Submitted:

17 July 2023

Posted:

18 July 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Experimental program

2.1. Materials

2.2. Methods

3. Results and Discussion

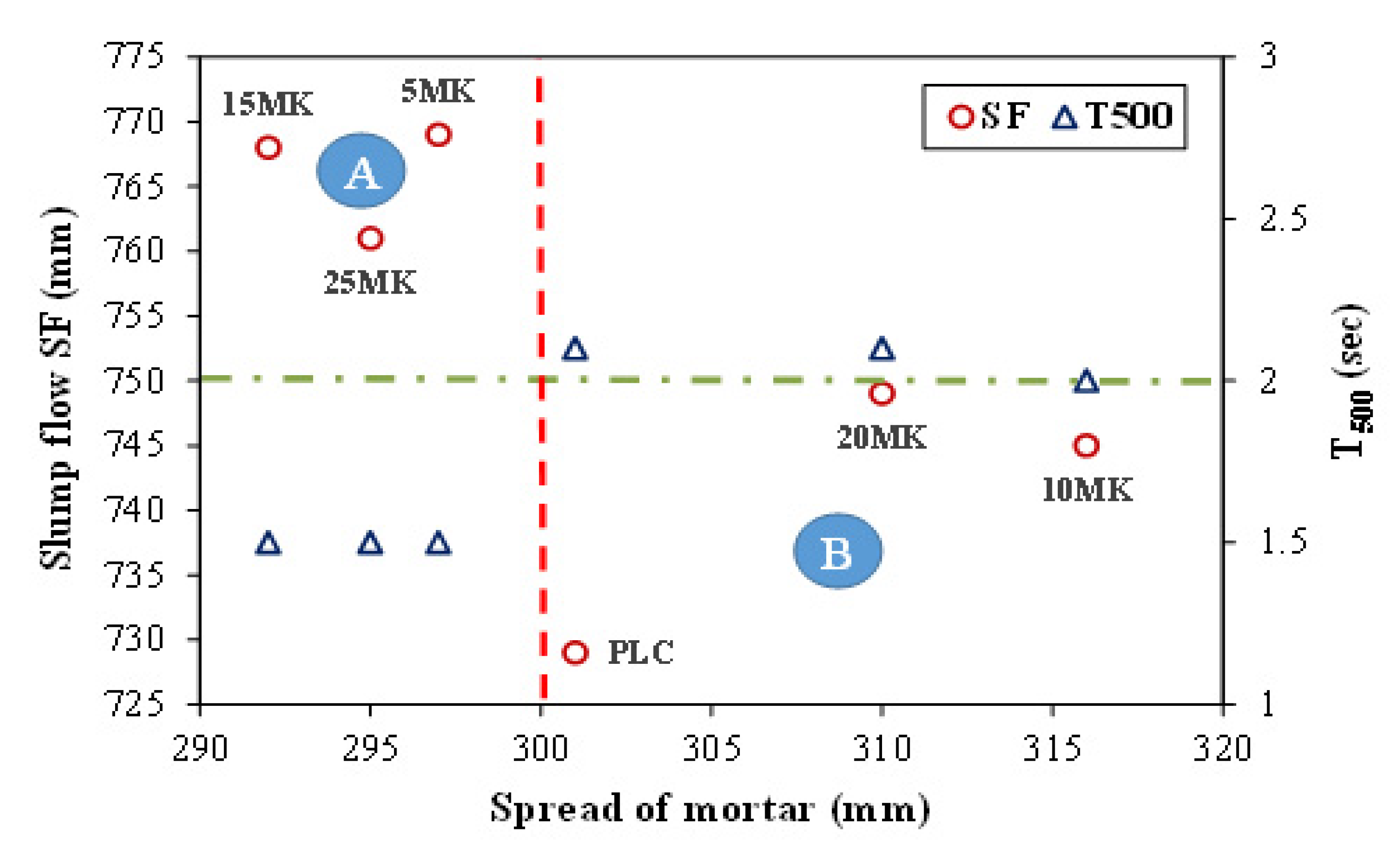

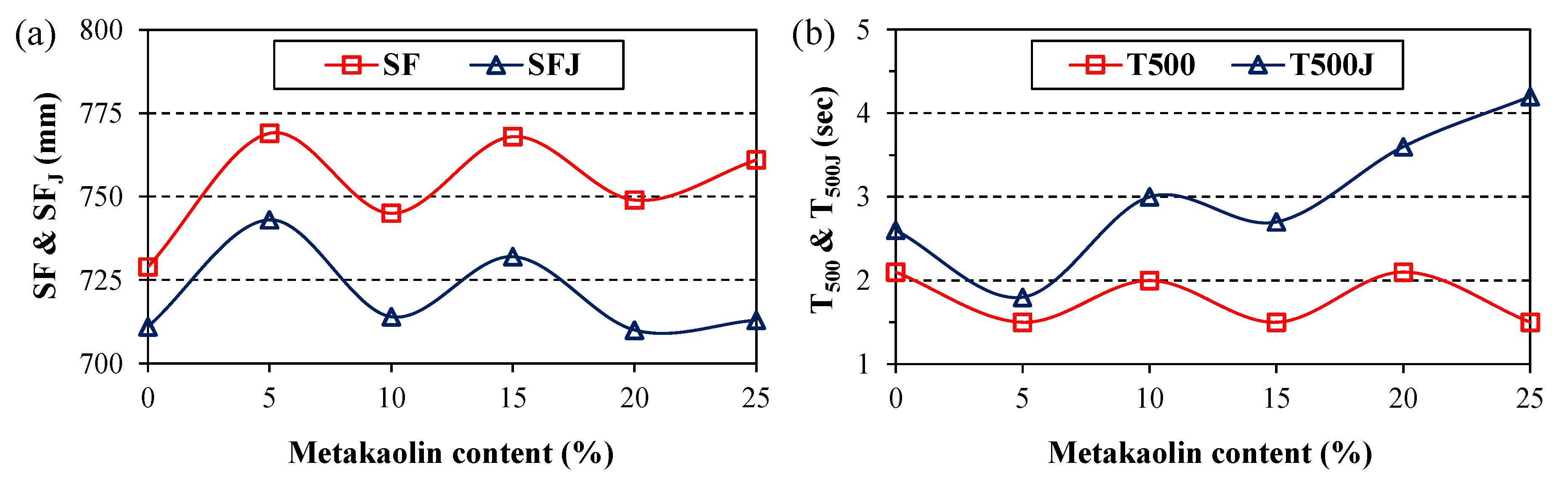

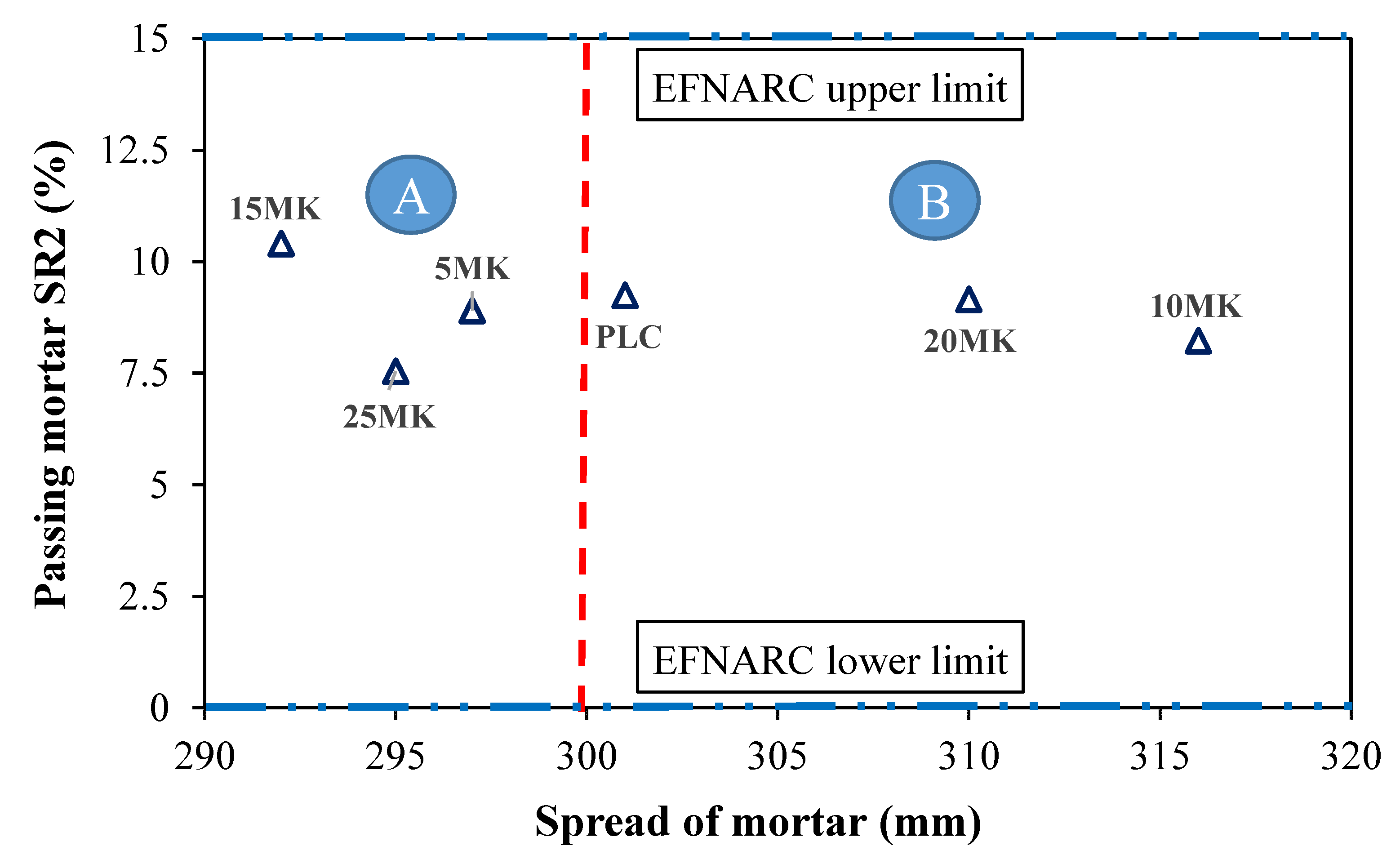

3.1. Filling ability tests of SCC vs. spread of mortar

- (1)

- either that the water content of the SCC will be checked and adjusted downwards in such a way that there will be a spread of category B and consequently, an SCC with a spread ≤ 750 mm and a flow time T500 ≥ 2 s will be produced but the W/B ratio will not be constant for all the mixtures or (2) adding a VEA to the SCC of category A, which belongs to the spreading class SF3 (760 to 850 mm), whose resistance to segregation is more difficult to control [22].

- (2)

- Thus, according to Safiuddin [26], it is recommended to use a VEA in SCC when the mixtures are too fluid and present a risk of segregation which should be improved without changing the primary proportions of concretes. However, the Japanese approach used in this work was developed for concretes without VEA [30] and is extended to concretes with VEA [25].

