1. Introduction

Fibre-Reinforced Polymer (FRP) composites that are reinforced with fibres have demonstrated a high degree of success in retrofitting concrete structures. Nonetheless, the bonding performance at the FRP-adhesive-concrete interface is very significant to the overall success of such retrofitting techniques. This can be attributed to the fact that the stress transferring and distributing medium between the FRP and the concrete substrate is the adhesive layer [

1]. Therefore, the nature of the adhesive is very critical in determining the bond strength of the FRP adhesive concrete system, and, therefore, the choice of a suitable bonding agent is critical in every retrofitting exercise.

Many attempts have been made to the production of sophisticated bonding agents to optimize the retrofitting systems. Among them, epoxy resin, which is an amorphous and highly crosslinked polymer, is still the most popular one to bond FRP materials with the substrates of the concrete elements that have deteriorated to restore their mechanical properties, such as strength, stiffness, and structural integrity [

1,

2,

3]. The popularity of epoxy-resin bonding systems can be explained by the favorable properties they have that include, but are not limited to, ease of processing, compatibility with a wide range of fibres, resistance to wear, good adhesion to heterogeneous substrates, and resistance to chemical attack [

1,

2,

4,

5,

6]. Nevertheless, along with these positive aspects, epoxy adhesives have some serious limitations, including poor fire resistance (high flammability) and the release of toxic fumes and steroids, which can negatively affect the skin. Also, at temperatures above their glass transition temperature (Tg), which is usually between 55 °C and 75 °C, the epoxy resins undergo a loss of important mechanical properties, including yield strength, which impairs the performance of the bond between FRP and adhesive and concrete and ultimately stress transfer capability [

7,

8].

Thus, cement-based adhesives (CBAs) made of mineral-derived materials have become an interesting and promising alternative to epoxy resins. CBAs have many benefits, such as no toxic fume emission, non-combustibility, and safe operation at high temperatures or under fire. They also cost less compared to polymer adhesives. It has been shown that CBAs are capable of effectively enhancing strong composite action between FRP composites and concrete, and thus they can be used in both externally bonded reinforcement (EBR) and near-surface-mounted (NSM) FRP retrofit applications [

7,

9,

10].

Considering the increasing trend in safer, more environmentally friendly, and flame-retardant retrofitting systems, the present review critically analyzes the possibility of nanomaterial-based CBAs being used as potential substitutes to conventional epoxy resins in FRP-concrete systems. The review summarizes current developments in nanotechnology-based improvements in CBAs and their impacts on the performance of interfacial bonds, mechanical strength, and long-term sustainability, as well as outlining research gaps and research directions.

2. Cement-Based Adhesives for Concrete Retrofitting

2.1. Overview of CBA-Based FRP Retrofitting Systems

The analysis of retrofitting of RC elements with FRP bonded with CBAs was explored in several studies [

11,

12,

13,

14]. As an example, Dai et al. [

13] examined flexural performance and failure of externally reinforced (RC) beams that are reinforced with textile-reinforced engineered cementitious composite (TR-ECC). They found that flexural capacity and yield load of the steel reinforcement increased by 119% and 61.3% respectively, when a single layer of carbon textile reinforcement was used with ECC as compared to an unstrengthened control beam. In addition, there was a 160% increase in flexural strength when two layers of carbon textile reinforcement were employed together with ECC. What was interesting was that some common failure modes like intermediate crack-induced (IC) debonding and plate-end debonding that are typical in externally bonded FRP systems were not observed. These significant improvements in flexural capacity and ductile failure behavior were explained by the combined strengthening effect of the textile reinforcement and ECC, and by the pseudo-plastic nature of the TR-ECC material.

Ombres [

11] investigated Fibre-Reinforced Cementitious Mortars (FRCM), which involves the flexural behaviour of externally bonded to a cementitious mortar (EB) by carbon fibre meshes. Results indicated that there was an increase in the ultimate load capacity of the strengthened beams between 10% and 44% relative to the control specimen. On the same note, Hashemi and Al-Mahaidi [

14] examined RC beams that were retrofitted using carbon FRP (CFRP) fabric and textile, together with cement-based bonding agents. Their study showed load-bearing capacity enhancements of 10% to 35% for beams strengthened with CFRP fabric and approximately 27% for those strengthened with CFRP textile, relative to the unstrengthened control beams. These results suggest that effective composite action can be achieved between CFRP, mortar, and concrete when cement mortar is employed as a bonding agent. Brückner et al. [

12] also demonstrated the effectiveness of flexural strengthening of RC slabs using textile fabric embedded in a cementitious matrix, showing improvements in ultimate load capacity without evidence of bond failure between the strengthening layers and the concrete substrate. However, another study involving externally bonded CFRP sheets applied with a polymer-modified mortar reported only a marginal gain in ultimate strength, with no observed enhancement in beam stiffness [

15].

2.2. Comparative Performance: CBAs vs Epoxy Adhesives

To identify the most effective bonding agents, further research [

9,

16,

17] has been conducted to compare the behaviour of FRP-strengthened concrete members bonded with either epoxy or cement-based adhesives. Täljsten and Blanksvärd [

9] investigated the flexural performance of RC slabs and small-scale concrete beams retrofitted using externally bonded CFRP grids with both adhesive types. They found that slabs bonded with a cementitious adhesive exhibited performance comparable to that of slabs bonded with epoxy resin. Notably, the cement-bonded slab exhibited a ductile failure mode, whereas the epoxy-bonded slabs failed in a brittle manner. In another study, Carolin et al. [

16] evaluated the flexural behaviour of RC beams strengthened with NSM-CFRP and recommended cement grout as a practical replacement for epoxy in on-site applications. More so, a study on shear strengthening of RC beams through externally bonded CFRP grid with cement-based and epoxy adhesives showed that cementitious bonding agents, when applied with CFRP grids, may provide an attractive alternative to epoxy-bonded CFRP sheets [

17].

Nevertheless, Burke et al. [

18] revealed that epoxy adhesives performed better in NSM-FRP strengthening systems of concrete structures in comparison to cementitious grout adhesives at room temperature (approximately 21 °C). Even though the cementitious bond adhesive showed some satisfactory bond behaviour, it led to an inefficiency in the use of the FRP reinforcement. In the replacement of epoxy by cement-based adhesives, a more conservative strain limit must be used to prevent debonding failures. As per the study conducted by Al-Mahmoud et al. [

19], mortar-strengthened beams showed lower ultimate load capacity and fewer cracks as compared to epoxy resin-strengthened beams. It was also observed that CFRP rods glued with epoxy resin were more adhesive to concrete. In a later research, Al-Mahmoud et al. [

20] confirmed the same results that epoxy resin exhibited more shear strength improvement than mortar.

2.3. Bond Behaviour and Pull-Out Performance in CBA–FRP Systems

Other researchers [

21,

22,

23] also confirmed the fact that final pull-out strengths of FRP bars in grooves filled with mortar were always less than bonded with epoxy, and debonding failure was also common at the mortar-concrete interface. The results of the most important studies analyzed in this part are summarized in

Table 1, that is, the structural performance and material interactions of FRP-reinforced concrete elements bonded with cement-based adhesives.

