Submitted:

02 November 2023

Posted:

03 November 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Experimental section

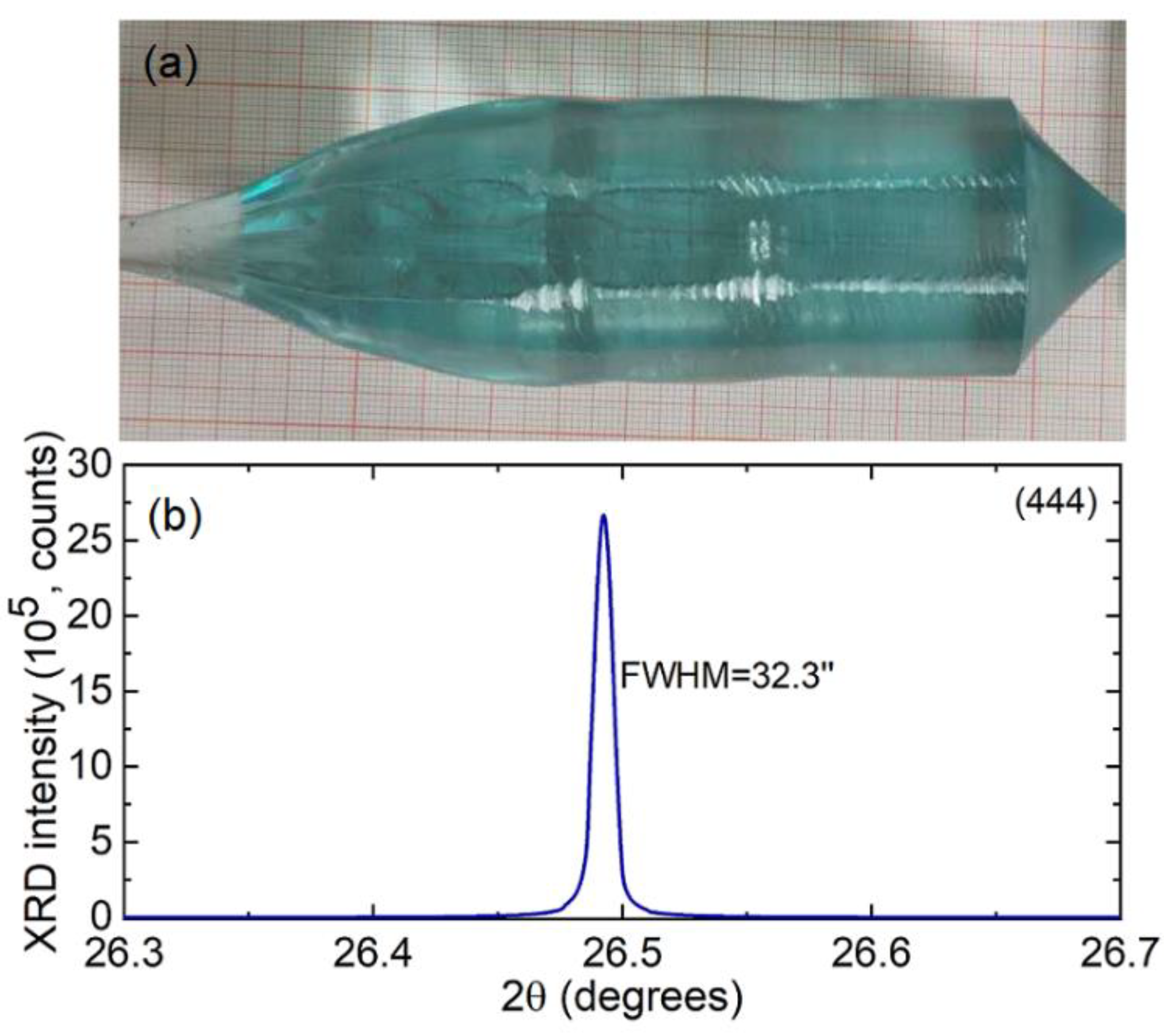

2.1. Crystal growth

2.2. Characterization methods

2.3. Laser characterization

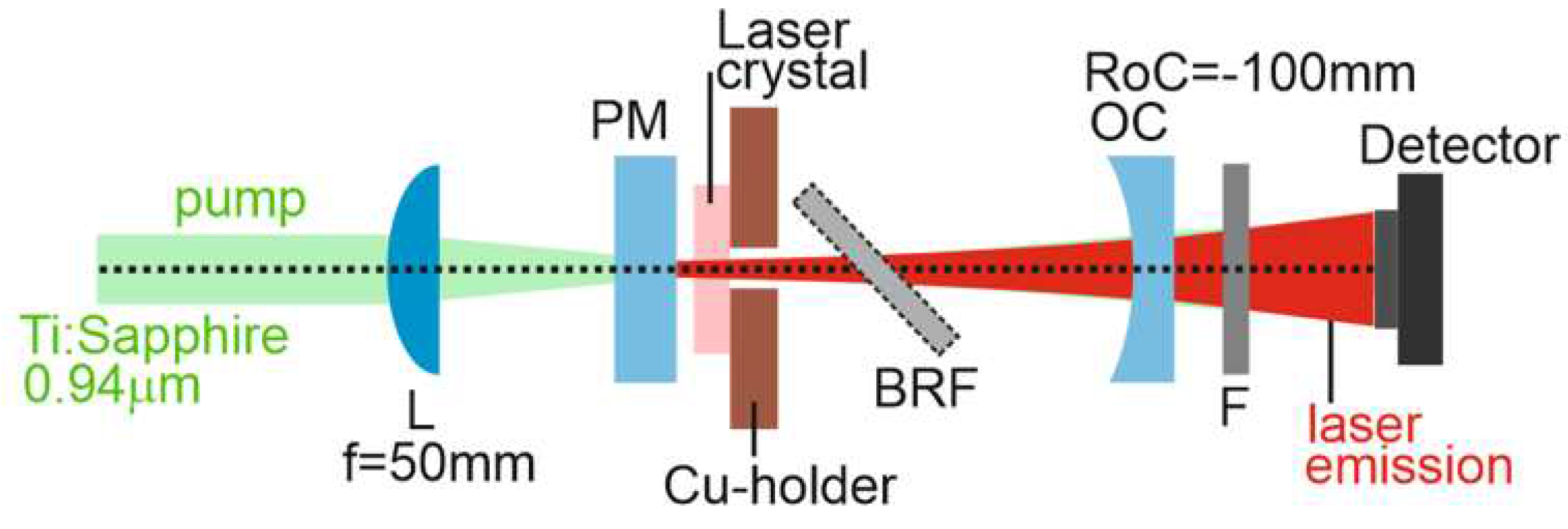

2.3.1. Laser set-up using Ti:Sapphire laser

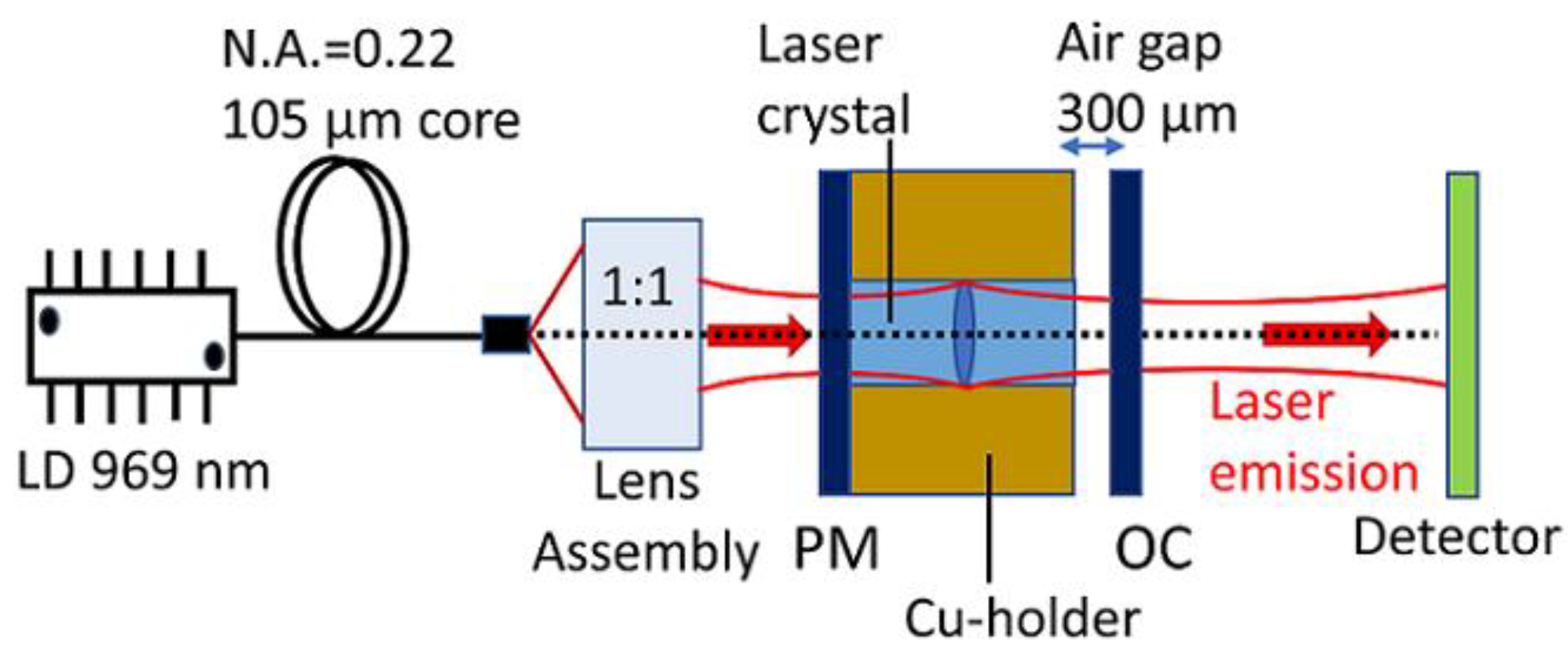

2.3.2. Power scaling using Diode pumping.

3. Results and discussion

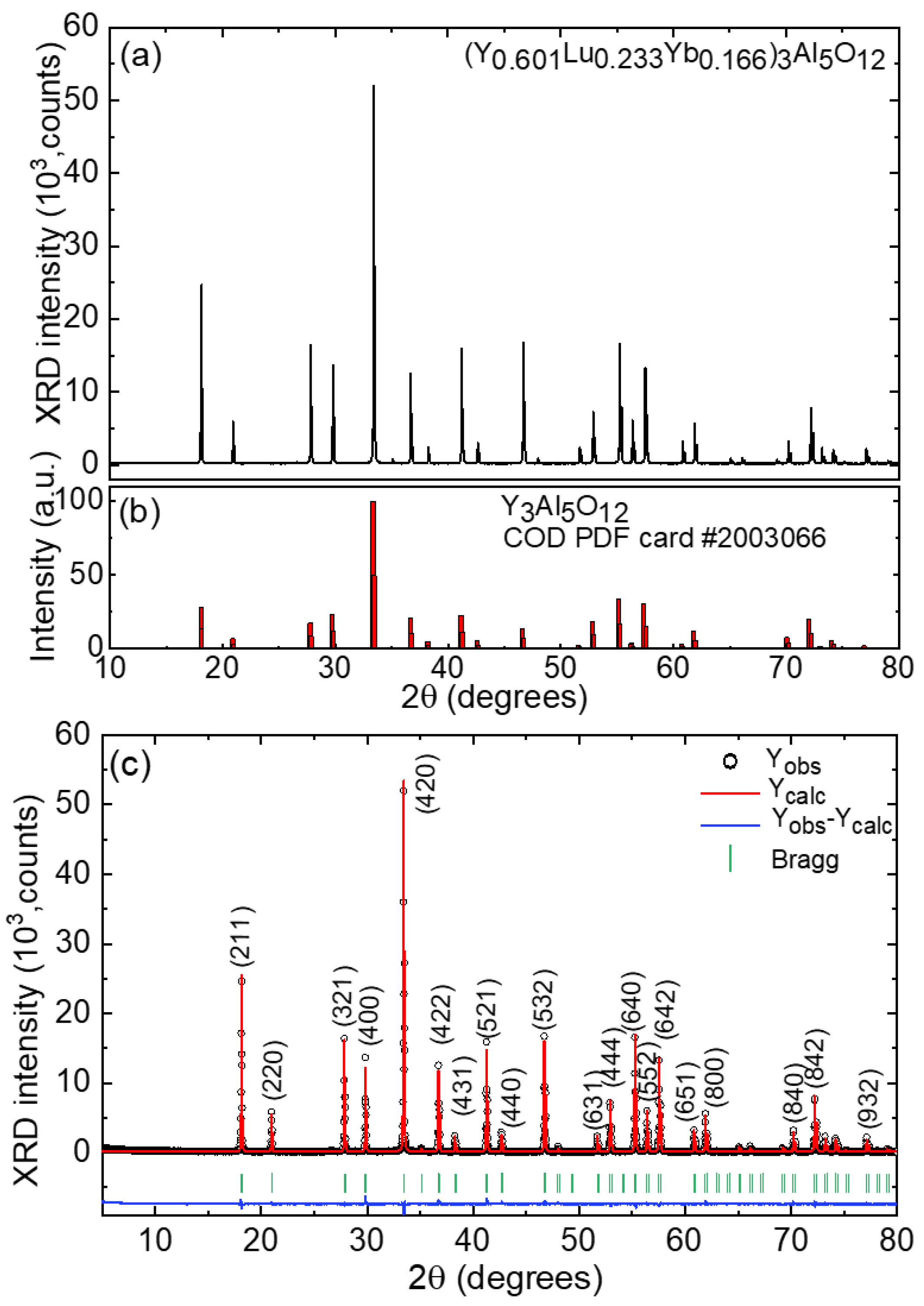

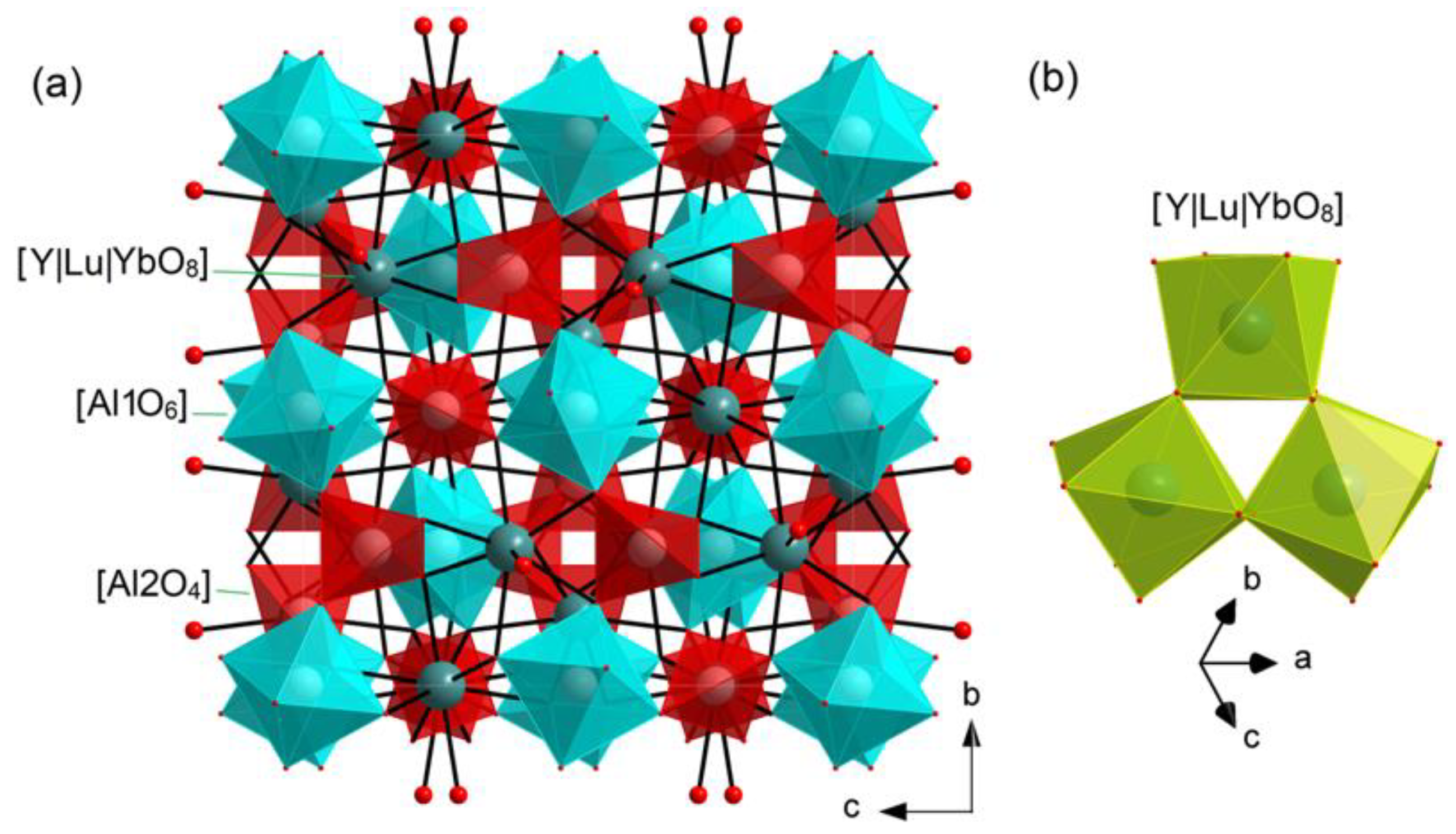

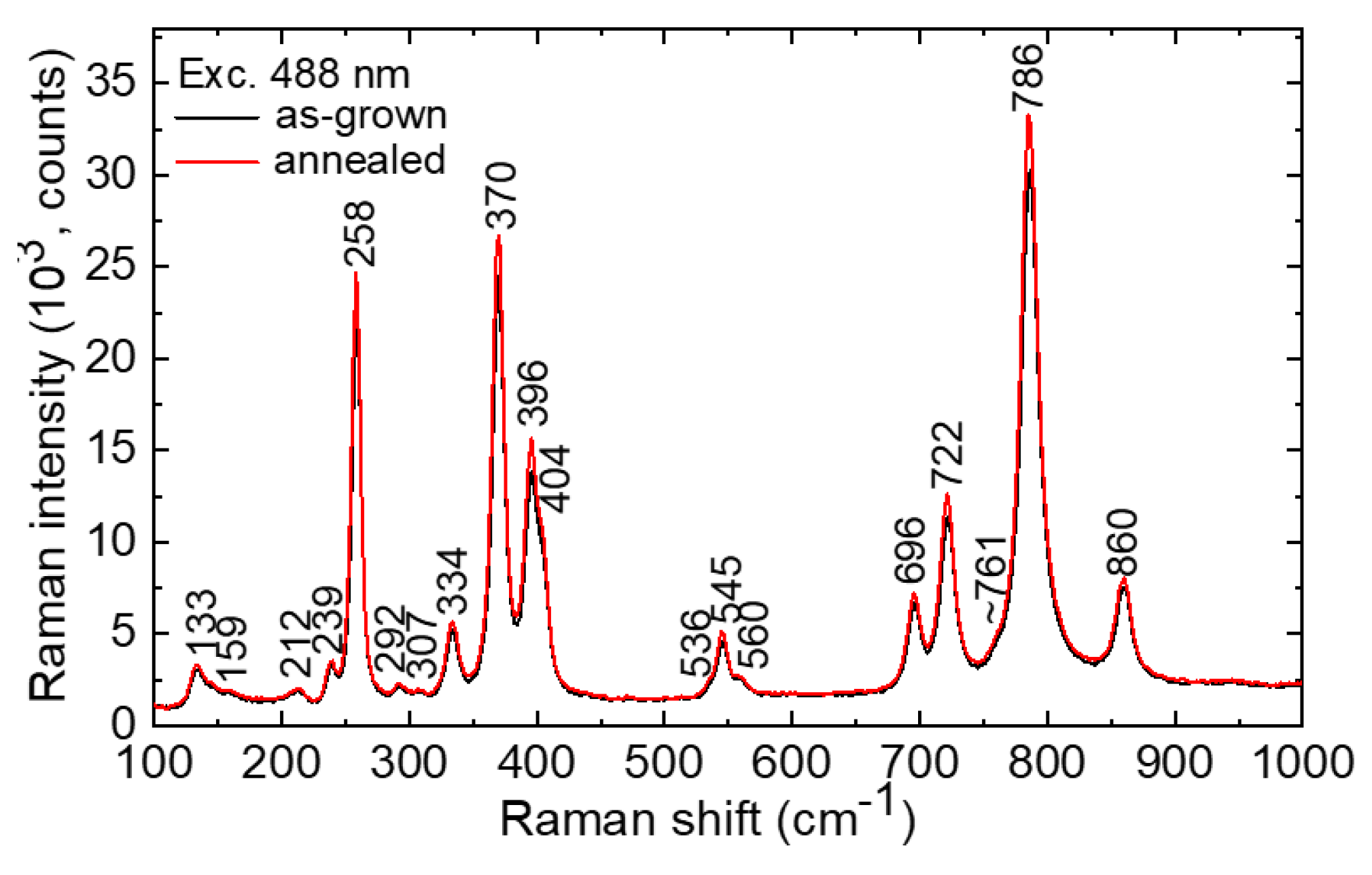

3.1. Crystal structure

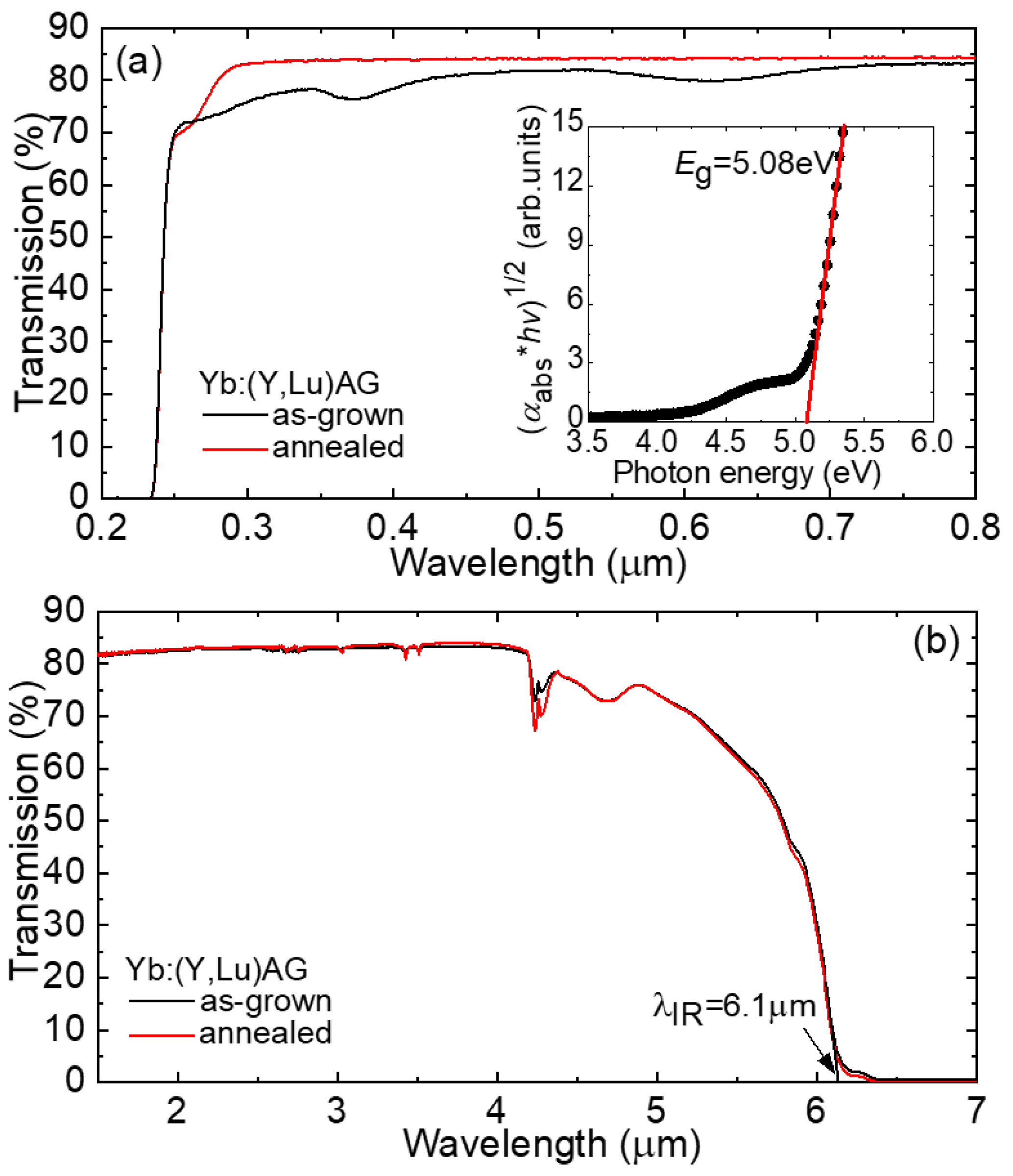

