Submitted:

19 September 2023

Posted:

20 September 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

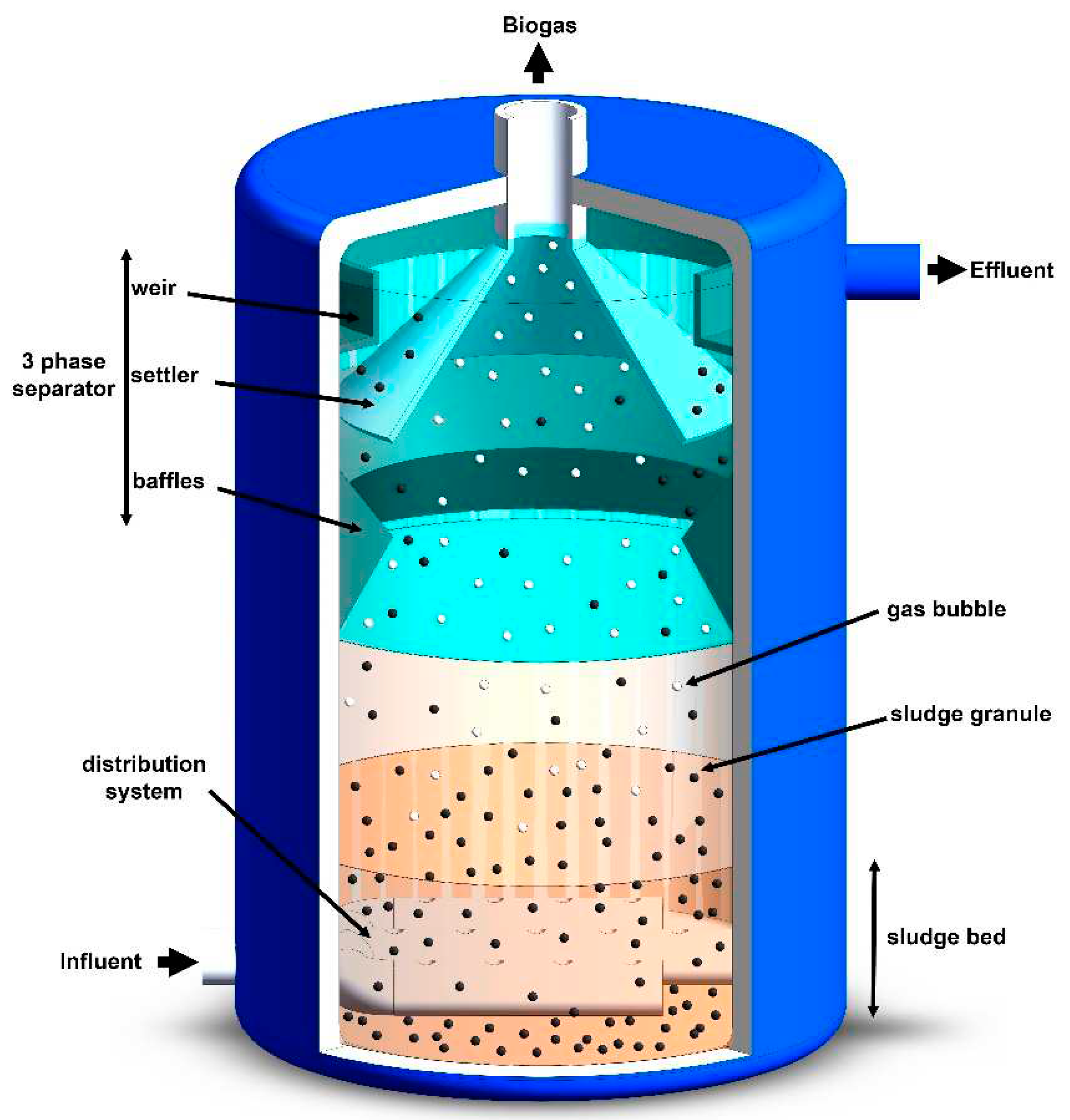

2. Up-flow anaerobic sludge blanket reactors

3. Mechanisms and influencing parameters in textile decolorization in UASB reactors

4. Dye wastewater treatment in UASB reactors

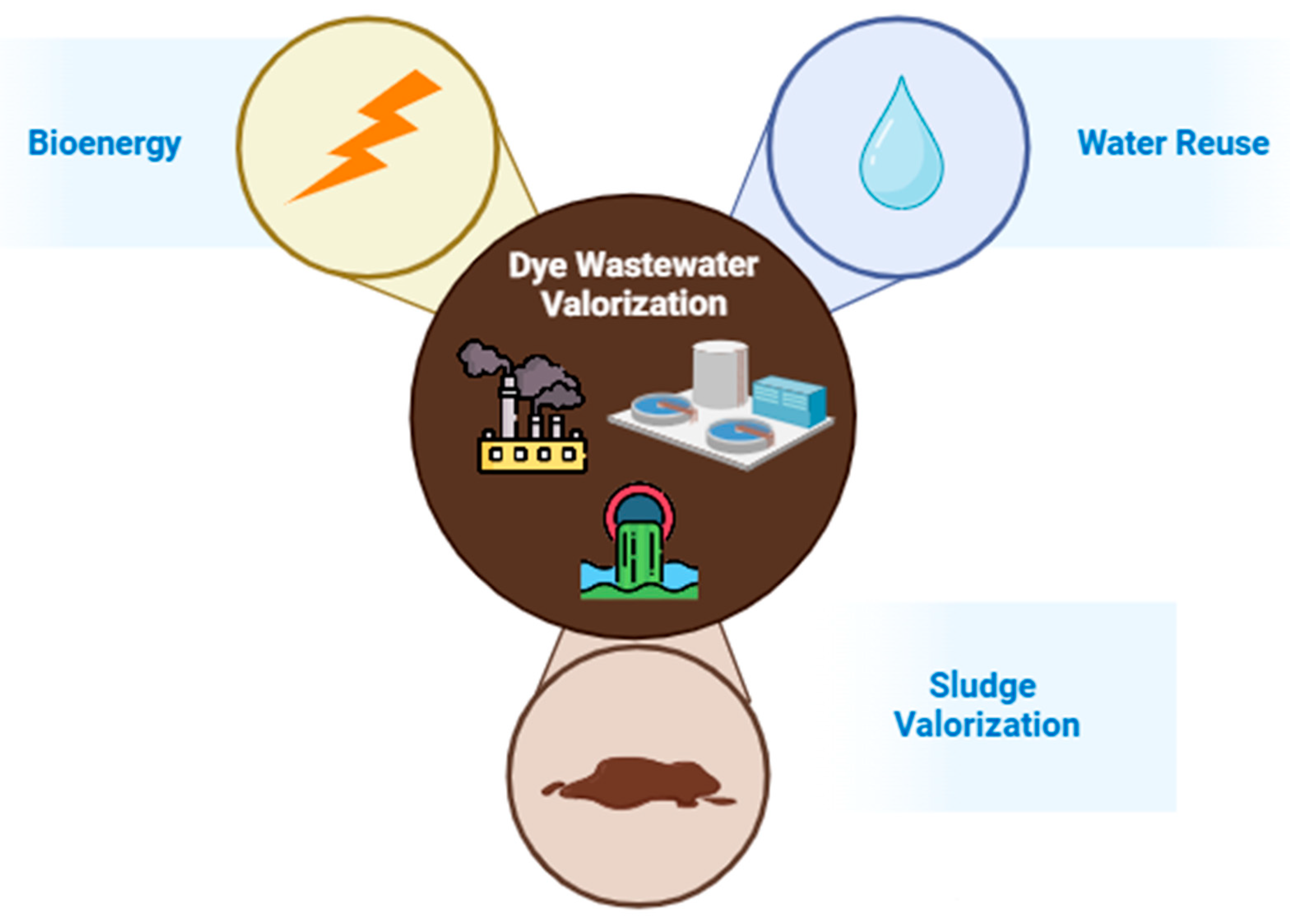

5. Dye wastewater valorization

5.1. Bioenergy production

5.2. Reclaimed water

5.3. Sludge valorization

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Holkar, CR; Jadhav, AJ; Pinjari, D.V.; Mahamuni, N.M.; Pandit, A.B. A Critical Review on Textile Wastewater Treatments: Possible Approaches. J. Environ. Manage. 2016, 182, 351–366. [CrossRef] [PubMed]

- Al-Tohamy, R.; Ali, S.S.; Li, F.; Okasha, K.M.; Mahmoud, Y.A.G.; Elsamahy, T.; Jiao, H.; Fu, Y.; Sun, J. A Critical Review on the Treatment of Dye-Containing Wastewater: Ecotoxicological and Health Concerns of Textile Dyes and Possible Remediation Approaches for Environmental Safety. Ecotoxicol. Environ. Saf. 2022, 231, 113160. [Google Scholar] [CrossRef] [PubMed]

