Submitted:

15 July 2023

Posted:

17 July 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

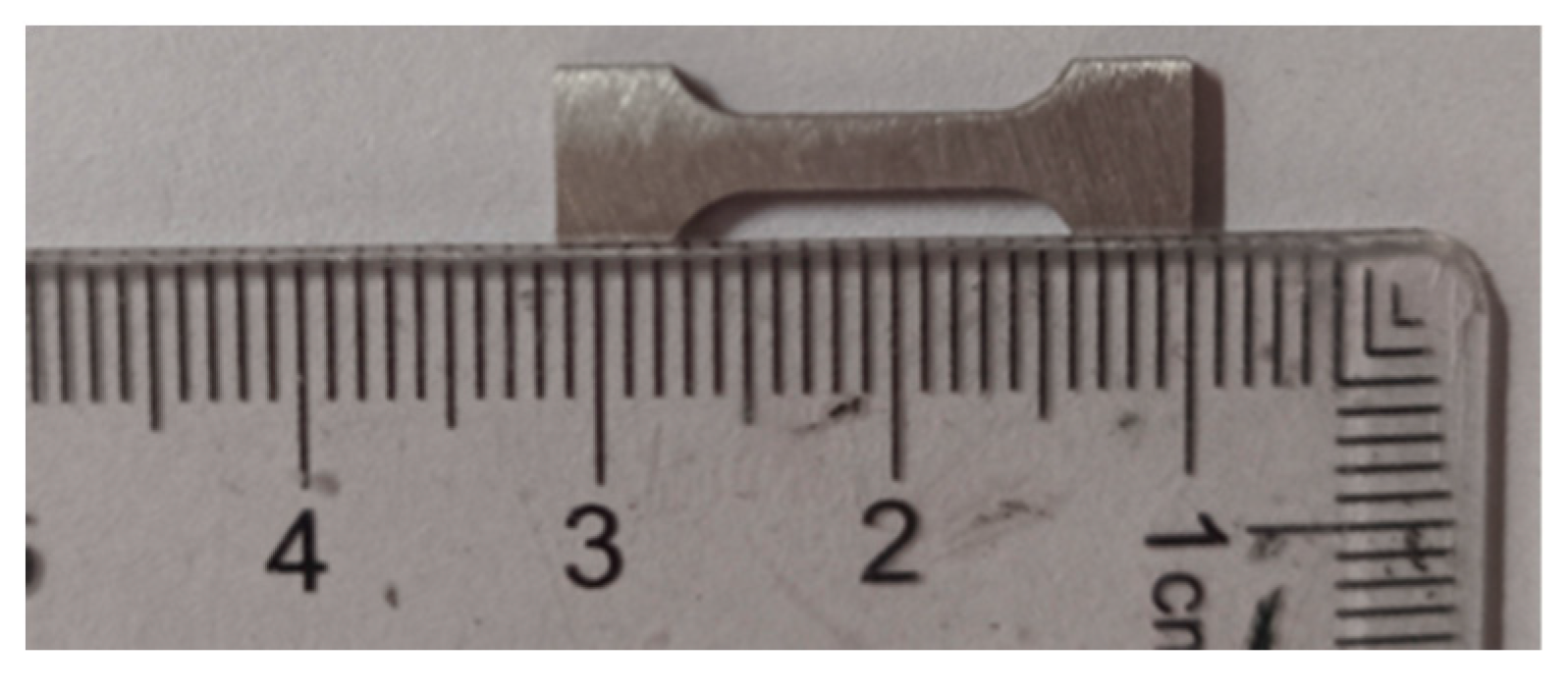

2. Materials and Methods

2.1. Preparation of Experimental Materials

2.2. Data Acquisition and Analysis Methods

3. Results

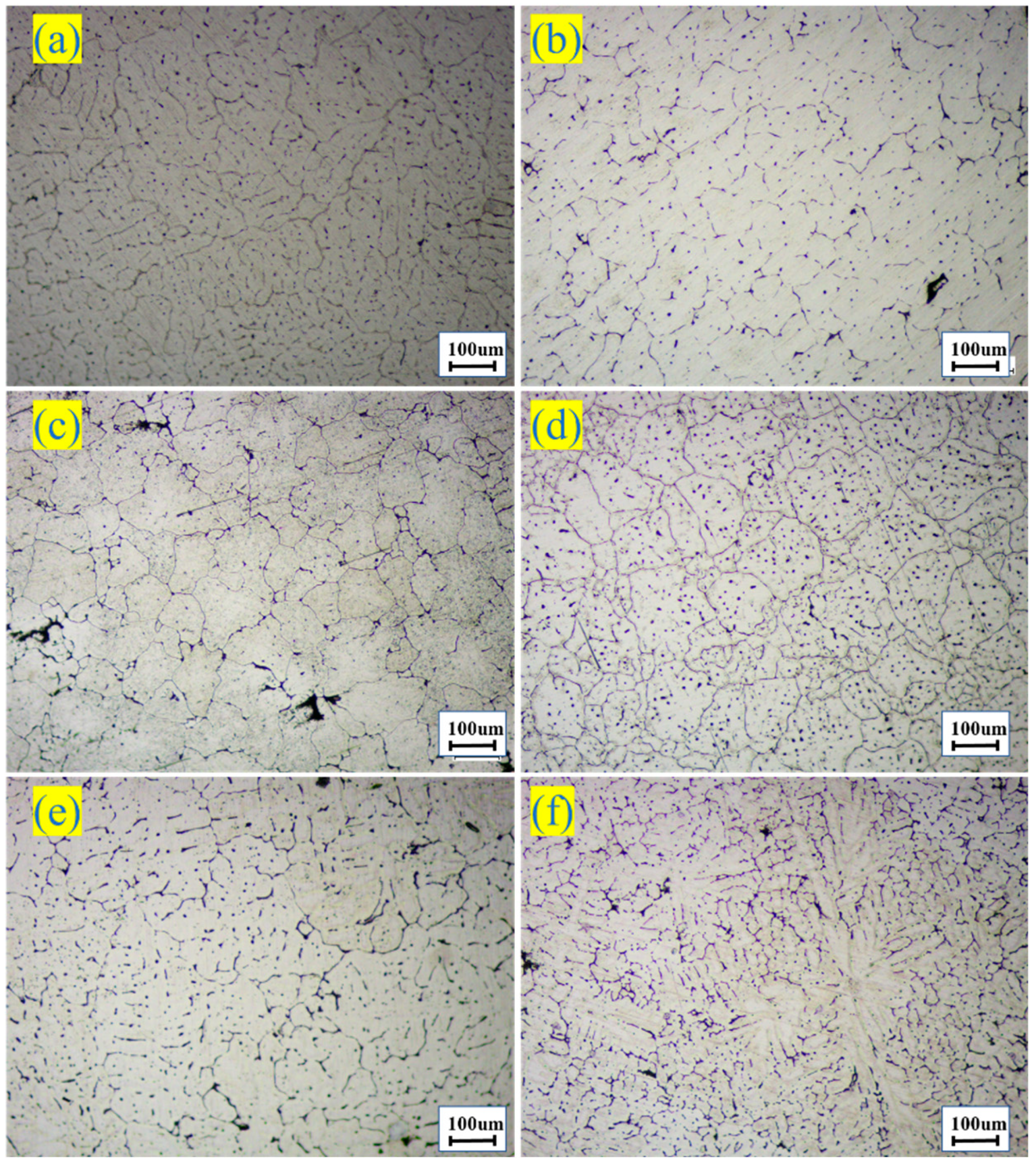

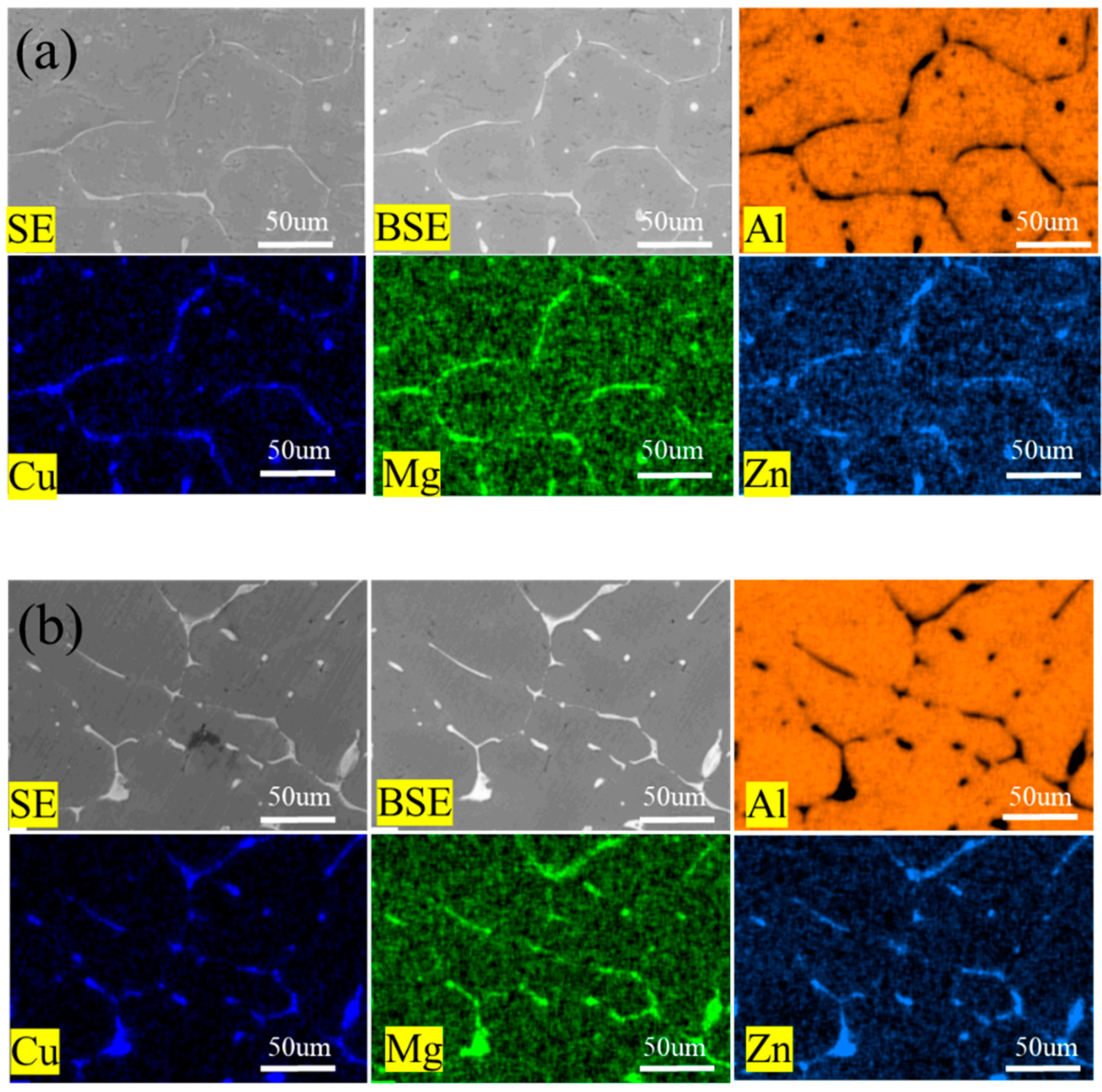

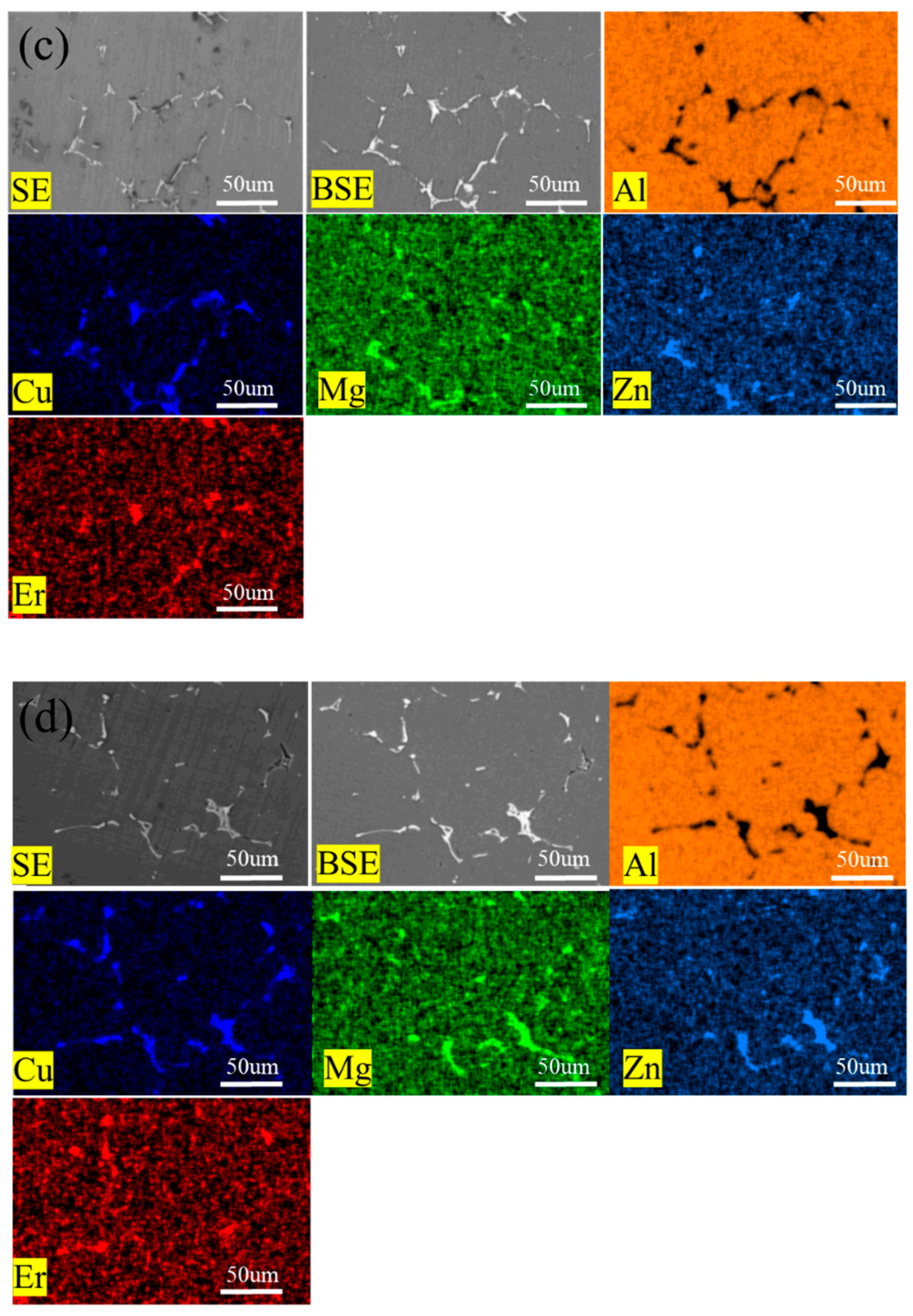

3.1. Microstructure and Mechanical Properties

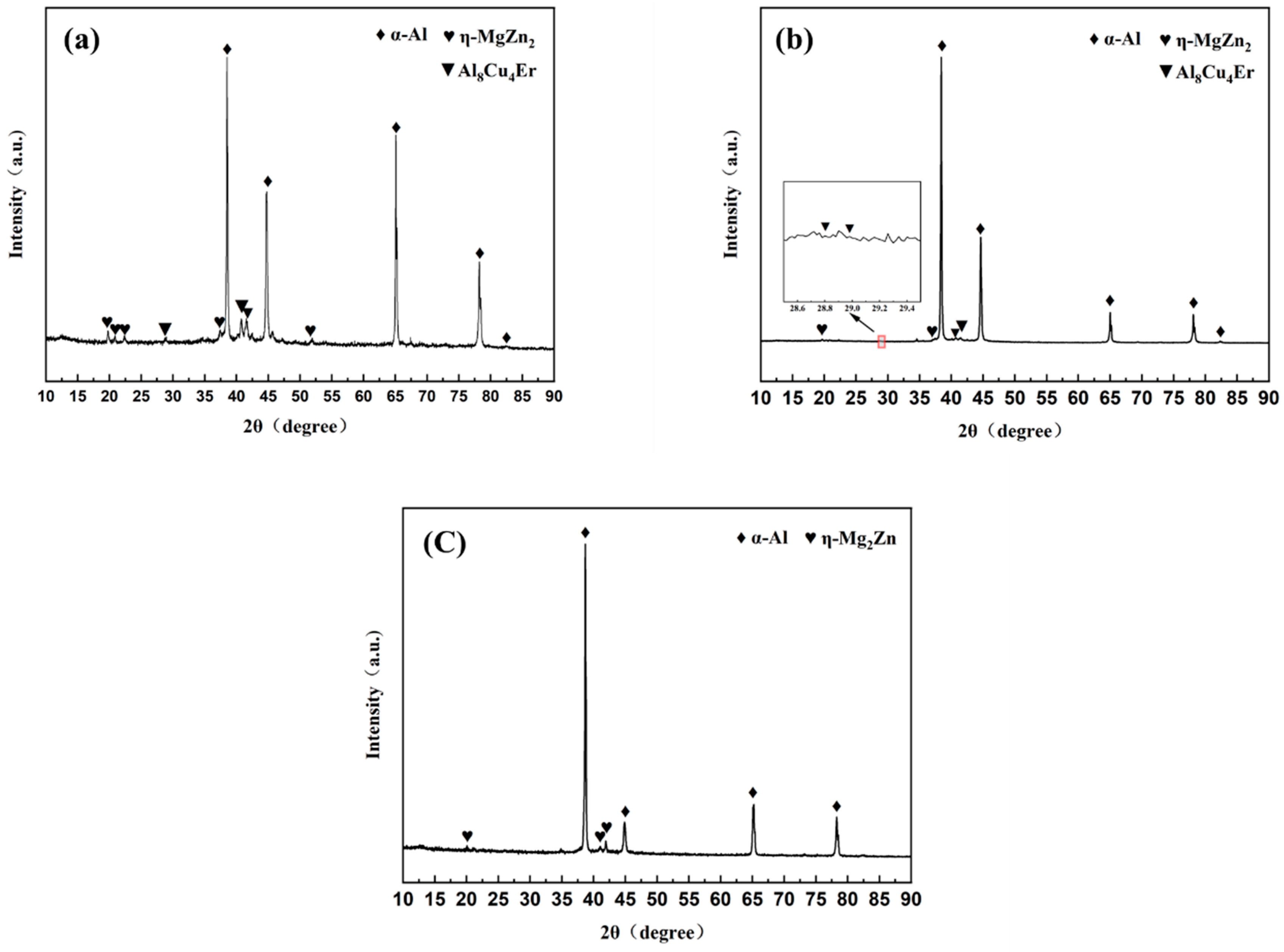

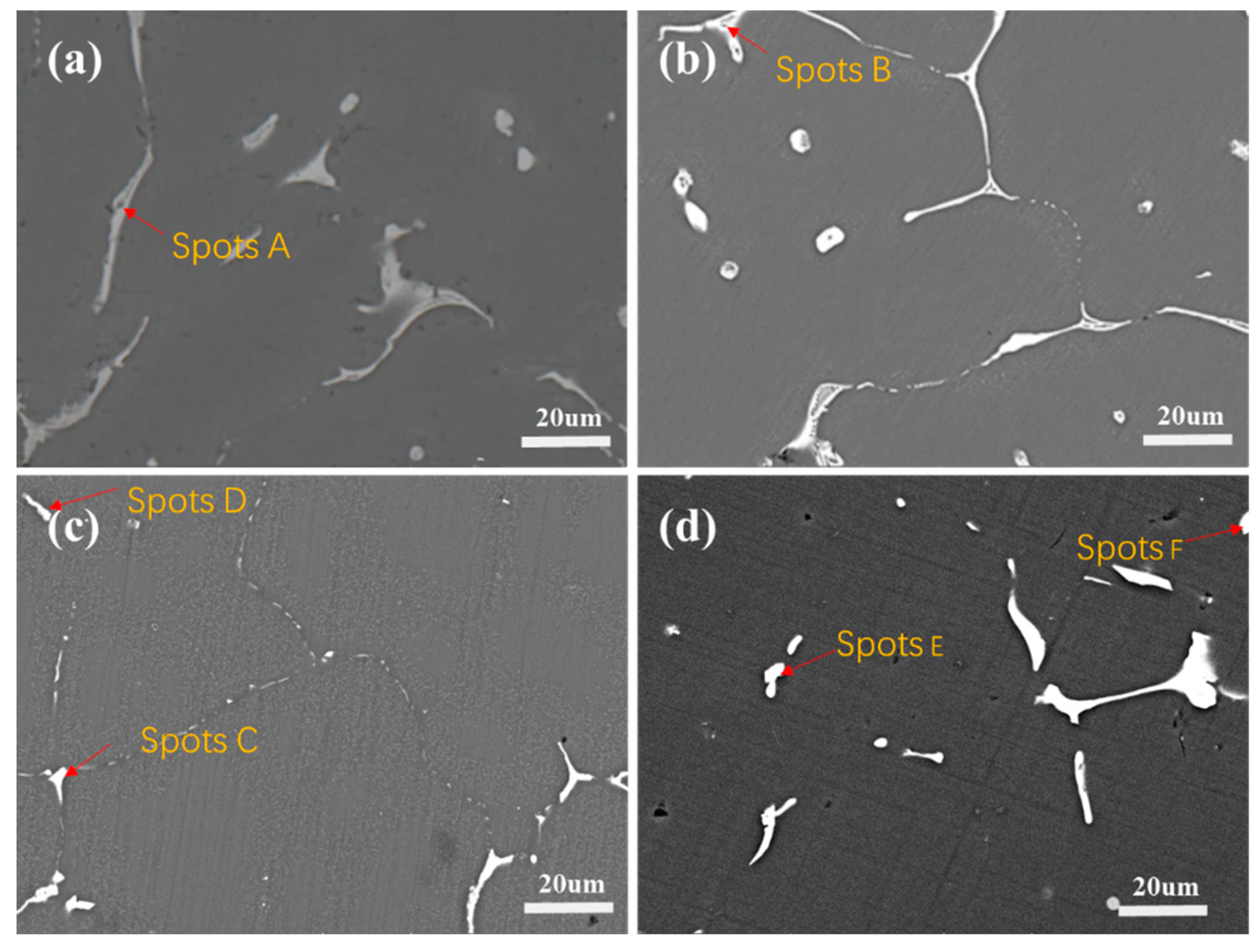

3.2. Phase Component Analysis

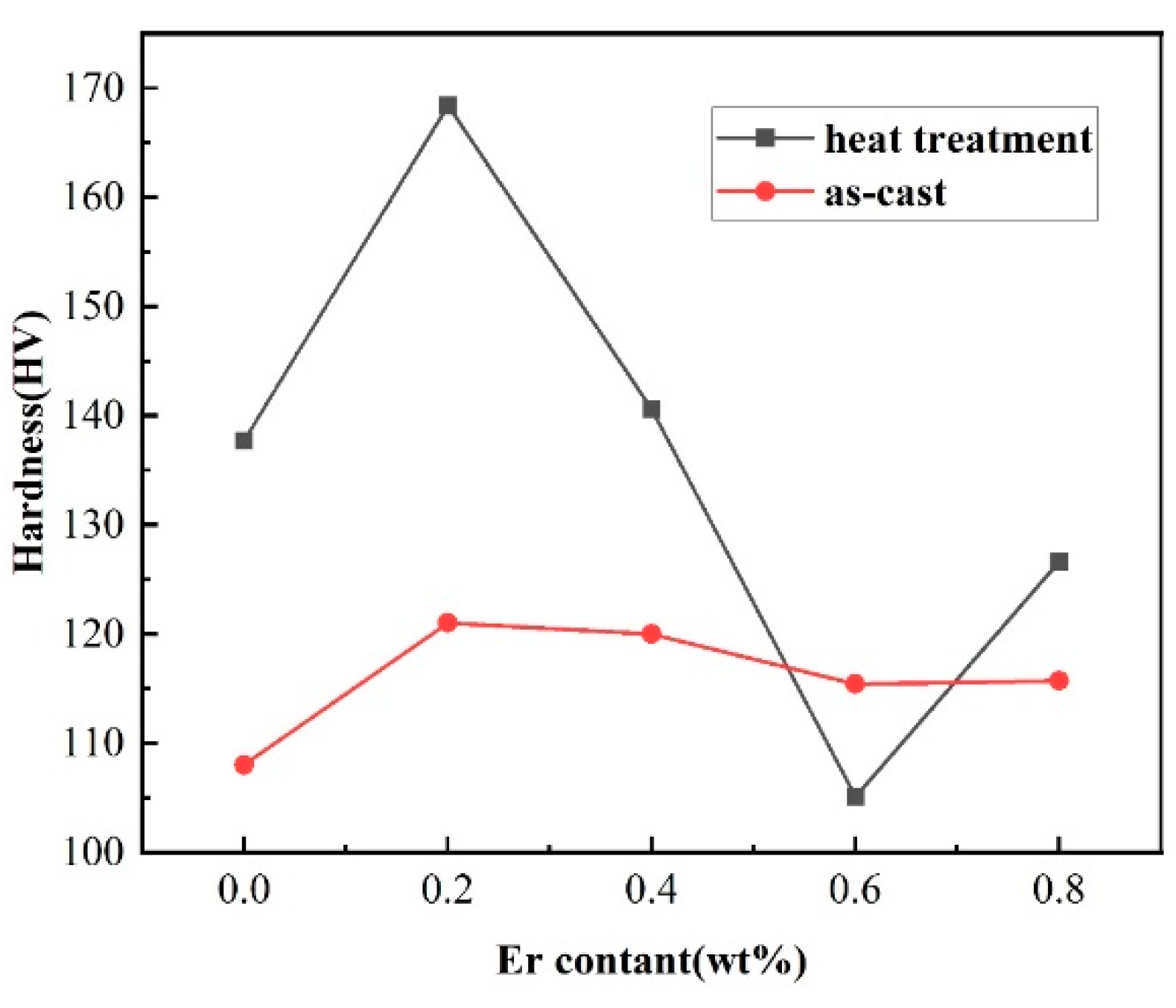

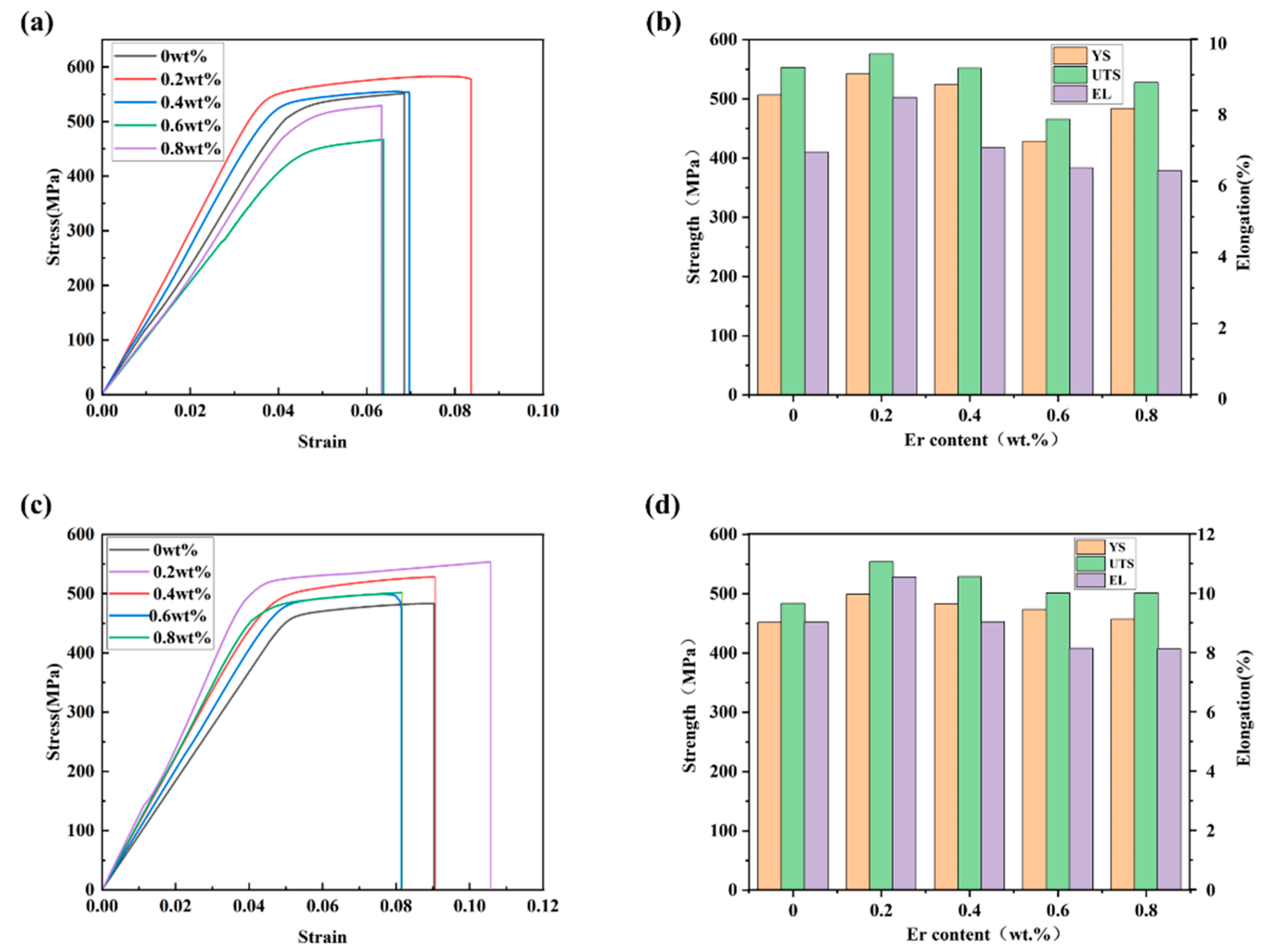

