Submitted:

02 August 2023

Posted:

03 August 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Viscoplastic Constitutive Equation

2.1. The Framework of Unified Viscoplastic Constitutive Model

2.2. Isotropic Viscoplastic Constitutive Model for 316 Stainless Steel

2.3. Anisotropic Viscoplastic Constitutive Model for Zircaloy-4

3. Computational Algorithm

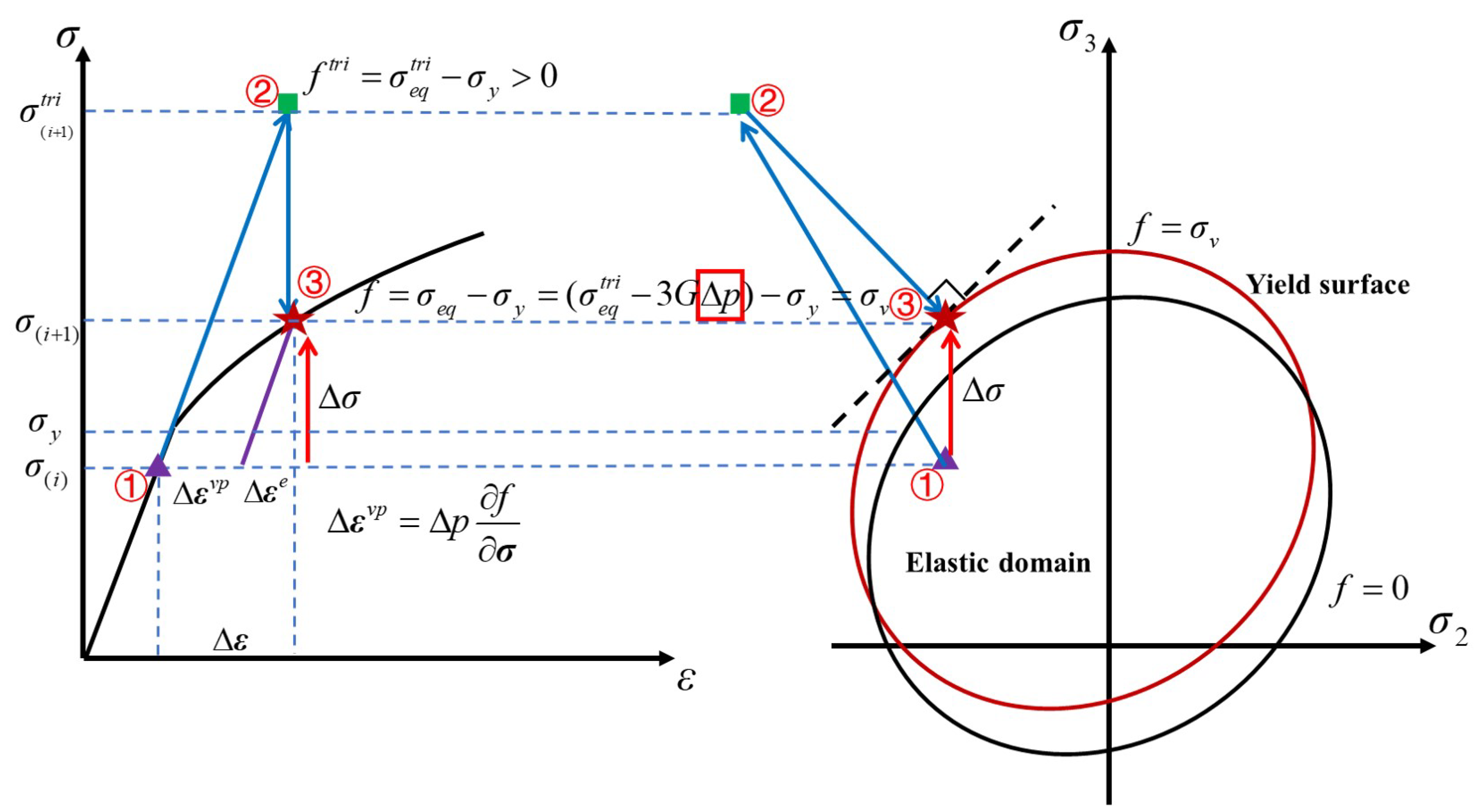

