Submitted:

16 October 2023

Posted:

17 October 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Test Setups

2.2.1. Slump Flow Test

2.2.2. T50 cm Slump Flow

2.2.3. V-Funnel Test

2.2.4. L-Box Test

2.2.5. J-Ring Test

| S. No. | Property | Test Methods | Unit | Typical Range Values |

|---|---|---|---|---|

| 1. | Filling ability | Slump flow | mm | 650 - 800 |

| 2. | T50 cm slump flow | sec | 2 - 5 | |

| 3. | V-funnel | sec | 6 - 12 | |

| 4. | Passing ability | L-box | (H2/H1) | 0.8 – 1.0 |

| 5. | U-box | (H2 - H1) mm | 0 - 30 | |

| 6. | J-ring | mm | 0 - 10 | |

| 7. | Segregation resistance | V-funnel at T5 minutes | sec | 0 - +3 |

2.3. Synthesis

3. Results

3.1. Self-Compacting Concrete

3.2. Self-curing concrete

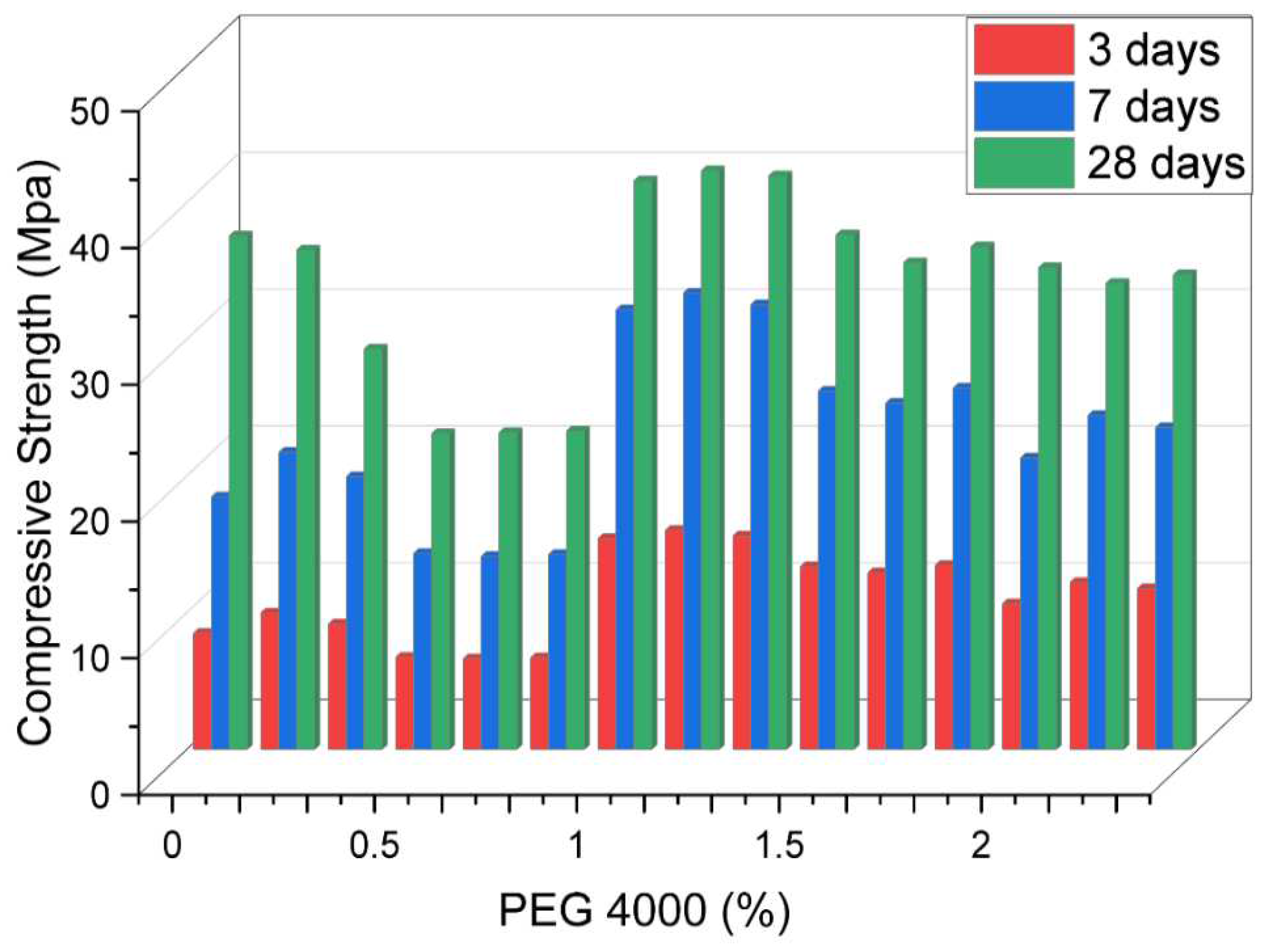

3.2.1. Compressive Strength

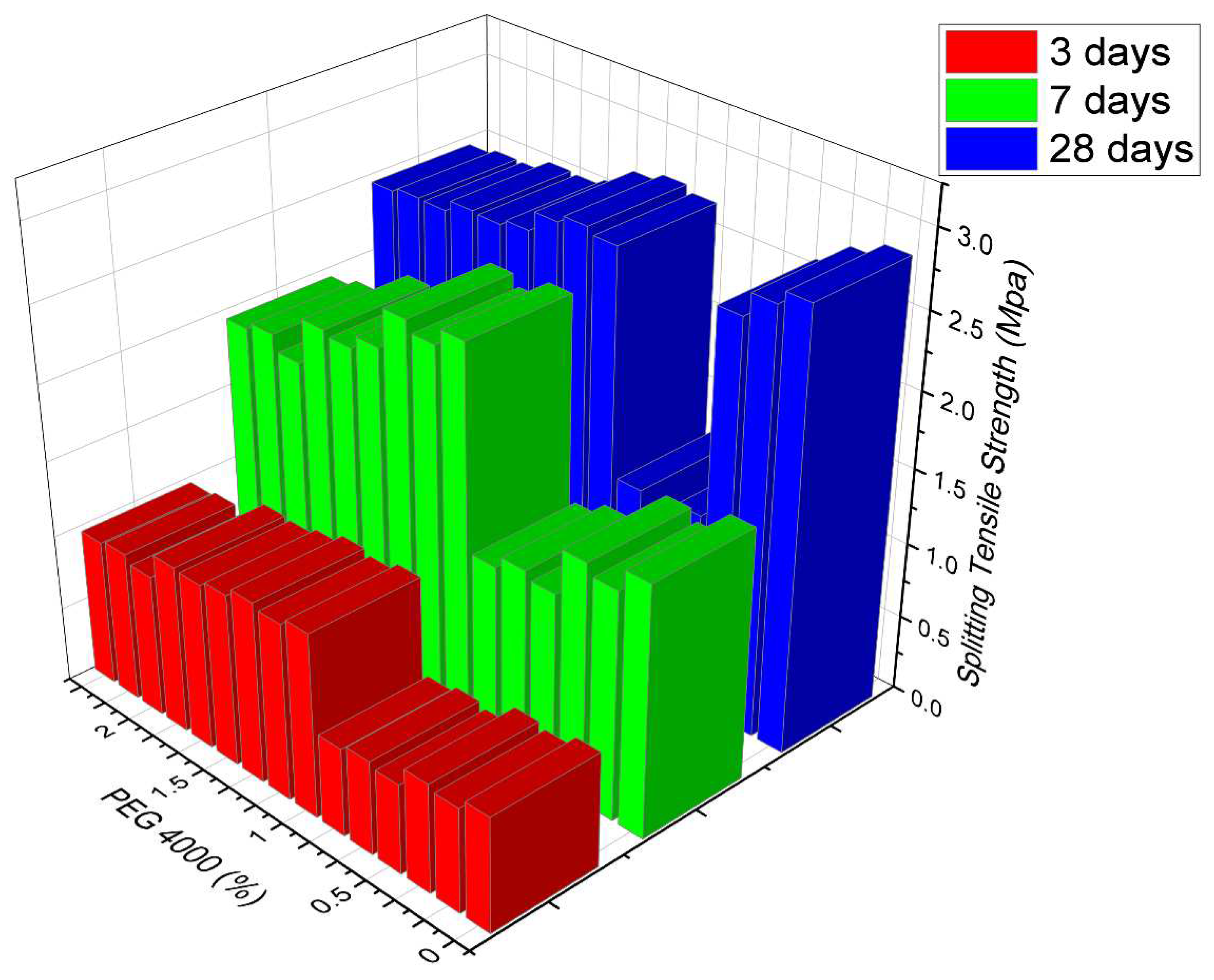

3.2.2. Splitting tensile strength

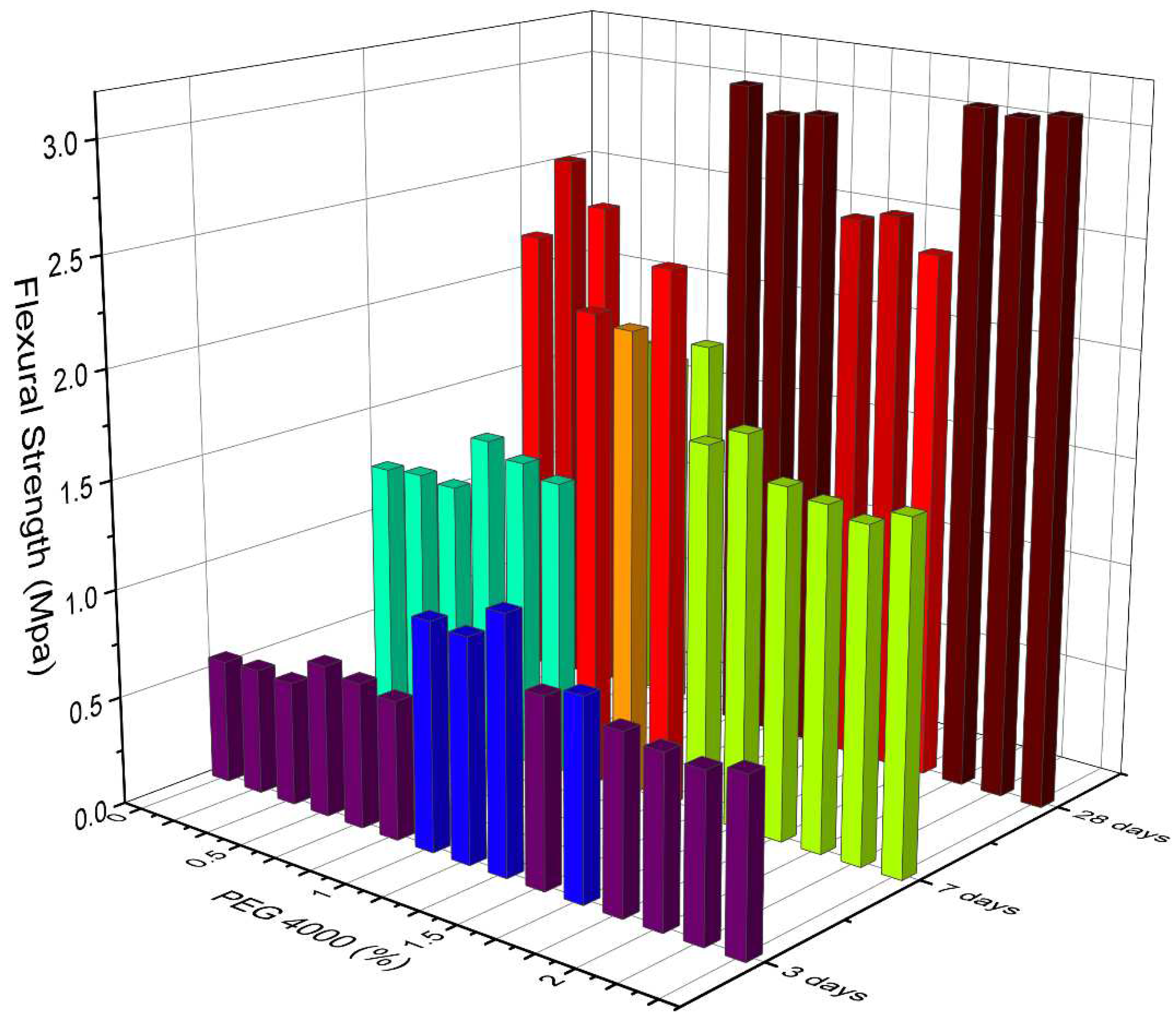

3.2.3. Flexural Strength

5. Conclusions

- Increasing the superplasticizer dosage (SNF%) enhances the flowability and possibility of the concrete mixture, while higher water-to-cement ratios (w/c) generally improve flowability and stability.

- Mixture number 9 (SNF 0.35, w/c 0.5) consistently exhibits excellent flowability and stability, making it a valuable choice. These findings offer insights for optimizing concrete mix designs, especially in applications where superior flowability and stability are essential. However, it's crucial to consider project-specific requirements when selecting the most suitable method based on the test results provided.