3.3. Mechanical Property

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kaibyshev R, Sakai T, Musin F, et al. Superplastic behavior of a 7055 aluminum alloy. Scripta materialia. 2001, 45, 1373. [CrossRef]

- Dursun T, Soutis C. Recent developments in advanced aircraft aluminium alloys. Materials & Design(1980-2015). 2014, 56, 862. [CrossRef]

- Yuan L Y, Han P W, Asghar G, et al. Development of high strength and toughness non-heated Al–Mg–Si alloys for high-pressure die-casting. Acta Metallurgica Sinica (English Letters). 2021, 34, 845. [CrossRef]

- Zhang C, Zhang Z, Liu M, et al. Effects of single-and multi-stage solid solution treatments on microstructure and properties of as-extruded AA7055 helical profile. Transactions of Nonferrous Metals Society of China. 2021, 31, 1885. [CrossRef]

- Ghiaasiaan R, Amirkhiz B S, Shankar S. Quantitative metallography of precipitating and secondary phases after strengthening treatment of net shaped casting of Al-Zn-Mg-Cu (7000) alloys. Materials Science and Engineering: A. 2017, 698, 206. [CrossRef]

- Ma J, Welo T, Wan D. The impact of thermo-mechanical processing routes on product quality in integrated aluminium tube bending process. Journal of Manufacturing Processes. 2021, 67, 503. [CrossRef]

