Submitted:

16 December 2025

Posted:

18 December 2025

You are already at the latest version

Abstract

The microstructural evolution and tensile behavior of Inconel 617 welded joints produced by gas tungsten arc welding (GTAW) with ERNiCrCoMo-1 filler were systematically investigated. Detailed microstructural characterization revealed that Cr-rich M₂₃C₆ and Ti-rich MC carbides are the dominant precipitates, while Mo-rich M₆C forms locally along grain boundaries after thermal exposure. The fusion and weld zones exhibit fine dendritic morphologies with uniformly distributed precipitates, resulting in significant strengthening through precipitation and dislocation-pinning mechanisms. Owing to the low heat input and compositional compatibility between the weld and base metals, the heat-affected zone remains extremely narrow and free of compositional transitions. The welded joint attains tensile strengths of 920 MPa at room temperature and 605.5 MPa at 750 °C, corresponding to joint efficiencies of 117% and 121%, respectively, with fracture consistently occurring in the base metal. Deformation analysis shows that plasticity at room temperature is governed by planar slip and dislocation entanglement, whereas deformation twinning predominates at elevated temperatures owing to the reduced stacking-fault energy and the pinning effect of M₂₃C₆ carbides. These results provide key insights into the deformation and strengthening mechanisms controlling the high-temperature performance of GTAW-welded Inconel 617 joints and offer guidance for their application in advanced nuclear and high-temperature energy systems.

Keywords:

