1. Introduction

The urgency of global decarbonization and the growing demand for sustainable energy carriers have positioned low-carbon ammonia, both blue and green, as a central component of the energy transition. Beyond its traditional role as a fertilizer feedstock, ammonia is emerging as a strategic vector for storing and transporting hydrogen, enabling large-scale decarbonization across energy-intensive sectors such as maritime transport, power generation, and heavy industry. In this context, countries with abundant natural gas reserves and advanced offshore capabilities face a unique opportunity to convert fossil resources into transitional low-carbon commodities, serving as key enablers of a sustainable hydrogen economy. The blue ammonia pathway, which combines natural gas reforming with carbon capture and storage (CCS), represents an intermediate yet essential step toward achieving this goal.

In Brazil, the pre-salt province exemplifies this challenge and opportunity. The pre-salt layer, discovered in 2006, extends over an area of nearly 150,000 square kilometers in the Santos and Campos basins and has become one of the world’s most productive ultra-deepwater frontiers. The region accounts for approximately 78% of Brazil’s total oil and gas output, with daily production exceeding 3.8 million barrels of oil equivalent in 2024, of which about 150 million cubic meters correspond to associated natural gas. However, around 60% of this gas is currently reinjected into the reservoirs due to the lack of high-capacity pipelines and processing infrastructure onshore. This practice, while technically necessary to maintain reservoir pressure, represents a significant economic and environmental inefficiency by limiting the full utilization of the country’s offshore resources and delaying Brazil’s potential role as a low-carbon fuel exporter.

The geographic and logistical constraints of the pre-salt region, located more than 200 kilometers offshore and in water depths exceeding 2,000 meters, pose considerable challenges for gas monetization. Transporting gas to shore through subsea pipelines or as liquefied natural gas (LNG) remains capital-intensive and technically complex. These limitations highlight the need for alternative solutions that enable gas processing and conversion directly at sea, minimizing reinjection and creating new value chains aligned with global decarbonization efforts.

Very Large Floating Structures (VLFS) offer an innovative solution for offshore industrialization, providing the stability and deck space needed to integrate production, processing, storage, and export operations at sea. Unlike Floating Production, Storage and Offloading (FPSO) units or Floating Liquefied Natural Gas (FLNG) vessels, which are mainly designed for extraction and short-term processing, VLFS platforms operate as stable, semi-permanent offshore complexes capable of hosting complete chemical production systems.

FPSOs focus on oil separation and storage, while FLNGs liquefy natural gas for transport within limited space, both constrained by weight and volume. In contrast, VLFS platforms offer vast deck areas and high load-bearing capacity, enabling the installation of large industrial units such as hydrogen reformers, CO₂ absorbers, and ammonia synthesis plants. Their superior hydrodynamic stability ensures continuous operation under offshore conditions, minimizing motion and vibration.

By combining hydrogen production, carbon capture, and ammonia synthesis within a single floating facility, VLFS platforms enable the full offshore transformation of natural gas into low-carbon products. This makes them a relevant bridge between deepwater gas production and international clean energy markets, positioning them as a next-generation offshore technology for sustainable industrial development.

The purpose of this article is to evaluate the engineering and logistical feasibility of implementing blue ammonia production systems on VLFS units in Brazil’s pre-salt region. The analysis covers process engineering and technological integration for large-scale offshore ammonia production, logistical architecture for ammonia transport, storage, and CO₂ management, as well as economic modeling to assess capital and operational expenditures and market competitiveness. It also discusses key challenges related to structural design, station-keeping, and regulatory adaptation.

Through a multidisciplinary approach combining offshore engineering, process modeling, and economic assessment, this study aims to contribute to the ongoing discussion on sustainable natural gas monetization and the development of Brazil’s emerging blue economy, positioning the country as a global leader in the low-carbon energy transition.

2. Materials and Methods

The bibliographic search conducted in the Scopus database for the period between 2000 and 2023 initially identified 5,694 documents related to ocean and naval engineering, covering topics such as ship hydrodynamics, marine structures, and ocean exploration. After refining the search and limiting the keyword to “VLFS” (Very Large Floating Structures), 89 publications were selected as directly relevant to the topic. This set of documents formed the basis for the bibliometric and literature review presented in this study.

The most frequent keywords found in the bibliometric mapping include Very Large Floating Structures, hydroelasticity, offshore wind energy, floating platforms, modular structures, marine structures, floating airports, floating cities, coastal engineering, ocean engineering, offshore energy, hydrodynamics, ammonia production, and hydrogen production. The co-occurrence analysis using VOSviewer revealed two main clusters. The first is related to structural and hydroelastic aspects of offshore engineering, while the second is focused on energy applications, especially those linked to renewable energy systems and offshore ammonia or hydrogen production.

The temporal distribution of publications shows that from 2000 to 2010, studies were mainly focused on hydroelasticity and structural analysis. From 2017 onwards, there was a substantial increase in research activity, peaking in 2018, 2022, and 2023, reflecting the growing global interest in applying VLFS for offshore renewable energy, particularly wind and hydrogen.

The country-based analysis shows that China leads the global research output with 22 publications, followed by the United States (11), Japan (8), the United Kingdom (7), and Brazil (4). Other countries with relevant contributions include France, Italy, Norway, South Korea, and Australia, each with three to four publications. The increasing number of publications from China, especially after 2018, demonstrates its scientific leadership in this field, along with Japan, Singapore, and South Korea, forming a strong Asian research network.

Regarding areas of knowledge, most of the studies belong to Engineering, Energy, and Environmental Science, confirming the multidisciplinary nature of VLFS research. The most cited journals are Ocean Engineering, Marine Structures, Renewable and Sustainable Energy Reviews, International Journal of Hydrogen Energy, and Journal of Cleaner Production.

Overall, the literature remains largely concentrated on technical and structural aspects such as hydrodynamic modeling and modular design, with limited studies addressing economic feasibility, regulatory frameworks, and environmental or social dimensions. The present research aims to fill part of this gap by integrating technological, economic, legal, and environmental perspectives to assess the potential of VLFS in the Brazilian offshore context, particularly for natural gas monetization and blue ammonia production in deep and ultra-deep waters.

