Submitted:

10 November 2023

Posted:

13 November 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

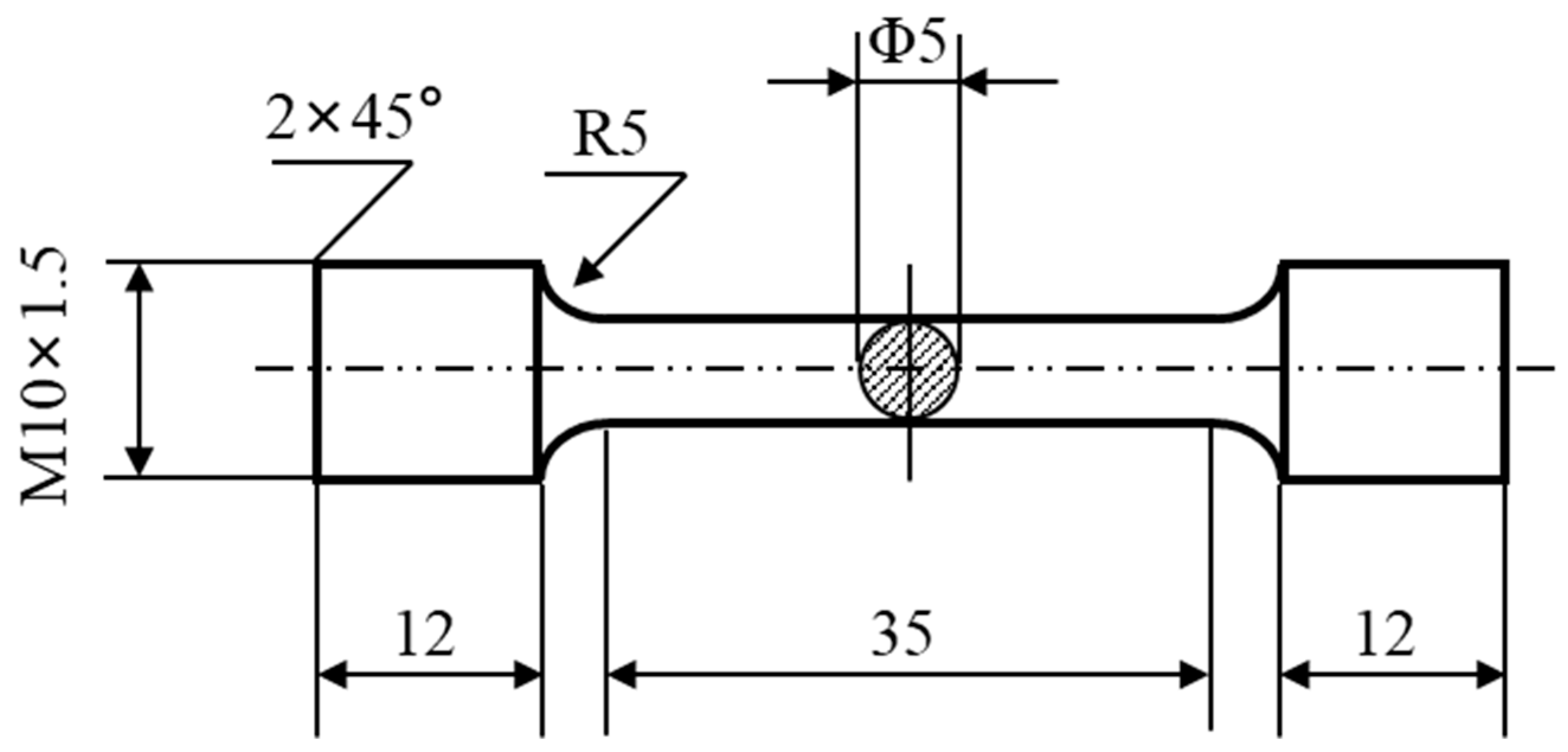

2. Materials and Methods

3. Results

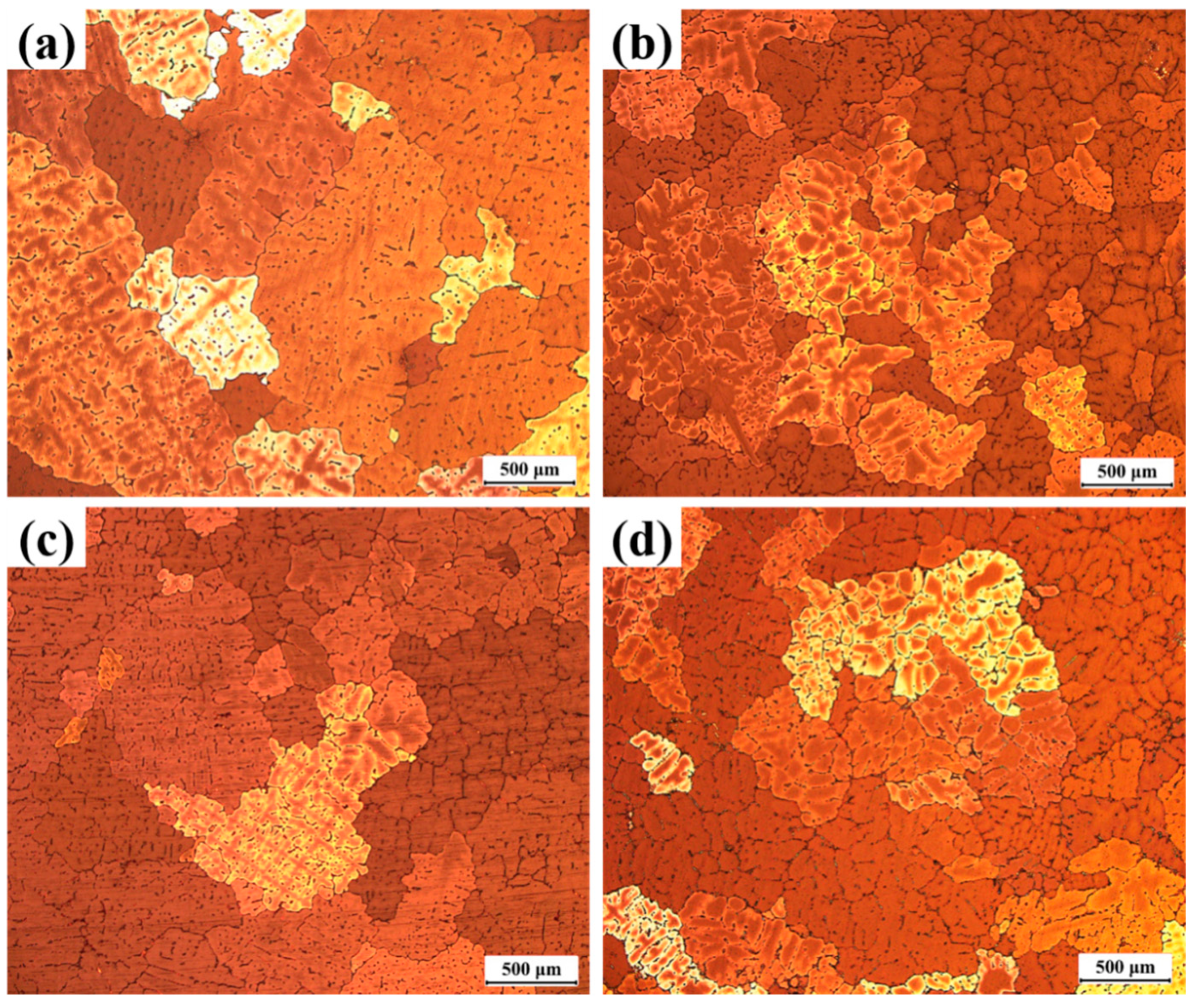

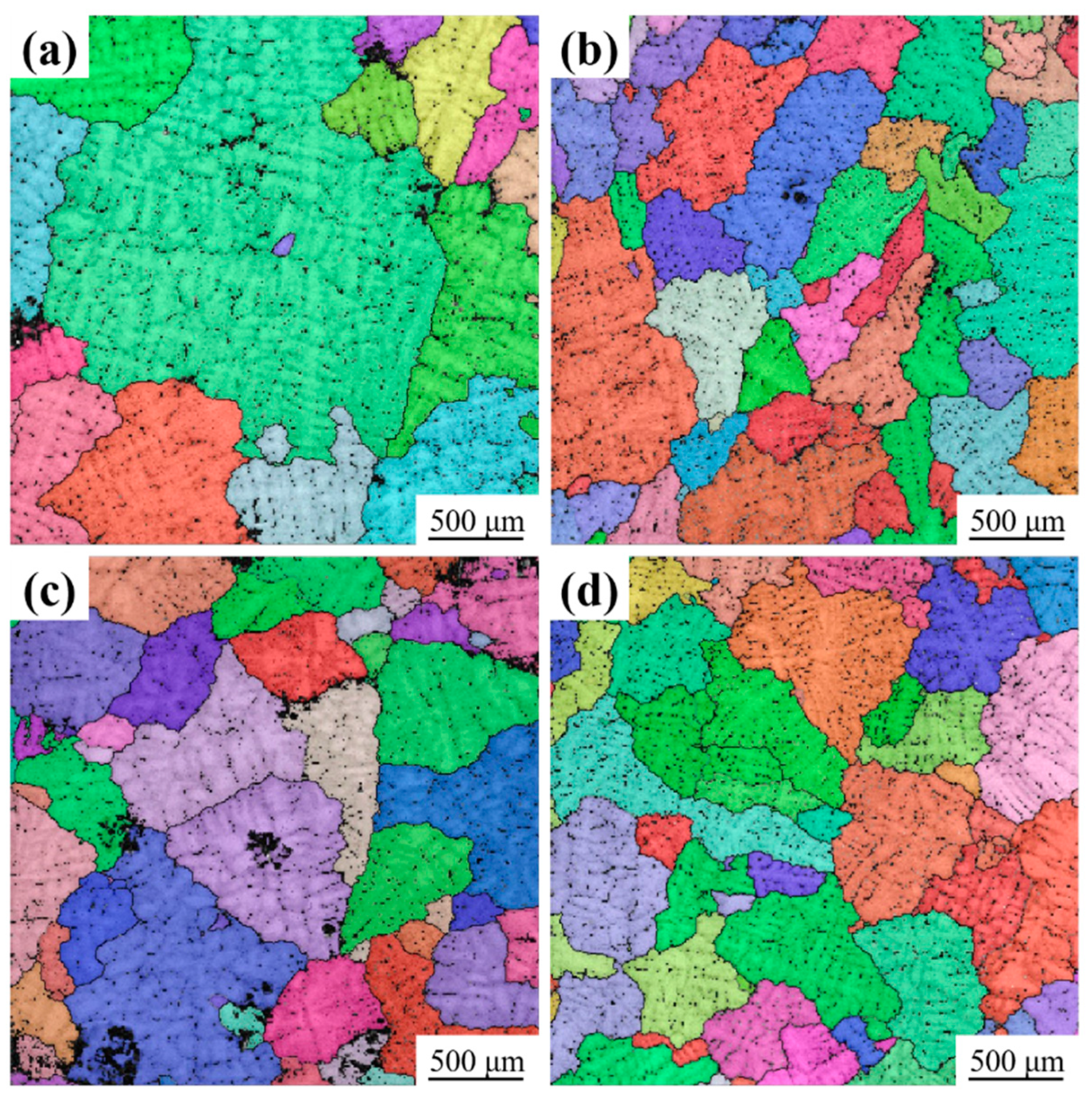

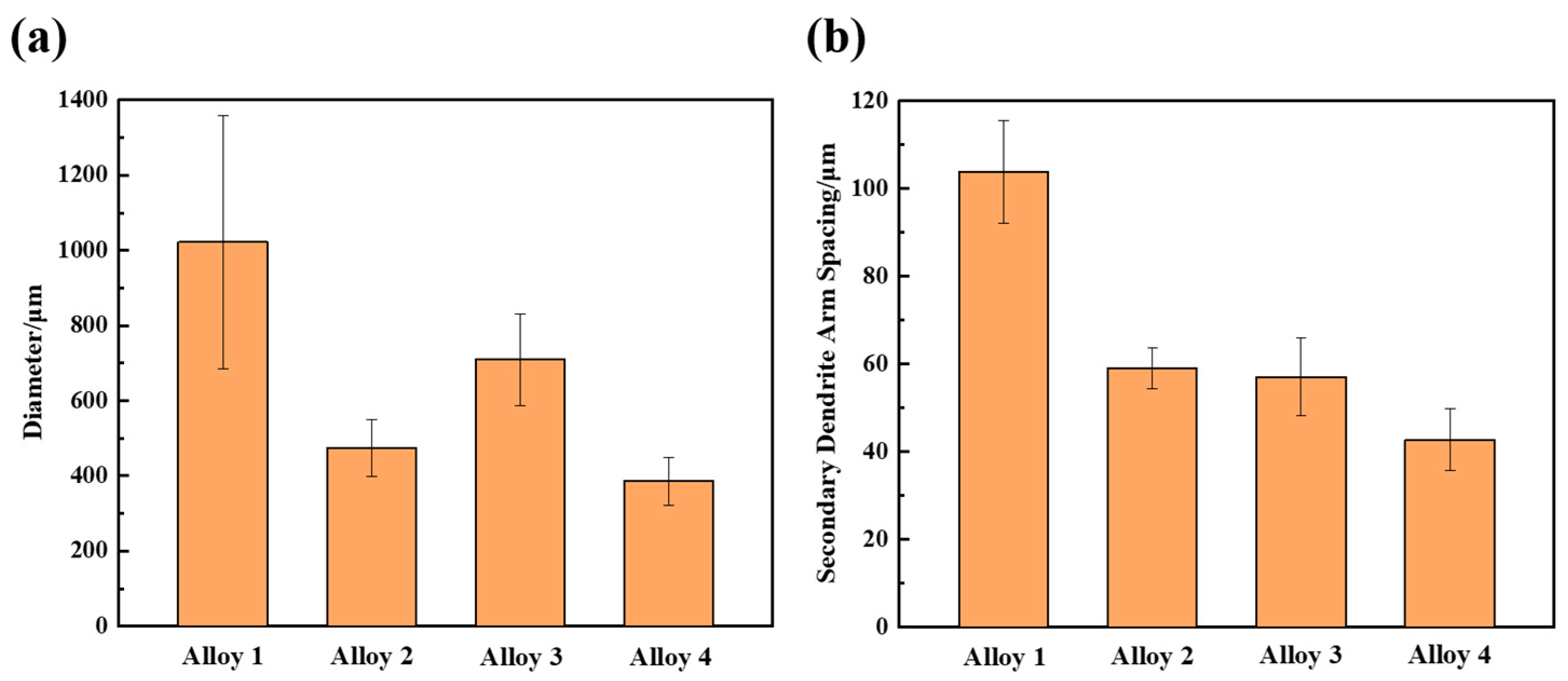

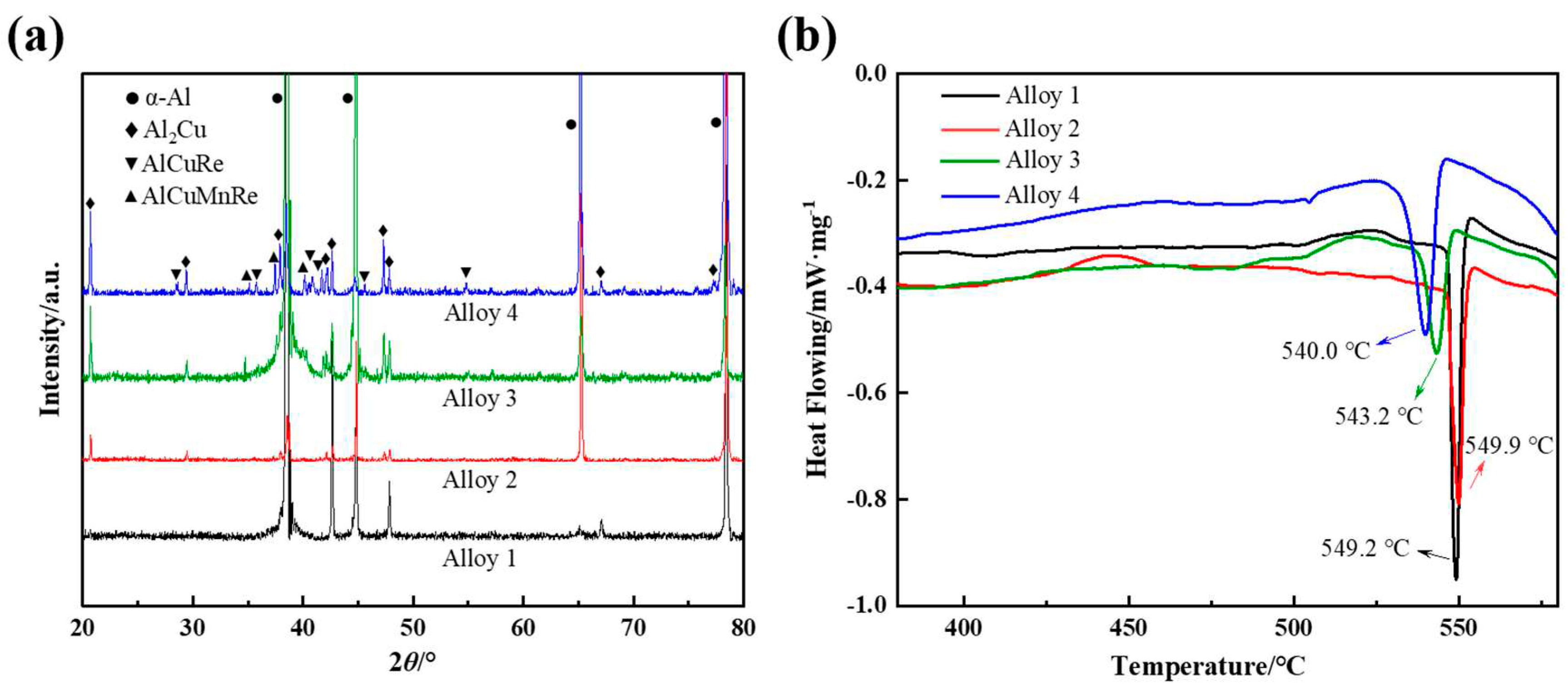

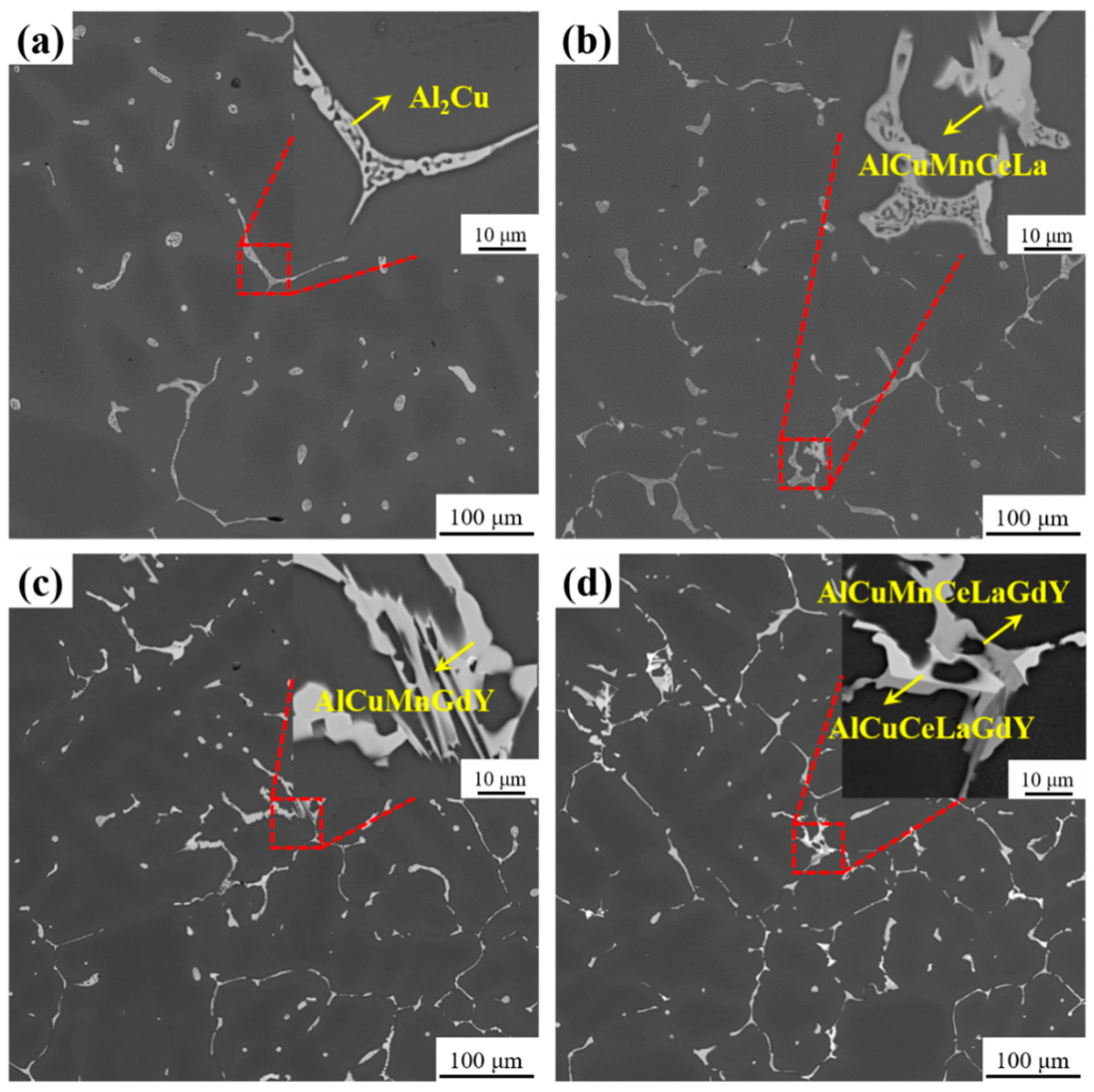

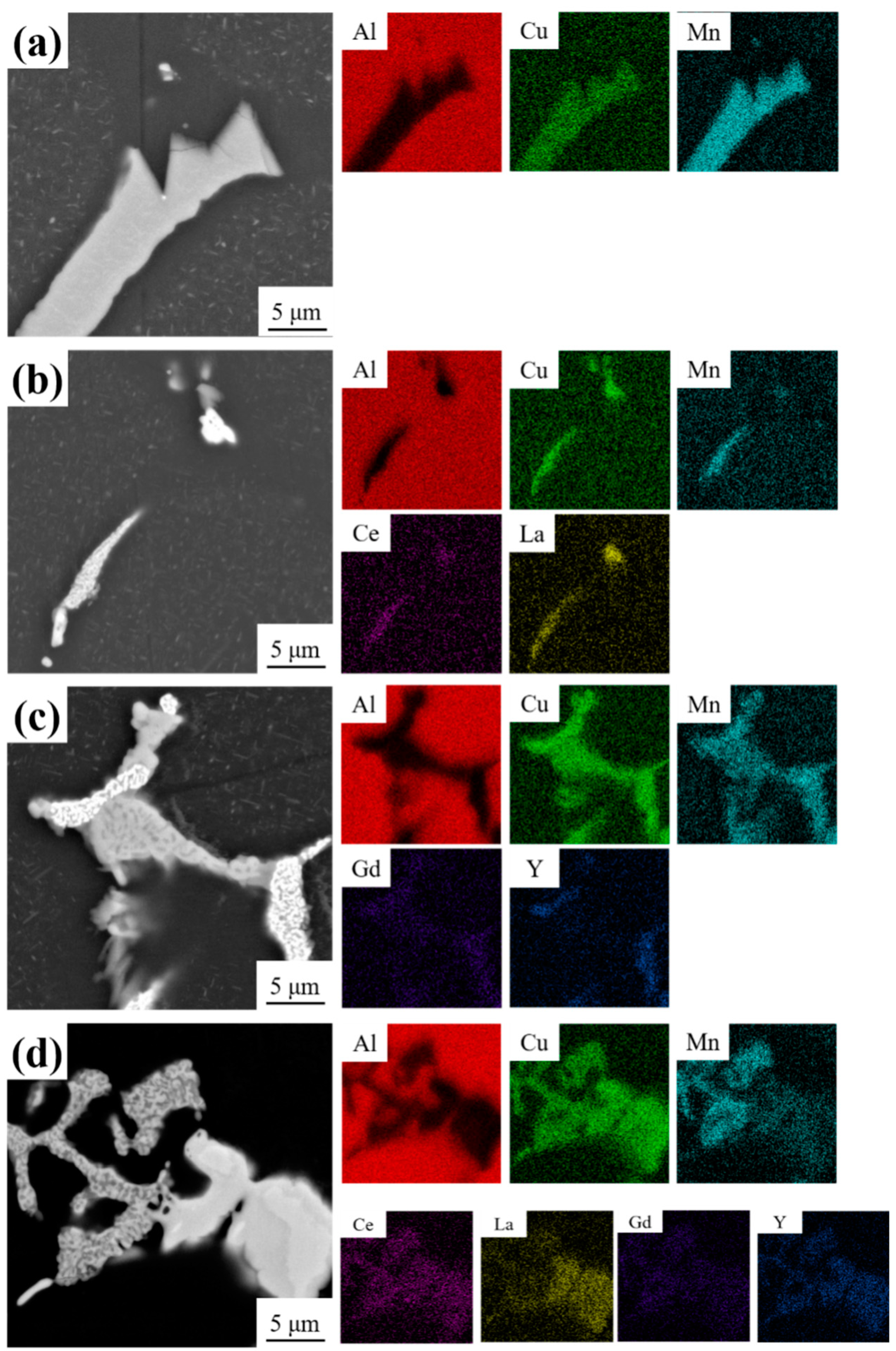

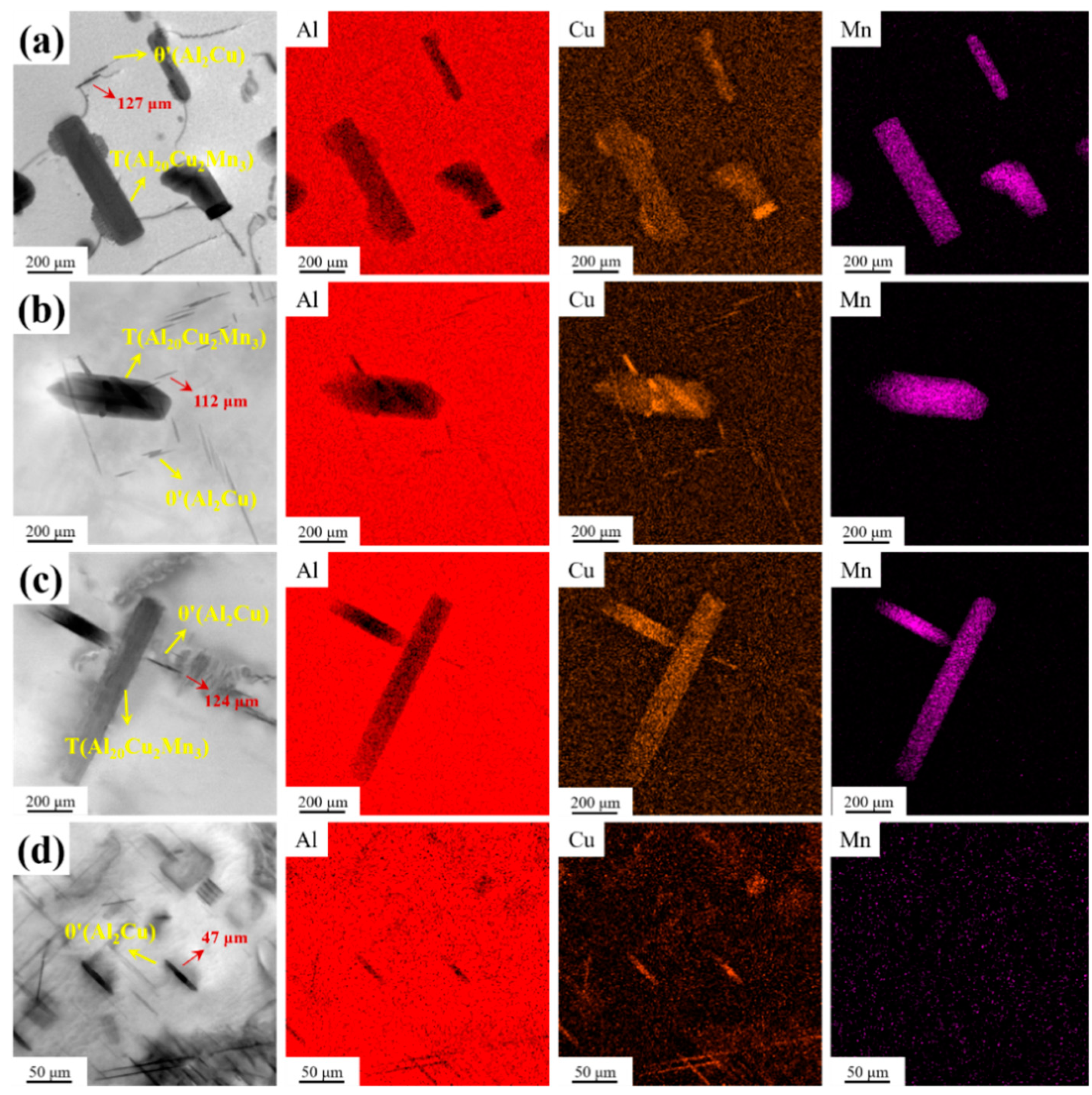

3.1. Microstructure

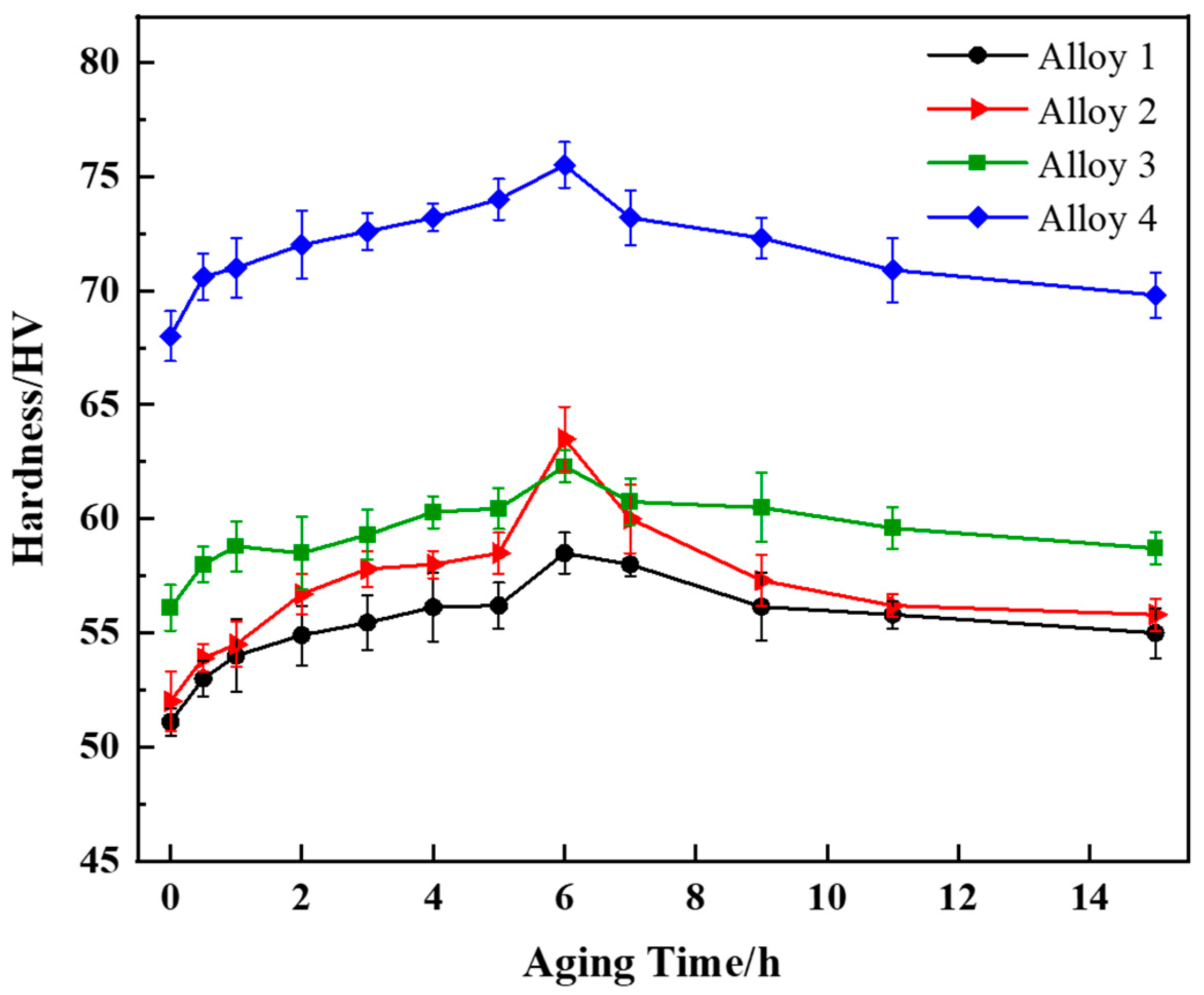

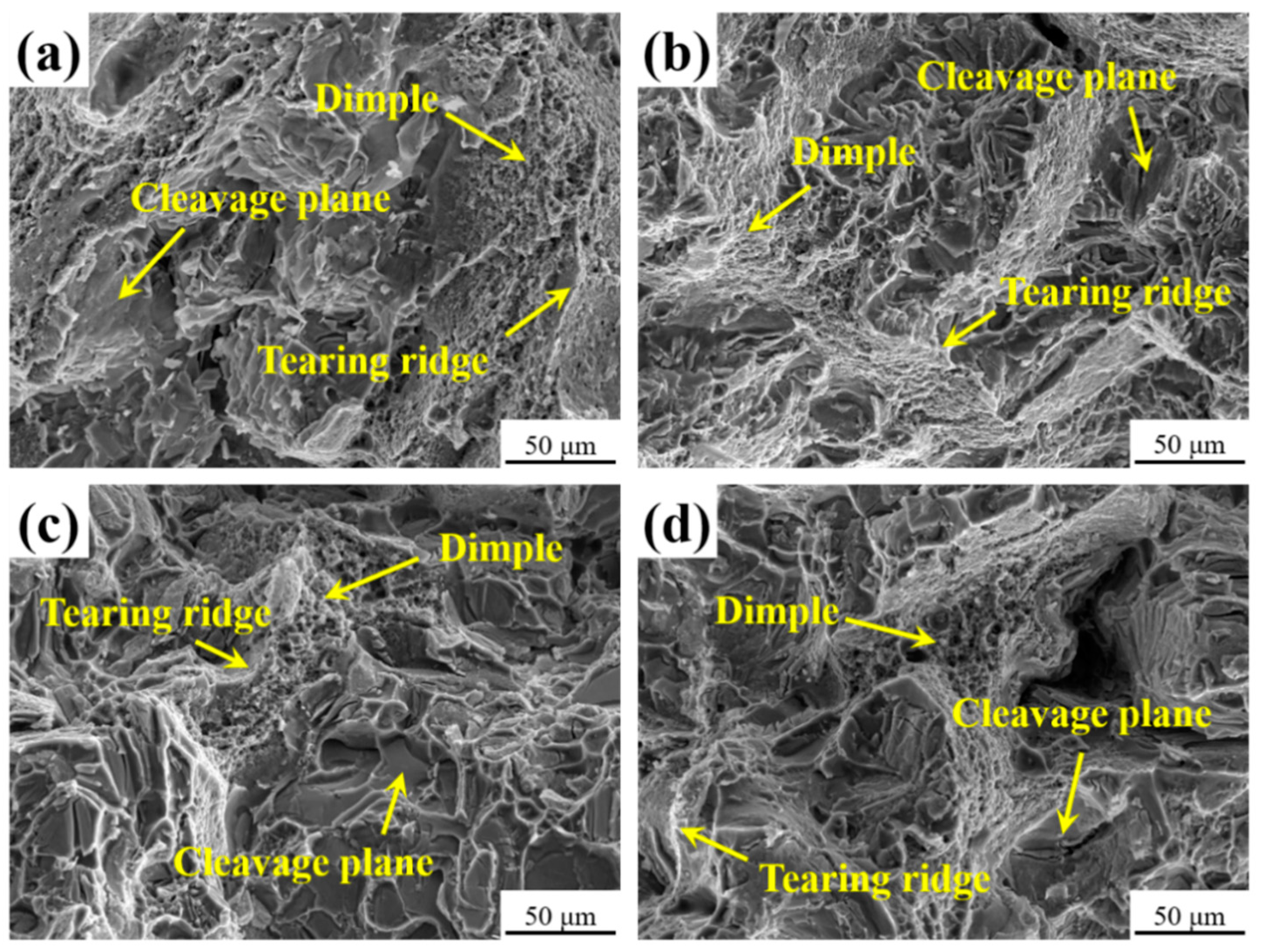

