Submitted:

05 December 2023

Posted:

07 December 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Lining Void form and Water Temperature Conditions

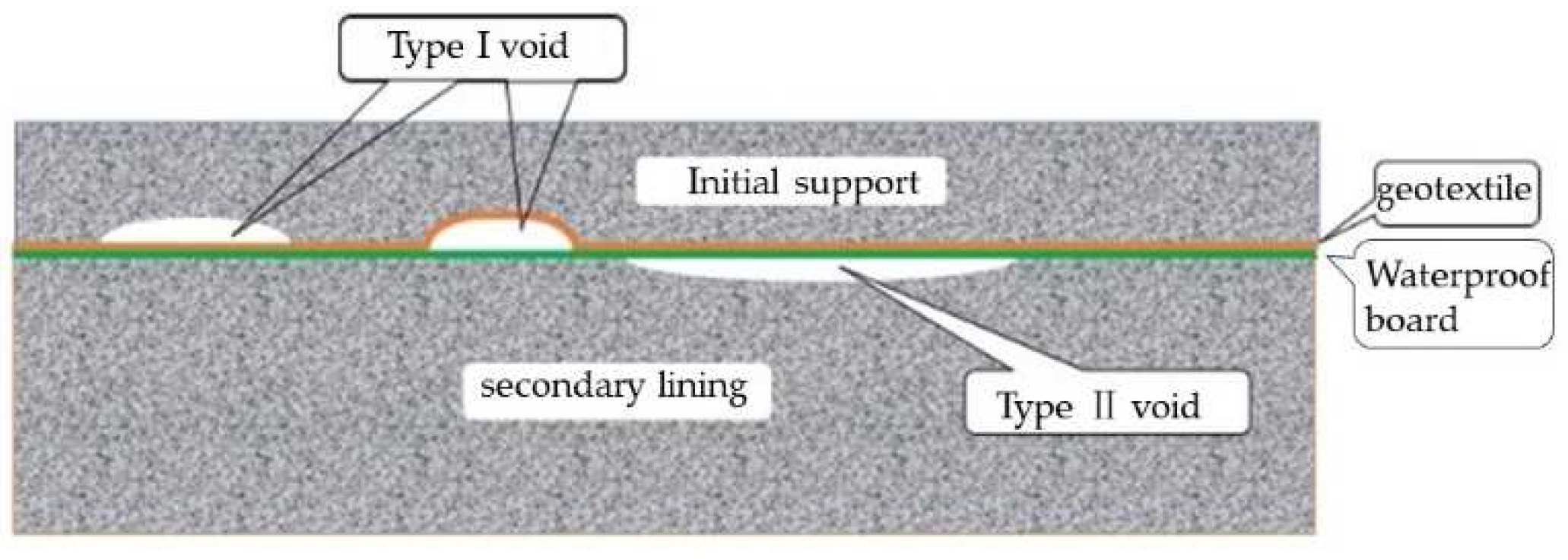

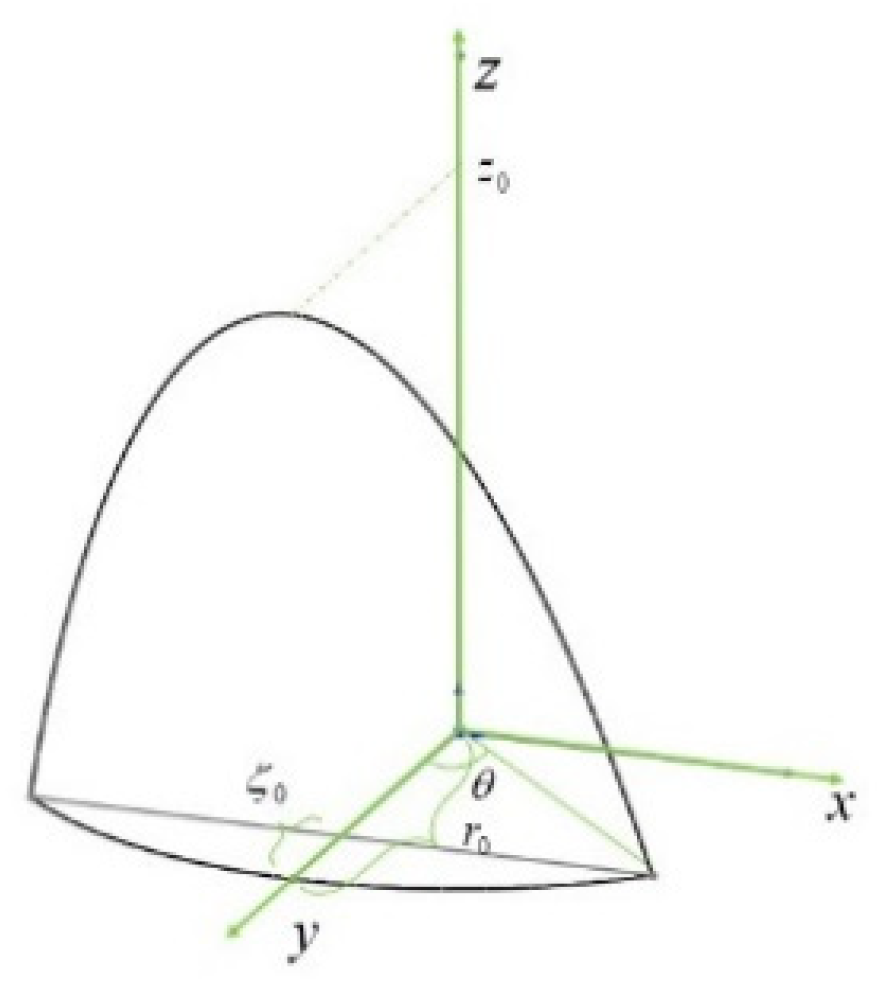

2.1. Lining Void Form

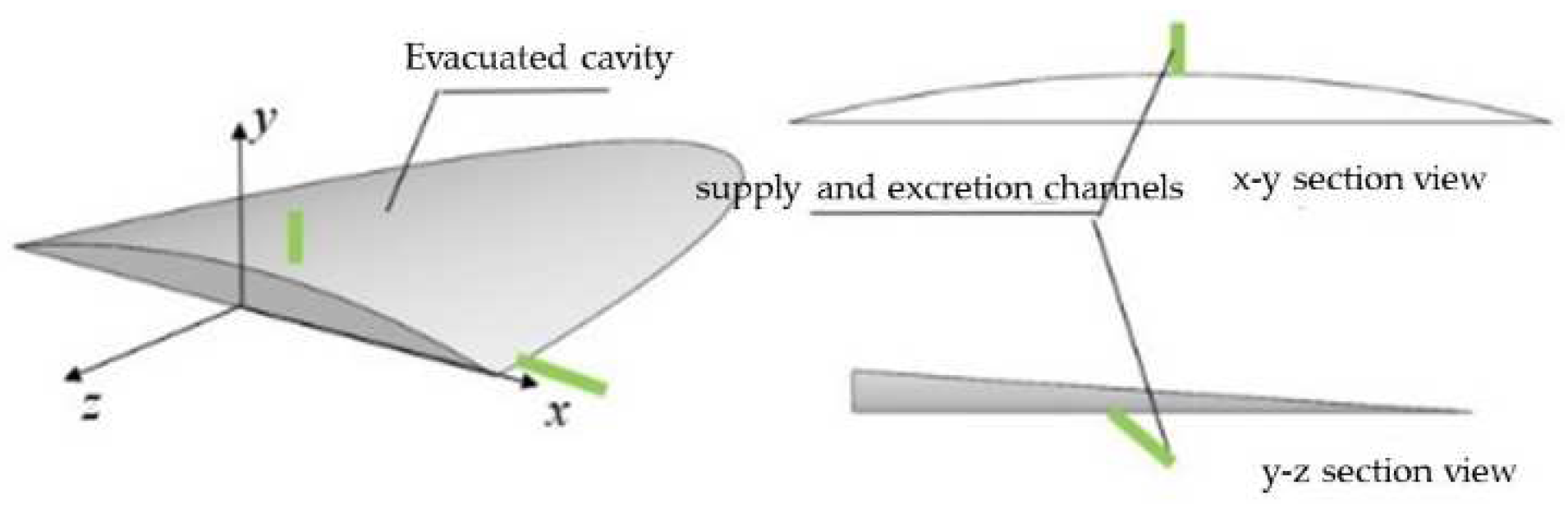

