Submitted:

21 May 2023

Posted:

22 May 2023

You are already at the latest version

Abstract

Keywords:

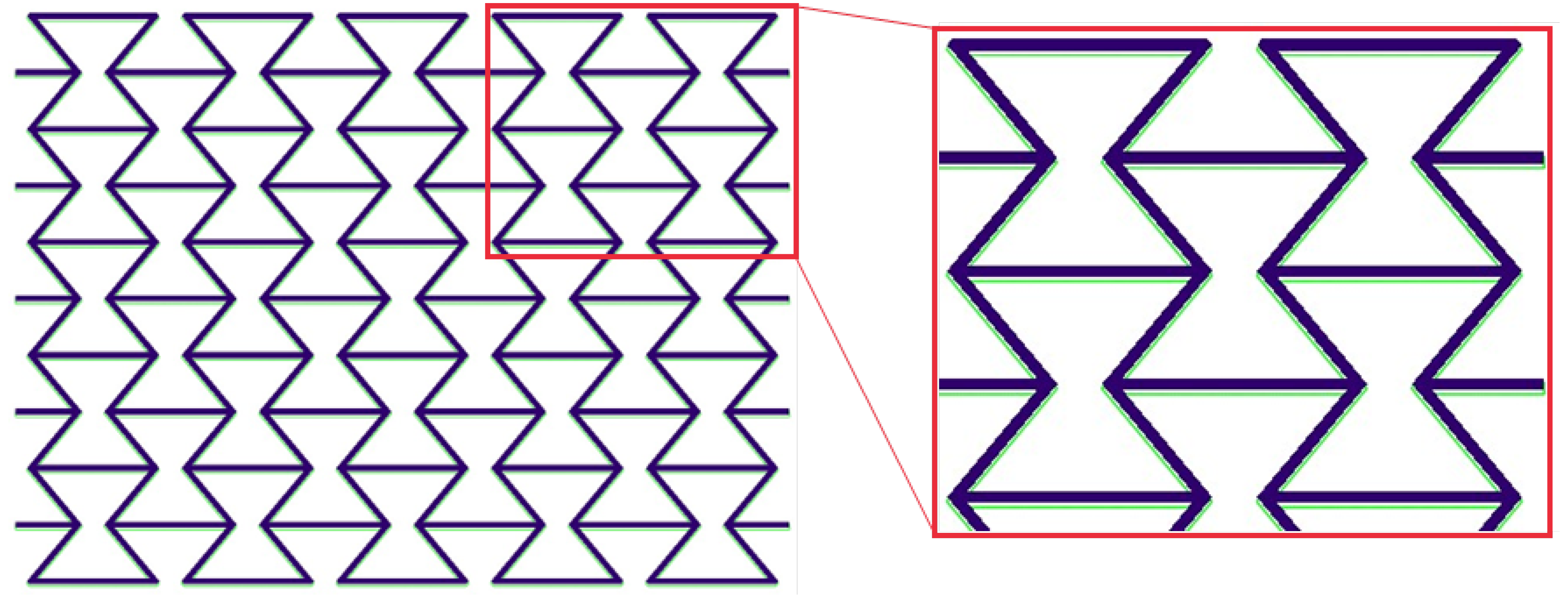

1. Introduction

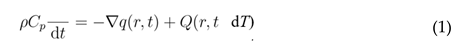

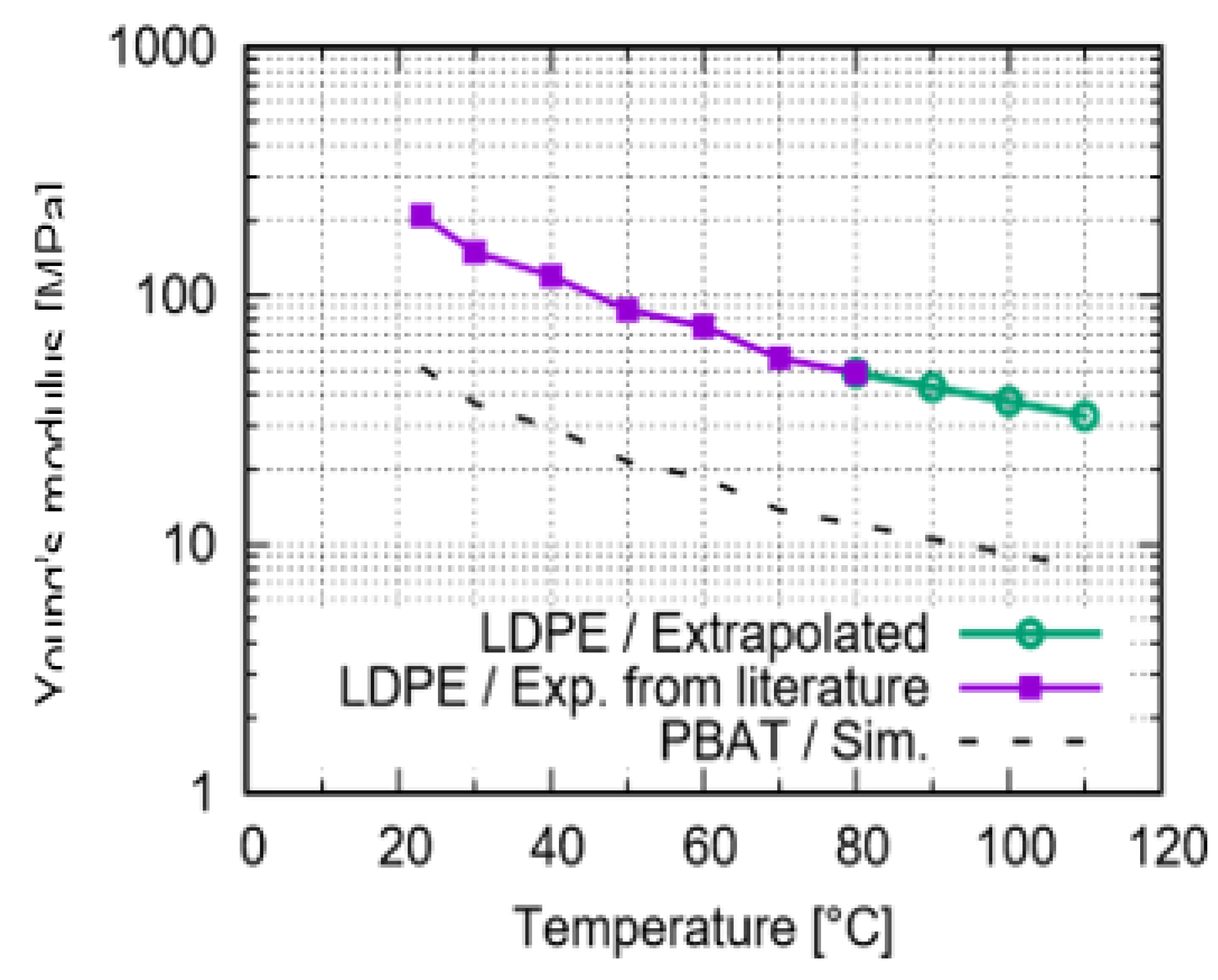

2. Material and Experiment

3. Process and FE Simulation

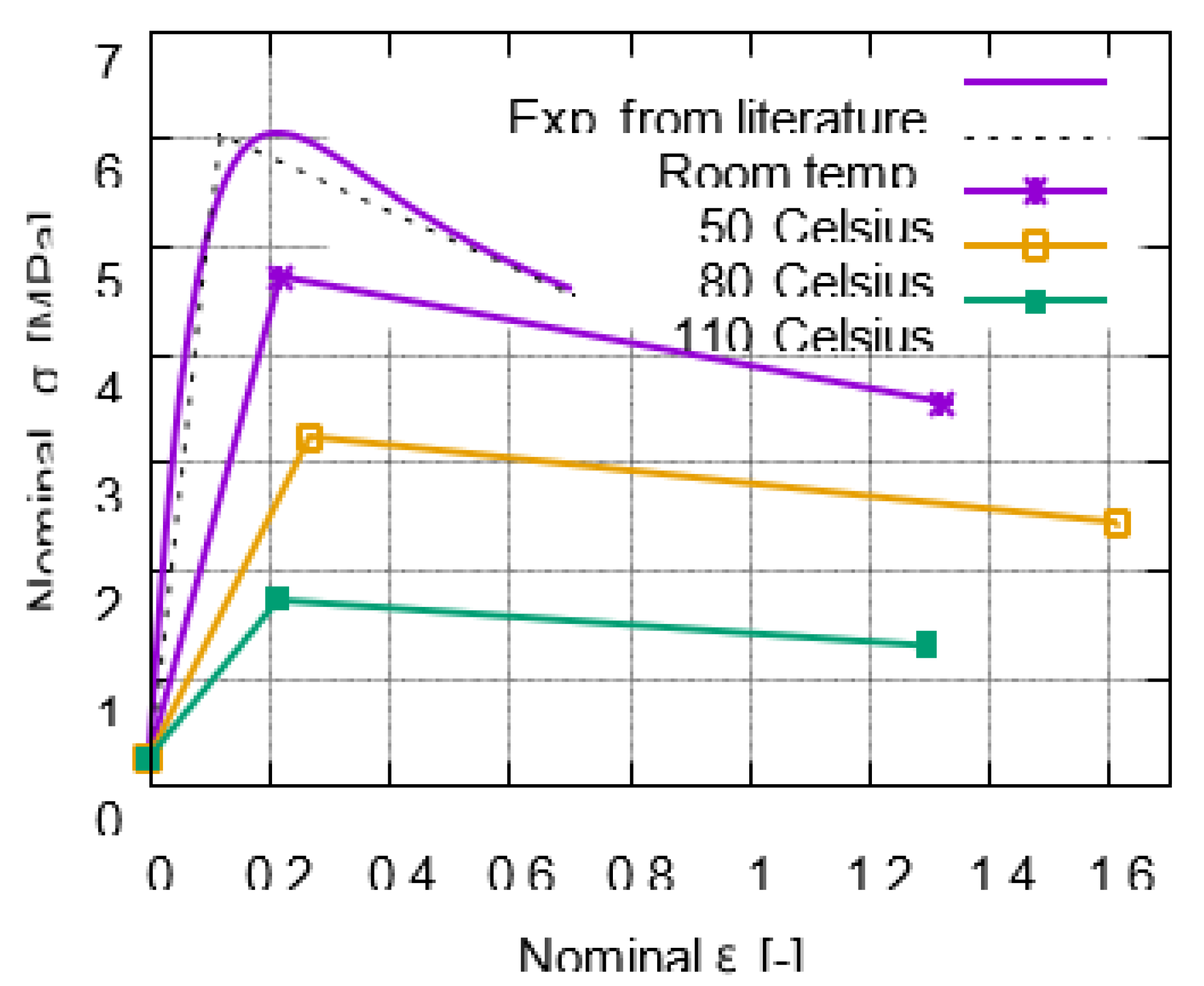

