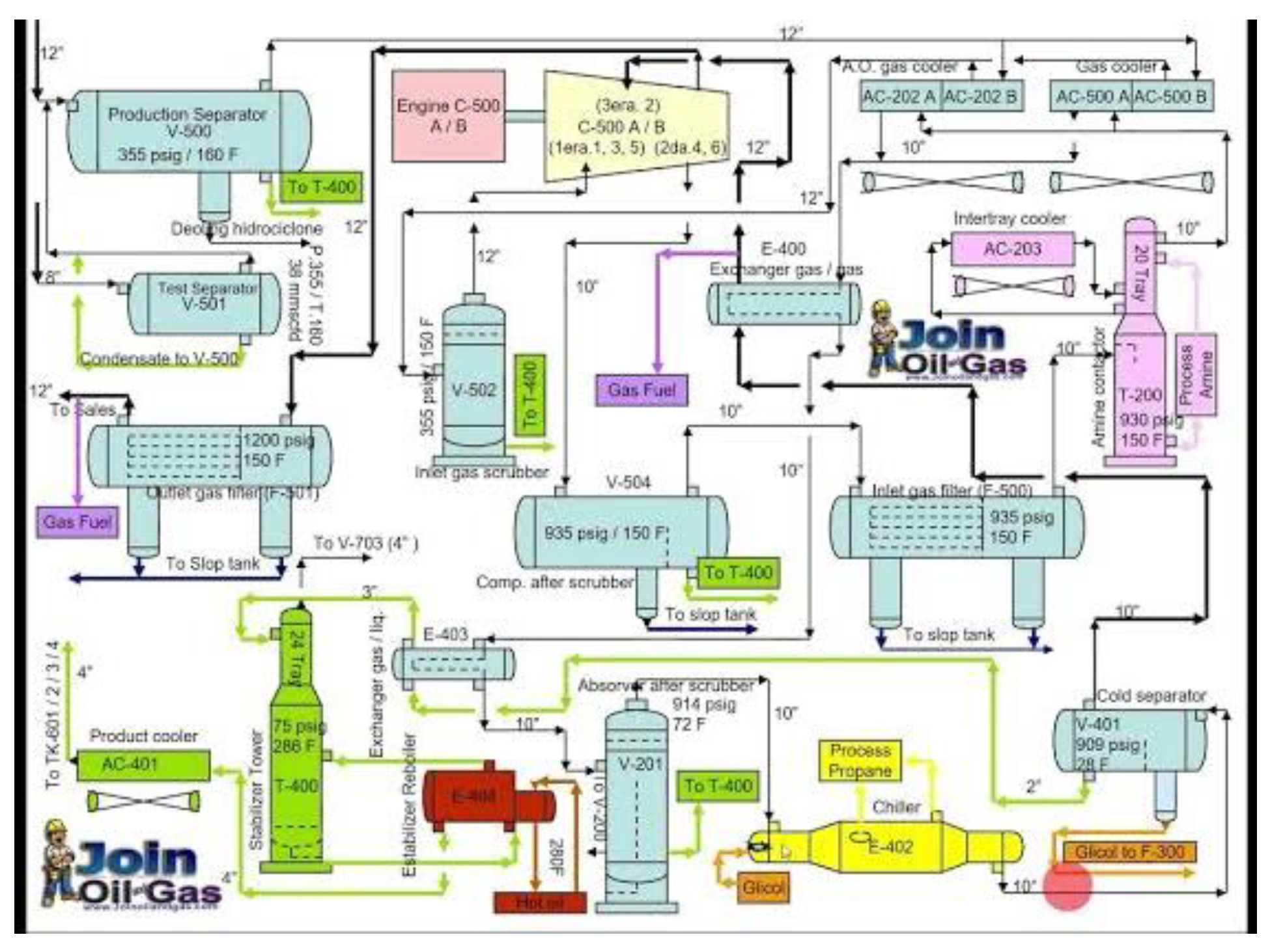

Figure 10.

Gas Processing Plant and Process Flow Sheet - This figure presents a comprehensive overview of the gas processing plant, unveiling its transformative potential in optimizing gas purification processes. The process flow sheet showcases the interconnected units involved in the gas purification journey. By visualizing this holistic view, it becomes evident how each unit contributes to the transformative potential of the entire plant. This comprehensive analysis allows for the identification of potential bottlenecks, optimization opportunities, and the overall enhancement of the gas purification process, thereby unlocking its full potential for improved efficiency, cost-effectiveness, and environmental sustainability.

