Submitted:

13 October 2023

Posted:

17 October 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

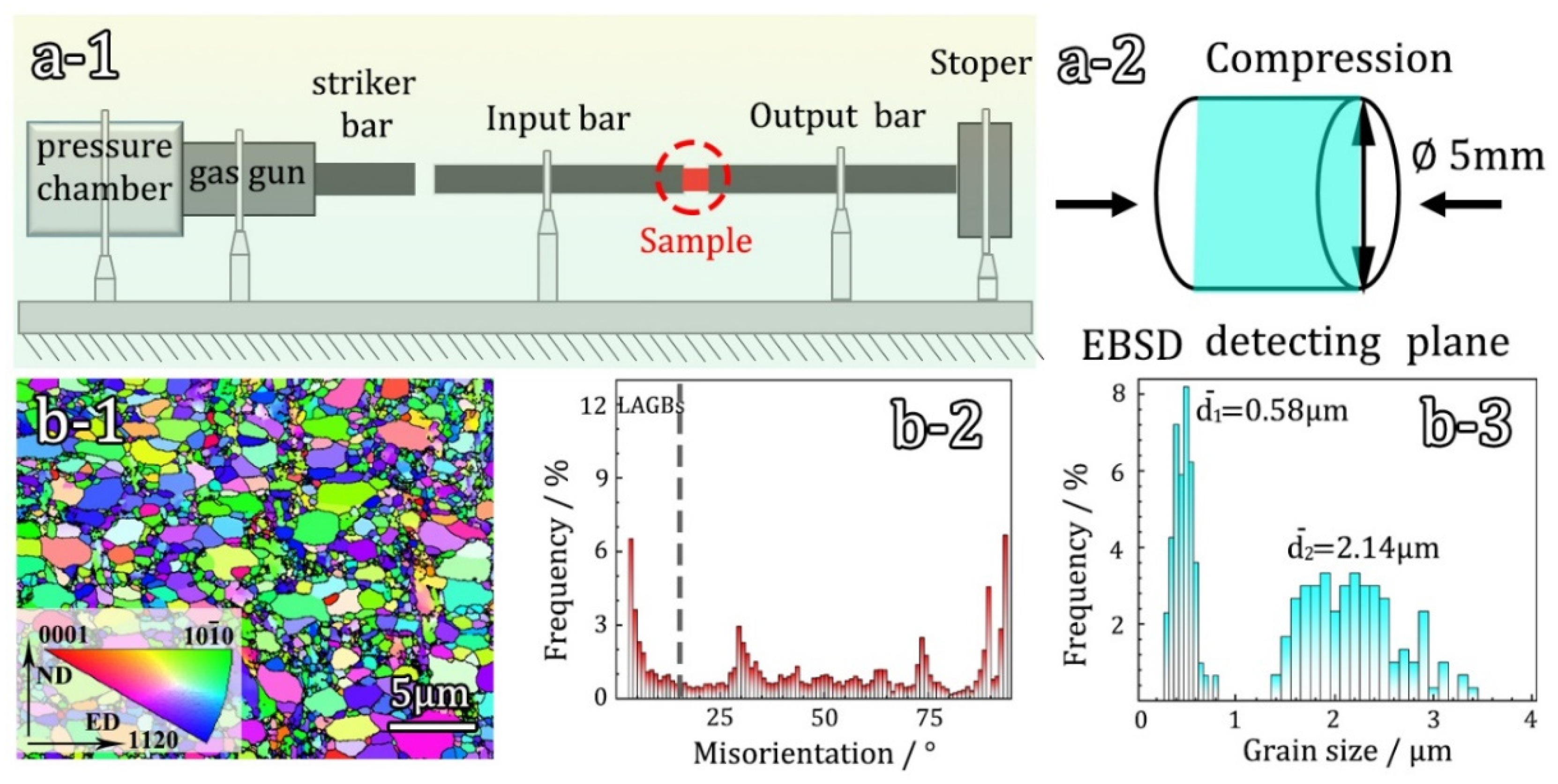

2. Experimental

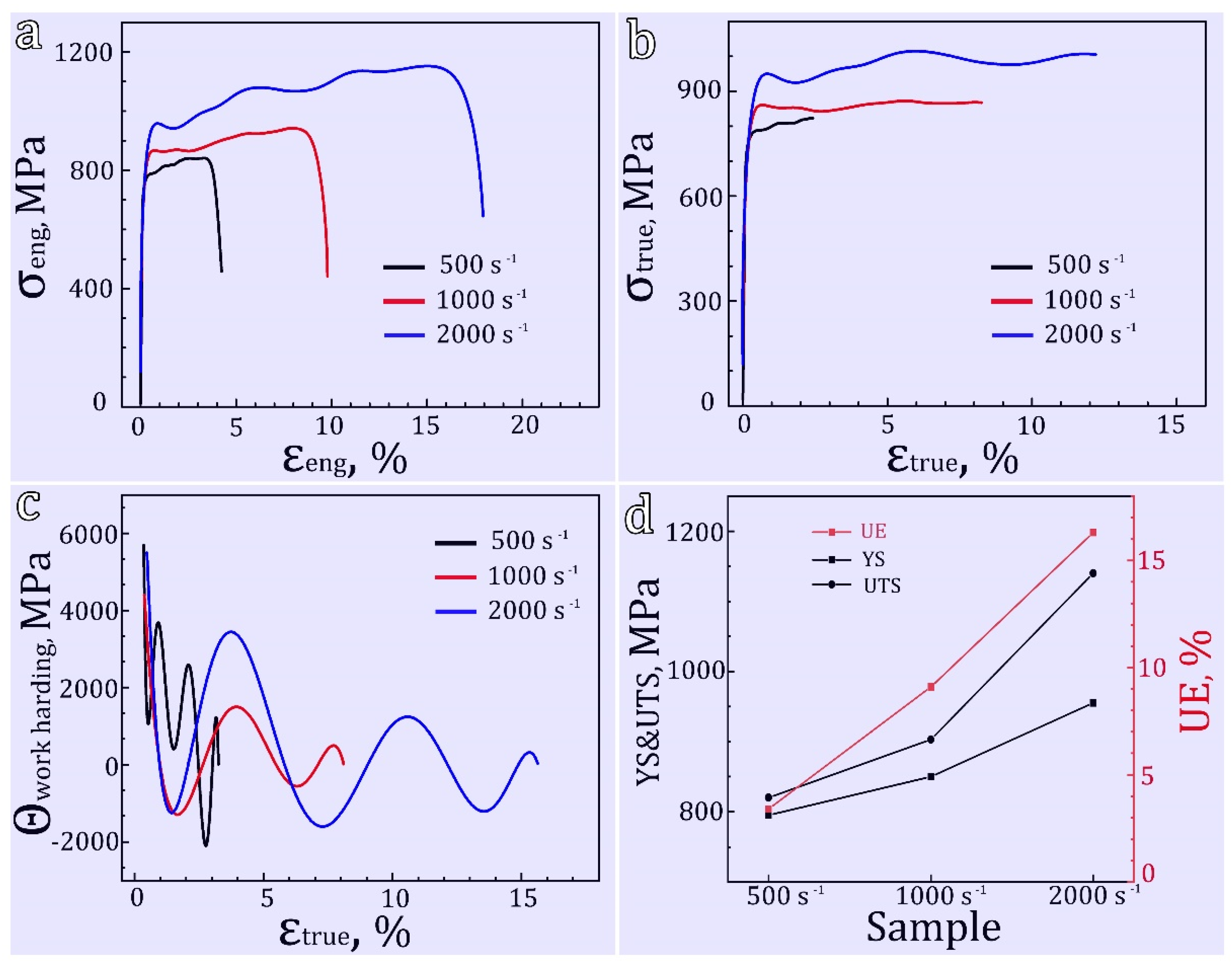

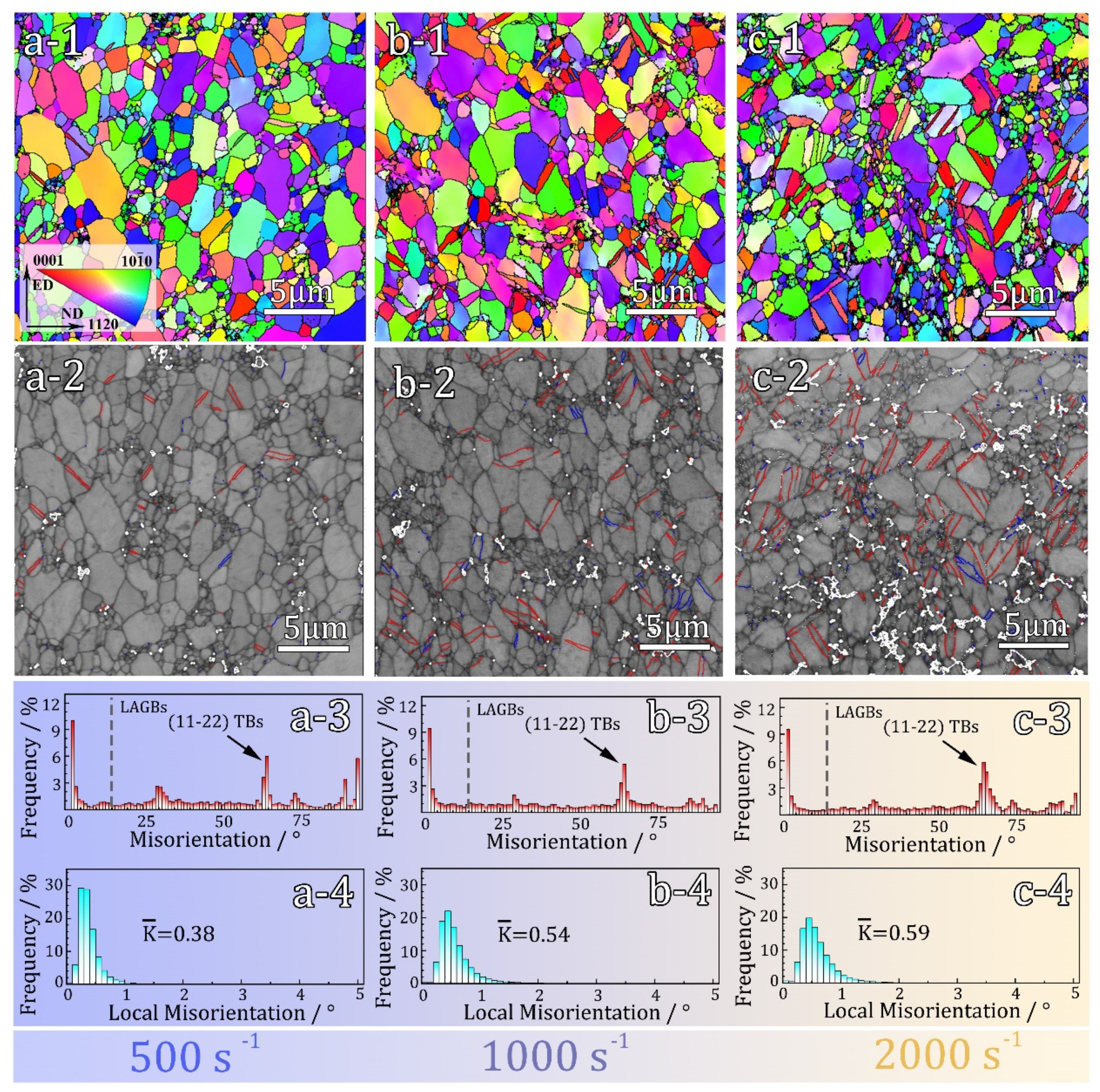