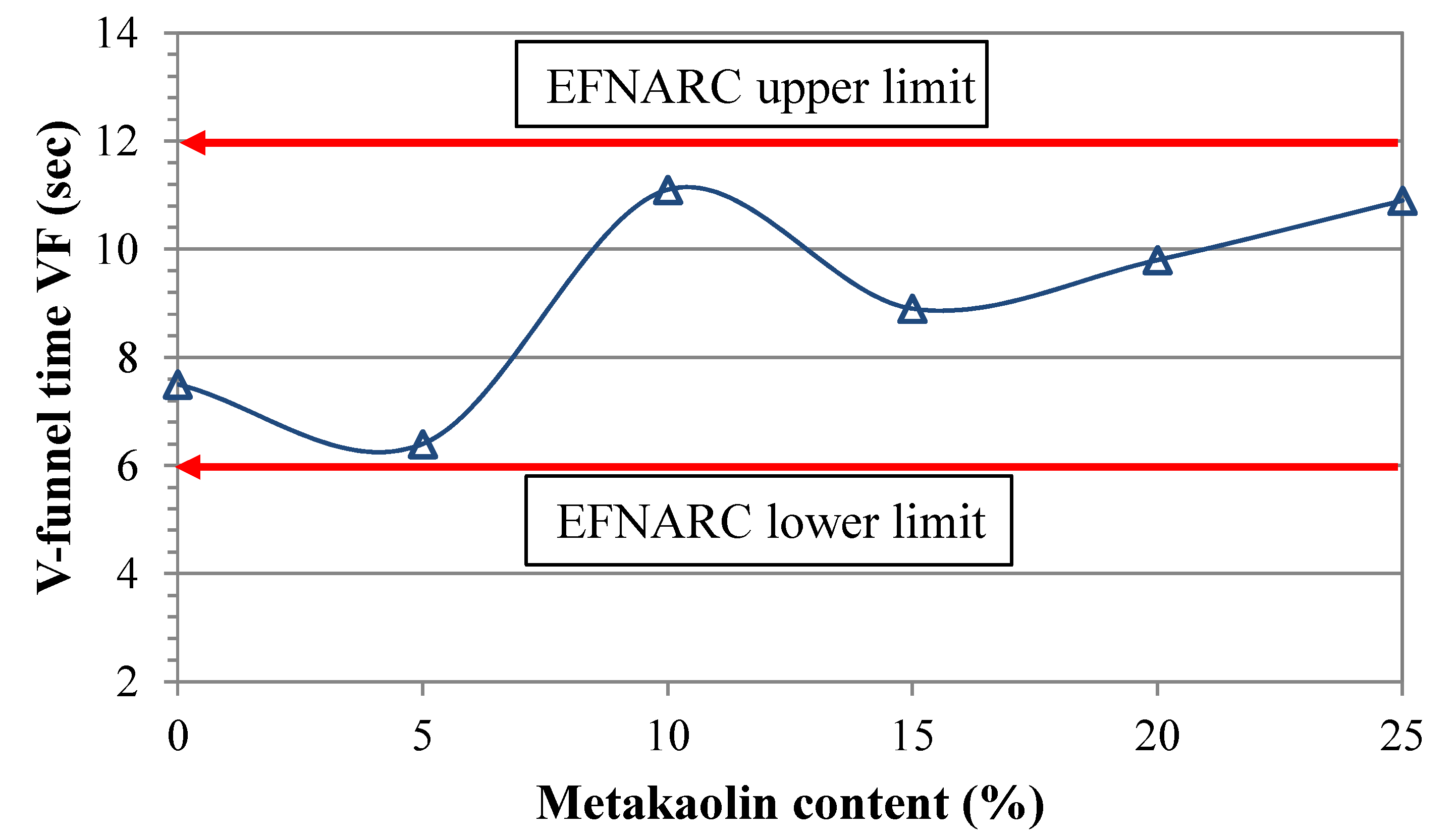

3.2. V-funnel flow time of SCC vs. spread of mortar

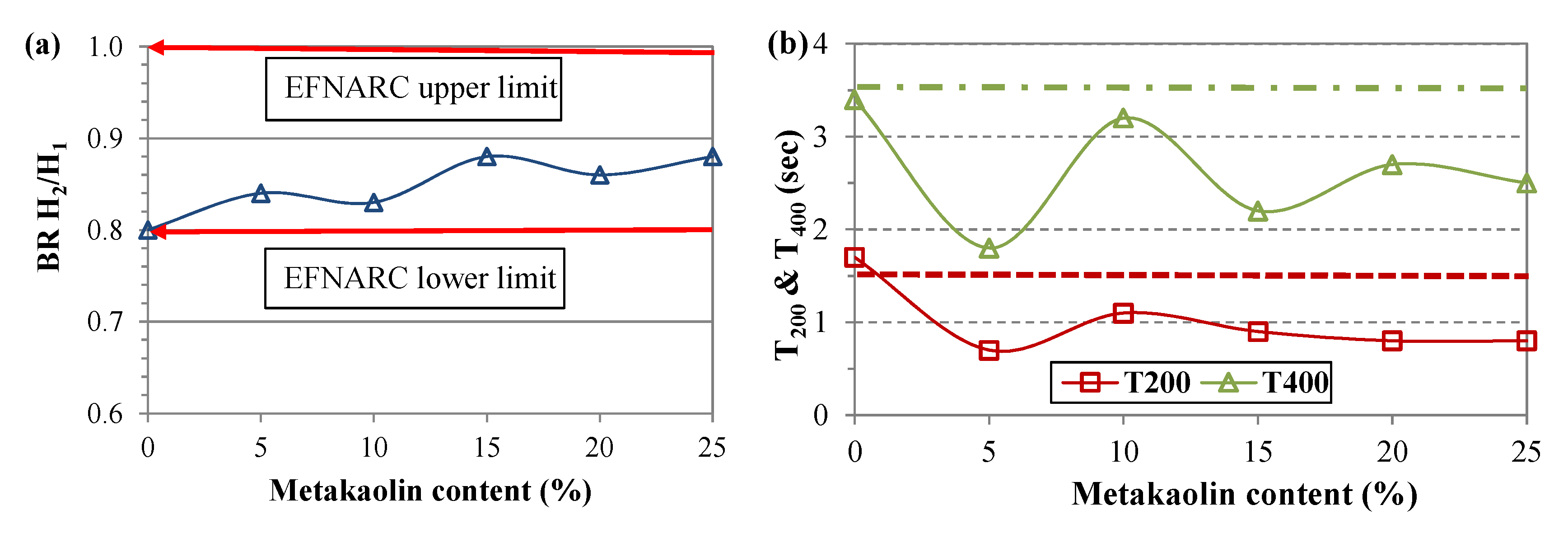

3.3. L-box test of SCC vs. spread of mortar

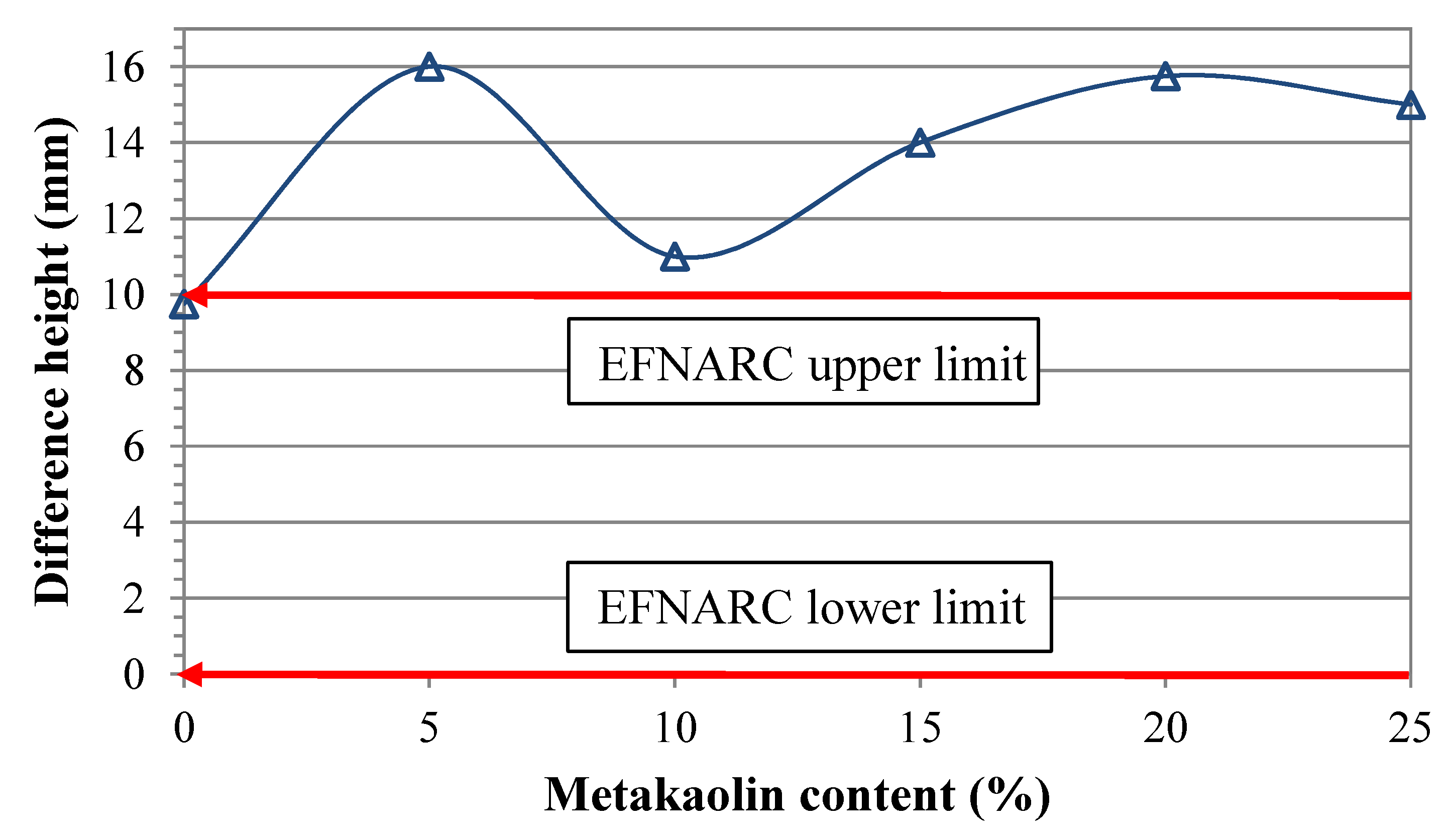

3.4. J-Ring difference height of SCC vs. spread of mortar

3.5. Segregation resistance test of SCC vs. spread of mortar

4. Conclusions

- ✓ A good relationship exists between the spreading of SCM and the fresh properties of the related SCC. The choice of spreading of SCM ≥ 300 mm (PLC, 10MK and 20MK) leads to the desired properties of SCC.

- ✓ The content of MK as cement substitution does not change the relationship between the SCM and its related SCC properties.