1. Introduction

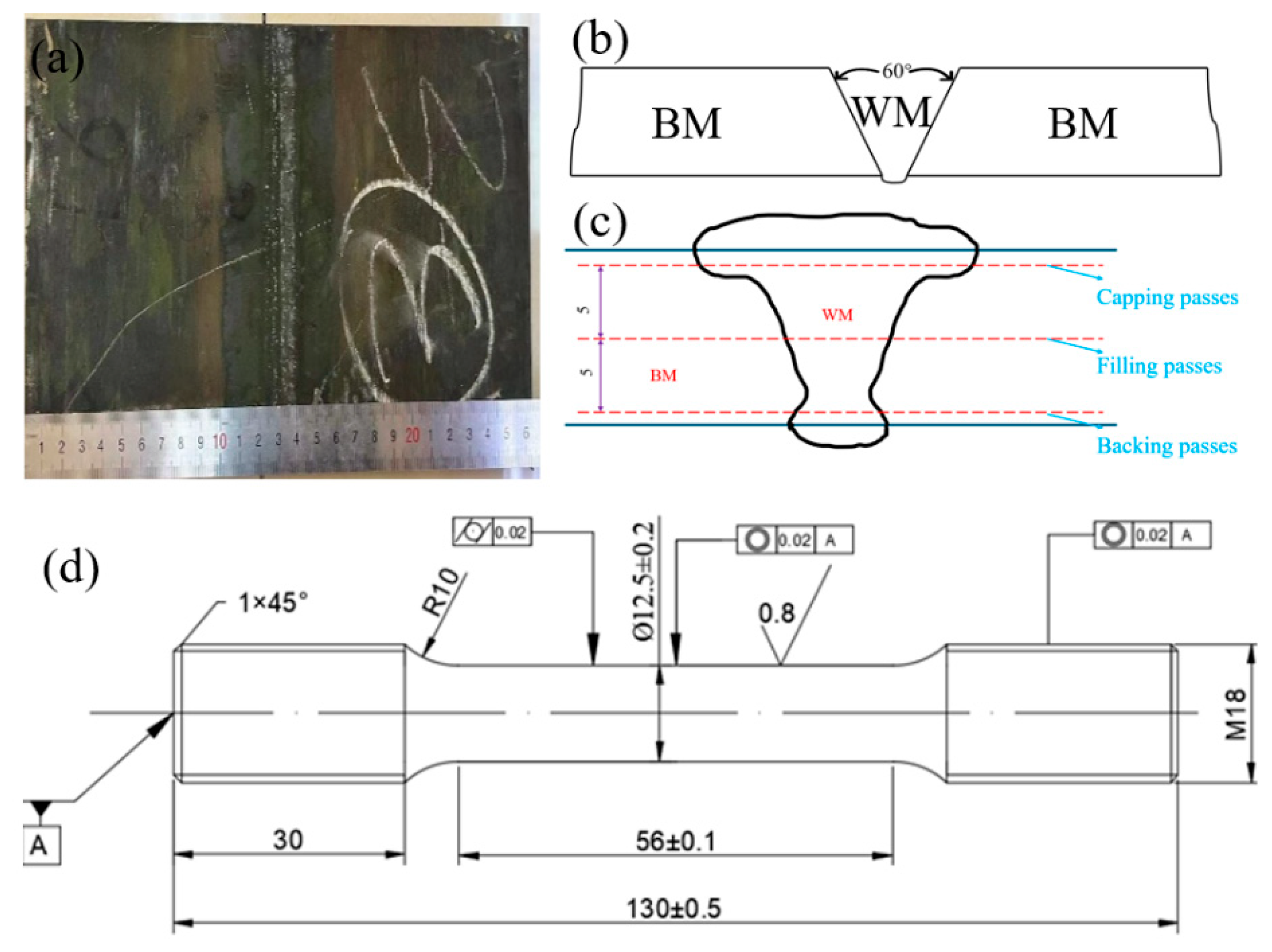

2. Materials and Methods

2.1. Materials and Experimental Procedures

2.2. Material Characterization

3. Results and Discussion

3.1. Microstructure of the Joint

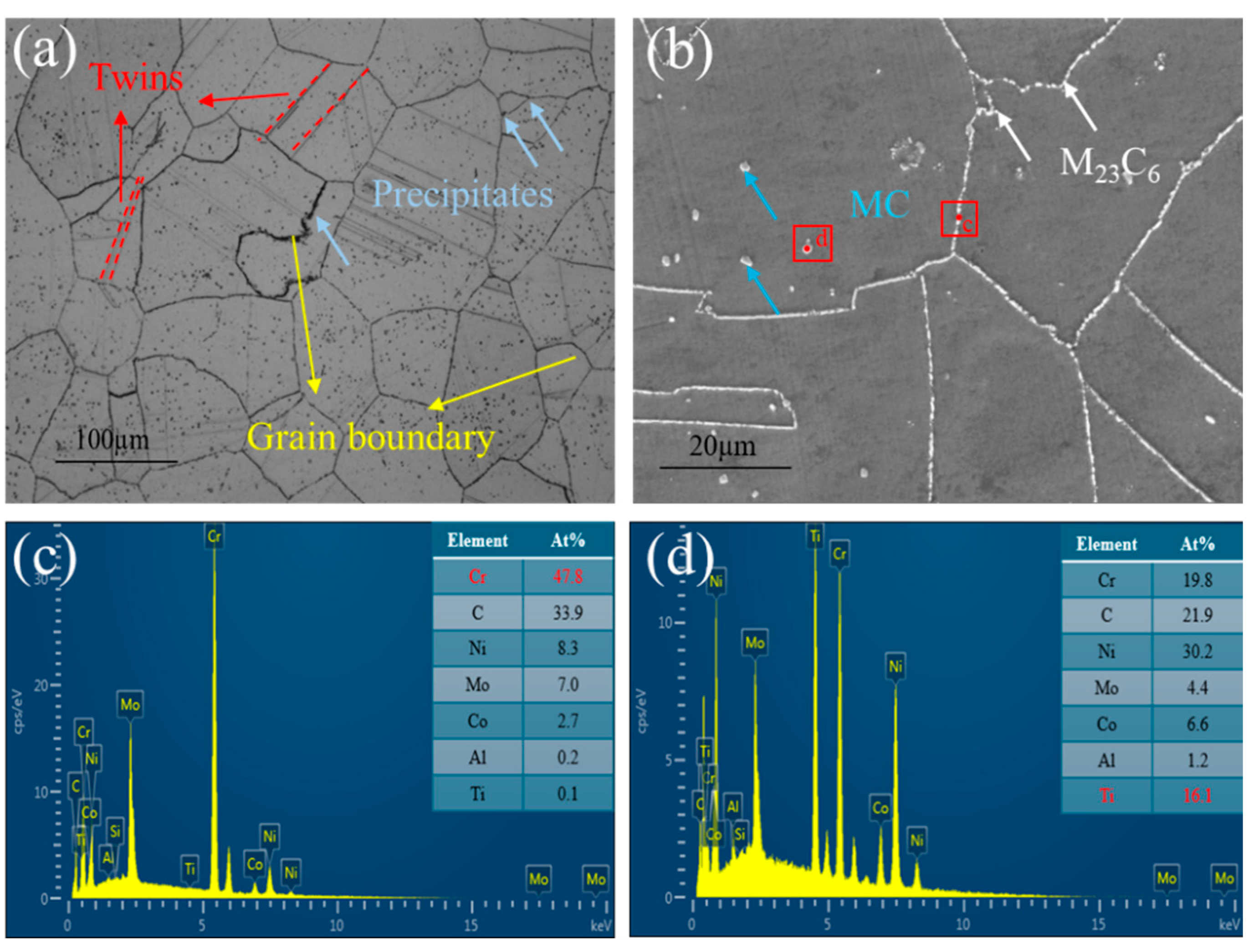

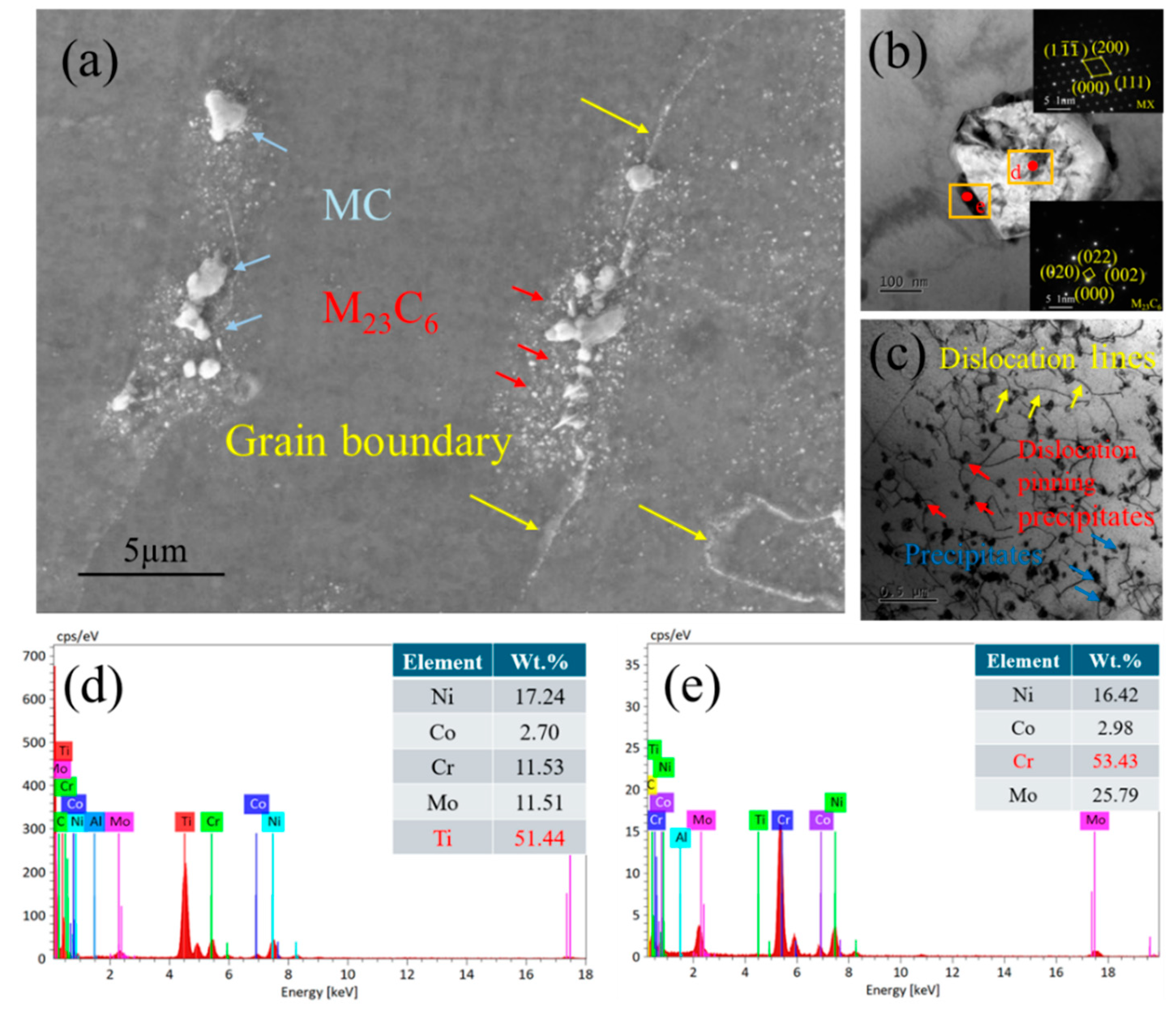

3.1.1. Microstructure and Analysis of the Base Metal

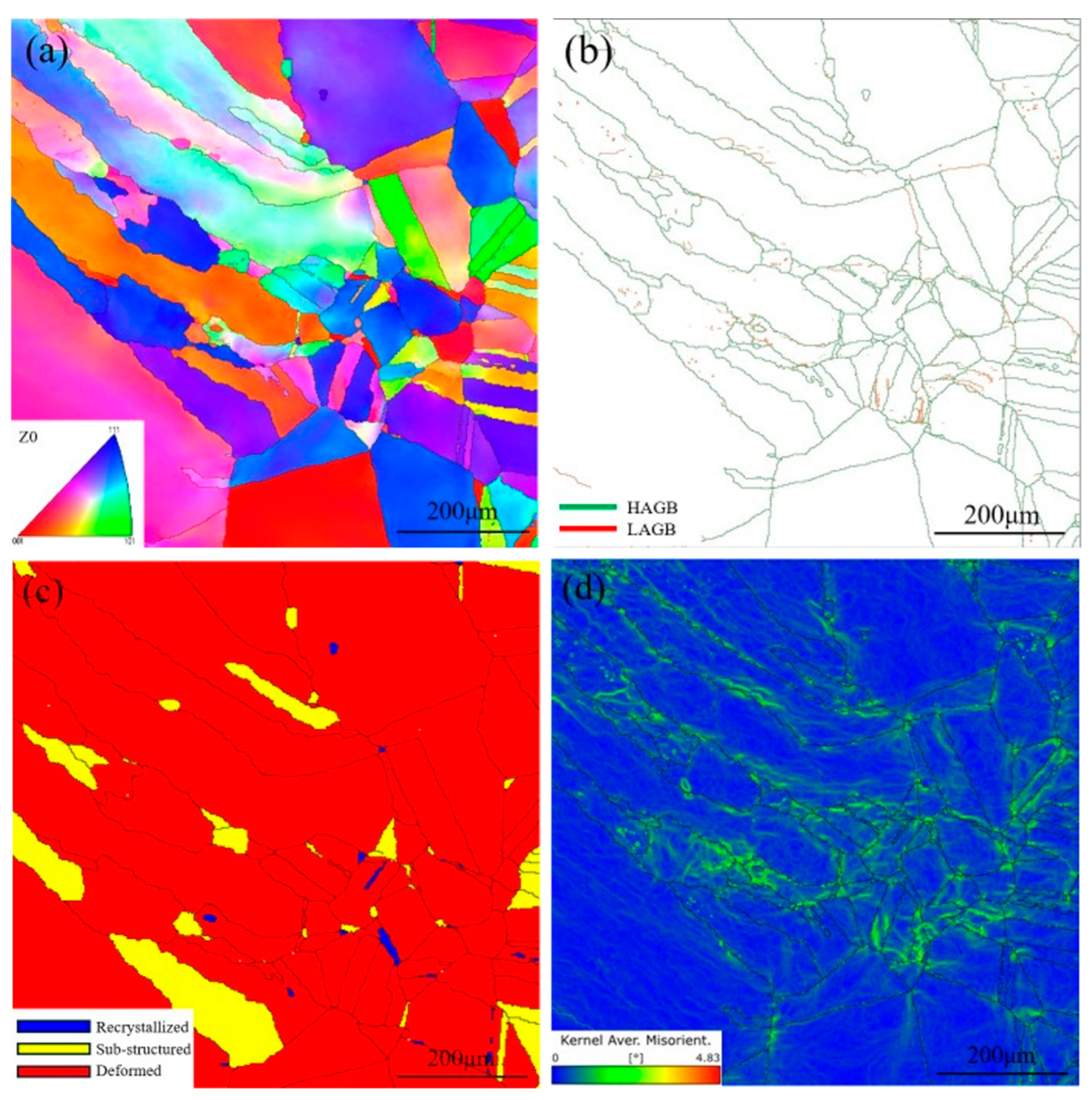

3.1.2. Microstructure and Analysis of the Fusion Zone

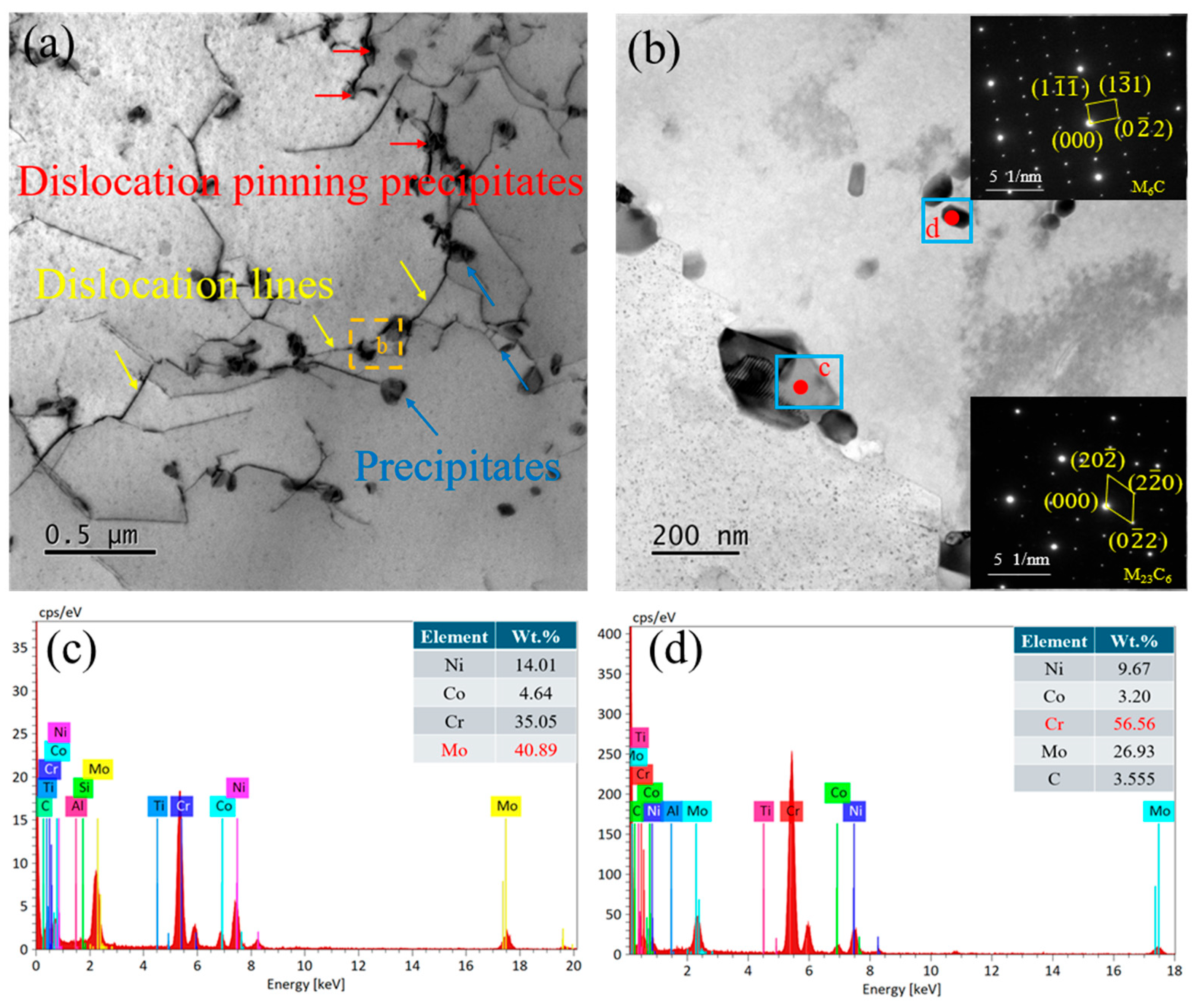

3.1.3. Microstructure and Analysis of the Weld Metal

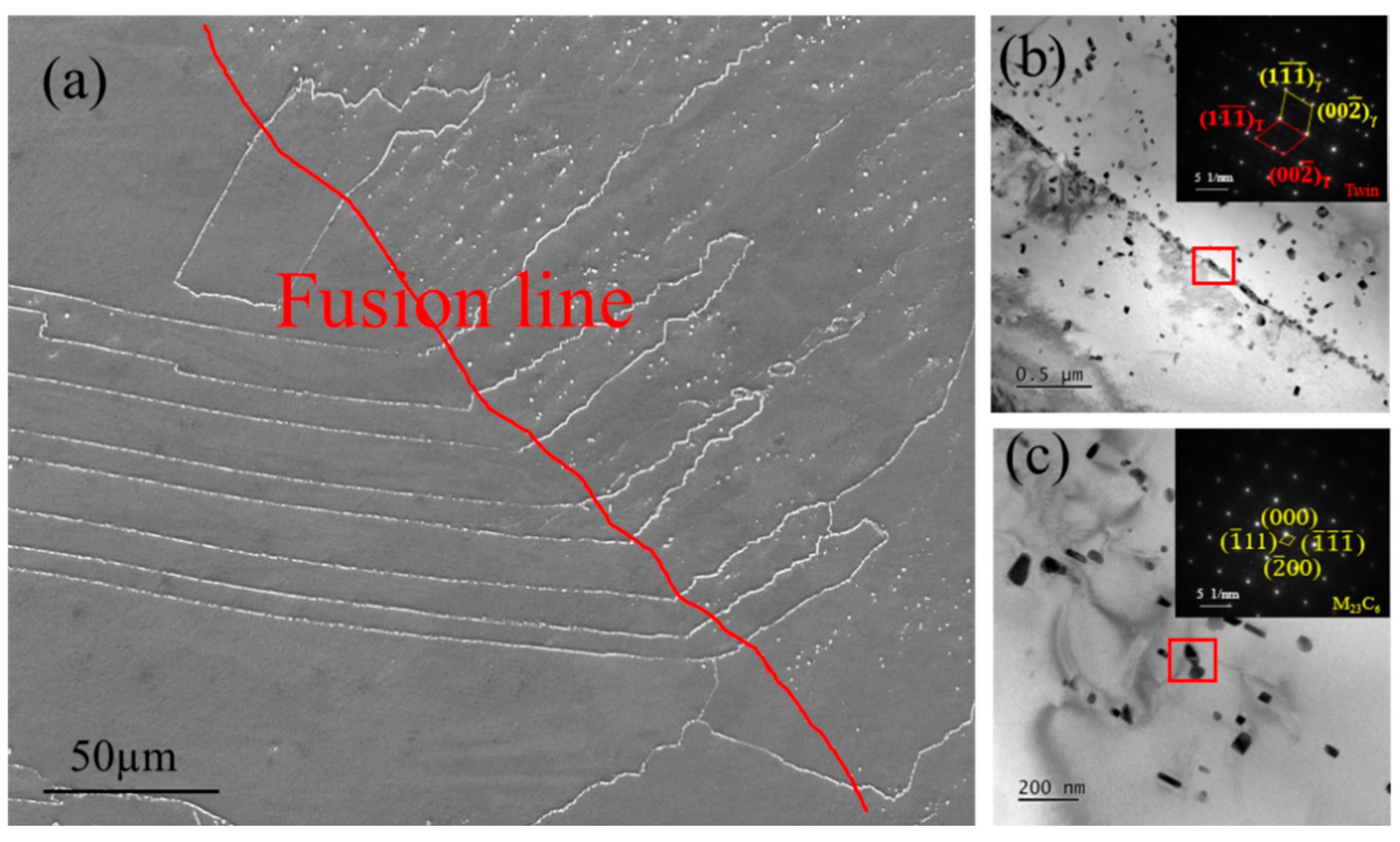

3.1.4. Microstructures at the Interface

3.2. Mechanical Properties

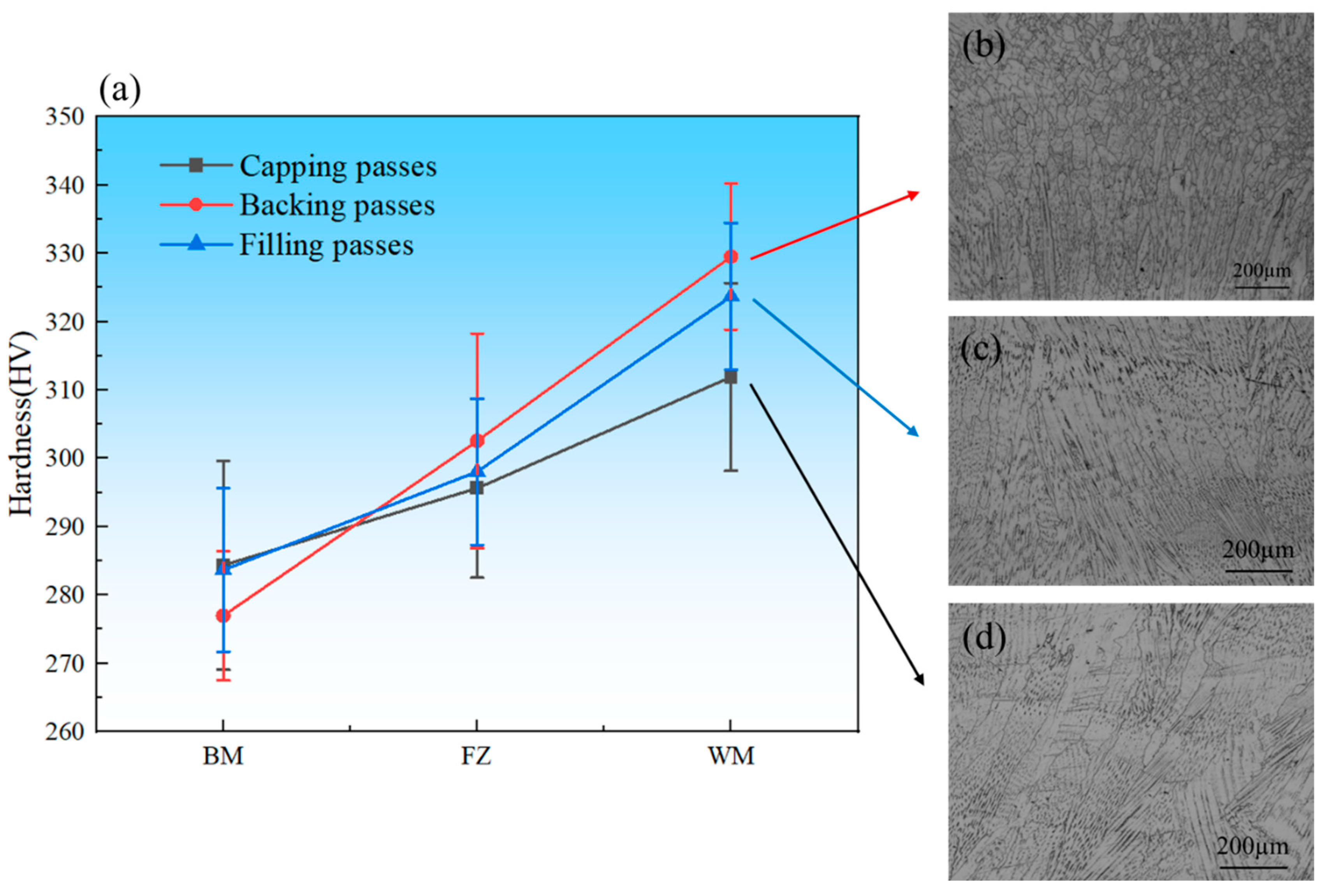

3.2.1. Microhardness

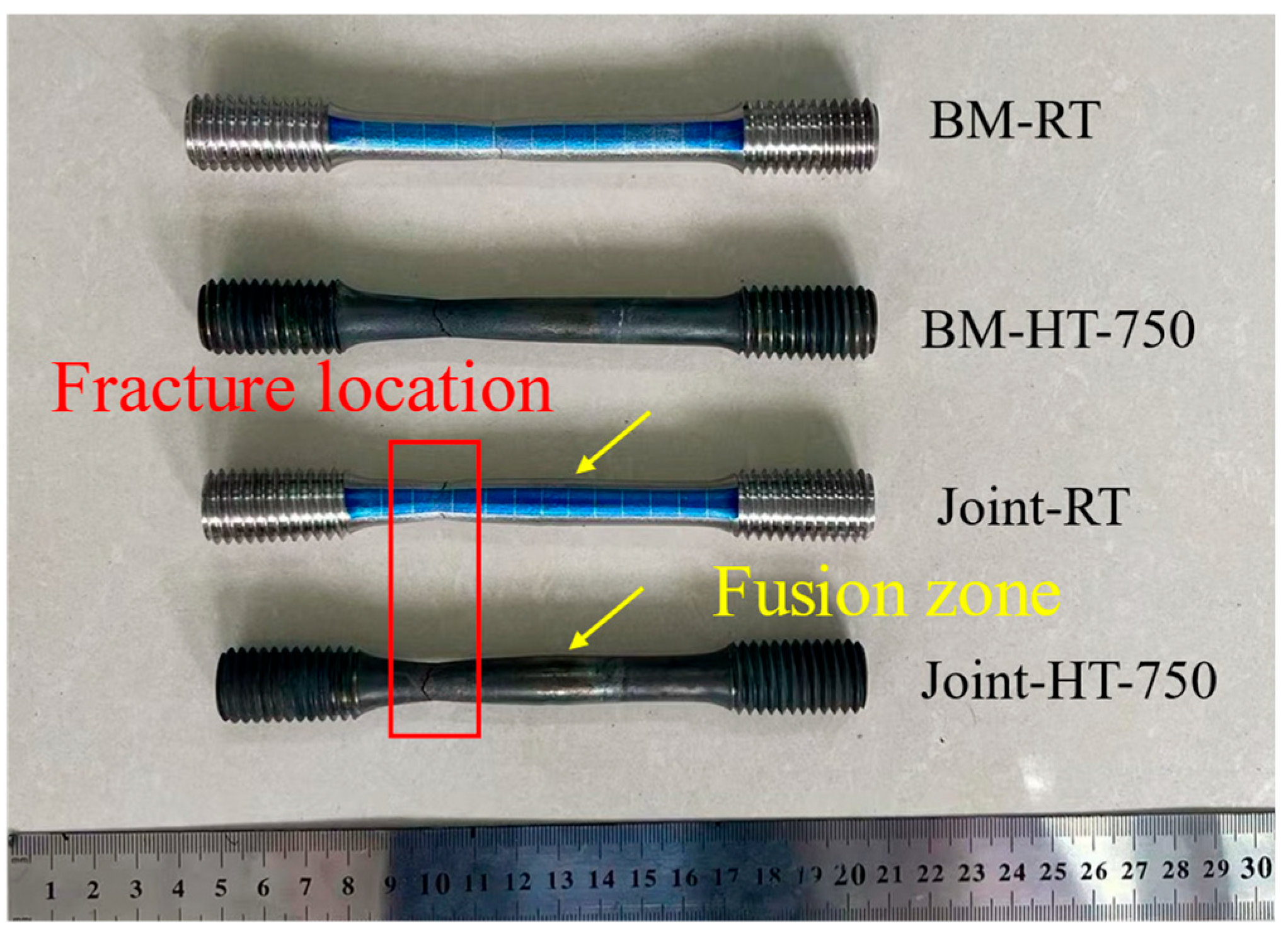

3.2.2. Tensile Properties

3.3. Fracture Morphology and Deformation Mechanism Analysis of Tensile Specimens

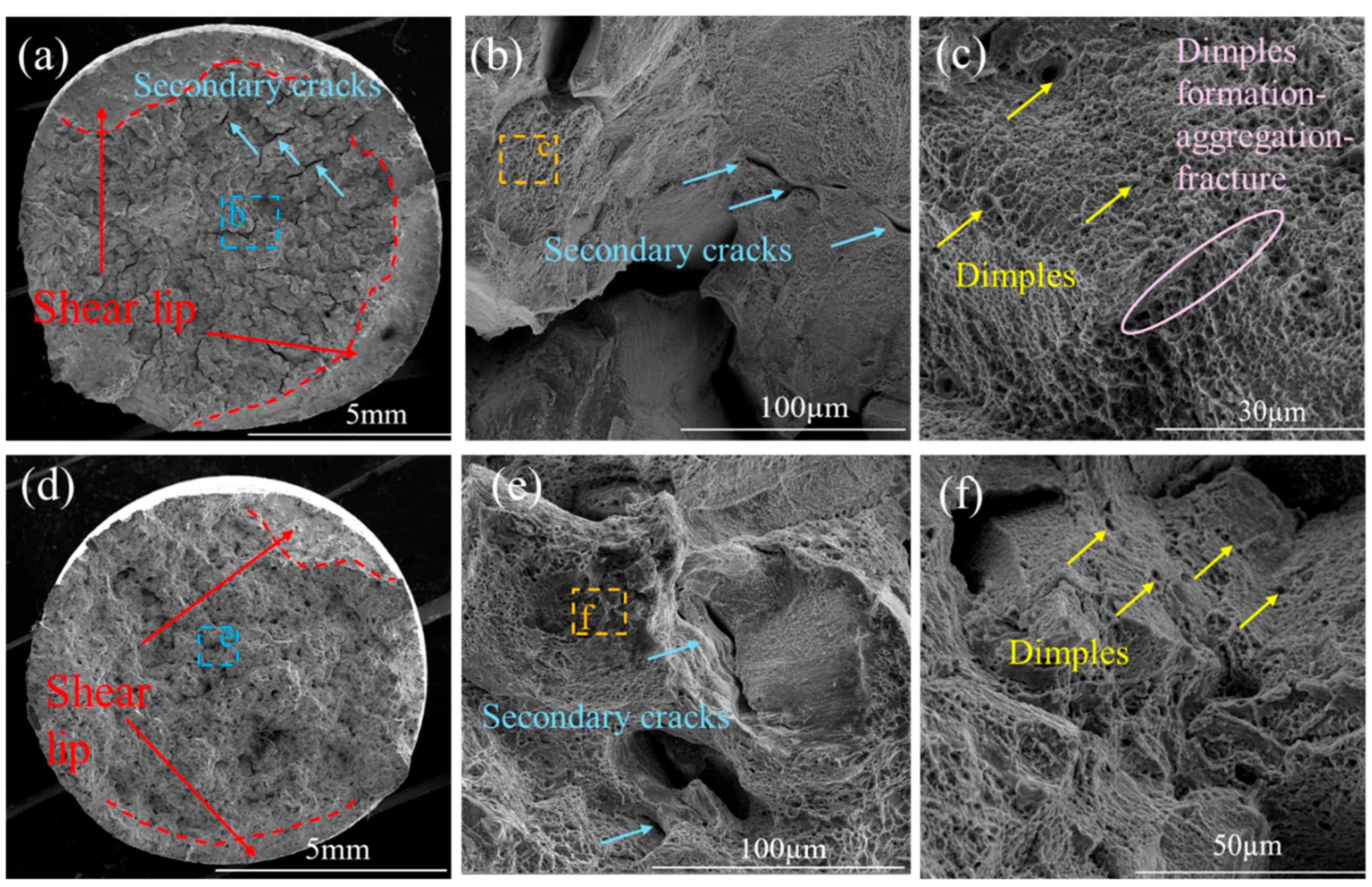

3.3.1. Fracture Morphology