2.4. Limitations of conventional CBAs

Previous research [

24,

25,

26] indicates that CBAs can be a good alternative to epoxy glues, which have a promising effect on composite performance; nevertheless, they also have several limitations. These weaknesses are mainly explained by the fact that they are vulnerable to hydrothermal conditions. Particularly, at high temperatures, CBAs experience physical and chemical changes that eventually degrade their mechanical characteristics. This degradation may alter their capacity to withstand heat transfer, and this may permit a longer thermal penetration across a wide temperature span (400 -1200 °C) and longer times. Also, the process of drying may affect the occurrence of restraint stresses in CBAs. Consequently, the peak of high-strength and non-polymerized cement-based adhesives is necessary to enhance the performance of retrofitting of the reinforced structure with FRP. This is possible by increasing the bond strength at the concrete-cement/FRP interfaces without compromising structural performance in the presence of fire. As with epoxy adhesives, the addition of nanoparticles to CBAs has been found to enhance overall performance by a significant amount.

3. Nanomaterial-Enhanced Cement-Based Adhesives

3.1. Forms of Nanomaterial-Enhanced Cement-Based Adhesives

The application of nanomaterials, including graphene oxide (GO), graphene nanoplatelets (GNPs), carbon nanofibres (CNFs), carbon nanotubes (CNTs), and nano silica (NS), in the CBAs has been demonstrated to impact their performance properties [

27,

28,

29,

30,

31,

32,

33,

34]. As an example, Mohammed et al. [

27] studied the effect of GO on the fresh and mechanical characteristics of CBAs. Their results showed GO is a potential additive in manufacturing high-strength CBAs. In this case, particularly the tensile strength of GO-modified mixes (GM) was raised by about 45% relative to the control mixes (CM). This was because GO was able to prevent the initiation and propagation of cracks, probably at nanoscale and up to the microscale, thus increasing tensile strength. Further, the compression strength of GM improved by 13.5% when compared to CM. This increase could be attributed to the GO-induced alteration in the pore structure whereby the fine pores are increased and, therefore, the cementitious microstructure becomes denser. Pull-off tests to determine the strength of bonding with concrete surfaces illustrated a 78% higher increase when GO-modified cement-based adhesives were applied with pre-treatment of surfaces. In fresh property, the initial setting time was reduced from 160 minutes in CM to 120 minutes in GM, probably because of the large surface area of GO. The same trend was noted in the final setting time, which reduced from 480 minutes in CM to 420 minutes in GM.

Mohammed et al. [

30] illustrated that the addition of GO in 0.01, 0.03, and 0.06 wt.% into the cement matrix increased the transport characteristics of the cement, such as lower water sorptivity and penetration of chloride ions. This enhancement was possibly attributable to an increase in gel pore, which was aided by GO, resulting in a tight cement paste microstructure. In a similar test, Mohammed et al. [

31] evaluated the effect of 0.06 wt.% GO on freeze-thaw durability of hardened cement. The outcomes showed that the weight loss was reduced from 0.25% in the reference mix to 0.8% in the GO-modified mix after 540 freeze-thaw cycles. This improvement was explained by the changes in pore structure, which limited the freezing of water in the finer pores and suppressed the nanoscale crack propagation. Also, the incorporation of GO encouraged the release of air in the mix, thus relieving the build-up of osmotic pressure. The air content in the GO mixes was also reported to increase by 40% as compared to the control mixes. GO also decreased the mesopore volume of the matrix, hence decreasing the uptake of water and enhancing compressive strength.

Alwash et al. [

32] examined the effects of GO, GNPs, and NS together on promoting the mechanical and durability of CBAs. The addition of 0.05 wt.% GO caused flexural strength to increase by 24% although chloride penetration depth increased slightly, and compressive strength was not significantly improved. Additionally, compressive and flexural strengths were raised by 29% and 37%, respectively, and chloride penetration was cut by 61% by adding 3 wt.% NS. There was once again an increase in compressive and flexural strengths in a hybrid mixture of 3 wt.% NS and 1.5 wt.% GO by 46% and 57%, respectively, and a 54% decrease in chloride penetration.

Al Muhit et al. [

33] examined the mechanical behaviour of cement composites with 0.01 wt.% and 0.05 wt.% GO additions, noting respective improvements in compressive strength of 3.4% and 29%. Abu Al-Rub et al. [

34] reported that incorporating treated and untreated CNFs and CNTs at concentrations of 0.1% and 0.2 wt.% improved the flexural strength, Young’s modulus, ductility, and toughness of cement paste by approximately 60%, 25%, 73%, and 170%, respectively. However, they recommended a 0.1 wt.% dosage as optimal for maintaining good dispersion of high-aspect-ratio nanofilaments, as 0.2 wt.% could lead to agglomeration and reduced effectiveness.

Table 2 summarizes the enhancements in CBAs resulting from the addition of nanoparticles.

3.2. Innovative High-Strength Self-Compacting Cementitious Adhesive (IHSSC-CA)

3.2.1. Development and Material Properties of IHSSC-CA

The innovative high-strength self-compacting cementitious adhesive (IHSSC-CA) represents an advanced formulation of nanomaterial-modified CBAs, developed by Mohammed et al. [

27]. This adhesive is made by adding GO and a superplasticizer in cement mortar as per the requirements mentioned in BS EN 196-1, BS EN 196-3, and BS EN 480-1. The resulting mixture proved to have a pot life of up to 120 minutes and a flow rate of 7.5%. Notably, IHSSC-CA demonstrated excellent mechanical performance, where the tensile, compressive, and pull-off strengths are 13.8 MPa, 101 MPa, and 1.2 MPa, respectively. These superior mechanical characteristics indicate that IHSSC-CA can have great potential for use in a wide variety of structural applications, as adhesive anchoring systems, FRP strengthening systems, and as a bonding interface between existing and freshly cast concrete elements.

