1. Introduction

Parallel robots offer several advantages (such as high speed and precision, high rigidity at low mass, higher payload capacity, etc.) compared to serial robots, due to the interconnection of the end-effector to the fixed platform by two or more parallel-mounted arms. Among the parallel robots available on the market, the 3-degrees-of-freedom (3-DOF) Delta robot is one of the most widely used in industrial applications, especially for “pick-and-place” tasks (assembly, packaging, etc.), which often require dynamic stability, high operating speeds, and high accelerations, along with high accuracy.

The Delta parallel robot, patented by Reymond Clavel in 1987 [

1], has a mobile platform connected to a fixed base by three articulated arms. This design includes a 3-DOF end-effector capable of performing linear movements in three-dimensional (3D) space.

The Delta parallel robot is renowned for its high speed and acceleration, making it ideal for applications that require fast and precise movements. Numerous studies have explored various aspects of this robot, including analytical modeling (kinematics and dynamics), CAD modeling and simulation, as well as analyses regarding the effect of joint clearances or element elasticities. Clearances in the joints are inevitable in the construction of any mobile mechanical system because of manufacturing tolerances and inherent assembly imperfections. These clearances negatively affect dynamic performance, reduce component lifespan, and generate unwanted vibrations due to the impact of contacting parts [

2].

The trajectory tracking accuracy (position, speed, and acceleration errors of the end-effector) and motor torques can be significantly affected due to inertial effects on flexible elements and the existence of joint clearances. Cretescu et al. [

2] conducted a study of a Delta robot in various scenarios: considering in turn the natural flexibility of the compliant elements, the clearance and friction in the spherical joints, as well as their cumulative effect. The paper concluded that the dynamic effect of these parameters is not additive, while significant reciprocal influences were identified.

Several other studies [

3,

4,

5] addressed the influence of clearances in kinematic joints on the kinematic and dynamic behavior or the positioning accuracy in the workspace of 3-DOF Delta parallel robots, the results being applicable to other parallel mechanisms. Thus, an elastic model of the Delta parallel robot was proposed by Zheng and Zhang [

5] exploiting the finite element method and Lagrange equations, which also includes the effect of clearance. The study provided a basis for error compensation and vibration reduction in industrial parallel robots. Ohno and Takeda [

6] analyzed the clearances that occur due to wear in the passive joints of a Delta parallel robot. The method utilizes a linearized model that correlates the clearance with the actuation torque difference, introducing stochastic variables. The experiments, performed on an industrial Delta robot with spherical joints having clearances between 0 and 0.15 mm, demonstrated the feasibility of fault detection by this method, validated through a stochastic evaluation of the clearance estimation performance. The same authors proposed another method to detect excessive clearances in the passive joints of parallel robots, tested on a Delta robot [

7]. Based on torque fluctuations on predefined trajectories, the proposed method allowed correct detection rates (true positives) of over 80% and error rates (false positives) under 10%.

A method for direct calculation of positioning errors, caused by clearances in passive spherical joints of parallel mechanisms, eliminating the need for numerical integration or iterations, was proposed and investigated by Ohno and Takeda [

8]. A model for spherical joints was proposed, defining the relationship between relative displacement and joint force, initially ignoring the clearance. Based on the principle of virtual work, a procedure was developed to determine the positioning errors resulting from clearances. Experiments performed on a Delta parallel robot validated the method, the calculated position errors being in concordance with the experimental ones.

Based on Hertz elastic theory, a study regarding the kinematic and dynamic behavior of a 3RRR planar parallel robot, when clearances in the 6 revolute joints were taken into consideration, is presented in [

9]. The dynamic behavior of a planar mechanism was investigated considering clearances, using a continuous contact force model, based on Hertz elastic theory along with a dissipative term.

Dynamic models of robots with parallel [

10,

11,

12] or hybrid [

13] mechanisms, which also include joint clearances, have been developed applying the modified Flores and Columb contact model. Numerical simulations explore the dynamic effects of clearances and load on robot orientation accuracy, concluding that larger clearances and higher load reduce accuracy, while smaller clearances and higher loads lead to a better stability of motion.