3.1. Simulation of additive manufacturing using FE method

3.1.1. Approach of additive manufacturing process simulation

3.1.2. Current process simulation

3.2. FE simulation with mechanical loading

4. Simulated Results with Comparison of Test Data

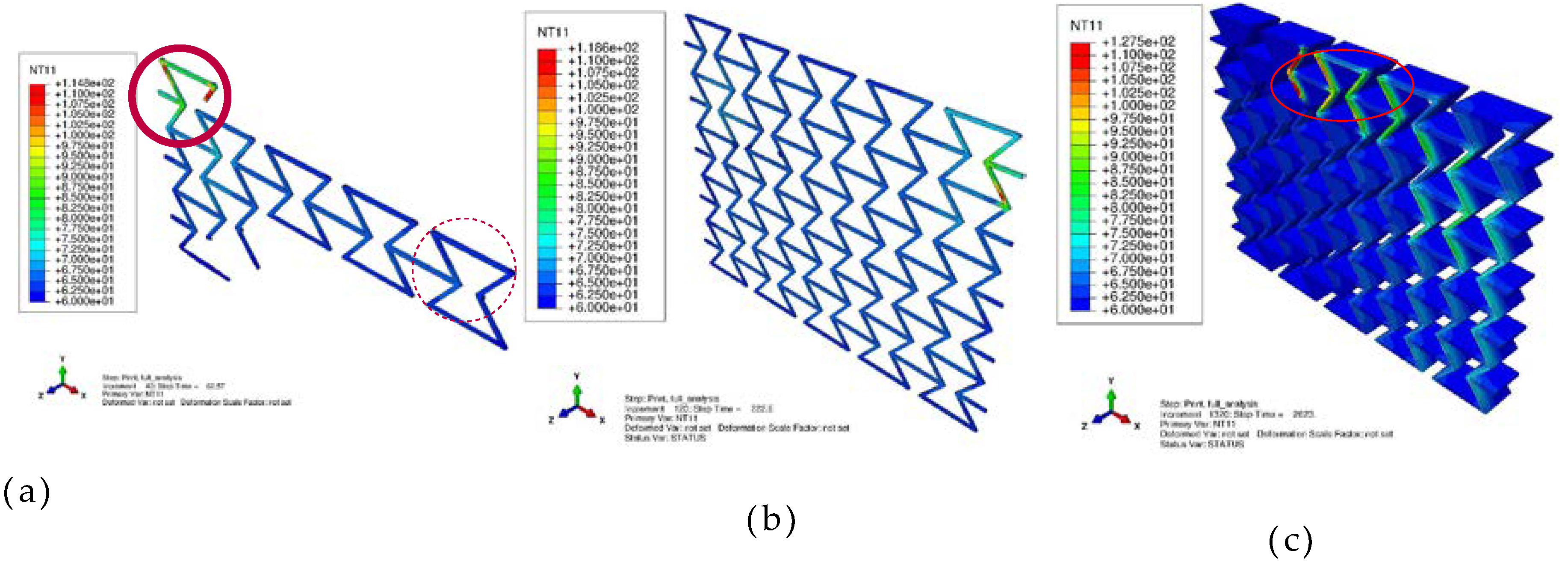

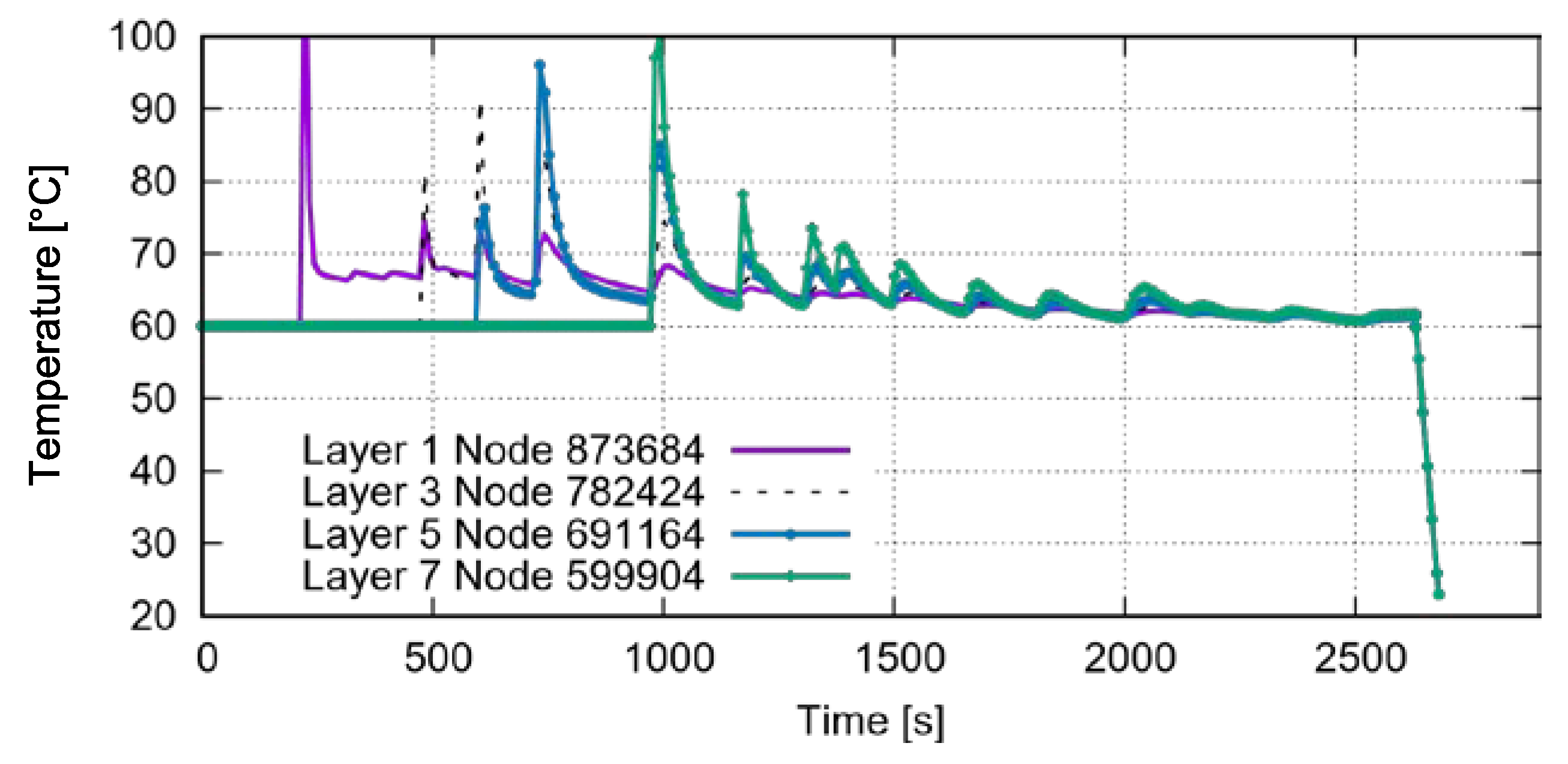