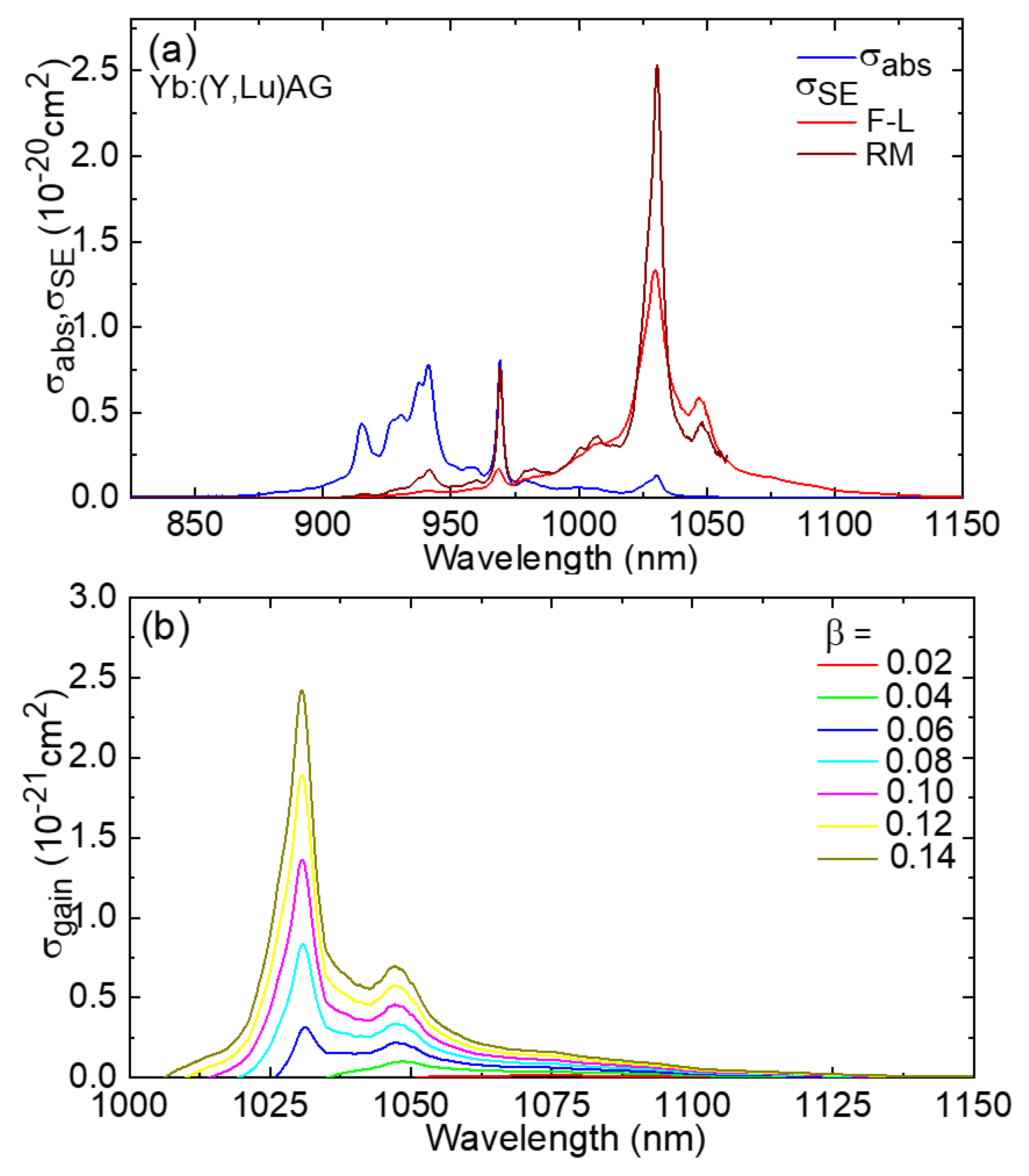

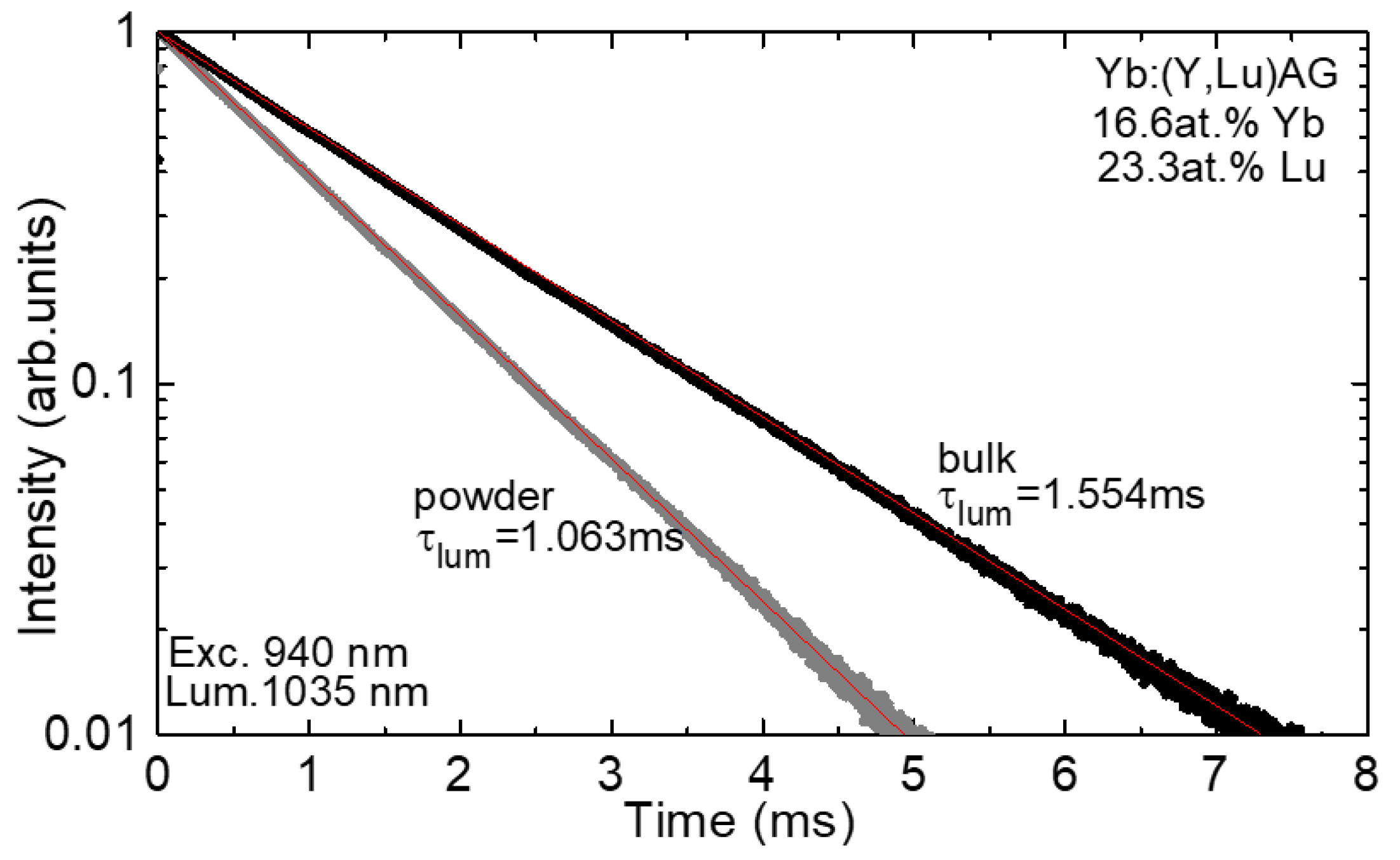

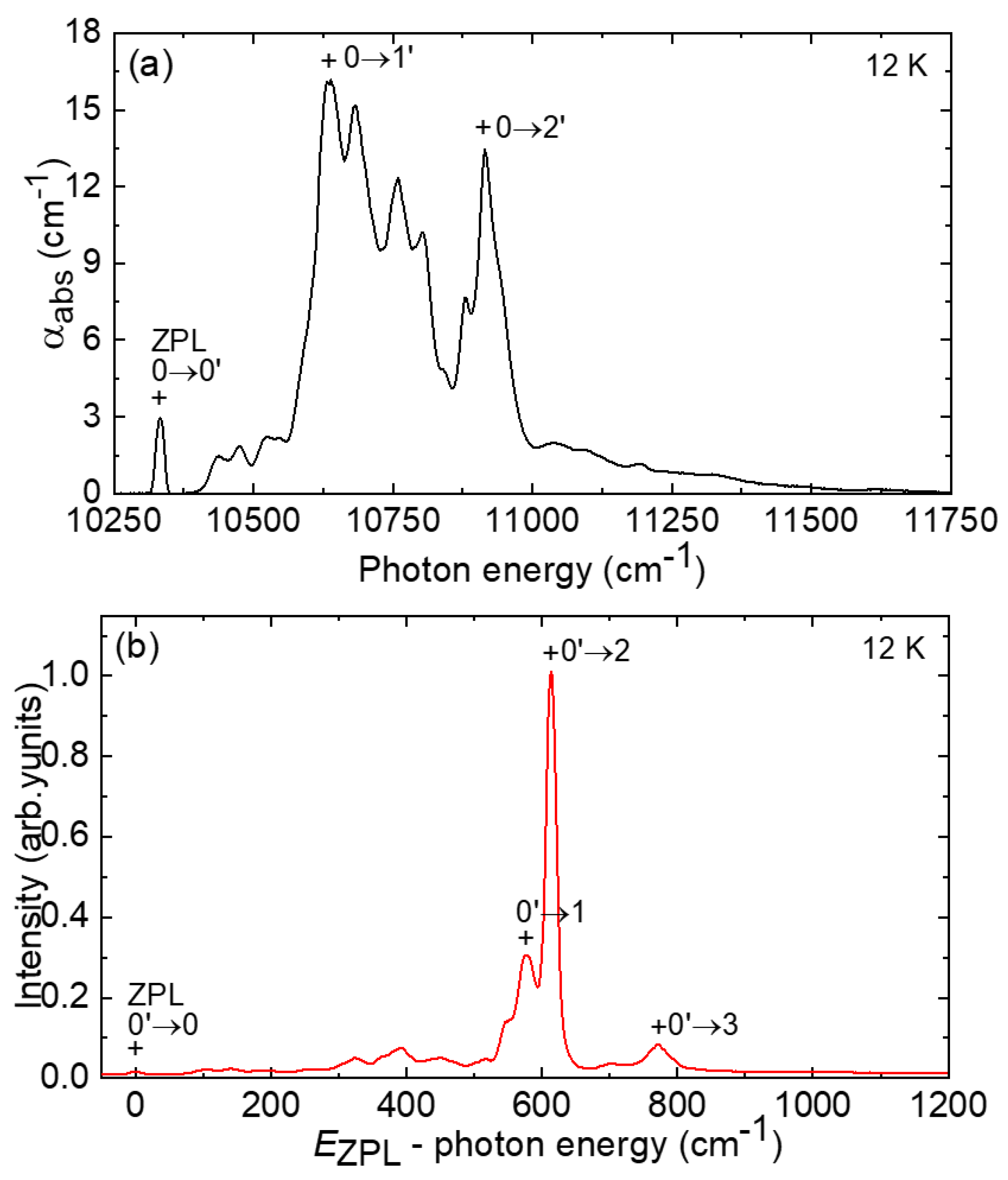

3.2. Optical spectroscopy

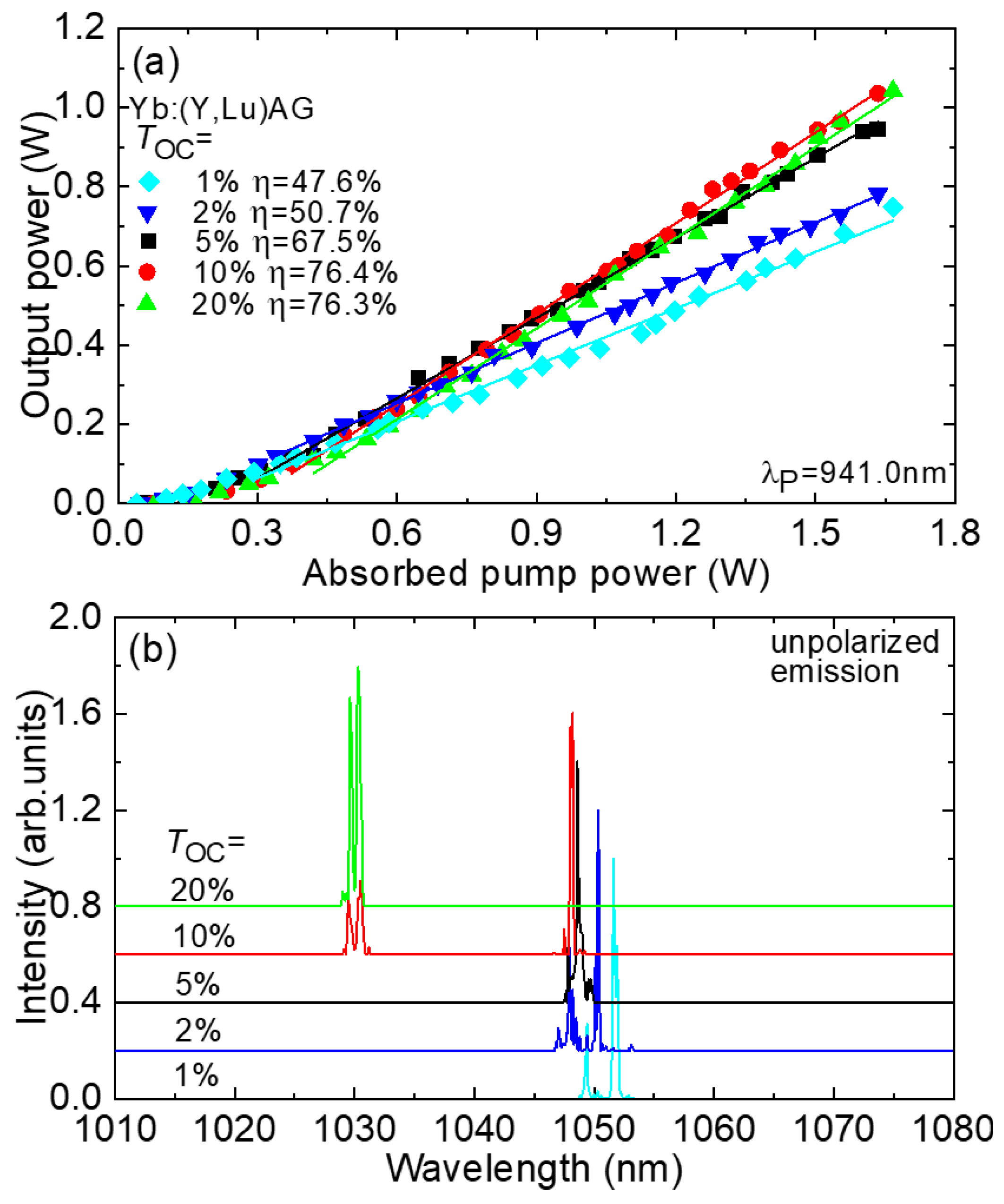

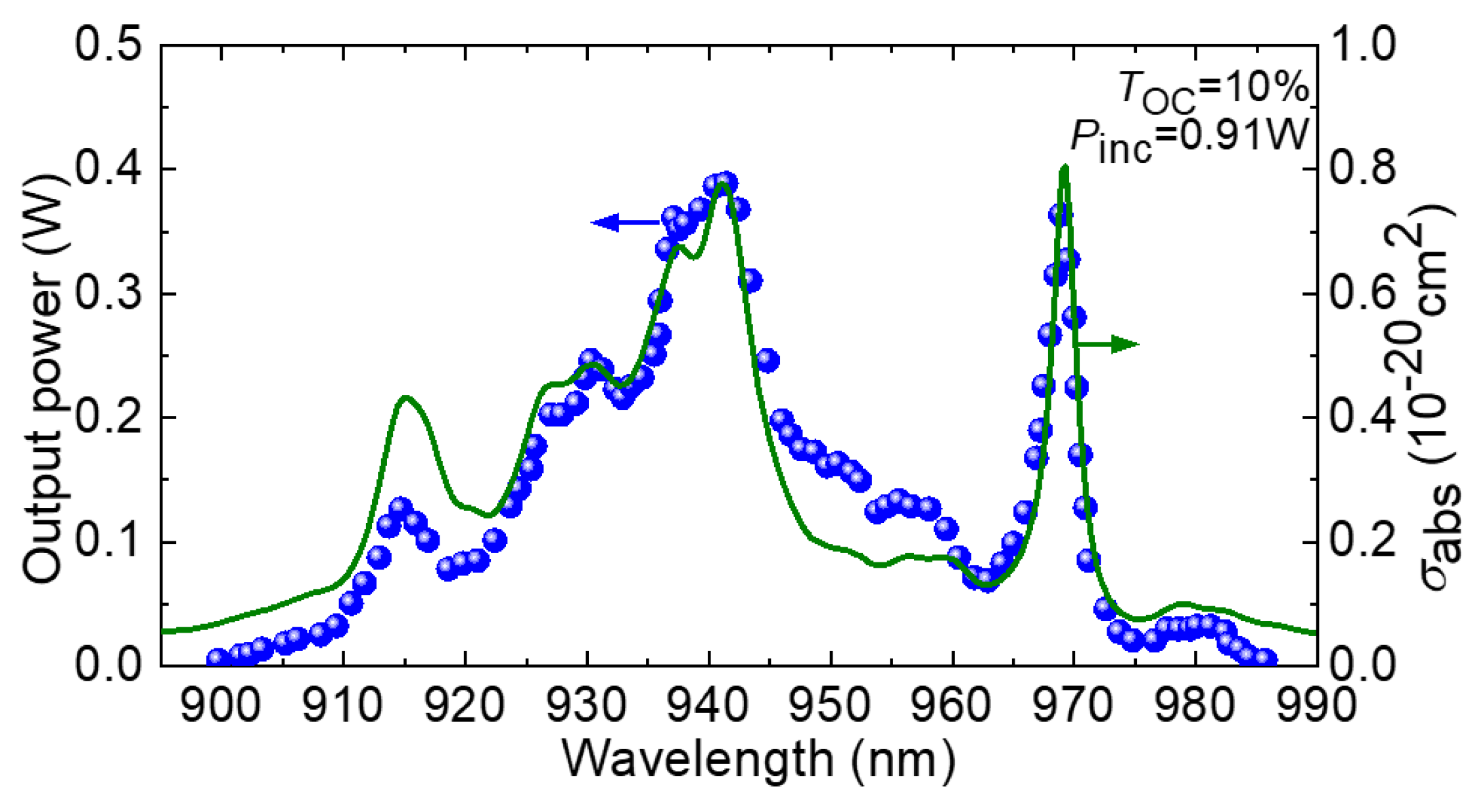

3.3. Laser performance

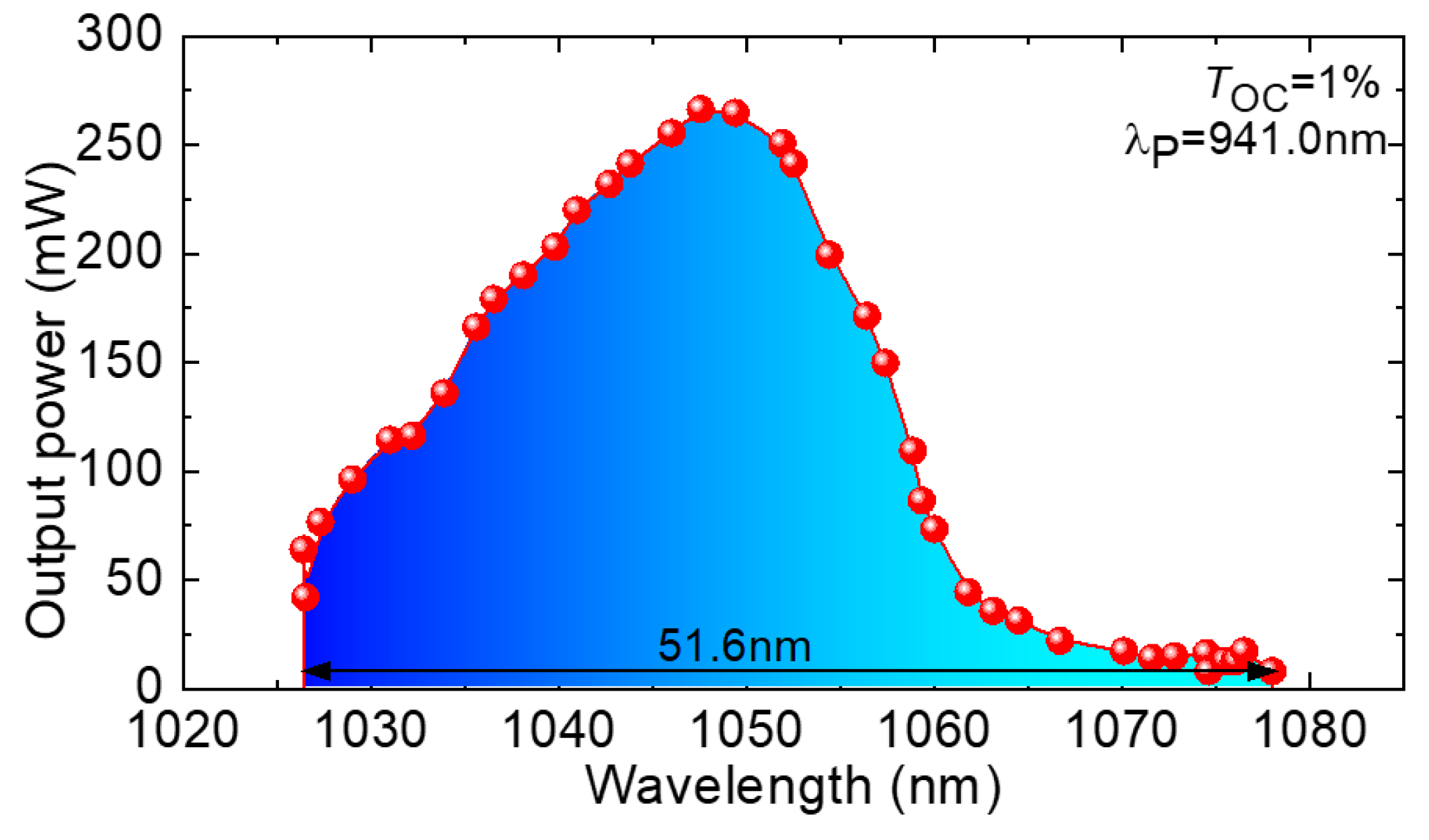

3.3.1. Laser performance using Ti:Sapphire pumping

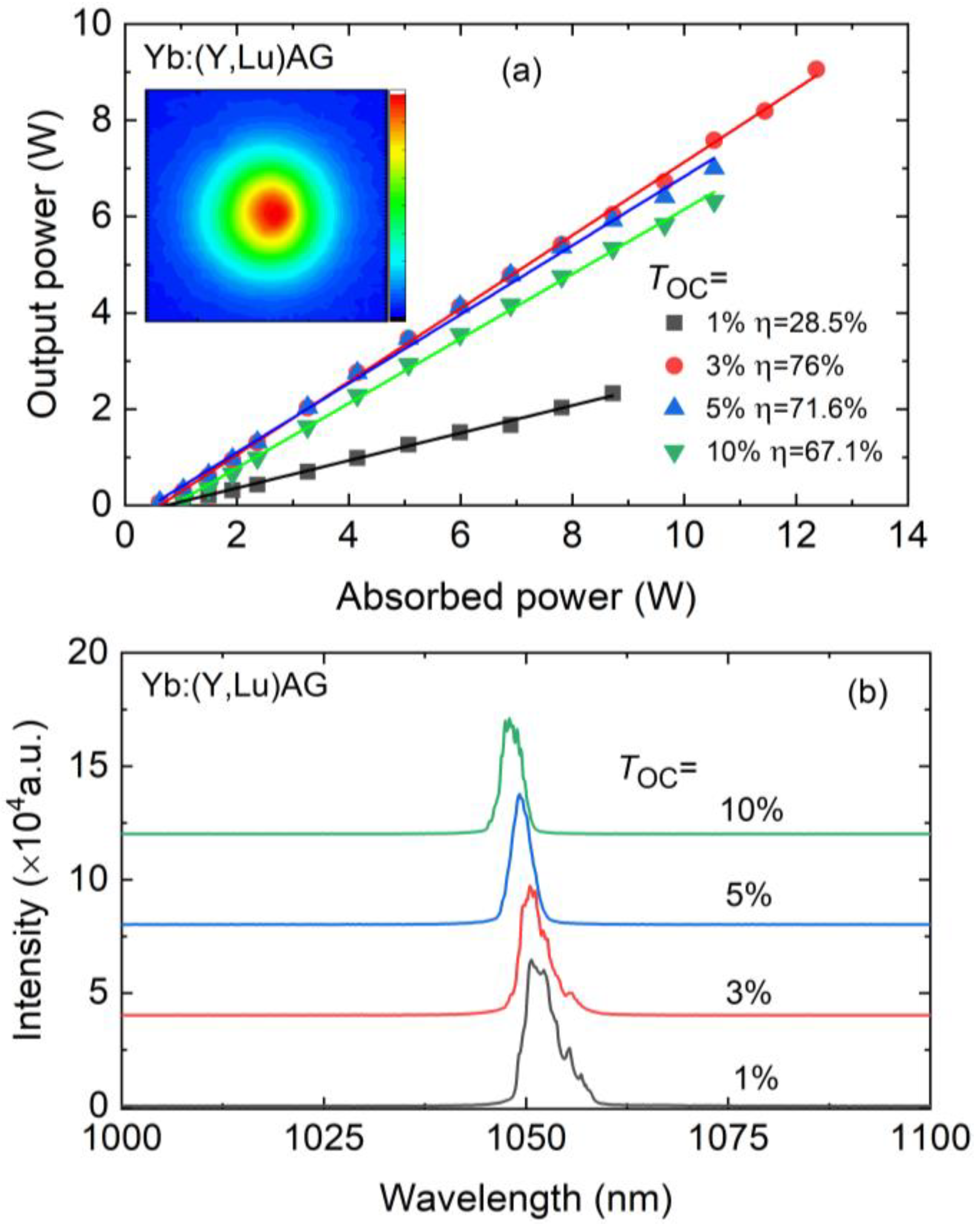

3.3.2. Diode pumped Laser performance

4. Conclusion

Acknowledgements

References

- Taira, T.; Tulloch, W.M.; Byer, R.L. Modeling of Quasi-Three-Level Lasers and Operation of Cw Yb:YAG Lasers. Appl. Opt. 1997, 36, 1867–1874. [Google Scholar] [CrossRef]