- In summary, the data suggests that the concentration of PEG 4000 significantly influences the material's strength. Lower concentrations, such as 0.5%, may have a positive effect up to a certain point but might not provide sustained improvement over the curing period.

- Concentrations of 1% and 2% demonstrated consistent and significant enhancement in strength throughout the 28-day period. It shows that the higher concentrations of PEG 4000 can be more effective in improving the material strength. However, it is important to consider the material's specific requirements and desired properties when determining the optimal concentration of PEG 4000.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Uysal, M. Self-Compacting Concrete Incorporating Filler Additives: Performance at High Temperatures. Constr. Build. Mater. 2012, 26, 701–706. [Google Scholar] [CrossRef]

- Safiuddin, M.; Salam, M.A.; Jumaat, M.Z. Key Fresh Properties of Self-Consolidating High-Strength POFA Concrete. J. Mater. Civ. Eng. 2014, 26, 134–142. [Google Scholar] [CrossRef]

- Tao, J.; Yuan, Y.; Taerwe, L. Compressive Strength of Self-Compacting Concrete during High-Temperature Exposure. J. Mater. Civ. Eng. 2010, 22, 1005–1011. [Google Scholar] [CrossRef]

- Okrajnov-Bajic, R.; Vasovic, D. Self-Compacting Concrete and Its Application in Contemporary Architectural Practice. Spatium 2009, 28–34. [Google Scholar] [CrossRef]

- Su, N.; Hsu, K.C.; Chai, H.W. A Simple Mix Design Method for Self-Compacting Concrete. Cem. Concr. Res. 2001, 31, 1799–1807. [Google Scholar] [CrossRef]

- Noumowé, A.; Carré, H.; Daoud, A.; Toutanji, H. High-Strength Self-Compacting Concrete Exposed to Fire Test. J. Mater. Civ. Eng. 2006, 18, 754–758. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoglu, M.; Azez, O.A.; Öz, H.Ö. Effect of Nano Silica on the Workability of Self-Compacting Concretes Having Untreated and Surface Treated Lightweight Aggregates. Constr. Build. Mater. 2016, 115, 371–380. [Google Scholar] [CrossRef]

- Praveen Kumar Gupta, Rakesh Kumar, Y. K. Gupta, P.K.M. Effect of Acidic Environment on Self Compacting Concrete. Int. J. Civ. Eng. Technol. 2017, 8, 595–606. [Google Scholar]

- Deneme, I.Ö. Modelling of Compressive Strength of Self-Compacting Concrete Containing Fly Ash by Gene Expression Programming. Rev. la Constr. 2020, 19, 346–358. [Google Scholar] [CrossRef]

- Rodriguez de Sensale, G.; Rodriguez Viacava, I.; Aguado, A. Simple and Rational Methodology for the Formulation of Self-Compacting Concrete Mixes. J. Mater. Civ. Eng. 2016, 28, 04015116. [Google Scholar] [CrossRef]

- Sarker, P.K. Self-Healing of Microcracks in High-Volume Fly-Ash-Incorporated Engineered Cementitious Composites. Civ. Eng. Dimens. 2015, 17, 133–139. [Google Scholar] [CrossRef]

