Submitted:

10 July 2023

Posted:

11 July 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

- Neat PA6,6 filament

- filament in PA6,6 + 5% rCF, i.e., with the addition of 5 wt.% of recycled CFs.

- filament in PA6,6 + 10% rCF, i.e., with the addition of 10 wt.% of recycled CFs.

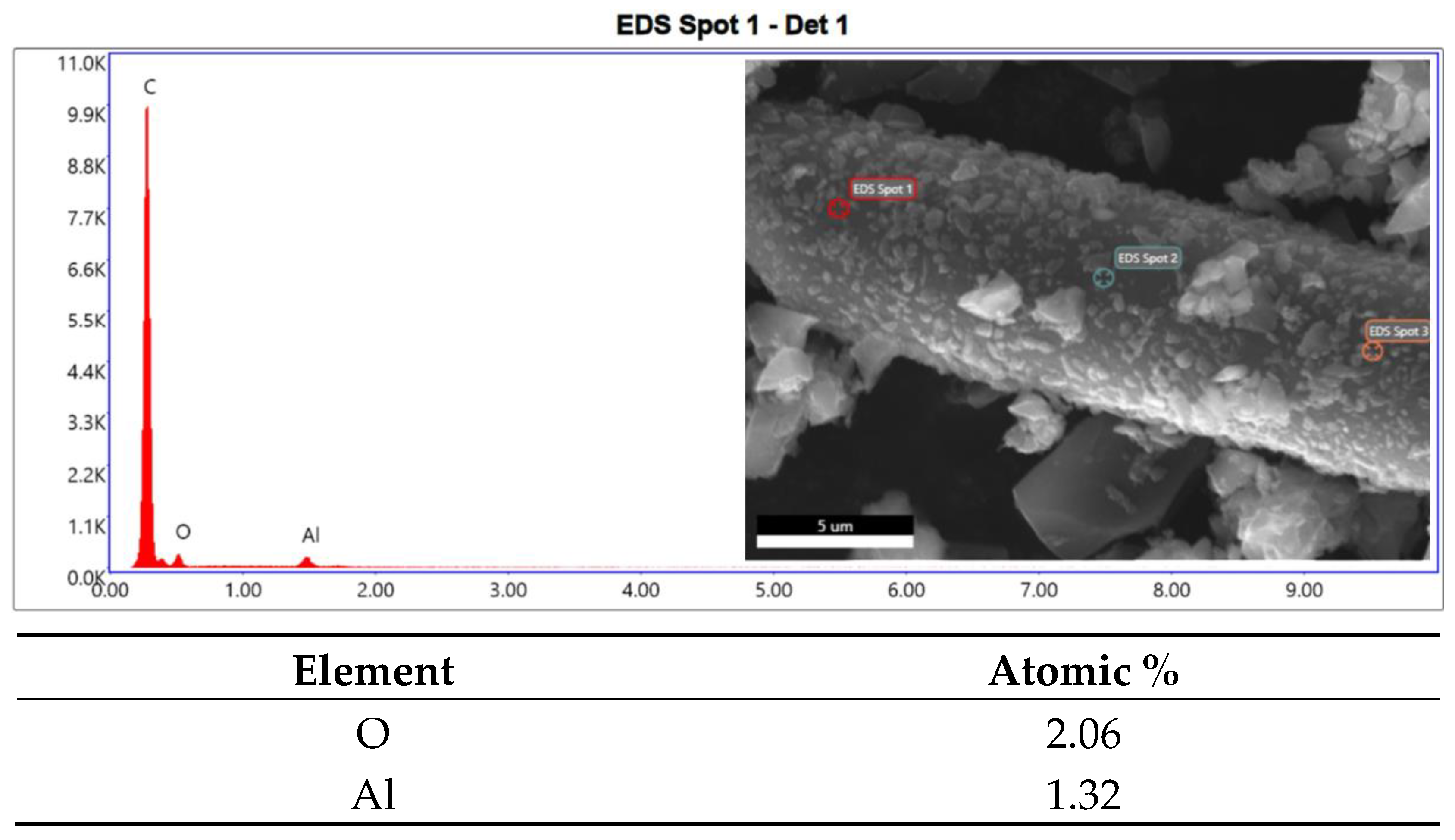

2.2.1. Filament extrusion for 3D printing

2.2.2. SEM analysis and sample preparation (carbon sputtering technique and cryogenic fracture)

2.2.3. Density measurements

2.2.4. Study of the dimensional distribution of the fibers

2.2.5. Tensile testing of the filaments

2.2.6. Study of fiber homogeneity within the filaments

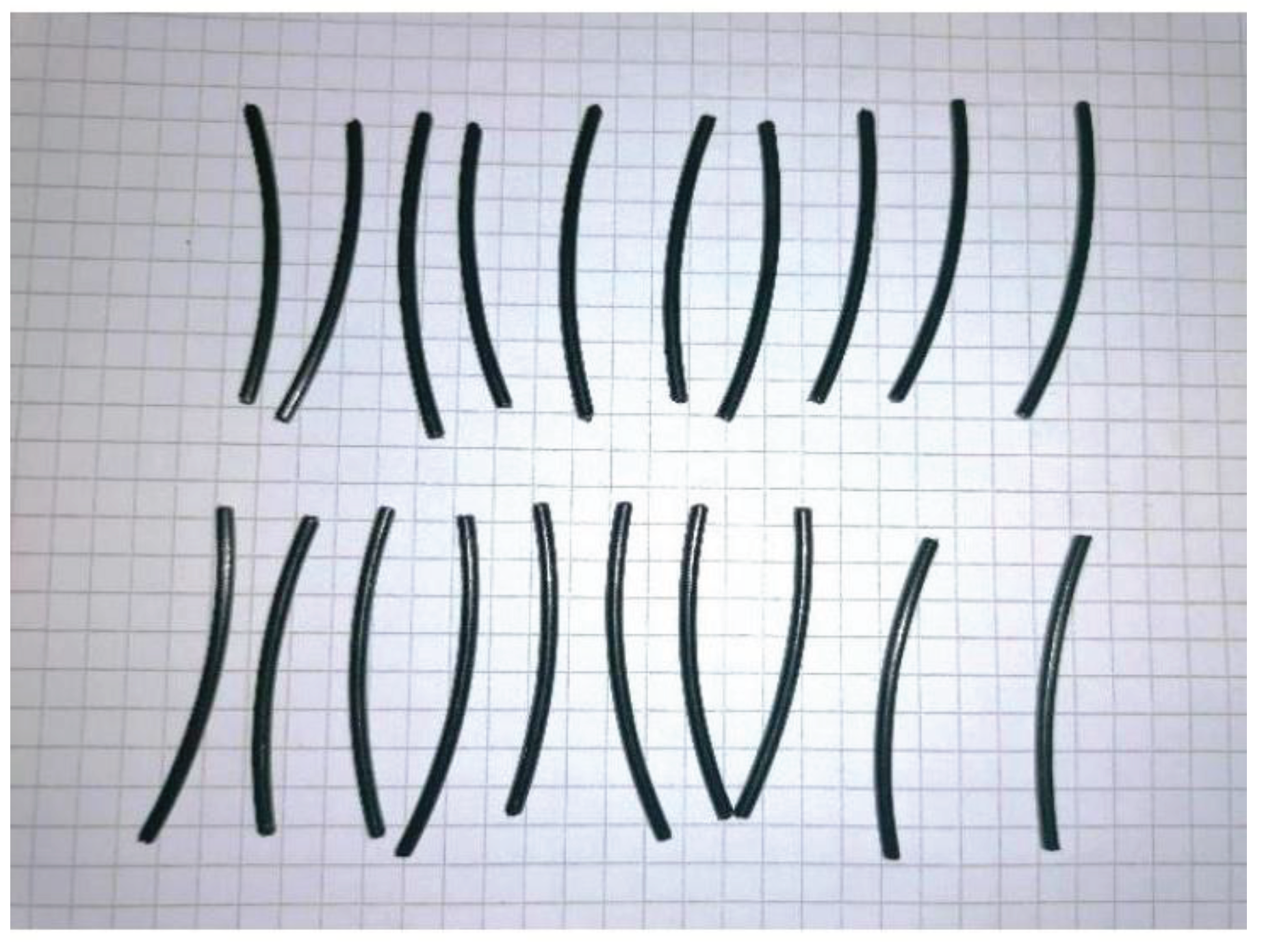

2.2.7. 3D Printing

2.2.8. Tensile Tests on the 3D Printed Samples

2.2.9. Microstructural analysis

3. Results

