Submitted:

17 August 2023

Posted:

22 August 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Experiment section

2.1. Reagents

2.2. Preparation of epoxy matrix modified by CTBN

- 5wt%, 8wt%, and 10wt% CTBN was added into the unmodified resin matrix based on E51, respectively.

- The unmodified and modified resin matrix was prepared with the weight ratio of E51: MTHPA: N, N-dimethylbenzylamine =100:90:2.

- The mixture is placed in the rotation agitator (Thinky Mixer ARE-310) to stir and defoam.

- The stirred liquid was slowly poured into the mold and put in the oven at 60℃ for vacuum defoaming for 30min.

- Put the mold into the oven for curing, and the procedure is 80℃ 4h, 140℃ 8h.

2.3. Preparation of resin matrix with synergic toughening of nano-SiO2 and CTBN

- Based on E51, CTBN with the optimal ratio was added, and nano-SiO2 with the additional amount of 0.25wt%, 0.5wt%, 0.75wt%, and 1.0wt% were added to tetrahydrofuran. Ultrasonic dispersion was carried out for 30min.

- Corresponding quality epoxy resin was added into the tetrahydrofuran nano-SiO2 solution and stirred for 5 minutes.

- The tetrahydrofuran in the resin was removed successively by rotating the evaporation apparatus and vacuum oven. The curing agent and accelerator were added at the ratio of E51: MTHPA: N, N-dimethylbenzylamine = 100:90:2. For the following steps, refer to section 2.2.

2.4. The preparation of GF/EP laminate composites toughened by nano SiO2 and CTBN

- The glass fiber cloth was cut into a rectangular fabric of the required size. The glass fiber cloth was washed with alcohol and put into the oven for drying.

- According to the configuration of the resin matrix, the epoxy resin matrix with different components of nano SiO2 and CTBN is prepared.

- Use a brush dipped in a small amount of glue to coat the glass fiber cloth, use a scraper to scrape off excess resin after coating, and then lay the 2nd ~ 12th layer in turn.

- After the 12th layer is laid, spread polyimide with a thickness of 25μm in the width direction as a prefab crack (this step is unnecessary for the preparation of shear strength laminate composite materials), and continue to apply the adhesive liquid on the remaining glass fiber cloth. The layering of the 13th to 24th layers is the same as④.

- After the 24th layer is covered, the system is put into a vacuum bag to vacuum and remove bubbles for 30min; ⑦ Put the system into the mold and use the hot press for hot pressing. The curing procedure is 80℃ 4h and 140℃ 8h. The thickness of the laminates was about 3 mm, with the fiber volume fraction 60~65%.