- Zhong H, Li S, Zhang Z, et al. Precipitation behavior, mechanical properties, and corrosion resistance of rare earth–modified Al-Zn-Mg-Cu alloys. Materials Today Communications. 2022, 31, 103732. [CrossRef]

- HE Y, Zhang X, You J. Effect of minor Sc and Zr on microstructure and mechanical properties of Al-Zn-Mg-Cu alloy. Transactions of Nonferrous Metals Society of China. 2006, 16, 1228. [CrossRef]

- Fang H C, Chao H, Chen K H. Effect of Zr, Er and Cr additions on microstructures and properties of Al–Zn–Mg–Cu alloys. Materials Science and Engineering: A. 2014, 610, 10. [CrossRef]

- Chen B A, Pan L, Wang R H, et al. Effect of solution treatment on precipitation behaviors and age hardening response of Al–Cu alloys with Sc addition. Materials Science and Engineering: A. 2011, 530, 607. [CrossRef]

- Chen B A, Liu G, Wang R H, et al. Effect of interfacial solute segregation on ductile fracture of Al–Cu–Sc alloys. Acta materialia. 2013, 61, 1676. [CrossRef]

- Jiang L, Li J K, Cheng P M, et al. Experiment and modeling of ultrafast precipitation in an ultrafine-grained Al–Cu–Sc alloy. Materials Science and Engineering: A. 2014, 607, 596. [CrossRef]