- ✓ The choice of spreading value of the SCM must target for an SCC with a Dmax equal to 20 mm: spread value of SCC between 600 mm and 750 mm, flow time (Tv) of 10 s, filing rate value between 0.80 and 0.85 and Pj value ≤ 10 mm.

- ✓ The use of VEA for SCC with higher spread (class SF) and low viscocity (class VS1) is needed to have a good resistance to seggregation.

References

- AFGC. Recommendations for the use of self-compacting concrete. Scientific and technical documents. 2008 [English ed.].

- Haddad, O. Contribution to the development of tools for the formulation of SCC related to fresh properties and strength at early ages. PhD thesis. University of Cergy–Pontoise, France, 2007 [in French].

- Assié, S. Durability of self-compacting concrete. PhD thesis. INSA de Toulouse, France, 2004 [in French].

- Jin, J. Properties of mortar for self-compacting concrete. PhD thesis. University College London, (January 2002).

- Turcry, Ph. , Loukili A. Different approaches for the formulation of self-compacting concrete : influence on the rheological and mechanical characteristics. Revue Française de Génie Civil. Taylor & Francis 7 (4) (2003) 425–450 [in French].

- Okamura, H. , Ouchi M. Self-compacting concrete. Journal of advanced Concrete Technology. Japan Concrete Institute1 (1) (2003) 5–15.

- Niknezhad, D. Contribution for the study of mechanical behaviour, shrinkage and transport properties of self-compacting concrete with mineral additions: Experimental and numerical approach. PhD thesis. INSA Rennes, 2015 [in French].

- Turcry, P. Shrinkage and cracking of self-compacting concrete.: influence of the formulation. PhD thesis. Ecole Centrale de Nantes, 2004 [in French].