2.5. Test and characterization

3. Results and Discussion

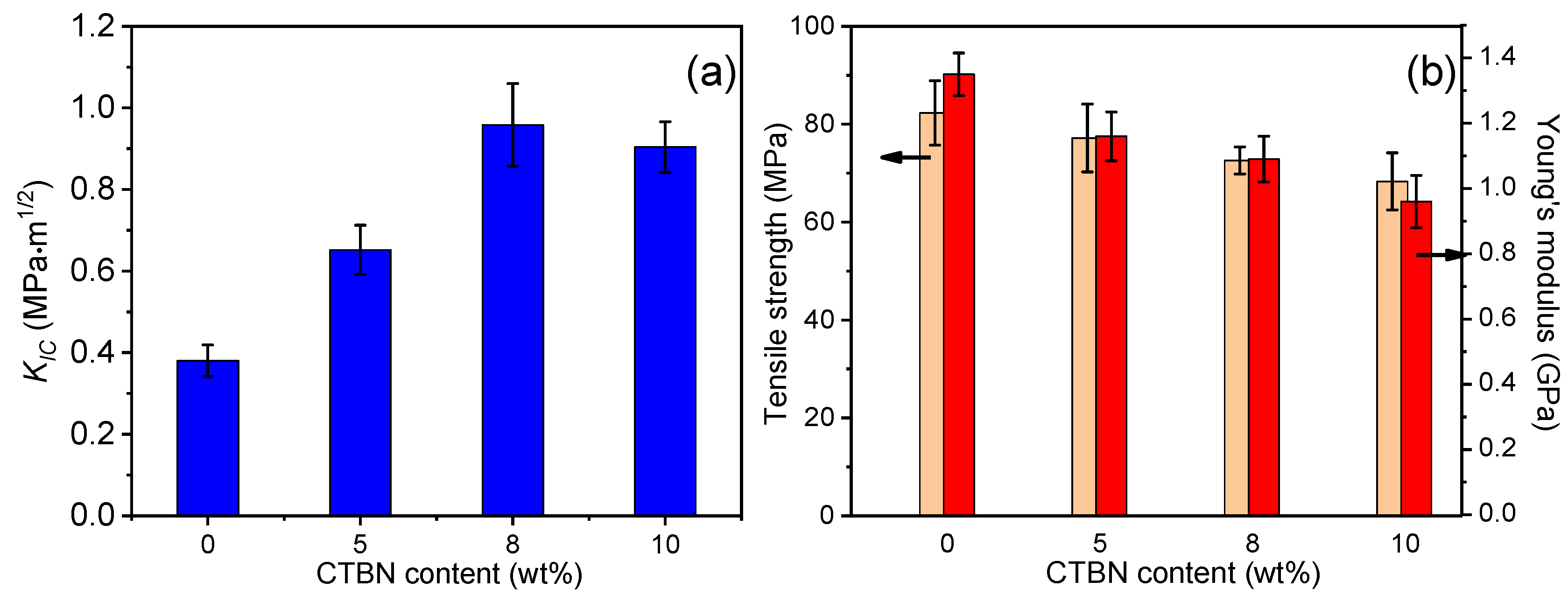

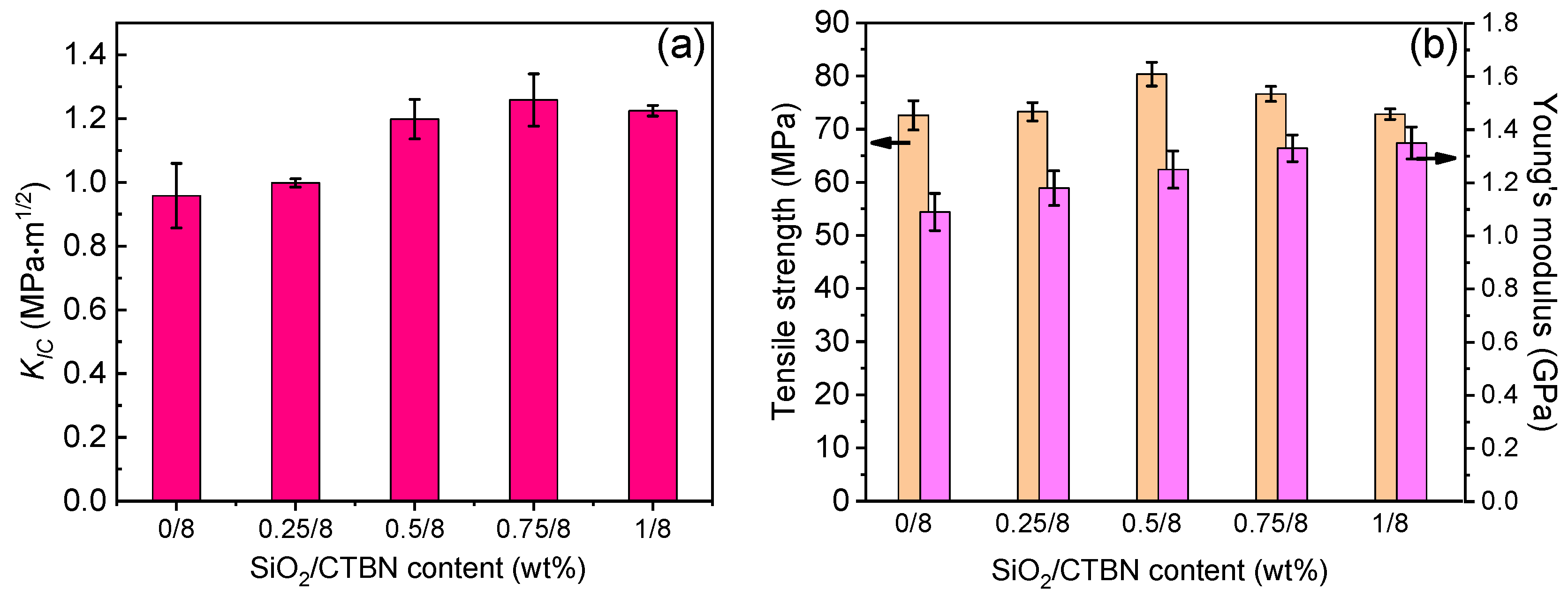

3.1. Mechanical properties of epoxy matrix modified by particles

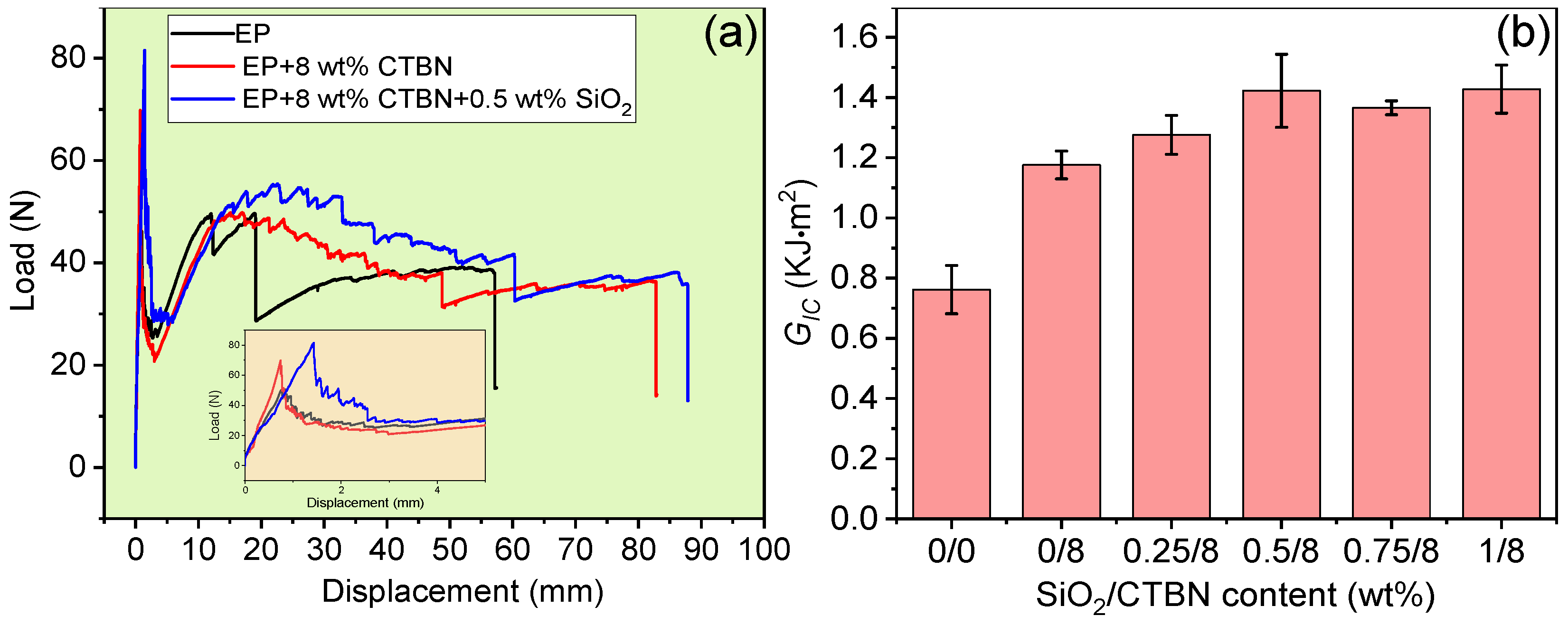

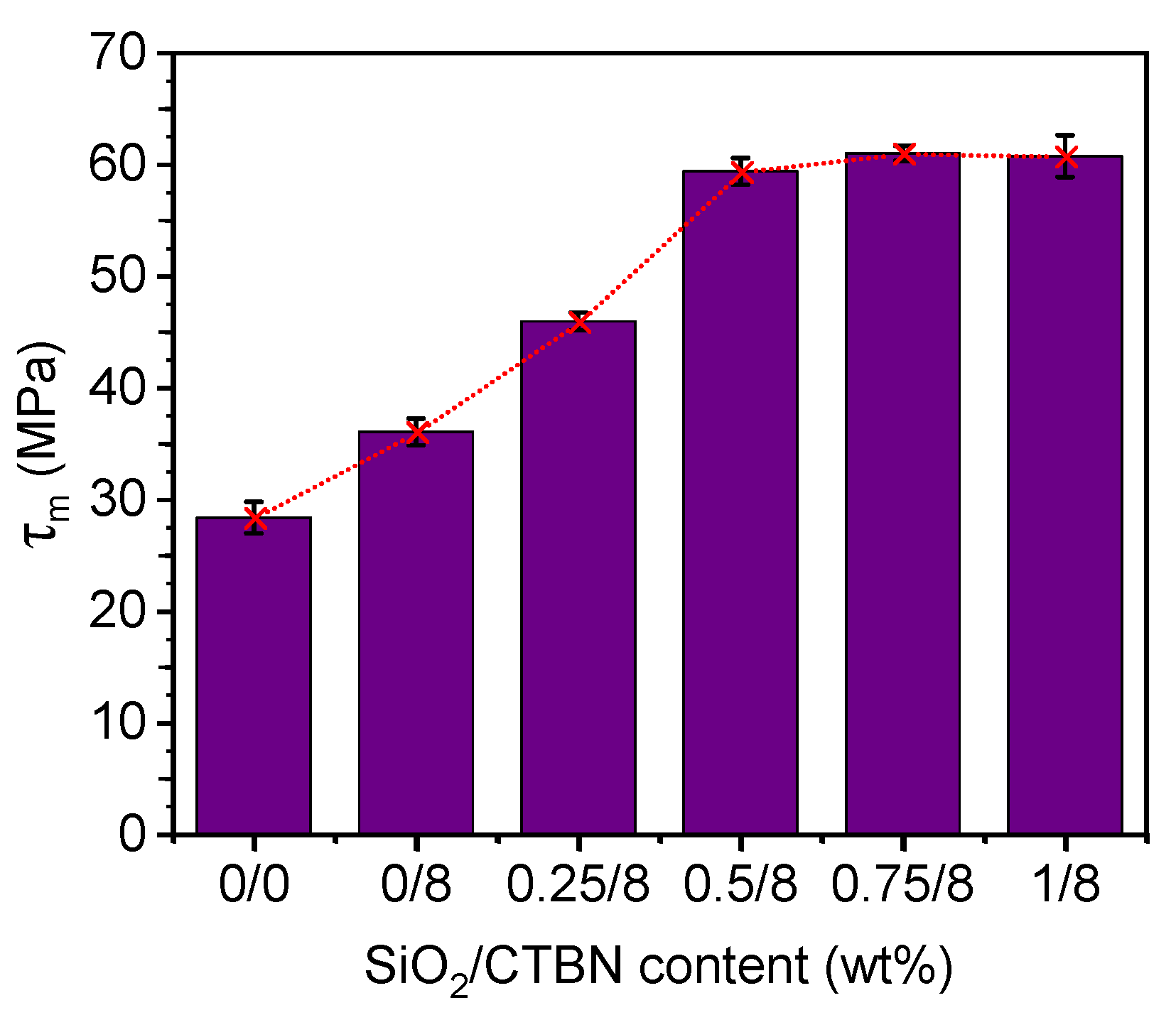