Another approach frequently employed in dynamic modeling is the Newton-Euler (N-E) method. Thus, such N-E models applied to parallel mechanisms are presented in [

14,

15,

16], numerical simulations showing that impact and friction forces lead to irregular wear in the spherical joint, and prolonged wear amplifies contact force fluctuations and reduces the motion stability of the mechanism. The results show that irregular clearance (due to wear) significantly amplifies vibrations and contact force, compared to regular clearance. Hysteresis is also observed in the displacement, speed, and acceleration curves. Thus, irregular clearances caused by wear deteriorate the mechanism’s performance, intensifying wear and reducing its stability and reliability.

The Lagrange multipliers method was also utilized in dynamic studies of parallel mechanisms, planar [

17] or spatial [

18], including clearances in the spherical joints. Chen and Guo [

17] indicated that a single clearance has a minimal impact on dynamic characteristics, which remain close to ideal values. Mojtaba Varedi Koulaei et al. [

18] showed that the optimal design of clearances significantly reduces linear and angular accelerations, as well as contact forces, ensuring a smooth evolution of motion. The validity of the algorithm was confirmed by comparative simulations in ADAMS software.

The design and analysis of a multidimensional vibration isolator for protecting precise equipment mounted on vehicles, with a design based on a parallel mechanism with joint clearances, was addressed by Gao et al. [

19]. The main goal was to establish the kinematic and dynamic equations of the isolator and to evaluate its vibration isolation capacity in the presence of clearances. The results demonstrated the isolator’s efficiency in reducing multidimensional vibrations but also showed the sensitivity of the first-order resonance peak to the increase of clearances.

Using the Multi Body Systems (MBS) method, Xu et al. [

20] proposed a methodology for the analysis of dynamic response and system consistency with multiple revolute clearance joints. An improved impact force model and a modified friction force model were employe for modeling the impact and friction in these joints. The results demonstrated that clearances have a minimal impact on displacement and angular velocity but significantly influence angular acceleration.

Yu and Tian [

21] proposed and investigated a method for compensating the position errors of parallel robots, caused by joint clearances. Thus, a joint error model was developed for a 3-RRR planar parallel robot and the impact of clearances on link lengths and angular displacements were analyzed. The trajectory errors of the end-effector were reduced by 99% compared to the uncompensated trajectory, validating the method’s efficiency in compensating for structural errors and ensuring the position accuracy of the parallel robot.

The study presented by Xin et al. [

22] introduced an actuation acceleration-based kinematic modeling and identification method for 6-PSU (Prismatic-Spherical-Universal joints) robots with clearances. The clearance direction was correlated with the force applied to the joint, determined by the acceleration of the prismatic actuators. The clearances were modeled as variations of link lengths, experimentally identified and compensated, and the simulations and experiments validated the method’s efficiency, demonstrating an improvement in the accuracy of the kinematic model.

An elastodynamic model of kinematic chains, using spatial beam elements and kineto-elastodynamic theory was developed by Guo et al. [

23]. The model aimed to obtain rigid-flexible dynamic behavior of a hybrid parallel robot utilized for the precise polishing of aspherical optical mirrors, combining a serial-parallel manipulator with a two-rotor grinding system. Thus, the dynamic effect of joint clearances was introduced into the model and the load distribution and the impact of chain elasticity and clearances on motion errors were analyzed.

Dynamic analysis, with an emphasis on the impact of joint clearances, was addressed by Chen et al. [

24] in the case of a new type of spatial parallel robot, for which a virtual prototype was created in Adams. Numerical simulations allowed obtaining the kinematic response and contact forces, concluding that clearances and friction significantly influence the robot’s dynamics (assuming rigid bodies).

Zhang et al. [

25] analyzed the impact of joint clearances on the precision and efficiency of a 2-DOF planar parallel robot, utilized in high-speed and high-precision packaging equipment. The simulations demonstrated that the size of the clearances directly affects the packaging precision and speed, offering a reference point for the design and selection of packaging equipment.

The paper proposes an analysis utilizing ADAMS software regarding the effect of spherical joint clearances on the kinematic and dynamic behavior of a Delta parallel robot. This work aims to analyze the dynamic impact of clearances in all spherical joints (upper and lower), considered both separately and combined. Also, various values of spherical joint clearances were taken into consideration, to establish the correlation between the value of clearances and trajectory accuracy corroborated with motor torque errors.

The rest of the paper is organized as follows: the problem formulation is described in

Section 2, the main results obtained and their analysis are presented in

Section 3, and the conclusions are drawn in the final section.