3.2.2. Bond Behaviour in NSM-FRP Applications

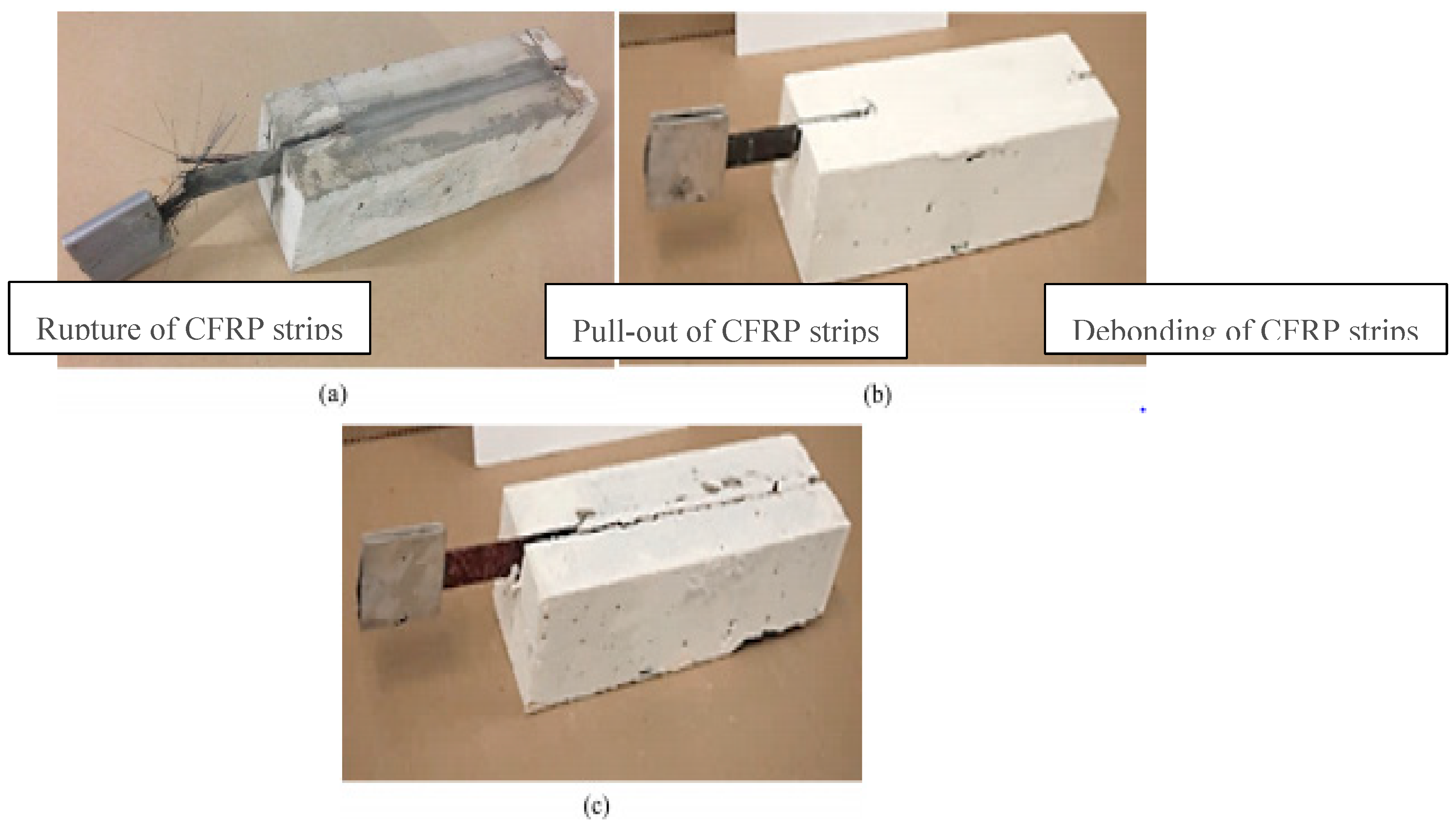

Mohammed et al. [

35,

36] and Al-Saadi et al. [

37] performed a series of experiments on NSM-CFRP-strengthened concrete specimens using three different adhesives, i.e., epoxy, polymer cement-based adhesive (PCA), and the IHSSC-CA under monotonic pull-out loading up to failure. In terms of ease of application in NSM-CFRP systems, the results of this study showed the superiority of IHSSC-CA because of its self-compacting characteristics, improved flowability, and workability. Additionally, the specimens that were bonded with IHSSC-CA showed better composite interaction between the CFRP reinforcement and the concrete substrate, so they had higher bond strength with more ductile behaviour than those bonded with epoxy or PCA. As shown in [

35], the failure modes were also different for the adhesives, with IHSSC-CA showing less surface damage and better load transfer. The higher surface roughness in CFRP strips with IHSSC-CA bond was explained by the formation of a uniform adhesive layer, which helped more evenly distribute stress and activate more CFRP threads

Figure 1 to resist the loading. This reduced the risk of the localized concentrations of stress, which were more prominent in the epoxy and PCA-bonded specimens. Furthermore, the improved interlocking of IHSSC-CA with the CFRP threads, which was made possible by its high fluidity, contributed to improved bond behaviour. On contrary, specimens bonded with PCA and epoxy exhibited large and irregular surface deformation on the CFRP, which is probably attributed to the non-uniformity of the adhesive distribution and the lack of mechanical interlock, which is also attributed to the high viscosity of polymer-rich composition.

To investigate the bond behaviour between the concrete substrate and NSM-CFRP strips with the use of PCA and innovative high-strength self-compacting cementitious adhesive (IHSSC-CA), the pull-out tests (single lap shear tests) were carried out on concrete prisms with fatigue loading conditions [

26]. The results showed that specimens using IHSSC-CA had higher performances with longer fatigue life and higher ability to withstand high fatigue loads than specimens bonded with PCA. This improvement was attributed to the superior mechanical and bond strength properties of IHSSC-CA. Pore structure analysis further verified that with the more effective composite interaction between the CFRP strips and the concrete substrate when IHSSC-CA were used, the specimens could withstand higher fatigue loading ranges and have higher durability compared with the specimens bonded with PCA.

3.2.3. Thermal Performance and Elevated-Temperature Bond Behaviour

Moreover, because of the high fluidity, self-compacting properties, and long pot life of IHSSC-CA, it was observed from the visual inspection that a constant and continuous adhesive layer completely encapsulated the CFRP strip along the bonded length with a minimal number of voids. This helped to achieve a uniform stress distribution and promoted full composite action between the NSM-CFRP reinforcement and the adhesive-concrete interface. In contrast, specimens glued with PCA exhibited partial coverage of the CFRP surface, an inconsistent adhesive layer, voids, and surface cracking. These deficiencies were mainly due to the low fluidity and lower pot life of PCA, which made proper compaction difficult. As a result, the stress was unevenly distributed and only localized in the bonded regions, resulting in incomplete composite action. Therefore, NSM-CFRP specimens with IHSSC-CA showed much better fatigue performance and life cycles than specimens with PCA.