3.2. Interlayer properties of GF/EP laminated composites toughened by SiO2 and CTBN

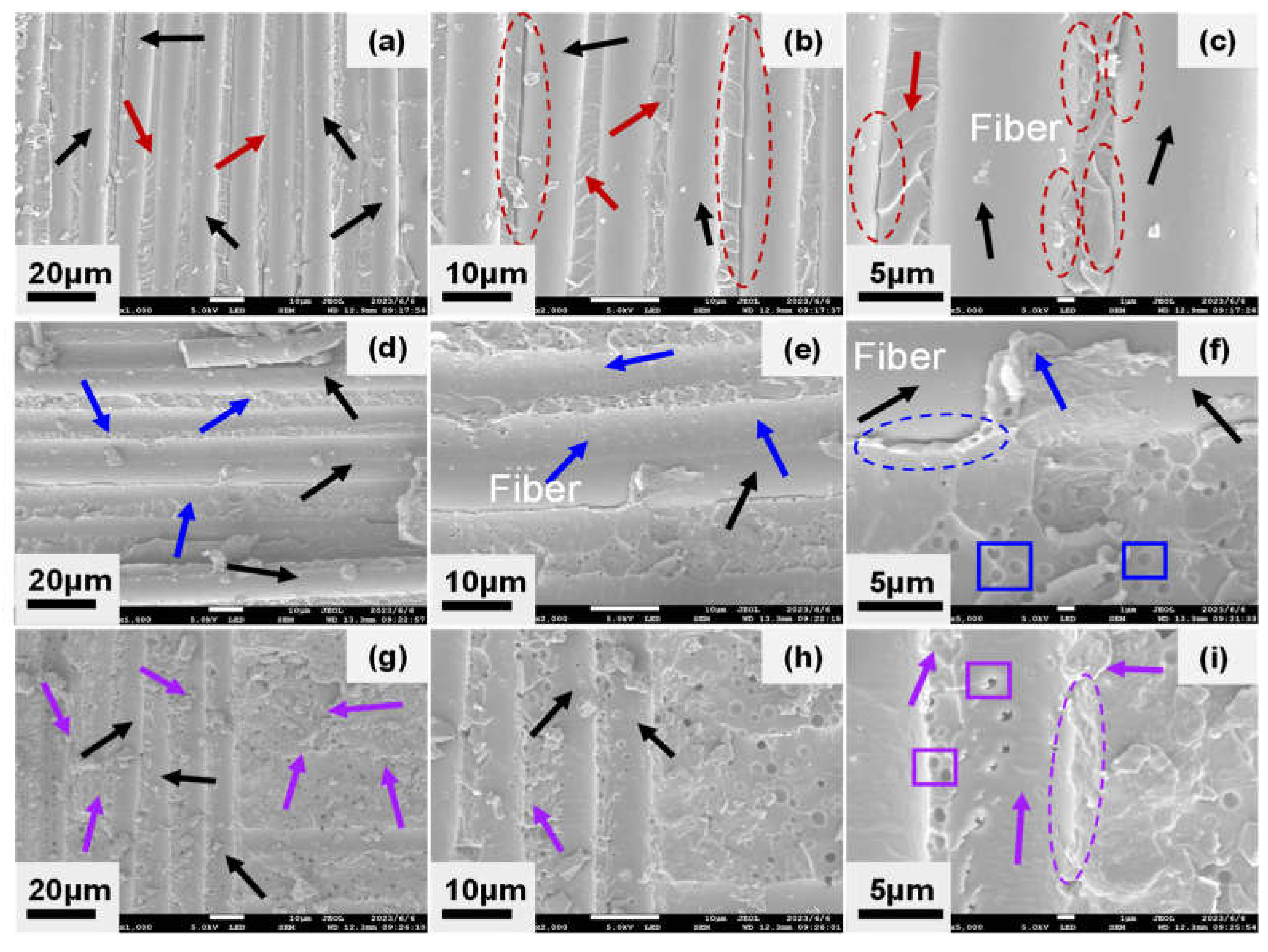

3.3. Fracture Behavior Analysis of GF/EP laminate composites toughened by nano SiO2 and CTBN

4. Conclusion

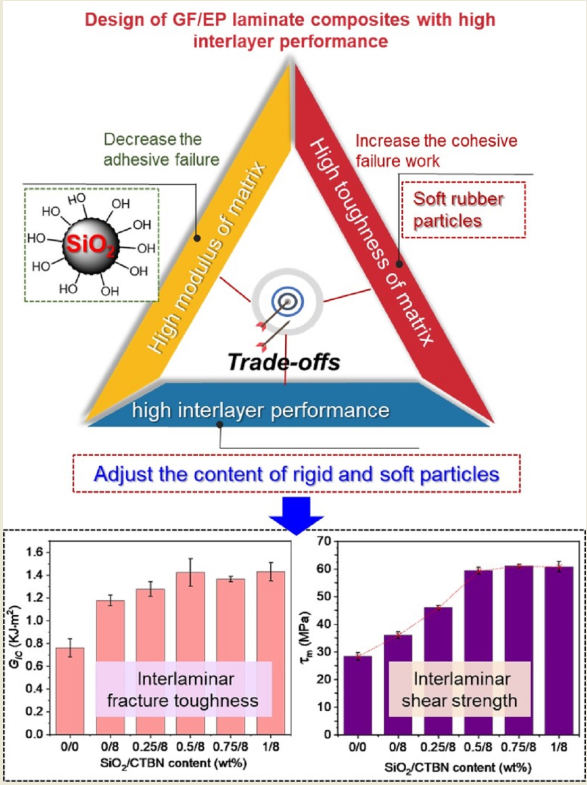

- When flexible CTBN rubber particles and nano-SiO2 are used as