2. Problem Formulation

The dynamic effect analysis of joint clearances, addressed in this paper, focuses on the SIAX D3 1600 Delta parallel robot [

26], available on the market for various industrial applications.

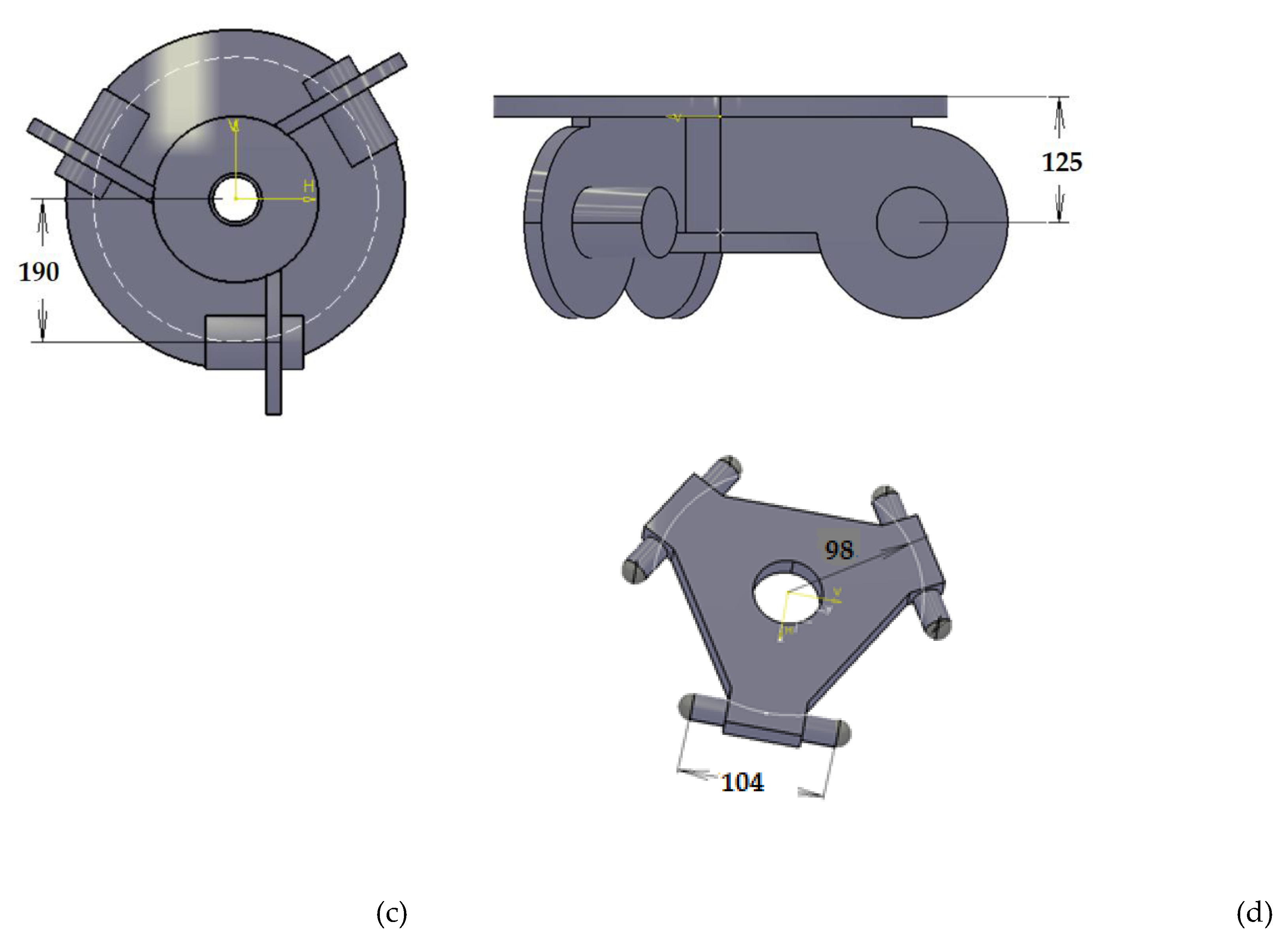

The effect of clearances from the Delta robot spherical joints can be studied numerically by developing, in the first stage, a CAD model in a 3D modeling software, such as CATIA, followed in the second stage by ADAMS simulation. Because ADAMS does not easily allow the creation of elements with complex geometric shapes, a 3D CAD model in CATIA became a useful option, followed by exporting the 3D bodies (in IGES format) and importing them into ADAMS. Thus, an accurate CAD model can be obtained in ADAMS that reflects closely the existing physical robot [

2].

