Submitted:

17 August 2023

Posted:

18 August 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

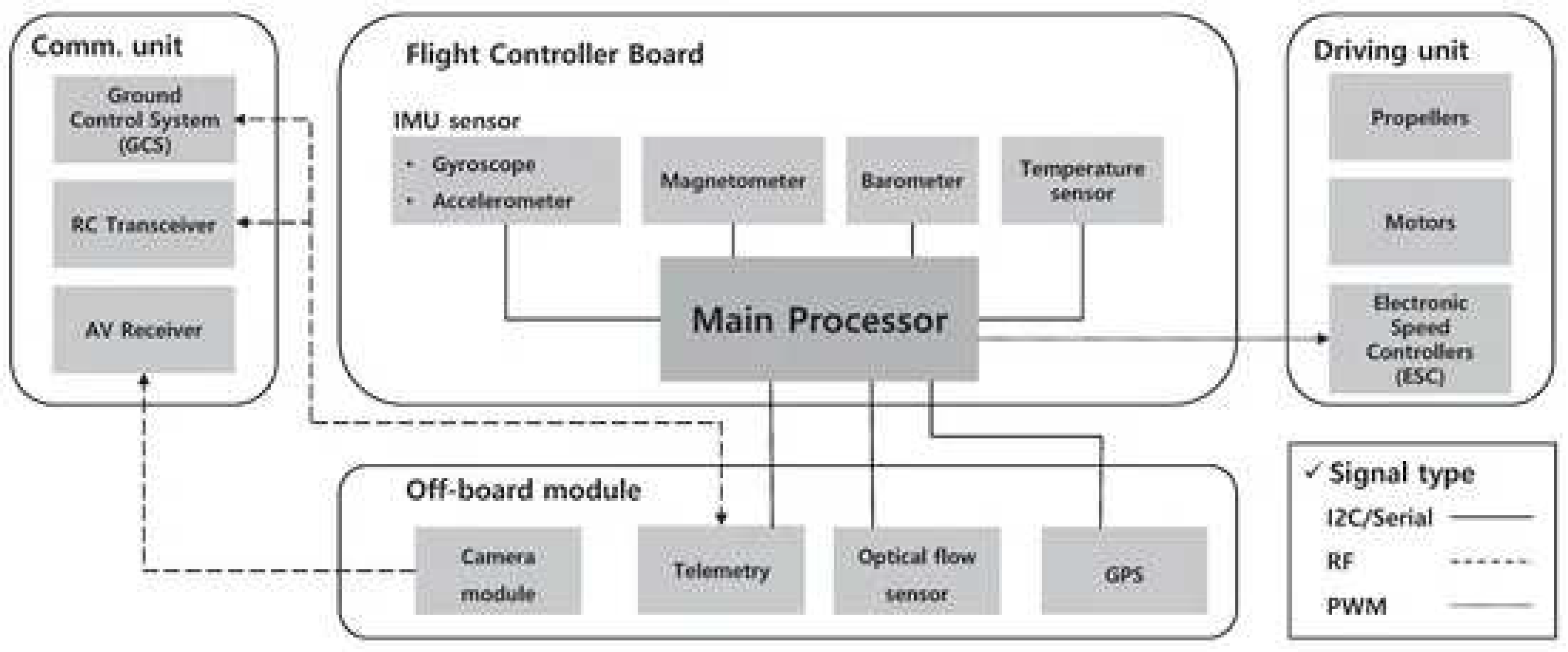

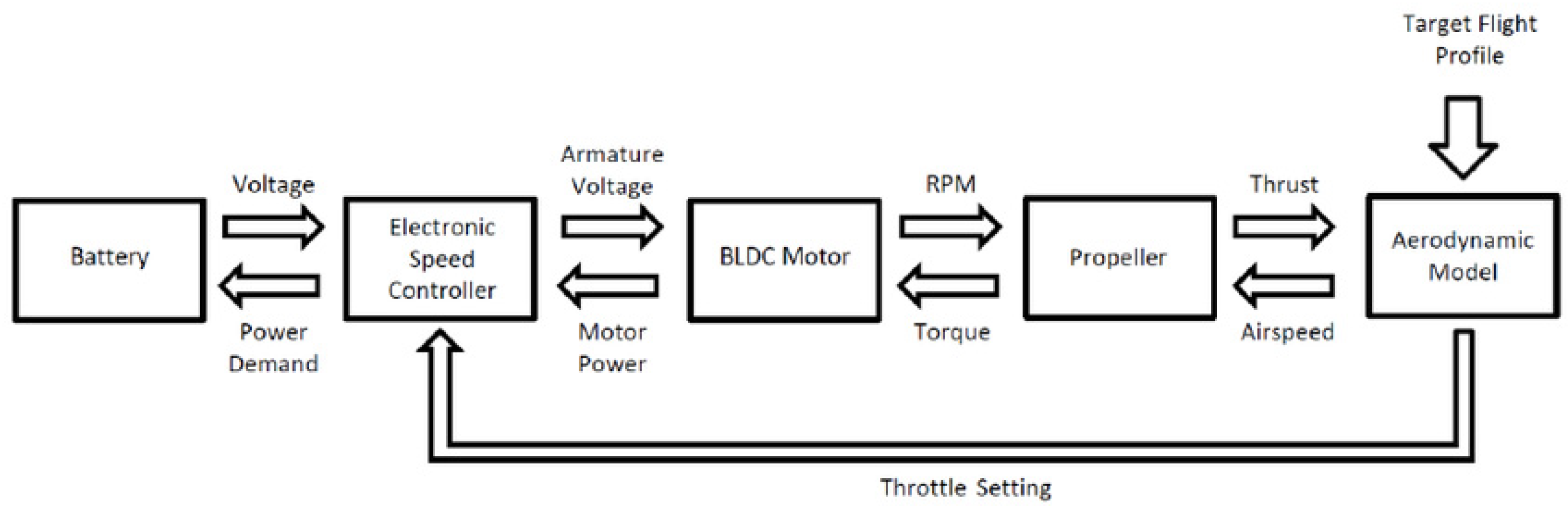

2. Unmanned Aerial Vehicle (UAV)

2.1. Unmanned Aerial Vehicle (UAV) Power Sources

2.2. Battery – Based Supply Techniques

2.2.1. Battery Powered Unmanned Aerial Vehicle (UAV)

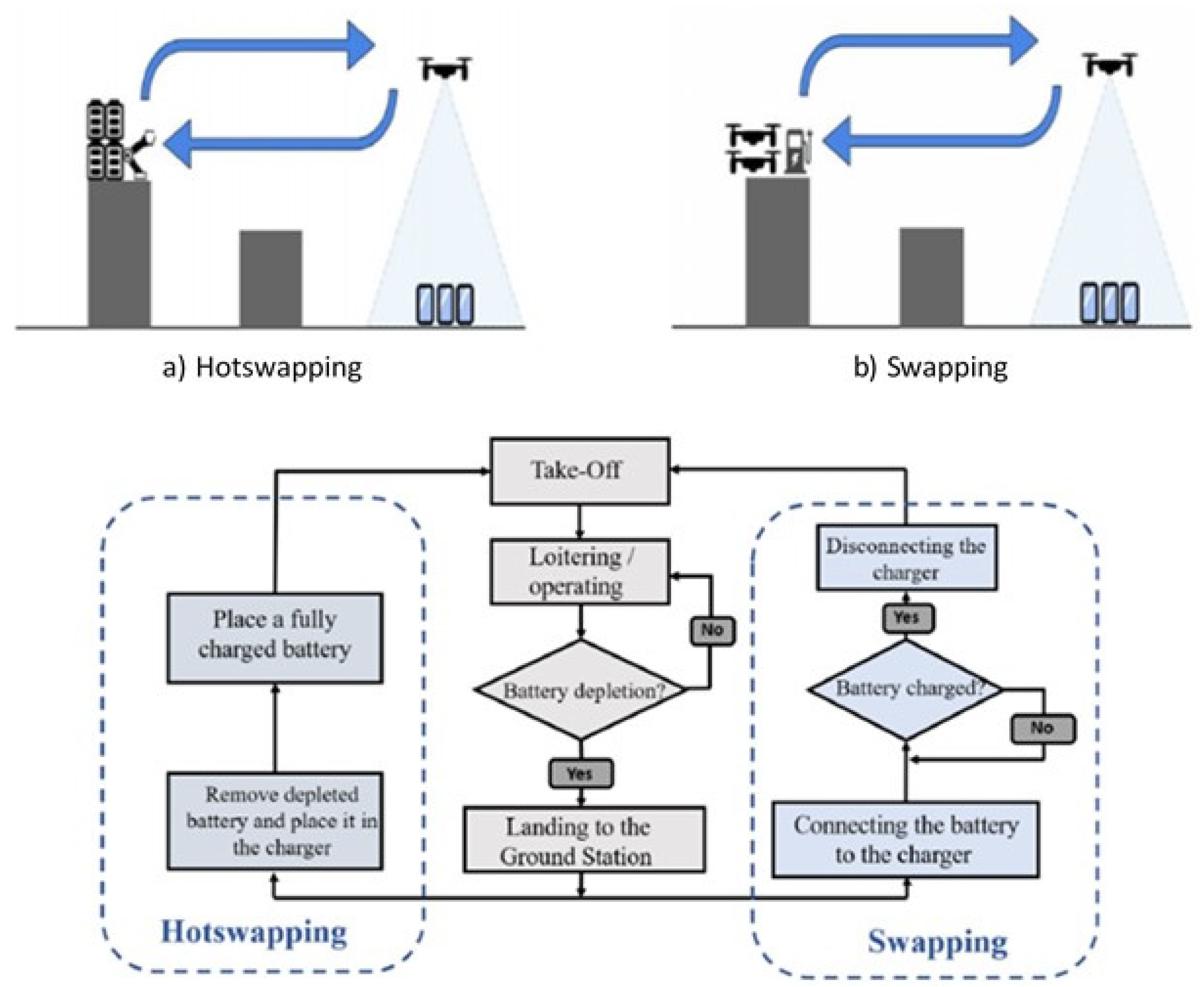

2.2.2. Swapping Method Algorithm

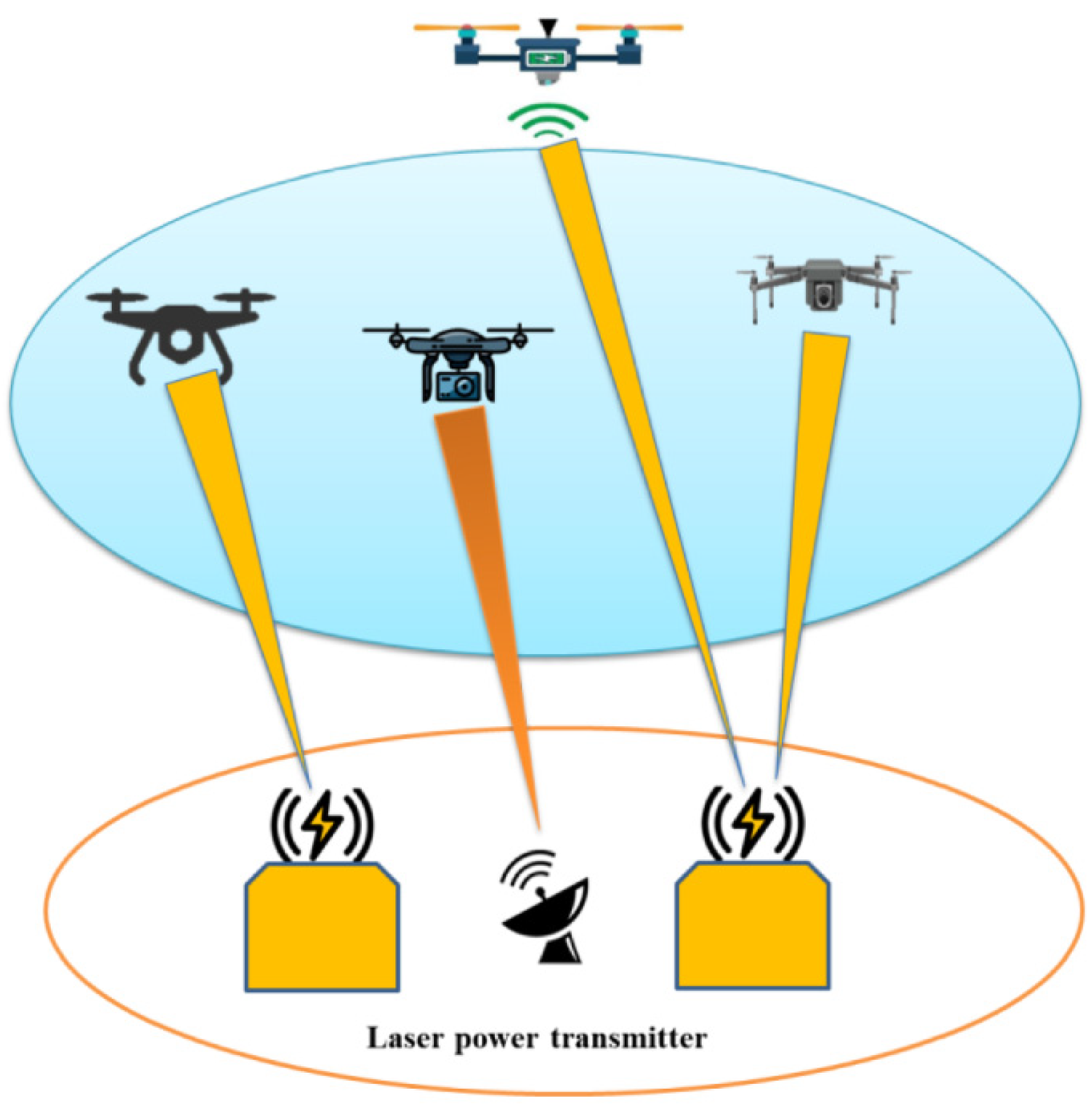

2.2.3. Laser-beam inflight recharging

2.2.4. Tethered UAVs

2.3. Fuel Cell Powered UAVs

| Power supplying technique | Advantages | Limitations and drawbacks |

|---|---|---|

| Swapping | Hydrogen-powered UAVs offer the advantage of unlimited operating time, making them a viable option for long-range missions. Unlike battery-powered UAVs that require multiple battery packs or frequent recharging, hydrogen-powered UAVs rely on a single energy source, namely hydrogen fuel. This significantly reduces the weight and complexity of power management systems. With a hydrogen fuel cell system, the UAV can continuously generate electrical energy by combining hydrogen and oxygen, producing water vapor as a by-product. This continuous power generation eliminates the need for carrying multiple batteries or landing for recharging, allowing the UAV to operate for extended periods without interruption. The reduction in weight and complexity of power management systems brings several benefits. Firstly, the overall weight of the UAV is reduced, enabling increased payload capacity or longer flight durations. Secondly, the simplified power management system decreases the risk of component failures and improves overall reliability. Moreover, the reduced complexity also simplifies maintenance and servicing, contributing to more efficient operations. These advantages make hydrogen-powered UAVs particularly suitable for long-range missions where endurance and uninterrupted operation are crucial. Applications such as aerial surveillance, environmental monitoring, and remote sensing can greatly benefit from the extended operating time and reduced power management requirements of hydrogen-powered UAVs. However, it is important to consider the infrastructure for hydrogen storage, transportation, and refuelling, as well as safety considerations associated with handling hydrogen gas. Proper infrastructure development, safety protocols, and regulations are necessary to support the widespread adoption of hydrogen-powered UAVs and ensure their safe and efficient operation. |