3.1. Return Mapping Algorithm

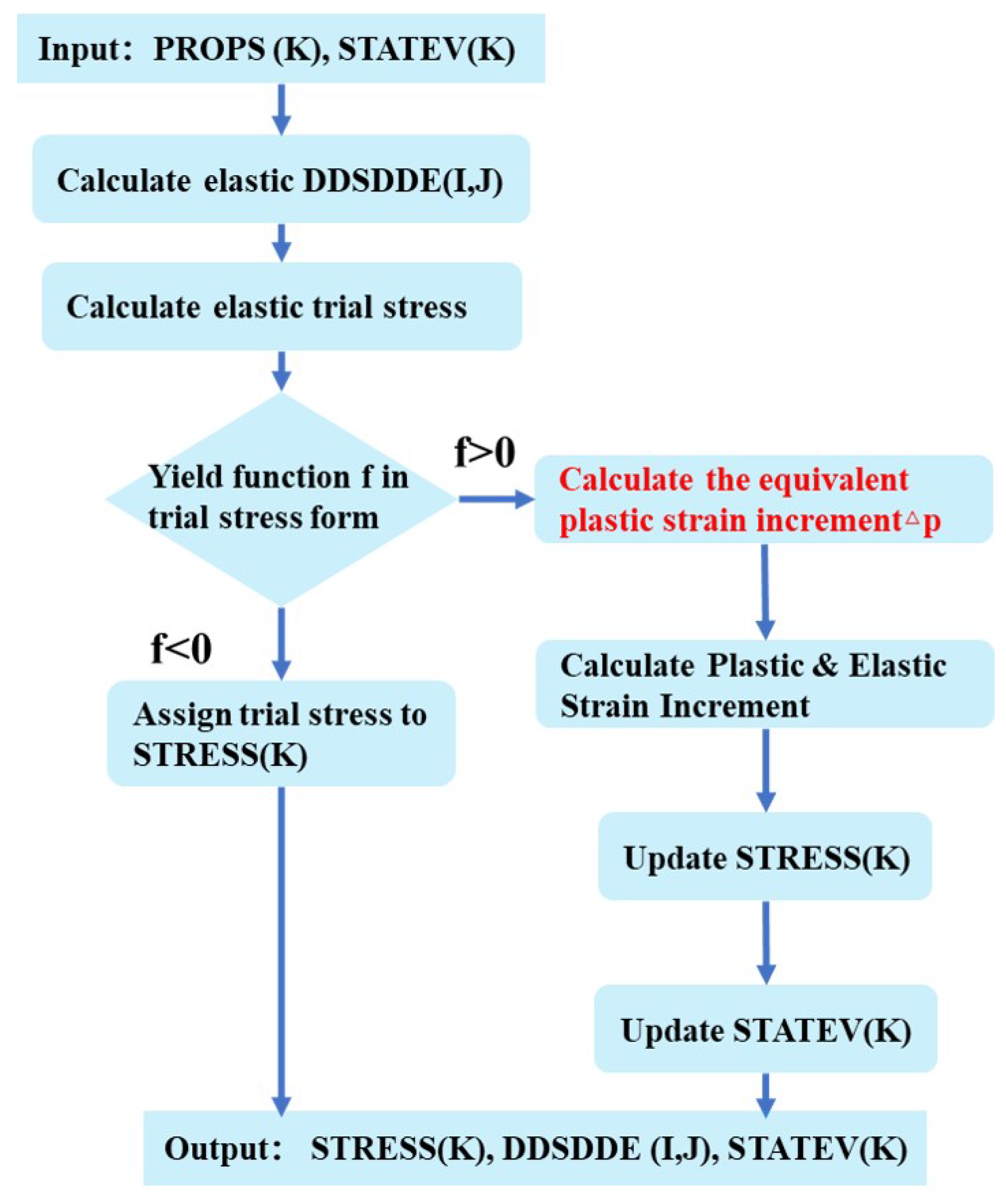

3.2. Stress Update Algorithm of 316 Stainless Steel Model

3.3. Stress Update Algorithm of Zircaloy-4 Model