- Mariraj Mohan, S.; Swathi, T. A Review on Upflow Anaerobic Sludge Blanket Reactor: Factors Affecting Performance, Modification of Configuration and Its Derivatives. Water Environ. Res. 2022, 94, 1–27. [Google Scholar] [CrossRef] [PubMed]

- Pereira Silva, T.; Guimarães de Oliveira, M.; Marques Mourão, J.M.; Bezerra dos Santos, A.; Lopes Pereira, E. Monte Carlo-Based Model for Estimating Methane Generation Potential and Electric Energy Recovery in Swine Wastewater Treated in UASB Systems. J. Water Process Eng. 2023, 51, 103399. [Google Scholar] [CrossRef]

- Alcaraz-Ibarra, S.; Mier-Quiroga, M.A.; Esparza-Soto, M.; Lucero-Chávez, M.; Fall, C. Treatment of Chocolate-Processing Industry Wastewater in a Low-Temperature Pilot-Scale UASB: Reactor Performance and in-Situ Biogas Use for Bioenergy Recovery. Biomass and Bioenergy 2020, 142, 105786. [Google Scholar] [CrossRef]

- Arthur, P.M.A.; Konaté, Y.; Sawadogo, B.; Sagoe, G.; Dwumfour-Asare, B.; Ahmed, I.; Williams, M.N.V. Performance Evaluation of a Full-Scale Upflow Anaerobic Sludge Blanket Reactor Coupled with Trickling Filters for Municipal Wastewater Treatment in a Developing Country. Heliyon 2022, 8, e10129. [Google Scholar] [CrossRef]

- Senthilkumar, M.; Gnanapragasam, G.; Arutchelvan, V.; Nagarajan, S. Treatment of Textile Dyeing Wastewater Using Two-Phase Pilot Plant UASB Reactor with Sago Wastewater as Co-Substrate. Chem. Eng. J. 2011, 166, 10–14. [Google Scholar] [CrossRef]

- de Almeida, R.; de Souza Guimarães, C. Up-Flow Anaerobic Sludge Blanket Reactors in Dye Removal: Mechanisms, Influence Factors, and Performance. In; 2022; pp. 201–227 ISBN 9789811905452.

- Muduli, M.; Chanchpara, A.; Choudhary, M.; Saravaia, H.; Haldar, S.; Ray, S. Critical Review on Sustainable Bioreactors for Wastewater Treatment and Water Reuse. Sustain. Water Resour. Manag. 2022, 8, 159. [Google Scholar] [CrossRef]

- van Lier, J.B.; van der Zee, F.P.; Frijters, CTMJ; Ersahin, M.E. Celebrating 40 Years Anaerobic Sludge Bed Reactors for Industrial Wastewater Treatment. Rev. Environ. Sci. Bio/Technology 2015, 14, 681–702. [CrossRef]

- Haugen, F.; Bakke, R.; Lie, B.; Hovland, J.; Vasdal, K. Optimal Design and Operation of a UASB Reactor for Dairy Cattle Manure. Comput. Electron. Agric. 2015, 111, 203–213. [Google Scholar] [CrossRef]

- Li, H.; Han, K.; Li, Z.; Zhang, J.; Li, H.; Huang, Y.; Shen, L.; Li, Q.; Wang, Y. Performance, Granule Conductivity and Microbial Community Analysis of Upflow Anaerobic Sludge Blanket (UASB) Reactors from Mesophilic to Thermophilic Operation. Biochem. Eng. J. 2018, 133, 59–65. [Google Scholar] [CrossRef]

- Mainardis, M.; Buttazzoni, M.; Goi, D. Up-Flow Anaerobic Sludge Blanket (Uasb) Technology for Energy Recovery: A Review on State-of-the-Art and Recent Technological Advances. Bioengineering 2020, 7. [Google Scholar] [CrossRef] [PubMed]

- Shinde, R.; Hackula, A.; O’Shea, R.; Barth, S.; Murphy, J.D.; Wall, D.M. Demand-Driven Biogas Production from Upflow Anaerobic Sludge Blanket (UASB) Reactors to Balance the Power Grid. Bioresour. Technol. 2023, 385, 129364. [Google Scholar] [CrossRef] [PubMed]