The use of a ground station (GS) in the context of battery-powered UAVs can introduce certain challenges and considerations. While a GS can provide benefits such as battery charging or swapping capabilities, it also brings along some limitations that impact operational efficiency. One of the major concerns is the increased cost associated with deploying and maintaining a GS. As the number of batteries and UAVs in operation increases, the infrastructure and resources required for the GS also need to scale accordingly. This can result in higher costs for equipment, maintenance, and operational management. Another challenge is the coordination and cooperation between UAVs and the GS. Efficient communication and synchronization are essential for smooth operations. UAVs need to interact with the GS to initiate battery charging or swapping processes, which requires effective communication protocols and coordination algorithms. Failure in communication or synchronization can disrupt the operations and lead to inefficiencies. Autonomous swapping, which involves landing and battery changing operations, can introduce additional issues. Precise UAV positioning during landing is crucial to ensure safe and accurate battery swapping. Any errors or discrepancies in landing can affect the efficiency and reliability of the swapping process. Designing and implementing robust algorithms and mechanisms to achieve precise positioning and seamless battery changing operations is a complex task. Furthermore, autonomous swapping systems need to address concerns related to the compatibility of different UAV models and battery types. Ensuring that the swapping mechanism is compatible with a wide range of UAVs and batteries adds complexity to the system design and may require customization or adaptation for different configurations. Overall, while the concept of a ground station and autonomous swapping holds promise for extending UAV operational time, it is important to address the challenges associated with cost, cooperation between UAVs and the GS, and the technical issues related to landing and battery changing operations. Thorough planning, system design, and testing are necessary to achieve efficient and reliable autonomous swapping systems in practical applications. |

| Laser-beam charging |

The concept of wireless refuelling offers significant advantages for UAVs, including the potential for unlimited operating time and extended mission durations. With this approach, UAVs can receive a continuous supply of power without the need to land or swap batteries. This eliminates the limitations imposed by battery capacity and enables persistent missions. By utilizing a wireless power transfer system, UAVs can remain in air while receiving power from a ground station or an aerial power link area. This continuous power supply ensures that the UAVs can operate without interruption, effectively extending their operating range and mission capabilities. The use of a single energy source in wireless refuelling simplifies the power management system of the UAV. There is no need to manage multiple batteries or swap them out, reducing the weight and complexity associated with power management. This streamlined approach enhances the overall efficiency and reliability of the UAV system. Wireless refuelling also eliminates the need for UAVs to land, reducing the risks and challenges associated with take-off and landing operations. This improves safety and minimizes potential damage or wear and tear on the UAVs during landing and take-off manoeuvres. With unlimited operating time and extended range, wireless refuelling opens up possibilities for a wide range of applications. UAVs can be deployed for persistent surveillance, long-range mapping, remote sensing, and other missions that require continuous operation over extended periods. However, it's important to note that wireless refuelling is still an emerging technology, and further research and development are needed to optimize its efficiency, safety, and scalability. Challenges such as power efficiency, regulatory considerations, and infrastructure requirements must be addressed to fully realize the potential of wireless refuelling for UAVs. |

While wireless refuelling using laser beams offers potential benefits for UAVs, there are certain constraints and considerations that need to be addressed. One of these constraints is the necessity of a ground station (GS) equipped with a laser transmitter to provide power to the UAVs. This means that the UAVs need to operate within a certain range of the GS to maintain a reliable power transfer. This range limitation can restrict the operating area of the UAVs and may not be suitable for missions that require long-range coverage or operations in remote areas. Another constraint is related to the operating heights of the UAVs during laser beam refuelling. In order to maintain a consistent power transfer, the UAVs typically need to operate at reduced heights, which can be influenced by regulations and safety considerations. For instance, the Federal Aviation Administration (FAA) sets maximum altitude restrictions for small UAVs, limiting their operating height to 400 feet. Compliance with these regulations may further restrict the altitude range for UAVs using laser beam refuelling. Obstruction of the laser beam is another consideration. The laser beam used for refuelling needs a clear path between the GS and the UAV. This means that obstacles such as buildings, trees, or other structures can obstruct the beam, potentially interrupting the power transfer. Careful planning and positioning of the GS and the UAVs are required to minimize the risk of obstruction and ensure a reliable power supply. Furthermore, the range of laser beams used for wireless refuelling is typically limited compared to the range of traditional propulsion systems. This can impact the operational range of the UAVs, especially for missions that require long-distance coverage or operations in remote areas. Overall, while wireless refuelling using laser beams offers advantages such as extended flight duration and continuous operation, the necessity of a GS, constraints related to operating heights and beam obstruction, and reduced range need to be carefully considered when evaluating its suitability for specific UAV missions. Proper planning, regulatory compliance, and technological advancements are necessary to overcome these constraints and fully leverage the benefits of laser beam refuelling for UAVs. |

| Tethered UAVs |

Wireless refuelling using laser beams offers the potential for unlimited operating time for UAVs without the need to land. By utilizing a single energy source, such as a ground station equipped with a laser transmitter, the UAVs can receive a continuous and uninterrupted power supply while in flight. This eliminates the need for frequent battery changes or recharging, allowing for persistent operation and extended mission durations. In addition to providing power, wireless refuelling also enables safe and effective data transfer between the UAV and the ground station. Along with power, the laser beam can be used to transmit data and communication signals, ensuring seamless connectivity and information exchange between the UAV and the ground control. The ability to operate continuously and receive power and data transfer wirelessly offers several advantages. It enables UAVs to perform long-duration missions without interruption, making them suitable for applications that require persistent surveillance, monitoring, or data gathering. It also reduces the logistical challenges and risks associated with manual battery replacement or refuelling operations, as the UAVs can remain in air and operational throughout their mission. Moreover, wireless refuelling contributes to increased safety by eliminating the need for frequent take offs and landings, which can be risky manoeuvres for UAVs. The continuous operation and avoidance of landing procedures minimize the chances of accidents or incidents during mission execution. Overall, wireless refuelling with a single energy source provides UAVs with the capability for unlimited operating time, persistent operation, safe data transfer, and reduced reliance on ground-based support. These advantages make it an attractive solution for various applications where extended flight durations, continuous operation, and efficient data transfer are essential. |

While wireless refuelling offers the advantage of unlimited operating time and eliminates the need for landing or battery replacement, it does come with certain limitations. One of these limitations is the necessity of a ground station (GS) to provide the power supply or laser transmitter. The GS serves as the central hub for supplying power or transmitting the laser beam to the UAV in flight. Additionally, wireless refuelling methods often have constraints related to the operating area of the UAV. For example, laser beams used for power transfer may have limited range or be affected by obstructions, such as buildings or other objects that can block or interfere with the transmission. This can restrict the operational altitude and area of the UAV, requiring it to operate within a specific range from the GS to maintain a consistent power supply. Another concern with wireless refuelling is the potential for UAV damage in case of tethering loss. In some cases, UAVs may be tethered to the power source or laser transmitter through physical connections, such as cables or beams. If the tethering connection is lost or severed, it can lead to a sudden loss of power or disruption in the energy transfer, which may result in the UAV losing control or experiencing a sudden shutdown. This can potentially lead to damage to the UAV or compromise the mission's success. To mitigate these limitations and concerns, careful planning, system redundancy, and safety measures need to be implemented. This may involve the use of backup power sources or redundant laser transmitters to ensure uninterrupted operation and minimize the risk of power loss. Additionally, thorough risk assessments and safety protocols should be in place to prevent or mitigate potential damage to the UAV in case of tethering loss or system failures. Overall, while wireless refuelling offers advantages such as unlimited operating time and no landing requirements, it is important to consider the necessity of a GS, the limitations on operating area, and the potential risks associated with tethering loss. Proper planning, robust systems, and safety measures can help address these concerns and ensure the efficient and safe operation of UAVs using wireless refuelling methods. |

2.3.1. Fuel cells efficiency issue

2.3.2. Fuel storage

- Compressed hydrogen gas: Hydrogen gas is stored in tanks under high pressure. This method allows for easier storage and refuelling compared to other techniques. However, it requires high-pressure tanks, which can add weight and volume to the UAV.

- Liquid hydrogen: Hydrogen is stored in a liquid state at very low temperatures. This method provides a higher energy density compared to compressed gas storage. However, it requires specialized cryogenic storage systems and insulation, which can add complexity and weight to the UAV.