4.1. Numerical results predicted by process simulation

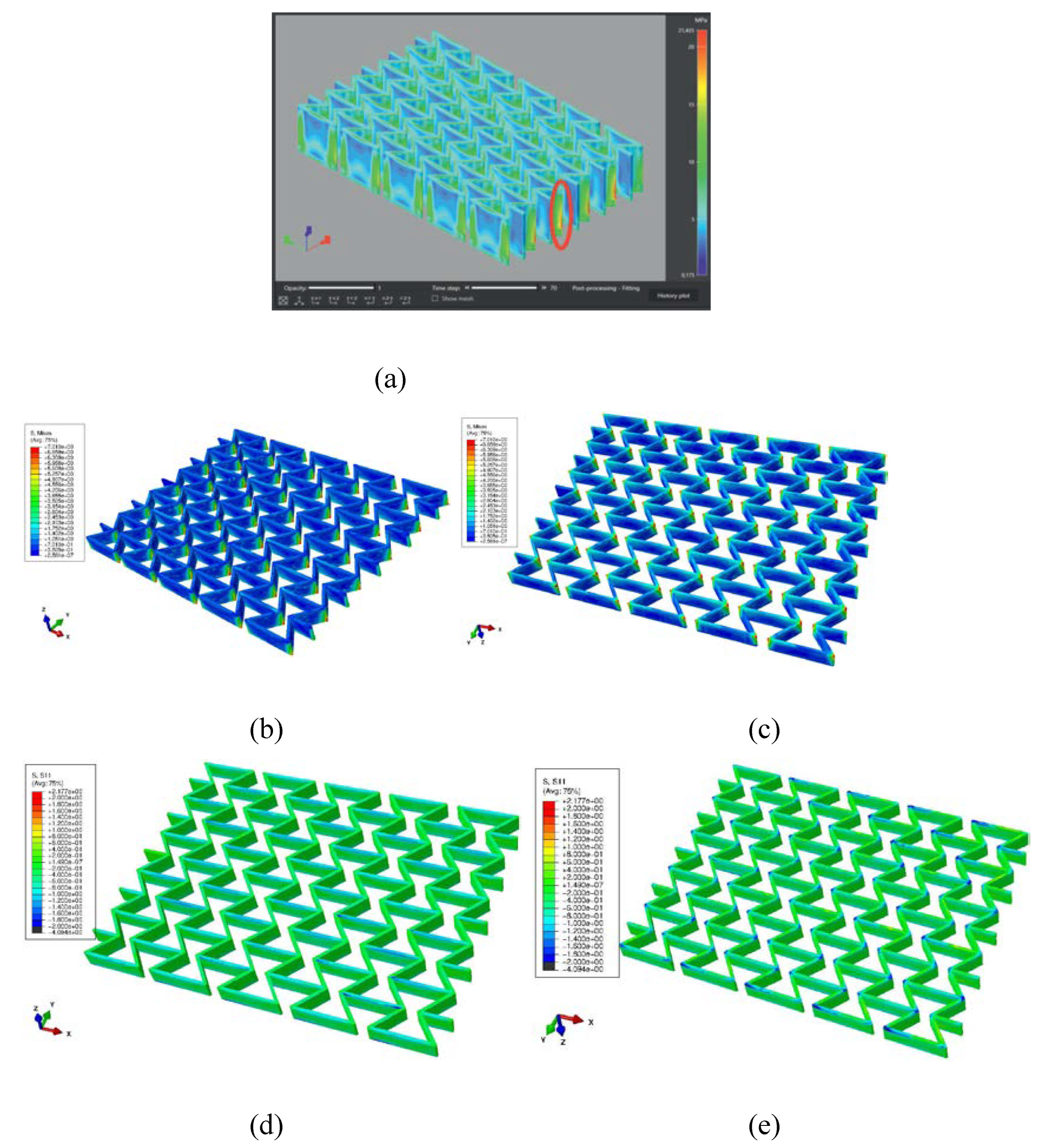

4.2. Numerical results predicted by mechanical simulation

5. Discussion

5.1. Residual stress and warpage

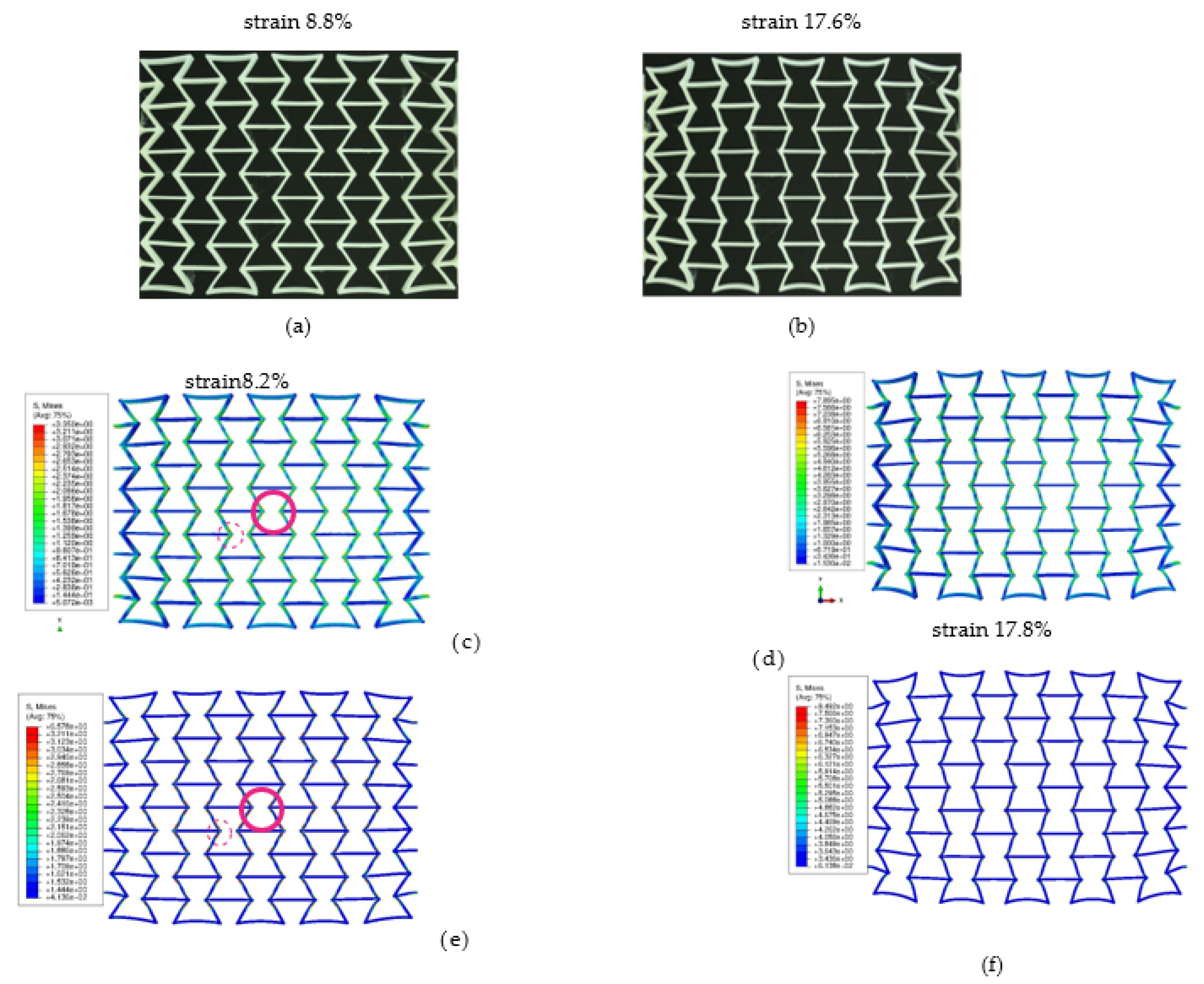

5.2. Auxetic structural deformation behavior

6. Conclusion

- FE-based process simulation:

- -

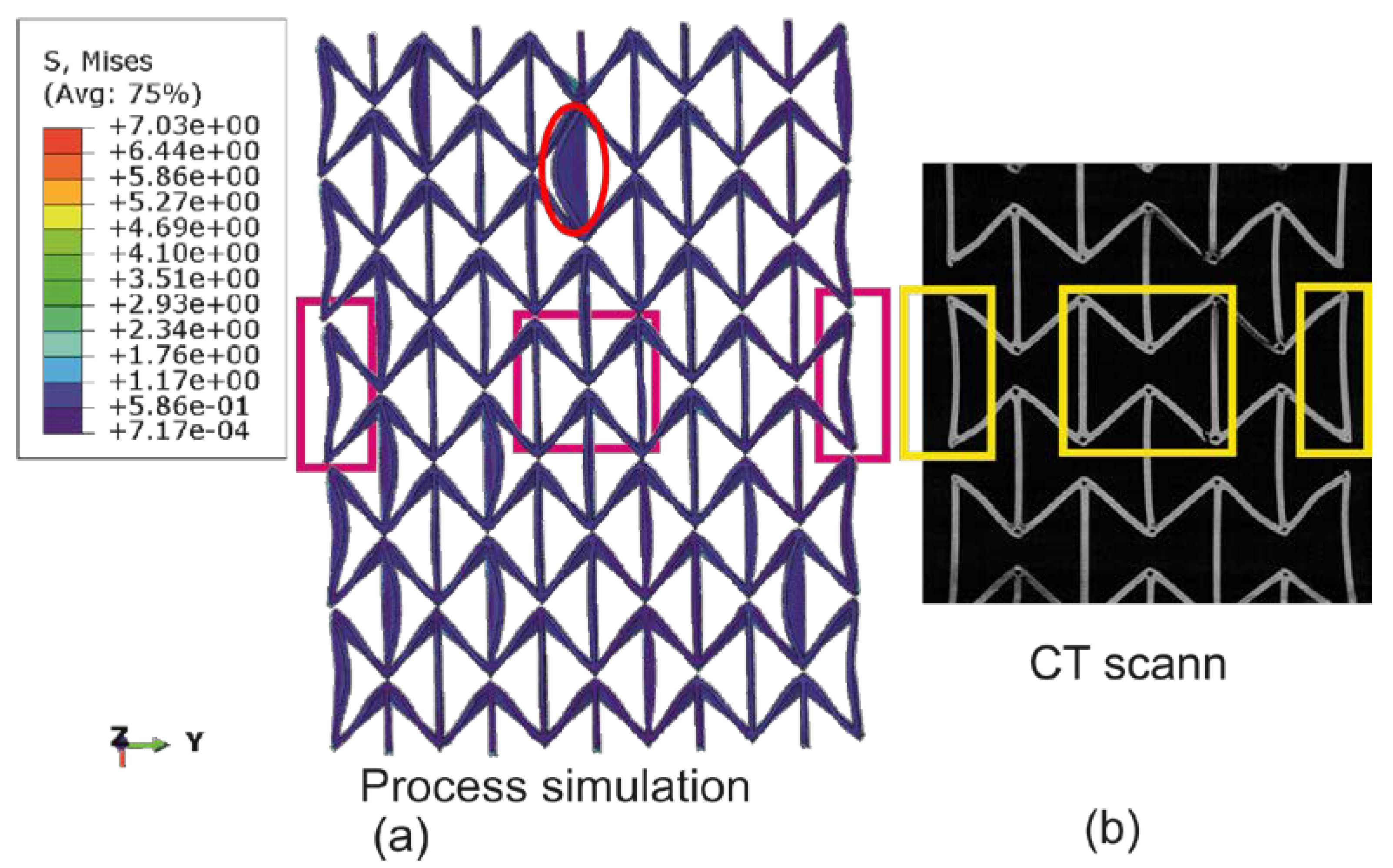

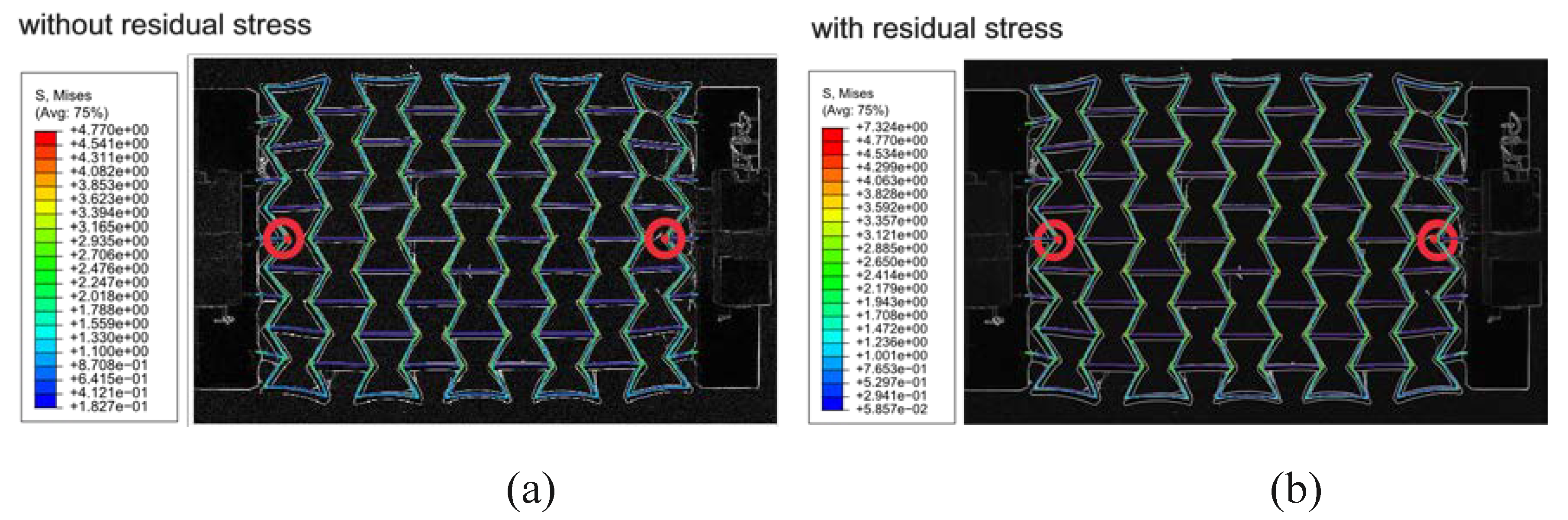

- After cooling down, the junction places of the two inclined struts present higher residual stress than other places in the cell.

- -

- After cooling down, the inhomogeneous warpage among cells or inside one cell is well predicted compared to the µCT measured real specimen.