This section presents the methodological framework used to assess the engineering, technological, and economic feasibility of implementing blue ammonia production systems on Very Large Floating Structures (VLFS) in Brazil’s pre-salt region. The approach integrates process engineering design, technology readiness assessment (TRL), and comparative economic modeling at different production scales. The methodological structure follows three key steps: identification and selection of Best Available Technologies (BAT) for offshore application, conceptual process design and mass-energy balance, and preliminary techno-economic evaluation.

The technological selection was guided by a systematic literature review and benchmarking of industrial processes, focusing on mature, efficient, and commercially proven routes for offshore deployment. Data and insights were derived from technical literature, the International Energy Agency (IEA, 2021; 2023), the U.S. Department of Energy (DOE, 2022), and the VLFS in Brazil: Sustainable Monetization of Natural Gas and the Offshore Energy Transition (Santos et al., 2025), which provided empirical parameters and performance data for pre-salt conditions. The review identified three critical process chains for blue ammonia production.

The first concerns hydrogen production from natural gas, for which three main reforming routes were evaluated based on technological maturity and suitability for offshore deployment. Steam Methane Reforming (SMR) is the most established industrial process, operating at temperatures between 800 and 950 °C and reaching a Technology Readiness Level (TRL) of 9, according to the International Energy Agency (IEA, 2023) and Canan (2022). Autothermal Reforming (ATR), in contrast, integrates partial oxidation and steam reforming within a single reactor, operating with a mixture of oxygen and steam supplied by an air separation unit (ASU).

This configuration achieves hydrogen yields above 70%, offers a compact and modular design suitable for constrained offshore environments, and has been adopted in several blue hydrogen and blue ammonia projects worldwide, such as the Haldor Topsoe and Air Products facilities in Saudi Arabia and the Netherlands (IEA, 2022; Santos et al., 2025). Partial Oxidation (POx), the third route, is an exothermic process that provides simpler thermal control and faster startup but results in lower hydrogen efficiency (around 60%) and is generally considered at TRL 8 (Lim et al., 2021). Comparative assessments have demonstrated that ATR offers the most favorable balance between efficiency, system compactness, and process flexibility. These characteristics make it the preferred choice for integration into Very Large Floating Structures (VLFS), where modularization and thermal integration are essential to minimize the platform’s footprint and energy losses (Canan, 2022; Santos et al., 2025).

The second process chain analyzed concerns carbon dioxide capture. The assessment focused on processes with high selectivity, operational maturity, and reliability for handling gas streams with high CO₂ concentrations typical of reforming systems. Three alternatives were examined: chemical absorption, physical adsorption, and membrane separation. Chemical absorption, using amine-based solvents such as monoethanolamine (MEA) or methyldiethanolamine (MDEA), achieves capture efficiencies of 90–95% and has been proven in large-scale operations in the power and refining sectors, representing a TRL of 10 (EIA, 2021; IEA, 2023).

The physical adsorption route, which relies on solid sorbents under pressure swing adsorption (PSA) conditions, exhibits a lower maturity (TRL 8) and is typically employed for smaller-scale hydrogen purification rather than bulk CO₂ capture (Lim et al., 2021). Meanwhile, membrane separation technologies, though compact and suitable for modular applications, remain under development (TRL 7–8) and present challenges related to selectivity, fouling, and long-term material stability in high-pressure environments (Lee et al., 2020; IEA, 2022). Based on these criteria, the chemical absorption process was selected for the conceptual design due to its high maturity, operational reliability, and adaptability to the offshore context. Its capability for continuous operation, solvent regeneration, and compatibility with waste heat recovery systems makes it particularly advantageous for integration within the heat and power loops of the ATR and ammonia synthesis units (Santos et al., 2025; Canan, 2022).

The third process chain involves ammonia synthesis. The Haber-Bosch process, developed in the early 20th century and continuously optimized since then, remains the global standard for large-scale ammonia production. It operates at temperatures between 400 and 500 °C and pressures of 150–300 bar over an iron-based catalyst, converting hydrogen and nitrogen into ammonia (NH₃). The nitrogen feedstock is produced by a cryogenic Air Separation Unit (ASU), which also supplies oxygen to the ATR, thus allowing for efficient integration between hydrogen production, CO₂ capture, and ammonia synthesis (IEA, 2023; Santos et al., 2025). The process exhibits high reliability and process continuity, with conversion rates of 15–20% per pass and overall synthesis efficiency above 95% when integrated with hydrogen recycling loops. Moreover, the recovery and reuse of reaction heat contribute to energy self-sufficiency and improved thermal efficiency, typically reducing the specific energy consumption of blue ammonia to 7.2–7.8 GJ per ton of NH₃ produced, consistent with modern blue hydrogen-ammonia facilities in operation (Canan, 2022; IEA, 2023).

Consequently, the conceptual process adopted in this study combines Autothermal Reforming (ATR) for hydrogen production, amine-based chemical absorption for CO₂ capture, and the Haber-Bosch process for ammonia synthesis. This configuration represents the optimal balance between technological maturity, process efficiency, and modular adaptability, meeting the operational and logistical constraints of offshore applications on VLFS platforms. It enables high hydrogen conversion, CO₂ capture, and stable ammonia production under offshore conditions, providing a technically feasible and economically competitive pathway for low-carbon energy production in Brazil’s pre-salt region (Santos et al., 2025; Lim et al., 2021; IEA, 2023).

3. Conceptual Design and Mass-Energy Balance

3.1. Location and Offshore Configuration, Process and Installed Capacity

The conceptual VLFS-based blue ammonia production plant is strategically located near the Búzios Field, within the Santos Basin, approximately 200 kilometers offshore from Rio de Janeiro. This area represents one of the most productive hydrocarbon provinces in the world and the core of Brazil’s pre-salt development. According to the Agência Nacional do Petróleo, Gás Natural e Biocombustíveis (ANP, 2024), the Santos Basin accounts for over 75% of national oil and gas production, with individual fields such as Búzios, Tupi, and Mero producing more than 30 million cubic meters of associated gas per day. Despite this abundance, logistical and infrastructural challenges, particularly the absence of large-capacity pipelines and the high cost of liquefaction and transport, result in the reinjection of approximately 60% of the associated gas. This configuration makes the region ideal for deploying offshore gas conversion solutions that reduce reinjection rates and add value to underutilized natural gas resources (ANP, 2024; Santos et al., 2025).