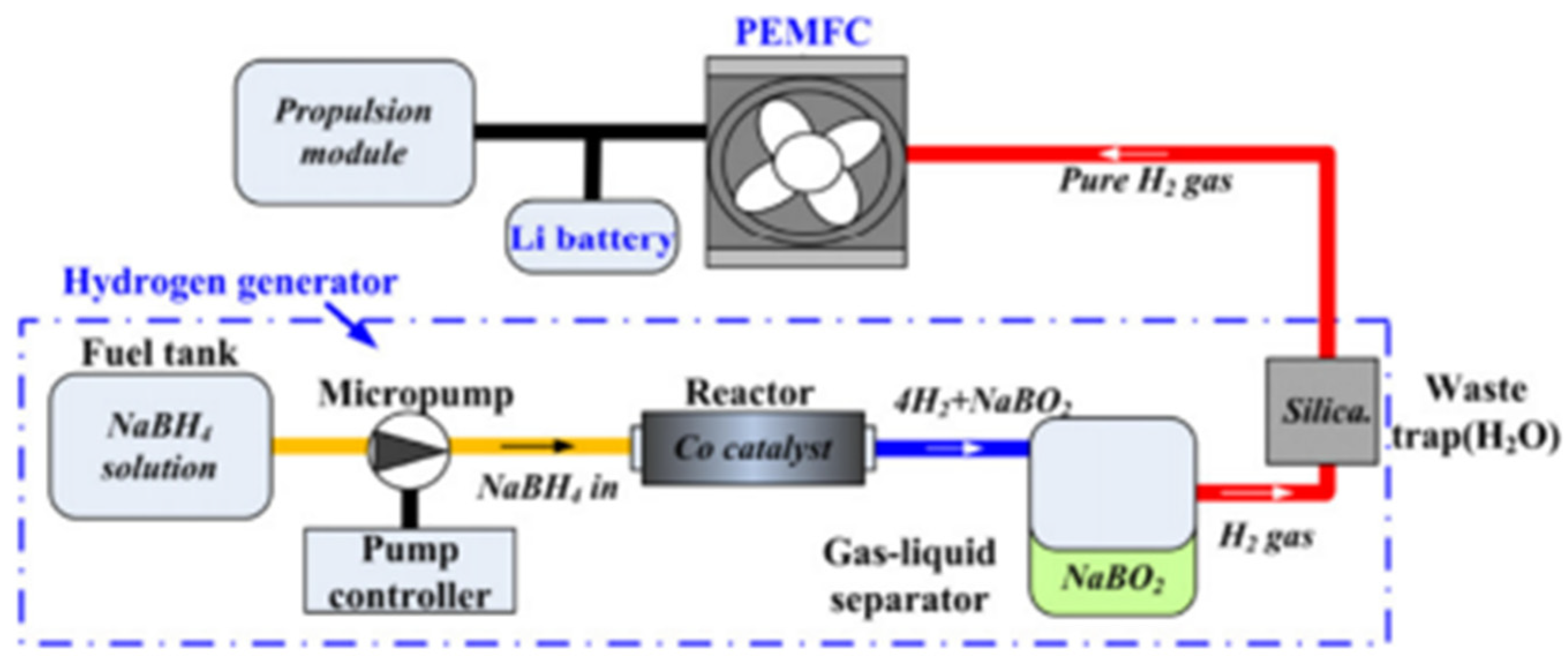

- Chemical hydrogen generation: Hydrogen is generated onboard the UAV through chemical reactions, such as the reaction between a metal hydride and water. This method offers the advantage of generating hydrogen as needed, eliminating the need for storing large quantities of hydrogen. However, it requires additional components and can have limitations in terms of hydrogen generation rate.

2.4. Hybrid Power Sources (Fuel cell and battery)

| Type | Energy density (Wh/kg) |

Power density (W/kg) |

Cycle life (Times) |

Efficiency (%) |

|---|---|---|---|---|

| Lead-acid battery | 30-40 | 200-300 | 300-400 | 75 |

| Ni-MH battery | 60-80 | 800-1500 | 1000 | 75 |

| Li-ion battery | 100-120 | 600-2000 | 1000 | 90 |

| Supercapacitor | 4-15 | 1000-10,0000 | 100,000 | 85-98 |

| Type | Advantages | Disadvantages |

|---|---|---|

| Lead-acid battery | Affordable, rapid discharging rate, and high recyclability. | Inadequate performance in low temperature conditions. |

| Ni-MH battery | High energy density, quick charging and discharging, and extended lifespan. | Pronounced self-discharge rate, necessity for cooling system, and higher manufacturing expenses. |

| Li-ion battery | Elevated voltage, superior energy density, lightweight, durable cycle life, minimal self-discharge, absence of memory effect, and eco-friendly. | Reduced lifespan in high-temperature environments, susceptibility to overcharging and over-discharging, and stringent security requirements. |

| Supercapacitor | Swift charging and discharging capabilities, absence of pollution, and remarkably | Limited energy density. |

| Energy sources |

Architecture | Advantages | Limitations and drawbacks |

|---|---|---|---|

| Thermal energy |

Gas turbine engine | Impressive ratio of power to weight, coupled with extended duration of operation. | Extremely poor fuel efficiency and elevated noise levels. |

| ICE | Exceptionally high power and energy densities, extended endurance, and significant payload range. | Decreased efficiency, thermal and acoustic signatures, greenhouse gas emissions, and high fuel costs. | |

| One electrical source |

Battery | Significant energy density and storage (rather than generation), resulting in a rapid response to power demand. | Limited power density, decreased endurance, and prolonged recharging time with the presence of "memory effect" in certain battery types. To enhance autonomy, additional batteries need to be added, leading to increased weight and cost. |

| Fuel cell | Significant energy density, instant refuelling without the presence of a "memory effect," allowing for increased autonomy by using more fuel within the same stack, resulting in weight reduction. | Due to the process of energy generation, there is a slower response to power demand in fuel cells. Additionally, auxiliary equipment such as compressors and regulators are required for their operation. Challenges related to the lack of hydrogen distribution infrastructure, issues with hydrogen storage, safety concerns, and the high cost of hydrogen production are also present. | |

| Hybrid power supply |

Fuel cell and Battery |

The high energy and power densities of the hybrid power supply result in increased endurance and faster response time. This allows for efficient energy generation and storage, enhancing the overall performance of the system. | The use of a hybrid power supply system leads to an increase in weight, as additional components such as controllers and converters are required to manage the system. This introduces added complexity to the UAV, further contributing to the overall weight. |

| Fuel cell, Battery, and solar cells | The inclusion of an additional energy source in a hybrid power supply system results in improved endurance for the UAV. This extra source provides clean and readily available energy, which leads to a decrease in energy costs and saves on hydrogen usage. | Large UAV wings are necessary for the implementation of a hybrid power supply system. However, this configuration is not suitable for rotary-wing UAVs. Additionally, an energy storage device is required to store and manage the energy generated by the system. The hybrid system also necessitates the use of an Energy Management System (EMS) and Maximum Power Point Tracking (MPPT) to optimize the power flow and ensure efficient operation. | |

| Fuel cell, Battery, and supercapacitor | The hybrid system consisting of a fuel cell, battery, and supercapacitor offers several advantages. It provides very high power density, enabling efficient and rapid charging. It also contributes to reduced weight and minimized fluctuations in the direct current (DC) bus. The system exhibits a very long lifetime, thanks to its reduced internal resistance, and experiences minimal heat loss. These features make the hybrid system highly desirable for various applications, ensuring optimal performance and reliability. | The integration of an Energy Management System (EMS) is essential in the hybrid system, which includes a fuel cell, battery, and supercapacitor. The EMS plays a crucial role in coordinating and regulating the power flow between these components. It ensures efficient utilization of the energy sources, manages charging and discharging processes, and maintains the stability of the system. Additionally, the voltage regulation of the supercapacitor is necessary to ensure its proper operation and prevent any voltage-related issues. The EMS and supercapacitor voltage regulation contribute to the overall performance and reliability of the hybrid system. |

3. Conclusion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhai Q, Meng K, Dong ZY, and Ma J. “Modeling and Analysis of Lithium Battery Operations in Spot and Frequency Regulation Service Markets in Australia Electricity Market.” IEEE Trans Ind Informatics. (2017);13(5):2576–86. [CrossRef]

- Horla, D., Giernacki, W., Báča, T. et al. AL-TUNE: A Family of Methods to Effectively Tune UAV Controllers in In-flight Conditions. J Intell Robot Syst, 2021, 103, 5. [CrossRef]

- Tsmots, I.; Teslyuk, V.; Łukaszewicz, A.; Lukashchuk, Y.; Kazymyra, I.; Holovatyy, A.; Opotyak, Y. An Approach to the Implementation of a Neural Network for Cryptographic Protection of Data Transmission at UAV. Drones 2023, 7, 507. https://doi.org/10.3390/drones7080507. [CrossRef]