3.1. Preliminary Analysis of PA6,6 Neat and Composite Filaments for 3D Printing

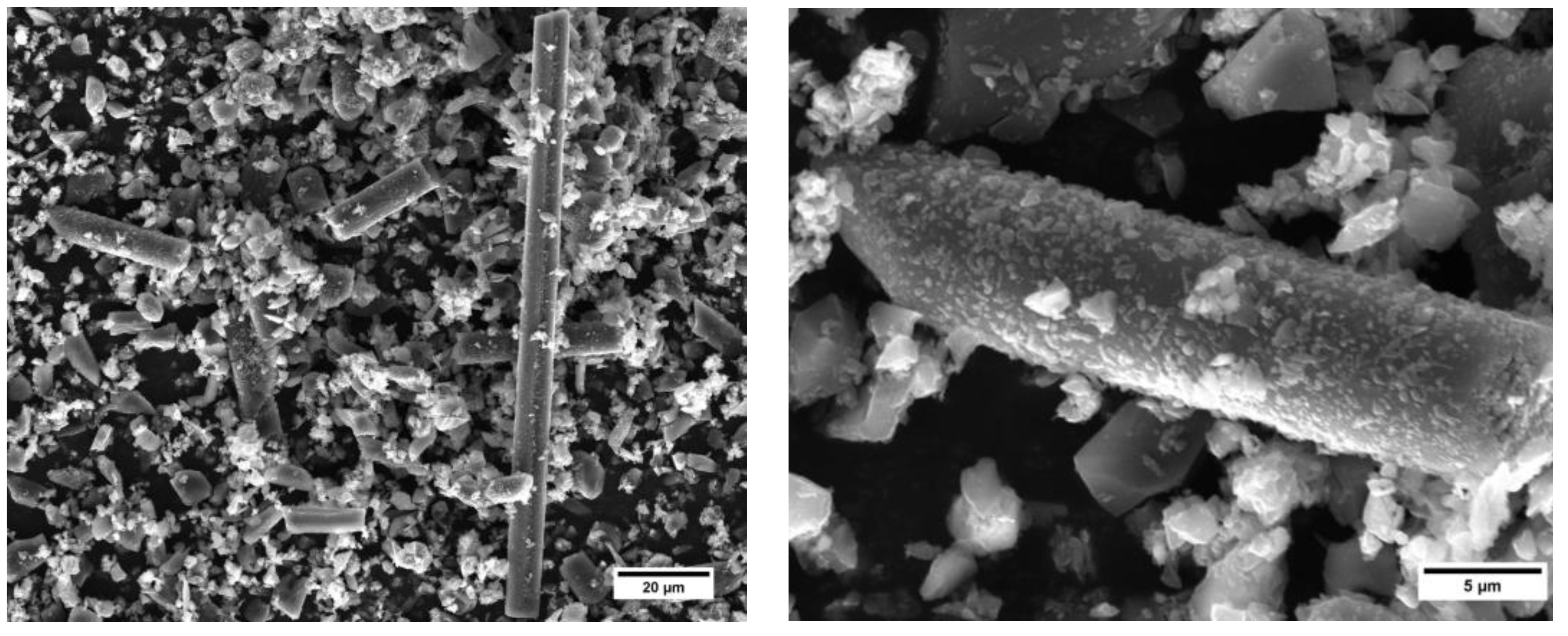

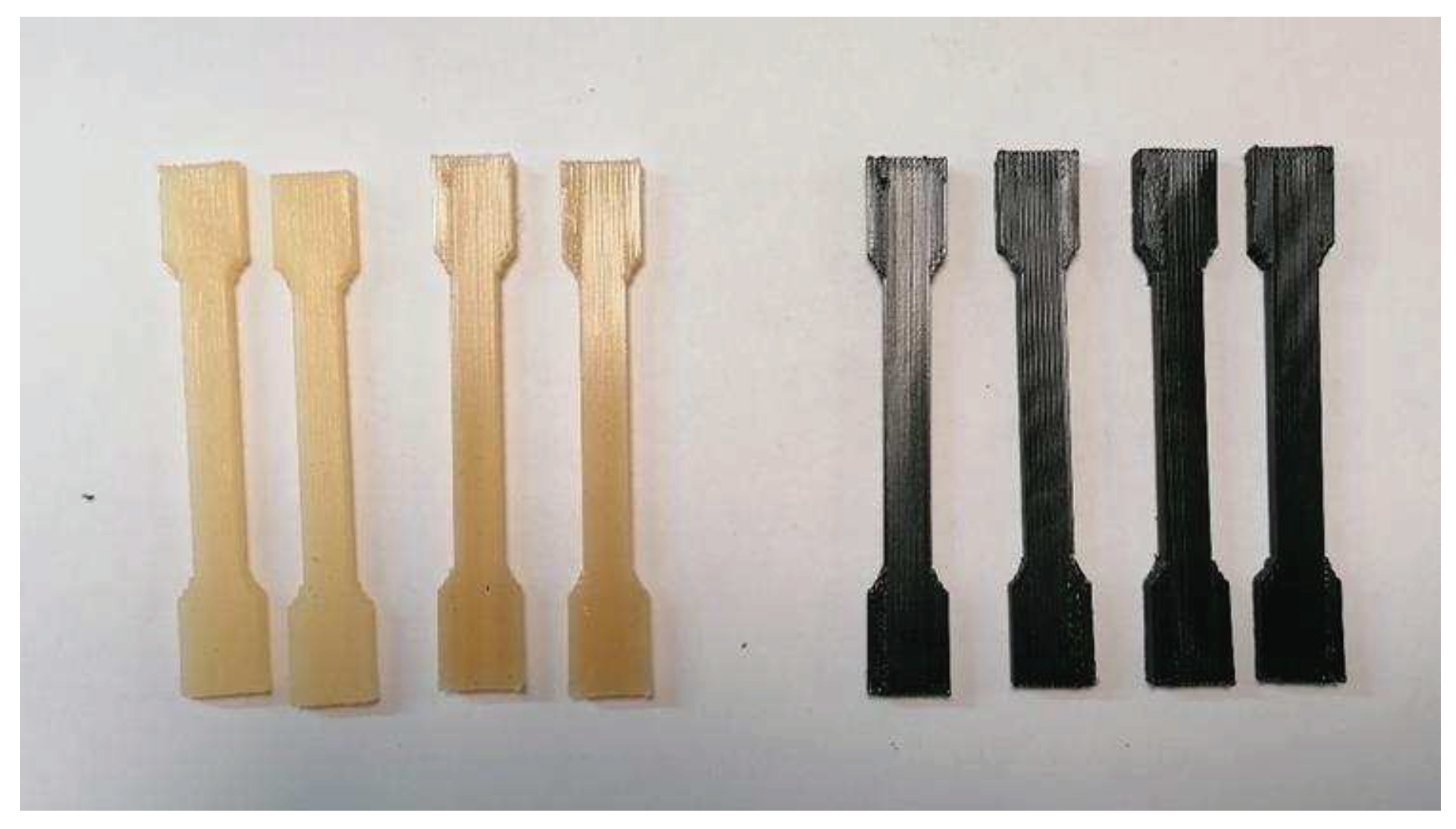

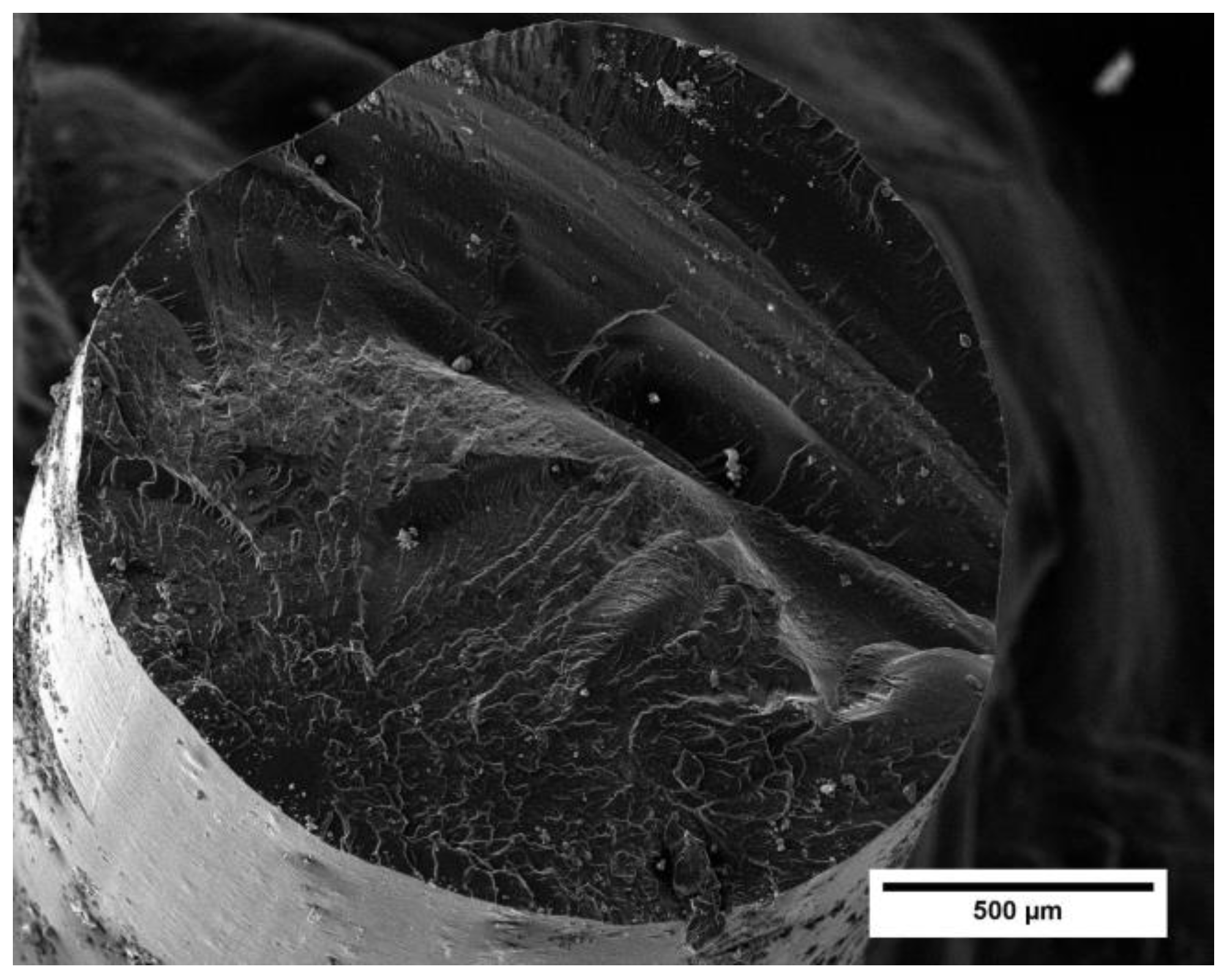

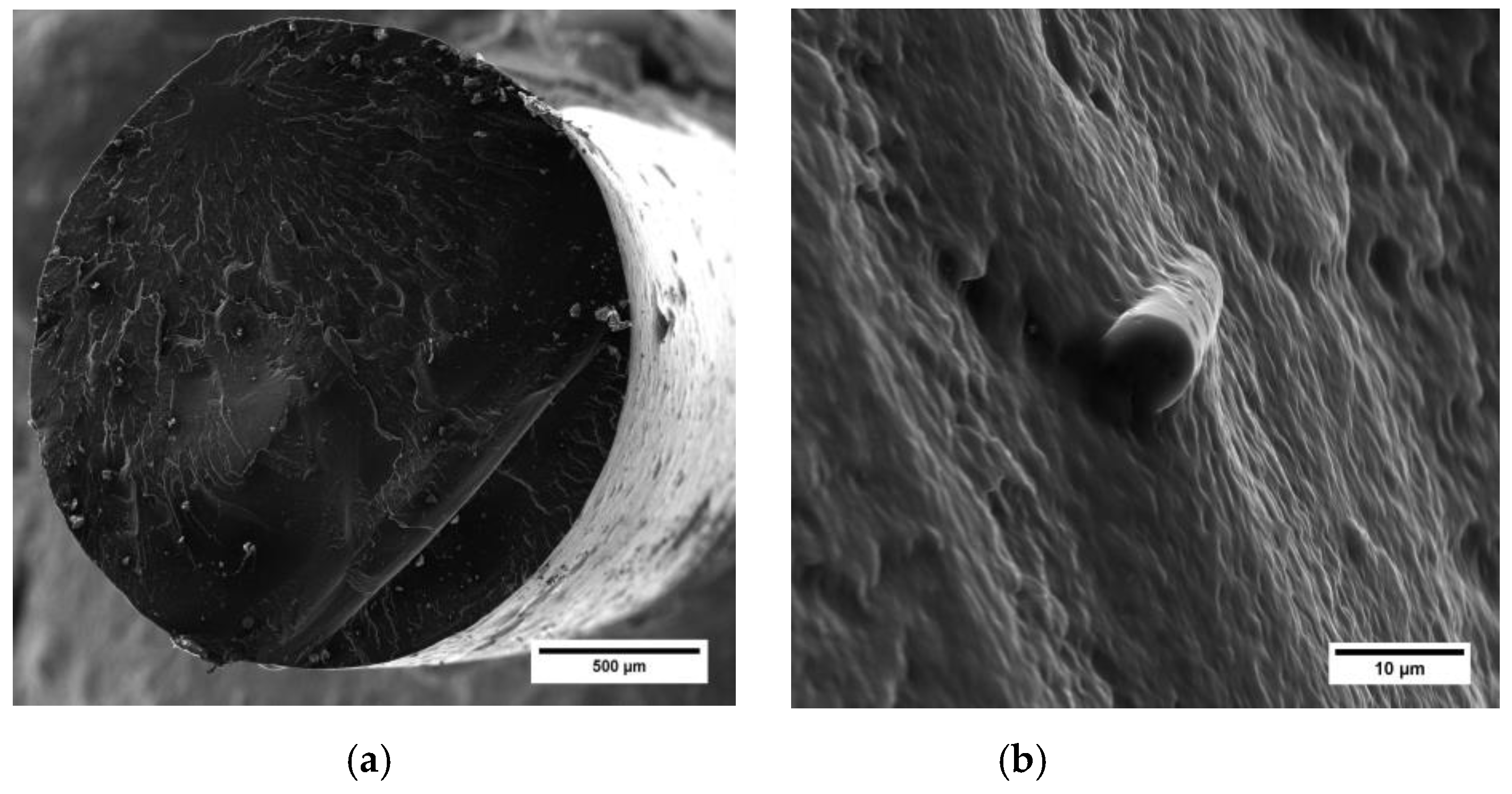

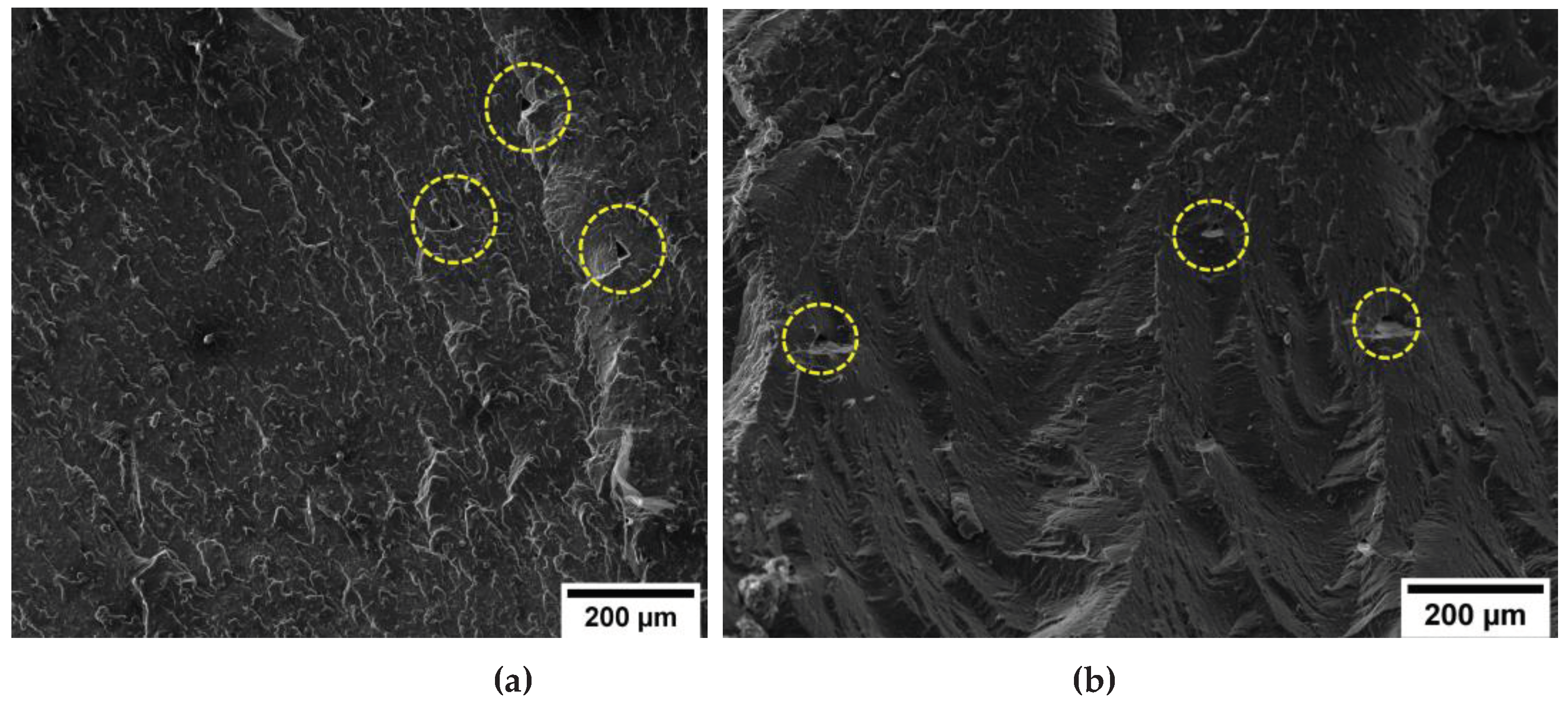

3.1.1. SEM Analysis of Filament Fracture Surfaces

3.1.2. Evaluation of the Effective Percentage of Reinforcement

3.1.3. Dimensional Study of Carbon Microfibers

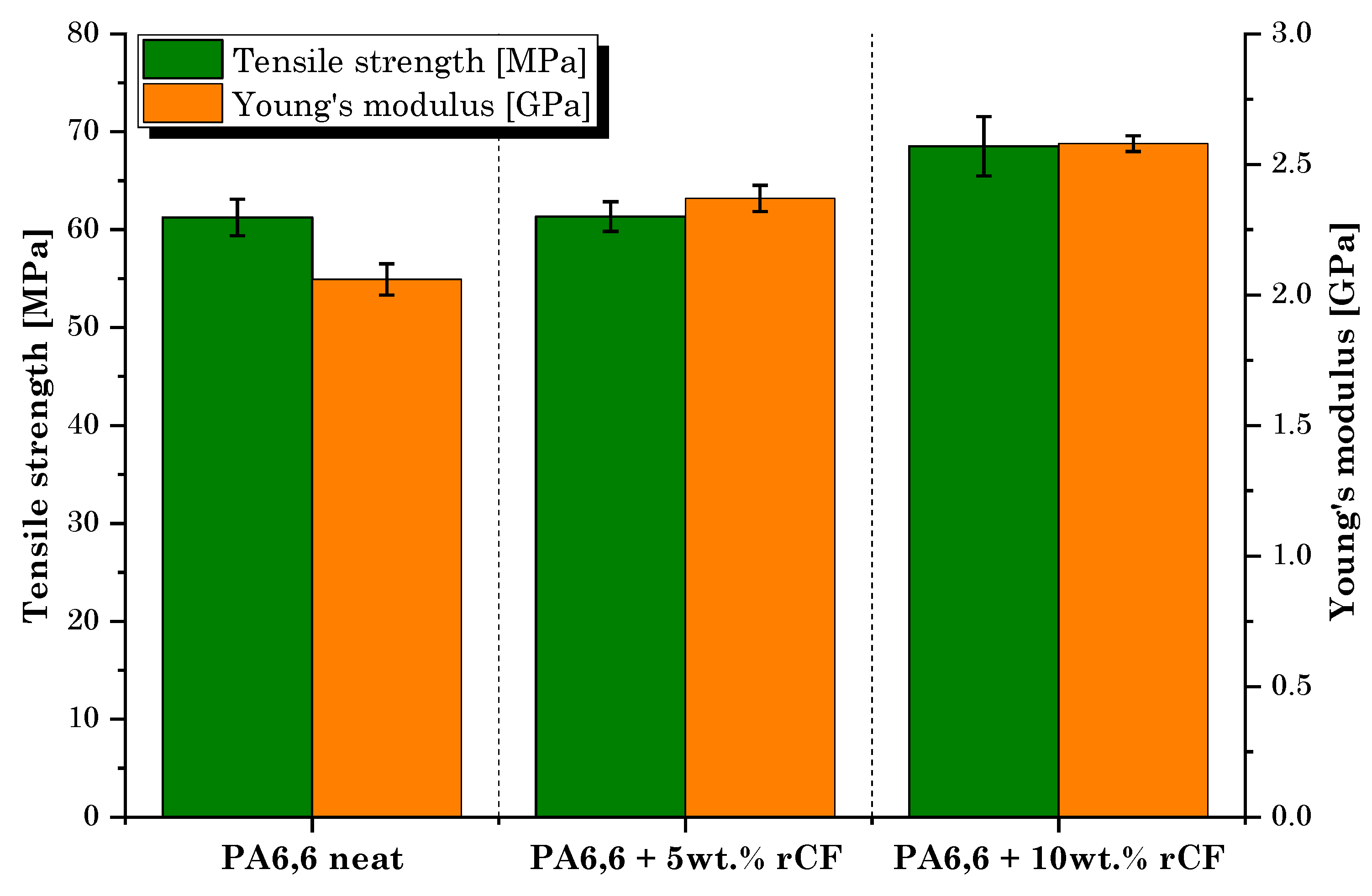

3.1.4. Tensile Tests on 3D Printing Filaments

3.2. Characterization of Tensile Properties of Neat PA6,6 and Resulting Composites

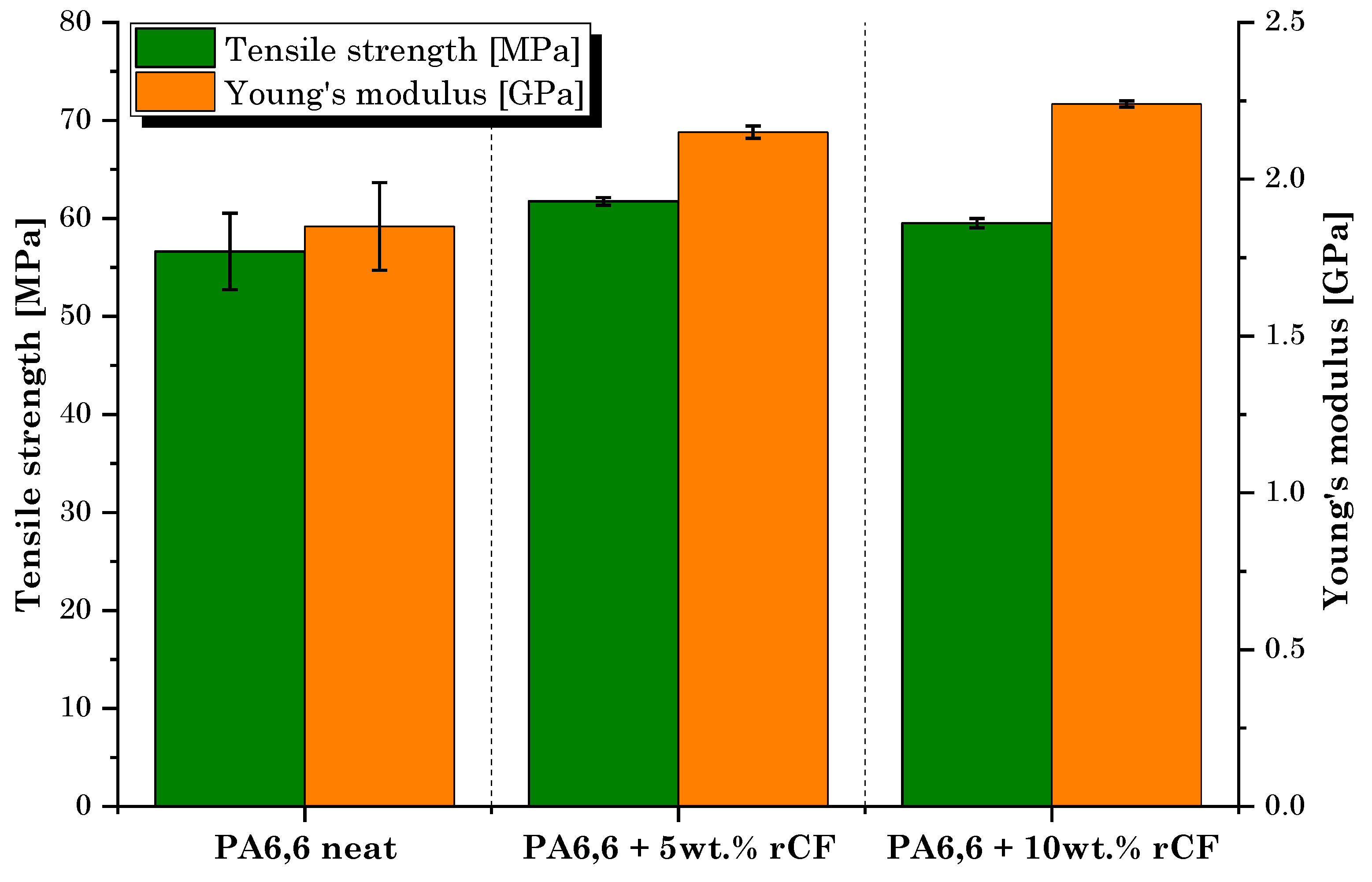

3.2.1. Tensile Tests on 3D Printed Specimens

3.2.2. Microstructural Analysis

4. Optimization Hypothesis

6. Conclusions