- Jiang L, Li J K, Liu G, et al. Length-scale dependent microalloying effects on precipitation behaviors and mechanical properties of Al–Cu alloys with minor Sc addition. Materials Science and Engineering: A. 2015, 637, 139. [CrossRef]

- Wen S P, Xing Z B, Huang H, et al. The effect of erbium on the microstructure and mechanical properties of Al–Mg–Mn–Zr alloy. Materials Science and Engineering: A. 2009, 516, 42. [CrossRef]

- Zhong H, Li S, Zhang Z, et al. Precipitation behavior, mechanical properties, and corrosion resistance of rare earth–modified Al-Zn-Mg-Cu alloys. Materials Today Communications. 2022, 31, 103732. [CrossRef]

- Li D, Zhang Z, Li S, et al. Microstructure, mechanical properties and fatigue crack growth behavior of an Al-Zn-Mg-Cu-Si-Zr-Er alloy fabricated by laser powder bed fusion. International Journal of Fatigue. 2023, 172, 107636. [CrossRef]

- Schreiber J M, Omcikus Z R, Eden T J, et al. Combined effect of hot extrusion and heat treatment on the mechanical behavior of 7055 AA processed via spray metal forming. Journal of alloys and compounds. 2014, 617, 135. [CrossRef]

- Liu L L, Pan Q L, Wang X D, et al. The effects of aging treatments on mechanical property and corrosion behavior of spray formed 7055 aluminium alloy. Journal of Alloys and Compounds. 2018, 735, 261. [CrossRef]