- -

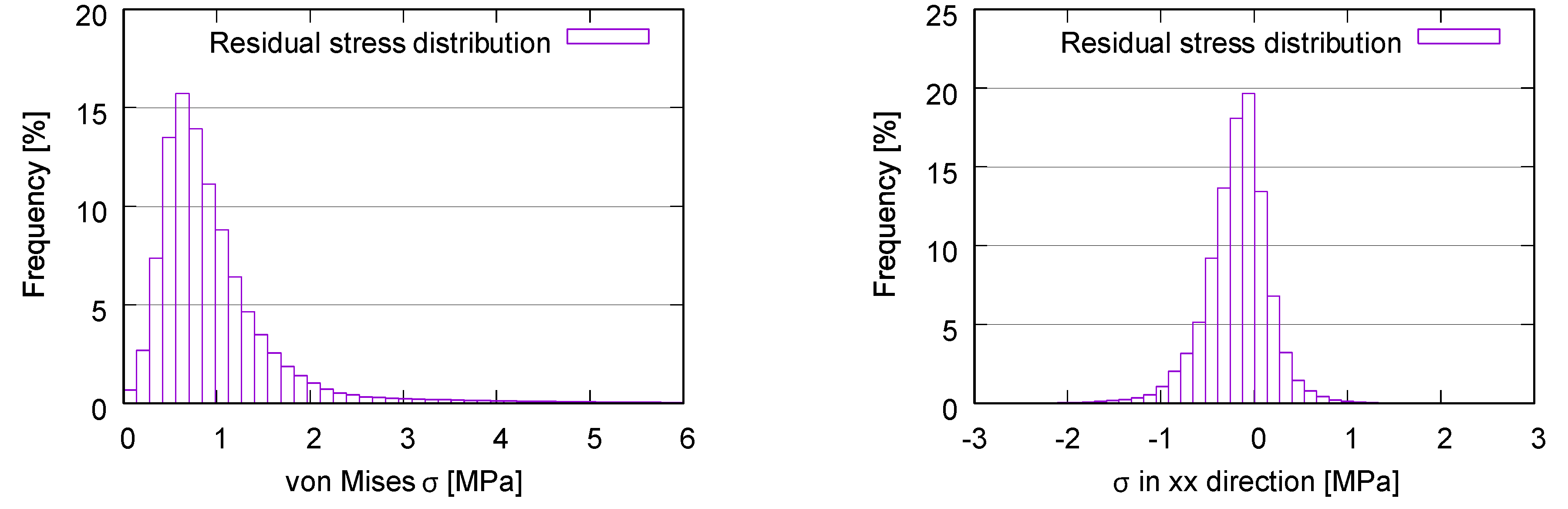

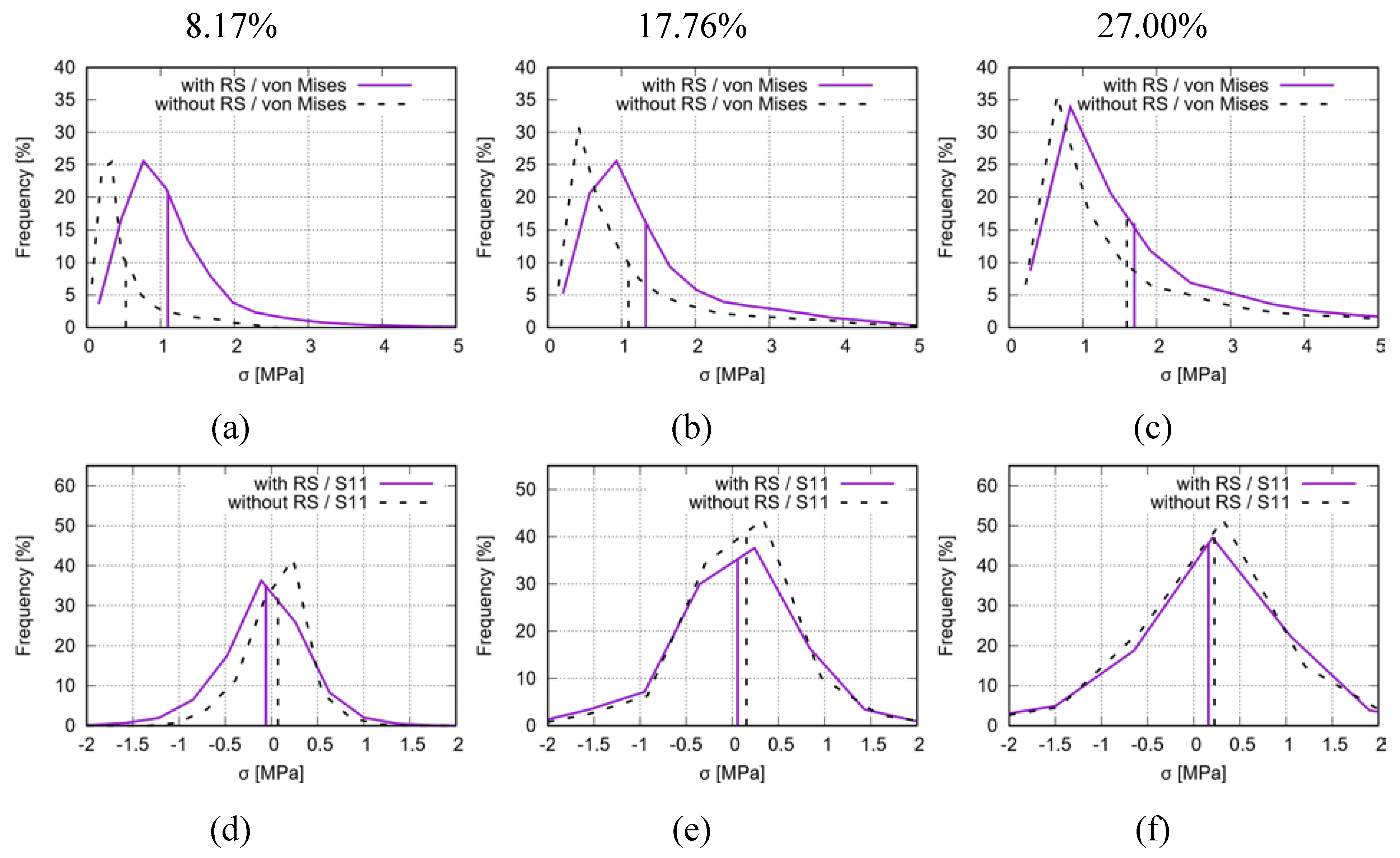

- The histogram shows a mean value of the RS, taking von Mises stress as an indicating factor, slightly less than 1 MPa, which can be served as a reference value in estimating the real residual stress.