- Ismail, M.K.; Hassan, A.A.A. Influence of Mixture Composition and Type of Cementitious Materials on Enhancing the Fresh Properties and Stability of Self-Consolidating Rubberized Concrete. J. Mater. Civ. Eng. 2016, 28, 04015075. [Google Scholar] [CrossRef]

- Ling, T.C.; Poon, C.S.; Kou, S.C. Influence of Recycled Glass Content and Curing Conditions on the Properties of Self-Compacting Concrete after Exposure to Elevated Temperatures. Cem. Concr. Compos. 2012, 34, 265–272. [Google Scholar] [CrossRef]

- García, L.; Valcuende, M.; Balasch, S.; Fernández-LLebrez, J. Study of Robustness of Self-Compacting Concretes Made with Low Fines Content. J. Mater. Civ. Eng. 2013, 25, 497–503. [Google Scholar] [CrossRef]

- Vivek K; Bhavana B; Prema Kumar W P; Prathap Kumar M T Experimental Investigation on Properties of Self-Compacting and Self-Curing Concrete with Silica Fume and Light Weight Aggregates. Int. J. Eng. Res. 2015, V4, 203–210. [CrossRef]

- Verma, M.; Nigam, M. Mechanical Behaviour of Self Compacting and Self Curing Concrete. Int. J. Innov. Res. Sci. Eng. Technol. 2017, 6, 14361–14366. [Google Scholar] [CrossRef]

- Demie, S.; Nuruddin, M.F.; Shafiq, N.; Fadhil, M.; Shafiq, N. Effects of Micro-Structure Characteristics of Interfacial Transition Zone on the Compressive Strength of Self-Compacting Geopolymer Concrete. Constr. Build. Mater. 2020, 41, 91–98. [Google Scholar] [CrossRef]

- Journal, I.; Engineering, O. Flexural Behaviour of Self Compacting Self Curing Concrete Beam. 2015, 2, 37–40. [Google Scholar]

- Bingöl, A.F.; Tohumcu, I. Effects of Different Curing Regimes on the Compressive Strength Properties of Self Compacting Concrete Incorporating Fly Ash and Silica Fume. Mater. Des. 2013, 51, 12–18. [Google Scholar] [CrossRef]

- Akanksha, M.; Patil, A.; Vyawahare, P.M.R. Comparative Study on Durability of Self Cured SCC and Normally Cured SCC. 2014, 3, 1201–1208. [Google Scholar]

- Aggarwal, P.; Siddique, R.; Aggarwal, Y.; Gupta, S.M. Leonardo Electronic Journal of Practices and Technologies Self-Compacting Concrete-Procedure for Mix Design. Leonardo Electron. J. Pract. Technol. 2008, 15–24. [Google Scholar]

- Dhir, R.K.; Hewlett, P.C.; Dyer, T.D. Durability of “self-Cure” Concrete. Cem. Concr. Res. 1995, 25, 1153–1158. [Google Scholar] [CrossRef]

- Mallikarjuna Reddy, V.; Praveen, R. Effect of Polyethylene Glycol in Self-Curing of Self Compacting Concrete. Int. J. Recent Technol. Eng. 2019, 8, 7280–7283. [Google Scholar] [CrossRef]

- Persson, B. A Comparison between Mechanical Properties of Self-Compacting Concrete and the Corresponding Properties of Normal Concrete. Cem. Concr. Res. 2001, 31, 193–198. [Google Scholar] [CrossRef]

- Junaid, S.M.; Saddam, S.; Junaid, M.; Yusuf, K.; Huzaifa, S.A. Self-Curing Concrete. 2015, 1, 1–7. [Google Scholar]

- Massana, J.; Reyes, E.; Bernal, J.; León, N.; Sánchez-Espinosa, E. Influence of Nano- and Micro-Silica Additions on the Durability of a High-Performance Self-Compacting Concrete. Constr. Build. Mater. 2018, 165, 93–103. [Google Scholar] [CrossRef]

- Fareed Ahmed, M.; Fadhil Nuruddin, M.; Shafiq, N. Compressive Strength and Workability Characteristics of Low-Calcium Fly Ash-Based Self-Compacting Geopolymer Concrete. World Acad. Sci. Eng. Technol. 2011, 74, 8–14. [Google Scholar] [CrossRef]

- El-Dieb, A.S. Self-Curing Concrete: Water Retention, Hydration and Moisture Transport. Constr. Build. Mater. 2007, 21, 1282–1287. [Google Scholar] [CrossRef]

- Mousa, M.I.; Mahdy, M.G.; Abdel-Reheem, A.H.; Yehia, A.Z. Physical Properties of Self-Curing Concrete (SCUC). HBRC J. 2015, 11, 167–175. [Google Scholar] [CrossRef]

- Łaz´niewska-Piekarczyk, B. The Influence of Selected New Generation Admixtures on the Workability, Air-Voids Parameters and Frost-Resistance of Self Compacting Concrete. Constr. Build. Mater. J. 2012, 31, 310–319. [Google Scholar] [CrossRef]

- Hameed, M.H.; Abbas, Z.K.; Ali Al-Ahmed, A.H. Fresh and Hardened Properties of Nano Self-Compacting Concrete with Micro and Nano Silica. IOP Conf. Ser. Mater. Sci. Eng. 2020, 671, 012079. [Google Scholar] [CrossRef]

- IS 2386 (Part VI) Methods of Test for Aggregates for Concrete Part VI Measuring Mortar Making Properties of Fine Aggregate. Bur. Indian Stand. 1997, 2386.