- Song W W,Lin G Y; Li Q. Influence of conditioning time before artificial aging on the microstructure and proper ties of 7055 aluminium alloy extruded tube. Nonferrous Metals Science and Engineering. 2018, 9, 37. [CrossRef]

- Peng X, Li Y, Liang X, et al. Precipitate behavior and mechanical properties of enhanced solution treated Al-Zn-Mg-Cu alloy during non-isothermal ageing. Journal of Alloys and Compounds. 2018, 735, 964. [CrossRef]

- Azarniya A, Taheri A K, Taheri K K. Recent advances in ageing of 7xxx series aluminum alloys: A physical metallurgy perspective. Journal of Alloys and Compounds. 2019, 781, 945. [CrossRef]

- Jia Z, Xie Z, Xiang K, et al. Effect of heat treatment and extrusion processing on the microstructure and mechanical properties of spray formed 7055 alloy. Materials Characterization. 2022, 183, 111619. [CrossRef]

- Mondal C, Mukhopadhyay A K. On the nature of T (Al2Mg3Zn3) and S (Al2CuMg) phases present in as-cast and annealed 7055 aluminum alloy. Materials Science and Engineering: A. 2005, 391, 367. [CrossRef]

- Wang F, Wen M, Zhang H, et al. Effects of under-aging treatment on microstructure and mechanical properties of squeeze-cast Al-Zn-Mg-Cu alloy. Transactions of Nonferrous Metals Society of China. 2018, 28, 1920. [CrossRef]

- Yang X B, Chen J H, Liu J Z, et al. Spherical constituent particles formed by a multistage solution treatment in Al–Zn–Mg–Cu alloys. Materials characterization. 2013, 83.

- Liang J M, Guo X Q, Zheng Y F, et al. Effect of extrusion temperature on microstructural evolution and intergranule bonding of Al–7Si–0.3 Mg (wt%) alloy rods produced by extrusion of granule compacts. Journal of Materials Processing Technology. 2016, 232, 78. [CrossRef]

- Zhang N, Lei C, Tang H, et al. Double-step aging treatment of high strength Al-5 Mg-3Zn-1Cu (wt%) cast alloy. Materials Letters. 2022, 322, 132514. [CrossRef]

- Emani S V, Benedyk J, Nash P, et al. Double aging and thermomechanical heat treatment of AA7075 aluminum alloy extrusions. Journal of materials science. 2009, 44, 6384. [CrossRef]

- Chen K, Liu H, Zhang Z, et al. The improvement of constituent dissolution and mechanical properties of 7055 aluminum alloy by stepped heat treatments. Journal of Materials Processing Technology. 2003, 142, 190. [CrossRef]

- Li Y, Zhang Y, Han S, et al. Research on the effect of aging time on the microstructure of 7055 aluminum alloy. Vacuum. 2020, 171, 108944. [CrossRef]

- Chuan L E I, Wang Q, Tang H, et al. Effects of Mg content on microstructure and mechanical properties of low Zn-containing Al− xMg− 3Zn− 1Cu cast alloys. Transactions of Nonferrous Metals Society of China. 2022, 32, 721. [CrossRef]

- Guo Y, Wei W, Shi W, et al. Effect of Er and Zr additions and aging treatment on grain refinement of aluminum alloy fabricated by laser powder bed fusion. Journal of Alloys and Compounds. 2022, 912, 165237. [CrossRef]

- Ghiaasiaan R, Zeng X, Shankar S. Controlled diffusion solidification (CDS) of Al-Zn-Mg-Cu (7050): microstructure, heat treatment and mechanical properties. Materials Science and Engineering: A. 2014, 594, 260. [CrossRef]

- Jia P, Cao Y, Geng Y, et al. Studies on the microstructures and properties in phase transformation of homogenized 7050 alloy. Materials Science and Engineering: A. 2014, 612, 335. [CrossRef]

- Huang R, Li M, Yang H, et al. Effects of Mg contents on microstructures and second phases of as-cast Al–Zn–Mg–Cu alloys. Journal of Materials Research and Technology. 2022, 21, 2105. [CrossRef]

| Point | Al | Mg | Cu | Zn | Er | Fe | Phase |

|---|---|---|---|---|---|---|---|

| Spots A | 58.98 | 15.89 | 21.75 | 15.21 | 0 | 0 | α-Al+η-Mg(Zn,Al,Cu)2 |

| Spots B | 59.52 | 18.27 | 7.95 | 14.27 | 0 | 0 | α-Al+η-Mg(Zn,Al,Cu)2 |

| Spots C | 58.78 | 3.39 | 28.45 | 6.01 | 3.36 | 0 | Al8Cu4Er |

| Spots D | 82.45 | 1.33 | 5.25 | 1.84 | 0 | 9.14 | α-Al+η-Mg(Zn,Al,Cu)2 |

| Spots E | 58.27 | 1.57 | 27.92 | 6.28 | 4.98 | 0.98 | Al8Cu4Er |

| Spots F | 25.90 | 32.61 | 16.78 | 24.70 | 0 | 0 | α-Al+η-Mg(Zn,Al,Cu)2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).