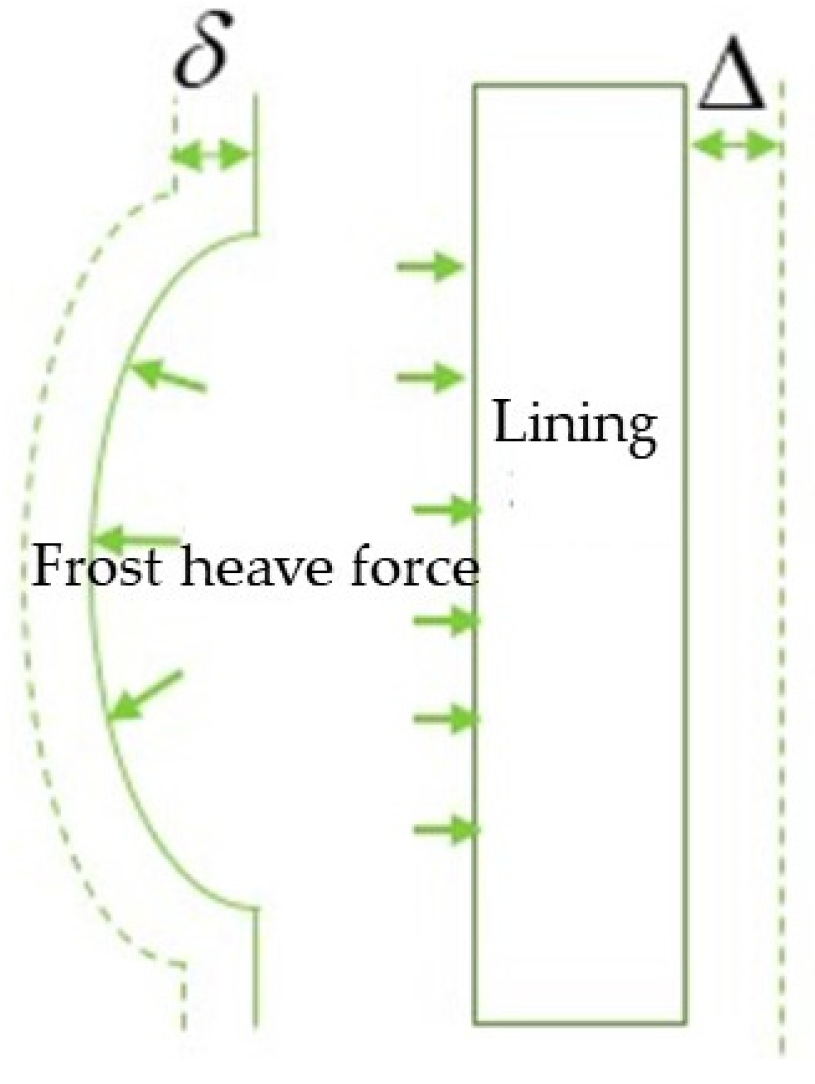

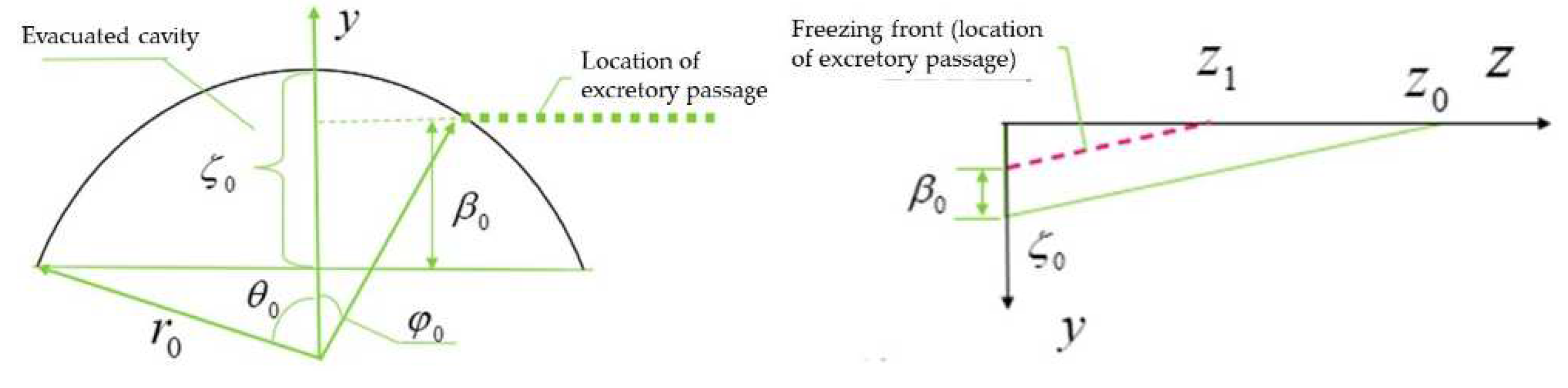

2.2. Conditions for Supply and Discharge of Empty Accumulated Water behind the Lining

2.3. Short-Period Fluctuation Model of Lining Surface Temperature

3. Simulation Analysis of the Formation Mechanism and Evolution Process of Frost Heave Force