The installed nominal capacity of the proposed offshore plant is 2,100 metric tons of ammonia per day (tNH₃/day), equivalent to an annual output of roughly 700,000 tons under continuous operation. This production scale was selected to balance the trade-offs between modular construction feasibility, energy integration efficiency, and economy of scale. It allows the VLFS platform to function as a self-contained industrial hub, capable of producing, storing, and exporting ammonia directly via marine carriers. This capacity is also consistent with international benchmarks for medium-scale blue ammonia facilities, such as the Saudi Aramco–Air Products blue ammonia plant (Neom Project, 2023) and the ExxonMobil–CF Industries collaboration in Louisiana (2024), both of which operate at scales between 1,500 and 3,000 tNH₃/day. The chosen capacity aligns with the average carrying capacity of modern ammonia carriers (30,000–50,000 tons per vessel), facilitating efficient maritime logistics and enabling direct export from offshore production points to global energy hubs (IEA, 2023; Lim et al., 2021).

3.2. Conceptual Block Flow Diagram and System Integration

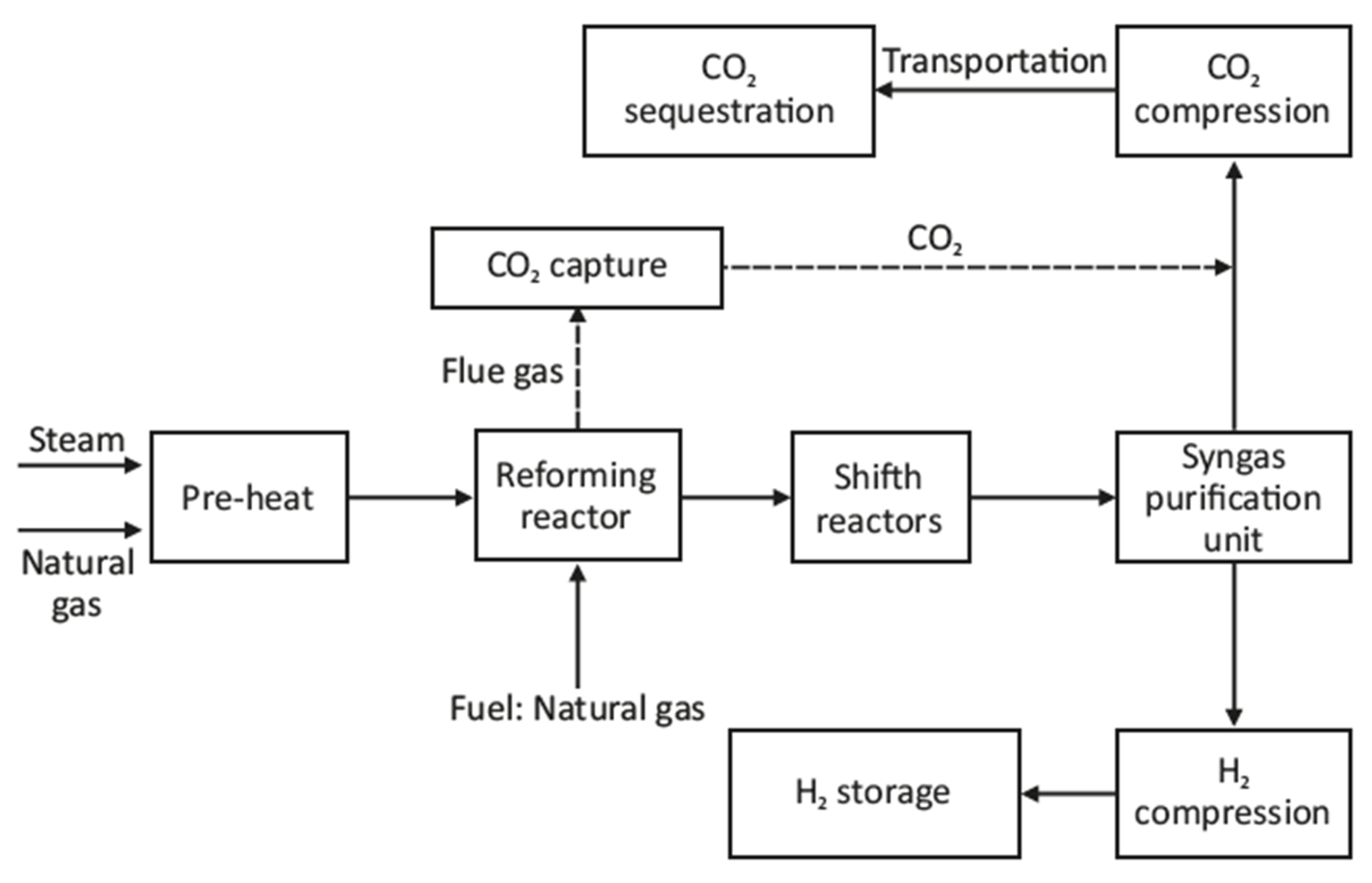

The installed nominal capacity of the proposed offshore plant is 2,100 metric tons of ammonia per day (tNH₃/day), equivalent to an annual output of roughly 700,000 tons under continuous operation. This production scale was selected to balance the trade-offs between modular construction feasibility, energy integration efficiency, and economy of scale. It allows the VLFS platform to function as a self-contained industrial hub, capable of producing, storing, and exporting ammonia directly via marine carriers. This capacity is also consistent with international benchmarks for medium-scale blue ammonia facilities, such as the Saudi. The conceptual process flow diagram (PFD) of the VLFS-based ammonia production unit comprises nine major process and utility subsystems, designed for maximum integration of heat, power, and mass flows. Each subsystem was selected to ensure operational reliability, high efficiency, and compatibility with offshore modularization (Santos et al., 2025; Canan, 2022). The simplified block flow diagram of the system is presented in

Figure 1, illustrating the main process steps from natural gas reforming to hydrogen purification, carbon capture, and CO₂ sequestration.