3. Results and Discussion

4. Conclusion

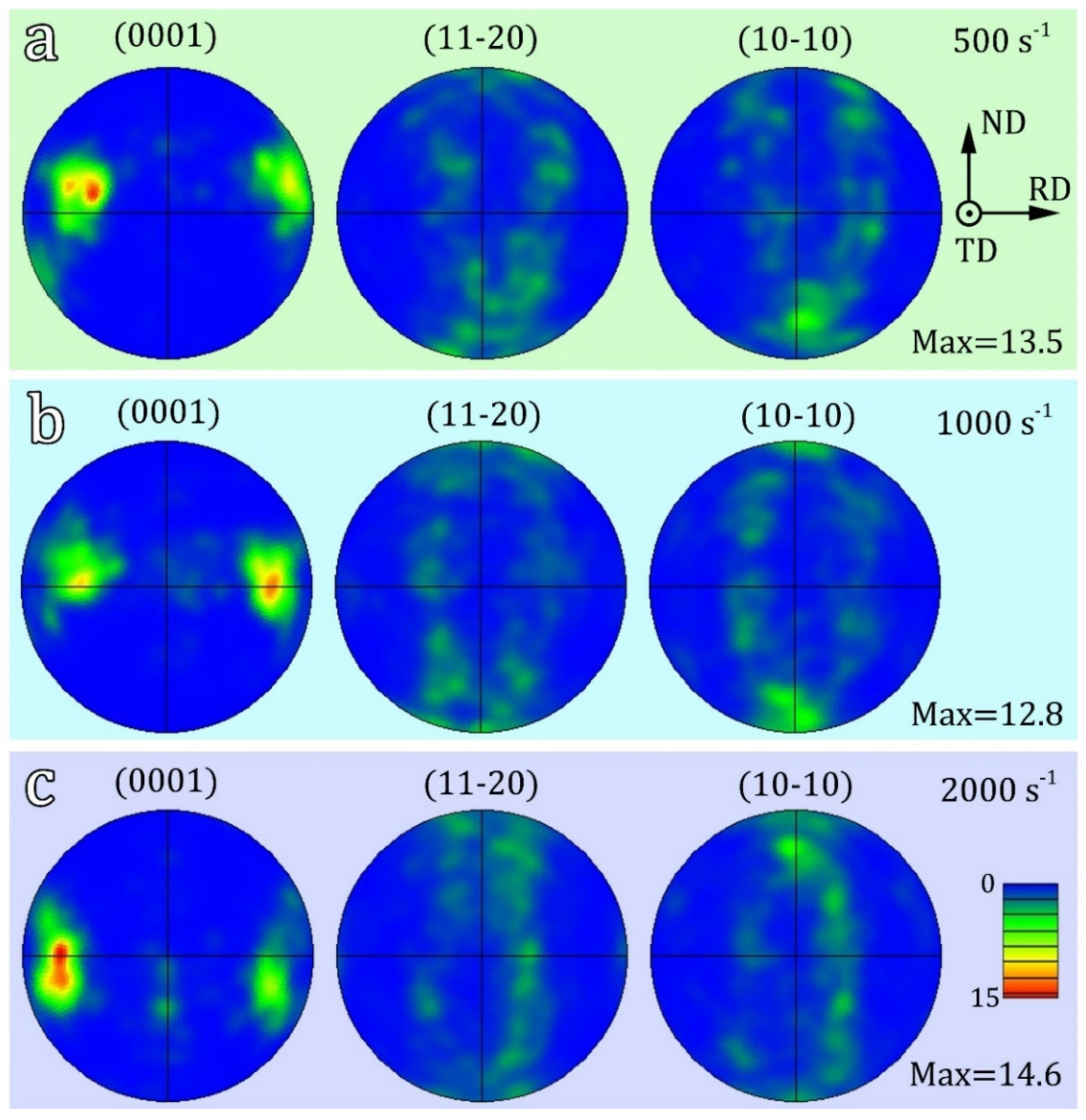

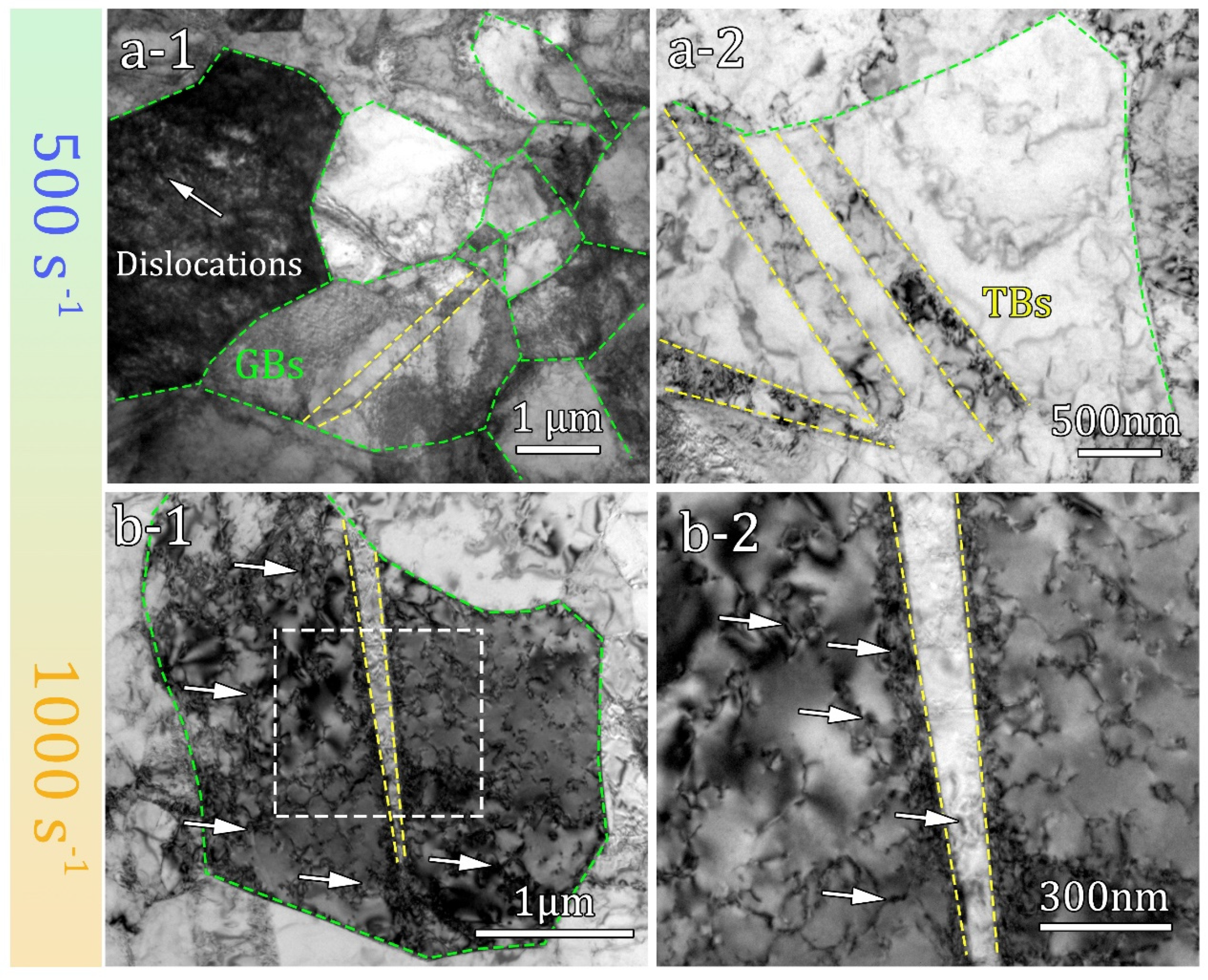

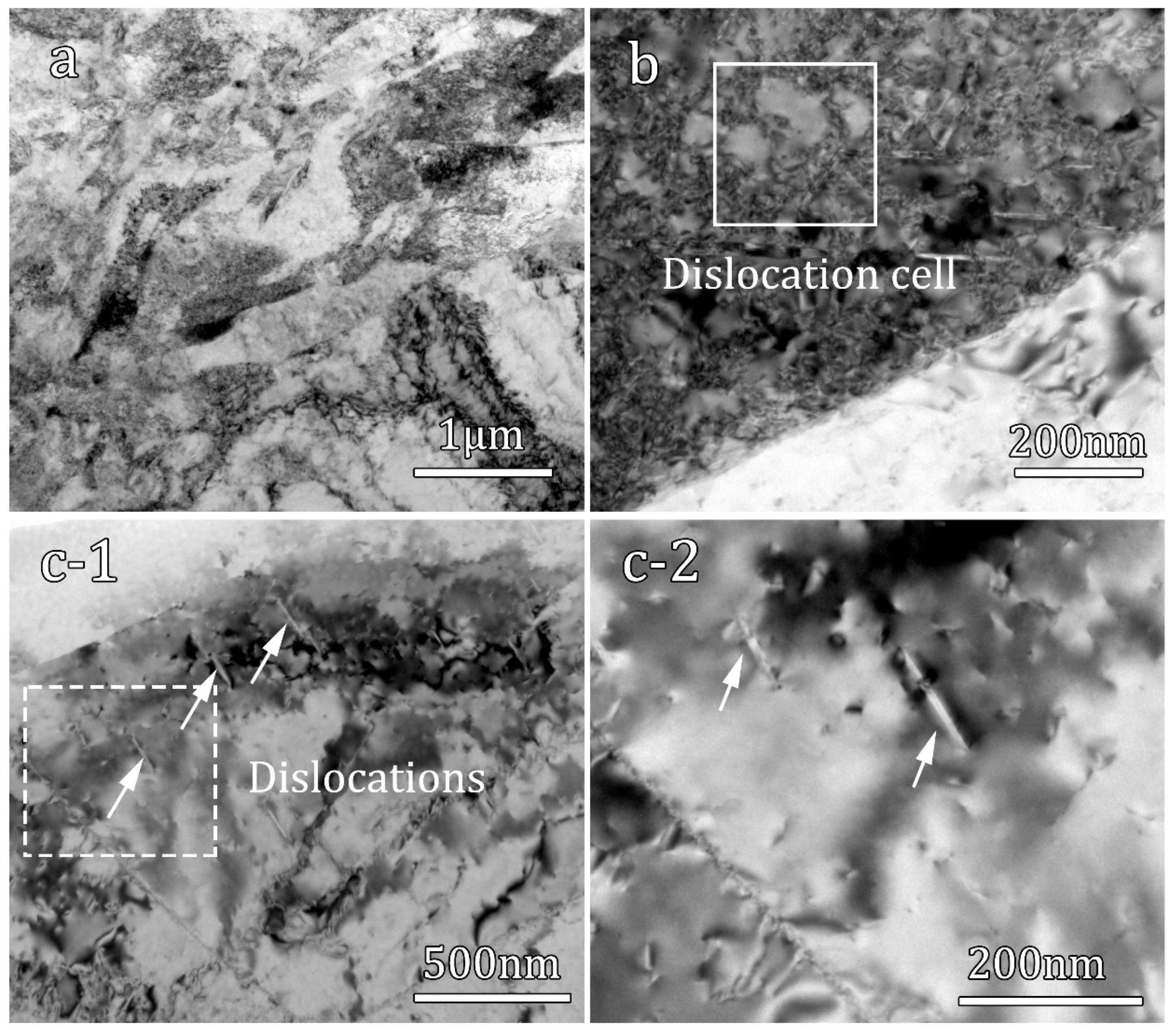

- The mechanical responses and deformation mechanisms of hetero-structured pure titanium samples