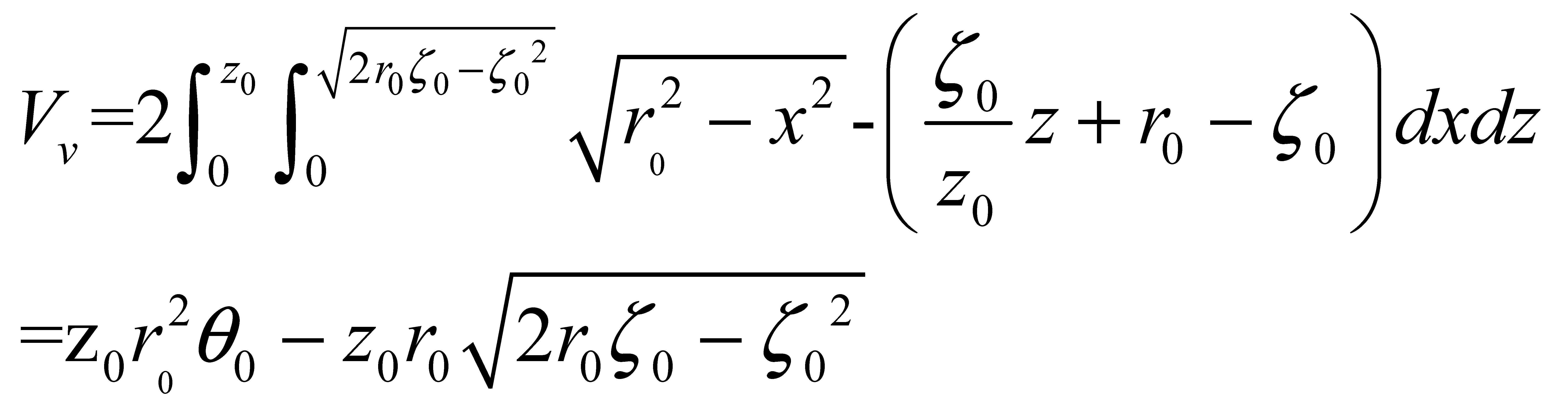

3.1. Effect of Excretion Conditions on Frost Heave Force

3.2. Frost-Heaving Mechanism of Voided Water behind Lining under Short-Period Fluctuation Conditions

- 1)

- Numerical simulation plan

- ①

- Boundary conditions

- ②

- Supply and excretion conditions

- ③

- Grid and parameters

- 2)