- Mirmohamadsadeghi, S.; Karimi, K.; Tabatabaei, M.; Aghbashlo, M. Biogas Production from Food Wastes: A Review on Recent Developments and Future Perspectives. Bioresour. Technol. Reports 2019, 7, 100202. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, H.-L.; Yang, S.-F.; Tay, J.-H. Mechanisms and Models for Anaerobic Granulation in Upflow Anaerobic Sludge Blanket Reactor. Water Res. 2003, 37, 661–673. [Google Scholar] [CrossRef]

- Hulshoff Pol, L.W.; de Castro Lopes, S.I.; Lettinga, G.; Lens, P.N.L. Anaerobic Sludge Granulation. Water Res. 2004, 38, 1376–1389. [Google Scholar] [CrossRef]

- Jahan, N.; Tahmid, M.; Shoronika, A.Z.; Fariha, A.; Roy, H.; Pervez, M.N.; Cai, Y.; Naddeo, V.; Islam, M.S. A Comprehensive Review on the Sustainable Treatment of Textile Wastewater: Zero Liquid Discharge and Resource Recovery Perspectives. Sustain. 2022, 14, 1–38. [Google Scholar] [CrossRef]

- Gonzalez-Gutierrez, L. V.; Escamilla-Silva, E.M. Reactive Red Azo Dye Degradation in a UASB Bioreactor: Mechanism and Kinetics. Eng. Life Sci. 2009, 9, 311–316. [Google Scholar] [CrossRef]

- Singh, K.; Arora, S. Removal of Synthetic Textile Dyes From Wastewaters: A Critical Review on Present Treatment Technologies. Crit. Rev. Environ. Sci. Technol. 2011, 41, 807–878. [Google Scholar] [CrossRef]

- Volschan Junior, I.; de Almeida, R.; Cammarota, M.C. A Review of Sludge Pretreatment Methods and Co-Digestion to Boost Biogas Production and Energy Self-Sufficiency in Wastewater Treatment Plants. J. Water Process Eng. 2021, 40, 101857. [Google Scholar] [CrossRef]

- Dai, R.; Chen, X.; Luo, Y.; Ma, P.; Ni, S.; Xiang, X.; Li, G. Inhibitory Effect and Mechanism of Azo Dyes on Anaerobic Methanogenic Wastewater Treatment: Can Redox Mediator Remediate the Inhibition? Water Res. 2016, 104, 408–417. [Google Scholar] [CrossRef] [PubMed]

- Amaral, F.M.; Kato, M.T.; Florêncio, L.; Gavazza, S. Color, Organic Matter and Sulfate Removal from Textile Effluents by Anaerobic and Aerobic Processes. Bioresour. Technol. 2014, 163, 364–369. [Google Scholar] [CrossRef] [PubMed]

- Field, JA; Cervantes, F.J.; van der Zee, F.P.; Lettinga, G. Role of Quinones in the Biodegradation of Priority Pollutants: A Review. Water Sci. Technol. 2000, 42, 215–222. [CrossRef]

- Cervantes, F.J.; Garcia-Espinosa, A.; Moreno-Reynosa, M.A.; Rangel-Mendez, J.R. Immobilized Redox Mediators on Anion Exchange Resins and Their Role on the Reductive Decolorization of Azo Dyes. Environ. Sci. Technol. 2010, 44, 1747–1753. [Google Scholar] [CrossRef] [PubMed]

- Baêta, B.E.L.; Aquino, S.F.; Silva, S.Q.; Rabelo, C.A. Anaerobic Degradation of Azo Dye Drimaren Blue HFRL in UASB Reactor in the Presence of Yeast Extract a Source of Carbon and Redox Mediator. Biodegradation 2012, 23, 199–208. [Google Scholar] [CrossRef]

- dos Santos, A.B.; Traverse, J.; Cervantes, F.J.; van Lier, J.B. Enhancing the Electron Transfer Capacity and Subsequent Color Removal in Bioreactors by Applying Thermophilic Anaerobic Treatment and Redox Mediators. Biotechnol. Bioeng. 2005, 89, 42–52. [Google Scholar] [CrossRef]

- Garcia, J.-L.; Patel, B.K.C.; Ollivier, B. Taxonomic, Phylogenetic, and Ecological Diversity of Methanogenic Archaea. Anaerobe 2000, 6, 205–226. [Google Scholar] [CrossRef]

- Chen, Y.; Feng, L.; Li, H.; Wang, Y.; Chen, G.; Zhang, Q. Biodegradation and Detoxification of Direct Black G Textile Dye by a Newly Isolated Thermophilic Microflora. Bioresour. Technol. 2018, 250, 650–657. [Google Scholar] [CrossRef]