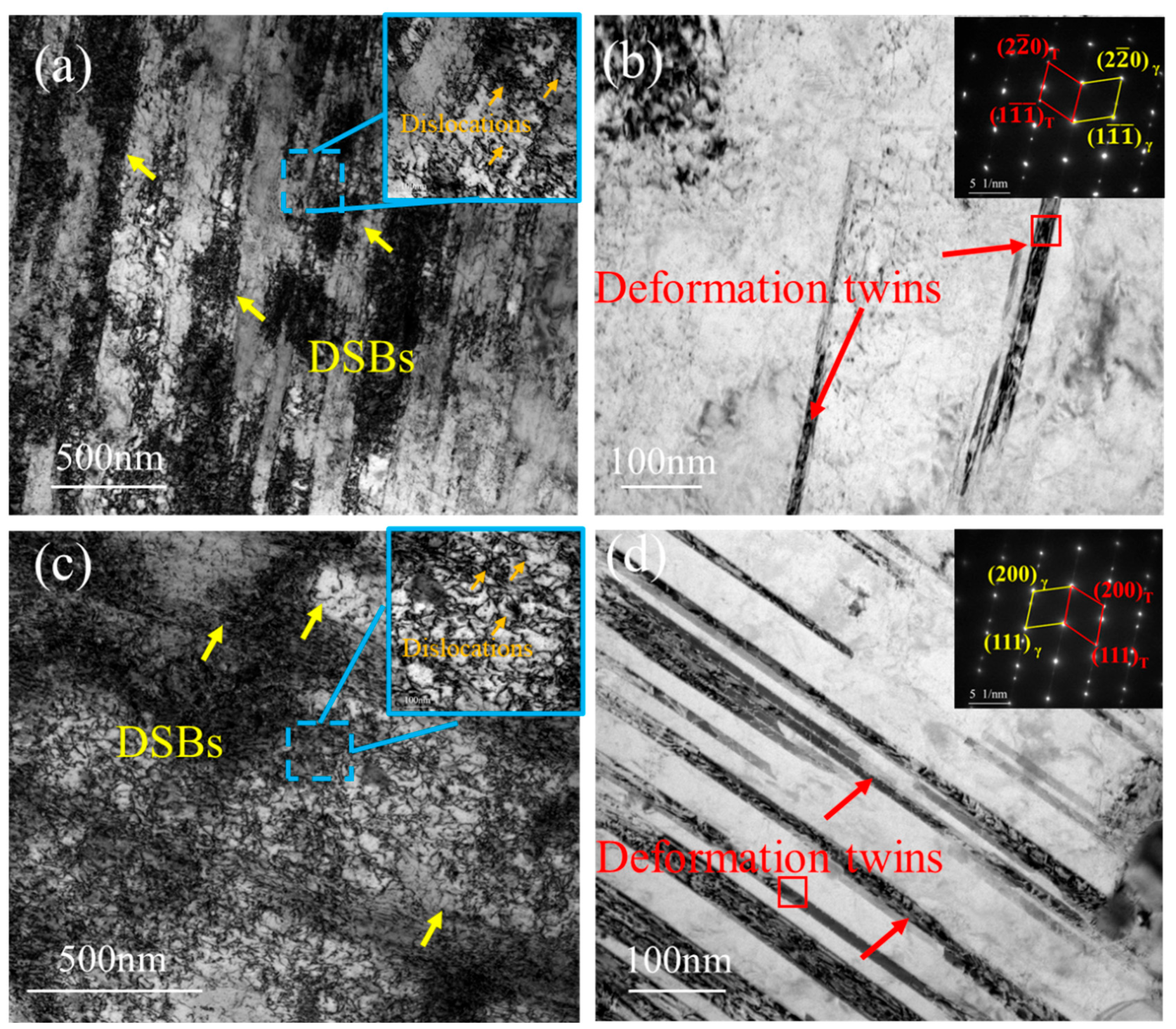

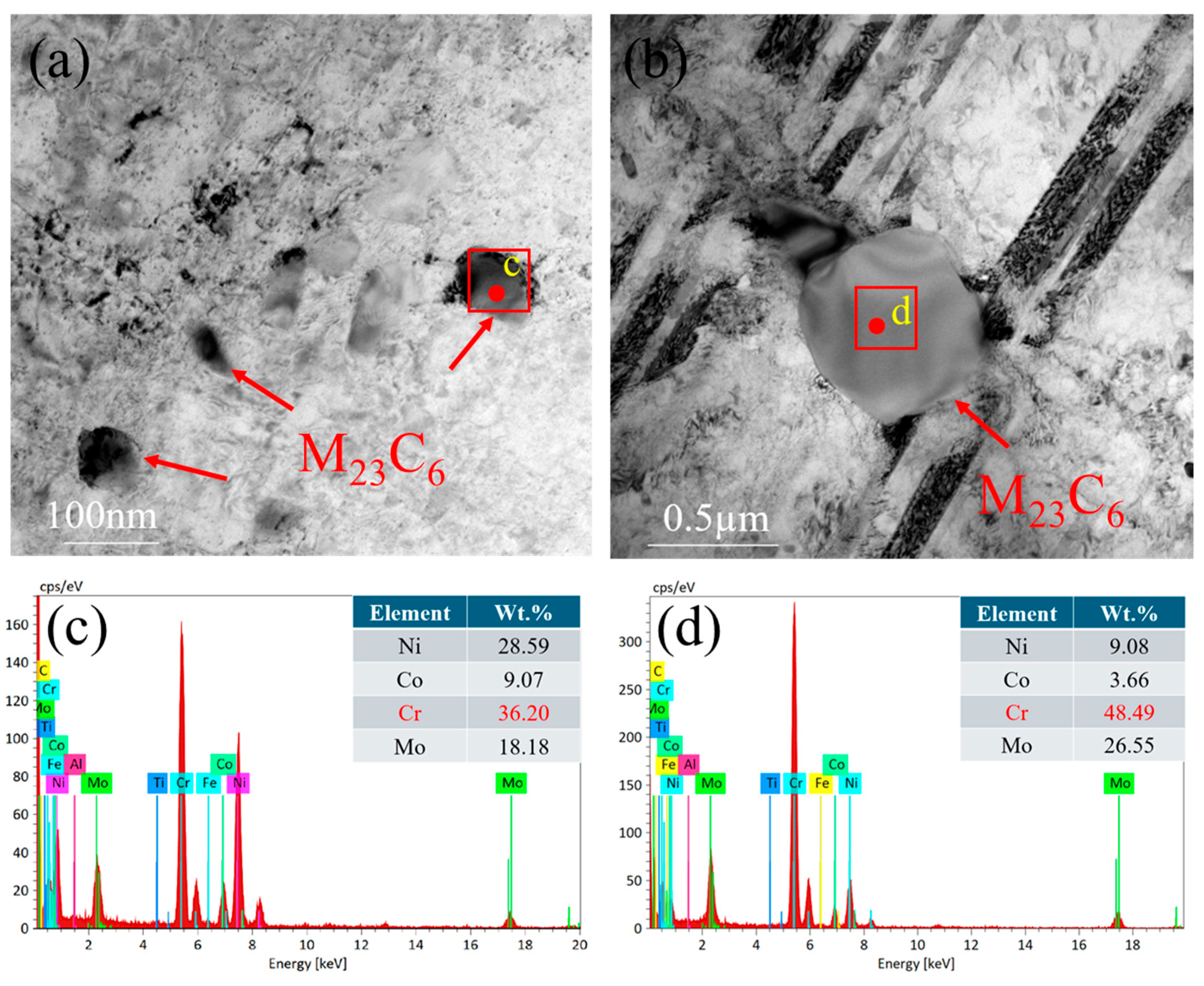

3.3.2. Deformation Microstructure and Precipitation Analysis of the Joint

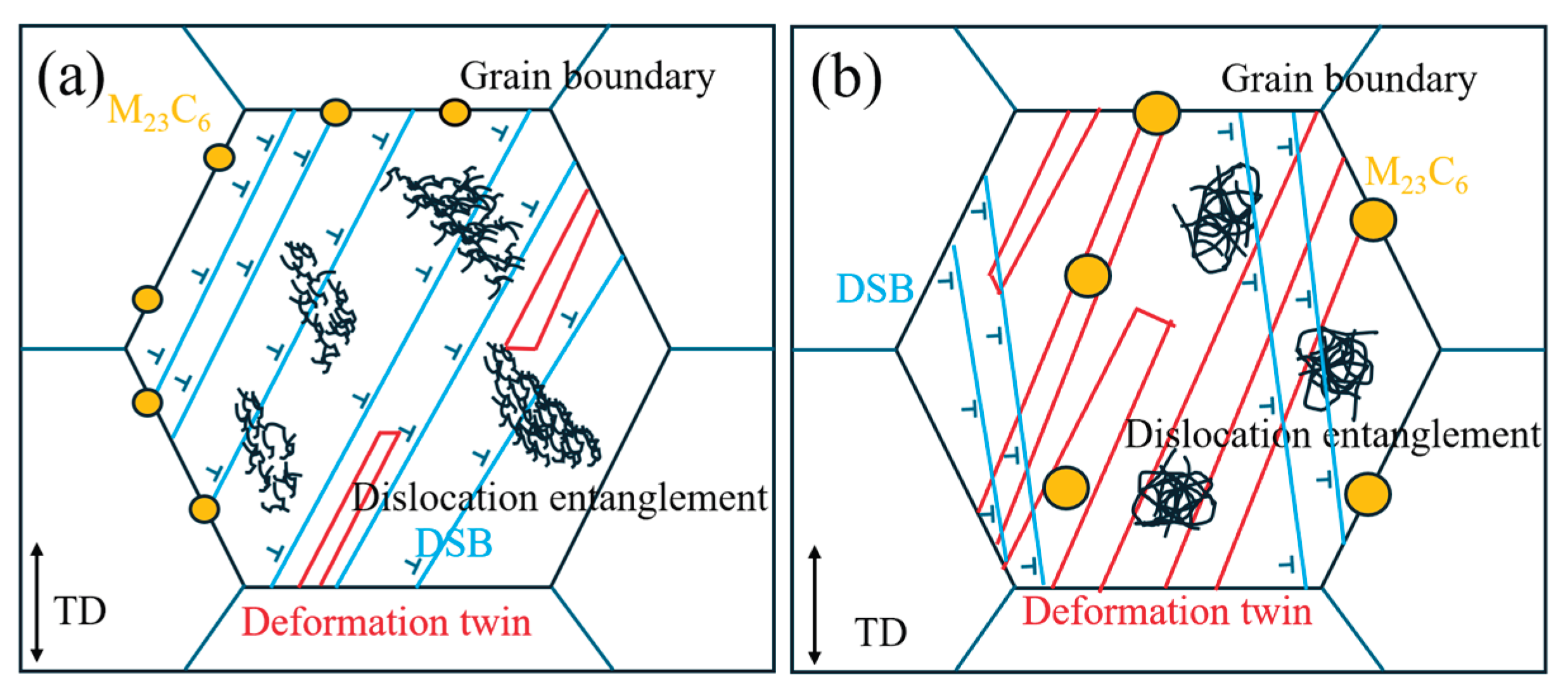

3.3.3. Overview of the Deformation Mechanisms in the Tensile Behavior of the Joint

4. Conclusions

- (1)

- The primary precipitates in the base metal are Cr-rich M₂₃C₆ and Ti-rich MC. In the welded joint, precipitates are mainly concentrated in the fusion zone and weld metal, predominantly comprising M₂₃C₆ and MC. The fusion-line region experiences multiple thermal cycles, leading to grain growth and partial recrystallization. These precipitates serve as pinning sites for dislocations, thereby enhancing strength but concurrently reducing plasticity.

- (2)

- The weld metal and base metal exhibit excellent compositional compatibility and co-crystallization at the interface, with no discernible microstructural or compositional