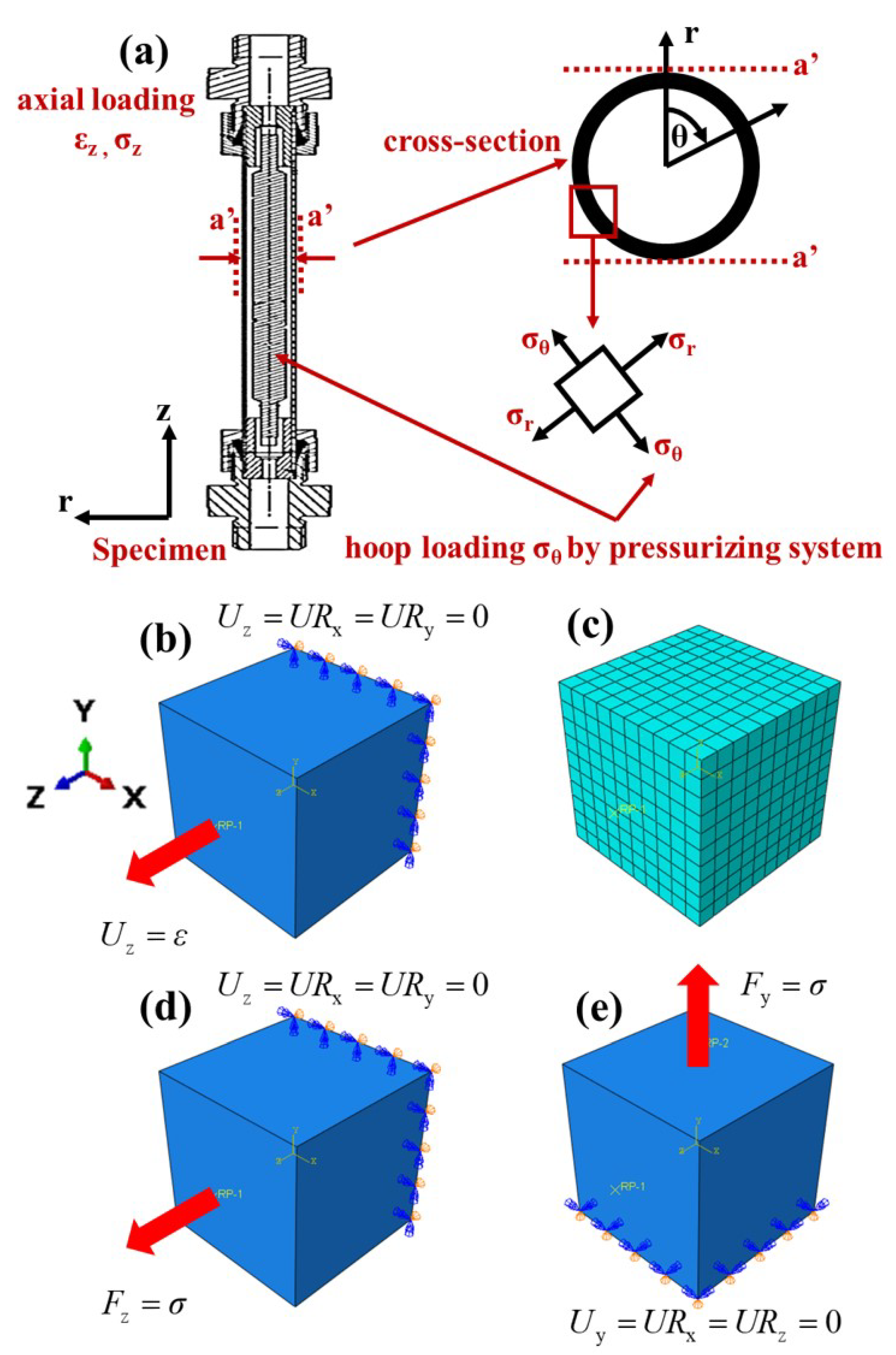

4. Verification and Validation of FE Modeling and UMAT Code

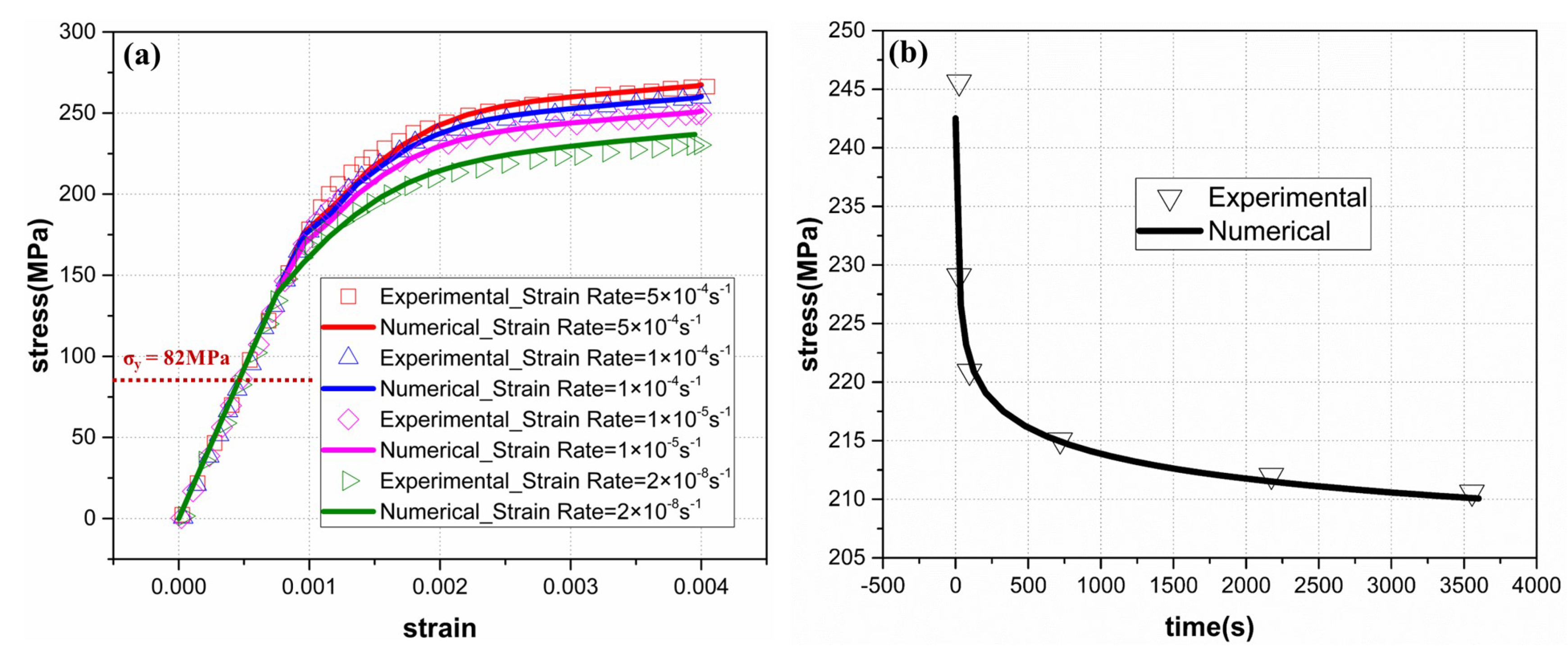

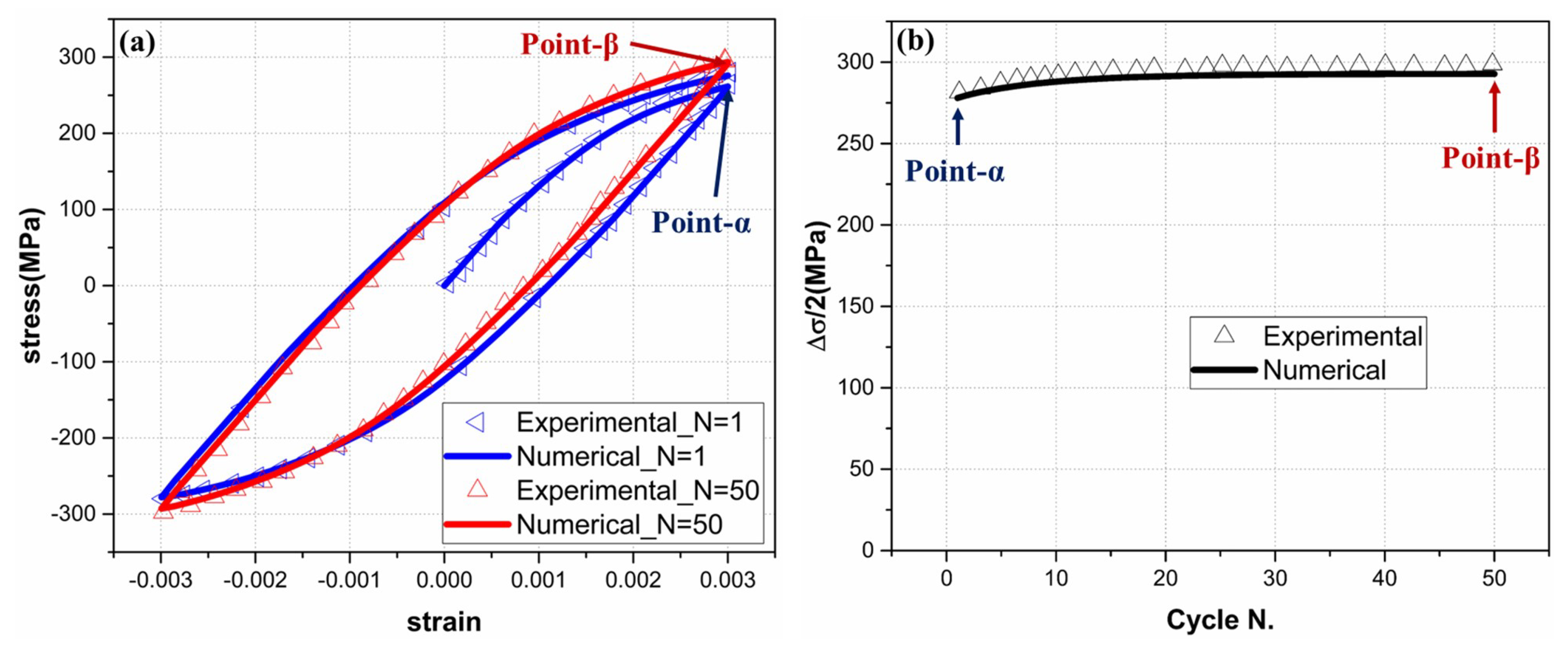

