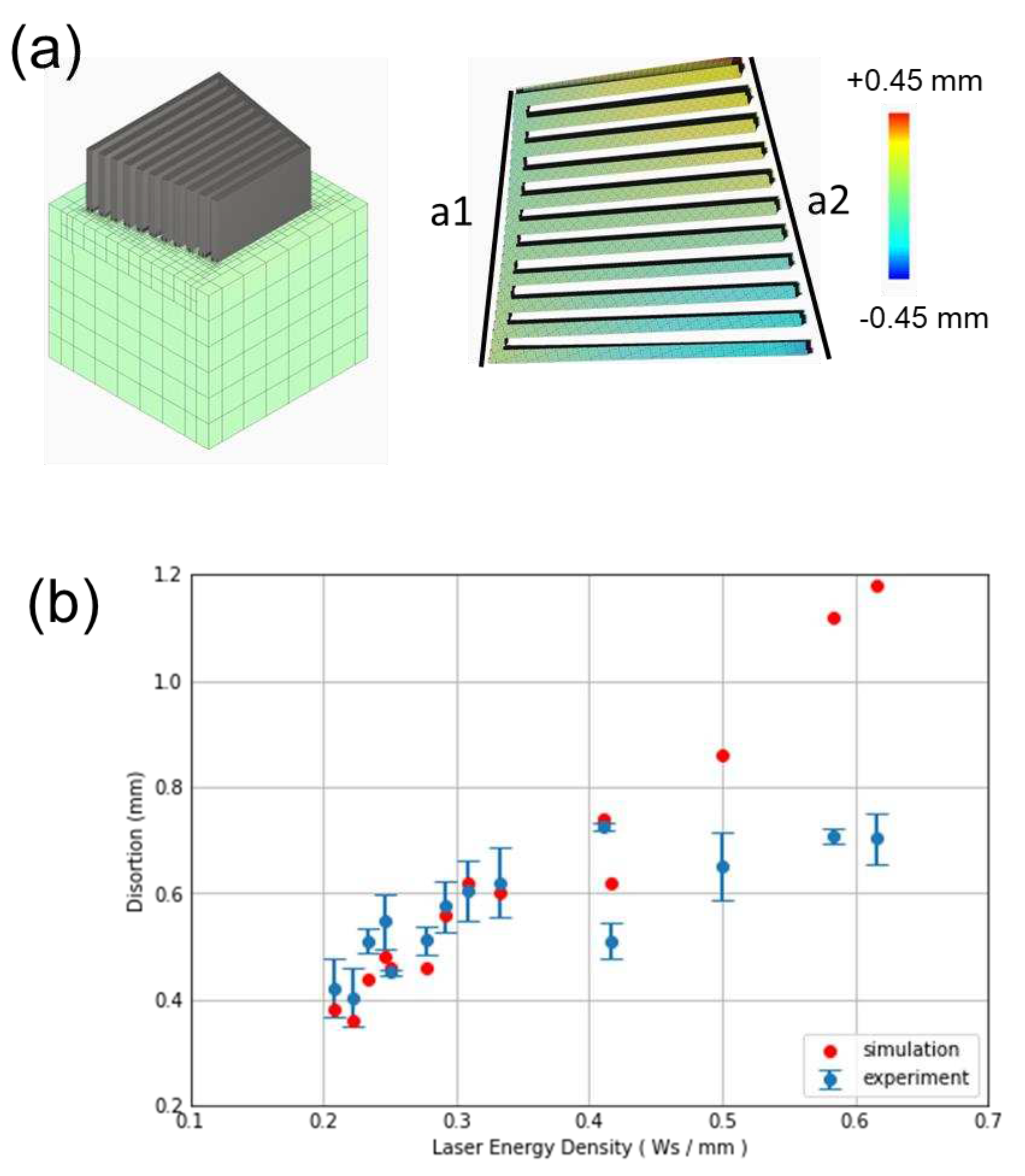

1. Introduction

Additive manufacturing was developed to address the need for producing complex structures on 3D design models [

1,

2]. While early 3D printing primarily focused on prototyping, there has been a recent surge in the use of metal 3D printing for production [

3,

4]. Design for additive manufacturing (DfAM) has been receiving attention due to its potential to decrease part quantities and cut down on assembly time [

5,

6].

With the expanding applications of additive manufacturing, there is a growing need for robust joint structures capable of connecting multiple printed parts [

7]. These joint structures must be able to accommodate high aspect ratios and incorporate heterogeneous materials, catering to specialized requirements such as damage tolerance or core loss reduction [8-10].

Unlike traditional manufacturing, there is a lack of systematic research and established practices specifically focused on the joinability of additive manufactured metal parts. The quality of joints is influenced by surface roughness and thermal distortion [

11]. For instance, when fabricating stacked magnetic slits, insufficient air gaps might result in parts adhering to each other [

12]. Shape optimization methods can help mitigate these issues and minimize core loss [

12,

13]. However, limitations in wall thickness pose challenges for high-density additive manufacturing. Ongoing research aims to improve bonding, develop new materials and advance additive manufacturing technologies to address these challenges.