are closely related to the strain rate. As the strain rate increases from 500 s-1 to 2000 s-1, dislocation activities are the primary deformation carrier, but the dominance of dislocation slipping reduces and the dislocation configurations undergo changes. Conversely, there is an increase in the percentage of deformation twinning with higher strain rates.

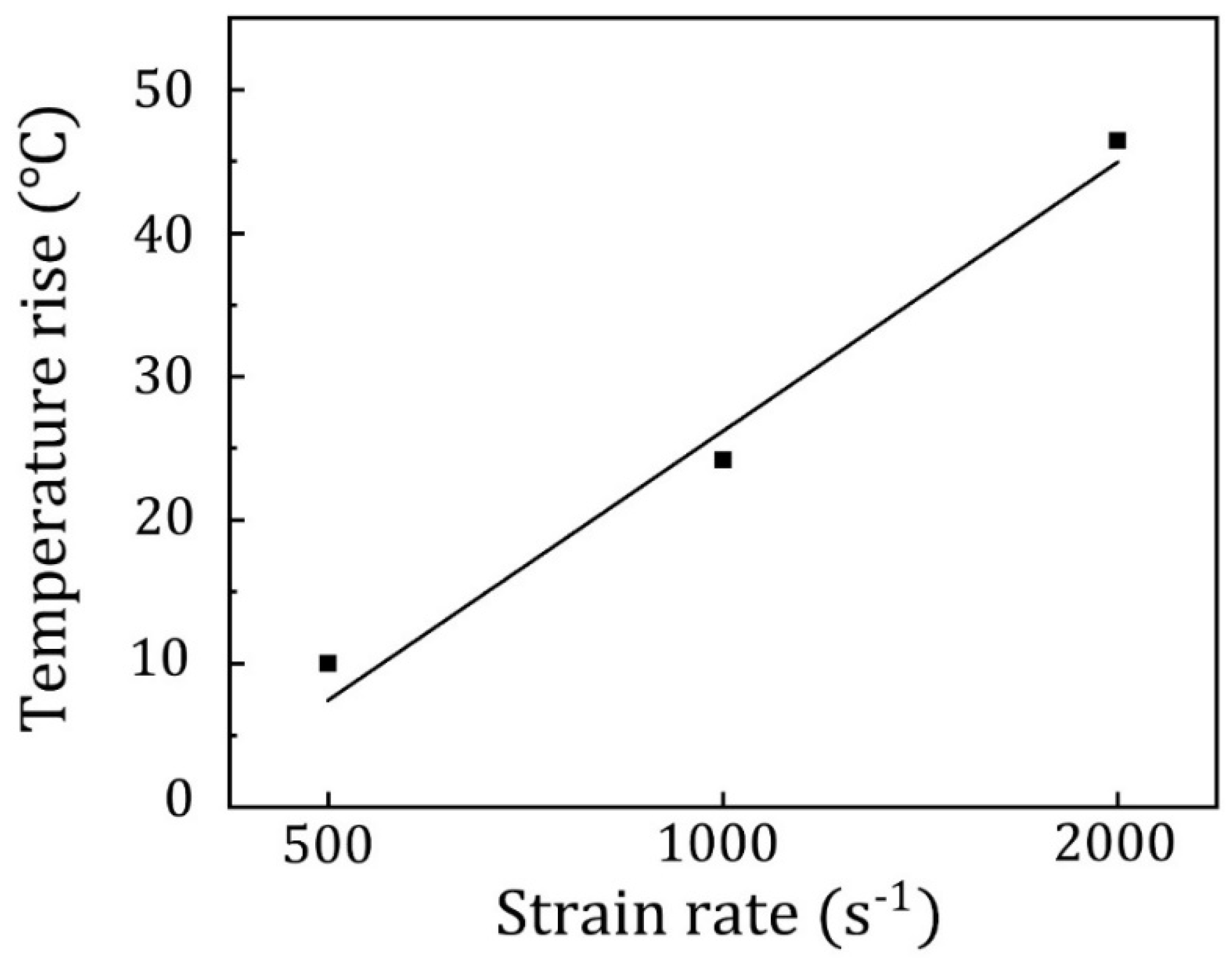

- It has been found that under different high deformation rates (500 s-1, 1000 s-1, 2000 s-1), the changes in texture are relatively minimal,, and the degree of temperature rise is low (far lower than the recrystallization temperature). Consequently, the alterations in these two influential factors are insufficient to induce changes in the deformation mechanism.

