Submitted:

20 November 2025

Posted:

21 November 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Sample and Study Area Description

2.2. Experimental Design and Control Group

2.3. Measurement Methods and Quality Control

2.4. Data Processing and Model Equations

2.5. Software Tools and Statistical Validation

3. Results and Discussion

3.1. Penetration Depth Performance

3.2. Torque Output and Model Accuracy

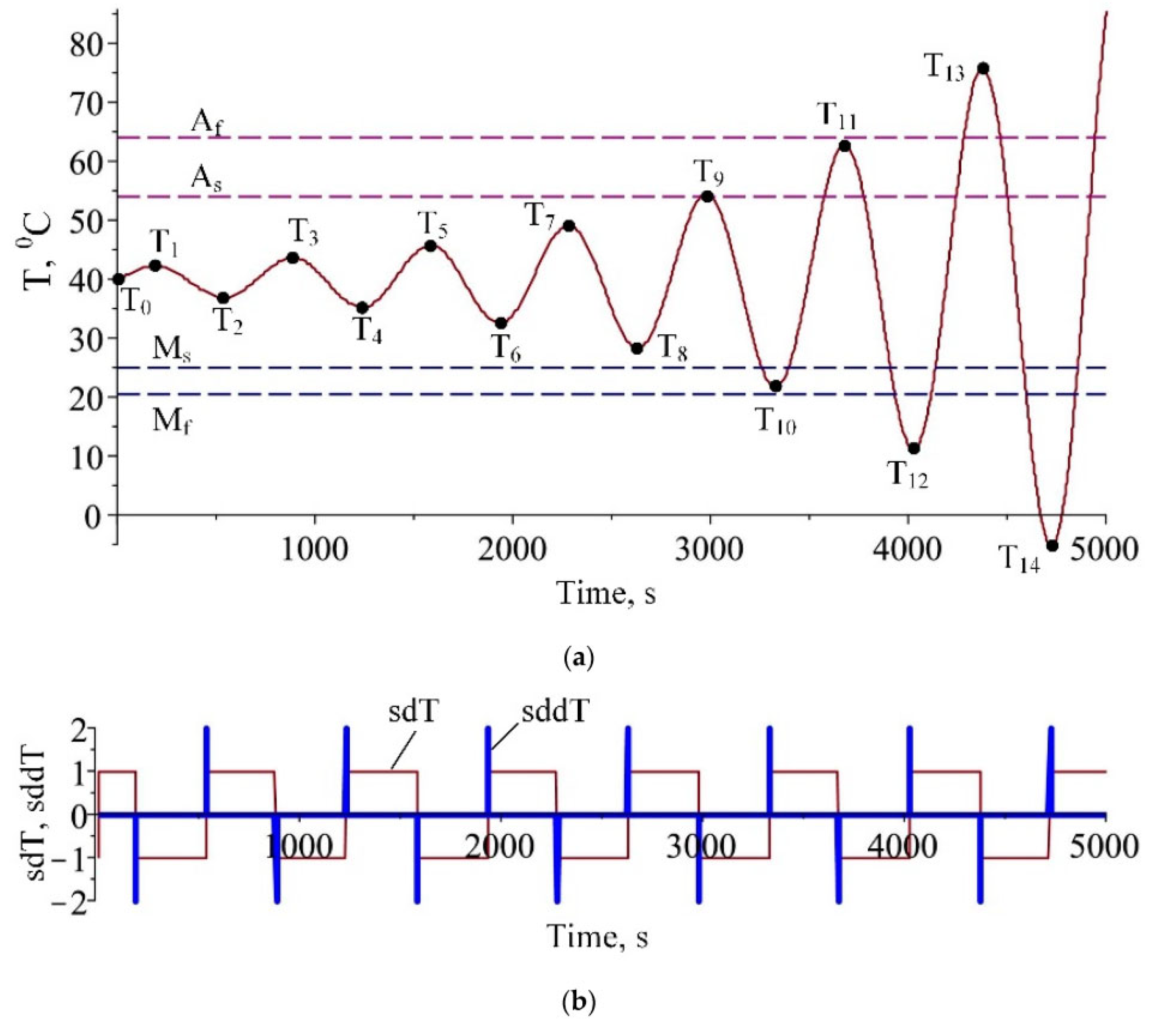

3.3. Cycle Repeatability and Fatigue

3.4. Practical Constraints and Design Considerations

4. Conclusions

References

- Naclerio, N. D. (2023). Leveraging Compliance and Anisotropy to Address Robotic Challenges (Doctoral dissertation, University of California, Santa Barbara).