It is widely recognized that the generation and relaxation of thermal stress are dependent on the direction of additive manufacturing. Therefore, taking into account the direction of stacking is vital when producing products with the minimized thermal distortion [

14,

15]. Specifically, the finger joint shape, created by connecting thin plates, is susceptible to the thermal distortion [

16]. However, the finger joint shape could significantly lower eddy currents in the stack of soft magnetic materials, thereby enhancing the power efficiency of the electromagnet.

Therefore, this study aims to experimentally explore the manufacturing of interlocking joints with varying thicknesses using SUS 17-4PH powder as a model material for such structures. Feasibility and reliability are assessed through additive manufacturing simulations.

2. Materials and Methods

2.1. Design of interlocking structures

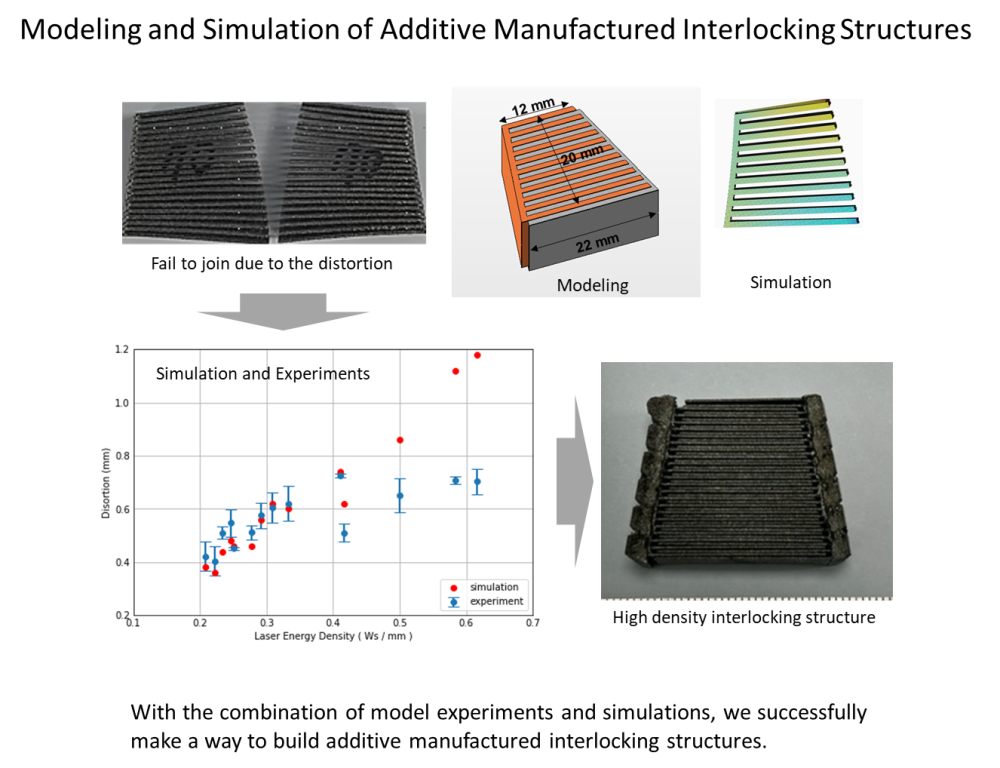

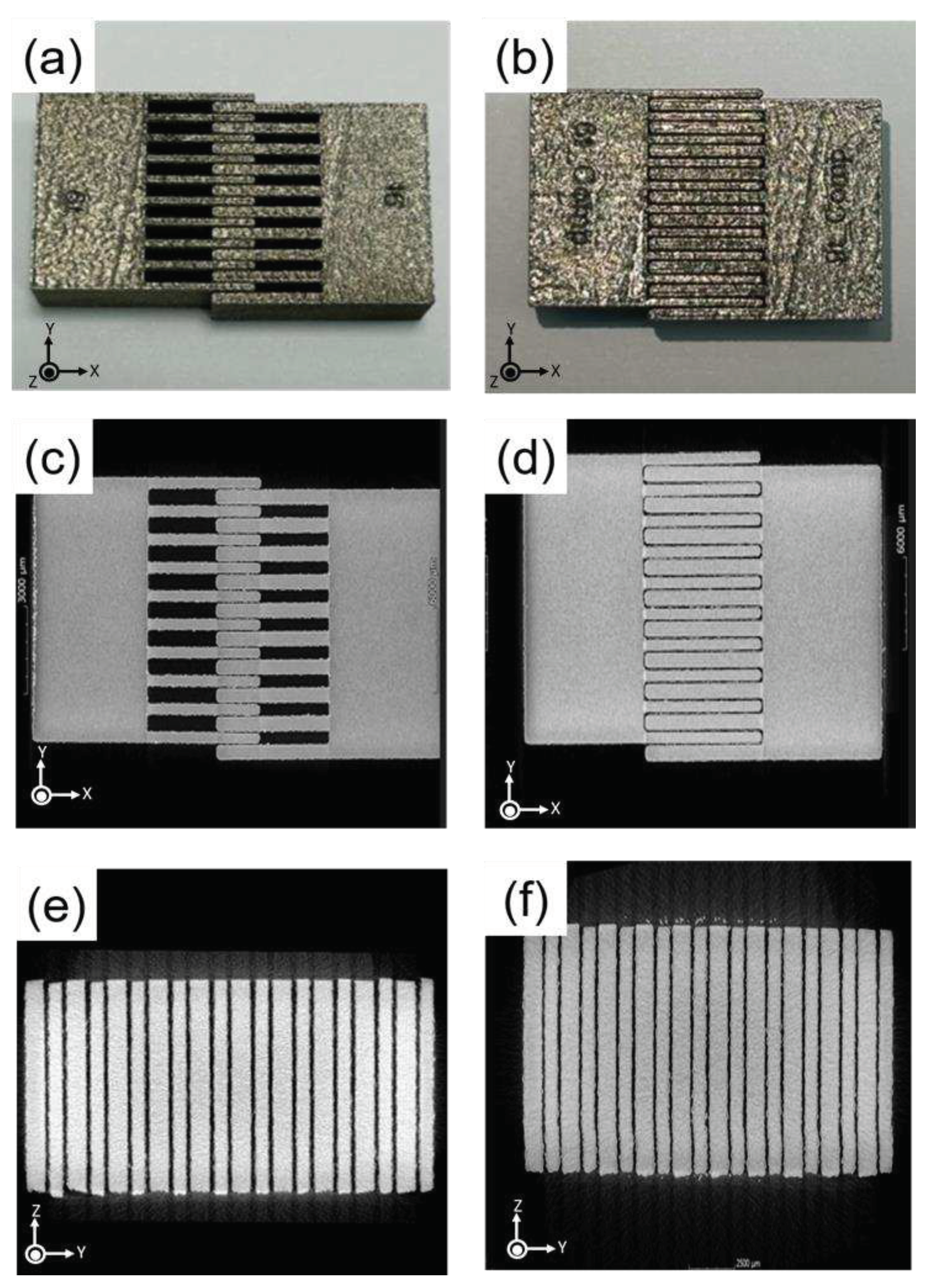

Investigating the effect of the building direction on the joinability, the model interlocking structure was designed as shown in Fig. 1(a) [

15]. The model consists of thick base and 11 highly elongated arms. The thickness of arms (denoted as “t”) changes from 0.5 to 1.0 mm and the distance between adjacent arms were fixed as 2.0 mm. Avoiding the dehiscence in the adjacent arms during sample preparation, the base with 10 mm long was selected. Two interlocking structures can be geometrically joined as shown in Fig. 1(a), which makes two overlapped rectangles. The joining margin is necessary because of the precision margin of error and the distortion during manufacturing. While the joining of two slimmest arm, 0.5 mm, leads 50% filling up the spacing, the thickest arm, 1.0 mm, reaches full density if it connected. Two distinct building direction, a parallel and perpendicular to build plate were considered. The other building directions such as 45, 60° to the build plate were also fabricated but there was no significant difference to the perpendicular to the build plate.