As illustrated, the process begins with the preheating of the natural gas and steam mixture, which is then fed into the reforming reactor where methane (CH₄) is converted into syngas, a mixture primarily composed of hydrogen (H₂), carbon monoxide (CO), and carbon dioxide (CO₂). The reforming process may be autothermal, combining partial oxidation and steam reforming within a single reactor to achieve higher thermal efficiency and compact design, suitable for offshore modular applications.

The hot syngas leaving the reformer is directed to a series of shift reactors, where carbon monoxide reacts with steam to form additional hydrogen and CO₂ via the water–gas shift reaction (CO + H₂O → CO₂ + H₂). After the shift stage, the gas passes through a syngas purification unit, typically employing pressure swing adsorption (PSA) or membrane separation to achieve high-purity hydrogen. The purified hydrogen stream is then compressed and routed to H₂ storage or directly to the ammonia synthesis loop (Haber–Bosch unit).

Meanwhile, the CO₂-rich flue gas from the reformer undergoes chemical absorption in the CO₂ capture unit, using amine-based solvents such as MEA or MDEA to achieve removal efficiencies above 90%. The captured CO₂ is then dehydrated, compressed, and transported to nearby geological reservoirs for sequestration, leveraging existing pre-salt CO₂ injection infrastructure operated by Petrobras (ANP, 2024; EIA, 2021). This closed-loop carbon management scheme enables the plant to operate with near-zero net emissions while maintaining high energy recovery efficiency.

This integrated configuration allows effective utilization of process heat and pressure gradients to minimize external power demand, enhancing overall system performance. The combined operation of reforming, shift conversion, CO₂ capture, and hydrogen compression represents a tightly coupled network optimized for offshore deployment. Such thermal and material integration is essential for achieving energy self-sufficiency levels exceeding 70% in offshore blue ammonia plants, ensuring both environmental and operational sustainability under pre-salt conditions (IEA, 2023; Santos et al., 2025).

To achieve this high level of integration, the process design of the VLFS-based blue ammonia system was divided into a sequence of interconnected subsystems, each performing a specific role in gas treatment, hydrogen generation, carbon capture, and ammonia synthesis. The design emphasizes modularity, compactness, and efficient energy recovery, ensuring that all process units can operate safely and continuously within the constraints of offshore environments. The main subsystems are described below.

Feed Gas Pre-Treatment and Desulfurization

The natural gas feed from the Búzios subsea manifold is first routed through a desulfurization unit, which removes hydrogen sulfide (H₂S) and other sulfur compounds to prevent catalyst poisoning in downstream reforming and synthesis processes. This stage typically uses zinc oxide (ZnO) beds and amine sweetening for bulk sulfur removal. Offshore integration demands compact, skid-mounted reactors capable of operating at pressures above 50 bar and temperatures around 350 °C (EIA, 2021).

Water-Gas Shift Conversion (WGS)

The syngas is cooled and sent to high- and low-temperature shift reactors, where carbon monoxide reacts with steam to form additional hydrogen and CO₂:

The conversion efficiency exceeds 95%, increasing the hydrogen yield while concentrating CO₂ for subsequent capture (Lim et al., 2021).

CO₂ Capture, Drying, and Compression

The CO₂-rich gas is directed to an amine-based absorption system using MDEA or MEA solvent. The CO₂ capture rate reaches 90–95%, with the recovered CO₂ dehydrated and compressed for geological reinjection in nearby pre-salt reservoirs. The integration with FPSO injection infrastructure allows for closed-loop carbon management offshore, aligning with Brazil’s emerging CCS roadmap (ANP, 2024; Santos et al., 2025).

Methanation and Purification

Residual CO and CO₂ traces in the hydrogen stream are converted to methane in the methanation unit, protecting the ammonia synthesis catalyst from poisoning. This step also ensures the gas meets stringent purity requirements (>99.9% H₂).

Ammonia Synthesis Loop (Haber-Bosch)

Hydrogen and nitrogen, sourced from the Air Separation Unit (ASU), react over an iron-based catalyst under 150–300 bar and 400–500 °C conditions. The reaction follows:

Due to thermodynamic limitations, per-pass conversions reach 15–20%, but unreacted gases are recycled through a loop system with mechanical compressors. The loop efficiency typically exceeds 95% overall ammonia conversion, and the exothermic reaction heat is recovered in steam generators to supply energy for upstream processes (IEA, 2023; Canan, 2022).

Air Separation Unit (ASU)

The cryogenic ASU supplies high-purity nitrogen (>99.9%) for ammonia synthesis and oxygen (>95%) for the ATR. This dual output allows tight energy and process coupling between hydrogen and ammonia production units, reducing external utility needs by up to 20% (Lim et al., 2021).

Desalination and Water Treatment Systems

Given the offshore location, all process water is supplied by a reverse osmosis (RO) and multi-effect distillation (MED) desalination system integrated into the VLFS hull. The combined system produces 1,200–1,500 tons/day of demineralized water, supporting both process steam generation and cooling circuits.

Power Generation and Heat Recovery

Power and heat integration are achieved through a combined heat and power (CHP) system using offgas from the reforming and methanation units. Gas turbines and heat recovery steam generators (HRSG) provide electricity and steam for process use. Waste heat from the ATR and synthesis loops is recovered to achieve energy self-sufficiency levels exceeding 70%, minimizing dependence on external power supply (IEA, 2023; Santos et al., 2025).

Mass and Energy Balance

Based on steady-state modeling, the VLFS ammonia production plant consumes approximately 60,000 Nm³/h of natural gas and 1,200 tons/day of water, producing 2,100 tons/day of ammonia and 1,600 tons/day of captured CO₂. The specific energy consumption is estimated at 7.4 GJ/tNH₃, consistent with current blue ammonia benchmarks (IEA, 2023; Canan, 2022). The integrated design achieves a total CO₂ capture rate above 90%, while process heat recovery and turbine cogeneration reduce the net carbon intensity to below 0.4 tCO₂/tNH₃, aligning with the IEA’s Net Zero Emissions (NZE) 2050 Scenario.