- IS 2386 (Part IV) Methods of Test for Aggregates for Concrete Part IV Mechanical Properties. Bur. Indian Stand. 1997, 2386.

- IS 383 1970 Specification for Coarse and Fine Aggregates from Natural Sources for Concrete. Bur. Indian Stand. 1997, 1–20.

- IS 2386 (Part III) Methods of Test for Aggregates for Concrete Part III Specific Gravity, Density, Voids, Absorption and Bulking. Bur. Indian Stand. 1997, 2386.

- IS 2386 (Part VIII) Methods of Test for Aggregates for Concrete Part VIII Petrographic Examination. Bur. Indian Stand. 1997, 2386.

- IS 2386 (Part II) Methods of Test for Aggregates for Concrete Part II Estimation of Deleterious Materials and Organic Impurties. Bur. Indian Stand. 1998, 2386.

- IS 2386 (PartV) Methods of Test for Aggregates for Concrete Part V Soundness. Bur. Indian Stand. 1997.

- IS 2386 (Part I) Methods of Test for Aggregates for Concrete Part I Particle Size and Shape. Bur. Indian Stand. 1997, 2386.

- IS 2386 (Part VII) Methods of Test for Aggregates for Concrete Part VII Alkali Aggregate Reactivity. Bur. Indian Stand. 1997.

- IS 9103 1999 Concrete Admixture -Specification; 2018.

- IS 12119 1987 General Requirements for Pan Mixers for Concrete; 1999. 12.

- Suriya, D.; Chandar, S.P.; Ravichandran, P.T. Impact of M-Sand on Rheological, Mechanical, and Microstructural Properties of Self-Compacting Concrete. Buildings 2023, 13. [Google Scholar] [CrossRef]

- Bušić, R.; Miličević, I.; Dokšanović, T.; Grubišić, M. Durability Performance and Thermal Resistance of Structural Self-Compacting Concrete Improved with Waste Rubber and Silica Fume. Buildings 2023, 13. [Google Scholar] [CrossRef]

- Mathews, M.E.; Kiran, T.; Nammalvar, A.; Andrushia, A.D.; Alengaram, U.J. Efficacy of Fire Protection Techniques on Impact Resistance of Self-Compacting Concrete. Buildings 2023, 13. [Google Scholar] [CrossRef]

- de Souza, M.H.B.; Silva, L.R.R.; Ribeiro, V.A. dos S.; Gonçalves, P.C.; Melo, M. de L.N.M.; Gomes, C.E.M.; dos Santos, V.C. Influence of Superabsorbent Polymer in Self-Compacting Mortar. Buildings 2023, 13. [Google Scholar] [CrossRef]

- Marzouk, H.A.; Arab, M.A.; Fattouh, M.S.; Hamouda, A.S. Effect of Agricultural Phragmites, Rice Straw, Rice Husk, and Sugarcane Bagasse Ashes on the Properties and Microstructure of High-Strength Self-Compacted Self-Curing Concrete. Buildings 2023, 13. [Google Scholar] [CrossRef]

- Evangeline, S. Self Curing Concrete and Its Inherent Properties. Int. J. Eng. Res. Appl. 2014, 4, 66–71. [Google Scholar]

- K, S.; K, V.M.; Kaulgud, N. Morphology Based Surface Crack Detection. J. Adv. Res. Sci. 2015, 1, 15–20. [Google Scholar]

- Studies, P.; Self, O.; Concrete, C.; The, W.; Of, A.; Glycol, P. Self Curing Concrete Project 2014; 2014.