- Khatib, J. M. , Siddique, R., Halliday, C., & Khatib, S. (2014). Lime activated fly ash paste in the presence of metakaolin. Procedia Engineering 95, 415–418. [CrossRef]

- Khatib, J. M. , Baalbaki, O., & ElKordi, A. A. (2018). Metakaolin. In Waste and supplementary cementitious materials in concrete (pp. 493-511). Woodhead Publishing. [CrossRef]

- Ouldkhaoua, Y. , Benabed, B., Abousnina, R., Kadri, E. H., & Khatib, J. (2020). Effect of using metakaolin as supplementary cementitious material and recycled CRT funnel glass as fine aggregate on the durability of green self-compacting concrete. Construction and Building Materials, 235, 117802. [CrossRef]

- Singh, H. , & Siddique, R. (2022). Utilization of crushed recycled glass and metakaolin for development of self-compacting concrete. Construction and Building Materials, 348, 128659. Construction and Building Materials. [CrossRef]

- Barkat, A. , Kenai S., Menadi B., Kadri E., Soualhi H. Effects of local metakaolin addition on rheological and mechanical performance of self-compacting limestone cement concrete. Journal of Adhesion Science and Technology 33(9) (2019) 963–985.

- European Standard EN 206–9. Concrete – Part 9: Additional rules for Self-compacting Concrete (SCC). European Committee for Standardization. 2010.

- Domone, P. Mortar tests for self-consolidating concrete – Simple evaluation of materials and mixture proportions. A contribution from ACI Committee 236. Concrete International (April 2006) 39–45.

- Turk, K. Viscosity and hardened properties of self-compacting mortars with binary and ternary cementitious blends of fly ash and silica fume. Construction and Building Materials 37 (2012) 326–334. [CrossRef]

- Safiuddin, Md. , West J.S., Soudki K.A. Flowing ability of the mortars formulated from self-compacting concretes incorporating rice husk ash. Construction and Building Materials 25 (2011) 973–978. [CrossRef]

- Domone, P. , Jin J. Properties of mortar for Self-Compacting Concrete. Proceedings of RILEM International Symposium on Self-Compacting Concrete. Stockholm (September 1999). RILEM Proceedings PRO 7, Paris 109–120.

- Hassan, A.A.A. , Ismail M.K., Mayo J. Mechanical properties of self-consolidating concrete containing lightweight recycled aggregate in different mixture compositions. Journal of Building Engineering 4(2015) 113–126. [CrossRef]

- Perlot, C. , Rougeau P., Dehaudt S. Slurry of metakaolin combined with limestone addition for self-compacted concrete. Application for precast industry. Cement & Concrete Composites 44 (2013) 50–57. [CrossRef]

- Chai H-W. Design and testing of self-compacting concrete. PhD thesis. University of London, 1998. [CrossRef]

- EFNARC. European guidelines for self-compacting concrete: specification, production and use, Self-compacting concrete. European project group 2005.

- RILEM Report 23. Self-compacting concrete – State-of-the-Art Report of RILEM Technical Committee 174-SCC, RILEM publications (2000).

- EFNARC. Specification and guidelines for self-compacting concrete. Norfolk (UK), European federation for specialist construction chemicals and concrete systems; 2002 [English ed.].

- Sedran, T. Rheology and rheometers of concrete. Application to self compacting concrete. PhD thesis. Ecole nationale des ponts et chaussées, Paris, 1999 [in French].

- Safiuddin, Md. Development of Self-Consolidating High Performance Concrete Incorporating Rice Husk Ash. PhD thesis. University of Waterloo, Ontario, Canada, 2008.

- Yahia, A. , Tanimura M., Shimabukuro A., Shimoyama Y. Effect of Rheological Parameters on Self-Compactability of Concrete Containing Various Mineral Admixtures. Proceedings of the First International RILEM Symposium on Self-Compacting Concrete. Stockholm, Sweden (1999) 523–535.

- Barbhuiya S. Effects of fly ash and dolomite powder on the properties of self-compacting concrete. Construction and Building Materials 25 (2011) 3301–3305. [CrossRef]

- Khayat, K.H. Workability, testing, and performance of self-consolidating concrete. ACI Materials Journal 96 (3) (1999) 346–354.

- Phan, T.-H. Rheology and stability of cement pastes used in the formulation of fluid concretes. PhD thesis. Ecole normale supérieure de Cachan, 2007 [in French].

