Submitted:

11 January 2026

Posted:

12 January 2026

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Samples and Study Object Description

2.2. Experimental Design and Control Configuration

2.3. Measurement Method and Quality Control

2.4. Data Processing and Model Formulation

2.5. Performance Indicators and Data Analysis

3. Results and Discussion

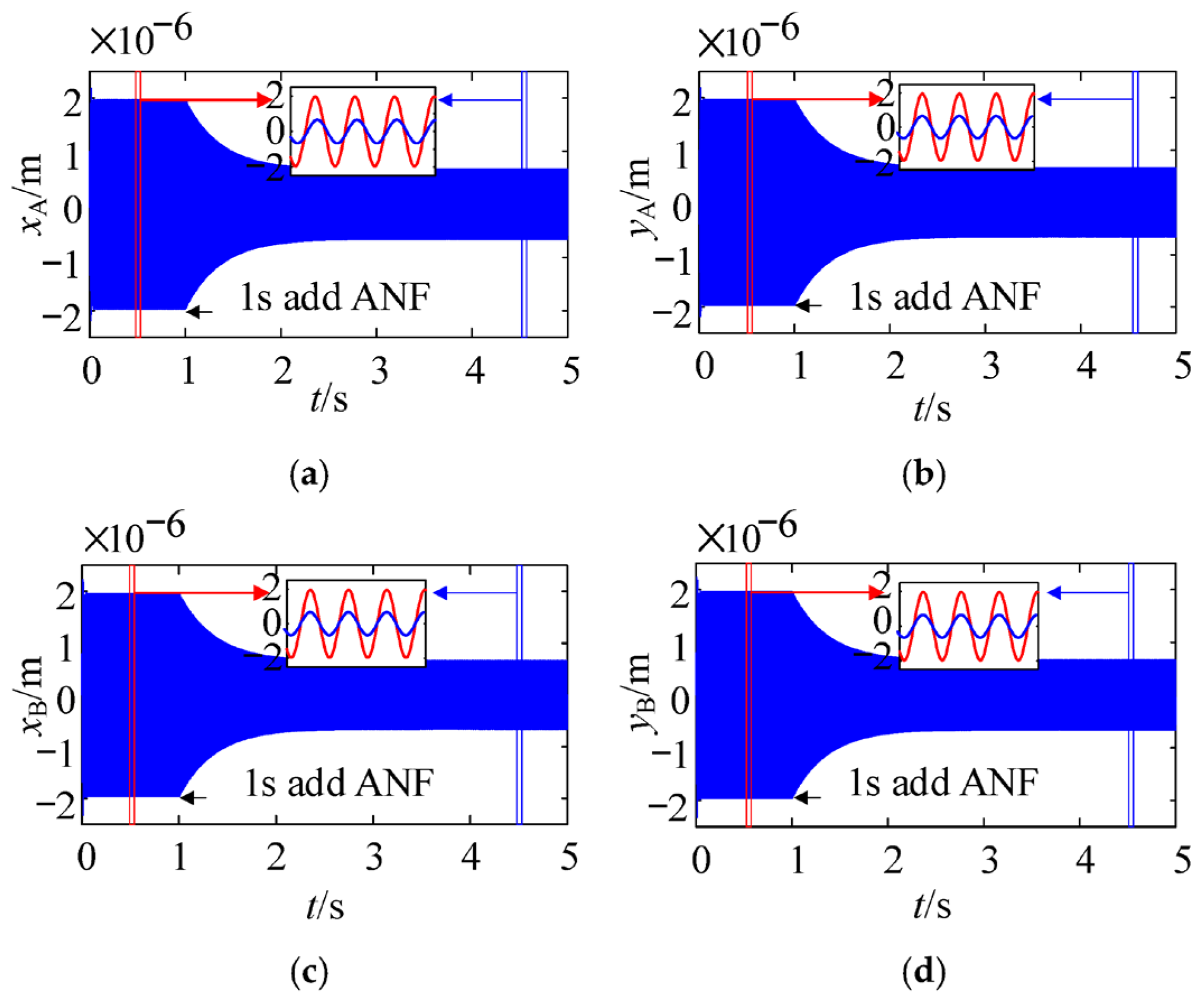

3.1. Response Reduction Under Different Residual Unbalance Levels

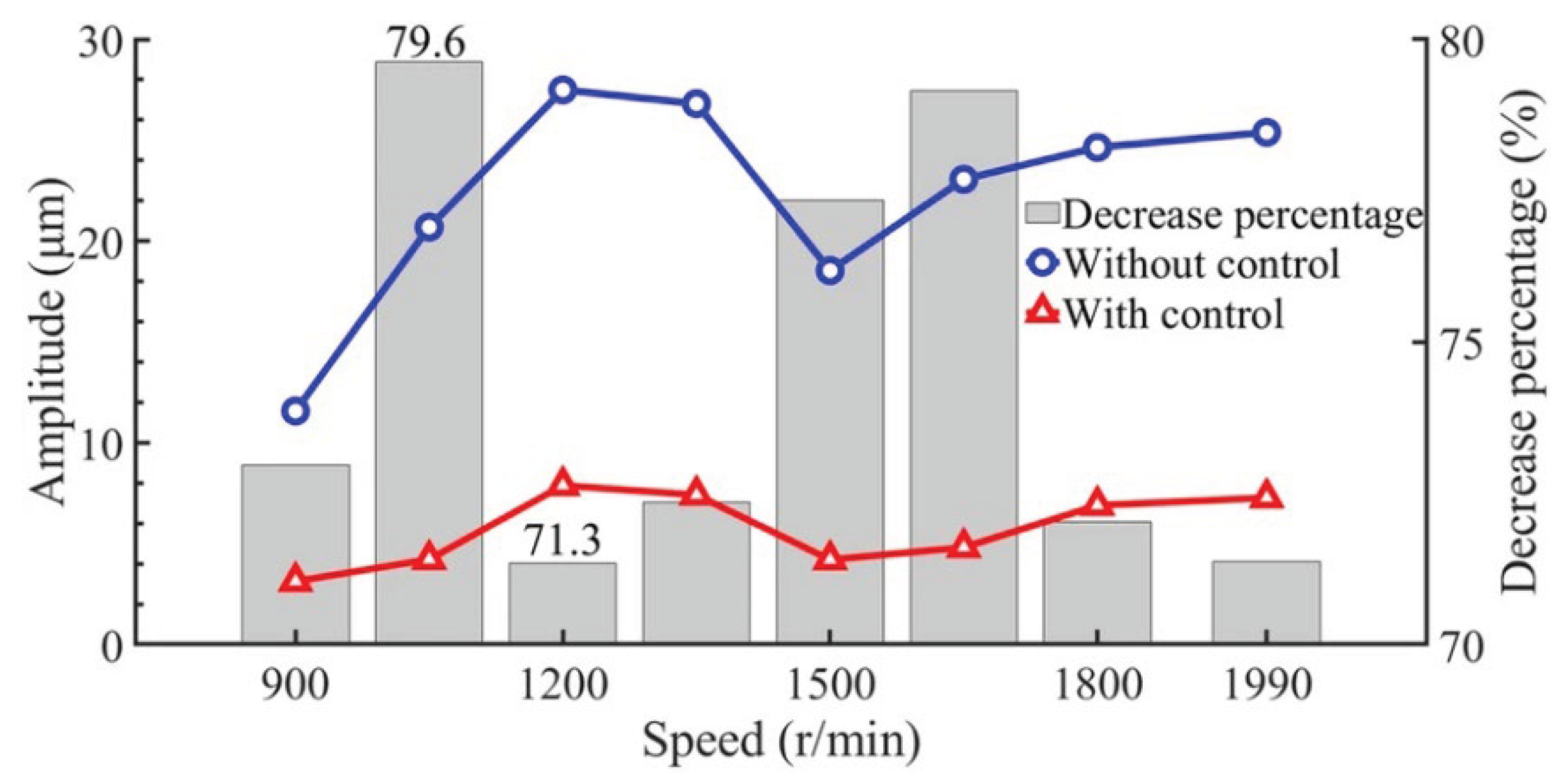

3.2. Influence of Rotational Speed Variation

3.3. Effect of Measurement Noise on Control Performance

3.4. Comparison with Existing Studies and Practical Implications

4. Conclusion

References

- Perez, R. X. (Ed.) Design, modeling and reliability in rotating machinery; John Wiley & Sons, 2022. [Google Scholar]

- Kianfar, S. The technological foundations of residual stress evolution in manufacturing of next-generation lightweight automotive powertrain components. Doctoral dissertation, University of British Columbia, 2022. [Google Scholar]

- Chen, F.; Liang, H.; Li, S.; Yue, L.; Xu, P. Design of Domestic Chip Scheduling Architecture for Smart Grid Based on Edge Collaboration. 2025. [Google Scholar] [PubMed]

- Sanjrani, A. N.; Huang, H. Z.; Shah, S. A.; Hussain, F.; Punhal, M.; Narejo, A.; Zhang, B. High-speed train wheel set bearing analysis: Practical approach to maintenance between end of life and useful life extension assessment. Results in Engineering 2025, 25, 103696. [Google Scholar] [CrossRef]