- Auxetic structural tensile deformation:

- -

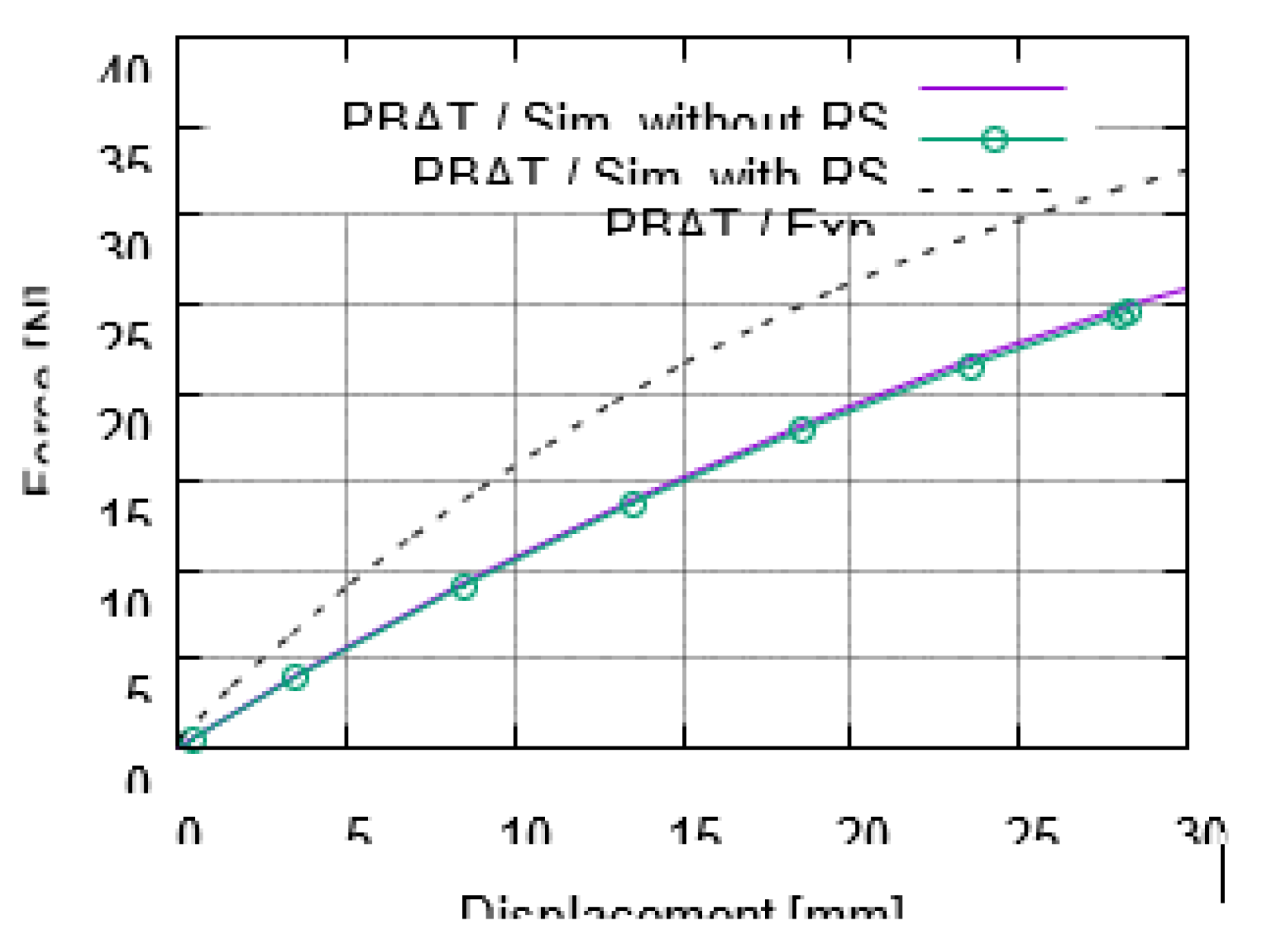

- The force-displacement curve predicted by the FE model considering the RS 490 shows negligible softer behavior compared to the one without. Both FE curves capture the highly non-linear and evolution behavior of the experimental one, where the numerical result behaves softer than reality.