The mass and energy balance of the offshore blue ammonia production system was developed by considering the main input and output streams: natural gas as feedstock, water for steam generation and process utilities, the produced ammonia, and the captured carbon dioxide. The process integrates an autothermal reforming (ATR) unit, a Haber–Bosch ammonia synthesis loop, and a carbon capture and compression system based on monoethanolamine (MEA) absorption. This configuration allows a high degree of thermal integration and process efficiency suitable for offshore operation.

Natural gas consumption is one of the most critical parameters in the balance. For each metric ton of ammonia produced, the process requires between 28 and 35 MMBtu of natural gas, equivalent to roughly 8.2–10.3 MWh per ton of NH₃. These values are consistent with benchmarks for efficient industrial-scale ATR systems. The heat recovered from the reforming reactions is used to generate high-pressure steam, which supplies energy to the compressors, pumps, and refrigeration units in the synthesis and storage sections.

The overall process efficiency is estimated at 55–60%. The carbon capture and compression units add a modest energy penalty of about 0.3–0.6 MWh per ton of ammonia, depending on the CO₂ purity required for injection. The overall process captures approximately 1.6 tons of CO₂ per ton of NH₃, aligning with best-practice benchmarks reported by AEA (2020) and EIA (2021). This demonstrates that the integration of carbon capture with offshore production achieves high environmental performance while maintaining industrial energy efficiency.

Economic Modeling and Scenario Analysis

Based on steady-state modeling, the VLFS ammonia production plant consumes approximately 60,000 Nm³/h of natural gas and 1,200 tons/day of water, producing 2,100 tons/day of ammonia and 1,600 tons/day of captured CO₂. The specific energy consumption is estimated at 7.4 GJ/tNH₃, consistent with current blue ammonia benchmarks (IEA, 2023; Canan, 2022). The integrated design achieves a total CO₂ capture rate above 90%, while process heat recovery and turbine cogeneration reduce the net carbon intensity to below 0.4 tCO₂/tNH₃, aligning with the IEA’s Net Zero Emissions (NZE) 2050 Scenario.

The economic evaluation was based on a two-level modeling approach designed to compare the effects of production scale. The large-scale industrial model represents a fully integrated offshore complex producing around 730,000 tons of ammonia per year (2,100 tons per day). The small-scale modular model represents a reduced-capacity configuration producing about 26,780 tons per year (77.4 tons per day). While the first model targets commercial viability through economies of scale, the second focuses on technology demonstration and operational validation under offshore conditions.

The results reveal a dependence on scale. The large-scale configuration benefits from spreading fixed costs over a greater production volume, resulting in a specific CAPEX of around 2,000 USD per ton-year. In contrast, the modular plant shows a specific CAPEX close to 75,000 USD per ton-year, which makes it economically unfeasible without subsidies or strategic partnerships. Thus, while the modular model plays an important role in advancing technology readiness and reducing future risks, only the industrial-scale configuration presents real commercial potential under realistic market conditions.

The total capital expenditure (CAPEX) for the large-scale plant was estimated at 1.45 billion USD, including 120 million USD for gas reforming units, 180 million USD for CO₂ capture and compression, 150 million USD for ammonia synthesis and storage, 100 million USD for the air separation unit, 200 million USD for power generation and utilities, 400 million USD for the Very Large Floating Structure (VLFS) and anchoring systems, and 300 million USD for engineering, management, and contingencies. The annual operational expenditure (OPEX) is approximately 150 million USD, mainly driven by natural gas consumption, maintenance, labor, insurance, and CO₂ transport and storage costs. Offshore project costs were adjusted by a factor of two to three relative to onshore installations, in line with industry benchmarks for complexity and logistics (Hydelta, 2024; AEA, 2020).

The financial analysis considered a 30-year project lifetime, a 10% annual discount rate, and equity financing. Two primary indicators were used: Net Present Value (NPV) and Payback Time (PBT). In the base case, with gas priced at 6 USD per MMBtu and ammonia at 700 USD per ton, the project achieved an NPV of 2.08 billion USD and a payback period of four years. In the optimistic case (gas at 2 USD per MMBtu and ammonia at 1,100 USD per ton), the NPV rose to 5.6 billion USD, and the payback time decreased to two years. Conversely, in the pessimistic case (gas at 10 USD per MMBtu and ammonia at 300 USD per ton), the project generated a negative NPV of –1.4 billion USD, showing how financial performance is highly sensitive to feedstock and product prices.

The sensitivity analysis explored five combined scenarios of natural gas and ammonia prices: pessimistic (10 and 300 USD), moderately unfavorable (8 and 500 USD), base (6 and 700 USD), moderately favorable (4 and 900 USD), and optimistic (2 and 1,100 USD). The results confirmed that project profitability improves exponentially as gas prices decrease and ammonia market values increase. These outcomes reinforce the strategic relevance of ensuring access to competitively priced pre-salt associated gas and securing long-term offtake agreements for low-carbon ammonia exports to Europe and Asia.

| Scenario |

Natural Gas Price (USD/MMBtu) |

Ammonia Price (USD/t) |

Financial Result |

| Pessimistic |

10 |

300 |

NPV = –USD 1.44 billion |

| Moderately Unfavorable |

8 |

500 |

NPV ≈ neutral |

| Base Case |

6 |

700 |

NPV = +USD 2.08 billion / Payback 4 years |

| Moderately Favorable |

4 |

900 |

NPV > +USD 3.8 billion |

| Optimistic |

2 |

1,100 |

NPV = +USD 5.6 billion / Payback 2 years |

| |

10 |

300 |

NPV = –USD 1.44 billion |

The two-level modeling approach demonstrates that offshore blue ammonia production becomes financially viable only at large industrial scales, where economies of scale offset high offshore CAPEX and OPEX. The modular configuration, while not profitable, remains essential as a transitional step for technical validation, regulatory adaptation, and risk reduction before full-scale deployment. This approach, consistent with international low-carbon technology development practices, combines technical prudence with long-term strategic vision toward establishing sustainable offshore industrial hubs for natural gas monetization using Very Large Floating Structures.