transition zone. Plastic deformation near the interface is mainly concentrated on the base-metal side, indicating strong metallurgical bonding and structural stability of the interface during welding.

- (3)

- The welded joints exhibit excellent mechanical integrity, achieving tensile strengths of 920 MPa at room temperature and 605.5 MPa at 750 °C, corresponding to joint efficiencies of 117% and 121%, respectively. All fractures occur within the base metal, confirming the high quality and reliability of the welds.

- (4)

- The hardness of the welded joint varies significantly across different welding passes, with the highest value of 329 HV observed in the backing pass and the lowest of 311 HV in the cap pass. The weld metal exhibits higher hardness than the base metal, primarily due to grain refinement and precipitation strengthening during welding. The elevated hardness and strength of the weld region are attributed to grain refinement, precipitation hardening, and dislocation–precipitate interactions, consistent with the Hall–Petch relationship. The dense distribution of M₂₃C₆ precipitates and the fine dendritic substructure collectively contribute to local strengthening.

- (5)

- Deformation behavior is strongly temperature-dependent. At room temperature, plasticity is governed by planar slip and dislocation entanglement, with limited twinning. At elevated temperatures, deformation twinning becomes the dominant mechanism due to the reduced stacking-fault energy and the pinning effect of M₂₃C₆ carbides on dislocation motion. These mechanisms collectively account for the excellent high-temperature strength and ductility of the GTAW-welded Inconel 617 joints.

References

- Chen, Y; Xu, M; Zhang, T; et al. Grain refinement and mechanical properties improvement of Inconel 625 alloy fabricated by ultrasonic-assisted wire and arc additive manufacturing. J Alloys Compd. 2022, 910, 164957. [Google Scholar] [CrossRef]