3.2. Mechanical Properties

4. Discussion

5. Conclusions

- (1)

- The incorporation of 0.2 wt.% CeLa + 0.1 wt.% GdY into the alloy results in sufficient refinement of the α-Al grains, which changes from dendrites to equiaxed crystals. The volume of Al2Cu phase diminishes while the amount of RE-containing phase increases. The average grain size and SADS of α-Al reduce from 1135 µm and 103.75 µm to 372 µm and 42.8 µm, respectively.

- (2)

- After the combined addition of 0.2 wt% CeLa + 0.1 wt% GdY, the alloy exhibits a bright white AlCuRE phase and a grey AlCuMnRE phase. The secondary phases are closely connected to the matrix grains. The inclusion of RE decreases the precipitation temperature of the θ′ phase, leading the matrix to precipitate numerous finely dispersed θ′ phases. The alloy has excellent overall mechanical properties. The average of UTS, YS and EL of the alloy were measured to be 260.9 MPa, 243.7 MPa and 1.52 % respectively.

Data Availability Statement

Acknowledgments

References

- MICHI R A, SISCO K, BAHL S, et al. A creep-resistant additively manufactured Al-Ce-Ni-Mn alloy [J]. Acta Materialia, 2022, 227. [CrossRef]

- DAR S M, LIAO H, XU A. Effect of Cu and Mn content on solidification microstructure, T-phase formation and mechanical property of Al Cu Mn alloys [J]. Journal of Alloys and Compounds, 2019, 774: 758-67. [CrossRef]

- WANG J, YANG Z, MA Z, et al. Effect of the addition of cerium on the microstructure evolution and thermal expansion properties of cast Al-Cu-Fe alloy [J]. Materials Research Express, 2021, 8(3). [CrossRef]

- TIAN W, HU M, CHEN X, et al. Effect of Ce addition on microstructure, mechanical properties and corrosion behavior of Al-Cu-Mn-Mg-Fe alloy [J]. Materials Research Express, 2020, 7(3). [CrossRef]