- Holovatyy A., Łukaszewicz A., Teslyuk V., Ripak N. (2022): Development of AC Voltage Stabilizer with Microcontroller-Based Control System In: 2022 IEEE 17th International Conference on Computer Sciences and Information Technologies (CSIT), 2022, Institute of Electrical and Electronics Engineers, pp.527-530. [CrossRef]

- Pytka J., Budzynski P., Tomilo P., Laskowski J., Michalowska J., Gnapowski E., Blazejczak D., Lukaszewicz A. (2021): IMUMETER - AI-based sensor for airplane motion measurements 2021 IEEE International Workshop on Metrology for AeroSpace, MetroAeroSpace 2021 - Proceedings, art. no. 9511767, pp. 692-697. [CrossRef]

- Pytka, J.; Budzyński, P.; Łyszczyk, T.; Józwik, J.; Michałowska, J.; Tofil, A.; Błażejczak, D.; Laskowski, J. Determining wheel forces and moments on aircraft landing gear with a dynamometer sensor. Sensors 2020, 20, 227. https://doi.org/10.3390/s20010227. [CrossRef]

- Chandran, N.K.; Sultan, M.T.H.; Łukaszewicz, A.; Shahar, F.S.; Holovatyy, A.; Giernacki, W. Review on Type of Sensors and Detection Method of Anti-Collision System of Unmanned Aerial Vehicle. Sensors 2023, 23, 6810. https://doi.org/10.3390/s23156810. [CrossRef]

- Łukaszewicz, A.; Szafran, K.; Józwik, J. CAx techniques used in UAV design process. In Proceedings of the 2020 IEEE 7th International Workshop on Metrology for AeroSpace (MetroAeroSpace), Pisa, Italy, 22–24 June 2020; pp. 95–98. https://doi.org/10.1109/MetroAeroSpace48742.2020.9160091. [CrossRef]

- Kotarski, D.; Piljek, P.; Pranjić, M.; Grlj, C.G.; Kasać, J. A Modular Multirotor Unmanned Aerial Vehicle Design Approach for Development of an Engineering Education Platform. Sensors 2021, 21, 2737. https://doi.org/10.3390/s21082737. [CrossRef]

- Krznar, M.; Piljek, P.; Kotarski, D.; Pavković, D. Modeling, Control System Design and Preliminary Experimental Verification of a Hybrid Power Unit Suitable for Multirotor UAVs. Energies 2021, 14, 2669. https://doi.org/10.3390/en14092669. [CrossRef]

- Turk, I.; Ozbek, E.; Ekici, S.; Karakoc, T.H. A conceptual design of a solar powered UAV and assessment for continental climate flight conditions. Int. J. Green Energy 2022, 19, 638–648. https://doi.org/10.1080/15435075.2021.1954008. [CrossRef]

- Rodríguez-Sevillano, Á.A.; Casati-Calzada, M.J.; Bardera-Mora, R.; Nieto-Centenero, J.; Matías-García, J.C.; Barroso-Barderas, E. Rapid Parametric CAx Tools for Modelling Morphing Wings of Micro Air Vehicles (MAVs). Aerospace 2023, 10, 467. https://doi.org/10.3390/aerospace10050467. [CrossRef]

- Ozbek, E.; Ekici, S.; Karakoc, T.H. Unleashing the Potential of Morphing Wings: A Novel Cost Effective Morphing Method for UAV Surfaces, Rear Spar Articulated Wing Camber. Drones 2023, 7, 379. https://doi.org/10.3390/drones7060379. [CrossRef]

- Kotarski, D.; Piljek, P.; Pranjić, M.; Kasać, J. Concept of a Modular Multirotor Heavy Lift Unmanned Aerial Vehicle Platform. Aerospace 2023, 10, 528. https://doi.org/10.3390/aerospace10060528. [CrossRef]

- Miatliuk, K.; Lukaszewicz, A.; Siemieniako, F. Coordination method in design of forming operations of hierarchical solid objects. 2008 International Conference on Control, Automation and Systems, ICCAS 2008, art. no. 4694220, pp. 2724 - 2727. https://doi.org/10.1109/ICCAS.2008.4694220. [CrossRef]

- Grodzki, W.; Łukaszewicz, A. Design and manufacture of unmanned aerial vehicles (UAV) wing structure using composite materials. Mater. Werkst. 2015, 46, 269–278. https://doi.org/10.1002/mawe.201500351. [CrossRef]

- Parparita, M.; Bere, P.; Józwik, J.; Biruk-Urban, K. Design and Manufacturing of a Small Sized UAV Wing. 2023 IEEE 10th International Workshop on Metrology for AeroSpace (MetroAeroSpace), Milan, Italy, 2023, 187-192. https://doi.org/10.1109/MetroAeroSpace57412.2023.10190041. [CrossRef]

- Leleń, M.; Józwik; J. Analysis of technological parameters of hydroabrasive cutting of multilayer aerospace structures of aluminium alloy - carbon composite type. 2023 IEEE 10th International Workshop on Metrology for AeroSpace (MetroAeroSpace), Milan, Italy, 2023, 638-643, https://doi.org/10.1109/MetroAeroSpace57412.2023.10189961. [CrossRef]

- Šančić, T.; Brčić, M.; Kotarski, D.; Łukaszewicz, A. Experimental Characterization of Composite-Printed Materials for the Production of Multirotor UAV Airframe Parts. Materials 2023, 16, 5060. https://doi.org/10.3390/ma16145060. [CrossRef]

- Tomiło, P.; Pytka, J.; Józwik, J.; Gnapowski, E.; Muszyński T.; Łukaszewicz, A. Latent Neural Network For `Recognition of Annomalies in 3D-Print of a Scale Model for Wind Tunnel Measurements. 2023 IEEE 10th International Workshop on Metrology for AeroSpace (MetroAeroSpace), Milan, Italy, 2023, 688-692, https://doi.org/10.1109/MetroAeroSpace57412.2023.10190049. [CrossRef]

- Alwateer M, Loke SW, and Fernando N. “Enabling drone services: Drone crowdsourcing and drone scripting.” IEEE Access. (019);7:110035–49. [CrossRef]

- Pan ZF, An L, and Wen CY. “Recent advances in fuel cells based propulsion systems for unmanned aerial vehicles.” Appl Energy. (2019);240:473–85. [CrossRef]

- Berger, G.S.; Teixeira, M.; Cantieri, A.; Lima, J.; Pereira, A.I.; Valente, A.; Castro, G.G.R.d.; Pinto, M.F. Cooperative Heterogeneous Robots for Autonomous Insects Trap Monitoring System in a Precision Agriculture Scenario. Agriculture 2023, 13, 239. https://doi.org/10.3390/agriculture13020239. [CrossRef]

- Nowakowski M.; Kurylo, J. Usability of Perception Sensors to Determine the Obstacles of Unmanned Ground Vehicles Operating in Off-Road Environments. Appl. Sci. 2023, 13, 4892. https://doi.org/10.3390/app13084892. [CrossRef]

- Silarski, M.; Nowakowski, M. Performance of the SABAT Neutron-Based Explosives Detector Integrated with an Unmanned Ground Vehicle: A Simulation Study. Sensors 2022, 22, 9996. https://doi.org/10.3390/s22249996. [CrossRef]

- Puchalski R, Giernacki W. UAV Fault Detection Methods, State-of-the-Art. Drones. 2022; 6(11):330. [CrossRef]

- Alwateer M, Loke SW, and Zuchowicz AM. “Drone services: issues in drones for location-based services from human-drone interaction to information processing.” J Locat Based Serv. (2019);13(2):94–127. [CrossRef]

- Tang L and Shao G. “Drone remote sensing for forestry research and practices.” J For Res. (2015);26(4):791–7. [CrossRef]

- RS Components. Xu Y, Yang Y, Jiang H, Zhang Y, and Xu Y. “Energy-efficient multi-UAV coverage deployment in UAV networks: A game-theoretic framework.” China Commun. (2018);15(10):194–209.