synergistic toughening agents to toughen the epoxy resin base, when 8wt% CTBN and 0.5wt% nano-SiO2 are added to the resin, the fracture toughness of epoxy resin is increased by 215.8%. The tensile strength is only decreased by 2.3%, showing the best comprehensive performance.

- The synergistic toughening effect of 8wt% CTBN and 0.5wt% nano-SiO2 increased the GIC platform value of the GF/EP laminate composite by 86.8% and the interlaminate shear strength by 109.2%.

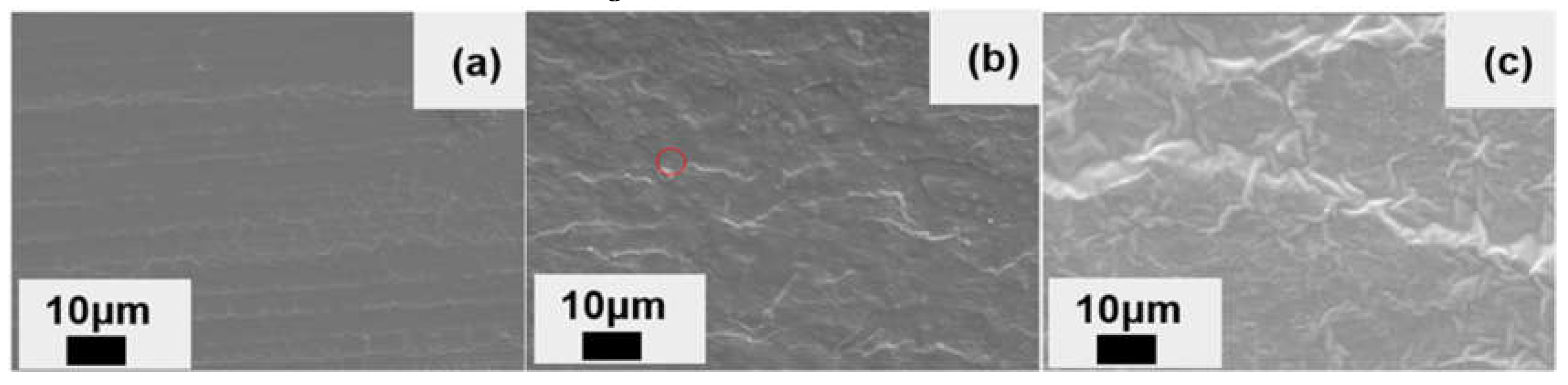

- The cross-section analysis of GF/EP laminated composites shows that the addition of flexible CTBN rubber particles and rigid nano-SiO2 makes the interface adhesive failure of GF/EP laminated composites change to matrix cohesion failure. When cracks expand in the interlayer matrix, the cavitation of the two particles and the plastic deformation of the matrix is the toughening mechanism of the interlayer properties of the composite.