- Wu, C., Chen, H., Zhu, J., & Yao, Y. (2025). Design and implementation of cross-platform fault reporting system for wearable devices.

- Kim, M. S., Heo, J. K., Rodrigue, H., Lee, H. T., Pané, S., Han, M. W., & Ahn, S. H. (2023). Shape memory alloy (SMA) actuators: The role of material, form, and scaling effects. Advanced Materials, 35(33), 2208517. [CrossRef]

- Wu, C., Zhu, J., & Yao, Y. (2025). Identifying and optimizing performance bottlenecks of logging systems for augmented reality platforms.

- Mittal, V., Lotwin, M., & Shah, R. (2025, June). A Review of Bio-Inspired Actuators and Their Potential for Adaptive Vehicle Control. In Actuators (Vol. 14, No. 7, p. 303). [CrossRef]

- Bilodeau, R. A., & Kramer, R. K. (2017). Self-healing and damage resilience for soft robotics: A review. Frontiers in Robotics and AI, 4, 48. [CrossRef]

- Sabetamal, H., Carter, J. P., Nazem, M., & Sloan, S. W. (2016). Coupled analysis of dynamically penetrating anchors. Computers and Geotechnics, 77, 26-44. [CrossRef]

- Samarakoon, S. B. P., Muthugala, M. V. J., & Elara, M. R. (2025). Tiling Robotics: A New Paradigm of Shape-Morphing Reconfigurable Robots. Advanced Intelligent Systems, 7(9), 2400417. [CrossRef]

- Luo, D., Gu, J., Qin, F., Wang, G., & Yao, L. (2020, October). E-seed: Shape-changing interfaces that self drill. In Proceedings of the 33rd Annual ACM Symposium on User Interface Software and Technology (pp. 45-57).

- Nargatti, K., & Ahankari, S. (2022). Advances in enhancing structural and functional fatigue resistance of superelastic NiTi shape memory alloy: A Review. Journal of Intelligent Material Systems and Structures, 33(4), 503-531. [CrossRef]

- Hu, W. (2025, September). Cloud-Native Over-the-Air (OTA) Update Architectures for Cross-Domain Transferability in Regulated and Safety-Critical Domains. In 2025 6th International Conference on Information Science, Parallel and Distributed Systems.

- Wang, C., Smieszek, N., & Chakrapani, V. (2021). Unusually high electron affinity enables the high oxidizing power of layered birnessite. Chemistry of Materials, 33(19), 7805-7817.

- Sun, X., Wei, D., Liu, C., & Wang, T. (2025). Multifunctional Model for Traffic Flow Prediction Congestion Control in Highway Systems. Authorea Preprints.

- Demiral, M. (2025). Strength in Adhesion: A Multi-Mechanics Review Covering Tensile, Shear, Fracture, Fatigue, Creep, and Impact Behavior of Polymer Bonding in Composites. Polymers, 17(19), 2600. [CrossRef]

- Yuan, M., Wang, B., Su, S., & Qin, W. (2025). Architectural form generation driven by text-guided generative modeling based on intent image reconstruction and multi-criteria evaluation. Authorea Preprints.

- Chen, F., Li, S., Liang, H., Xu, P., & Yue, L. (2025). Optimization Study of Thermal Management of Domestic SiC Power Semiconductor Based on Improved Genetic Algorithm.

- McCracken, J. M., Donovan, B. R., & White, T. J. (2020). Materials as machines. Advanced Materials, 32(20), 1906564.

- Zhu, W., & Yang, J. (2025). Causal Assessment of Cross-Border Project Risk Governance and Financial Compliance: A Hierarchical Panel and Survival Analysis Approach Based on H Company's Overseas Projects.

- Nemat-Nasser, S., & Guo, W. G. (2006). Superelastic and cyclic response of NiTi SMA at various strain rates and temperatures. Mechanics of materials, 38(5-6), 463-474. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).