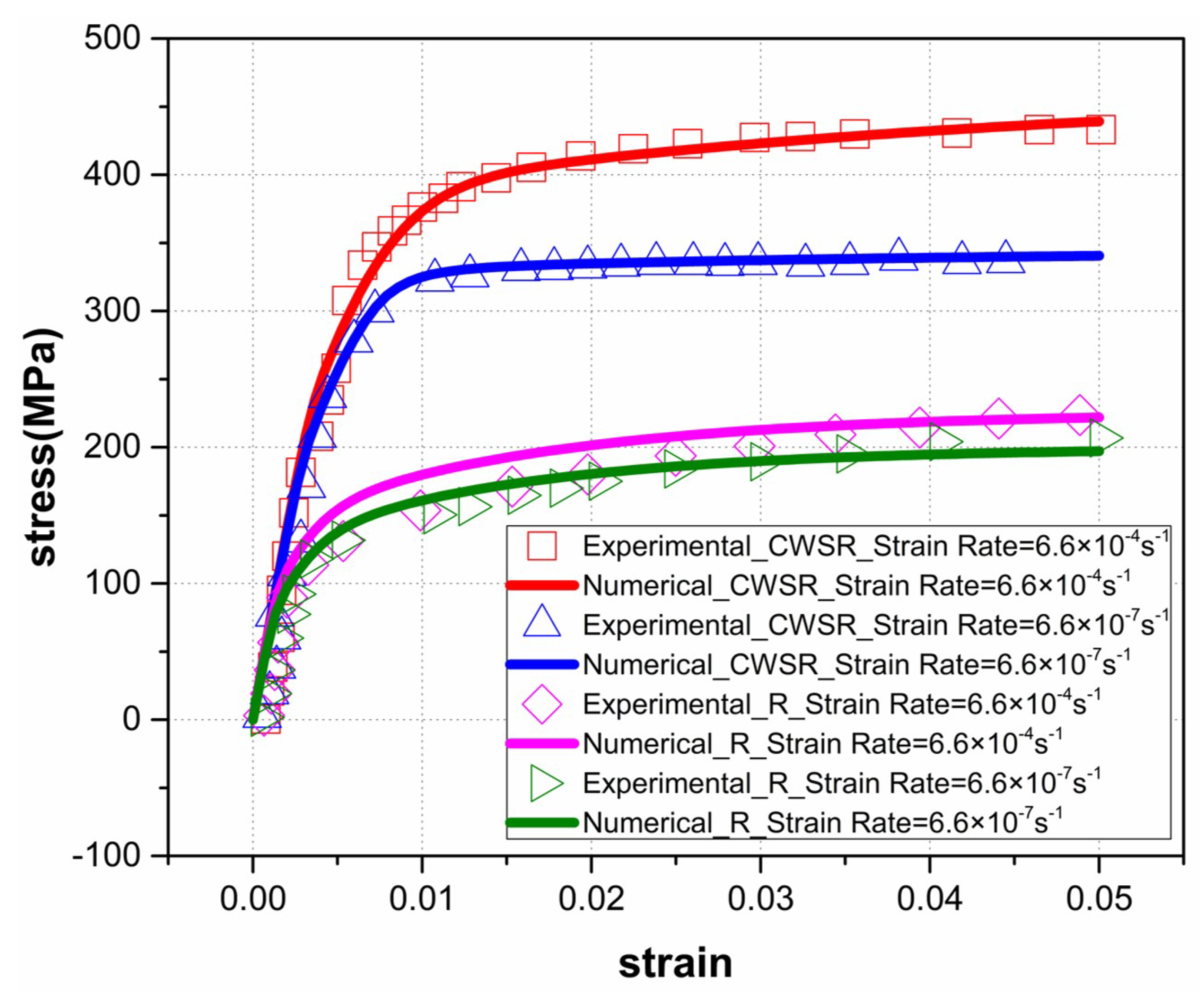

4.1. 316 Stainless Steel

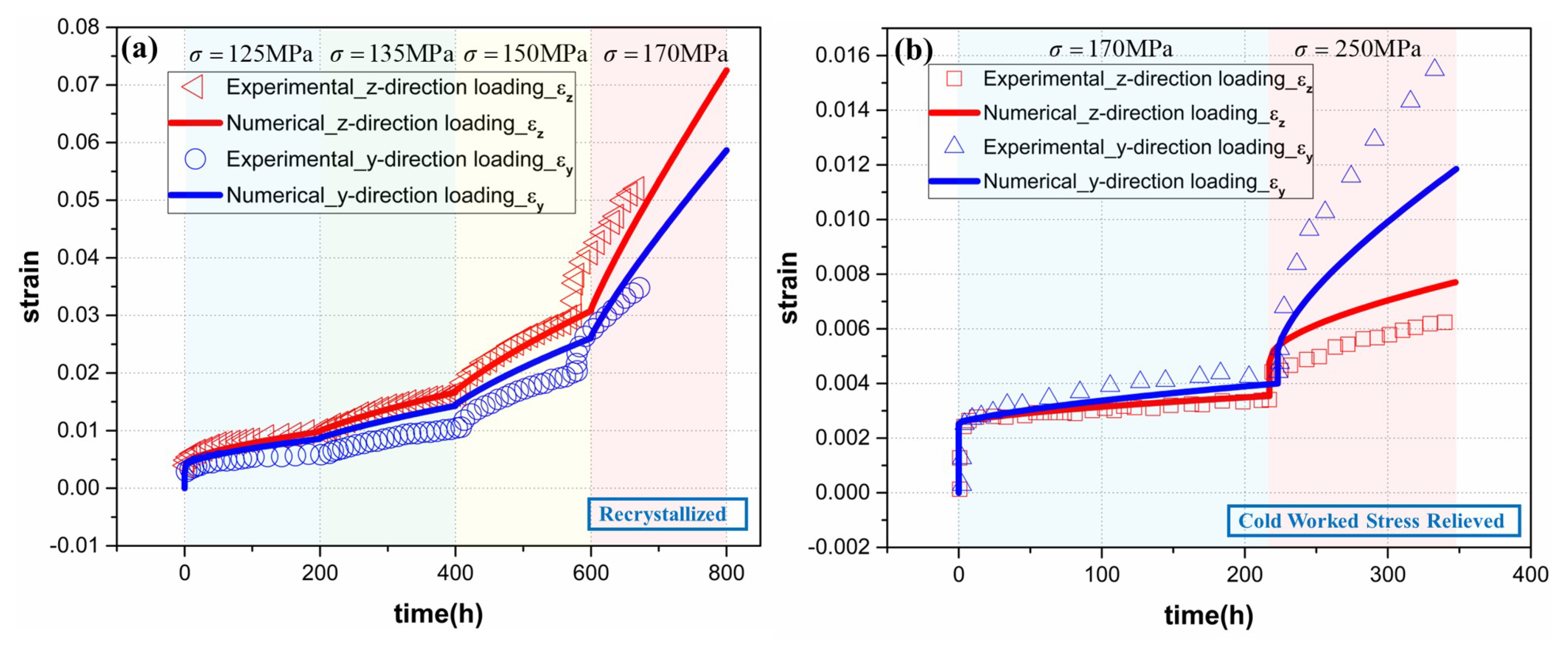

4.2. Zircaloy-4

5. Conclusions

Author Contributions

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cox, B. Pellet-clad interaction (PCI) failures of zirconium alloy fuel cladding—a review. Journal of nuclear materials 1990, 172, 249–292. [Google Scholar] [CrossRef]