- YU X, DAI H, LI Z, et al. Improved Recrystallization Resistance of Al–Cu–Li–Zr Alloy through Ce Addition [J]. Metals, 2018, 8(12). [CrossRef]

- YAO D, QIU F, JIANG Q, et al. Effect of Lanthanum on Grain Refinement of Casting Aluminum-Copper Alloy [J]. International Journal of Metalcasting, 2013, 7(1): 49-54. [CrossRef]

- MAHMOUD M G, SAMUEL A M, DOTY H W, et al. Effect of the Addition of La and Ce on the Solidification Behavior of Al–Cu and Al–Si–Cu Cast Alloys [J]. International Journal of Metalcasting, 2019, 14(1): 191-206. [CrossRef]

- RAVANDI S, MARDARE C C, ZENGER T, et al. Samarium influence on current induced atomic displacement in Aluminium and Copper combinatorial thin film alloys [J]. Thin Solid Films, 2020, 702. [CrossRef]

- GUO Y, WANG Y, CHEN H, et al. First-principles study on stability, electronic, mechanical and thermodynamic properties of Al-Cu-RE ternary compounds [J]. Solid State Communications, 2019, 287: 63-7. [CrossRef]

- AMER S, BARKOV R, POZDNIAKOV A. Microstructure and Mechanical Properties of Novel Quasibinary Al-Cu-Yb and Al-Cu-Gd Alloys [J]. Metals, 2021, 11(3). [CrossRef]

- ZHANG L G, DONG H Q, HUANG G X, et al. Thermodynamic assessment of the Al–Cu–Gd system [J]. Calphad, 2009, 33(4): 664-72. [CrossRef]

- ZHANG H, LIU Y, FAN T. Three-Dimensional Network Structure and Mechanical Properties of Al-Cu-Ni-Fe Cast Alloys with Gd Micro-addition [J]. Metallurgical and Materials Transactions A, 2021, 52(6): 2613-29. [CrossRef]

- XIE H, ZHAO J, CAO J, et al. Effect of Minor Er Additions on the Microstructures and Mechanical Properties of Cast Al-Cu-Mg-Ag Alloys [J]. Materials, 2021, 14(15). [CrossRef]