- Tsigkis, V; Rahman, M S; Hackel, L; et al. Helium tribology of Inconel 617 subjected to laser peening for high temperature nuclear reactor applications. Appl Surf Sci. 2022, 577, 151961. [Google Scholar] [CrossRef]

- Sah, I; Park, J; Kim, E S. Fatigue life curves of alloy 617 in the temperature range of 800–950° C. Nucl Eng Technol. 2023, 55, 546–554. [Google Scholar] [CrossRef]

- Chen, M S; Wang, G Q; Li, H B; et al. Annealing treatment methods and mechanisms for refining mixed and coarse grains in a solution treatment nickel-based superalloy. Adv Eng Mater. 2019, 21, 1900558. [Google Scholar] [CrossRef]

- He, D G; Lin, Y C; Tang, Y; et al. Influences of solution cooling on microstructures, mechanical properties and hot corrosion resistance of a nickel-based superalloy. Mater Sci Eng A 2019, 746, 372–383. [Google Scholar] [CrossRef]

- Adamiec, J; Konieczna, N. Assessment of the hot cracking susceptibility of the Inconel 617 nickel-based alloy. Arch Metall Mater. 2021, 66. [Google Scholar] [CrossRef]

- Zhang, Y; Jing, H; Xu, L; et al. Design and performance of weld filler metal to match an advanced heat-resistant Fe-Cr-Ni alloy. Mater Sci Eng A. 2018, 721, 103–116. [Google Scholar] [CrossRef]

- Zhao, L; Jing, H; Xu, L; et al. Investigation on mechanism of type IV cracking in P92 steel at 650° C. J Mater Res. 2011, 26, 934–943. [Google Scholar] [CrossRef]

- Zhao, L; Jing, H; Xu, L; et al. Experimental study on creep damage evolution process of Type IV cracking in 9Cr–0.5 Mo–1.8 W–VNb steel welded joint. Eng Fail Anal. 2012, 19, 22–31. [Google Scholar] [CrossRef]

- Zhang, Y; Jing, H; Xu, L; et al. Microstructure and mechanical performance of welded joint between a novel heat-resistant steel and Inconel 617 weld metal. Mater Charact. 2018, 139, 279–292. [Google Scholar] [CrossRef]