- -

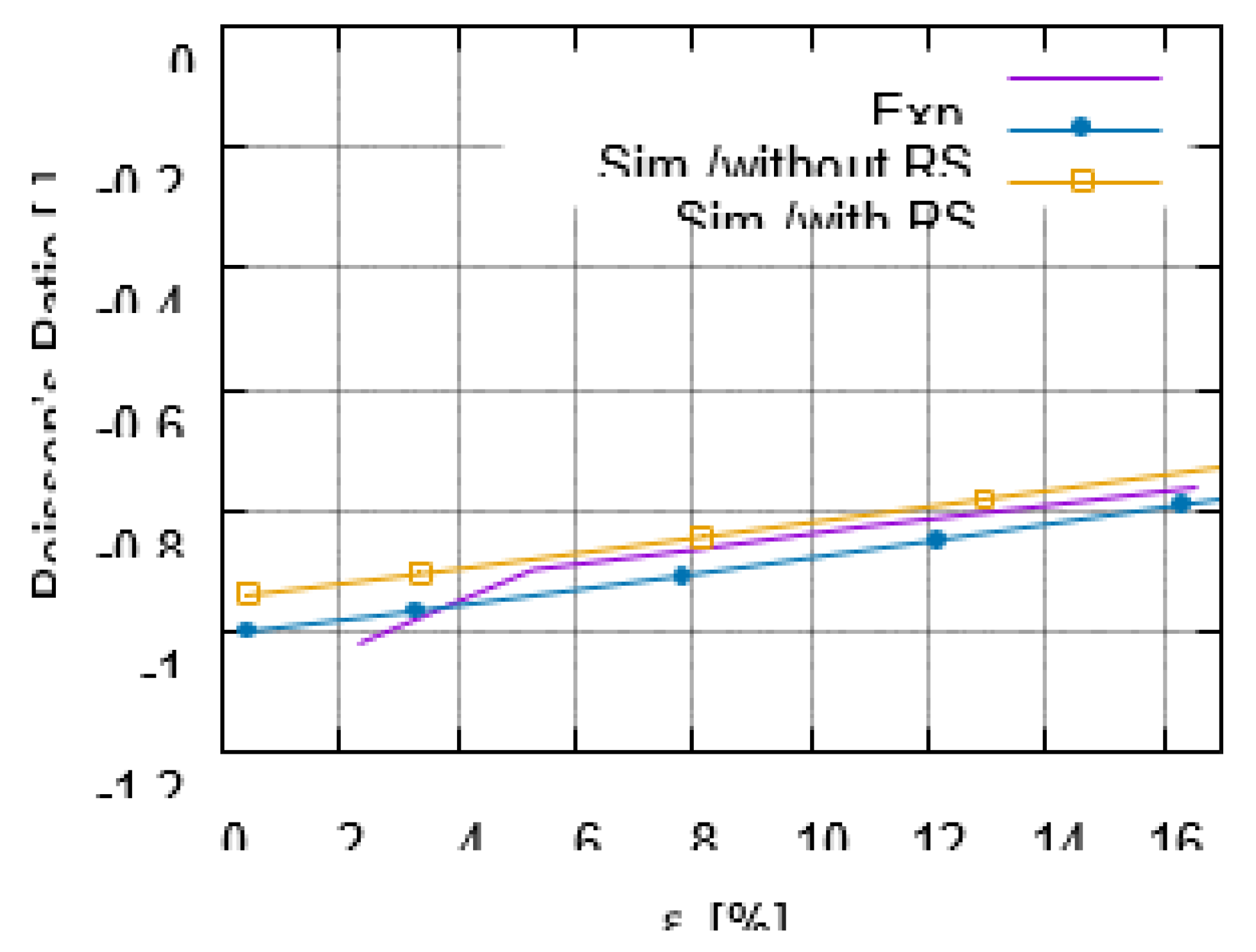

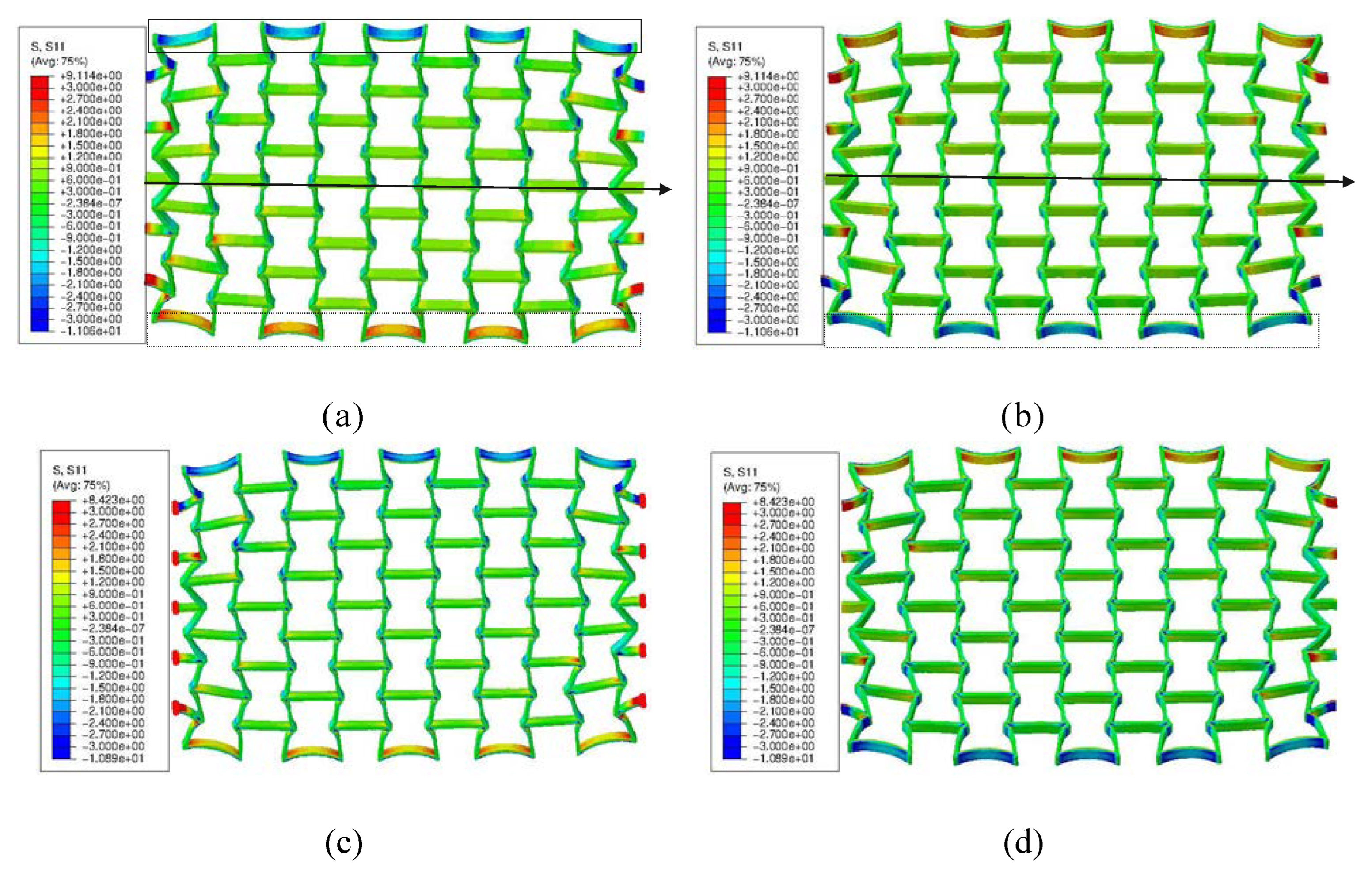

- At the beginning of loading, the RS illustrates a stronger influence on the global stresses (von Mises stress and stress in the loading direction) of the 495 auxetic structure. From about 15% global (engineering) strain on, the global stresses predicted by FE models with and without RS approach to each other.

- -

- The Poisson’s ratio evolution predicted by both FE models matches the experimental result very well for the auxetic structure. The FE model, with consideration of the RS, presents an even better mapping of the experimental 500 one.

- -

- The RS affects the topological deformation much less than the stress value and distribution. By overlapping the deformed status of the auxetic structure from the test and the FE calculation, it shows that both FE models can predict the real auxetic deformation characteristics in detail.

- -

- The FE results predicted by both models show that the deformation and stress distribution present symmetric behavior according to the geometric middle line paralleling the loading direction.

- -

- Generally, RS negatively affects the auxetic deformation behavior.

Author Contributions

Funding

Data Availability Statement

References

- K. E. Evans, Auxetic polymers: a new range of materials, Endeavour 15 (4) (1991) 170–174 (1991). [CrossRef]

- K. Wojciechowski, Remarks on “Poisson ratio beyond the limits of the elasticity theory”, Journal of the Physical Society of Japan 72 (7) (2003) 1819–1820 (2003). [CrossRef]

- X. Ren, R. Das, P. Tran, T. Ngo, Y. Xie, Auxetic metamaterials and structures: a 525 review, Smart Mater. Struct. 27 (23001) (2018). [CrossRef]

- J. Grima, R. Gatt, Perforated sheets exhibiting negative Poisson’s ratios, Advanced Engineering Materials 12 (2010) 460–464 (2010). [CrossRef]

- R. Almgren, An isotropic three-dimensional structure with Poisson’s ratio=-1, Journal of Elasticity 15 (1985) 427–430 (1985). [CrossRef]

- L. Ai, X.-L. Gao, Metamaterials with negative Poisson’s ratio and nonpositive thermal expansion, Composite Structures 162 (2017) 70–84 (2017). [CrossRef]

- S. Pandini, A. Pegoretti, Time and temperature effects on Poisson’s ratio of poly(butylene terephthalate, eXPRESS Polymer Letters 5 (8) (2011) 685–697 (2011). [CrossRef]

- L. J. Gibson, M. Ashby, G. S. Schajer, C. I. Robertson, The mechanics of twodimensional cellular materials, Proceedings of the Royal Society of London. A. 382 (1982) 25–42 (1982). [CrossRef]