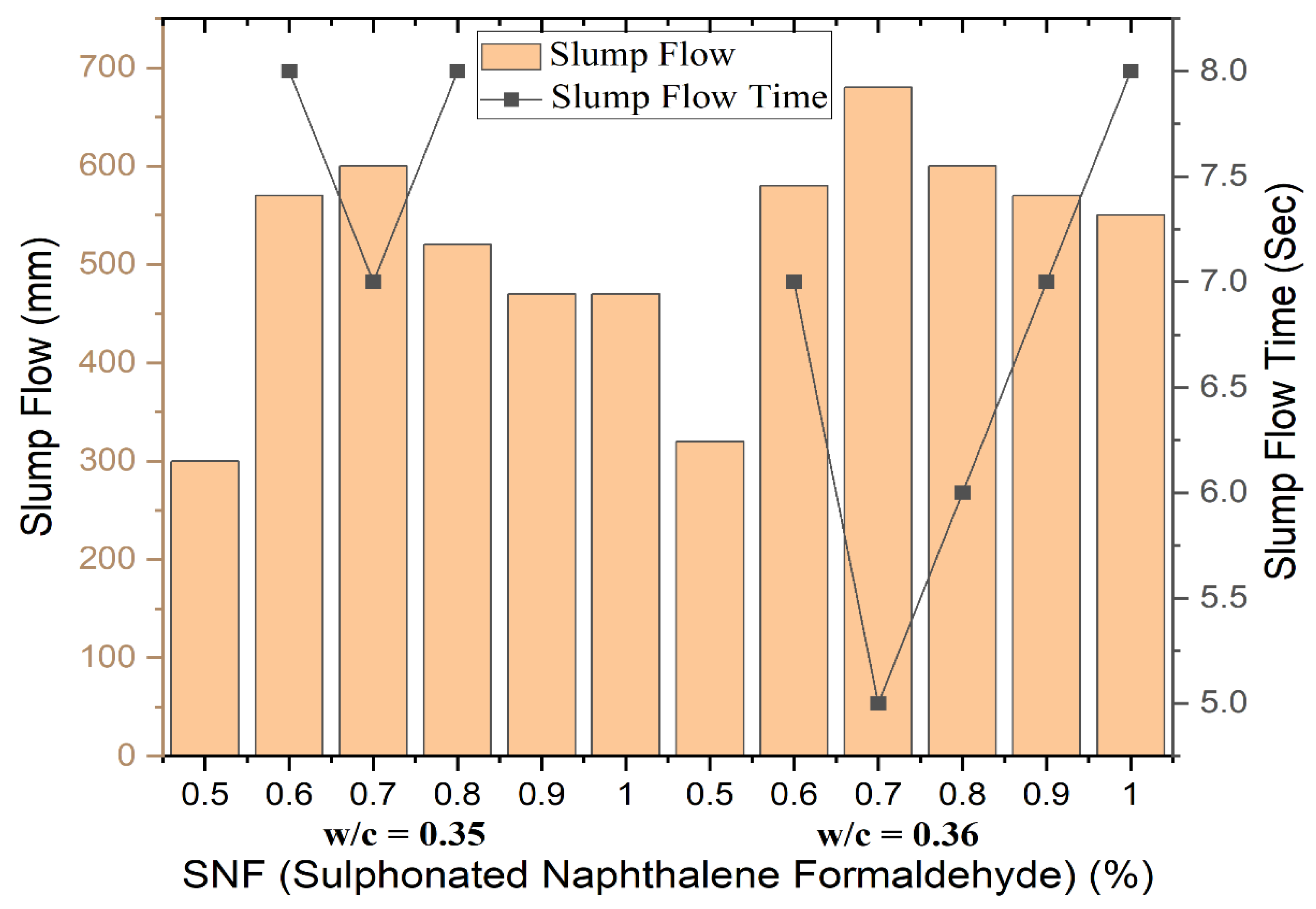

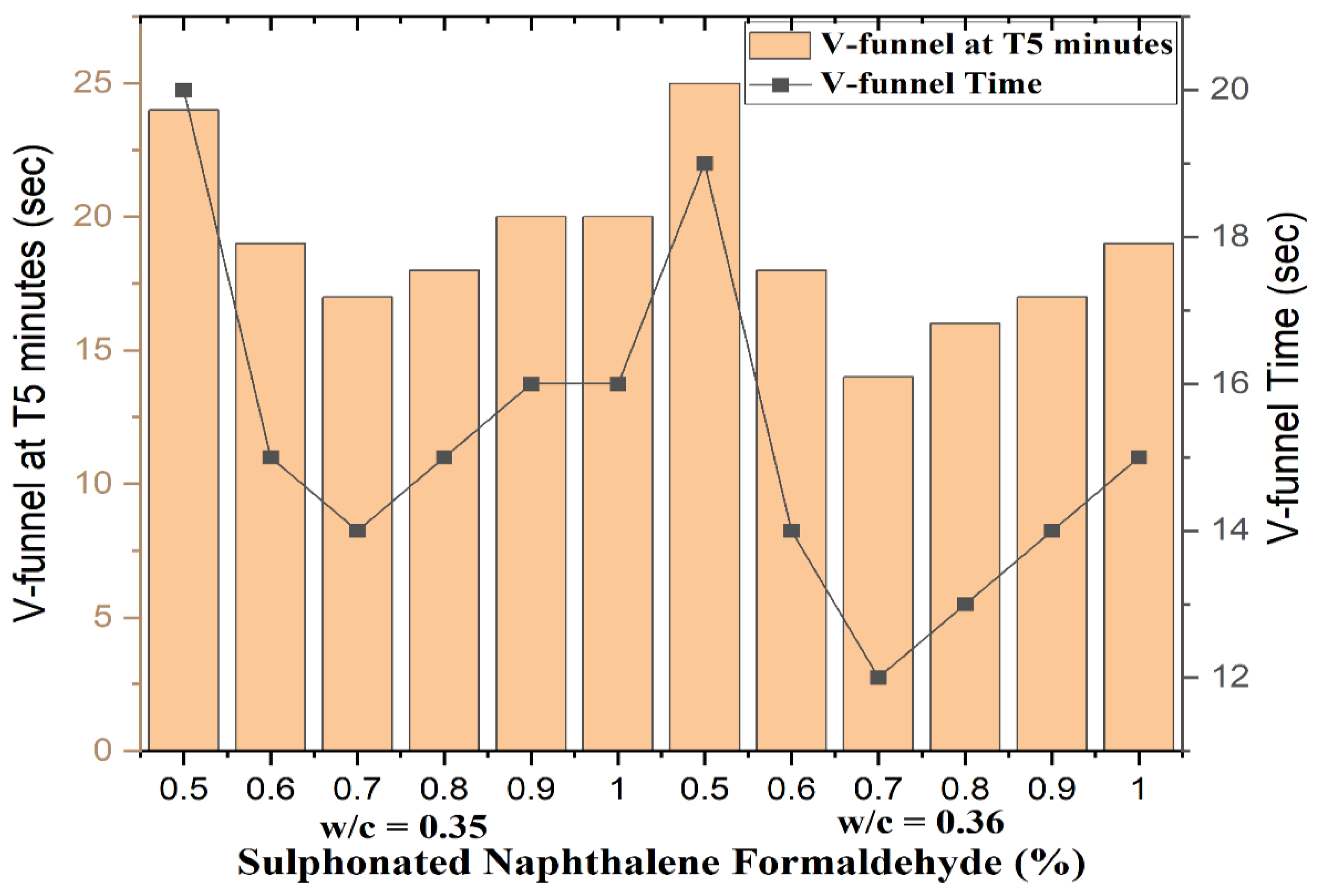

| Mix No. | w/c | SNF (%) | Slump flow table diameter (in mm) | T50 cm slump flow (sec) | V-funnel Time (sec) | V-funnel at T5 minutes (sec) |