- AMER S, YAKOVTSEVA O, LOGINOVA I, et al. The Phase Composition and Mechanical Properties of the Novel Precipitation-Strengthening Al-Cu-Er-Mn-Zr Alloy [J]. Applied Sciences, 2020, 10(15). [CrossRef]

- FAN L, HAO Q-T, HAN W-K. Dual characteristic of trace rare earth elements in a commercial casting Al–Cu–X alloy [J]. Rare Metals, 2014, 34(5): 308-13. [CrossRef]

- CZERWINSKI, F. Cerium in aluminum alloys [J]. Journal of Materials Science, 2020, 55(1): 24-72. [CrossRef]

- CHEN Z, CHEN P, LI S. Effect of Ce addition on microstructure of Al20Cu2Mn3 twin phase in an Al–Cu–Mn casting alloy [J]. Materials Science and Engineering: A, 2012, 532: 606-9. [CrossRef]

- XINXIANG Y, DENGFENG Y, ZHIMING Y. Effects of Cerium and Zirconium Microalloying Addition on the Microstructures and Tensile Properties of Novel Al-Cu-Li Alloys [J]. Rare Metal Materials and Engineering, 2016, 45(8): 1917-23. [CrossRef]

- GUO T-B, ZHANG F, DING W-W, et al. Effect of Micro-scale Y Addition on the Fracture Properties of Al–Cu–Mn Alloy [J]. Chinese Journal of Mechanical Engineering, 2018, 31(1). [CrossRef]

- XIAO D H, WANG J N, DING D Y. Effect of minor cerium additions on microstructure and mechanical properties of cast Al – Cu – Mg – Ag alloy [J]. Materials Science and Technology, 2013, 20(10): 1237-40. [CrossRef]

- CHEN Z, CHEN P, MA C. Microstructures and mechanical properties of Al-Cu-Mn alloy with La and Sm addition [J]. Rare Metals, 2012, 31(4): 332-5. [CrossRef]

- MAMZURINA O I, AMER S M, GLAVATSKIKH M V, et al. Microstructure and Mechanical Properties of Novel Heat Resistant Cast Al-Cu-Yb(Gd)-Mg-Mn-Zr Alloys [J]. Metals, 2022, 12(12). [CrossRef]

- GUO T-B, ZHANG F, DING W-W, et al. Effect of Micro-scale Y Addition on the Fracture Properties of Al–Cu–Mn Alloy [J]. Chinese Journal of Mechanical Engineering, 2018, 31(1): 79. [CrossRef]

- ZHAO B, ZHAN Y, TANG H. High-temperature properties and microstructural evolution of Al–Cu–Mn-RE (La/Ce) alloy designed through thermodynamic calculation [J]. Materials Science and Engineering: A, 2019, 758: 7-18. [CrossRef]

- ZENG H X, YU H Y, ZHOU Q, et al. Clarifying the effects of La and Ce in the grain boundary diffusion sources on sintered NdFeB magnets [J]. Materials Research Express, 2019, 6(10). [CrossRef]

- SHUAI L, ZOU X, RAO Y, et al. Synergistic Effects of La and Y on the Microstructure and Mechanical Properties of Cast Al-Si-Cu Alloys [J]. Materials, 2022, 15(20). [CrossRef]

- WANG Y, YUE C, SU M, et al. Effect of Ce on Hot Tearing Sensitivity of As-Cast Al-Cu-Mg-Y Alloy [J]. Journal of Materials Engineering and Performance, 2022, 31(8): 6349-59. [CrossRef]

- BAI Z, QIU F, LIU Y, et al. Age Hardening and Mechanical Properties of Cast Al Cu Alloy Modified by La and Pr [J]. Advanced Engineering Materials, 2014, 17(2): 143-7. [CrossRef]

- SONG Z-X, LI Y-D, LIU W-J, et al. Effect of La and Sc Co-Addition on the Mechanical Properties and Thermal Conductivity of As-Cast Al-4.8% Cu Alloys [J]. Metals, 2021, 11(11). [CrossRef]

- LIU T, DONG Q, FU Y, et al. Effect of addition of La and Ce on solidification behavior of Al-Cu alloys [J]. Materials Letters, 2022, 324. [CrossRef]

- DU J, DING D, ZHANG W, et al. CeLa enhanced corrosion resistance of Al-Cu-Mn-Mg-Fe alloy for lithium battery shell [J]. Applied Surface Science, 2017, 422: 221-7. [CrossRef]

- ZHANG F, SHI D, HE Z, et al. Precipitated phase characteristics and fracture behaviour of cast Al–Cu–Mn alloy [J]. Journal of Materials Research and Technology, 2023, 25: 2815-25. [CrossRef]

- SONG M, XIAO D, ZHANG F. Effect of Ce on the thermal stability of the Ω phase in an Al-Cu-Mg-Ag alloy [J]. Rare Metals, 2009, 28(2): 156-9. [CrossRef]

- YU X, ZHAO Z, SHI D, et al. Enhanced High-Temperature Mechanical Properties of Al–Cu–Li Alloy through T1 Coarsening Inhibition and Ce-Containing Intermetallic Refinement [J]. Materials, 2019, 12(9). [CrossRef]

| Alloys | Cu | Mn | CeLa | GdY | Al |

|---|---|---|---|---|---|

| Alloy 1 | 4.0 | 1.05 | 0 | 0 | Balance |

| Alloy 2 | 4.0 | 1.05 | 0.20 | 0 | Balance |

| Alloy 3 | 4.0 | 1.05 | 0 | 0.10 | Balance |

| Alloy 4 | 4.0 | 1.05 | 0.20 | 0.10 | Balance |

| Alloys | UTS (MPa) | YS (MPa) | EL (%) |

|---|---|---|---|

| Alloy 1 | 190.5±2 | 95.4±3 | 3.71±0.5 |

| Alloy 2 | 215.8±3 | 104.5±4 | 4.27±0.6 |

| Alloy 3 | 240.8±2 | 206.9±3 | 1.29±0.3 |

| Alloy 4 | 260.9±4 | 243.7±2 | 1.52±0.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).