- Samuchiwal, S.; Gola, D.; Malik, A. Decolourization of Textile Effluent Using Native Microbial Consortium Enriched from Textile Industry Effluent. J. Hazard. Mater. 2021, 402, 123835. [Google Scholar] [CrossRef]

- Karatas, M.; Dursun, S. ; Argun, ME The Decolorization of Azo Dye Reactive Black 5 in a Sequential Anaerobic-Aerobic System. Ekoloji 2010, 19, 15–23. [Google Scholar]

- Ryue, J.; Lin, L.; Kakar, F.L.; Elbeshbishy, E.; Al-Mamun, A.; Dhar, B.R. A Critical Review of Conventional and Emerging Methods for Improving Process Stability in Thermophilic Anaerobic Digestion. Energy Sustain. Dev. 2020, 54, 72–84. [Google Scholar] [CrossRef]

- Liu, T.; Schnürer, A.; Björkmalm, J.; Willquist, K.; Kreuger, E. Diversity and Abundance of Microbial Communities in UASB Reactors during Methane Production from Hydrolyzed Wheat Straw and Lucerne. Microorganisms 2020, 8, 1394. [Google Scholar] [CrossRef] [PubMed]

- Daud, MK; Rizvi, H. ; Akram, M.F.; Ali, S.; Rizwan, M.; Nafees, M.; Jin, Z.S. Review of Upflow Anaerobic Sludge Blanket Reactor Technology: Effect of Different Parameters and Developments for Domestic Wastewater Treatment. J. Chem. 2018, 2018, 1–13. [Google Scholar] [CrossRef]

- Amaral, F.M.; Florêncio, L.; Kato, M.T.; Santa-Cruz, P.A.; Gavazza, S. Hydraulic Retention Time Influence on Azo Dye and Sulfate Removal during the Sequential Anaerobic–Aerobic Treatment of Real Textile Wastewater. Water Sci. Technol. 2017, 76, 3319–3327. [Google Scholar] [CrossRef]

- Işik, M.; Sponza, D.T. Effects of Alkalinity and Co-Substrate on the Performance of an Upflow Anaerobic Sludge Blanket (UASB) Reactor through Decolorization of Congo Red Azo Dye. Bioresour. Technol. 2005, 96, 633–643. [Google Scholar] [CrossRef]

- Haider, A.; Khan, S.J.; Nawaz, M.S.; Saleem, M.U. Effect of Intermittent Operation of Lab-Scale Upflow Anaerobic Sludge Blanket (UASB) Reactor on Textile Wastewater Treatment. Desalin. WATER Treat. 2018, 136, 120–130. [Google Scholar] [CrossRef]

- de Barros, A.N.; da Silva, M.E.R.; Firmino, P.I.M.; de Vasconcelos, E.A.F.; dos Santos, A.B. Impact of Microaeration and the Redox Mediator Anthraquinone-2,6-Disulfonate on Azo Dye Reduction and By-Products Degradation. CLEAN - Soil, Air, Water 2018, 46, 1700518. [Google Scholar] [CrossRef]

- Bahia, M.; Passos, F.; Adarme, O.F.H.; Aquino, S.F.; Silva, S.Q. Anaerobic-Aerobic Combined System for the Biological Treatment of Azo Dye Solution Using Residual Yeast. Water Environ. Res. 2018, 90, 729–737. [Google Scholar] [CrossRef]

- Fazal, S.; Huang, S.; Zhang, Y.; Ullah, Z.; Ali, A.; Xu, H. Biological Treatment of Red Bronze Dye through Anaerobic Process. Arab. J. Geosci. 2019, 12, 415. [Google Scholar] [CrossRef]

- Gadow, S.I.; Li, Y.-Y. Development of an Integrated Anaerobic/Aerobic Bioreactor for Biodegradation of Recalcitrant Azo Dye and Bioenergy Recovery: HRT Effects and Functional Resilience. Bioresour. Technol. Reports 2020, 9, 100388. [Google Scholar] [CrossRef]

- Carvalho, J.R.S.; Amaral, F.M.; Florencio, L.; Kato, M.T.; Delforno, T.P.; Gavazza, S. Microaerated UASB Reactor Treating Textile Wastewater: The Core Microbiome and Removal of Azo Dye Direct Black 22. Chemosphere 2020, 242, 125157. [Google Scholar] [CrossRef] [PubMed]