- Shah, S.; Luintel, M. C.; Bhattrai, S. Comprehensive review on vibration response and dynamic analysis of rotating blades under thermal environment: S. Shah et al. International Journal of Dynamics and Control 2025, 13(7), 264. [Google Scholar] [CrossRef]

- Gui, H.; Fu, Y.; Wang, Z.; Zong, W. Research on Dynamic Balance Control of Ct Gantry Based on Multi-Body Dynamics Algorithm. 2025. [Google Scholar] [PubMed]

- Zhang, Y.; Xie, Z.; Zhai, L.; Shao, M. Unbalanced vibration suppression of a rotor with Rotating-Frequency faults using signal purification. Mechanical Systems and Signal Processing 2023, 190, 110153. [Google Scholar] [CrossRef]

- Sipp, D.; Schmid, P. J. Linear closed-loop control of fluid instabilities and noise-induced perturbations: a review of approaches and tools. Applied Mechanics Reviews 2016, 68(2), 020801. [Google Scholar] [CrossRef]

- Wu, S.; Cao, J.; Su, X.; Tian, Q. Zero-Shot Knowledge Extraction with Hierarchical Attention and an Entity-Relationship Transformer. 2025 5th International Conference on Sensors and Information Technology, March 2025; IEEE; pp. 356–360. [Google Scholar]

- Narisimha Murty, T.; Mehta, K.; Mutra, R. R.; Mallikarjuna Reddy, D. Vibration mitigation in high-speed rotor-bearing systems with various control schemes. Journal of Vibration Engineering & Technologies 2025, 13(2), 1–35. [Google Scholar]

- Sheu, J. B.; Gao, X. Q. Alliance or no alliance—Bargaining power in competing reverse supply chains. European Journal of Operational Research 2014, 233(2), 313–325. [Google Scholar] [CrossRef]

- Lee, D. H.; Lee, J. H.; Ahn, J. W. Mechanical vibration reduction control of two-mass permanent magnet synchronous motor using adaptive notch filter with fast Fourier transform analysis. IET electric power applications 2012, 6(7), 455–461. [Google Scholar] [CrossRef]

- Narumi, K.; Qin, F.; Liu, S.; Cheng, H. Y.; Gu, J.; Kawahara, Y.; Yao, L. Self-healing UI: Mechanically and electrically self-healing materials for sensing and actuation interfaces. In Proceedings of the 32nd Annual ACM Symposium on User Interface Software and Technology, October 2019; pp. 293–306. [Google Scholar]

- Morrison, T. M.; Pathmanathan, P.; Adwan, M.; Margerrison, E. Advancing regulatory science with computational modeling for medical devices at the FDA's Office of Science and Engineering Laboratories. Frontiers in medicine 2018, 5, 241. [Google Scholar] [CrossRef] [PubMed]

- Feng, H. High-Efficiency Dual-Band 8-Port MIMO Antenna Array for Enhanced 5G Smartphone Communications. Journal of Artificial Intelligence and Information 2024, 1, 71–78. [Google Scholar]

- Anderson, B. D.; Dehghani, A. Challenges of adaptive control–past, permanent and future. Annual reviews in control 2008, 32(2), 123–135. [Google Scholar] [CrossRef]

- Chen, F.; Liang, H.; Yue, L.; Xu, P.; Li, S. Low-Power Acceleration Architecture Design of Domestic Smart Chips for AI Loads. 2025. [Google Scholar] [PubMed]

- Song, X.; Wu, H.; Wang, Z.; Zou, Y.; Sa, X.; Zhao, Z. A Review of Control Techniques for Imbalance-Induced Vibration in Magnetically Suspended Rotor Systems. Applied Sciences 2025, 15(24), 13249. [Google Scholar] [CrossRef]

- Cho, S.; Jeon, K.; Kim, C. W. Vibration analysis of electric motors considering rotating rotor structure using flexible multibody dynamics-electromagnetic-structural vibration coupled analysis. Journal of Computational Design and Engineering 2023, 10(2), 578–588. [Google Scholar] [CrossRef]

- Yuan, M.; Wang, B.; Su, S.; Qin, W. Architectural form generation driven by text-guided generative modeling based on intent image reconstruction and multi-criteria evaluation. Authorea Preprints 2025. [Google Scholar]

- Malghan, P. G.; Hota, M. K. A review on ECG filtering techniques for rhythm analysis. Research on Biomedical Engineering 2020, 36(2), 171–186. [Google Scholar] [CrossRef]

- Wu, C.; Chen, H.; Zhu, J.; Yao, Y. Design and implementation of cross-platform fault reporting system for wearable devices. 2025. [Google Scholar] [PubMed]

- Staino, A.; Basu, B. Dynamics and control of vibrations in wind turbines with variable rotor speed. Engineering Structures 2013, 56, 58–67. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).