Author Contributions

Conflicts of Interest

References

- J. Karger-Kocsis, H. Mahmood, A. Pegoretti, Recent advances in fiber/matrix interphase engineering for polymer composites, Progress in Materials Science 73 (2015) 1-43. [CrossRef]

- R. Shrivastava, K.K. Singh, Interlaminar fracture toughness characterization of laminated composites: a review, Polymer Reviews 60 (2020) 542-593. [CrossRef]

- S. Sasidharan, A. Anand, Interleaving in Composites for High-Performance Structural Applications, Industrial & Engineering Chemistry Research 62 (2022) 16-39. [CrossRef]

- D. De Cicco, Z. Asaee, F. Taheri, Use of Nanoparticles for Enhancing the Interlaminar Properties of Fiber-Reinforced Composites and Adhesively Bonded Joints-A Review, Nanomaterials 7 (2017). [CrossRef]

- J. Qiu, Y. Li, F. Xu, X. Hu, Y. Xiao, Strain induced crack initiation and the subsequent crack propagation of fiber-reinforced resin composites, Composites Part A: Applied Science and Manufacturing 155 (2022). [CrossRef]

- Z. Fan, M.H. Santare, S.G. Advani, Interlaminar shear strength of glass fiber reinforced epoxy composites enhanced with multi-walled carbon nanotubes, Composites Part A: Applied Science and Manufacturing 39 (2008) 540-554. [CrossRef]

- N.T. Kamar, M.M. Hossain, A. Khomenko, M. Haq, L.T. Drzal, A. Loos, Interlaminar reinforcement of glass fiber/epoxy composites with graphene nanoplatelets, Composites Part A: Applied Science and Manufacturing 70 (2015) 82-92. [CrossRef]

- H. Zhou, X. Du, H.-Y. Liu, H. Zhou, Y. Zhang, Y.-W. Mai, Delamination toughening of carbon fiber/epoxy laminates by hierarchical carbon nanotube-short carbon fiber interleaves, Composites Science and Technology 140 (2017) 46-53.

- F. Yildirim, M. Aydin, A. Avci, Mechanical properties of nano-SiO2 reinforced 3D glass fiber/epoxy composites, International Journal of Materials Research 108 (2017) 308-321.

- R.C. Zhuang, T. Burghardt, E. Maeder, Study on interfacial adhesion strength of single glass fibre/polypropylene model composites by altering the nature of the surface of sized glass fibres, Composites Science and Technology 70 (2010) 1523-1529. [CrossRef]

- N. Ning, M. Wang, G. Zhou, Y. Qiu, Y. Wei, Effect of polymer nanoparticle morphology on fracture toughness enhancement of carbon fiber reinforced epoxy composites, Composites Part B: Engineering 234 (2022). [CrossRef]

- Z. Li, Y. Wang, J. Cao, X. Meng, R.M. Aamir, W. Lu, T. Suo, Effects of loading rates on mode I interlaminar fracture toughness of carbon/epoxy composite toughened by carbon nanotube films, Composites Part B: Engineering 200 (2020). [CrossRef]

- P. Xu, Y. Yu, D. Liu, M. He, G. Li, X. Yang, Enhanced interfacial and mechanical properties of high-modulus carbon fiber composites: Establishing modulus intermediate layer between fiber and matrix based on tailored-modulus epoxy, Composites Science and Technology 163 (2018) 26-33. [CrossRef]

- K. Lu, W. Zhu, Q. Su, G. Li, X. Yang, Correlation between compression strength and failure mechanism of carbon fiber composite with tailored modulus of amide acid/SiO2 synergistically stiffened epoxy matrix, Composites Science and Technology 202 (2021). [CrossRef]

- P.J.L. Lazar, R. Sengottuvelu, E. Natarajan, Assessments of Secondary Reinforcement of Epoxy Matrix-Glass Fibre Composite Laminates through Nanosilica (SiO2), Materials 11 (2018). [CrossRef]