The inclined interlocking structure which leads trapezoid was designed as shown in Fig. 1(b) to estimate the dehiscence, one of major reasons of failure in the interlocking structures. While it consists of 11 arms with 2 mm spacing similar to the previous model, only 1mm thick base structure was applied to investigate systematically the distortion of arms with additive manufacturing conditions such as laser power and scan speed. If the distortion is bigger than the margin, the interlocking structures cannot be joined. To estimate the dehiscence, the difference between the length of base part(a1) and the distance between the outer arms(a2) shown in Fig. 1(b) were characterized.

2.2. Additive manufacturing of interlocking structures

The interlocking structures were made with commercially available 17-4PH stainless steel (SUS 17-4PH, Koswire Co.). SUS 17-4PH is a good candidate model for predicting the distortion during processing and releasing from the build plate as the material parameters for simulation were available in Netfabb Local Simulation. Using Laser powder bed fusion (LPBF) machine, (Concept Laser M2, General Electric), The interlocking structures to investigate the effect of building direction were prepared with laser power of 370 W and scan speed of 1,350 mm/s in perpendicular and parallel to the build plate shown in

Figure 1(a).

By the way, the inclined structures were prepared with 14 different processing conditions to estimate the effect of laser power density on the dehiscence. Laser power changes from 370 W to 200 W while Laser scan speed changes from 600 mm/s to 1500 mm/s. The detailed processing conditions are shown in the

Table 1.prior to publication.