- the extrusion parameters have been successfully optimized to obtain composites filaments suitable for 3D printing processing;

- the mechanical characterization on the printed filaments revealed that the rCF increased the Young’s modulus and tensile strength up to 25% and 11% of the composites (10 wt.%. of rCF), in comparison to the performance of neat sample, respectively.

- tensile tests on printed specimens highlighted a similar increment in strength performance (+ 16% in Young’s modulus and + 9% in tensile strength for 5 wt.% rCF and + 21% in Young’s modulus and + 5% in tensile strength, for 10 wt.% rCF). SEM analysis showed microstructures not affected by the common defects induced by the layer-by-layer deposition of additive fabrication. This demonstrates the achievement of well-selected printing parameters for the processing of the composites developed in the present work;

- the average length of microfibers employed in this research was estimated at 30 μm, too short for consistently improving the strength. In addition, a complication factor for the present case is the gradual reduction in size that the fibers undergo following extrusion. The dimensional optimization of the output rCF fraction from the milling process is undoubtedly a challenge to be faced in order to maximize the mechanical performance of composites.

- The field of additive manufacturing is currently in continuous expansion and this, combined with the increasing interest in the field of eco-sustainable and circular composite materials, places this research in a strategic position particularly suitable for future studies and improvements.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Giorgini, L.; Benelli, T.; Brancolini, G.; Mazzocchetti, L. Recycling of carbon fiber reinforced composite waste to close their life cycle in a cradle-to-cradle approach. Current opinion in green and sustainable chemistry 2020, 26, 100368. [Google Scholar] [CrossRef]

- Naqvi, S. R.; Prabhakara, H. M.; Bramer, E. A.; Dierkes, W.; Akkerman, R.; Brem, G. A critical review on recycling of end-of-life carbon fibre/glass fibre reinforced composites waste using pyrolysis towards a circular economy. Resources, conservation and recycling 2018, 136, 118–129. [Google Scholar] [CrossRef]

- Zhang, J.; Chevali, V. S.; Wang, H.; Wang, C. H. Current status of carbon fibre and carbon fibre composites recycling. Composites Part B: Engineering 2020, 193, 108053. [Google Scholar] [CrossRef]

- Valente, M.; Rossitti, I.; Biblioteca, I.; Sambucci, M. Thermoplastic Composite Materials Approach for More Circular Components: From Monomer to In Situ Polymerization, a Review. J. Compos. Sci. 2022, 6, 132. [Google Scholar] [CrossRef]

- Nunes, A. O.; Viana, L. R.; Guineheuc, P. M.; da Silva Moris, V. A.; de Paiva, J. M. F.; Barna, R.; Soudais, Y. Life cycle assessment of a steam thermolysis process to recover carbon fibers from carbon fiber-reinforced polymer waste. The International Journal of Life Cycle Assessment 2018, 23, 1825–1838. [Google Scholar] [CrossRef]

- Anane-Fenin, K.; Akinlabi, E. T.; Akinlabi, E. T. Recycling of fibre reinforced composites: A review of current technologies. In Proceedings of the DII-2017 Conference on Infrastructure Development and Investment Strategies for Africa, Livingstone, Zambia, 30 August – 1 September 2017. [Google Scholar]