|---|---|---|---|---|---|---|

| 1 | .35 | .5 | 300 | - | 20 | 24 |

| 2 | .35 | .6 | 570 | 8 | 15 | 19 |

| 3 | .35 | .7 | 600 | 7 | 14 | 17 |

| 4 | .35 | .8 | 520 | 8 | 15 | 18 |

| 5 | .35 | .9 | 470 | - | 16 | 20 |

| 6 | .35 | 1.0 | 470 | - | 16 | 20 |

| 7 | .36 | .5 | 320 | - | 19 | 25 |

| 8 | .36 | .6 | 580 | 7 | 14 | 18 |

| 9 | .36 | .7 | 680 | 5 | 12 | 14 |

| 10 | .36 | .8 | 600 | 6 | 13 | 16 |

| 11 | .36 | .9 | 570 | 7 | 14 | 17 |

| 12 | .36 | 1.0 | 550 | 8 | 15 | 19 |

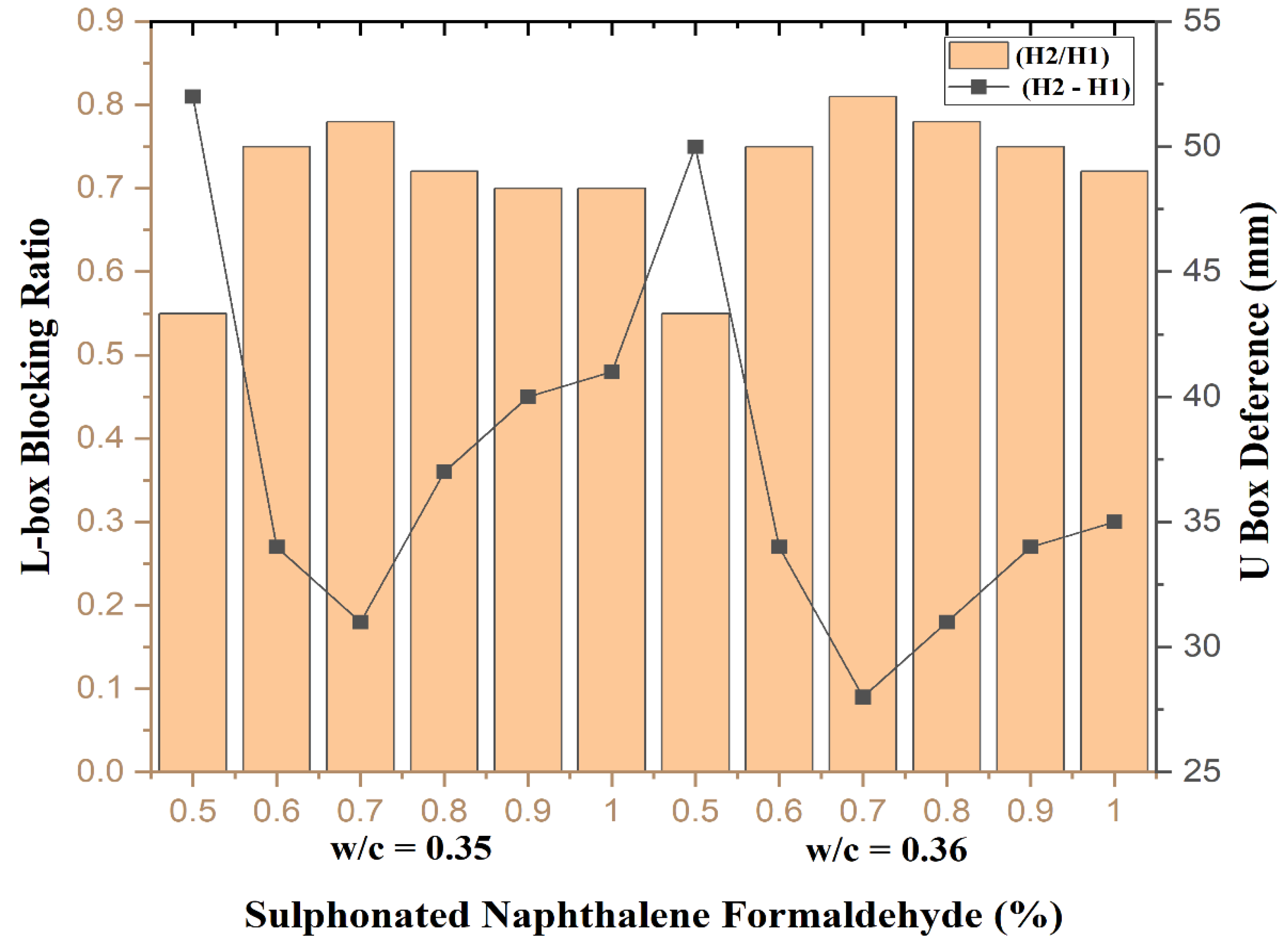

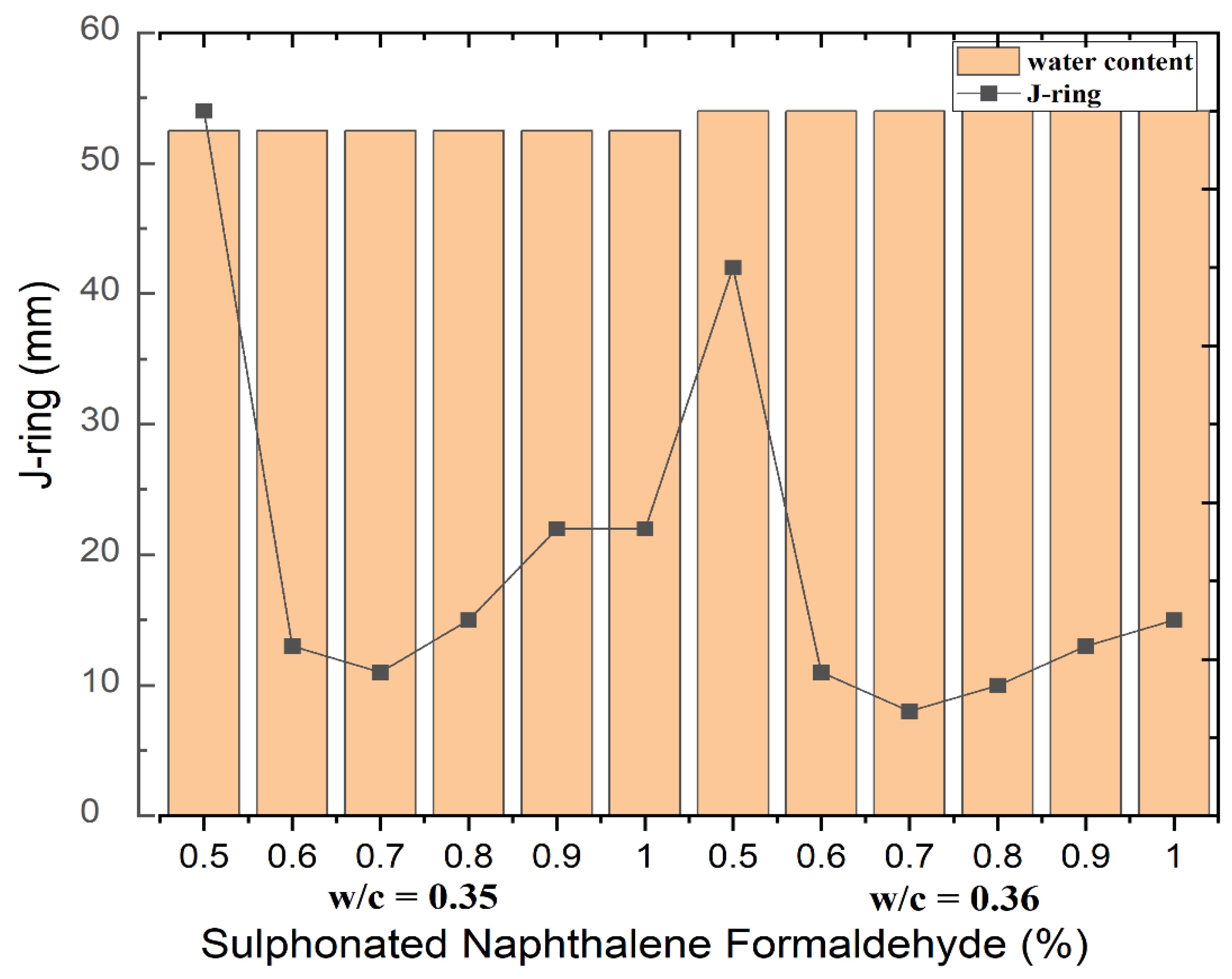

| Mix No. | w/c | SNF (%) | L-box Blocking Ratio (H2/H1) | U Box Difference (H2 - H1) mm | J-ring (mm) |

|---|---|---|---|---|---|

| 1 | .35 | .5 | 0.55 | 52 | 54 |

| 2 | .35 | .6 | 0.75 | 34 | 13 |