- Claesson A, Svensson L, Nordberg P, Ringh M, Rosenqvist M, Djarv T, Samuelsson J, Hernborg O, Dahlbom P, Jansson A, and Hollenberg J. “Claesson et al. - 2017 - Drones may be used to save lives in out of hospital cardiac arrest due to drowning.pdf.” Resuscitation. (2017);114:152–6. [CrossRef]

- Loke SW, Alwateer M, and Abeysinghe Achchige Don VSA. “Virtual space boxes and drone-as-reference-station localisation for drone services: An approach based on signal strengths.” DroNet 2016 - Proc 2nd Work Micro Aer Veh Networks, Syst Appl Civ Use, co-located with MobiSys 2016. (2016);45–8.

- Shukla A, Xiaoqian H, and Karki H. “Autonomous tracking and navigation controller for an unmanned aerial vehicle based on visual data for inspection of oil and gas pipelines.” Int Conf Control Autom Syst. (2016);0:194–200. [CrossRef]

- Michałowska J., Tofil A., Józwik J., Pytka J., Legutko S., Siemiątkowski Z., Łukaszewicz A. (2019): Monitoring the risk of the electric component imposed on a pilot during light aircraft operations in a high-frequency electromagnetic field, Sensors (Switzerland), Vol. 19 (24), art. no. 5537. [CrossRef]

- Bacco M, Berton A, Ferro E, Gennaro C, Gotta A, Matteoli S, Paonessa F, Ruggeri M, Virone G, and Zanella A. “Smart farming: Opportunities, challenges and technology enablers.” 2018 IoT Vert Top Summit Agric - Tuscany, IOT Tuscany 2018. (2018);1–6. [CrossRef]

- Thakar, PS, Markana, A, Miyani, PB. Robust temperature tracking and estimation for resistive heater circuit board with implementation. Adv Control Appl. 2023; 5( 2):e147. https://doi.org/10.1002/adc2.147. [CrossRef]

- Ding G, Wu Q, Zhang L, Lin Y, Tsiftsis TA, and Yao YD. “An Amateur Drone Surveillance System Based on the Cognitive Internet of Things.” IEEE Commun Mag. (2018);56(1):29–35. [CrossRef]

- Yoo S, Kim K, Jung J, Chung AY, Lee J, Lee SK, Lee HK, and Kim H. “A multi-drone platform for empowering drones’ teamwork.” In: Proceedings of the Annual International Conference on Mobile Computing and Networking, MOBICOM. 2015. p. 275–7.

- Lee J, Kim K, Yoo S, Chung AY, Lee JY, Park SJ, and Kim H. “Constructing a reliable and fast recoverable network for drones.” 2016 IEEE Int Conf Commun ICC 2016. (2016). [CrossRef]

- Zhou J, Zhang B, Xiao W, Qiu D, and Chen Y. “Nonlinear Parity-Time-Symmetric Model for Constant Efficiency Wireless Power Transfer: Application to a Drone-in-Flight Wireless Charging Platform.” IEEE Trans Ind Electron. (2019);66(5):4097–107. [CrossRef]

- Lu M, Bagheri M, James AP, and Phung T. “Wireless Charging Techniques for UAVs: A Review, Reconceptualization, and Extension.” IEEE Access. (2018);6:29865–84. [CrossRef]

- Sato A and Naknishi H. “Observation and measurement in disaster areas using industrial use unmanned helicopters.” In: 12th IEEE International Symposium on Safety, Security and Rescue Robotics, SSRR 2014 - Symposium Proceedings. 2014. [CrossRef]

- Mikołajczyk, T., Mikołajewski, D., Kłodowski, A., Łukaszewicz, A., Mikołajewska, E., Paczkowski, T., Macko, M., Skornia, M. (2023). Energy Sources of Mobile Robot Power Systems: A Systematic Review and Comparison of Efficiency. Applied Sciences-Basel, 13, 1–24. [CrossRef]

- Afridrones Aviation CC. “Afridrones” [Internet]. 2020 [cited 2023 Jun 15]. Available from: https://afridrones.com/home_190315/.

- Vanchiappan A, Joe G, Yun-Sung L, and Srinivasan M. “Insertion-type electrodes for nonaqueous Li-ion capacitors.” Chem Rev. (2014);114(23):11619–35. [CrossRef]

- Ci S, Lin N, and Wu D. “Reconfigurable Battery Techniques and Systems: A Survey.” IEEE Access. (2016);4:1175–89. [CrossRef]

- Rajashekara K. “Present status and future trends in electric vehicle propulsion technologies.” IEEE J Emerg Sel Top Power Electron. (2013);1(1):3–10. [CrossRef]

- Vidal C, Gross O, Gu R, Kollmeyer P, and Emadi A. “XEV Li-Ion Battery Low-Temperature Effects-Review.” IEEE Trans Veh Technol. (2019);68(5):4560–72. [CrossRef]

- Wagner FT, Lakshmanan B, and Mathias MF. “Electrochemistry and the future of the automobile.” In: 11AIChE - 2011 AIChE Annual Meeting, Conference Proceedings. 2011. [CrossRef]

- Karden E, Ploumen S, Fricke B, Miller T, and Snyder K. “Energy storage devices for future hybrid electric vehicles.” J Power Sources. (2007);168(1 SPEC. ISS.):2–11. [CrossRef]

- Kim T, Qiao W, and Qu L. “Power electronics-enabled self-X multicell batteries: A design toward smart batteries.” IEEE Trans Power Electron. (2012);27(11):4723–33. [CrossRef]

- Song M, Zhu D, Zhang L, Wang X, Chen Y, Mi R, Liu H, Mei J, and Lau LWM. “Improved charging performances of Li2O2 cathodes in non-aqueous electrolyte lithium-air batteries at high test temperatures.” In: ICMREE 2013 - Proceedings: 2013 International Conference on Materials for Renewable Energy and Environment. 2013. p. 513–5. [CrossRef]

- Meng J, Luo G, and Gao F. “Lithium polymer battery state-of-charge estimation based on adaptive unscented kalman filter and support vector machine.” IEEE Trans Power Electron. (2016);31(3):2226–38. [CrossRef]

- 53. Kranjec, B.; Sladic, S.; Giernacki, W.; Bulic, N. PV System Design and Flight Efficiency Considerations for Fixed-Wing Radio-Controlled Aircraft—A Case Study. Energies 2018, 11, 2648. https://doi.org/10.3390/en11102648 ] on board of the UAV. [CrossRef]

- RS Components. “Fiamm 12V Faston F1 Sealed Lead Acid Battery, 2Ah” [Internet]. [cited 2023 May 18]. Available from: https://za.rs-online.com/web/p/lead-acid-batteries/8431308/.

- RS Components. “RS PRO 12V NiMH Rechargeable Battery Pack, 2Ah - Pack of 1” [Internet]. [cited 2023 May 18]. Available from: https://za.rs-online.com/web/p/rechargeable-battery-packs/ 7770400/.

- RS Components. “Samsung, INR-18650 20R, 3.6V, 18650, Lithium-Ion Rechargeable Battery, 2Ah” [Internet]. [cited 2023 May 18]. Available from: https://za.rs-online.com/web/p/speciality-size-rechargeable-batteries/ 8182992/.

- RS Components. “RS PRO 12V NiCd Rechargeable Battery Pack, 1.8Ah - Pack of 1” [Internet]. [cited 2023 May 18]. Available from: https://za.rs-online.com/web/p/rechargeable-battery-packs/1253427.

- RS Components. “RS PRO Alkaline AA Battery 1.5V” [Internet]. [cited 2023 May 18]. Available from: https://za.rs-online.com/web/p/aa-batteries/7442199/.

- RS Components. “RS PRO, 3.7V, Lithium Polymer Rechargeable Battery, 2Ah” [Internet]. [cited 2023 May 18]. Available from: https://za.rs-online.com/web/p/speciality-size-rechargeable-batteries/1251266.

- RS Components. “RS PRO PR44 Button Battery, 1.4V, 11.6mm Diameter” [Internet]. [cited 2023 May 18]. Available from: https://za.rs-online.com/web/p/button-batteries/8010730.

- Mantech Electronics. “LITHIUM CELL / BATTERY AA 3V6 2.2AH 14x50.”.

- NASA. “Technology Readiness Level Definitions.” (1989);1. Available from: https://www.nasa.gov/pdf/458490main_TRL_Definitions.pdf.