- Koehler, E.P. Aggregates in Self-Consolidating Concrete. PhD thesis. The University of Texas at Austin, 2007.

- Domone, P.L. , Chai H.-W., Jin J. Optimum mix proportioning of self-compacting concrete. Proceedings on International Conference on Innovation in Concrete Structures: Design and Construction. University of Dundee, September 1999. ed Dhir R K and Jones M R, Thomas Telford, London, 277–285.

- Domone, P.L. Self-compacting concrete: An analysis of 11 years of case studies. Cement & Concrete Composites 28 (2006) 197–208. [CrossRef]

- De Schutter, G. Guidelines for Testing Fresh Self-Compacting Concrete. European Research Project: Measurement of Properties of Fresh Self-Compacting Concrete, TESTING-SCC, (September 2005).

- Siddique, R. , Klaus J. Influence of metakaolin on the properties of mortar and concrete: A review. Applied Clay Science 43 (2009) 392–400. [CrossRef]

- Escadeillas, G. Cements with limestone fillers: contribution to their optimization by studying the mechanical and physical properties. PhD thesis. University of Paul-Sabatier Toulouse, France, 1988 [in French].

- Felekoğlu, B. , Türkel S., Baradan B. Effect of Water/Cement Ratio on the Fresh and Hardened Properties of Self-Compacting Concrete. Building and Environment 42 (2007) 1795–1802. [CrossRef]

- Sonebi, M. , Grünewald S., Walraven J. Filling Ability and Passing Ability of Self-Consolidating Concrete. ACI Materials Journal 104 (2) (2007) 162–170.

- Sua-iam, G. , Sokrai P., Makul N. Novel Ternary Blends of Type 1 Portland Cement, Residual Rice Husk Ash, and Limestone Powder to Improve the Properties of Self-Compacting Concrete. Construction and Building Materials125 (2016) 1028–1034. [CrossRef]

- European Standard EN 12350–12. Testing fresh concrete – Part 12: Self-compacting concrete – J-ring test. European Committee for Standardization. 2010.

- Liu, M. Wider application of additions in Self-compacting concrete. PhD thesis. University College London, 2009.

- Yan, W. , Cui W., Qi L. Effect of aggregate gradation and mortar rheology on static segregation of self-compacting concrete. Construction and Building Materials 259 (2020) 119816.

- El-Barrak, M. Contribution to the study of the aptitude to flow of self-compacting concrete at the fresh state. PhD thesis. University of Toulouse III, France, 2005 [in French].

- Prakash, R. , Raman S. N., Divyah N., Subramanian C., Vijayaprabha C., Praveenkumar S. Fresh and mechanical characteristics of roselle fibre reinforced self-compacting concrete incorporating fly ash and metakaolin. Construction and Building Materials 290 (2021) 123209. [CrossRef]

| Sieve size (mm) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 16 | 12.5 | 10 | 8 | 6.3 | 5 | 2.5 | 1.25 | 0.63 | 0.315 | 0.16 | 0.08 | |

| 15– 8 mm | 100 | 98 | 61 | 26 | 6 | 1 | 0 | – | – | – | – | – |

| 8– 3 mm | 100 | 100 | 100 | 98 | 77 | 50 | 5 | 1 | 1 | 1 | – | – |

| Sand | 100 | 100 | 100 | 100 | 100 | 100 | 99 | 98 | 91 | 51 | 9 | 2.55 |

| Category | A | B | ||||

|---|---|---|---|---|---|---|

| MK (%) | 5MK | 15MK | 25MK | PLC | 10MK | 20MK |

| SP (%) | 1.1 | 1.5 | 2.0 | 1.1 | 1.3 | 1.8 |

| Spread (mm) | 297 | 292 | 295 | 301 | 316 | 310 |

| V-funnel (s) | 5.10 | 6.25 | 9.45 | 4.20 | 5.15 | 8.00 |

| Slump flow (mm) | 769 | 768 | 761 | 729 | 745 | 749 |

(s) (s) |

1.50 | 1.50 | 1.50 | 2.10 | 2.00 | 2.10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).