- Bahia, M.; Borges, T.A.; Passos, F.; Aquino, S.F. de; Silva, S. de Q. Evaluation of a Combined System Based on an Upflow Anaerobic Sludge Blanket Reactor (UASB) and Shallow Polishing Pond (SPP) for Textile Effluent Treatment. Brazilian Arch. Biol. Technol. 2020, 63, 1–8. [Google Scholar] [CrossRef]

- Malik, R.A.; Vistanty, H.; Suhardi, S.H. Performance of Anaerobic Co-Digestion with Honey Processing Wastewater as Co-Substrate for Treating Synthetic Wastewater Containing Commercial Anthraquinone Dye Remazol Blue RSP: Effect of C:N Ratio and HRT. Bioresour. Technol. Reports 2022, 19, 101157. [Google Scholar] [CrossRef]

- Saleem, M.U.; Khan, S.J.; Shahzad, H.M.A. ; Zeshan Performance Evaluation of Integrated Anaerobic and Aerobic Reactors for Treatment of Real Textile Wastewater. Int. J. Environ. Sci. Technol. 2022, 19, 10325–10336. [Google Scholar] [CrossRef]

- Albahnasawi, A.; Yüksel, E.; Gürbulak, E.; Duyum, F. Fate of Aromatic Amines through Decolorization of Real Textile Wastewater under Anoxic-Aerobic Membrane Bioreactor. J. Environ. Chem. Eng. 2020, 8, 104226. [Google Scholar] [CrossRef]

- Varjani, S.; Rakholiya, P.; Shindhal, T.; Shah, A. V.; Ngo, H.H. Trends in Dye Industry Effluent Treatment and Recovery of Value Added Products. J. Water Process Eng. 2021, 39, 101734. [Google Scholar] [CrossRef]

- Pavičić, J.; Novak Mavar, K.; Brkić, V.; Simon, K. Biogas and Biomethane Production and Usage: Technology Development, Advantages and Challenges in Europe. Energies 2022, 15, 2940. [Google Scholar] [CrossRef]

- Ampese, L.C.; Sganzerla, W.G.; Di Domenico Ziero, H.; Mudhoo, A.; Martins, G.; Forster-Carneiro, T. Research Progress, Trends, and Updates on Anaerobic Digestion Technology: A Bibliometric Analysis. J. Clean. Prod. 2022, 331, 130004. [Google Scholar] [CrossRef]

- Katal, R.; Zare, H.; Rastegar, SO; Mavaddat, P.; Darzi, GN Removal of Dye and Chemical Oxygen Demand (COD) Reduction from Textile Industrial Wastewater Using Hybrid Bioreactors. Environ. Eng. Manag. J. 2014, 13, 43–50. [CrossRef]

- Işik, M.; Sponza, D.T. Anaerobic/Aerobic Sequential Treatment of a Cotton Textile Mill Wastewater. J. Chem. Technol. Biotechnol. 2004, 79, 1268–1274. [Google Scholar] [CrossRef]

- Işik, M. Efficiency of Simulated Textile Wastewater Decolorization Process Based on the Methanogenic Activity of Upflow Anaerobic Sludge Blanket Reactor in Salt Inhibition Condition. Enzyme Microb. Technol. 2004, 35, 399–404. [Google Scholar] [CrossRef]

- Chrispim, M.C.; Scholz, M.; Nolasco, M.A. Biogas Recovery for Sustainable Cities: A Critical Review of Enhancement Techniques and Key Local Conditions for Implementation. Sustain. Cities Soc. 2021, 72, 103033. [Google Scholar] [CrossRef]

- Gadow, S.I.; Estrada, A.L.; Li, Y.-Y. Characterization and Potential of Two Different Anaerobic Mixed Microflora for Bioenergy Recovery and Decolorization of Textile Wastewater: Effect of C/N Ratio, Dye Concentration and PH. Bioresour. Technol. Reports 2022, 17, 100886. [Google Scholar] [CrossRef]

- Wei, J.; Hao, X.; van Loosdrecht, M.C.M.; Li, J. Feasibility Analysis of Anaerobic Digestion of Excess Sludge Enhanced by Iron: A Review. Renew. Sustain. Energy Rev. 2018, 89, 16–26. [Google Scholar] [CrossRef]

- Apollo, S.; Onyango, M.S.; Ochieng, A. Integrated UV Photodegradation and Anaerobic Digestion of Textile Dye for Efficient Biogas Production Using Zeolite. Chem. Eng. J. 2014, 245, 241–247. [Google Scholar] [CrossRef]