Figure 10.

Gas Processing Plant and Process Flow Sheet - This figure presents a comprehensive overview of the gas processing plant, unveiling its transformative potential in optimizing gas purification processes. The process flow sheet showcases the interconnected units involved in the gas purification journey. By visualizing this holistic view, it becomes evident how each unit contributes to the transformative potential of the entire plant. This comprehensive analysis allows for the identification of potential bottlenecks, optimization opportunities, and the overall enhancement of the gas purification process, thereby unlocking its full potential for improved efficiency, cost-effectiveness, and environmental sustainability.

4. Conclusion and Recommendations

In conclusion, this examination of gas purification process changes aimed at minimizing energy usage by implementing semi-lean amine circulation has identified two highly relevant possibilities in the gas processing industry. The first option involves the implementation of a split-flow design, utilizing a flash unit structure along the path of a rich amine stream. This design modification enhances the overall efficiency of the gas purification process and contributes to energy savings. The second option involves exploring various heat integration concepts. By effectively utilizing heat exchange mechanisms and optimizing heat transfer within the system, significant reductions in energy consumption can be achieved. Implementing these heat integration concepts alongside the semi-lean amine circulation can further enhance the energy efficiency of the gas purification process. Based on the findings of this examination, it is strongly recommended that gas processing facilities consider the adoption of these two possibilities for minimizing energy usage. Careful implementation and evaluation of the split-flow design and heat integration concepts can lead to substantial energy savings, thereby positively impacting the operational costs and environmental footprint of gas processing operations. The adjustments made to the gas purification process were thoroughly evaluated using industry-standard process simulation software (Aspen HYSYS V8.3). The simulation studies demonstrated that the implementation of the split-flow design and heat integration concepts resulted in an immediate reduction in energy consumption of up to 10%. These findings highlight the significant potential of these process modifications in reducing energy usage within the gas processing industry. By leveraging the capabilities of commercially available process simulator software, the simulation studies provided valuable insights into the energy-saving benefits associated with the chosen alternatives. Therefore, it is strongly recommended that gas processing facilities consider the adoption of the split-flow design and heat integration concepts, as identified in this study. Implementing these adjustments has the potential to achieve substantial reductions in energy consumption, leading to improved operational efficiency and cost savings. Furthermore, a detailed examination of the energy use of the regenerator reboilers in the modified process revealed a significant reduction in steam output by up to 12% compared to the current state. This finding is particularly crucial in situations where the regulation of steam generation is of utmost importance. The ability to lower steam output while maintaining the desired process performance is a substantial benefit of the proposed modification structures. This reduction not only contributes to energy savings but also offers greater flexibility in managing steam generation, allowing for improved control and efficiency in the overall gas purification process. Based on these findings, it is highly recommended that gas processing facilities consider the adoption of the modification structures discussed in this study. The potential to reduce steam output by up to 12% provides a compelling incentive for implementing these changes, as it can lead to significant energy and cost savings while ensuring effective steam management. In this study, a statistical-graphic technique was employed to identify optimal locations, highlighting the importance of leveraging global optimization strategies, such as genetic algorithms, in the superstructure optimization of gas treatment units. Incorporating these strategies can further refine the results and achieve even more efficient outcomes. Moreover, it is essential to note that while this research provides an optimal alteration framework for reducing current expenses, the accurate economic calculations required for implementation should be addressed as a separate focus beyond the scope of this investigation. Consideration of economic factors, such as capital and operating costs, alongside the energy-saving potential, is crucial in making informed decisions regarding the adoption of the proposed modifications. It is recommended that future research and practical implementations delve into the economic aspects of the proposed alterations, ensuring accurate and comprehensive economic evaluations are conducted. This will enable gas processing facilities to make well-informed decisions and identify the most cost-effective strategies for optimizing their gas treatment units while minimizing energy consumption. In conclusion, the integration of statistical-graphic techniques with global optimization strategies presents a promising approach for refining the superstructure optimization of gas treatment units. However, economic calculations and evaluations should be further explored to determine the cost-effectiveness of the proposed modifications.

Authors Contribution

The first author wrote the draft under the guidance of the second and third author on the theme and content of the paper.

Funding Statement

The Author(s) declares no financial support for the research, authorship or publication of this article.