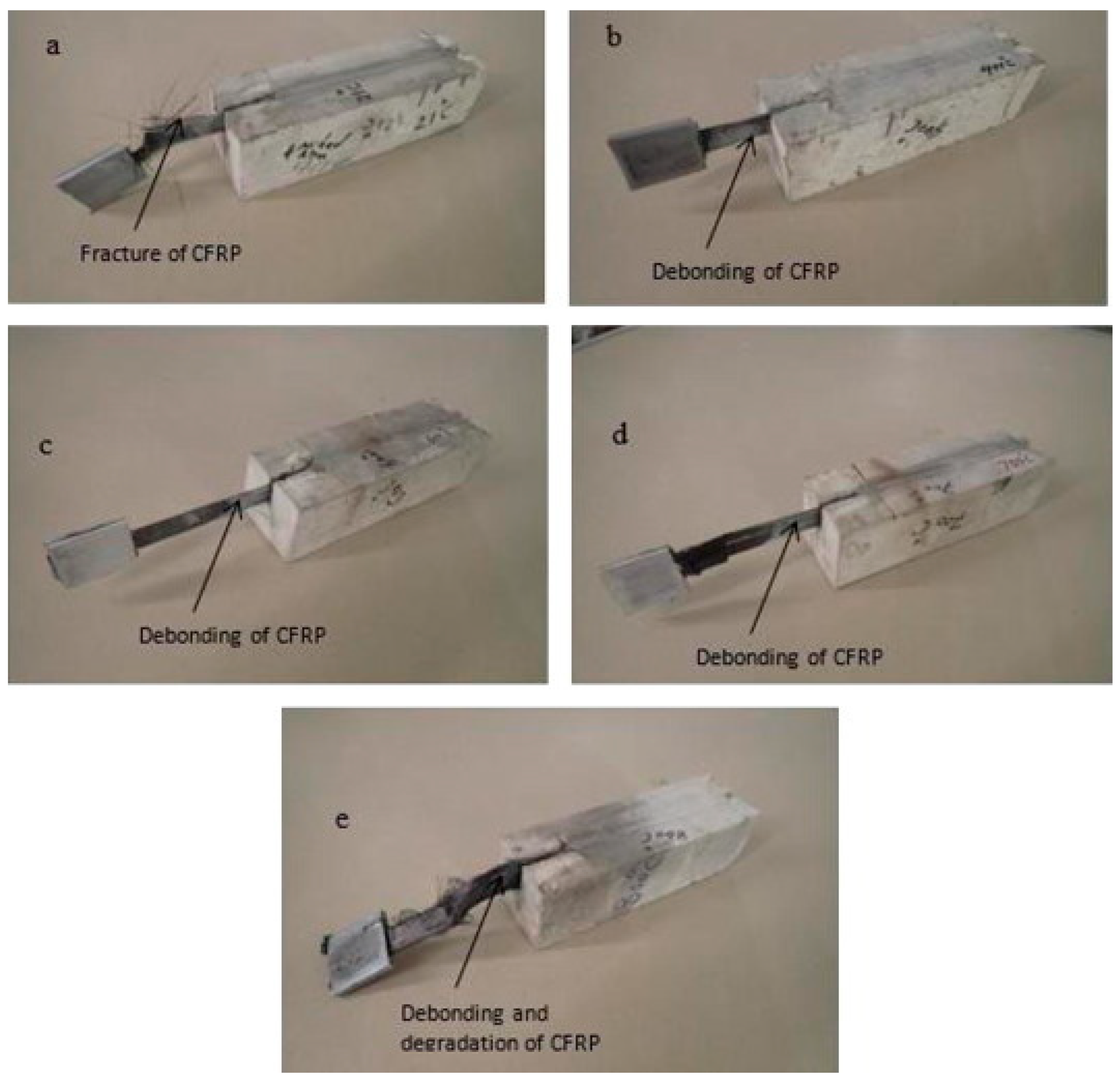

Mohammed et al. [

38] assessed the mechanical behaviour of Normal Strength Concrete (NSC) and IHSSC-CA at high temperatures. In addition, the bond performance of NSM-CFRP strengthened concrete prisms was investigated by direct pull-out (single-lap shear) tests under ambient and high temperatures. The results showed that the compressive strength of IHSSC-CA decreased by 11.5%, 21.2%, and 40% after being exposed to 400 °C, 600 °C, and 800 °C, respectively. In contrast, NSC had significantly higher strength losses of 23.6%, 45.5%, and 76.4% at the same temperatures. A similar trend was noticed for the tensile strength. For IHSSC-CA, tensile strength decreased by 15.4% and 31.5% at 400 °C and 600 °C, respectively, with 60.8% of the initial tensile strength retained at 800 °C. In comparison, NSC exhibited a much sharper decrease in the tensile strength, which is reduced to 50% at 400 °C and 28% at 600 °C, reaching the minimum value of 0.3 MPa at 800 °C. These results suggest that IHSSC-CA has better thermal resistance and keeps better mechanical performance and bond integrity under high temperatures.

Figure 2 shows the failure modes of the specimens tested.

The results of the pull-out tests further showed the good bond performance of IHSSC-CA. At room temperature (21 °C), the average pull-out force attained 34.5 kN, which is close to the value of 41 kN for similar specimens bonded with epoxy adhesive [

39]. Notably, failure at 21 °C occurred through fracture of the CFRP strip itself, with no debonding observed, demonstrating the high bonding capacity and reliability of IHSSC-CA under mechanical loading.

3.2.4. Structural Behaviour of IHSSC-CA in Full-Scale RC Members

Al-Saadi et al. [

40] studied the structural performance of 10 reinforced concrete (RC) girders that were strengthened and repaired using NSM-CFRP strips bonded with either IHSSC-CA or traditional epoxy adhesives. Five of the beams were subjected to monotonic loading up to the point of failure, while the other five were fatigued. The experimental results showed that girders attached with epoxy adhesive had a higher level and accelerated strain development in the concrete, steel reinforcement, and CFRP strips during the fatigue test. In addition, these beams exhibited greater crack width expansion, greater deflection, more significant stiffness degradation, and faster damage accumulation compared to those strengthened and repaired with IHSSC-CA.

These observations give more insight into the better performance of IHSSC-CA in the strengthening of RC beams under fatigue conditions, especially in terms of structural serviceability and practical application. Furthermore, the specimens with IHSSC-CA showed better bond performance and better stress transfer from CFRP reinforcement to the concrete substrate and between internal steel reinforcement and the surrounding concrete. This increased interaction was attributed to the ability of IHSSC-CA to maintain composite action in the NSM-CFRP system under repeated loading conditions.