2.3. Joinability test and X-ray CT analysis

Two interlocking structures with distinct arm thickness were aligned in the designed plate. Two parts was pushed within 0.1 MPa pressure to test the joinability measuring the distance between base parts of them. If two interlocking structures are fully joined, the distance between base parts is around 10 mm while the distance is almost 20 mm if they do not join. We performed at least 5 tests for each configuration and the results were classified as fully joined (‘O’ less than 11 mm), half joined (‘∆’ , between 11 mm and 19 mm) and not joined (‘X’ more than 19 mm). To investigate of the joined structure, X-ray CT was introduced to characterize the blocking area carefully.

For inclined structures, the distortions were estimated by computer vision. From 1,200 dpi scanned images of sample, the length difference in the base and arm parts were carefully measured by pixel.

2.4. Simulation of the distortion in additive manufacturing

Netfabb Local Simulation (commercially available from Autodesk) was applied to predict the amount of thermal strain as a function of building direction. The simulation parameters for laser power, scan speed, thickness and scanning strategy were set to be identical with those used in the experiment. The amount of deformation in the perpendicular direction of the joint arm is essential to estimate joinability. Considerations were made to ensure accurate meshing and simulation results. The voxel mesh size was set to be at least twice the minimum wall thickness and was maintained at half the size of the slit. Preserving symmetry during the meshing process was crucial to avoid artifacts and inaccuracies in the simulation. Thus, careful attention was given to meshing operations to maintain reliability.

With the consideration of distortion, the compensated design could be obtained in Netfabb Local Simulation. The displacement of each mesh was individually calculated, and the negative movement was applied. Finally, the compensated structures for interlocking models were prepared.

3. Results

3.1. The effect of building direction on joinability of interlocking structures

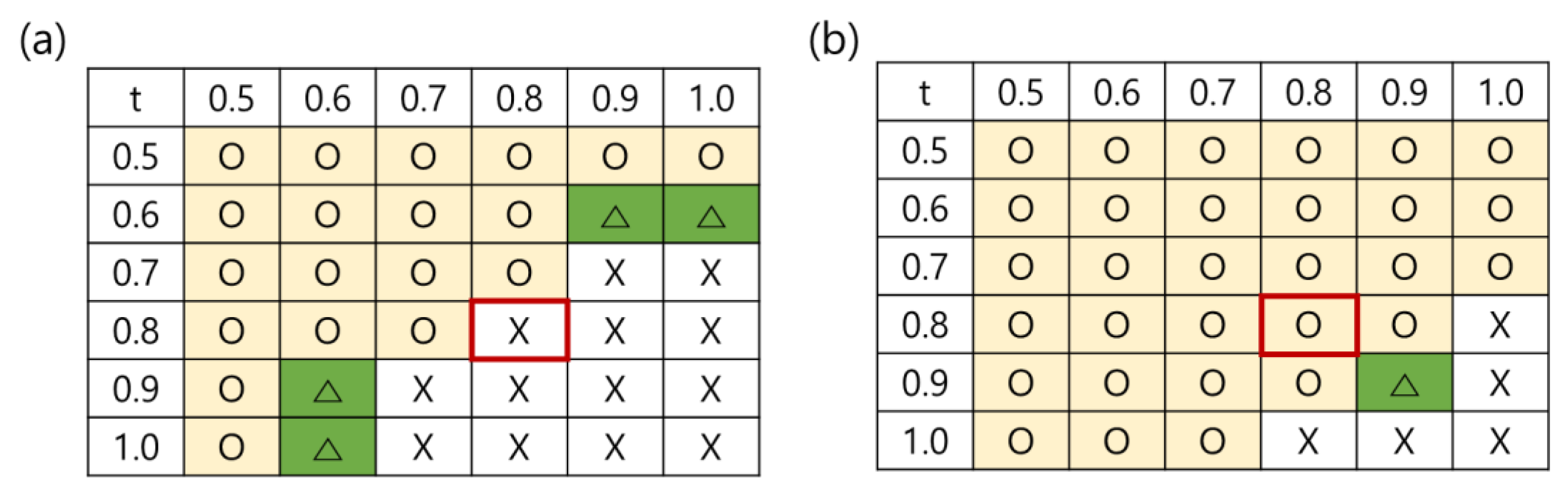

The assembly experiments on joint specimens manufactured by PBF processes were conducted with different thicknesses and orientations with respect to the build plate. The results were summarized in

Table 2.

Table 2(a) shows the results for specimens printed parallel to the build plate. The assembly success varied depending on the thickness of the joint arm (denoted as "t"). For a joint arm thickness of 0.5 mm, all dimensions were successfully assembled. However, as the joint arm thickness increased to 0.6 mm, the assembly with 0.9 mm and 1.0 mm specimens was not perfect. Further, at a joint arm thickness of 0.7 mm, only the 0.9 mm and 1.0 mm specimens failed to assemble, and for 0.8 mm joint arm thickness, assembly failures occurred from 0.8 mm to 1.0 mm specimens. In the case of joint arm thicknesses of 0.9 mm and 1.0 mm, the 0.5 mm specimen was completely assembled, while the 0.6 mm specimen only achieved partial assembly, and the remaining dimensions were not assembled.