- Wang, C.A.; Fan, T.Y.; Lacovara, P.; Choi, H.K.; Aggarwal, R.L. Room-Temperature Diode-Pumped Yb:YAG Laser. Opt. Lett. 1991, 16, 1089–1091. [Google Scholar]

- Aggarwal, R.L.; Ripin, D.J.; Ochoa, J.R.; Fan, T.Y. Measurement of Thermo-Optic Properties of Y3Al5O12, Lu3Al5O12, YAIO3, LiYF4, LiLuF4, BaY2F8, KGd(WO4)2, and KY(WO4)2 Laser Crystals in the 80–300K Temperature Range. J. Appl. Phys. 2005, 98, 103514. [Google Scholar] [CrossRef]

- Paschotta, R.; Schaer, S.F.; Au, J.A. der; Keller, U.; Moser, M.; Hönninger, C. High-Power Diode-Pumped Passively Mode-Locked Yb:YAG Lasers. Opt. Lett. 1999, 24, 1281–1283. [Google Scholar]

- Emanuel, M.A.; Avizonis, P. V.; Monroe, R.S.; Honea, E.C.; Harris, D.G.; Beach, R.J.; Mitchell, S.C.; Payne, S.A.; Skidmore, J.A.; Sutton, S.B. High-Power Dual-Rod Yb:YAG Laser. Opt. Lett. 2000, 25, 805–807. [Google Scholar]

- Innerhofer, E.; Südmeyer, T.; Brunner, F.; Häring, R.; Aschwanden, A.; Paschotta, R.; Hönninger, C.; Kumkar, M.; Keller, U. 60-W Average Power in 810-Fs Pulses from a Thin-Disk Yb:YAG Laser. Opt. Lett. 2003, 28, 367–369. [Google Scholar] [CrossRef]

- Canibano, H.; Ródenas, A.; Jaque, D.; Petrosyan, A.G.; Boulon, G.; Guyot, Y.; Brenier, A.; Eganyan, A. Growth, Spectroscopic, and Laser Properties of Yb3+-Doped Lu3Al5O12 Garnet Crystal. JOSA B, 2006, 23, 676–683. [Google Scholar]