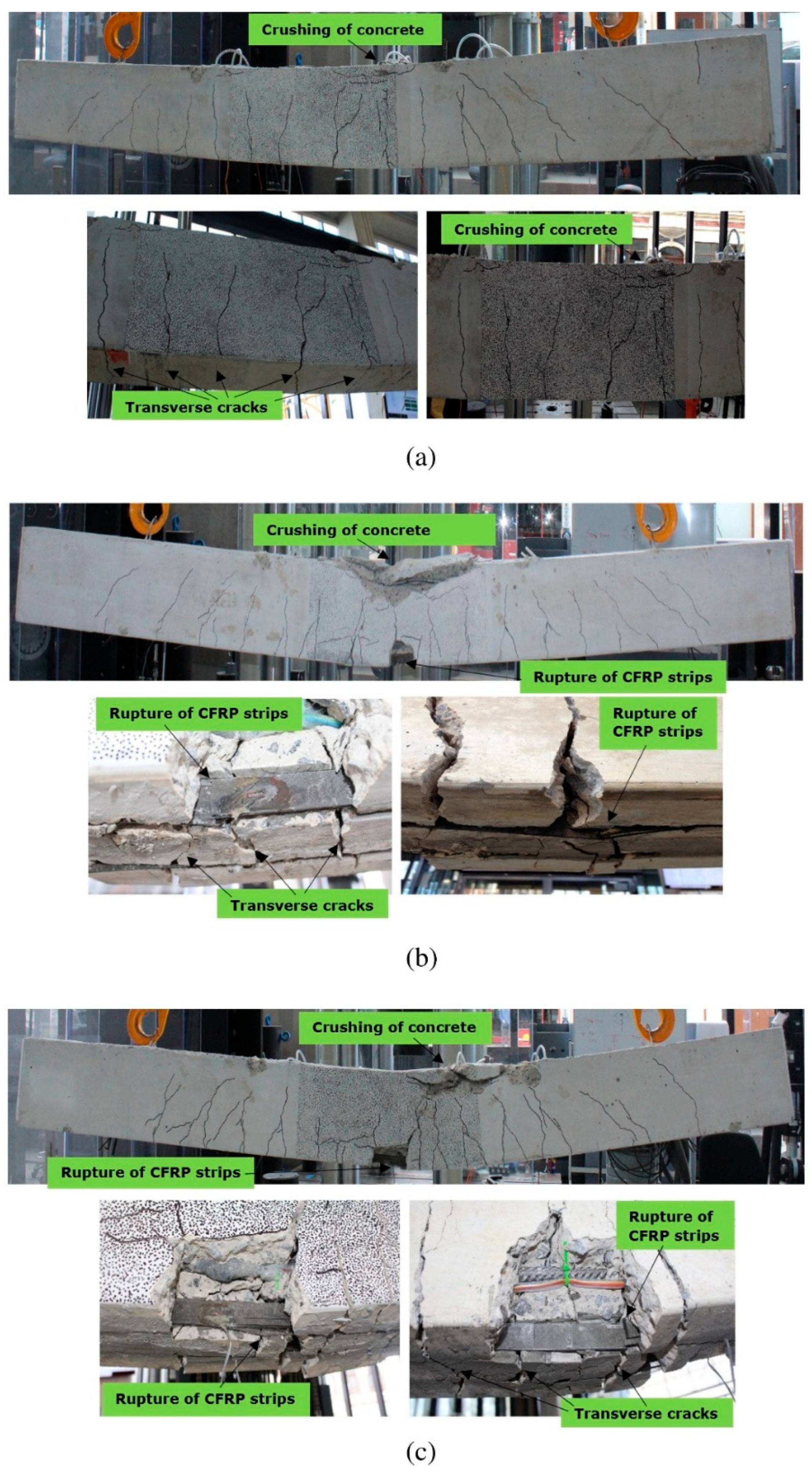

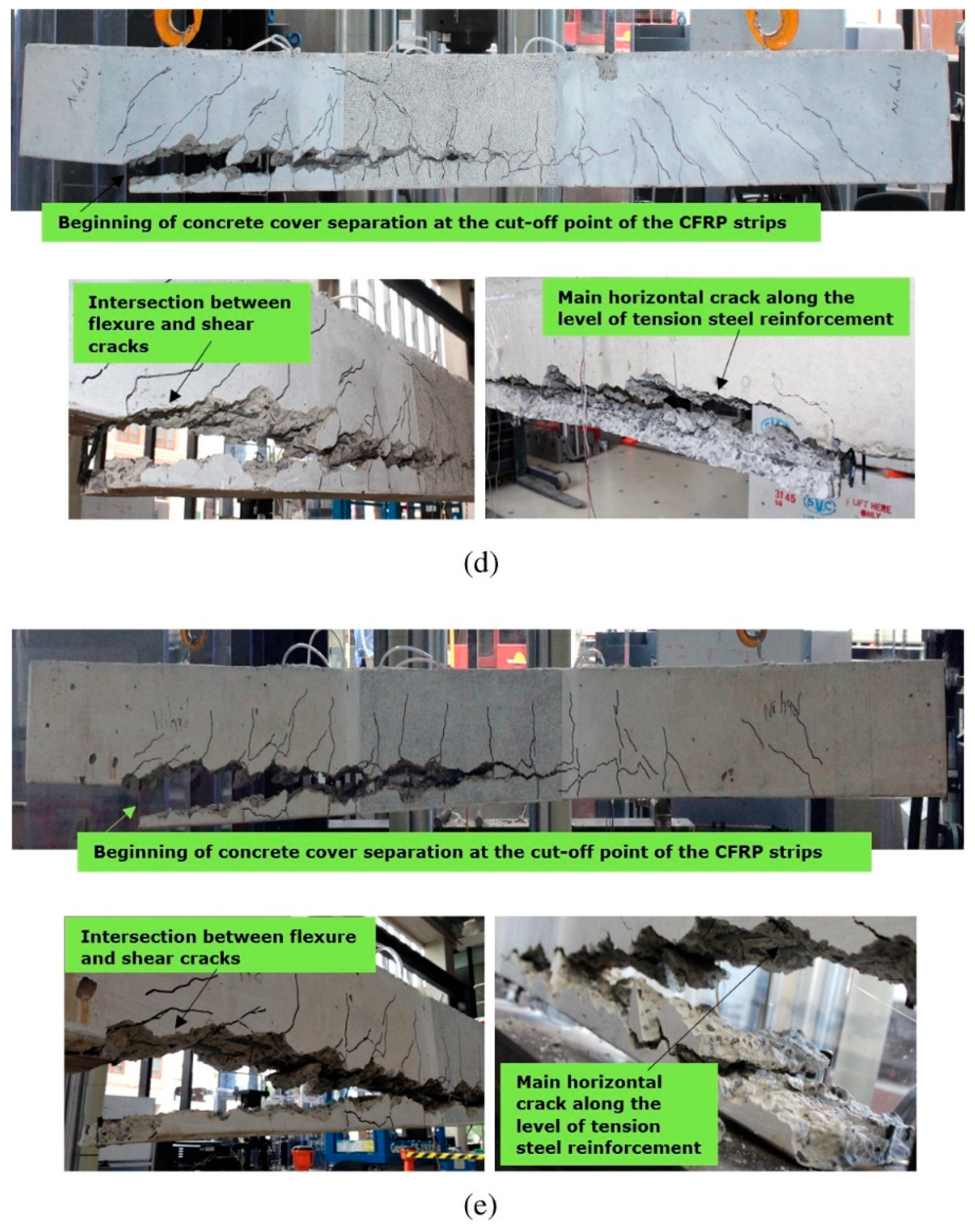

Al-Saadi et al. [

41] performed flexural tests on full-size reinforced concrete (RC) beams repaired and reinforced using NSM-CFRP strips bonded on either epoxy adhesive or IHSSC-CA. As RTD results showed, the use of brittle adhesives, such as epoxy, for bonding the CFRP to ductile RC beams reduced the ductility. In contrast, with the use of more ductile bonding material, such as IHSSC-CA, the ductility of the strengthened and repaired beams was improved. Specifically, ultimate flexural capacity increased by 43% and 53% of the control beam for epoxy-repaired and strengthened beams, respectively. However, these enhancements were accompanied by decreases in ductility (as measured by deflection) of 38% and 44% respectively. On the other hand, the ductility of beams repaired and strengthened with IHSSC-CA has shown 88% and 59% improvements, and 28% and 21% improvements in the ultimate flexural capacity, respectively. These findings suggest that while epoxy-bonded beams have higher load-carrying capacity, probably due to the higher tensile strength of epoxy adhesive (32 MPa) as compared to IHSSC-CA (18.6 MPa), the use of IHSSC-CA significantly enhances the ductility and provides a more balanced solution where the strength and deformability of the structure are important.