Table 2(b) presents the results for specimens printed perpendicular to the build plate. Here, the assembly success was generally better than those printed parallel to the build plate. For joint arm thicknesses ranging from 0.5 mm to 0.7 mm, all dimensions were successfully assembled. At a joint arm thickness of 0.8 mm, only the 1.0 mm specimen failed to assemble. With a joint arm thickness of 0.9 mm, partial assembly was achieved for the 0.9 mm specimen, while the 1.0 mm specimen was not assembled. Finally, for a joint arm thickness of 1.0 mm, assembly was made up to the dimensions of 0.7 mm, and specimens from 0.8 mm to 1.0 mm was not assembled.

It was observed that parallel printing exhibited more assembly failures and required sufficient margin for successful assembly. In contrast, perpendicular printing showed minimal thermal deformation and achieved successful assembly for most dimensions. This result can be understood that the printing area of arms in perpendicular direction are smaller than those in parallel direction at the given layer. It demonstrates the building policy can significant affect the joinability in the interlocking structure.

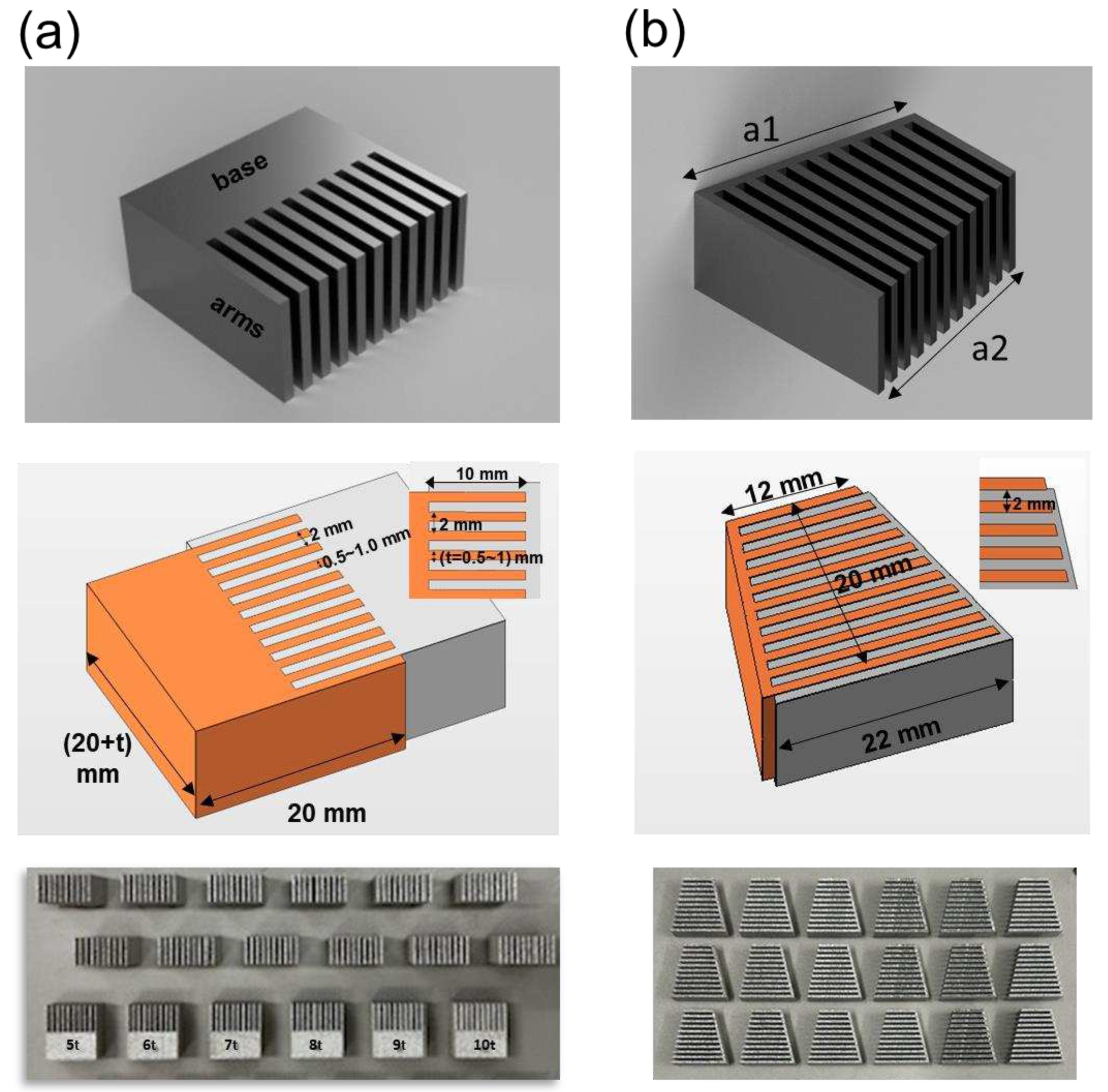

To analyze quantitively the thermal stress and residual stress, additive manufacturing simulations were performed using Netfabb Local Simulation [

17]. In Fig. 2(a), two distinct building directions to the build plate was shown.