- Veselský, K.; Šulc, J.; Jelínková, H.; Nejezchleb, K.; Škoda, V. Yb Doping Concentration and Temperature Influence on Yb:LuAG Thermal Lensing. S.P.I.E. 2016, 9726, 281–286. [Google Scholar]

- Fredrich-Thornton, S.T.; Beil, K.; Peters, R.; Tellkamp, F.; Kränkel, C.; Petermann, K.; Huber, G. Thermal and Laser Properties of Yb:LuAG for KW Thin Disk Lasers. Opt. Express, 2 2010, 18, 20712–20722. [Google Scholar]

- Fu, Y.; Li, J.; Wang, C.; Xie, T.; Li, W.; Wu, L.; Pan, Y. Fabrication and Properties of Highly Transparent Yb:LuAG Ceramics. J. Alloys Compd. 2016, 664, 595–601. [Google Scholar] [CrossRef]

- Nakao, H.; Ueda, K.; Shirakawa, A.; Yagi, H.; Yanagitani, T. CW and Mode-Locked Operation of Yb3+-Doped Lu3Al5O12 Ceramic Laser. Opt. Express, 2012, 20, 15385–15391. [Google Scholar] [CrossRef]

- Yu, H.; Xu, J.; Xu, Z.; Xu, X.; Liang, X.; Zhao, Z.; He, J.; Li, J. LD Pumped Yb:LuAG Mode-Locked Laser with 7.63ps Duration. Opt. Express, 2009, 17, 11537–11542. [Google Scholar]

- Baer, C.R.E.; Petermann, K.; Marchese, S. V.; Peters, R.; Engqvist, A.G.; Huber, G.; Keller, U.; Golling, M.; Kränkel, C.; Maas, D.J.H.C.; et al. Efficient Femtosecond High Power Yb:Lu2O3 Thin Disk Laser. Opt. Express, 2007, 15, 16966–16971. [Google Scholar]

- Kisel, V.; Rudenkov, A.; Petrosyan, A.; Hovhannesyan, K.; Yasukevich, A.; Kuleshov, N. Spectroscopy and Continuous Wave Laser Performance of Yb3+:LuAlO3 Crystal. Opt. Lett. 2016, 41, 5805–5808. [Google Scholar]

- Lin, H.; Tonelli, M.; Pirzio, F.; Agnesi, A.; Volpi, A.; Lieto, A. Di; Cittadino, G. Crystal Growth, Spectroscopic Characterization, and Sub-100 Femtosecond Mode-Locked Operation of a Yb:LiLuF4 Laser. JOSA B, 2016, 33, 2350–2356. [Google Scholar] [CrossRef]

- Dong, J.; Ueda, K.; Kaminskii, A.A. Laser-Diode Pumped Efficient Yb:LuAG Microchip Lasers Oscillating at 1030 and 1047 Nm. Laser Phys. Lett. 2010, 7, 726–733. [Google Scholar] [CrossRef]