- Kalogirou SA. “Industrial Process Heat, Chemistry Applications, and Solar Dryers.” In: Solar Energy Engineering. 2009. p. 391–420.

- DRONEII.com. “Drone Energy Sources – Pushing the Boundaries of Electric Flight” [Internet]. [cited 2020 Jul 30]. Available from: https://droneii.com/drone-energy-sources.

- Ganguly S, Das S, Kargupta K, and Bannerjee D. “Optimization of Performance of Phosphoric Acid Fuel Cell (PAFC) Stack using Reduced Order Model with Integrated Space Marching and Electrolyte Concentration Inferencing.” Comput Aided Chem Eng. (2012);31:1010–4. [CrossRef]

- Kumar V, Rudra R, Hait S, Kumar P, and Kundu PP. “Performance trends and status of microbial fuel cells.” Prog Recent Trends Microb Fuel Cells. (2018);7–24. [CrossRef]

- Haile SM, Boysen DA, Chisholm CRI, and Merie RB. “Solid acids as fuel cell electrolytes.” Nature. (2001);410(6831):910–3. [CrossRef]

- Chen B, Li X, and Evangelou S. “Comparative Study of Hybrid Powertrain Architectures from a Fuel Economy Perspective.” In: 14th International Symposium on Advanced Vehicle Control, AVEC’18. 2018. p. 1–6.

- Haile SM, Chisholm CRI, Sasaki K, Boysen DA, and Uda T. “Solid acid proton conductors: From laboratory curiosities to fuel cell electrolytes.” Faraday Discuss. (2007);134:17–39. [CrossRef]

- Rajabi MS, Beigi P, and Aghakhani S. “Drone Delivery Systems and Energy Management: A Review and Future Trends.” (2022); Available from: http://arxiv.org/abs/2206.10765.

- Shah SD. “Electrification of transport and oil displacement: How plug-ins could lead to a 50 percent reduction in US. demand for oil.” Plug-in Electr Veh What Role Washington? (2009);22–44.

- Yilmaz M and Krein PT. “Review of battery charger topologies, charging power levels, and infrastructure for plug-in electric and hybrid vehicles.” IEEE Trans Power Electron. (2013);28(5):2151–69.

- Traub LW. “Range and endurance estimates for battery-powered aircraft.” J Aircr. (2011);48(2):703–7. https://doi.org/10.2514/1.c031027. [CrossRef]

- Wang Y, Chen KS, Mishler J, Cho SC, and Adroher XC. “A review of polymer electrolyte membrane fuel cells: Technology, applications, and needs on fundamental research.” Appl Energy. (2011);88(4):981–1007. [CrossRef]

- Burke A and Miller M. “Comparisons of Ultracapacitors and Advanced Batteries for Pulse Power in Vehicle Applications : Performance , Life , and Cost.” Electronics. :855–66.

- Suzuki KAO, Kemper Filho P, and Morrison JR. “Automatic Battery Replacement System for UAVs: Analysis and Design.” Recent Dev Unmanned Aircr Syst. (2011);563–86.

- Jain AK, Mathapati S, Ranganathan VT, and Narayanan V. “Integrated starter generator for 42-V powernet using induction machine and direct torque control technique.” IEEE Trans Power Electron. (2006);21(3):701–10. [CrossRef]

- Swieringa KA, Hanson CB, Richardson JR, White JD, Hasan Z, Qian E, and Girard A. “Autonomous battery swapping system for small-scale helicopters.” Proc - IEEE Int Conf Robot Autom. (2010);3335–40. [CrossRef]

- Kraemer D, Hu L, Muto A, Chen X, Chen G, and Chiesa M. “Photovoltaic-thermoelectric hybrid systems: A general optimization methodology.” Appl Phys Lett. (2008);92(24). [CrossRef]

- Bocewicz G, Nielsen P, Banaszak Z, and Thibbotuwawa A. “A declarative modelling framework for routing of multiple UAVs in a system with mobile battery swapping stations.” In: Advances in Intelligent Systems and Computing. 2019. p. 429–41. [CrossRef]

- Emadi A, Rajashekara K, Williamson SS, and Lukic SM. “Topological overview of hybrid electric and fuel cell vehicular power system architectures and configurations.” IEEE Trans Veh Technol. (2005);54(3):763–70. [CrossRef]

- Steilen M and Jörissen L. “Hydrogen Conversion into Electricity and Thermal Energy by Fuel Cells.” In: Electrochemical Energy Storage for Renewable Sources and Grid Balancing. 2015. p. 143–58. [CrossRef]

- Thanomjit C, Patcharavorachot Y, and Arpornwichanop A. “Design and Thermal Analysis of a Solid Oxide Fuel Cell System Integrated with Ethanol Steam Reforming.” Comput Aided Chem Eng. (2012);30:287–91. [CrossRef]

- Uzunoglu M and Alam MS. “Fuel-Cell Systems for Transportations.” In: Power Electronics Handbook, Fourth Edition. 2017. p. 1091–112.

- Dharmalingam S, Kugarajah V, and Sugumar M. “Membranes for microbial fuel cells.” In: Biomass, Biofuels, Biochemicals: Microbial Electrochemical Technology: Sustainable Platform for Fuels, Chemicals and Remediation. 2018. p. 143–94.

- Fathabadi H. “Plug-In Hybrid Electric Vehicles: Replacing Internal Combustion Engine with Clean and Renewable Energy Based Auxiliary Power Sources.” IEEE Trans Power Electron. (2018);33(11):9611–8. [CrossRef]

- Mehta V and Cooper JS. “Review and analysis of PEM fuel cell design and manufacturing.” Fuel Cells Compend. (2005);469–501. [CrossRef]

- Mohammed OA, Lowther DA, Lean MH, and Alhalabi B. “On the creation of a generalized design optimization environment for electromagnetic devices.” IEEE Trans Magn. (2001);37(5 I):3562–5. [CrossRef]

- Rhoads GD, Wagner NA, Taylor BJ, Keen DB, and Bradley TH. “Design and flight test results for a 24 hour fuel cell unmanned aerial vehicle.” In: 8th Annual International Energy Conversion Engineering Conference. 2010. [CrossRef]

- Barreras F, Lozano A, Valiño L, Marín C, and Pascau A. “Flow distribution in a bipolar plate of a proton exchange membrane fuel cell: Experiments and numerical simulation studies.” J Power Sources. (2005);144(1):54–66. [CrossRef]

- Gong A, MacNeill R, Verstraete D, and Palmer JL. “Analysis of a Fuel-Cell/Battery /Supercapacitor Hybrid Propulsion System for a UAV Using a Hardware-in-the-Loop Flight Simulator.” 2018 AIAA/IEEE Electr Aircr Technol Symp EATS 2018. (2018). [CrossRef]

- Kim, S.-G.; Lee, E.; Hong, I.-P.; Yook, J.-G. Review of Intentional Electromagnetic Interference on UAV Sensor Modules and Experimental Study. Sensors 2022, 22, 2384. https://doi.org/10.3390/s22062384. [CrossRef]