A summary of the reviewed studies involving mechanical, bond, and durability performance of IHSSC-CA in NSM-CFRP systems is shown in

Table 3, highlighting its superior properties with an advantage over traditional epoxy and polymer cement-based alternatives.

Furthermore, the use of RC beams repaired and strengthened with IHSSC-CA was observed to fail by rupture of CFRP strips after a large amount of deformation, which showed a ductile failure mode. In contrast, beams bonded with epoxy adhesive failed suddenly because of the separation of the concrete cover, which resulted from the loss of composite action in the NSM-CFRP system. The failure modes of the tested beams are shown in

Figure 3.

In addition, IHSSC-CA proved better load transfer efficiency between the RC beams and the CFRP strips as compared to the epoxy adhesive. Notably, the residual strength of beams bonded using IHSSC-CA was also quite high beyond the peak load, which was not the case for the epoxy-bonded specimens. This post-peak strength retention is one of the main merits of IHSSC-CA in the application of NSM-CFRP because it improves structural safety and serviceability during the service life of rehabilitated RC structures.

4. Conclusions

This review dealt with the development and use of cement-based adhesives (CBAs) in the structural retrofitting of concrete members using fibre-reinforced polymer (FRP) composites. The limitations on performance of traditional CBAs were evaluated, and recent progress in which nanomaterial-modified CBAs were used was critically discussed. Based on the review that has been done, the following conclusions can be drawn up:

Traditional CBAs have proven to have limited effectiveness in FRP-based retrofitting systems because of their relatively low mechanical properties, less-than-optimal bond performance, and poor compatibility with reinforcement materials when compared to conventional epoxy adhesives.

The incorporation of nanomaterials, such as nano silica, carbon nanotubes, graphene oxide, and others into CBAs has enhanced the mechanical strength, durability and interfacial bonding between CBAs and concrete substrates and FRP reinforcements to a great extent. These enhancements overcome some of the limitations of unmodified CBAs and facilitate their wider use in retrofitting practices.

Even at low dosages (typically 0.01%-5% by weight), nanomaterials have shown a double and quadruple improvement in the mechanical performance of CBAs, especially tensile and compressive strength and bond efficiency, thus improving structural reliability and service life.

Among the promising advancements, innovative high-strength self-compacting cementitious adhesives (IHSSC-CAs) have been developed as alternatives to epoxy and polymer-modified adhesives, which are viable and sustainable. These materials not only provide improved bond strength, stiffness, fatigue resistance, and residual performance of both externally bonded (EBR) and near-surface-mounted (NSM) FRP systems but also have a variety of practical advantages, such as high-flowability, workability, and extended open time during application.

Unlike epoxies, IHSSC-CAs are environmentally friendly from the very start, not emitting toxic fumes and creating safer conditions for workers working on-site during the retrofitting processes.

Overall, nanotechnology-enhanced CBAs are an attractive solution for sustainable, high-performance, and durable FRP retrofitting systems. Continued research is required to optimize mix design, standardize testing methods, and assess long-term performance in real-world applications so that further adoption of these next-generation adhesives in the construction industry can be supported.

5. Recommendations for Future Work

Despite an increasing interest in nanomaterial-modified CBAs, such as IHSSC-CAs, for the retrofit of concrete structures with FRP systems, there is still a lack of research. To close these gaps and pave the way toward this transition of these high-performance materials from laboratory invention to the field, the research directions listed below are proposed as paths to research in the future:

The current nano-modified CBAs research study is primarily focused on small-scale elements. Future work should examine the performance of large-scale retrofitted elements using both EBR- and NSM-FRP techniques under different loading and environmental conditions. Moreover, since the two systems experience different stress distribution and bond mechanisms, tailored investigations are required to get a deeper insight into the interaction of nano-modified CBAs with each of these systems at structural scales.

Nanomaterial-modified CBAs may interact in different ways with different types of FRP reinforcements (e.g., carbon, glass, and basalt). Further studies are required to understand the physicochemical interactions between nanomaterials, cementitious matrices, and reinforcement surfaces and the collective role on bond strength and load transfer mechanisms, as well as durability.

Retrofitting involves both reinforcement materials and cementitious substrates, which have inherently different mechanical and chemical properties. Future work should discuss how to prepare compatible and synergistic formulations that optimise performance and compensate for the differences in shrinkage, thermal expansion, and adhesion behaviour. Novel hybrid systems with epoxy-CBA blends or staged applications may also show promising results.

Apart from organic matrix like epoxy, in the case of inorganic cement-based substrates, there are unique possibilities in the surface functionalization of nanomaterials to enhance dispersion, bonding, and reactivity. Research is required on tailored functionalization approaches that improve the mechanical and thermal properties of CBAs while maintaining the flowability and workability.

Theoretical modelling and numerical simulation of nanomaterial-enhanced CBAs in FRP retrofitting systems are not well developed. Establishing predictive models for mechanical behaviour, interfacial bond performance, and durability over time will be crucial for the standardization of design and for its implementation on a large scale.

-

Researchers are encouraged to draw on recent key reviews and research that investigate:

The current approach of carbon- and silicon-based nanomaterials used to enhance the mechanical, thermal, and the microstructural properties of epoxy and cement-based adhesives used in FRP-retrofitted systems [

42,

43,

44].

The first known study on the use of nanomaterial-enhanced epoxy adhesives (NMEAs) in NSM-FRP retrofit applications [

45].

The critical role of bonding agents in bond behaviour in NSM-FRP systems [

46].

The performance of different bonding agents in repairing heat-damaged concrete beams [

47,

48].

For more information on advancements in structural retrofitting and bonding systems, interested researchers can also find significant insights in recent studies [

48,

49,

50,

51,

52]. All those studies provide foundational knowledge and pave the way for future interdisciplinary innovations in concrete retrofitting systems.

Uniform dispersion of nanomaterials (e.g., GO, CNTs, CNFs) within cementitious matrices is crucial to realise their intended benefits. Future research should focus on optimising dispersion methods (e.g., ultrasonication, surfactants, or functionalisation) and on evaluating their impact on the rheological, mechanical, and interfacial properties of nanomodified CBAs to ensure reliable field performance.

While nanomaterial-enhanced CBAs show promising laboratory-scale performance, their scalability, cost-effectiveness, and practical implementation under field conditions remain open questions. Future studies should address life-cycle costs, material availability, and comparative performance with conventional solutions, especially for large-scale retrofitting projects.