- Freezing and thawing analysis of empty accumulated water

- ①

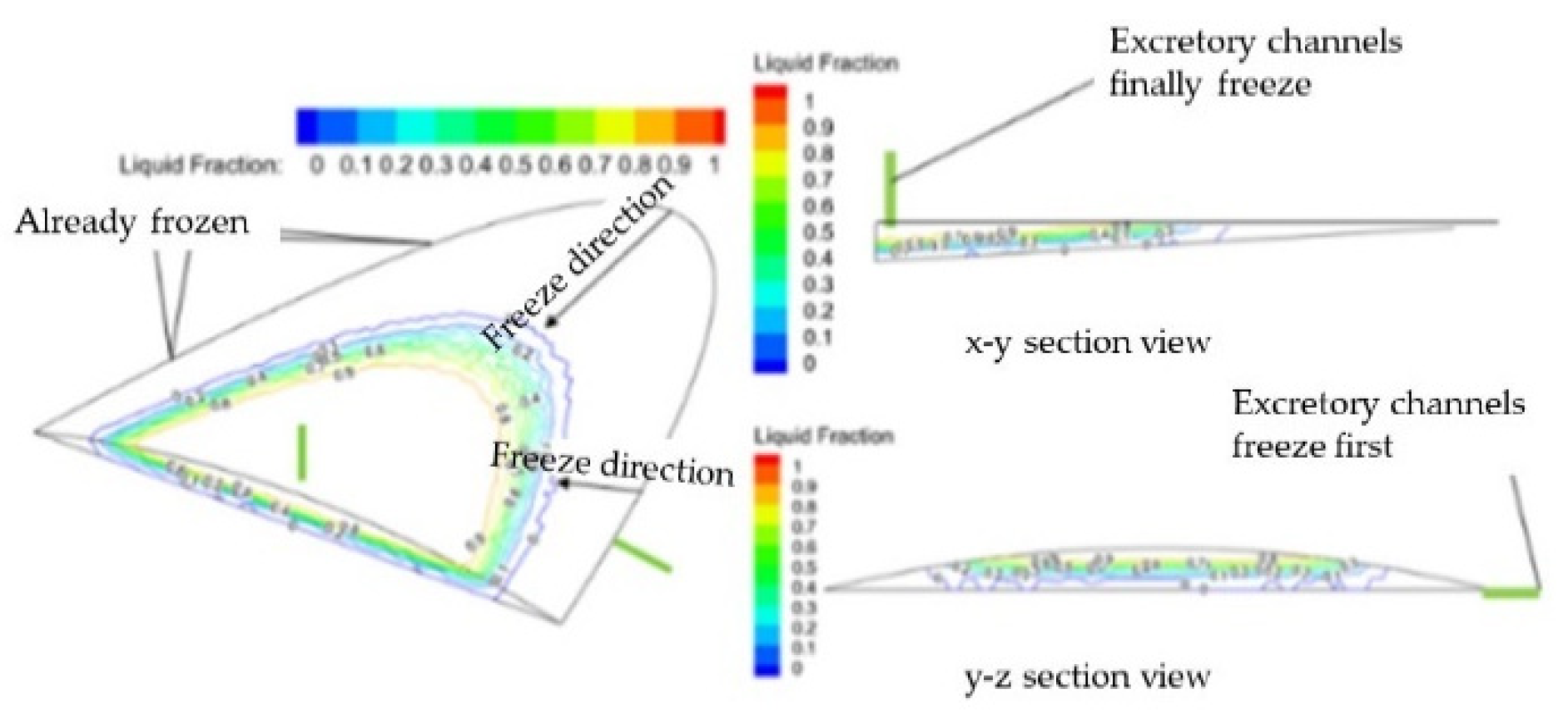

- Freezing process of water inside the void

- ②

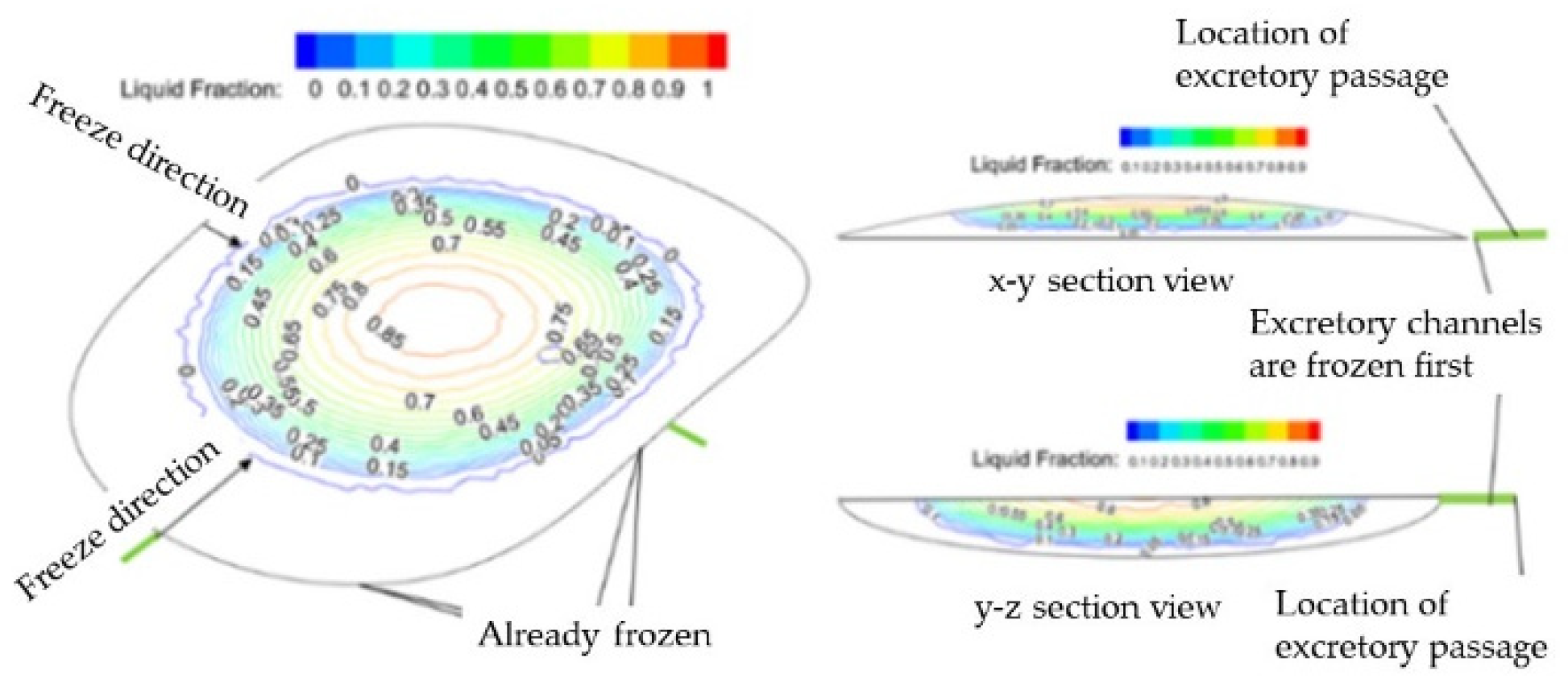

- Melting process of water inside the void

- ③

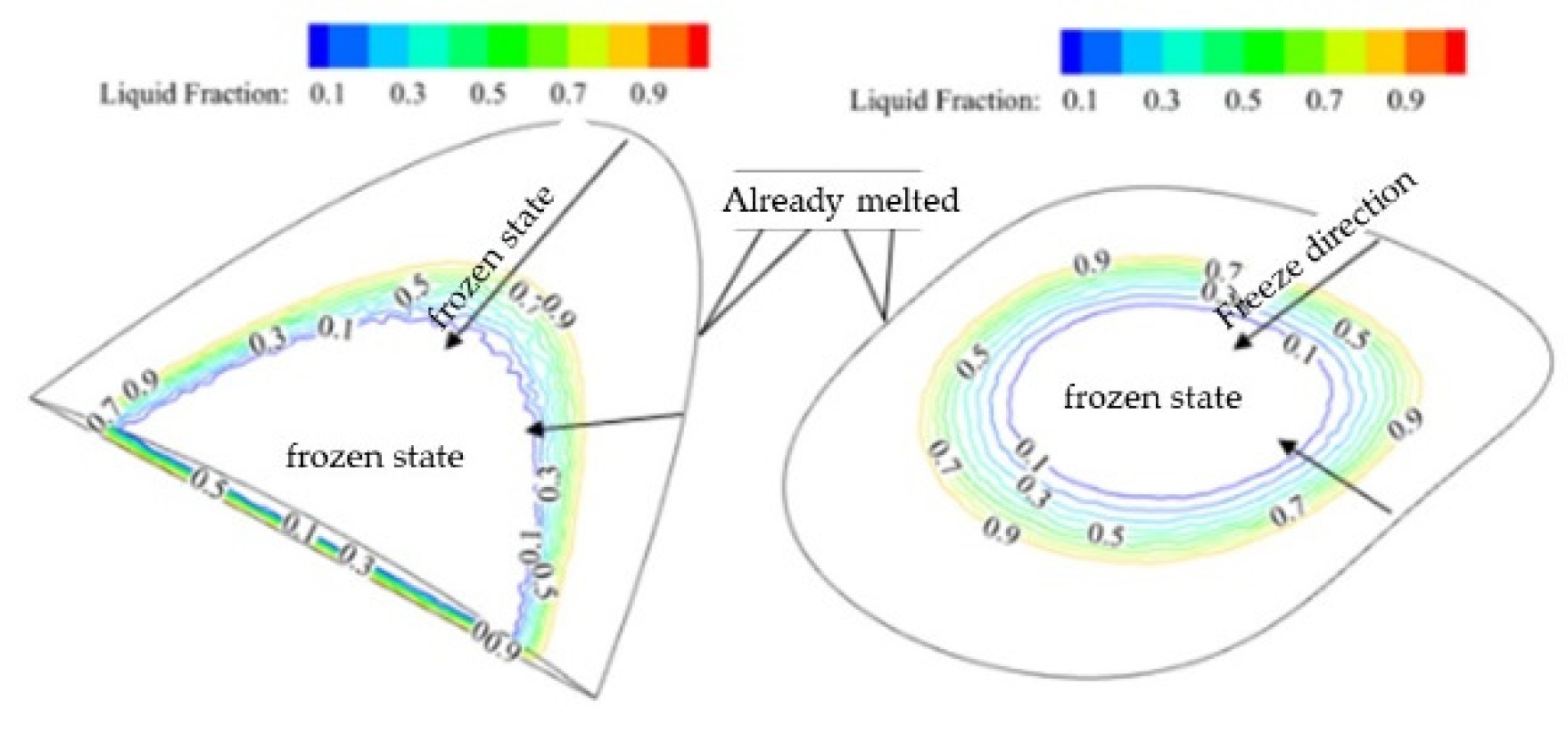

- The formation mechanism of frost heave force within the void

4. Calculation and Analysis Model of Frost Heave Force

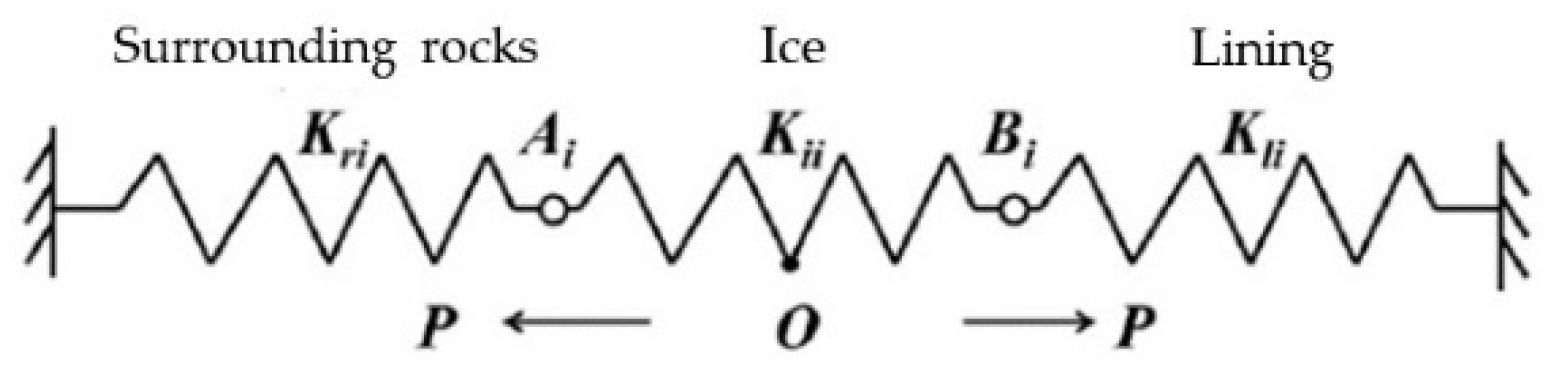

4.1. Frost Heave Force Calculation Model

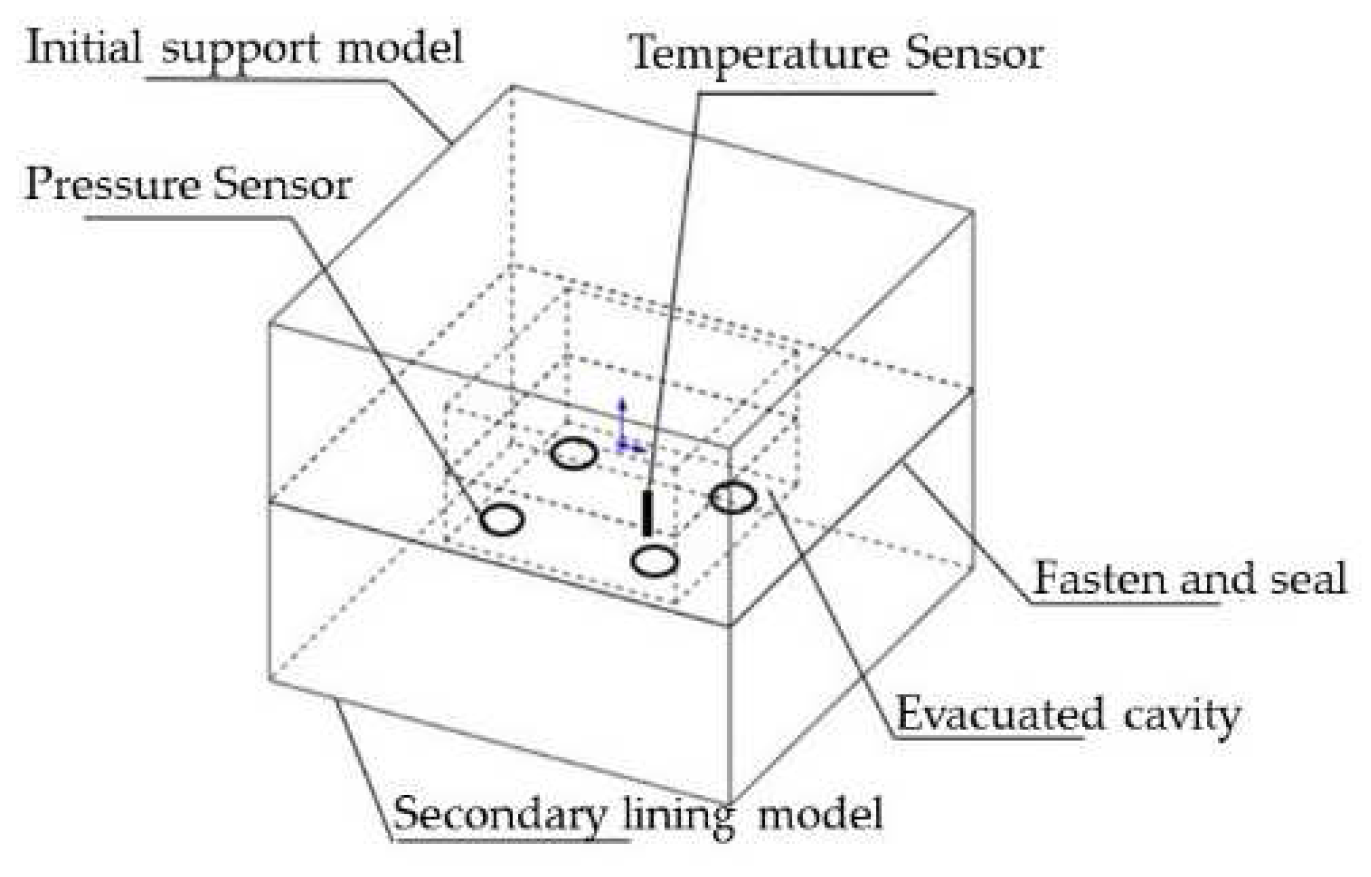

4.2. Frost-Heaving Force of Circular Wedge-Shaped Voiding without Considering Drainage Conditions

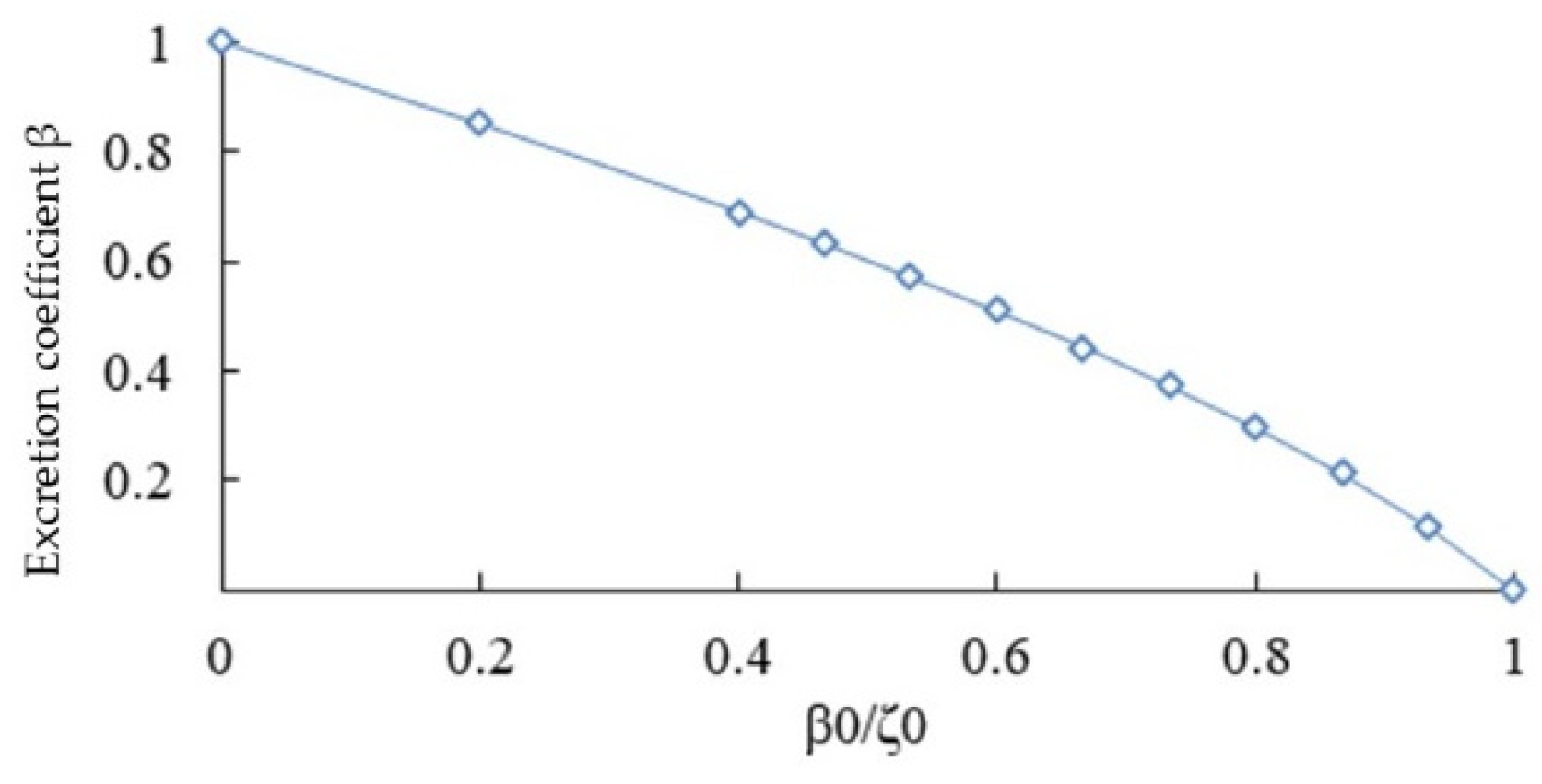

4.3. Considering the Frost Heaving Force of Circular Wedge Hollowing under Drainage Conditions

5. Conclusions

- (1)

- Based on the positional relationship between voids and waterproof panels, two types of void definitions are proposed, and the water temperature conditions of voids are revealed. That is, type I