Figure 2(b) displayed the simulation results for a specimen printed with the additive manufacturing direction parallel to the build plate. The red areas indicated inward deformation of the joint arm, while the blue areas represented outward deformation. It was evident that the joint arm experienced significant deformation inward due to thermal and residual stress. In contrast,

Figure 2(c) showed only the uniform displacement in joint arms when they printed perpendicular to the build plate. Consequently, the building policy that the interlocking structure prints perpendicular to the build plate was an effective approach to improve assembly properties, by minimizing the influence of thermal stress and residual stress on the joint arm. These simulation results are consistent with the experimental observations. maintain reliability.

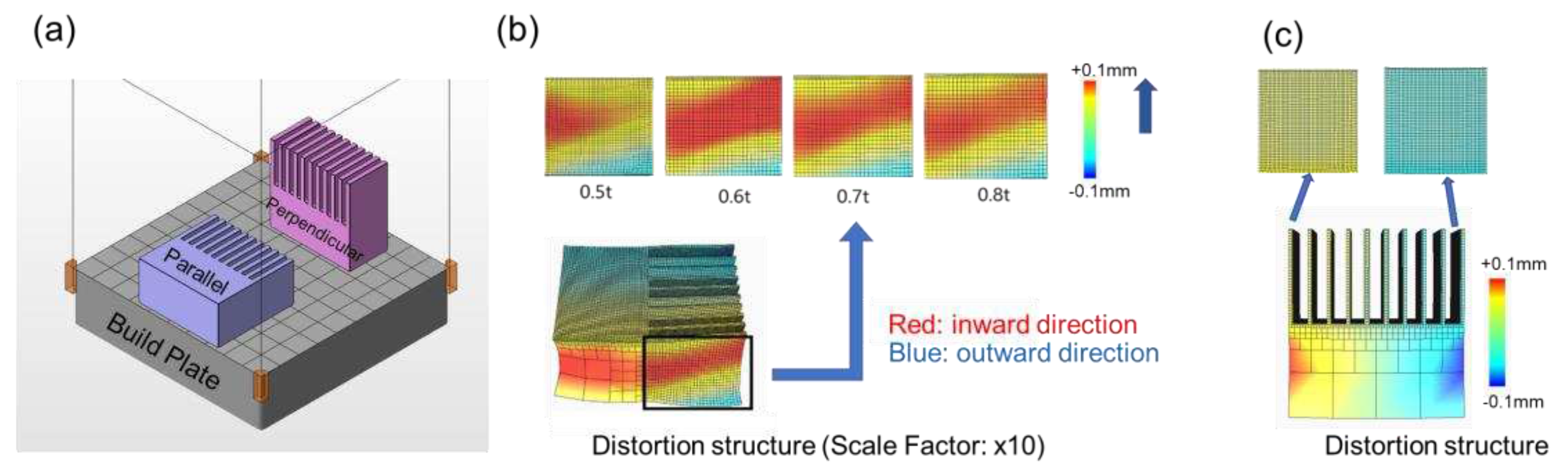

3.2. The effect of laser energy density on the dehiscence in interlocking structures

One of the major reasons for the failure to join the additive manufactured interlocking structures is the dehiscence of arms when the original structure is not symmetrical. In Fig. 3(a), the simulation result of the inclined models with 370 W laser power and 900 mm/s scan speed shows the dehiscence of joint arms, 0.41 mm after releasing the build plate. The dehiscence can be measured by the difference between base length(a1) and total arm spacing(a2) shown in Fig. 3(a). It is found that the open-up of the joint arms due to the thermal stress are expected.

Figure 3(b) shows the experimental and calculated dehiscence as a function of laser energy density, laser power per scan speed. As the laser energy density increases, the calculated distortions, represented as red dots, are increasing. It is common that the thermal distortion increases as the laser power is higher and scan speed is slower. The experimental measurements of the dehiscence in the lower laser energy density, 0.35 W∙s/mm, are reasonably consistent with the calculations. It indicates that the materials parameters for simulation are well calibrated within the suitable processing conditions. It is worth to mention that the one of recommendation values for laser power and scan speed in SUS 17-4PH are 370 W and 1,350 mm/s, respectively, which leads is 0.27 W∙s/mm. Therefore, the dehiscence of joint arms can be predicted by simulations within the general processing condition.

However, as the laser energy intensity increases, the measured distortions in experiments are much lower than the calculated one. This inconsistency can be understood that the high laser energy density decreases the density with the key-hole effect and so on. The thermal stress model in the simulation software does not significantly consider the decrease of density to the keyhole effect on thin wall problems.

With the combination of calculations and model experiments, the dehiscence in the interlocking structures is investigating systemically. It shows that the dehiscence in the interlocking structure is strongly related to the laser energy density within the processing conditions and can be calculated with the simulations [

18]. The higher laser energy density, the difference between the experiments and calculation increases which seems to be related to the decrease of density and so on.