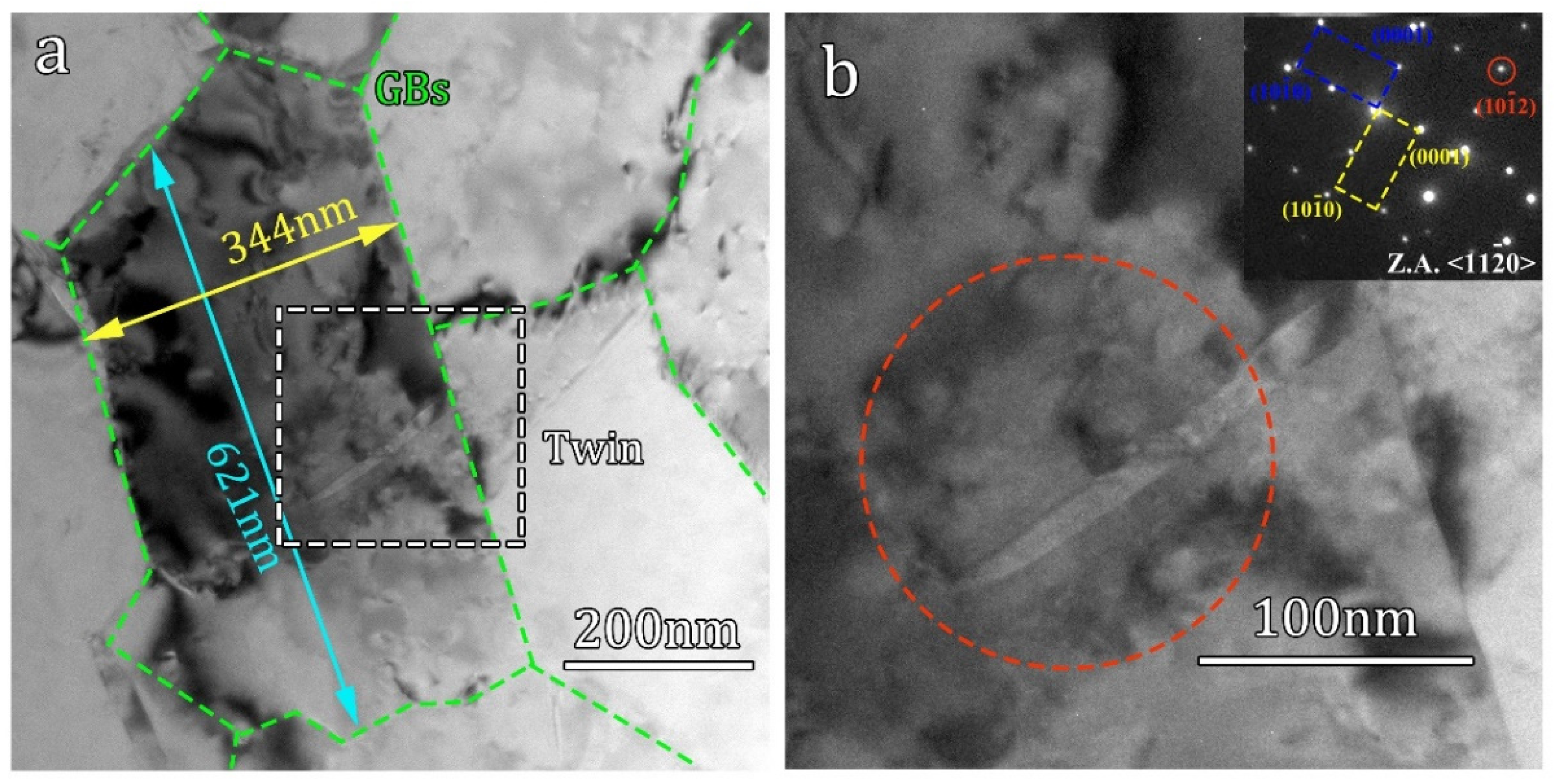

- When subjected to a strain rate of 2000 s-1, martensitic phase transformation is identified in the deformed Ti sample. Moreover, nanoscale twin lamellae are observed within the ultrafine grain, which can be attributed to the high flow stress. A modified Hall-Petch model is proposed, and the obtained can be used to effectively establish the correlation between the stress required for twinning and the grain size.

Author Contributions

Acknowledgment

Conflict of Interest

References

- Özcan, Mutlu, and Christoph Hämmerle. "Titanium as a Reconstruction and Implant Material in Dentistry: Advantages and Pitfalls." Materials 5, no. 9 (2012): 1528-45. [CrossRef]

- Konstantinov, A. S., P. M. Bazhin, A. M. Stolin, E. V. Kostitsyna, and A. S. Ignatov. "Ti-B-Based Composite Materials: Properties, Basic Fabrication Methods, and Fields of Application (Review)." Composites Part A: Applied Science and Manufacturing 108 (2018): 79-88. [CrossRef]

- Yan, Na, Zezhou Li, Yongbo Xu, and Marc A. Meyers. "Shear Localization in Metallic Materials at High Strain Rates." Progress in Materials Science 119 (2021). [CrossRef]

- Lei, Lei, Qinyang Zhao, Yongqing Zhao, Cong Wu, Shixing Huang, Weiju Jia, and Weidong Zeng. "Gradient Nanostructure, Phase Transformation, Amorphization and Enhanced Strength-Plasticity Synergy of Pure Titanium Manufactured by Ultrasonic Surface Rolling." Journal of Materials Processing Technology 299 (2022). [CrossRef]