4. Discussion

The two-level modeling approach demonstrates that offshore blue ammonia production becomes financially viable only at large industrial scales, where economies of scale offset high offshore CAPEX and OPEX. The modular configuration, while not profitable, remains essential as a transitional step for technical validation, regulatory adaptation, and risk reduction before full-scale deployment. This approach, consistent with international low-carbon technology development practices, combines technical prudence with long-term strategic vision toward establishing sustainable offshore industrial hubs for natural gas monetization using Very Large Floating Structures. The results obtained in this study shows that blue ammonia production on Very Large Floating Structures (VLFS) represents a technically feasible yet economically sensitive solution for sustainable natural gas monetization in offshore environments such as Brazil’s pre-salt region. While the process integration of Autothermal Reforming (ATR), carbon capture and storage (CCS), and ammonia synthesis demonstrates technological maturity, the overall feasibility depends on strategic economic, engineering, and logistical conditions. The following subsections discuss the implications of these results from the perspective of industrial scalability, systems engineering, and global competitiveness.

4.1. Economies of Scale and Industrial Viability

Economies of scale emerge as the dominant factor determining the financial viability of offshore ammonia production. Large-scale configurations enable the dilution of fixed costs associated with the platform, utilities, power generation, safety systems, and maritime logistics across a greater production volume. This results in a dramatic reduction in the specific capital cost, from approximately 75,000 USD per ton-year in small-scale modular units to around 2,000 USD per ton-year in industrial-scale facilities (AEA, 2020; Hydelta, 2024). Such a difference directly reflects the benefits of shared infrastructure and optimized process integration that are only achievable at higher production capacities. This distinction between scales is explicitly summarized in the comparative analysis of the two conceptual models developed for this study, as shown in

Table 1. The comparison highlights the profound financial implications of scale on offshore blue ammonia projects.

Table 1.

Summary of Main Process Streams and Energy Flows for Offshore Blue Ammonia Production on VLFS.

Table 1.

Summary of Main Process Streams and Energy Flows for Offshore Blue Ammonia Production on VLFS.

| Stream |

Input/Output |

Flowrate |

Notes |

| Natural Gas (CH₄) |

Input |

60,000 Nm³/h |

Feedstock for reforming |

| Water (H₂O) |

Input |

1,200 t/day |

Steam generation and process |

| Electricity |

Input |

1.2 kWh/kg NH₃ |

Self-generated by gas turbine integration |

| Ammonia (NH₃) |

Output |

2,100 t/day |

Final product |

| CO₂ Captured |

Output |

1,600 t/day |

90% capture efficiency |

| Waste Heat Recovery |

Output |

25–30% process energy recovered |

Used for steam and power generation |

| Aspect |

Model 1: Large Scale |

Model 2: Small Scale |

| Main Objective |

Commercial viability and industrial-scale production |

Technology demonstration (R&D) |

| Production Capacity |

730,000 tons/year (≈2,100 tons/day) |

26,780 tons/year (≈77.4 tons/day) |

| Operational Regime |

95% availability |

95% availability |

| Total Estimated CAPEX |

USD 1.45 billion |

USD 2.0 billion |

| Specific CAPEX |

~USD 2,000 per ton/year |

~USD 75,000 per ton/year |

| Economy of Scale |

Present, with strong positive impact |

Absent, leading to economic infeasibility |

The capital intensity of offshore projects further reinforces the importance of scale. The estimated total CAPEX of 1.45 billion USD positions the VLFS ammonia plant among the largest single industrial investments in Brazil’s energy sector. This figure covers the integrated costs of reforming units, CO₂ capture systems, ammonia synthesis and storage, air separation, power generation, and floating infrastructure (Santos et al., 2025). Although these costs are comparable to those of conventional floating LNG (FLNG) systems, the economic margin for ammonia production is narrower due to the dependence on feedstock price and global ammonia demand. As such, financial feasibility requires access to competitively priced natural gas, preferably associated gas from pre-salt fields that would otherwise be reinjected, and the establishment of long-term offtake agreements for low-carbon ammonia.

The simulation of price scenarios confirms this dependency. The project only achieves positive net present values when natural gas prices remain below 6 USD per MMBtu and ammonia market prices exceed 700 USD per ton. Under these conditions, the large-scale model yields an NPV of 2.08 billion USD with a four-year payback period, whereas unfavorable scenarios quickly erode profitability. This sensitivity highlights that offshore blue ammonia is a high-CAPEX, high-risk investment, requiring financial instruments such as carbon credits, green bonds, or government-backed guarantees to mitigate market volatility. The results are consistent with international experiences where large-scale blue ammonia facilities, such as those in Saudi Arabia and the Netherlands, have relied on policy incentives or strategic partnerships to secure financial stability (IEA, 2023; Canan, 2022).

4.2. Systems Engineering and Offshore Integration Challenges

From an engineering standpoint, the main challenge of offshore blue ammonia production lies not in the maturity of individual technologies, but in the complexity of integrating multiple high-capacity process units within a confined, dynamic floating environment. The technologies involved, ATR, chemical CO₂ absorption, cryogenic air separation, and the Haber–Bosch synthesis loop, are all well-established, with Technology Readiness Levels (TRL) between 9 and 10. However, their offshore deployment requires advanced systems engineering to ensure operational safety, energy efficiency, and spatial optimization (Santos et al., 2025; Lim et al., 2021).

The VLFS platform must accommodate heavy equipment, large pressurized vessels, heat exchangers, and rotating machinery, all subject to dynamic loads from waves, wind, and currents. This creates a need for integrated structural and process design to minimize vibration transmission, maintain process stability, and ensure safety compliance. Thermal integration is another critical challenge: efficient heat recovery between reforming, CO₂ capture, and synthesis units is essential to achieve energy self-sufficiency levels exceeding 70%, as indicated in the mass and energy balance. The combination of heat exchangers, waste heat boilers, and power turbines requires precise control and redundancy to prevent cascading failures.