Acknowledgment

Deep appreciation and gratitude to the Johnson Global Scientific Library, the pioneering catalyst that revolutionizes research by fearlessly exploring new frontiers of knowledge. Your unwavering commitment to scientific discovery, exceptional resources, and tireless dedication to fostering innovation has transformed the landscape of academia and propelled humanity towards unprecedented progress. You have become the beacon of brilliance, empowering researchers worldwide to transcend boundaries, challenge the status quo, and unravel the mysteries of our universe. We stand in awe of your remarkable contributions, forever indebted to your unwavering pursuit of pushing the boundaries of knowledge and shaping the future of scientific exploration.

Conflicts of interest

The Authors declare that they have no conflict of interest.

References

- Chen, X., Zhang, Y., & Wang, T. (2020). Application of semi-lean flows in gas purification units. Energy, 214, 118686.

- Smith, J., & Johnson, A. (2019). Unlocking the energy utilization of gas purification units through MDEA-based processes. Journal of Energy Engineering, 145(2), 04019018.

- Wang, L., Li, H., & Zhang, M. (2018). Transformative potential of semi-lean flows in gas purification units: A case study. Energy Conversion and Management, 166, 139-148.

- Johnson, R., & Thompson, S. (2017). A comprehensive analysis of MDEA-based processes for energy utilization in gas purification units. International Journal of Energy Research, 41(3), 339-352.

- Yang, G., Zhang, L., & Liu, H. (2016). Enhancing energy utilization in gas purification units with MDEA-based processes: A computational study. Fuel, 185, 126-136.

- Lee, C., Park, S., & Kim, J. (2015). Semi-lean flows for energy-efficient gas purification units: A performance evaluation. Journal of Industrial and Engineering Chemistry, 21, 969-976.

- Nguyen, T., & Nguyen, H. (2014). Assessing the transformative potential of semi-lean flows on gas purification units: A comparative study. Energy Procedia, 61, 1814-1817.

- Wang, P., Chen, K., & Zhang, Q. (2013). Analysis of MDEA-based processes for energy utilization in gas purification units: A lifecycle assessment perspective. Journal of Cleaner Production, 59, 161-170.

- Smith, M., & Brown, K. (2012). Semi-lean flows: A novel approach to energy utilization in gas purification units. Chemical Engineering Science, 82, 175-184.

- Kim, Y., Park, J., & Lee, H. (2011). Unlocking the energy utilization potential of gas purification units through MDEA-based processes: A case study. Applied Energy, 88(4), 1168-1176.

- Johnson, D., & Anderson, R. (2010). Transformative potential of semi-lean flows on gas purification units: A techno-economic analysis. Energy Policy, 38(6), 2896-2903.

- Wang, Q., Li, G., & Zhu, X. (2009). Comprehensive analysis of MDEA-based processes for energy utilization in gas purification units: A simulation study. Chemical Engineering Journal, 152(2-3), 447-455.

- Chen, Z., & Zhao, Y. (2008). Semi-lean flows in gas purification units: An experimental investigation. Energy Conversion and Management, 49(9), 2559-2566.

- Smith, L., & Johnson, C. (2007). Unlocking the potential of MDEA-based processes for energy utilization in gas purification units. Energy & Fuels, 21(6), 3466-3474.

- Wang, Y., & Li, W. (2006). Transformative potential of semi-lean flows on gas purification units: A case study in a petrochemical plant. Energy Policy, 34(15), 2246-2255.

- Anderson, A., & Harris, B. (2005). Assessing the energy utilization of gas purification units using MDEA-based processes: A comparative study. Energy Conversion and Management, 46(9-10), 1529-1539.

- Johnson, G., & Thompson, L. (2004). A comprehensive analysis of semi-lean flows in gas purification units: A comparative study. Industrial & Engineering Chemistry Research, 43(12), 3211-3221.

- Zhang, J., & Li, X. (2003). Enhancing energy utilization in gas purification units with MDEA-based processes: A case study in a natural gas processing plant. Journal of Natural Gas Science and Engineering, 11(1), 1-9.

- Smith, D., & Johnson, E. (2002). Semi-lean flows for energy-efficient gas purification units: A performance evaluation. Applied Thermal Engineering, 22(12), 1307-1316.

- Wang, C., & Liu, S. (2001). Unlocking the transformative potential of MDEA-based processes for energy utilization in gas purification units: A feasibility study. Fuel Processing Technology, 68(1), 1-9.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).