- Wang, Mingsai, Yanfei Wang, Qiong He, Wei Wei, Fengjiao Guo, Wuli Su, and Chongxiang Huang. "A Strong and Ductile Pure Titanium." Materials Science and Engineering: A 833 (2022): 142534. [CrossRef]

- Won, Jong Woo, Seulbi Lee, Woo Chul Kim, Yong-Taek Hyun, and Dong Won Lee. "Significantly Increased Twinning Activity of Pure Titanium During Room-Temperature Tensile Deformation by Cryogenic-Deformation Treatment." Materials Science and Engineering: A 862 (2023). [CrossRef]

- Zhao, S., R. Zhang, Q. Yu, J. Ell, R. O. Ritchie, and A. M. Minor. "Cryoforged Nanotwinned Titanium with Ultrahigh Strength and Ductility." Science 373, no. 6561 (2021): 1363-68. [CrossRef]

- Huang, Zhaowen, Yang Cao, Jinfeng Nie, Hao Zhou, and Yusheng Li. "Microstructures and Mechanical Properties of Commercially Pure Ti Processed by Rotationally Accelerated Shot Peening." Materials 11, no. 3 (2018). [CrossRef]

- Zhou, Ping, Dawu Xiao, Chunli Jiang, Ge Sang, and Dongli Zou. "Twin Interactions in Pure Ti under High Strain Rate Compression." Metallurgical and Materials Transactions A 48, no. 1 (2016): 126-38. [CrossRef]

- Jia, Hailong, Knut Marthinsen, and Yanjun Li. "Revealing Abnormal {112¯1} Twins in Commercial Purity Ti Subjected to Split Hopkinson Pressure Bar." Journal of Alloys and Compounds 783 (2019): 513-23. [CrossRef]

- Wang, Tong Bo, Bo Long Li, Mian Li, Ying Chao Li, and Zuo Ren Nie. "The Dynamic Mechanical Behavior and Microstructural Evolution of Commercial Pure Titanium." Advanced Materials Research 968 (2014): 7-11. [CrossRef]

- Gurao, N. P., Rajeev Kapoor, and Satyam Suwas. "Deformation Behaviour of Commercially Pure Titanium at Extreme Strain Rates." Acta Materialia 59, no. 9 (2011): 3431-46. [CrossRef]

- Deguchi, Misaki, Shigeto Yamasaki, Masatoshi Mitsuhara, Hideharu Nakashima, Genki Tsukamoto, and Tomonori Kunieda. "Tensile Deformation Behaviors of Pure Ti with Different Grain Sizes under Wide-Range of Strain Rate." Materials 16, no. 2 (2023): 529. [CrossRef]

- Xu, Feng, Xiyan Zhang, Haitao Ni, and Qing Liu. "Deformation Twinning in Pure Ti During Dynamic Plastic Deformation." Materials Science and Engineering: A 541 (2012): 190-95. [CrossRef]

- Wu, X., M. Yang, F. Yuan, G. Wu, Y. Wei, X. Huang, and Y. Zhu. "Heterogeneous Lamella Structure Unites Ultrafine-Grain Strength with Coarse-Grain Ductility." Proc Natl Acad Sci U S A 112, no. 47 (2015): 14501-5. [CrossRef]

- Tanaka, Y., M. Kondo, N. Miyazaki, and R. Ueji. "Deformation Behavior of Pure Titanium at a Wide Range of Strain Rates." Journal of Physics: Conference Series 240 (2010). [CrossRef]

- Li, Qiang, Y. B. Xu, and M. N. Bassim. "Dynamic Mechanical Behavior of Pure Titanium." Journal of Materials Processing Technology 155-156 (2004): 1889-92. [CrossRef]

- Xu, Shun, and Jian Wang. "Deformation Twins Stimulated by {112¯2} Twinning in Adjacent Grain in Titanium." Acta Materialia 229 (2022). [CrossRef]

- Huang, Z. W., S. B. Jin, H. Zhou, Y. S. Li, Y. Cao, and Y. T. Zhu. "Evolution of Twinning Systems and Variants During Sequential Twinning in Cryo-Rolled Titanium." International Journal of Plasticity 112 (2019): 52-67. [CrossRef]

- Yu, Qian, Raja K. Mishra, and Andrew M. Minor. "The Effect of Size on the Deformation Twinning Behavior in Hexagonal Close-Packed Ti and Mg." Jom 64, no. 10 (2012): 1235-40. [CrossRef]

- Li, Lifei, Zheng Zhang, and Gongtian Shen. "Effect of Grain Size on the Tensile Deformation Mechanisms of Commercial Pure Titanium as Revealed by Acoustic Emission." Journal of Materials Engineering and Performance 24, no. 5 (2015): 1975-86. [CrossRef]

- Yu, Kehang, Xin Wang, Subhash Mahajan, Irene J. Beyerlein, Penghui Cao, Timothy J. Rupert, Julie M. Schoenung, and Enrique J. Lavernia. "Twin Nucleation from Disconnection-Dense Sites between Stacking Fault Pairs in a Random Defect Network." Materialia 30 (2023). [CrossRef]

- Mittemeijer, Eric J. "The Crystal Imperfection;Structure Defects." (2021).