Another key step toward project implementation is the basic design approval by a classification society such as the American Bureau of Shipping (ABS), Det Norske Veritas (DNV), or Bureau Veritas. This approval serves as a technical milestone validating the safety and structural adequacy of the offshore system. It ensures compliance with maritime regulations, including the Safety of Life at Sea Convention (SOLAS), the International Convention for the Prevention of Pollution from Ships (MARPOL), and the Code for the Construction and Equipment of Mobile Offshore Drilling Units (MODU Code), which establish global standards for operational safety, environmental protection, and structural integrity. This certification provides the foundation for subsequent construction and financing, and only after obtaining it can the project advance to the detailed engineering and procurement phases. The multidisciplinary integration of naval architecture, process engineering, and automation is therefore the decisive factor for transforming conceptual feasibility into operational reality (Hydelta, 2024; Canan, 2022).

4.3. Logistics and Competitive Advantages

From a logistical perspective, blue ammonia production offers distinct competitive advantages over alternative hydrogen carriers. One of the most significant is ammonia’s superior storage and transport properties. While liquid hydrogen requires cryogenic storage at approximately –253 °C, ammonia liquefies at –33 °C under atmospheric pressure, drastically reducing energy requirements for refrigeration and enabling the use of existing cryogenic infrastructure. This characteristic makes ammonia a more practical vector for international hydrogen transport, particularly over long maritime distances (Hånde and Wilhelmsen, 2019; Hammad and Dincer, 2018). As a result, blue ammonia serves as both a hydrogen carrier and a direct fuel, compatible with combustion turbines and shipping engines under emerging low-carbon standards.

In the Brazilian context, the offshore CO₂ logistics chain represents another key advantage. The country possesses extensive expertise in carbon capture and geological reinjection, developed through decades of enhanced oil recovery (EOR) and gas management operations in the Santos Basin. Petrobras has successfully demonstrated the reinjection of over 10 million tons of CO₂ annually into pre-salt reservoirs, positioning Brazil among the global leaders in offshore CCS deployment (ANP, 2024). Leveraging this existing infrastructure significantly reduces technical and regulatory barriers for implementing closed-loop CO₂ management systems in blue ammonia projects. The integration between VLFS units and nearby FPSOs or subsea injection wells can create a fully circular offshore carbon economy, turning what would be an emission liability into a climate asset.

Ammonia transport and export logistics also benefit from high technological maturity. The shipping of liquefied ammonia has been safely practiced for decades, with more than 200 ammonia carriers currently in operation worldwide. Existing standards from the International Maritime Organization (IMO) provide strong frameworks for storage, handling, and transport safety (IMO, 2023). The proposed offshore configuration would allow direct loading of ammonia into these vessels, eliminating the need for costly onshore terminals and enabling immediate export to global markets in Europe and Asia. This logistical efficiency, combined with Brazil’s geographic proximity to major Atlantic trade routes, could provide a significant competitive advantage in the emerging low-carbon fuels market.

The integration of large-scale process engineering, advanced floating infrastructure, and established logistics networks suggests that Brazil’s pre-salt region possesses the fundamental conditions to host a new generation of offshore industrial systems dedicated to blue ammonia production. However, realizing this potential will require coordinated action among government agencies, private investors, and research institutions to align technological readiness, regulatory adaptation, and market incentives.

Conclusions

The findings of this study indicate that large-scale blue ammonia production on Very Large Floating Structures (VLFS) in Brazil’s pre-salt region is both technically feasible and economically viable under realistic market conditions. The integrated offshore model, combining Autothermal Reforming (ATR), chemical CO₂ absorption, and the Haber–Bosch synthesis process, demonstrates a high degree of process efficiency, thermal integration, and environmental performance. When coupled with the logistical advantages of the Santos Basin, its proximity to abundant associated natural gas resources, existing offshore infrastructure, and established CO₂ reinjection expertise, this configuration provides a unique opportunity for Brazil to advance toward sustainable natural gas monetization while contributing to global decarbonization goals (Santos et al., 2025; IEA, 2023).

The economic modeling results confirm that project viability is strongly dependent on scale. Only at industrial capacities, on the order of 700,000 tons of ammonia per year, does the balance between capital investment and operational costs achieve positive financial outcomes. In the base case scenario, characterized by natural gas prices of 6 USD per MMBtu and ammonia prices of 700 USD per ton, the project yields a Net Present Value (NPV) of approximately 2.08 billion USD with a four-year payback period. This demonstrates the importance of economies of scale in diluting fixed offshore costs related to platform structure, utilities, and logistics. Conversely, small-scale modular configurations, although useful for technology demonstration and risk reduction, remain economically unfeasible without policy support or public-private partnerships (Hydelta, 2024; AEA, 2020).

From an engineering perspective, the study highlights that the main challenge lies not in the technological maturity of individual components but in the complexity of systems integration required for safe, efficient, and compact offshore operation. All primary processes involved, ATR, CO₂ capture, air separation, and ammonia synthesis, operate at Technology Readiness Levels (TRL) 9–10, confirming their industrial maturity. However, the integration of these units into a single floating platform demands advanced systems engineering to address constraints of weight distribution, vibration control, and dynamic stability. The success of such an endeavor depends on multidisciplinary coordination among process engineers, naval architects, and automation specialists, as well as on compliance with international offshore standards governed by classification societies such as DNV or ABS. The basic design approval of the VLFS ammonia platform should be considered a critical milestone for project viability, as it would validate structural safety and process operability under offshore conditions (Canan, 2022; Lim et al., 2021).

Logistically, blue ammonia production presents distinct advantages over other hydrogen carriers. Its liquefaction point of –33 °C, compared to –253 °C for hydrogen, drastically reduces energy consumption and storage complexity, enabling cost-effective maritime transport using established cryogenic tanker fleets. This makes ammonia an efficient and scalable vector for hydrogen trade, aligning with global strategies for low-carbon fuel distribution (Hånde and Wilhelmsen, 2019; Hammad and Dincer, 2018). Furthermore, Brazil’s long-standing experience with CO₂ reinjection in the Santos Basin provides a technical foundation for implementing offshore CCS, minimizing additional infrastructure needs and ensuring that captured carbon is safely and permanently stored in geological formations (ANP, 2024; EIA, 2021). The combination of these factors places Brazil in a favorable position to become a competitive exporter of low-carbon ammonia to energy-demanding regions such as Europe and East Asia.