- Pimenta, S.; Pinho, S. T. Recycling carbon fibre reinforced polymers for structural applications: Technology review and market outlook. Waste management 2011, 31, 378–392. [Google Scholar] [CrossRef] [PubMed]

- Mazzocchetti, L.; Benelli, T.; D'Angelo, E.; Leonardi, C.; Zattini, G.; Giorgini, L. Validation of carbon fibers recycling by pyro-gasification: The influence of oxidation conditions to obtain clean fibers and promote fiber/matrix adhesion in epoxy composites. Composites Part A: Applied Science and Manufacturing 2018, 112, 504–514. [Google Scholar] [CrossRef]

- Giorgini, L. , Benelli, T.; Mazzocchetti, L.; Leonardi, C.; Zattini, G.; Minak, G.,...; Tosi, C. Recovery of carbon fibers from cured and uncured carbon fiber reinforced composites wastes and their use as feedstock for a new composite production. Polymer composites 2015, 36, 1084–1095. [Google Scholar] [CrossRef]

- Sayam, A.; Rahman, A. M.; Rahman, M. S.; Smriti, S. A.; Ahmed, F.; Rabbi, M. F. ,...; Faruque, M. O. A review on carbon fiber-reinforced hierarchical composites: Mechanical performance, manufacturing process, structural applications and allied challenges. Carbon Letters 2022, 32, 1173–1205. [Google Scholar] [CrossRef]

- Fu, S. Y.; Lauke, B.; Mäder, E.; Yue, C. Y.; Hu, X.; Mai, Y. W. Hybrid effects on tensile properties of hybrid short-glass-fiber-and short-carbon-fiber-reinforced polypropylene composites. Journal of materials science 2001, 36, 1243–1251. [Google Scholar] [CrossRef]

- Dickson, A. N.; Abourayana, H. M.; Dowling, D. P. 3D printing of fibre-reinforced thermoplastic composites using fused filament fabrication—A review. Polymers 2020, 12, 2188. [Google Scholar] [CrossRef] [PubMed]

- Blok, L.G.; Woods, B.K.S. 3D printed composites Benchmarking the state-of-the-art. In Proceedings of the 21st International Conference on Composite Materials, Xi’an, China, 20-25 August 2017. http://www.iccm21.org/index.php?m=content&c=index&a=lists&catid=5. [Google Scholar]

- Ferreira, R. T. L.; Amatte, I. C.; Dutra, T. A.; Bürger, D. Experimental characterization and micrography of 3D printed PLA and PLA reinforced with short carbon fibers. Composites Part B: Engineering 2017, 124, 88–100. [Google Scholar] [CrossRef]

- Blok, L. G.; Longana, M. L.; Yu, H.; Woods, B. K. An investigation into 3D printing of fibre reinforced thermoplastic composites. Additive Manufacturing 2018, 22, 176–186. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Hu, Y.; Wang, H. Additive manufacturing of carbon fiber-reinforced plastic composites using fused deposition modeling: Effects of process parameters on tensile properties. Journal of composite materials 2017, 51, 451–462. [Google Scholar] [CrossRef]

- Wang, P.; Zou, B.; Ding, S.; Huang, C.; Shi, Z.; Ma, Y.; Yao, P. Preparation of short CF/GF reinforced PEEK composite filaments and their comprehensive properties evaluation for FDM-3D printing. Composites Part B: Engineering 2020, 198, 108175. [Google Scholar] [CrossRef]

- Giani, N.; Mazzocchetti, L.; Benelli, T.; Picchioni, F.; Giorgini, L. Towards sustainability in 3D printing of thermoplastic composites: Evaluation of recycled carbon fibers as reinforcing agent for FDM filament production and 3D printing. Composites Part A: Applied Science and Manufacturing 2022, 159, 107002. [Google Scholar] [CrossRef]

- Cardona, C.; Curdes, A. H.; Isaacs, A. J. Effects of filament diameter tolerances in fused filament fabrication. IU Journal of Undergraduate Research 2016, 2, 44–47. [Google Scholar] [CrossRef]

- Haq, R. H. A.; Marwah, O. F.; Rahman, M. A.; Haw, H. F.; Abdullah, H.; Ahmad, S. 3D Printer parameters analysis for PCL/PLA filament wire using Design of Experiment (DOE). Materials Science and Engineering 2019, 607, 012001. [Google Scholar] [CrossRef]

- Polline, M.; Mutua, J. M.; Mbuya, T. O.; Ernest, K. Recipe development and mechanical characterization of carbon fibre reinforced recycled polypropylene 3D printing filament. Open Journal of Composite Materials 2021, 11, 47–61. [Google Scholar] [CrossRef]

- Capone, C.; Di Landro, L.; Inzoli, F.; Penco, M.; Sartore, L. Thermal and mechanical degradation during polymer extrusion processing. Polymer Engineering & Science 2007, 47, 1813–1819. [Google Scholar] [CrossRef]

- Yasim-Anuar, T.A.T.; Ariffin, H.; Norrrahim, M.N.F.; Hassan, M.A.; Andou, Y.; Tsukegi, T.; Nishida, H. Well-Dispersed Cellulose Nanofiber in Low Density Polyethylene Nanocomposite by Liquid-Assisted Extrusion. Polymers 2020, 12, 927. [Google Scholar] [CrossRef]

- Bowman, S.; Jiang, Q.; Memon, H.; Qiu, Y.; Liu, W.; Wei, Y. Effects of styrene-acrylic sizing on the mechanical properties of carbon fiber thermoplastic towpregs and their composites. Molecules 2018, 23, 547. [Google Scholar] [CrossRef]

- Berzin, F.; Beaugrand, J.; Dobosz, S.; Budtova, T.; Vergnes, B. Lignocellulosic fiber breakage in a molten polymer. Part 3. Modeling of the dimensional change of the fibers during compounding by twin screw extrusion. Composites Part A: Applied Science and Manufacturing 2017, 101, 422–431. [Google Scholar] [CrossRef]

- Fu, S. Y.; Lauke, B.; Mäder, E.; Yue, C. Y.; Hu, X. J. C. P. A. A. S. Tensile properties of short-glass-fiber-and short-carbon-fiber-reinforced polypropylene composites. Composites Part A: Applied Science and Manufacturing 2000, 31, 1117–1125. [Google Scholar] [CrossRef]