| 3 | .35 | .7 | 0.78 | 31 | 11 |

| 4 | .35 | .8 | 0.72 | 37 | 15 |

| 5 | .35 | .9 | 0.7 | 40 | 22 |

| 6 | .35 | 1.0 | 0.7 | 41 | 22 |

| 7 | .36 | .5 | 0.55 | 50 | 42 |

| 8 | .36 | .6 | 0.75 | 34 | 11 |

| 9 | .36 | .7 | 0.81 | 28 | 8 |

| 10 | .36 | .8 | 0.78 | 31 | 10 |

| 11 | .36 | .9 | 0.75 | 34 | 13 |

| 12 | .36 | 1.0 | 0.72 | 35 | 15 |

| Mix No. | PEG4000 | Cement (kg/m3) | Water (kg/m3) | Fine aggregate (kg/m3) | Coarse aggregate (kg/m3) | SNF (%) |

|---|---|---|---|---|---|---|

| M1 | 0% | 550 | 198 | 880 | 720 | 0.7 |

| M2 | .5% | 550 | 198 | 880 | 720 | 0.7 |

| M3 | 1% | 550 | 198 | 880 | 720 | 0.7 |

| M4 | 1.5% | 550 | 198 | 880 | 720 | 0.7 |

| M5 | 2% | 550 | 198 | 880 | 720 | 0.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).