- A.C. Garg, Y.-W. Mai, Failure mechanisms in toughened epoxy resins-a review, Composites Science and Technology 31 (1988) 179-223. [CrossRef]

- Y. Zheng, Y. Zheng, R. Ning, Effects of nanoparticles SiO2 on the performance of nanocomposites, Materials Letters 57 (2003) 2940-2944. [CrossRef]

- Chatterjee, M.S. Islam, Fabrication and characterization of TiO2-epoxy nanocomposite, Materials Science and Engineering: A 487 (2008) 574-585. [CrossRef]

- S. Kango, S. Kalia, A. Celli, J. Njuguna, Y. Habibi, R. Kumar, Surface modification of inorganic nanoparticles for development of organic-inorganic nanocomposites-a review, Progress in Polymer Science 38 (2013) 1232-1261. [CrossRef]

- R. Bagheri, R.A. Pearson, Role of blend morphology in rubber-toughened polymers, Journal of Materials Science 31 (1996) 3945-3954. [CrossRef]

- J.Y. Qian, R.A. Pearson, V.L. Dimonie, O.L. Shaffer, M.S. ElAasser, The role of dispersed phase morphology on toughening of epoxies, Polymer 38 (1997) 21-30. [CrossRef]

- R. Bagheri, R.A. Pearson, Role of particle cavitation in rubber-toughened epoxies: 1. Microvoid toughening, Polymer 37 (1996) 4529-4538. [CrossRef]

- C.B. Bucknall, V.L.P. Soares, H.H. Yang, X.C. Zhang, Rubber toughening of plastics: rubber particle cavitation and its consequences, Macromolecular Symposia 101 (1996) 265-271. [CrossRef]

- R. Bagheri, B.T. Marouf, R.A. Pearson, Rubber-toughened epoxies: a critical review, Polymer Reviews 49 (2009) 201-225. [CrossRef]

- L. Becu, A. Maazouz, H. Sautereau, J.F. Gerard, Fracture behavior of epoxy polymers modified with core-shell rubber particles, Journal of Applied Polymer Science 65 (1997) 2419-2431. [CrossRef]

- J. Macan, K. Paljar, B. Burmas, G. Spehar, M. Leskovac, A. Gajovic, Epoxy-matrix composites filled with surface-modified SiO2 nanoparticles, Journal of Thermal Analysis and Calorimetry 127 (2017) 399-408. [CrossRef]

- J. Liu, C. Chen, Y. Feng, Y. Liao, Y. Ye, X. Xie, Y.W. Mai, Ultralow-Carbon Nanotube-Toughened Epoxy: The Critical Role of a Double-Layer Interface, ACS applied materials & interfaces 10 (2018) 1204-1216. [CrossRef]

- X.F. Yao, D. Zhou, H.Y. Yeh, Macro/microscopic fracture characterizations of SiO2/epoxy nanocomposites, Aerospace Science and Technology 12 (2008) 223-230.

- N. Domun, H. Hadavinia, T. Zhang, T. Sainsbury, G.H. Liaghat, S. Vahid, Improving the fracture toughness and the strength of epoxy using nanomaterials--a review of the current status, Nanoscale 7 (2015) 10294-10329. [CrossRef]

- P.R. Thakre, D.C. Lagoudas, J.C. Riddick, T.S. Gates, S.-J.V. Frankland, J.G. Ratcliffe, J. Zhu, E.V. Barrera, Investigation of the effect of single wall carbon nanotubes on interlaminar fracture toughness of woven carbon fiber-epoxy composites, Journal of Composite Materials 45 (2011) 1091-1107. [CrossRef]

- V. Eskizeybek, A. Avci, A. Gülce, The Mode I interlaminar fracture toughness of chemically carbon nanotube grafted glass fabric/epoxy multi-scale composite structures, Composites Part A: Applied Science and Manufacturing 63 (2014) 94-102. [CrossRef]

- Y. Liu, J.-P. Yang, H.-M. Xiao, C.-B. Qu, Q.-P. Feng, S.-Y. Fu, Y. Shindo, Role of matrix modification on interlaminar shear strength of glass fibre/epoxy composites, Composites Part B: Engineering 43 (2012) 95-98. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).