- Wei, Kang, Rong Hu, Dongdi Yin, Lirong Xiao, Song Pang, Yang Cao, Hao Zhou, Yonghao Zhao, and Yuntian Zhu. "Grain Size Effect on Tensile Properties and Slip Systems of Pure Magnesium." Acta Materialia 206 (2021). [CrossRef]

- Huang, Zhaowen, Donghui Wen, Xiaodong Hou, Yusheng Li, Biao Wang, and Anding Wang. "Grain Size and Temperature Mediated Twinning Ability and Strength-Ductility Correlation in Pure Titanium." Materials Science and Engineering: A 849 (2022). [CrossRef]

- Ahmadikia, Behnam, Leyun Wang, M. Arul Kumar, and Irene J. Beyerlein. "Grain Boundary Slip – Twin Transmission in Titanium." Acta Materialia 244 (2023). [CrossRef]

- Zhao, Hong, Nanjie Ding, Yuping Ren, Hongbo Xie, Bo Yang, and Gaowu Qin. "Shear-Induced Hexagonal Close-Packed to Face-Centered Cubic Phase Transition in Pure Titanium Processed by Equal Channel Angular Drawing." Journal of Materials Science 54, no. 10 (2019): 7953-60. [CrossRef]

- Zheng, XiaodongGong, MingyuXiong, TingGe, HualongYang, LixinZhou, YangtaoZheng, ShijianWang, JianMa, Xiuliang. "Deformation Induced Fcc Lamellae and Their Interaction in Commercial Pure Ti." Scripta Materialia 162 (2019). [CrossRef]

- Sun, J. L., P. W. Trimby, F. K. Yan, X. Z. Liao, N. R. Tao, and J. T. Wang. "Grain Size Effect on Deformation Twinning Propensity in Ultrafine-Grained Hexagonal Close-Packed Titanium." Scripta Materialia 69, no. 5 (2013): 428-31. [CrossRef]

- Palán, Jan, Radek Procházka, Jan Džugan, Jan Nacházel, Michal Duchek, Gergely Németh, Kristián Máthis, Peter Minárik, and Klaudia Horváth. "Comprehensive Evaluation of the Properties of Ultrafine to Nanocrystalline Grade 2 Titanium Wires." Materials 11, no. 12 (2018): 2522. [CrossRef]

- Zhu, Yuntian, and Xiaolei Wu. "Heterostructured Materials." Progress in Materials Science 131 (2023). [CrossRef]

- Zhu, Yuntian, Kei Ameyama, Peter M. Anderson, Irene J. Beyerlein, Huajian Gao, Hyoung Seop Kim, Enrique Lavernia, Suveen Mathaudhu, Hael Mughrabi, Robert O. Ritchie, Nobuhiro Tsuji, Xiangyi Zhang, and Xiaolei Wu. "Heterostructured Materials: Superior Properties from Hetero-Zone Interaction." Materials Research Letters 9, no. 1 (2020): 1-31. [CrossRef]

- Xu, Shun, Ping Zhou, Guisen Liu, Dawu Xiao, Mingyu Gong, and Jian Wang. "Shock-Induced Two Types of {101¯2} Sequential Twinning in Titanium." Acta Materialia 165 (2019): 547-60. [CrossRef]

- He, Y., B. Li, C. Wang, and S. X. Mao. "Direct Observation of Dual-Step Twinning Nucleation in Hexagonal Close-Packed Crystals." Nat Commun 11, no. 1 (2020): 2483. [CrossRef]

- Kou, Zongde, Yanqing Yang, Bin Huang, Xian Luo, Pengtao Li, Guangming Zhao, and Wei Zhang. "Observing the Dynamic101¯1twining Process in Pure Ti at Atomic Resolution." Scripta Materialia 139 (2017): 139-43. [CrossRef]

- Liao, Xiaozhou, Jian Wang, Jianfeng Nie, Yanyao Jiang, and Peidong Wu. "Deformation Twinning in Hexagonal Materials." MRS Bulletin 41, no. 4 (2016): 314-19. [CrossRef]

- Paudel, YubRaj, Deepesh Giri, Matthew W. Priddy, Christopher D. Barrett, Kaan Inal, Mark A. Tschopp, Hongjoo Rhee, and Haitham El Kadiri. "A Review on Capturing Twin Nucleation in Crystal Plasticity for Hexagonal Metals." Metals 11, no. 9 (2021). [CrossRef]

- Ovid'ko, I. A., R. Z. Valiev, and Y. T. Zhu. "Review on Superior Strength and Enhanced Ductility of Metallic Nanomaterials." Progress in Materials Science 94 (2018): 462-540. [CrossRef]

- Zherebtsov, S. V., G. S. Dyakonov, A. A. Salem, V. I. Sokolenko, G. A. Salishchev, and S. L. Semiatin. "Formation of Nanostructures in Commercial-Purity Titanium Via Cryorolling." Acta Materialia 61, no. 4 (2013): 1167-78. [CrossRef]

- Wang, L., Z. Zheng, H. Phukan, P. Kenesei, J. S. Park, J. Lind, R. M. Suter, and T. R. Bieler. "Direct Measurement of Critical Resolved Shear Stress of Prismatic and Basal Slip in Polycrystalline Ti Using High Energy X-Ray Diffraction Microscopy." Acta Materialia 132 (2017): 598-610. [CrossRef]

- Cao, Yang, Song Ni, Xiaozhou Liao, Min Song, and Yuntian Zhu. "Structural Evolutions of Metallic Materials Processed by Severe Plastic Deformation." Materials Science and Engineering: R: Reports 133 (2018): 1-59. [CrossRef]

- Yang, H., H. Li, J. Ma, D. Wei, J. Chen, and M. W. Fu. "Temperature Dependent Evolution of Anisotropy and Asymmetry of A-Ti in Thermomechanical Working: Characterization and Modeling." International Journal of Plasticity 127 (2020). [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).