Abbreviations

The following abbreviations are used in this manuscript:

| CBAs Cement-Based Adhesives |

| CNFs Carbon Nanofibers |

| CNTs Carbon Nanotubes |

| EB Externally Bonded |

| FRCM Fibre-Reinforced Cementitious Mortar |

| FRP Fibre-Reinforced Polymer |

| GO Graphene Oxide |

| GNPs Graphene Nanoplatelets |

| IC Intermediate Crack-Induced |

| IHSSC-CA Innovative High-Strength Self-Compacting Cementitious Adhesive |

| NS Nano Silica |

| NSC Normal Strength Concrete |

| NSM Near-Surface Mounted |

| PCA Polymer Cement-Based Adhesive |

| RC Reinforced Concrete |

| SEM Scanning Electron Microscopy |

| TR-ECC Textile-Reinforced Engineered Cementitious Composite |

References

- Irshidat, M.R.; Al-Saleh, M.H. Effect of using carbon nanotube modified epoxy on bond–slip behavior between concrete and FRP sheets. Constr. Build. Mater. 2016, 105, 511–518. [CrossRef]

- Abdullah, S.R.; Rosli, F.N.; Ali, N.; Abd Hamid, N.A.; Salleh, N. Modified epoxy for fibre reinforced polymer strengthening of concrete structures. Int. J. Integr. Eng. 2020, 12(9).

- Liu, S.; Chevali, V.S.; Xu, Z.; Hui, D.; Wang, H. A review of extending performance of epoxy resins using carbon nanomaterials. Compos. Part B Eng. 2018, 136, 197–214. [CrossRef]

- Johnsen, B.B.; Kinloch, A.J.; Mohammed, R.D.; Taylor, A.C.; Sprenger, S. Toughening mechanisms of nanoparticle-modified epoxy polymers. Polymer 2007, 48(2), 530–541. [CrossRef]

- Quan, D.; Urdániz, J.L.; Ivanković, A. Enhancing mode-I and mode-II fracture toughness of epoxy and carbon fibre reinforced epoxy composites using multi-walled carbon nanotubes. Mater. Des. 2018, 143, 81–92. [CrossRef]

- Ashrafi, B.; Guan, J.; Mirjalili, V.; Zhang, Y.; Chun, L.; Hubert, P.; Simard, B.; Kingston, C.T.; Bourne, O.; Johnston, A. Enhancement of mechanical performance of epoxy/carbon fiber laminate composites using single-walled carbon nanotubes. Compos. Sci. Technol. 2011, 71(13), 1569–1578. [CrossRef]

- Al-Abdwais, A.; Al-Mahaidi, R. Modified cement-based adhesive for near-surface mounted CFRP strengthening system. Constr. Build. Mater. 2016, 124, 794–800. [CrossRef]

- Tatar, J.; Milev, S. Durability of externally bonded fiber-reinforced polymer composites in concrete structures: A critical review. Polymers 2021, 13(5), 765. [CrossRef]

- Täljsten, B.; Blanksvärd, T. Mineral-based bonding of carbon FRP to strengthen concrete structures. J. Compos. Constr. 2007, 11(2), 120–128. [CrossRef]

- Al-Saadi, N.T.K.; Al-Mahaidi, R.; Abdouka, K. Bond behaviour between NSM CFRP strips and concrete substrate using single-lap shear testing with cement-based adhesives. Aust. J. Struct. Eng. 2016, 17(1), 28–38. [CrossRef]

- Ombres, L. Flexural analysis of reinforced concrete beams strengthened with a cement based high strength composite material. Compos. Struct. 2011, 94(1), 143–155. [CrossRef]

- Brückner, A.; Ortlepp, R.; Curbach, M. Textile reinforced concrete for strengthening in bending and shear. Mater. Struct. 2006, 39(8), 741–748. [CrossRef]

- Dai, J.G.; Wang, B.; Xu, S.L. Textile reinforced engineered cementitious composites (TR-ECC) overlays for the strengthening of RC beams. In Proceedings of the 2nd Asia-Pacific Conference on FRP Structures (APFIS 2009), 2009.

- Hashemi, S.; Al-Mahaidi, R. Experimental and finite element analysis of flexural behavior of FRP-strengthened RC beams using cement-based adhesives. Constr. Build. Mater. 2012, 26(1), 268–273. [CrossRef]

- Wiberg, A. Strengthening of Concrete Beams Using Cementitious Carbon Fibre Composites. Doctoral Dissertation, Byggvetenskap, 2003.

- Carolin, A.; Nordin, H.; Täljsten, B. Concrete beams strengthened with near surface mounted reinforcement of CFRP. In Proceedings of the International Conference on FRP Composites in Civil Engineering, Hong Kong, China, 12–15 December 2001; Volume 2; pp. 1059–1066.

- Blanksvärd, T.; Täljsten, B.; Carolin, A. Shear strengthening of concrete structures with the use of mineral-based composites. J. Compos. Constr. 2009, 13(1), 25–34. [CrossRef]

- Burke, P.J.; Bisby, L.A.; Green, M.F. Effects of elevated temperature on near surface mounted and externally bonded FRP strengthening systems for concrete. Cem. Concr. Compos. 2013, 35(1), 190–199. [CrossRef]

- Al-Mahmoud, F.; Castel, A.; François, R.; Tourneur, C. Strengthening of RC members with near-surface mounted CFRP rods. Compos. Struct. 2009, 91(2), 138–147. [CrossRef]

- Al-Mahmoud, F.; Castel, A.; Minh, T.Q.; François, R. Reinforced concrete beams strengthened with NSM CFRP rods in shear. Adv. Struct. Eng. 2015, 18(10), 1563–1574. [CrossRef]

- Al-Mahmoud, F.; Castel, A.; François, R.; Tourneur, C. Anchorage and tension-stiffening effect between near-surface-mounted CFRP rods and concrete. Cem. Concr. Compos. 2011, 33(2), 346–352. [CrossRef]

- Soliman, S.M.; El-Salakawy, E.; Benmokrane, B. Bond performance of near-surface-mounted FRP bars. J. Compos. Constr. 2011, 15(1), 103–111. [CrossRef]

- De Lorenzis, L.; Rizzo, A.; La Tegola, A. A modified pull-out test for bond of near-surface mounted FRP rods in concrete. Compos. Part B Eng. 2002, 33(8), 589–603. [CrossRef]

- Neville, A.M. Properties of Concrete, 5th ed.; Pearson Education: Harlow, UK, 2012.