3.3. Compensated structrue to improve joinability

These result shows that the design and control of thermal distortions are essential for interlocking structures to improve joinability. One of practical approaches to reduce the distortion is using the compensated structure with the simulation [

19]. Calculating the displacement of each mesh, compensated structure could be built with the negative movement in each position.

Here, experimental tests demonstrated that specimens with compensated design achieved better assembly compared to those manufactured in the previous parallel direction. The outward deformation of the joint arm in the specimen by implementing compensated design were applied based on predicted deformation amounts. Through the simulation, it was determined that the largest deformation occurred with a joint arm thickness of 0.6 mm.

Figure 4(a) depicted the assembly of normal 0.6 mm and 0.9 mm specimens manufactured in the conventional parallel direction, while

Figure 4(b) showed the assembly of compensated 0.6 mm and 0.9 mm specimens manufactured with compensated design. The conventional parallel assembly achieved only about 1/4 assembly, whereas the specimens with compensated design were perfectly assembled. The complex shapes of parts manufactured through metal 3D printing often result in non-uniform stress distribution at the assembly sites. Therefore, compensating of assembly parts, leading to increased stability and durability.

To further evaluate the assembly quality and deformation in relation to the compensated design, X-ray computed tomography (CT) was utilized. X-ray CT scans were performed on the assembly tests of 0.6 mm and 0.9 mm specimens manufactured in the parallel direction (

Figure 4c,e). Additionally, X-ray CT scans were conducted on the assembly tests of 0.6 mm and 0.9 mm specimens with the compensated design applied (

Figure 4d,f).

The X-ray CT measurements revealed that, when comparing joint tests with the same thickness, the assembly of specimens with compensated design exhibited superior results compared to those manufactured in the previous parallel direction. This finding, obtained through X-ray CT analysis, provided further evidence of the improved assembly quality achieved by implementing compensated design.

4. Discussion

The study focuses on achieving a high-density coupling structure in metal joints for product assembly. Additive manufacturing techniques were employed to predict and analyze thermal deformation during the manufacturing process, as well as the maximum deformation of the joint arm after cutting, using simulation. The results indicate that additive manufacturing in a perpendicular direction to the build plate leads to improved assembly properties due to reduced deformation caused by thermal strain during cutting, as compared to the parallel direction. Furthermore, incorporating simulation predictions into the design stage resulted in enhanced assembly for the compensated product, surpassing the parallel output.

Challenges arise when perpendicular manufacturing is not feasible or when the height of the printed object increases, resulting in the accumulation of thermal stress within the printed structure. In such cases, optimizing the printing height becomes crucial, and exploring the possibility of assembly by adjusting the angle towards the parallel direction becomes significant. Obtaining quantified values and results in this regard is vital to ensure reliability and stability in additive manufacturing, save time, and enhance the precision of printed objects.

Additionally, the study highlights the importance of magnetic 3D printing, which enables the production of parts with unique properties and functions not achievable with traditional 3D printing materials. Magnetic 3D printing offers the advantage of creating objects with magnetic properties, finding applications in various fields such as robotics, sensors, and electronics. It also allows to produce parts capable of changing shape or behavior in response to a magnetic field, facilitating the development of adaptable components and sensors. The ability to produce complex geometries that are not feasible with conventional manufacturing methods leads to cost savings, improved efficiency, and customization of parts for specific applications. Hence, research and development in magnetic 3D printing are crucial as it has the potential to revolutionize the manufacturing industry by enabling the production of objects with unique properties and functions.

5. Conclusions

In this study, we systematically studied the joinability of additive manufactured interlocking structures. Due to the distortion of interlocking arms during processing, the design margin is necessary. With the combination of simulations and experiments, it was found that the thermal distortion due to the building direction or the laser energy density play an important role in joinability. This study demonstrate that the amount of distortion related to the manufactured area in the layer and processing parameters such as laser power and scan speed can be estimated with simulations in SUS 17-4PH, which is essential to design the margin of interlocking structure. However, the inconsistency between calculated distortion and experimental observation occurs when the laser energy density is high to reduce the density of parts.

Moreover, with the simulated distortion results, the quality of interlocking could be improved with the compensated model. To ensure the joinability of the interlocking structure, it is noteworthy that the careful choice of building strategy and simulation is necessary in the fabrication of interlocking structures via additive manufacturing.

Author Contributions

Y.R.Kim and E.A. Kim performed all of the experiments, H.S. Lee carried out the additive manufacturing simulations. S. Won performed X-ray CT analysis. J.P. Choi, T.Ha and J.B.Jeon help deep and fruitful discussions. S.H. Kwon and H.S. Lee planned this research.

Funding

This work was also supported by National Research Foundation of Korea (NRF) funded by Ministry of Science and ICT (grant number: 2021M3D1A2047724).