- Jezequel, T.; Auzoux, Q.; Le Boulch, D.; Bono, M.; Andrieu, E.; Blanc, C.; Chabretou, V.; Mozzani, N.; Rautenberg, M. Stress corrosion crack initiation of Zircaloy-4 cladding tubes in an iodine vapor environment during creep, relaxation, and constant strain rate tests. Journal of Nuclear Materials 2018, 499, 641–651. [Google Scholar] [CrossRef]

- Hallstadius, L.; Johnson, S.; Lahoda, E. Cladding for high performance fuel. Progress in Nuclear Energy 2012, 57, 71–76. [Google Scholar] [CrossRef]

- Azevedo, C.d.F. Selection of fuel cladding material for nuclear fission reactors. Engineering Failure Analysis 2011, 18, 1943–1962. [Google Scholar] [CrossRef]

- Berna, G.; Beyer, G.; Davis, K.; Lanning, D. FRAPCON-3: A computer code for the calculation of steady-state, thermal-mechanical behavior of oxide fuel rods for high burnup. Technical report, US Nuclear Regulatory Commission (NRC), Washington, DC (United States). Div. of Systems Technology; Pacific Northwest National Lab.(PNNL), Richland, WA (United States); Idaho National Lab.(INL), Idaho Falls, ID (United States), 1997.

- Hughes, T. FPIN2 analysis of metal fueled pins. Technical report, Argonne National Lab.(ANL), Argonne, IL (United States), 1985.

- Yagnik, S.; Rashid, Y.; Dunham, R.; Montgomery, R. Fuel Analysis and Licensing Code: FALCON MOD01, Volume 1: Theoretical and Numerical Bases. EPRI, Palo Alto, CA, USA 2004, 1011307. [Google Scholar]

- Allison, C.; Berna, G.; Chambers, R.; Coryell, E.; Davis, K.; Hagrman, K.; McComas, M. SCDAP/RELAP5/MOD3. 1 Code Manual Volume IV: MATPRO. NUREG/CR 1993, 6150, 20555–0001. [Google Scholar]

- Williamson, R.L.; Hales, J.; Novascone, S.; Tonks, M.; Gaston, D.; Permann, C.; Andrs, D.; Martineau, R. Multidimensional multiphysics simulation of nuclear fuel behavior. Journal of Nuclear Materials 2012, 423, 149–163. [Google Scholar] [CrossRef]

- Newman, C.; Hansen, G.; Gaston, D. Three dimensional coupled simulation of thermomechanics, heat, and oxygen diffusion in UO2 nuclear fuel rods. Journal of Nuclear Materials 2009, 392, 6–15. [Google Scholar] [CrossRef]

- Williamson, R.L.; Hales, J.D.; Novascone, S.R.; Pastore, G.; Gamble, K.A.; Spencer, B.W.; Jiang, W.; Pitts, S.A.; Casagranda, A.; Schwen, D.; et al. BISON: A flexible code for advanced simulation of the performance of multiple nuclear fuel forms. Nuclear Technology 2021, 207, 954–980. [Google Scholar] [CrossRef]

- Williamson, R. Enhancing the ABAQUS thermomechanics code to simulate multipellet steady and transient LWR fuel rod behavior. Journal of Nuclear Materials 2011, 415, 74–83. [Google Scholar] [CrossRef]

- Phan, V.T.; Messner, M.; Sham, T.L. A unified engineering inelastic model for 316H stainless steel. In Proceedings of the Pressure Vessels and Piping Conference; 2019. [Google Scholar] [CrossRef]

- Chaboche, J.L. A review of some plasticity and viscoplasticity constitutive theories. International journal of plasticity 2008, 24, 1642–1693. [Google Scholar] [CrossRef]

- Chaboche, J.; Rousselier, G. On the plastic and viscoplastic constitutive equations—Part I: Rules developed with internal variable concept. Journal of Pressure Vessel Technology 1983. [Google Scholar] [CrossRef]

- Chaboche, J.L.; Rousselier, G. On the plastic and viscoplastic constitutive equations—Part II: application of internal variable concepts to the 316 stainless steel. Journal of Pressure Vessel Technology 1983. [Google Scholar] [CrossRef]

- Chaboche, J.L. Constitutive equations for cyclic plasticity and cyclic viscoplasticity. International journal of plasticity 1989, 5, 247–302. [Google Scholar] [CrossRef]