- Al-Saadi, N.T.K.; Mohammed, A.; Al-Mahaidi, R. Fatigue performance of NSM CFRP strips embedded in concrete using innovative high-strength self-compacting cementitious adhesive (IHSSC-CA) made with graphene oxide. Compos. Struct. 2017, 163, 44–62. [CrossRef]

- Al-Saadi, N.T.K.; Mohammed, A.; Al-Mahaidi, R.; Sanjayan, J. A state-of-the-art review: Near-surface mounted FRP composites for reinforced concrete structures. Constr. Build. Mater. 2019, 209, 748–769. [CrossRef]

- Mohammed, A.; Al-Saadi, N.T.K.; Al-Mahaidi, R. Utilization of graphene oxide to synthesize high-strength cement-based adhesive. J. Mater. Civ. Eng. 2017, 29(4), 04016258. [CrossRef]

- Lv, S.; Liu, J.; Sun, T.; Ma, Y.; Zhou, Q. Effect of GO nanosheets on shapes of cement hydration crystals and their formation process. Constr. Build. Mater. 2014, 64, 231–239. [CrossRef]

- Chuah, S.; Pan, Z.; Sanjayan, J.G.; Wang, C.M.; Duan, W.H. Nano reinforced cement and concrete composites and new perspective from graphene oxide. Constr. Build. Mater. 2014, 73, 113–124. [CrossRef]

- Mohammed, A.; Sanjayan, J.G.; Duan, W.H.; Nazari, A. Incorporating graphene oxide in cement composites: A study of transport properties. Constr. Build. Mater. 2015, 84, 341–347. [CrossRef]

- Mohammed, A.; Sanjayan, J.G.; Duan, W.H.; Nazari, A. Graphene oxide impact on hardened cement expressed in enhanced freeze–thaw resistance. J. Mater. Civ. Eng. 2016, 28(9), 04016072. [CrossRef]

- Alwash, D.; Kalfat, R.; Du, H.; Al-Mahaidi, R. Development of a new nano modified cement-based adhesive for FRP strengthened RC members. Constr. Build. Mater. 2021, 277, 122318. [CrossRef]

- Al Muhit, B.A.; Nam, B.H.; Zhai, L.; Zuyus, J. Effects of microstructure on the compressive strength of graphene oxide-cement composites. In Proceedings of the Transportation Research Board 94th Annual Meeting, Washington, DC, USA, 2015.

- Abu Al-Rub, R.K.; Tyson, B.M.; Yazdanbakhsh, A.; Grasley, Z. Mechanical properties of nanocomposite cement incorporating surface-treated and untreated carbon nanotubes and carbon nanofibers. J. Nanomech. Micromech. 2012, 2(1), 1–6. [CrossRef]

- Mohammed, A.; Al-Saadi, N.T.K.; Al-Mahaidi, R. Assessment of bond strength of NSM CFRP strips embedded in concrete using cementitious adhesive made with graphene oxide. Constr. Build. Mater. 2017, 154, 504–513. [CrossRef]

- Mohammed, A.; Al-Saadi, N.T.K.; Al-Mahaidi, R. Assessing the contribution of the CFRP strip of bearing the applied load using near-surface mounted strengthening technique with innovative high-strength self-compacting cementitious adhesive (IHSSC-CA). Polymers 2018, 10(1), 66. [CrossRef]

- Al-Saadi, N.T.K.; Mohammed, A.; Al-Mahaidi, R. Bond performance of NSM CFRP strips embedded in concrete using direct pull-out testing with cementitious adhesive made with graphene oxide. Constr. Build. Mater. 2018, 162, 523–533. [CrossRef]

- Mohammed, A.; Al-Saadi, N.T.K.; Al-Mahaidi, R. Bond behaviour between NSM CFRP strips and concrete at high temperature using innovative high-strength self-compacting cementitious adhesive (IHSSC-CA) made with graphene oxide. Constr. Build. Mater. 2016, 127, 872–883. [CrossRef]

- Khshain, N.T.; Al-Mahaidi, R.; Abdouka, K. Bond behaviour between NSM CFRP strips and concrete substrate using single-lap shear testing with epoxy adhesive. Compos. Struct. 2015, 132, 205–214. [CrossRef]

- Al-Saadi, N.T.K.; Mohammed, A.; Al-Mahaidi, R. Fatigue performance of near-surface mounted CFRP strips embedded in concrete girders using cementitious adhesive made with graphene oxide. Constr. Build. Mater. 2017, 148, 632–647. [CrossRef]

- Al-Saadi, N.TK.; Mohammed, A.; Al-Mahaidi, R. Performance of RC beams rehabilitated with NSM CFRP strips using innovative high-strength self-compacting cementitious adhesive (IHSSC-CA) made with graphene oxide. Compos. Struct. 2017, 160, 392–407. [CrossRef]

- Al-Zu'bi, M.; Fan, M.; Anguilano, L. Advances in bonding agents for retrofitting concrete structures with fibre reinforced polymer materials: A review. Constr. Build. Mater. 2022, 330, 127115. [CrossRef]

- Al-Zu'bi, M.; Anguilano, L.; Fan, M. Effect of incorporating carbon- and silicon-based nanomaterials on the physico-chemical properties of a structural epoxy adhesive. Polym. Test. 2023, 128, 108221. [CrossRef]

- Al-Zu'bi, M.; Anguilano, L.; Fan, M. Carbon-based and silicon-based nanomaterials for enhanced structural adhesives. Solid State Phenom. 2023, 354, 151–159. [CrossRef]

- Al-Zu'bi, M.; Fan, M.; Anguilano, L. Near-surface mounted-FRP flexural retrofitting of concrete members using nanomaterial-modified epoxy adhesives. J. Build. Eng. 2024, 84, 108549. [CrossRef]

- Al-Zu'bi, M.; Fan, M.; Bertolesi, E.; Anguilano, L. A review on retrofitting concrete members with near-surface mounted-fiber reinforced polymer composites. Struct. Concr. 2024, 25(3), 2242–2268. [CrossRef]

- Shhabat, M.; Al-Zu'bi, M.; Abdel-Jaber, M. A review of repairing heat-damaged RC beams using externally bonded and near-surface mounted CFRP composites. Compos. Part C Open Access 2024, 15, 100519. [CrossRef]

- Ashteyat, A.; Shhabat, M.; Alkhalaileh, A.; Al-Zu'bi, M.; Abdel-Jaber, M.T. Behavior of ultra-high-performance concrete under elevated temperatures: A comprehensive review. Results Eng. 2025, 26, 104960. [CrossRef]

- Al-Zu'bi, M.; Fan, M.; Al Rjoub, Y.; Ashteyat, A.; Al-Kheetan, M.J.; Anguilano, L. The effect of length and inclination of carbon fiber reinforced polymer laminates on shear capacity of NSM-retrofitted RC beams. Struct. Concr. 2021, 22(6), 3677–3691. [CrossRef]

- Al-Zu'bi, M.; Fan, M.; Anguilano, L. Parametric investigation of flexural performance of concrete prisms retrofitted with near-surface mounted FRP bars. Compos. Part C Open Access 2023, 12, 100421. [CrossRef]

- Al-Zu'bi, M. Next-generation bonding agents for sustainable FRP retrofitting of concrete structures. In Adhesives – Properties, Modifications, Typical and Innovative Applications; IntechOpen: London, UK, 2025; pp. 37–51. [CrossRef]

- Al-Zu’bi, M. Nanomaterial-modified epoxy adhesives for structural retrofitting. Res. Dev. Mater. Sci. 2025, 21(3), RDMS.001012. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).