- Basyrova, L.; Maksimov, R.; Shitov, V.; Baranov, M.; Mikhaylovsky, V.; Khubetsov, A.; Dymshits, O.; Mateos, X.; Loiko, P. Effect of SiO2 Addition on Structural and Optical Properties of Yb:Lu3Al5O12 Transparent Ceramics Based on Laser Ablated Nanopowders. J. Alloys Compd. 2019, 806, 717–725. [Google Scholar] [CrossRef]

- Basyrova, L.; Loiko, P.; Maksimov, R.; Shitov, V.; Serres, J.M.; Griebner, U.; Petrov, V.; Aguiló, M.; Díaz, F.; Mateos, X. Comparative Study of Yb:Lu3Al5O12 and Yb:Lu2O3 Laser Ceramics Produced from Laser-Ablated Nanopowders. Ceram. Int. 2021, 47, 6633–6642. [Google Scholar] [CrossRef]

- Kuwano, Y.; Suda, K.; Ishizawa, N.; Yamada, T. Crystal Growth and Properties of (Lu,Y)3Al5O12. J. Cryst. Growth 2004, 260, 159–165. [Google Scholar] [CrossRef]

- Pirri, A.; Toci, G.; Li, J.; Xie, T.; Pan, Y.; Babin, V.; Beitlerova, A.; Nikl, M.; Vannini, M. High Efficiency Laser Action in Mildly Doped Yb:LuYAG Ceramics. Opt. Mater. (Amst). 2017, 73, 312–318. [Google Scholar] [CrossRef]

- Balashov, V. V.; Zakharov, L.Y.; Inyushkin, A. V.; Kanaev, A.Y.; Kozlov, A.B.; Kozlova, S.M.; Koromyslov, A.L.; Lopukhin, K. V.; Luzanov, V.A.; Pervakov, K.S.; et al. Comparative Study of LuxY1-xAG (x=0..1) Laser Ceramics Doped with 5% Yb3+. Ceram. Int. 2022, 48, 6294–6301. [Google Scholar] [CrossRef]

- Cheng, S.; Xu, X.; Li, D.; Zhou, D.; Wu, F.; Zhao, Z.; Xu, J. Growth and Spectroscopic Properties of Yb:Lu1.5Y1.5Al5O12 Mixed Crystal. Opt. Mater. (Amst). 2010, 33, 112–115. [Google Scholar] [CrossRef]

- Lv, S.; Gao, C.; Tian, Z.; Su, X.; Wang, G.; Zhu, G.; Wang, B.; Kumar, S.; Xu, X.; Yu, H.; et al. Diode-Pumped Continuous-Wave Dual-Wavelength and Q-Switched Yb:LuYAG Lasers. Opt. Commun. 2021, 478, 126356. [Google Scholar] [CrossRef]

- Shim, J.B.; Yoshikawa, A.; Nikl, M.; Pejchal, J.; Yoon, D.H.; Isshiki, M.; Fukuda, T. Growth and Characterization of Yb3+-Doped (Lu,Y)AlO3 Fiber Single Crystals Grown by the Micro-Pulling-down Method. Japanese J. Appl. Physics, Part 1 Regul. Pap. Short Notes Rev. Pap. 2004, 43, 7661–7664. [Google Scholar] [CrossRef]

- Kaminskii, A.A.; Rhee, H.; Lux, O.; Eichler, H.J.; Bagayev, S.N.; Yagi, H.; Ueda, K.; Shirakawa, A.; Dong, J. Stimulated Raman Scattering in “Garnet” Lu3Al5O12 Ceramics - A Novel Host-Materiel for Ln- and TM-Lasant Ions. Laser Phys. Lett. 2011, 8, 458–464. [Google Scholar] [CrossRef]

- Papagelis, K.; Ves, S. Infrared Spectroscopy and Lattice Dynamical Calculations of Gd3Al5O12, Tb3Al5O12 and Lu3Al5O12 Single Crystals. J. Phys. Chem. Solids 2003, 64, 599–605. [Google Scholar] [CrossRef]

- Tang, F.; Cao, Y.; Huang, J.; Liu, H.; Guo, W.; Wang, W. Fabrication and Laser Behavior of Composite Yb:YAG Ceramic. J. Am. Ceram. Soc. 2012, 95, 56–69. [Google Scholar] [CrossRef]

- Tauc, J. Optical Properties and Electronic Structure of Amorphous Ge and Si. Mater. Res. Bull. 1968, 3, 37–46. [Google Scholar] [CrossRef]

- Aull, B.F.; Jenssen, H.P. Vibronic Interactions in Nd: YAG Resulting in Nonreciprocity of Absorption and Stimulated Emission Cross Sections. IEEE J. Quantum Electron. 1982, 18, 925–930. [Google Scholar] [CrossRef]

- Fan, T.Y.; Wynne, R.; Daneu, J.L. Thermal Coefficients of the Expansion and Refractive Index in YAG. Appl. Opt. 1999, 38, 3282–3284. [Google Scholar]

- Payne, S.A.; Chase, L.L.; Smith, L.K.; Kway, W.L.; Wyers, W.F. Infrared Cross-Section Measurements for Crystals Doped with Er3+, Tm3+, and Ho3+. IEEE J. Quantum Electron. 1992, 28, 2619–2630. [Google Scholar] [CrossRef]

| Parameter | Lu3+ content, at.% | Yb3+ content, at.% | Stoichiometry |

| Melt | 21.2 | 15.0 | (Y0.638Lu0.212Yb0.150)3Al5O12 |

| Crystal | 23.3 | 16.6 | (Y0.601Lu0.233Yb0.166)3Al5O12 |

| KRE | 1.10 | 1.11 | - |

| Parameter | Value |

| Crystal system | cubic |

| Space group (IT number, Z) | Iad – O10h (No. 230, Z = 8) |

| Hall symbol | -I 4bd 2c 3 |

| Laue class | m-3m |

| Reduced number of S.O. | 24 |

| General multiplicity | 96 |

| Calculated density (g/cm3) | 6.869 |

| Lattice constants: a = b = c (Å) |

11.9790(0) |

| α = β = γ (deg.) | 90 |

| Unit-cell volume (Å3) | 1718.944(0) |

| 2θ range (deg.) | 5 - 80 0.02 Cu Kα1 (λ = 1.5418 Å) |

| 2θ step | |

| Radiation | |

| No. of reflections | 100 |

| Refinement software | Match3! (crystal impact) software |

| Reliability factors |

Rp = 6.07%, Rwp = 7.95%, Rexp = 3.83% and χ2 = 4.31 |

| Atoms | sites | x/a | y/b | z/c | O.F. | Biso, Å2 |

| Y | 24c | 1/8 | 0 | 1/4 | 0.601 | 1.112(0) |

| Lu | 24c | 1/8 | 0 | 1/4 | 0.233 | 1.112(0) |

| Yb | 24c | 1/8 | 0 | 1/4 | 0.166 | 1.112(0) |

| Al1 | 16a | 0 | 0 | 0 | 1 | 1.131(2) |

| Al2 | 24d | 0.3750(0) | 0 | 1/4 | 1 | 1.636(8) |

| O | 96h | -0.0323(7) | 0.0541(3) | 0.1521(7) | 1 | 2.011(1) |

| Yb3+ multiplet | E, cm-1 | ||

| 2S+1LJ | (Y,Lu)AG | YAG | LuAG |

| 2F7/2 | 0 | 0 | 0 |

| 578 | 565 | 602 | |

| 613 | 612 | 643 | |

| 771 | 785 | 764 | |

| 2F5/2 | 10333 | 10327 | 10333 |

| 10636 | 10650 | 10643 | |

| 10915 | 10923 | 10908 |

| Crystal |

σabs, 10-20 cm2 |

λabs, nm |

Δλabs, nm |

σSE, 10-20 cm2 |

λem, nm |

τrad, ms |

| (Y,Lu)AG | 0.80 | 969.2 | <3 | 2.53 | 1030.6 | 1.00 |

| 0.78 | 941.0 | 19 | ||||

| YAG | 0.80 | 969.0 | 2.5 | 2.31 | ~1030 | 0.95 |

| 0.77 | ~942 | ~18 | ||||

| LuAG | 0.73 | 969.0 | <3 | 2.76 | 1030.4 | 1.01 |

| 0.79 | 940.7 | ~20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).