- Kumar, A; Pandey, C. The Behavior of Dissimilar Welded Joint of Alloy 617/P92 Steel at High Temperatures. J Mater Eng Perform. 2025, 1–9. [Google Scholar] [CrossRef]

- Kumar, A; Pandey, C. Creep rupture and microstructural analysis of dissimilar welded joints of P92 steel and Alloy 617. Weld Int. 2025, 39, 23–31. [Google Scholar] [CrossRef]

- Kumar, R; Sirohi, S. Microstructure and Mechanical Behavior Study of the GTAW Joint of AISI 310 and Modified 9Cr-1Mo (P91) Steel. J Mater Eng Perform. 2025, 1–19. [Google Scholar] [CrossRef]

- Dak, G; Guguloth, K; Bhattacharyya, A; et al. Failure study of creep and high-temperature tensile tested tungsten inert gas welded P92 steel and AISI 304L steel dissimilar weld joints. J Mater Eng Perform. 2025, 34, 658–685. [Google Scholar] [CrossRef]

- Kumar, A; Singhal, A; Sirohi, S; et al. Pulsed current GTAW Inconel 625/AISI 304 L steel dissimilar joint: Microstructure and mechanical properties. J Constr Steel Res. 2025, 231, 109602. [Google Scholar] [CrossRef]

- Hao, J; Wang, C; Duan, H; et al. Prediction model for austenite grain size in CGHAZ of TiN-containing steel: considering minimum pinning force and austenite coarsening dynamics. J Iron Steel Res Int. 2025, 1–15. [Google Scholar] [CrossRef]

- Shi, X; Liu, Y; Zhang, M; et al. Dual-constricted plasma arc cladding of Inconel 625 alloy: arc characteristics, microstructure, and corrosion resistance. J Mater Sci: Mater Eng. 2025, 20, 43. [Google Scholar] [CrossRef]

- Amirian, B; Asad, A; Krezan, L; et al. A new perspective on the mechanical behavior of Inconel 617 at elevated temperatures for small modular reactors. Scr Mater. 2025, 261, 116605. [Google Scholar] [CrossRef]

- Kumar, A; Pandey, C. Some studies on dissimilar welds joint P92 steel and Inconel 617 alloy for AUSC power plant application. Int J Press Vessels Pip. 2022, 198, 104678. [Google Scholar] [CrossRef]

- Kumar, A; Pandey, S M; Sirohi, S; et al. P92 steel and inconel 617 alloy welds joint produced using ERNiCr-3 filler with GTAW process: solidification mechanism, microstructure, mechanical properties and residual stresses. Pandey Arch Civ Mech Eng. 2023, 9. [Google Scholar] [CrossRef] [PubMed]

- Kumar, G P; Balasubramanian, K R. Experimental investigation on high-temperature tensile behavior of cold metal transfer pulse multi-control welding of Inconel 617 alloy. Results Surf Interfaces. 2023, 10, 100100. [Google Scholar] [CrossRef]

- Rathore, S; Kumar, A; Sirohi, S; et al. Role of buttering layer composition on microstructural heterogeneity and mechanical properties of Alloy 617 and P92 steel dissimilar welded joints for future Indian AUSC program. Int J Adv Manuf Technol. 2024, 133, 671–700. [Google Scholar] [CrossRef]

- Cui, Y; Xu, CL; Han, Q. Effect of ultrasonic vibration on unmixed zone formation. Scripta Mater. 2006, 55, 975–8. [Google Scholar] [CrossRef]

- Soysal, T; Kou, S; Tat, D; Pasang, T. Macrosegregation in dissimilar-metal fusion welding. Acta Mater. 2016, 110, 149–60. [Google Scholar] [CrossRef]

- Jian, H G; Wang, Y; Tang, X M; et al. Microstructure characteristics in multi-pass welding interface of Al-Mg alloy. Applied Mechanics and Materials. 2014, 584, 921–924. [Google Scholar] [CrossRef]

- Ghumman, K Z; Ali, S; Din, E U; et al. Experimental investigation of effect of welding parameters on surface roughness, micro-hardness and tensile strength of AISI 316L stainless steel welded joints using 308L filler material by TIG welding. J Mater Res Technol. 2022, 1, 220–236. [Google Scholar] [CrossRef]

- Song, J; Chen, Y; Hao, X; et al. Microstructure and mechanical properties of novel Ni–Cr–Co-based superalloy GTAW joints. J Mater Res Technol. 2024, 29, 2758–2767. [Google Scholar] [CrossRef]

- Singh, A N; Moitra, A; Bhaskar, P; et al. Effect of thermal aging on microstructure, hardness, tensile and impact properties of Alloy 617. Mater Sci Eng A. 2018, 710, 47–56. [Google Scholar] [CrossRef]

- Remy, L. The interaction between slip and twinning systems and the influence of twinning on the mechanical behavior of fcc metals and alloys. Metall Trans A. 1981, 12, 387–408. [Google Scholar] [CrossRef]

- Zhang, Y; Tao, N R; Lu, K. Effects of stacking fault energy, strain rate and temperature on microstructure and strength of nanostructured Cu–Al alloys subjected to plastic deformation. Acta Mater. 2011, 59, 6048–6058. [Google Scholar] [CrossRef]

- Meyers, M A; Vöhringer, O; Lubarda, V A. The onset of twinning in metals: a constitutive description. Acta Mater. 2001, 49, 4025–4039. [Google Scholar] [CrossRef]

- Kaoumi, D; Hrutkay, K. Tensile deformation behavior and microstructure evolution of Ni-based superalloy 617. J Nucl Mater. 2014, 454, 265–273. [Google Scholar] [CrossRef]

- Chomette, S; Gentzbittel, J M; Viguier, B. Creep behaviour of as received, aged and cold worked INCONEL 617 at 850 ℃ and 950 ℃. J Nucl Mater. 2010, 399, 266–274. [Google Scholar] [CrossRef]

- Kihara, S; Newkirk, J B; Ohtomo, A; et al. Morphological changes of carbides during creep and their effects on the creep properties of Inconel 617 at 1000 ℃. Metall Trans A 1980, 11, 1019–1031. [Google Scholar] [CrossRef]

- Roy, A K; Marthandam, V. Mechanism of yield strength anomaly of Alloy 617. Mater Sci Eng A. 2009, 517, 276–280. [Google Scholar] [CrossRef]

- Kourtoukova, G L; Demetry, C; Ramanath, S; et al. Design and tailoring of Ni–Sn–W composites for bonded abrasive applications. Mater Sci Eng A. 2000, 276, 58–69. [Google Scholar] [CrossRef]

| C | Si | Cr | Mo | Ti | Al | Co | Fe | Ni | |

|---|---|---|---|---|---|---|---|---|---|

| BM | 0.065 | 0.021 | 21.81 | 8.73 | 0.41 | 1.10 | 12.03 | 0.19 | Bal. |

| WM | 0.05 | 0.1 | 21.5 | 9.0 | 0.3 | 1.3 | 11.0 | 0.5 | Bal. |

| Sample No. | Tensile properties | |||

|---|---|---|---|---|

| UTS(Mpa) | YS(Mpa) | EL(%) | AR(%) | |

| BM-RT | 870 | 392 | 48 | 51 |

| BM-HT-750 | 560 | 301 | 47.5 | 45.5 |

| Joint-RT | 920 | 459 | 37 | 51 |

| Joint-HT-750 | 605.5 | 364 | 30 | 43.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).