- B. Galkin, L. A. DaSilva, UAVs as Mobile Infrastructure: Addressing Battery Lifetime, arXiv:1807.00996 [cs] (Jul. 2018). [CrossRef]

| Characteristics | Ni-Cd | Ni-Mh | LiPo | Li-S |

|---|---|---|---|---|

| Specific energy (Wh/kg) | 40 | 80 | 180 | 350 |

| Energy density (Wh/l) | 100 | 300 | 300 | 350 |

| Specific power (W/kg) | 300 | 900 | 2800 | 600 |

| Main Contribution | Advantages | Limitations |

|---|---|---|

| An aerial prototype utilizing multiple rotors designed for surveillance missions of extended duration by employing battery health monitoring. | The hardware prototype enables uninterrupted operation by taking into account battery health considerations. | The system does not include autonomous swapping, and its operation is managed using a laptop instead of an embedded controller. |

| The design, testing, and construction of an autonomous ground recharge station were carried out, incorporating a balancer and safer electrical contacts. | A hardware platform was developed that enabled autonomous swapping, utilizing an embedded controller. An optimization algorithm was implemented to minimize the recharge duration. | Although no flight test was conducted, the hardware platform focused on autonomous swapping and did not consider battery health as a factor in its design. |

| A planning and learning algorithm was developed and tested during a 3-hour long persistent flight involving three UAVs and over 100 battery swaps. | The design and hardware implementation of an automated refuelling system were carried out, and flight tests were conducted to evaluate its performance. | The discussion of system cost and the consideration of landing accuracy were not included in the analysis. |

| An automated swapping mechanism was implemented, incorporating online algorithms for energy management, vehicle health monitoring, and accurate landing. The system aimed to optimize the swapping process by efficiently managing energy resources, monitoring the health of the vehicles, and ensuring precise landing during the swapping operation. | The constructed platform is designed to sustain continuous operation of a single UAV indefinitely. It incorporates algorithms for precision landing, ensuring accurate and safe landing during the swapping process. Additionally, the platform includes battery health tracking algorithms to monitor and manage the condition of the batteries, optimizing their performance and lifespan. | The entire system, including all its components and functionalities, was not tested as a whole. While individual tests were conducted for specific aspects of the system, such as precision landing and battery health tracking, a comprehensive test involving the complete system was not performed. |

| A design for an autonomous docking platform was developed, incorporating the use of active infrared imaging. The system utilized a combination of a camera and an infrared filter to achieve precise and accurate docking between the unmanned aerial vehicle (UAV) and the docking platform. The active infrared imaging technology enabled the system to operate effectively both during the day and at night, enhancing the reliability and versatility of the docking process. | A hardware platform was created to enable accurate and fast swapping of components, specifically targeting an impressive swapping time of 8 seconds. The platform was designed to operate seamlessly during both daytime and night time conditions, ensuring its usability in various environments and lighting conditions. This capability allows for continuous and efficient operations, minimizing downtime and maximizing the overall efficiency of the system. | No flight tests were conducted to evaluate the performance of the hardware platform. Additionally, the study did not focus on discussing the specific improvements in endurance achieved through the implemented technology. |

| A dual-drum structure was implemented in the hardware platform to enable fast and efficient hot swapping. This design feature allows for quick replacement of batteries, enhancing the efficiency of the swapping process. | A flight test was conducted to evaluate the performance of the system, taking into account communication constraints. During the test, the system was assessed under real-world conditions, considering limitations in communication capabilities. This provided valuable insights into the system's performance and effectiveness in scenarios with communication constraints. | The study did not include tracking the health of the vehicle or monitoring its condition. Additionally, the experiments conducted had a maximum mission time of only 70 minutes. Therefore, the study did not focus on monitoring and assessing the overall health and performance of the vehicle throughout extended missions. |

| A declarative model was proposed to optimize the routing of a multi-agent system consisting of UAVs and mobile battery swapping stations (MBSs) for delivery missions. The model aimed to efficiently plan the routes and schedules of UAVs and MBSs to ensure timely battery replacements and loading/unloading of goods. However, it is important to note that the study primarily focused on the routing aspect and did not involve specific experiments or tests related to the functionality and feasibility of mobile battery swapping stations in the context of delivery missions. | The study focused on optimizing the distance travelled and the number of UAVs in the context of the proposed multi-agent system with mobile battery swapping stations. The goal was to find an optimal configuration that minimizes the overall distance travelled by the UAVs and maximizes the efficiency of the system. By optimizing these factors, the study aimed to enhance the performance and cost-effectiveness of the system. However, it should be noted that the feasibility and practicality of implementing the proposed optimizations were not specifically tested or evaluated in the study. | The study presented computational results related to the optimization of the travelled distance and the number of UAVs in the context of the multi-agent system with mobile battery swapping stations. However, it did not include experimental validation or testing of the proposed techniques. The focus of the study was on computational modelling and analysis, providing insights into the potential benefits of the proposed optimizations. The specific details and mechanisms of the swapping technique were not discussed in the study, as it primarily concentrated on the computational aspects of routing and optimization. |

| The study aimed to achieve precise UAV positioning after landing with minimal error. The researchers focused on developing techniques or algorithms that would ensure accurate positioning of the UAVs after the landing process. By minimizing the positioning error, they aimed to enhance the overall performance and efficiency of the system. However, it is important to note that the specific methods or approaches used to achieve precise UAV positioning after landing were not detailed in the information provided. | The research focused on achieving precise UAV positioning for swapping operations, regardless of any errors that may occur during the landing process. The objective was to develop techniques or strategies that would ensure accurate and reliable positioning of the UAVs during swapping, even if the initial landing had some degree of error. By addressing this challenge, the researchers aimed to enhance the efficiency and effectiveness of the swapping process, enabling seamless battery replacement and continuous operation of the UAVs. However, specific details about the methods or approaches employed to achieve precise positioning in the presence of landing errors were not provided in the given information. | The study reported a relatively long swapping duration, indicating that the process of replacing batteries in the system took a considerable amount of time. However, it should be noted that the entire system, including all its components and functionalities, was not tested as a whole. This means that while certain aspects of the swapping process may have been examined or validated individually, the complete integration and performance of the system were not assessed through comprehensive testing. As a result, the overall efficiency and effectiveness of the swapping mechanism, as well as its potential limitations or drawbacks, remain uncertain and require further investigation or evaluation. |

| Compressed H2 | Liquid H2 | |

| Properties | The most commonly used method for hydrogen storage in UAV applications is high-pressure storage. Hydrogen is stored at pressures ranging from 35 to 70 megapascals (MPa). At these high pressures, the density of hydrogen increases, reaching approximately 42 kg/m3 at 70 MPa | Hydrogen has a density of approximately 71 kg/m3 at 1 bar and a temperature of -252.87°C, which is extremely low. To store hydrogen in its liquid form, a thermal insulation system is necessary to maintain such low temperatures. While hydrogen storage has benefits for large-scale applications, it can be challenging on a smaller scale. The liquefaction process requires extremely low temperatures, making it costly and energy-intensive. It is more practical for large-scale production and distribution systems rather than small-scale applications. |

| Advantages | High-pressure storage offers several advantages. It is a relatively simple method, requiring a pressure vessel to contain the hydrogen gas. The storage mass penalty, or the additional weight of the storage system, is relatively low compared to other storage methods. Additionally, high-pressure storage allows for rapid refuelling capability, enabling quick turnaround times for UAV operations. However, there are certain drawbacks to high-pressure storage. One significant disadvantage is the low storage efficiency. The energy required to compress hydrogen to high pressures results in energy losses, reducing the overall storage efficiency. This can impact the range and endurance of the UAV. |

There are several advantages to using hydrogen as a fuel despite its low density. One advantage is its high energy density, which means that a relatively small volume of hydrogen can store a large amount of energy. This high energy density enables longer flight durations and increased operational efficiency for UAVs. Hydrogen storage also offers improved safety compared to other fuel options. Hydrogen is non-toxic and non-polluting, and it dissipates rapidly in the event of a leak. However, safety measures are still necessary due to its flammability and the potential for embrittlement of materials in the presence of hydrogen. |

| Disadvantages | Safety risks are also a concern with high-pressure storage. The high pressures involved in the storage process increase the potential for leaks or ruptures, which can be hazardous. Proper safety measures and precautions must be in place to mitigate these risks. Another consideration is the larger volume required for high-pressure storage systems. The pressure vessels need to be sized to accommodate the required amount of hydrogen at the specified pressure. This can increase the overall size and volume of the UAV, affecting its aerodynamics and payload capacity. In summary, high-pressure storage is a commonly used method for hydrogen storage in UAVs. It offers simplicity, low storage mass penalty, and rapid refuelling capabilities. However, it has drawbacks such as low storage efficiency, safety risks, and the need for larger storage volumes. These factors should be carefully considered when selecting the appropriate storage method for UAV applications. |

Handling and transporting hydrogen in its liquid form can be difficult due to the low temperatures involved and the need for specialized storage and transportation infrastructure. Additionally, the weight of the storage tanks can be significant, impacting the overall weight of the UAV. In summary, while hydrogen offers advantages such as high energy density, improved safety, and the potential for long-duration flights, there are challenges associated with its low density, high liquefaction energy requirements, impractical small-scale production, and the need for careful handling and storage. These factors must be carefully considered in the design and implementation of hydrogen storage systems for UAV applications. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).