Acknowledgments

This work was also supported by National Research Foundation of Korea (NRF) funded by Ministry of Science and ICT (grant number: 2021M3D1A2047724). The authors specially thanks to Autodesk Korea and VAXE(vaxe.co.kr) for sharing their software and knowledge.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bandyopadhyay, A.; Heer, B. Additive manufacturing of multi-material structures. Materials Science and Engineering: R: Reports 2018, 129, 1–16. [Google Scholar] [CrossRef]

- Lu, B.; Li, D.; Tian, X. Development trends in additive manufacturing and 3D printing. Engineering 2015, 1, 085–089. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.; Zuback, J.; Mukherjee, T.; Elmer, J.; Milewski, J.; Beese, A.M.; Wilson-Heid, A.d.; De, A.; Zhang, W. Additive manufacturing of metallic components–process, structure and properties. Progress in Materials Science 2018, 92, 112–224. [Google Scholar] [CrossRef]

- DebRoy, T.; Mukherjee, T.; Milewski, J.; Elmer, J.; Ribic, B.; Blecher, J.; Zhang, W. Scientific, technological and economic issues in metal printing and their solutions. Nature materials 2019, 18, 1026–1032. [Google Scholar] [CrossRef] [PubMed]

- Vaneker, T.; Bernard, A.; Moroni, G.; Gibson, I.; Zhang, Y. Design for additive manufacturing: Framework and methodology. CIRP Annals 2020, 69, 578–599. [Google Scholar] [CrossRef]

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. CIRP annals 2016, 65, 737–760. [Google Scholar] [CrossRef]

- Peralta Marino, G.; De la Pierre, S.; Salvo, M.; Díaz Lantada, A.; Ferraris, M. Modelling, additive layer manufacturing and testing of interlocking structures for joined components. Scientific Reports 2022, 12, 2526. [Google Scholar] [CrossRef] [PubMed]

- Tiismus, H.; Kallaste, A.; Belahcen, A.; Tarraste, M.; Vaimann, T.; Rassõlkin, A.; Asad, B.; Shams Ghahfarokhi, P. AC magnetic loss reduction of SLM processed Fe-Si for additive manufacturing of electrical machines. Energies 2021, 14, 1241. [Google Scholar] [CrossRef]

- Bayramlı, E.; Gölgelioğlu, Ö.; Ertan, H.B. Powder metal development for electrical motor applications. Journal of Materials Processing Technology 2005, 161, 83–88. [Google Scholar] [CrossRef]

- Guo, Y.; Zhu, J.G.; Lin, Z.W.; Zhong, J.J. 3D vector magnetic properties of soft magnetic composite material. Journal of magnetism and magnetic materials 2006, 302, 511–516. [Google Scholar] [CrossRef]

- Paul, R.; Anand, S.; Gerner, F. Effect of thermal deformation on part errors in metal powder based additive manufacturing processes. Journal of manufacturing science and Engineering 2014, 136, 031009. [Google Scholar] [CrossRef]

- Koo, B.; Jang, M.-S.; Nam, Y.G.; Yang, S.; Yu, J.; Park, Y.H.; Jeong, J.W. Structurally-layered soft magnetic Fe-Si components with surface insulation prepared by shell-shaping selective laser melting. Applied Surface Science 2021, 553, 149510. [Google Scholar] [CrossRef]

- Manninen, A.; Pippuri-Mäkeläinen, J.; Riipinen, T.; Lindroos, T.; Metsä-Kortelainen, S.; Antikainen, A. The Mitigation of Eddy-Current Losses in Ferromagnetic Samples Produced by Laser Powder Bed Fusion. IEEE Access 2022, 10, 115571–115582. [Google Scholar] [CrossRef]

- Byun, H.-S.; Lee, K.H. Determination of the optimal build direction for different rapid prototyping processes using multi-criterion decision making. Robotics and Computer-Integrated Manufacturing 2006, 22, 69–80. [Google Scholar] [CrossRef]

- Chowdhury, S.; Mhapsekar, K.; Anand, S. Part build orientation optimization and neural network-based geometry compensation for additive manufacturing process. Journal of Manufacturing Science and Engineering 2018, 140, 031009. [Google Scholar] [CrossRef]

- Sanaei, N.; Fatemi, A.; Phan, N. Defect characteristics and analysis of their variability in metal L-PBF additive manufacturing. Materials & Design 2019, 182, 108091. [Google Scholar]

- Pal, D.; Patil, N.; Zeng, K.; Stucker, B. An integrated approach to additive manufacturing simulations using physics based, coupled multiscale process modeling. Journal of Manufacturing Science and Engineering 2014, 136, 061022. [Google Scholar] [CrossRef]

- Jhabvala, J.; Boillat, E.; Antignac, T.; Glardon, R. On the effect of scanning strategies in the selective laser melting process. Virtual and physical prototyping 2010, 5, 99–109. [Google Scholar] [CrossRef]

- Afazov, S.; Okioga, A.; Holloway, A.; Denmark, W.; Triantaphyllou, A.; Smith, S.-A.; Bradley-Smith, L. A methodology for precision additive manufacturing through compensation. Precision Engineering 2017, 50, 269–274. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).