voiding with open drainage conditions is located on the outside of the waterproof board; type II voiding is located on the inside of the waterproofing board with semi-open drainage conditions; and the short-period fluctuation characteristics of the tunnel temperature are characterized by a sinusoidal function with a daily period.

- (2)

- Experiments combined with numerical simulations analyzed and summarized the formation mechanism and evolution process of the frost heaving force of deconcentrated water. Through experiments, the influence of different drainage conditions on frost heave force was found. On this basis, short-period fluctuations in temperature were considered, and the circular wedge-shaped and flying saucer-shaped voiding models were proposed. Through numerical simulation, it was found that the freezing and melting of voided water all started from the voiding The thinnest part of the edge develops towards the thicker part. During the freezing process of devoured water, type I devacuation will not produce frost heave force, while type II devacuation will produce greater frost heave force due to the freezing of the drainage channel. The process of frost heaving-melting, water replenishment-re-frost heaving of Type II devacuated water causes the frost heaving force to become larger and larger.

- (3)

- According to the relative position of the drainage channel and the void, the drainage coefficient is introduced, and an analytical model for the calculation and analysis of frost heave force is proposed. Taking the ratio of the frost heave force when there is water discharge and the frost heave force when there is no discharge as the discharge coefficient, it is found that the closer the discharge channel is to the relative position of the hollow bottom, the greater the discharge coefficient and the greater the frost heave force.

References