- Mo, J.; Hwang, J.-E.; Jegal, J.; Kim, J. Pretreatment of a Dyeing Wastewater Using Chemical Coagulants. Dye. Pigment. 2007, 72, 240–245. [Google Scholar] [CrossRef]

- Anjum, M.; Anees, M.; Qadeer, S.; Khalid, A.; Kumar, R.; Barakat, M.A. A Recent Progress in the Leachate Pretreatment Methods Coupled with Anaerobic Digestion for Enhanced Biogas Production: Feasibility, Trends, and Techno-Economic Evaluation. Int. J. Mol. Sci. 2023, 24, 763. [Google Scholar] [CrossRef]

- de Almeida, R.; Porto, R.F.; Quintaes, B.R.; Bila, D.M.; Lavagnolo, M.C.; Campos, J.C. A Review on Membrane Concentrate Management from Landfill Leachate Treatment Plants: The Relevance of Resource Recovery to Close the Leachate Treatment Loop. Waste Manag. Res. 2023, 41, 264–284. [Google Scholar] [CrossRef]

- de Almeida, R.; Pimenta de Oliveira, T.J.; Maurício Gouvea, R.; Carbonelli Campos, J. Technical and Economic Aspects of a Sequential MF + NF + Zeolite System Treating Landfill Leachate. J. Environ. Sci. Heal. Part A 2022, 0, 1–10. [Google Scholar] [CrossRef]

- Shindhal, T.; Rakholiya, P.; Varjani, S.; Pandey, A.; Ngo, H.H.; Guo, W.; Ng, HY; Taherzadeh, M.J. A Critical Review on Advances in the Practices and Perspectives for the Treatment of Dye Industry Wastewater. Bioengineered 2021, 12, 70–87. [CrossRef]

- Yao, J.; Wen, D.; Shen, J.; Wang, J. Zero Discharge Process for Dyeing Wastewater Treatment. J. Water Process Eng. 2016, 11, 98–103. [Google Scholar] [CrossRef]

- Erkanlı, M.; Yilmaz, L.; Çulfaz-Emecen, P.Z.; Yetis, U. Brackish Water Recovery from Reactive Dyeing Wastewater via Ultrafiltration. J. Clean. Prod. 2017, 165, 1204–1214. [Google Scholar] [CrossRef]

- Khosravi, A.; Karimi, M.; Ebrahimi, H.; Fallah, N. Sequencing Batch Reactor/Nanofiltration Hybrid Method for Water Recovery from Textile Wastewater Contained Phthalocyanine Dye and Anionic Surfactant. J. Environ. Chem. Eng. 2020, 8, 103701. [Google Scholar] [CrossRef]

- Cieślik, B.M.; Namieśnik, J.; Konieczka, P. Review of Sewage Sludge Management: Standards, Regulations and Analytical Methods. J. Clean. Prod. 2015, 90, 1–15. [Google Scholar] [CrossRef]

- Bratina, B.; Šorgo, A.; Kramberger, J.; Ajdnik, U.; Zemljič, L.F.; Ekart, J.; Šafarič, R. From Municipal/Industrial Wastewater Sludge and FOG to Fertilizer: A Proposal for Economic Sustainable Sludge Management. J. Environ. Manage. 2016, 183, 1009–1025. [Google Scholar] [CrossRef]

- Xiang, X.; Chen, X.; Dai, R.; Luo, Y.; Ma, P.; Ni, S.; Ma, C. Anaerobic Digestion of Recalcitrant Textile Dyeing Sludge with Alternative Pretreatment Strategies. Bioresour. Technol. 2016, 222, 252–260. [Google Scholar] [CrossRef]

- Chen, X.; Xiang, X.; Dai, R.; Wang, Y.; Ma, P. Effect of Low Temperature of Thermal Pretreatment on Anaerobic Digestion of Textile Dyeing Sludge. Bioresour. Technol. 2017, 243, 426–432. [Google Scholar] [CrossRef]

- Zhou, W.; Tuersun, N.; Zhang, Y.; Wang, Y.; Cheng, C.; Chen, X. Optimization and System Energy Balance Analysis of Anaerobic Co-Digestion Process of Pretreated Textile Dyeing Sludge and Food Waste. J. Environ. Chem. Eng. 2021, 9, 106855. [Google Scholar] [CrossRef]