- Al-Mazrouei, N.; Al-Marzouqi, A.H.; Ahmed, W. Characterization and Sustainability Potential of Recycling 3D-Printed Nylon Composite Wastes. Sustainability 2022, 14, 10458. [Google Scholar] [CrossRef]

- Wang, L.; Ma, G.; Liu, T.; Buswell, R.; Li, Z. Interlayer reinforcement of 3D printed concrete by the in-process deposition of U-nails. Cement and Concrete Research 2021, 148, 106535. [Google Scholar] [CrossRef]

- Lewicki, J. P.; Rodriguez, J. N.; Zhu, C.; Worsley, M. A.; Wu, A. S.; Kanarska, Y. ,...; King, M. J. 3D-printing of meso-structurally ordered carbon fiber/polymer composites with unprecedented orthotropic physical properties. Scientific reports 2017, 7, 43401. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Cotton, C.; Sun, J.; Heider, D.; Gu, B.; Sun, B.; Chou, T. W. Interfacial bonding strength of short carbon fiber/acrylonitrile-butadiene-styrene composites fabricated by fused deposition modeling. Composites Part B: Engineering 2018, 137, 51–59. [Google Scholar] [CrossRef]

- Liao, G.; Li, Z.; Cheng, Y.; Xu, D.; Zhu, D.; Jiang, S. ...; Zhu, Y. Properties of oriented carbon fiber/polyamide 12 composite parts fabricated by fused deposition modeling. Materials & Design 2018, 139, 283–292. [Google Scholar] [CrossRef]

- Dul, S.; Fambri, L.; Pegoretti, A. High-performance polyamide/carbon fiber composites for fused filament fabrication: mechanical and functional performances. Journal of Materials Engineering and Performance 2021, 30, 5066–5085. [Google Scholar] [CrossRef]

- Blanco, I.; Cicala, G.; Recca, G.; Tosto, C. Specific Heat Capacity and Thermal Conductivity Measurements of PLA-Based 3D-Printed Parts with Milled Carbon Fiber Reinforcement. Entropy 2022, 24, 654. [Google Scholar] [CrossRef]

- Tekinalp, H. L.; Kunc, V.; Velez-Garcia, G. M.; Duty, C. E.; Love, L. J.; Naskar, A. K. ,...; Ozcan, S. Highly oriented carbon fiber–polymer composites via additive manufacturing. Composites Science and Technology 2014, 105, 144–150. [Google Scholar] [CrossRef]

- Sang, L.; Wang, C.; Wang, Y.; Wei, Z. Thermo-oxidative ageing effect on mechanical properties and morphology of short fibre reinforced polyamide composites–comparison of carbon and glass fibres. RSC advances 2017, 7, 43334–43344. [Google Scholar] [CrossRef]

- Kiss, P.; Glinz, J.; Stadlbauer, W.; Burgstaller, C.; Archodoulaki, V. M. The effect of thermally desized carbon fibre reinforcement on the flexural and impact properties of PA6, PPS and PEEK composite laminates: A comparative study. Composites Part B: Engineering 2021, 215, 108844. [Google Scholar] [CrossRef]

- Kim, D. K.; Kang, S. H.; Han, W.; Kim, K. W.; Kim, B. J. Facile method to enhance the mechanical interfacial strength between carbon fibers and polyamide 6 using modified silane coupling agents. Carbon Letters 2022, 32, 1463–1472. [Google Scholar] [CrossRef]

- Crawford, R.J. Mechanical Behaviour of Composites. In Plastics Engineering, 3rd ed.; Editor Crawford, R.J., Ed.; Publisher: Butterworth-Heinemann, 1998; pp. 168–244. [Google Scholar]

- Tanaka, K. , Mizuno, S., Honda, H., Katayama, T., & Enoki, S. Effect of water absorption on the mechanical properties of carbon fiber/polyamide composites. Journal of Solid Mechanics and Materials Engineering 2013, 7, 520–529. [Google Scholar] [CrossRef]

| Properties | Values | Comments |

|---|---|---|

| Density | 1.14 g/cc | ISO 1183 |

| Water Absorption | 8.5% | ISO 62 |

| Moisture Absorption at Equilibrium | 2.5% | 23 °C/50% R.H.; ISO 62 |

| Tensile Strength, Yield | 83.0 Mpa | 50 mm/min; ISO 527 |

| Elongation at Break | 25% | 50 mm/min, Normal strain; ISO 527 |

| Elongation at Yield | 5.0% | 50 mm/min; ISO 527 |

| Tensile Modulus | 3.00 Gpa | 1 mm/min; ISO 527 |

| Flexural Strength | 117 Gpa | ASTM Test |

| Flexural Modulus | 2.90 Gpa | ASTM Test |

| Melting Point | 257 °C | 10 K/min ASTM Test |

| PA6,6 neat filament | PA6,6 + rCF | |

|---|---|---|

| Zone 1 Temperature, °C | 255 | 260 |

| Zone 2 Temperature, °C | 255 | 260 |

| Zone 3 Temperature, °C | 260 | 265 |

| Zone 4 Temperature, °C | 260 | 265 |

| Zone 5 Temperature, °C | 260 | 265 |

| Zone 6 Temperature, °C | 255 | 260 |

| Zone 7 Temperature, °C | 250 | 255 |

| Die Temperature, °C | 235 | 240 |

| Screw speed, rpm | 150 | 150 |

| Sample | std. dev. |

|---|---|

| PA6,6 neat | 1.129 ± 0.026 g/cm3 |

| PA6,6 + 5 wt.% rCF | 1.148 ± 0.019 g/cm3 |

| PA6,6 + 10 wt.% rCF | 1.164 ± 0.014 g/cm3 |

| Material | Method | Value |

|---|---|---|

| rCFs | helium pycnometer | 1.917 g/cm3 |

| PA6,6 neat filament | buoyancy balance | 1.129 g/cm3 |

| PA6,6 + 5 wt.% rCF filament | buoyancy balance | 1.148 g/cm3 |

| PA6,6 + 10 wt.% rCF filament | buoyancy balance | 1.164 g/cm3 |

| Percentage of rCF reinforcement | ||

| PA6,6 + 5 wt.% rCF filament | Rule of mixtures | 2.41 %v/v |

| PA6,6 + 10 wt.% rCF filament | 4.44 %v/v | |

| Material | Value |

|---|---|

| PA6,6 + 5 wt.% rCF filament | 3.40 %v/v |

| PA6,6 + 10 wt.% rCF filament | 6.79 %v/v |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).