- C. Mercer, T. Speck, J. Lee, D. S. Balint, M. Thielen, Effects of geome-540 try and boundary constraint on the stiffness and negative Poisson’s ratio behaviour of auxetic metamaterials under quasi-static and impact loading, International Journal of Impact Engineering 169 (104315) (2021) 1–12 (2021). [CrossRef]

- T. Masselter, G. Bold, M. Thielen, O. Speck, T. Speck, Bioinspired materials and 545 structures: A case study based on selected examples, in: G. Yang, L. Xiao, L. Lamboni (Eds.), Bioinspired Materials Science and Engineering, Wiley, Wuhan, 2018, pp. 251– 266 (2018). [CrossRef]

- Buhrig-Polaczek,¨ C. Fleck, T. Speck, P. Schuler,¨ S. Fischer, M. Caliaro, M. Thielen, Biomimetic cellular metals-using hierarchical structuring 550 for energy absorption, Bioinspir Biomim 11 (4) (2016) 045002 (2016). [CrossRef]

- S. Choi, Z. Ku, S. Kim, K. Choi, A. Urbas, Y. Kim, Silk is a natural metamaterial for self-cooling: An oxymoron?, in: 2018 Conference on Lasers and Electro-Optics (CLEO), 2018, pp. 1–2 (2018).

- P. U. Kelkar, H. S. Kim, K.-H. Cho, J. Y. Kwak, C.-Y. Kang, H.-C. Song, Cellular auxetic structures for mechanical metamaterials: A review, Sensors 20 (3132) (2020) 1–26 (2020). [CrossRef]

- R. Negrea, Brief review of metamaterials and auxetic materials, Automotive Series XXVII (31) (2021) 1–9 (2021). [CrossRef]

- T. D. Ngo, A. Kashani, G. Imbalzano, K. T. Nguyen, D. Hui, Additive manufacturing (3D printing): A review of materials, methods, applications and challenges, Composites Part B: Engineering 143 (2018) 172–196 (2018). [CrossRef]

- B. Praveena, N. Lokesh, B. Abdulrajak, N. Santhosh, B. Praveena, R. Vignesh, A 565 comprehensive review of emerging additive manufacturing (3D printing technology): Methods, materials, applications, challenges, trends and future potential, Materials Today: Proceedings 52 (2022) 1309–1313, international Conference on Smart and Sustainable Developments in Materials, Manufacturing and Energy Engineering (2022. [CrossRef]

- M. Manoj Prabhakar, A. Saravanan, A. Haiter Lenin, I. Jerin Leno, K. Mayandi, P. Sethu Ramalingam, A short review on 3D printing methods, process parameters and materials, Materials Today: Proceedings 45 (2021) 6108–6114, international Conference on Mechanical, Electronics and Computer Engineering 2020: Materials Science (2021). [CrossRef]

- Y. Schneider, V. Guski, S. Schmauder, J. Kadkhodapour, J. Hufert, A. Grebhardt, C. Bonten, Deformation behavior investigation of auxetic structure made of poly(butylene adipate-co-terephthalate) biopolymers using finite element method, Polymers 15 (7) (2023) 1–23 (2023). [CrossRef]

- ABAQUS/Standard, Hibbitt, Karlsson & Sorensen, Inc., 2020 (2020). ABAQUS, AM Modeler (2020)Download link: https://github.com/Dr-Ning-An/ebmabaqus.

- J. Hufert, A. Grebhardt, Y. Schneider, C. Bonten, S. Schmauder, Deformation behavior of 3D printed auxetic structures of thermoplast polyermers: PLA, PBAT, and blends, Polymers 15 (2) (2023). [CrossRef]

- J. Jiao, X. Zeng, X. Huang, An overview on synthesis, properties and applications of poly(butylene-adipate-co-terephthalate)–PBAT, Advanced Industrial and Engineering Polymer Research 3 (2020) 19–26 (2020). [CrossRef]

- B. Liu, T. Guan, G. Wu, Y. Fu, Y. Weng, Biodegradation behavior of degradable mulch with poly (butylene adipate-co-terephthalate) (PBAT) and poly (butylene 590 succinate) (PBS) in simulation marine environment, Polymers 14 (8) (2022) 1515–1– 12 (2022). [CrossRef]

- F. Ferreira, L. Cividanes, R. Gouveia, L. Lona, An overview on properties and applications of poly(butylene adipate-co-terephthalate)– PBAT based composites, Polymer Engineering and Science 59 (2019). [CrossRef]

- L. Jiang, M. P. Wolcott, J. Zhang, Study of biodegradable polylactide/poly(butylene adipate-co-terephthalate) blends, Biomacromelecules 7 (2006) 199–207 (2006). [CrossRef]

- M. Mori, A. Hansel, M. Fujishima, Machine Tool, Springer Berlin Heidelberg, Berlin, Heidelberg, 2014, pp. 792–801 (2014). [CrossRef]

- V. Pavelic, R. Tanbakuchi, P. S. Uyehara, A. O. und Myers, Experimental and computed temperature histories in gas tungsten arc welding of thin plates, Welding Journal Research Supplement 48 (1969) 296–305 (1969).

- N. Pierron, P. Sallamand, J. M. Jouvard, E. Cicala, S. Matte¨ı, Determination of an empirical law of aluminium and magnesium alloys absorption coefficient during Nd:.

- YAG laser interaction, Journal of Physics D: Applied Physics 40 (2007) 2096–2101 (2007). [CrossRef]

- Gibson, D. Rosen, B. Stucker, M. Khorasani, Material extrusion, in: Additive Manufacturing Technologies, in Additive Manufacturing Technologies, Springer International Publishing, Cham, 2021, pp. 171–201 (2021). [CrossRef]

- Q. Sun, Z. Shan, L. Zhan, S. Wang, X. Liu, Z. Li, S. Wu, Warp deformation model of polyetheretherketone composites reinforced with carbon fibers in additive manufacturing, Materials Research Express 8 (12) (2021) 125305 (2021). [CrossRef]

- N. An, G. Yang, K. Yang, J. Wang, M. Li, J. Zhou, Implementation of abaqus usersubroutines and plugin for thermal analysis of powder-bed electron-beam-melting additive manufacturing process, Materials Today Communications 27 (2021) 102307 (2021). [CrossRef]

- BASF (2013) 1–3Last visit May 03, 2022 (2013). [link]. URL https://documents.basf.com/c32f5c099d8e29ac42869b975517bdbdda6e62f4/ecoflex_F.

- Z. Ali, H. Youssef, H. M. Said, H. Saleh, Thermal stability of LDPE, iPP and their blends, Thermochimica Acta 438 (1) (2005) 70–75 (2005). [CrossRef]

- M. Ta¸sdemir, H. Biltekin, G. T. Caneba, Preparation and characterization of ldpe and 625 pp-wood fiber composites, Journal of Applied Polymer Science 112 (2009) 3095–3102 (2009). [CrossRef]

- M. Bednarik, D. Manas, M. Manas, A. Mizera, M. Reznicek, Effect of ionizing beta radiation on the mechanical properties of poly(ethylene) under thermal stress, MATEC Web of Conferences 76 (02019) (2016) 1–4 (2016). [CrossRef]

- ABAQUS/Standard, Hibbitt, Karlsson & Sorensen, Inc., 2018 (2018).

- O. Sahin, Finite element simulations of additively manufactured PBAT polymer with auxetic behavior in 2D and 3D (2022).

- Digimat AM, last visit Nov. 17, 2022 (2019).

- C. Hou, Numerical investigations on additive manufacturing of metamaterials with 2d structure (2020).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).