Nevertheless, the realization of such offshore industrial systems faces structural and regulatory challenges. The absence of a clear legal and regulatory framework governing offshore chemical production facilities, beyond those dedicated to oil, gas, and power generation, poses a significant barrier. Current Brazilian maritime legislation, largely adapted from petroleum operations, does not yet contemplate floating industrial plants that integrate chemical processes and carbon management systems. This regulatory vacuum introduces uncertainty regarding licensing, environmental compliance, and taxation, potentially delaying project implementation and increasing investor risk (Santos et al., 2025). Developing a specific legal framework for offshore industrial activities is therefore essential to unlock the potential of VLFS-based ammonia production.

The regulatory framework for the blue ammonia VLFS platforms must necessarily align with the three core pillars of international maritime law: the United Nations Convention on the Law of the Sea (UNCLOS), the International Convention for the Prevention of Pollution from Ships (MARPOL), and the International Convention for the SOLAS. UNCLOS (1982) establishes the general legal foundation, defining the jurisdiction and limits of maritime spaces (such as the EEZ) and setting out obligations for the protection of the marine environment. MARPOL (IMO), the main environmental treaty, regulates pollution control from any structure at sea, requiring strict compliance with standards for atmospheric emissions, effluent discharge (like ballast water and sewage), and waste management from the industrial plant, all of which are essential for environmental permitting. SOLAS (IMO) sets the minimum safety standards for operation and structure, covering requirements for the platform’s construction, stability, life-saving appliances, and fire protection, aimed at ensuring crew safety and the integrity of the ultra-deepwater installation.

The confluence of the necessity to monetize the pre-salt’s associated natural gas with the imperatives of the global energy transition elevates the proposal of offshore blue ammonia to the status of a strategic imperative for Brazil. The pre-salt region, characterized by high-yield reservoirs in ultra-deep waters and substantial gas production that is currently managed primarily through re-injection, provides the ideal structural prerequisites: an abundant feedstock and proven operational expertise in extreme marine environments. The adoption of Very Large Floating Structures (VLFS) for the integrated cycle of steam methane reforming, ammonia (NH3) synthesis, and, mainly CO2 injection (CCS), transcends mere resource optimization; it establishes a new technological frontier in hydrocarbon management.

However, for the demonstrated technological feasibility of the process engineering to be translated into scalable industrial reality, a profound institutional and regulatory adaptation is mandatory. The inherent uncertainty in capital-intensive, deepwater projects, particularly when incorporating novel floating industrial complexes (VLFS), necessitates the mitigation of non-technical risks. The creation of a clear regulatory and fiscal framework specifically for Floating Industrial Platforms (FIPs), one that addresses issues of environmental licensing, maritime jurisdiction, and incentive regimes for the production of low-carbon commodities, is essential to reducing the cost of capital and investor uncertainty. Furthermore, this model drives the development of a national value chain in advanced offshore engineering, fostering synergies between the naval industry, the petrochemical sector, and the energy domain.

The proposed VLFS-based blue ammonia model offers a potential pathway to address logistical challenges associated with pre-salt natural gas utilization while contributing to Brazil’s gradual integration into the emerging hydrogen economy. By combining advances in offshore engineering with evolving regulatory frameworks, this approach illustrates how technological innovation may support low-carbon energy strategies in resource-rich contexts. Although still dependent on further technical validation and regulatory adaptation, the model provides a conceptual contribution to ongoing discussions on sustainable offshore industrialization and the global energy transition.

Acknowledgments

We are grateful for the support of CNOOC Petroleum Brazil Ltda.,and the strategic importance of the support of ANP (National Agency of Petroleum, Natural Gas and Biofuels) through the regulation of the R&D tax (ANP Resolution No. 918/2023). We also thank the Institute of Energy and Environment - IEE - of the State University of São Paulo - USP - and its team of collaborators for the institutional and material support. We also thank all those who collaborated in some way in the development of this research.

References

- AEA. Offshore Blue Ammonia Production Economics. 2020.

- ANP – Agência Nacional do Petróleo, Gás Natural e Biocombustíveis. Boletim de Produção de Petróleo e Gás Natural, 2024. Available online: https://www.gov.br/anp/pt-br (accessed on 07 November 2025).

- Canan, L. Hydrogen and Ammonia Energy Systems: Efficiency and Maturity. 2022.

- Canan, P. Hydrogen Production Pathways: Efficiency and Technological Maturity. IEA Technical Report, 2022.

- EIA – U.S. Energy Information Administration. Ammonia and Hydrogen Market Review, 2021.

- EIA – U.S. Energy Information Administration. CO₂ Capture and Storage in Ammonia Production, 2021.

- Hånde, J.; Wilhelmsen, Ø. Thermophysical Properties of Hydrogen and Ammonia Liquefaction Systems. Int. J. Hydrogen Energy 2019, 44, 12345–12359. [CrossRef]

- Hammad, M.; Dincer, I. Comparative Energy Analysis of Hydrogen and Ammonia as Marine Fuels. J. Clean. Prod. 2018, 193, 674–685. [CrossRef]

- Hydelta. Emerging Technologies and Offshore Process Integration, 2024.

- IEA – International Energy Agency. Global Hydrogen Review 2021–2023. OECD/IEA: Paris, France, 2023. [CrossRef]

- IEA – International Energy Agency. Ammonia Technology Roadmap: Towards Net Zero. OECD/IEA: Paris, France, 2023. [CrossRef]

- IMO – International Maritime Organization. International Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk (IGC Code). London, UK, 2023.

- Lee, J.; Kim, S.; Park, J. Advances in Membrane-Based Carbon Capture Technologies. J. Membr. Sci. 2020, 598, 117781. [CrossRef]

- Lim, C.; Lee, J.; Canan, L. Blue Ammonia and Hydrogen as Energy Carriers. J. Clean. Prod. 2021, 320, 128780. [CrossRef]

- Lim, S.; Lee, J.; Canan, L. Ammonia Market and Applications Review. Renew. Sustain. Energy Rev. 2021, 152, 111678. [CrossRef]

- Santos, R.P.B.; Mendes, M.M.; Costa, H.K. VLFS in Brazil: Sustainable Monetization of Natural Gas and the Offshore Energy Transition. Synergia Editora: Rio de Janeiro, Brazil, 2025.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).