- Yildirir, E.; Ballice, L. Supercritical Water Gasification of Wet Sludge from Biological Treatment of Textile and Leather Industrial Wastewater. J. Supercrit. Fluids 2019, 146, 100–106. [Google Scholar] [CrossRef]

| Influencing parameters | Main aspects | Main findings | Reference |

|---|---|---|---|

| Dye structure and concentration |

|

|

[22,23] |

| Electron donors and redox mediators |

|

|

[24,25,26,27] |

| pH |

|

|

[28,29] |

| Temperature |

|

|

[27,30] |

| Organic loading rate (OLR.) |

|

|

[31,32,33] |

| Hydraulic retention time (HRT.) |

|

|

[34,35,36] |

| Scheme | Scale | UASB reactor conditions | Dye compounds | Treatability results | Reference | |||

|---|---|---|---|---|---|---|---|---|

| Type | Name | Concentration/ Amount | Color | COD | ||||

| UASB reactor | Lab | Continuous mode, 27ºC, HRT 24 h, OLR* | Azo dye | Reactive Red 2 | 50 mg L-1 | 51% | 89% | [38] |

| UASB reactor + Activated sludge process | Lab | Continuous mode, 16ºC – 29ºC, HRT 24h, OLR* | Azo dye | Yellow Gold Remazol | 50 mg L-1 | 85% | 67–88% | [39] |

| UASB reactor + shallow polishing pond | Lab | Continuous mode, 16ºC – 29ºC, HRT 24h, OLR* | Azo dye | Yellow Gold Remazol | 50 mg L-1 | 85% | 67–88% | [39] |

| UASB reactor | Lab | Continuous mode, temperature*, TRH 24h, OLR* | Azo dye | Red Bronze | 40–325 mg L-1 | 75–94% | 60–91% | [40] |

| UASB reactor + Aerated bioreactor | Lab | Continuous mode, 37±1 ºC, H.R.T. 6h, OLR 12.97 kg C.O.D. m-3 d-1 | Azo dye | 2-Naphthol Red | 0.1 g L-1 | 96% | 85.6% | [41] |

| UASB reactor + microaerated UASB reactor | Lab | Continuous mode, 25.0±1.4ºC, HRT*, OLR 1.27–1.50 kg m-3 d-1 | Azo dye | Direct Black 22 | 0.6 mM | 70– 78% | 67– 72% | [42] |

| UASB reactor + shallow polishing pond | Lab | Continuous mode, 16–29ºC, HRT 24 h, OLR* | − | Real textile wastewater | − | 50% | 80% | [43] |

| UASB reactor | Lab | Continuous mode, 27 – 29ºC, HRT 24 h, OLR 6.20 kg COD m-3 d-1 | Simulated wastewater containing Remazol blue RSP | 12.5 mg L-1 | 97.37±3.62% | 76.69±2.83% | [44] | |

| UASB reactor + SBR | Lab | Intermitent mode, 35ºC, HRT 48 h, OLR 0.74 – 0.90 kg COD m-3 d-1 | Real textile wastewater | − | 87.7% | 90.4% | [45] | |

| Scheme | UASB reactor conditions | Dye compound | Biogas production | Reference |

| UASB reactor | Temperature of 37ºC, H.R.T. 20h, OLR 3.86 kg C.O.D. m-3 d-1 | Azo dye mixture: Reactive Black 5, Direct Red 28, Direct Black 38, Direct Brown 2, and Direct Yellow 12 (250 mg L-1) | 2.26 L d-1 (70%CH4, v/v) | [52] |

| UASB + CSTR reactor | Temperature of 37ºC. HRT 3 – 30h, OLR 2 – 15 kg COD m-3 d-1 | Real textile wastewater | 0.36 – 0.94 L d-1 | [51] |

| UASB reactor | Temperature of 37ºC, HRT 18.3h, OLR 0.286 kg m-3 d-1 | Red Congo azo dye (100 mg L-1) | 2.0 – 2.7 L d-1 | [36] |

| UASB reactor | Temperature of 33ºC, H.R.T. 50h, O.L.R. 12 kg C.O.D. m-3 d-1 | Real textile wastewater | 36.04 L d-1 (79%CH4, v/v) | [50] |

| UASB reactor + aerobic system | Temperature of 37±1ºC, H.R.T. 6h, OLR 12.97 kg C.O.D. m-3 d-1 | 2-Naphthol Red (100 mg L-1) | 3.86 L CH4 m-3 d-1 | [41] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).