- Pan, H.Y.; Li, H.; Zhang, T.S.; Laghari, A.A.; Zhang, Z.T.; Yuan, Y.P.; Qian, B. A Portable Renewable Wind Energy Harvesting System Integrated S-rotor and H-rotor for Self-Powered Applications in High-Speed Railway Tunnels. Energy Conversion and Management 2019, 196, 56–68. [Google Scholar] [CrossRef]

- Li, Y.S.; Chen, S.G. Analytical Solution of Frost Heave Force for Noncircular Tunnels in Cold Region. Chinese Journal of Theoretical and Applied Mechanics 2019, 196, 56–68. [Google Scholar]

- Wu, H.B. A Research on Frost Heaveforce and Temperature Field Inside Long Road Tunnels in Cold Are. Master’s Thesis, Southwest Jiaotong University, Chengdu, China, 2015. [Google Scholar]

- He, B.G.; Liu, E.R.; Zhang, Z.Q.; Zhang, Y. Failure Modes of Highway Tunnel with Voids Behind the Lining Roof. Tunnelling and Underground Space Technology 2021, 117, 104147. [Google Scholar] [CrossRef]

- Zi, H.; Ding, Z.D.; Ji, X.F.; Liu, Z.C.; Shi, C.H. Effect of Voids On the Seismic Vulnerability of Mountain Tunnel. Soil Dynamics and Earthquake Engineering 2021, 148, 106833. [Google Scholar] [CrossRef]