- Hyde, C.J.; Sun, W.; Leen, S.B. Cyclic thermo-mechanical material modelling and testing of 316 stainless steel. International Journal of Pressure Vessels and Piping 2010, 87, 365–372. [Google Scholar] [CrossRef]

- Lim, L.; Dunne, F. The effect of volume fraction of reinforcement on the elastic-viscoplastic response of metal-matrix composites. International journal of mechanical sciences 1995, 38, 19–39. [Google Scholar] [CrossRef]

- Hyde, C.J.; Sun, W.; Hyde, T.; Rouse, J.; Farragher, T.; O’Dowd, N.P.; Leen, S. Cyclic viscoplasticity testing and modeling of a service-aged P91 steel. Journal of Pressure Vessel Technology 2014, 136, 044501. [Google Scholar] [CrossRef]

- Miled, B.; Doghri, I.; Delannay, L. Coupled viscoelastic–viscoplastic modeling of homogeneous and isotropic polymers: Numerical algorithm and analytical solutions. Computer methods in applied mechanics and engineering 2011, 200, 3381–3394. [Google Scholar] [CrossRef]

- Tian, J.; Li, J.; Xie, H.; Yang, Y.; Kan, Q. Finite element implementation of a temperature-dependent cyclic plastic model for SA508-3 steel. Metals 2018, 8, 955. [Google Scholar] [CrossRef]

- Murty, K.L.; Charit, I. Texture development and anisotropic deformation of zircaloys. Progress in nuclear energy 2006, 48, 325–359. [Google Scholar] [CrossRef]

- Murty, K.L.; Adams, B.L. Biaxial creep of textured zircaloy I: experimental and phenomenological descriptions. Materials Science and Engineering 1985, 70, 169–180. [Google Scholar] [CrossRef]

- Grosjean, C.; Poquillon, D.; Salabura, J.C.; Cloué, J.M. Experimental creep behaviour determination of cladding tube materials under multi-axial loadings. Materials Science and Engineering: A 2009, 510, 332–336. [Google Scholar] [CrossRef]

- Rautenberg, M.; Poquillon, D.; Pilvin, P.; Grosjean, C.; Cloué, J.M.; Feaugas, X. Thermal isocreep curves obtained during multi-axial creep tests on recrystallized Zircaloy-4 and M5™ alloy. Nuclear Engineering and Design 2014, 269, 33–37. [Google Scholar] [CrossRef]

- Delobelle, P. Synthesis of the elastoviscoplastic behavior and modelization of an austenitic stainless steel over a large temperature range, under uniaxial and biaxial loadings, part II: Phenomenological modelization. International journal of plasticity 1993, 9, 87–118. [Google Scholar] [CrossRef]

- Delobelle, P.; Robinet, P.; Geyer, P.; Bouffioux, P. A model to describe the anisotropic viscoplastic behaviour of Zircaloy-4 tubes. Journal of Nuclear Materials 1996, 238, 135–162. [Google Scholar] [CrossRef]

- Richard, F.; Delobelle, P.; Leclercq, S.; Bouffioux, P.; Rousselier, G. Modeling of the cold work stress relieved Zircaloy-4 cladding tubes mechanical behavior under PWR operating conditions. In Proceedings of the SMiRT 17 (Prague); 2003. [Google Scholar]

- Dunne, F.; Petrinic, N. Introduction to computational plasticity; OUP Oxford: Oxford, UK, 2005. [Google Scholar]

- Armstrong, P.J.; Frederick, C.; et al. A mathematical representation of the multiaxial Bauschinger effect; Technical report; Berkeley Nuclear Laboratories: Berkeley, CA, USA, 1966. [Google Scholar]

- Hill, R. A theory of the yielding and plastic flow of anisotropic metals. Proceedings of the Royal Society of London. Series A. Mathematical and Physical Sciences 1948, 193, 281–297. [Google Scholar]

- Marin, E.; McDowell, D. A semi-implicit integration scheme for rate-dependent and rate-independent plasticity. Computers & structures 1997, 63, 579–600. [Google Scholar]

| b | n | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| ]1*RT* | 185 | 0.3 | 82 | 8 | 60 | 58 | 2800 | 270 | 25 | 151 | 24 |

| ]1*550 | 141.26 | 0.3 | 31 | 31 | 27.8 | 86.3 | 6939 | 114.8 | 957.69 | 173 | 10 |

| Recrystallized Zircaloy-4 | Cold worked stress relieved Zircaloy-4 |

|---|---|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).