- Fan, L.; Zeng, Y.H.; H, C.; Cheng, X.H. Magnitude and Distribution of Frost Heave Force for Cold Region Strong Rock Tunnels. China Railway Science 2007, 28, 44–49. [Google Scholar]

- Wang, Y.W.; Zheng, J.Y. Study of Simplified Mechanical Models of Frost-Heaving of Water Behind Highway Tunnel Lining and Its Error Analysi. Tunnel Construction 2018, 38, 104–109. [Google Scholar]

- Yang, J.; Gong, L. Research on Remediation Techniques for Insufficient Lining Thickness of Voided Arch Roof in Operational Tunnels. Highway 2022, 67, 321–329. [Google Scholar]

- Du, P.L. Discussion on Causes, Remediation and Precautionary Measures for Unseen Voids in the Secondary Linings of High-speed Railway Tunnel. Railway Construction Technology 2019, 306, 101–104. [Google Scholar]

- Zhou, X.H.; Ren, X.C.; Ye, X.Q.; Tao, L.L.; Zeng, Y.H.; Liu, X.R. Temperature field and anti-freezing system for cold-region tunnels through rock with high geotemperatures. Tunnelling and Underground Space Technology 2021, 111, 103843. [Google Scholar] [CrossRef]

- Ding, Z.D.; Wen, J.C.; Ji, X.F.; Ren, Z.H.; Zhang, S. Experimental Investigation of the Mechanical Behavior of NC Linings in consideration of Voids and Lining Thinning. Advances in Civil Engineering 2020, 2020, 1–14. [Google Scholar] [CrossRef]

- Liu, H.Y.; Yuan, X.P.; Xie, T.C. A damage model for frost heaving pressure in circular rock tunnel under freezing-thawing cycles. Tunnelling and Underground Space Technology 2019, 83, 401–408. [Google Scholar] [CrossRef]

- Gao, Y.; Jiang, Y.J.; Li, B. Estimation of effect of voids on frequency response of mountain tunnel lining based on microtremor method. Tunnelling and Underground Space Technology 2014, 42, 184–194. [Google Scholar] [CrossRef]

- Wu, Y.M.; Li, W.B.; Fu, H.L.; Liu, M.J. Numerical simulation of freeze-thaw in short period of secondary lining at tunnel transition section in seasonal frozen area. Chinese Journal of Geotechnical Engineering 2017, 39, 1930–1935. [Google Scholar]

- Tan, X.J.; Chen, W.Z.; Yang, D.S.; Dai, Y.H.; Wu, G.J.; Yang, J.P.; Yu, H.D.; Tian, H.M.; Zhao, W.S. Study on the influence of airflow on the temperature of the surrounding rock in a cold region tunnel and its application to insulation layer design. Applied Thermal Engineering 2014, 67, 320–334. [Google Scholar] [CrossRef]

- Xu, P.; Wu, Y.M.; Wang, Z.J.; Huang, L. Distribution Laws of Freeze-Thaw Cycles and Unsaturated Concrete Experiments in Cold-Region Tunnels. Cold Regions Science and Technology 2020, 172, 102981–102985. [Google Scholar]

- Wu, Y.M.; Xu, P.; Huang, L.; Cai, Z.Y.; Hu, K.X. Progressive deterioration of tunnel lining in seasonal freezing zone and its engineering influence. J. Chang. Univ. (Nat. Sci. Ed.) 2021, 41, 63–72. [Google Scholar]

- Xu, P.; Wu, Y.M.; Huang, L.; Zhang, K. Study on the Progressive Deterioration of Tunnel Lining Structures in Cold Regions Experiencing Freeze–Thaw Cycles. Applied Sciences 2021, 11, 5903. [Google Scholar] [CrossRef]

- Feng, Q.; Jiang, B.S. Analytical Calculation on Temperature Field of Tunnels in Cold Region by Laplace Integral Transform. Journal of Mining & Safety Engineering 2012, 29, 391–395. [Google Scholar]

- Feng, Q.; Jiang, B.S. Analytical method for insulation layer thickness of highway tunnels with multilayer dielectric in cold regions. Chinese Journal of Geotechnical Engineering 2014, 36, 1879–1887. [Google Scholar]

- Wang, J.Y.; Hu, Y.F. A Discussion on Frost Heave Force Acting on Tunnel Lining. Journal of Railway Engineering Society 2004, 87–93. [Google Scholar]

- TB10003-2016; Code for Design of Railway Tunnel. State Railway Administration: Beijing, China, 2016.

- Zhang, Z.D.; Wang, L. Discussion on the design of tunnels in high elevation and bitter cold region. Modern Tunnelling Technology 2004, 41, 6. [Google Scholar]

| Parameter | Unit | Material name | |

| Water | Concrete | ||

| Density | kg/m3 | 998.2 | 2400 |

| Specific heat capacity | J/(kg·℃) | 4183 | 970 |

| Thermal Conductivity | W/(m·℃) | 0.60 | 1.28 |

| Viscosity | kg/(m·s) | 0.001 | — |

| Enthalpy | J/(kg·mol) | -2.58e8 | — |

| Heat of fusion | J/kg | 798 | — |

| Solid phase temperature | ℃ | -3 | — |

| Liquidus temperature | ℃ | 2 | — |

| Surrounding rock grade | I | II | III | IV | V |

|---|---|---|---|---|---|

| Elastic resistance coefficient | 1800-2800 | 1200-1800 | 500-1200 | 200-500 | 100-200 |

| 0 | 0.2 | 0.4 | 0.47 | 0.53 | 0.6 | 0.67 | 0.73 | 0.8 | 0.87 | 0.93 | 1 | |

| 1 | 0.85 | 0.69 | 0.63 | 0.57 | 0.51 | 0.44 | 0.37 | 0.3 | 0.21 | 0.12 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).