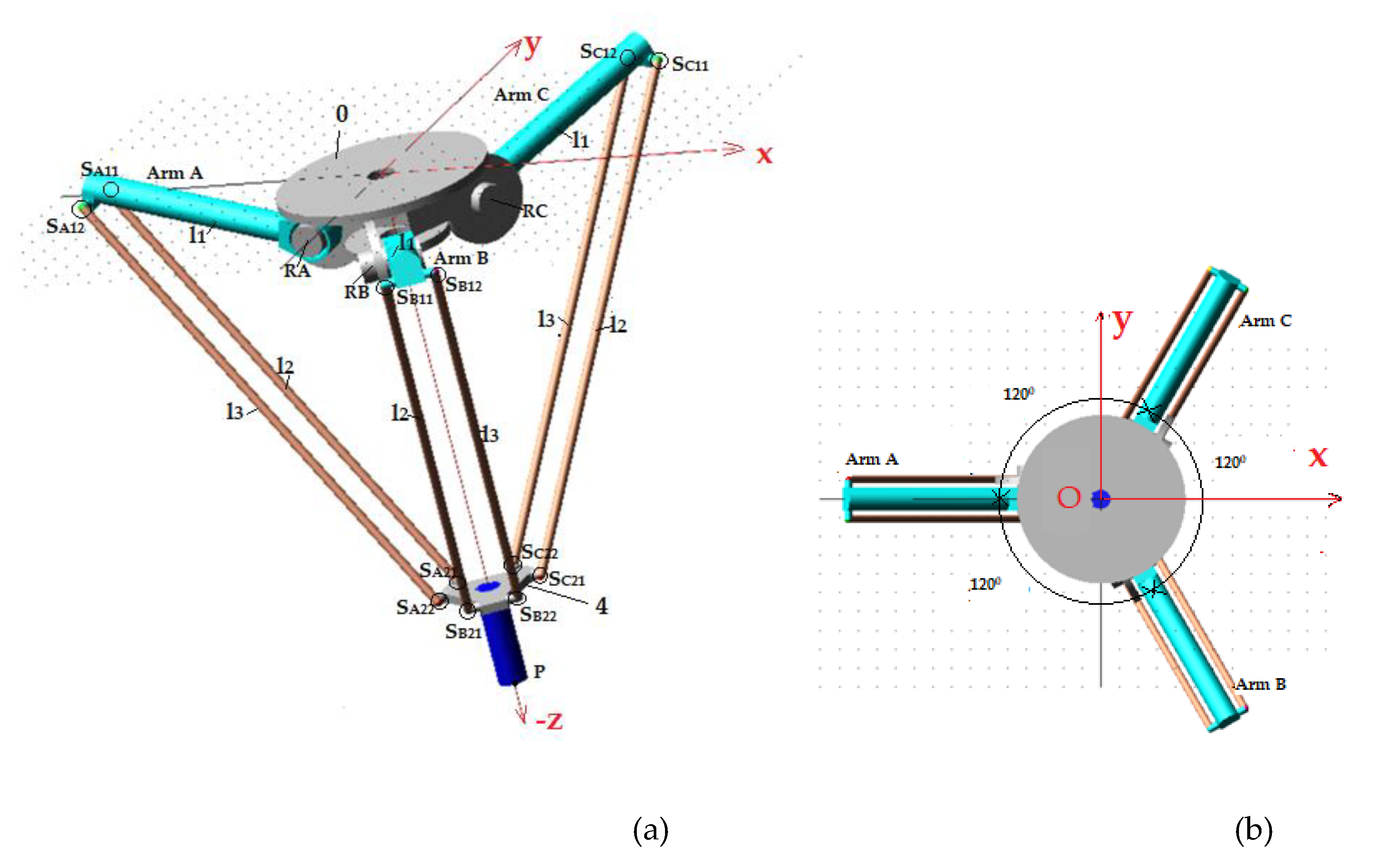

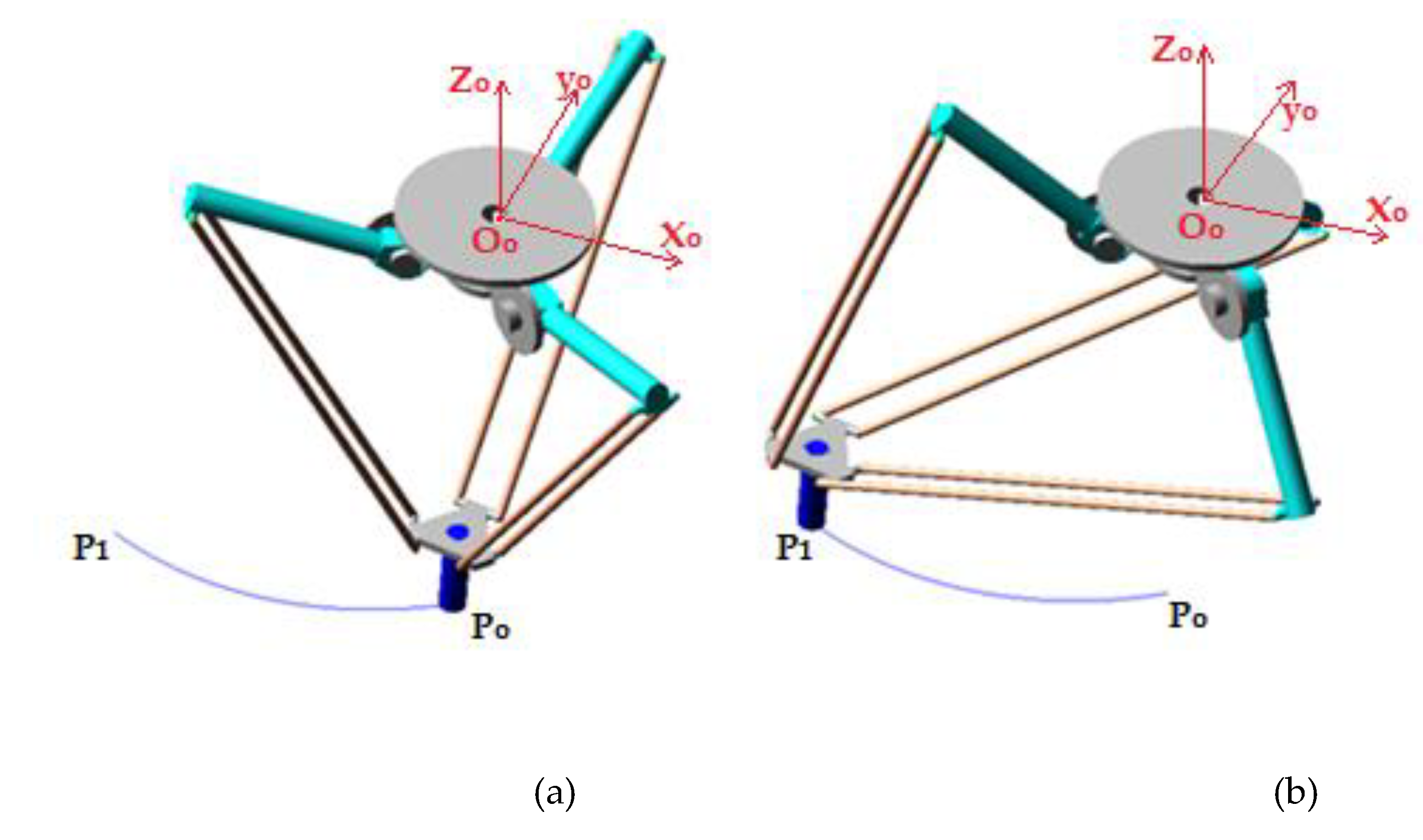

The Siax D3-1600 Delta robot (

Figure 1) is a 3-DOF parallel robot, the end-effector being constrained only to spatial translation movements, without changing orientation. It is composed by a fixed platform (0) and a mobile platform (4), interconnected by three arms (A, B, and C), each of which is provided with an actuation element (1) connected to the base by a motor revolute joint (R) [

2]. The three arms are equiangularly distributed in relation to the global coordinate system (X

0Y

0Z

0) of the robot, with the origin at point O—the center of the fixed platform in the upper plane. The Delta robot has a payload attached to the end-effector in the shape of a cylinder with a mass of 5 kg (the maximum admissible load). The characteristic point P is the origin of the end-effector’s mobile coordinate system and follows a spatial trajectory established to reach the maximum admissible speed and acceleration. The robot has a total mass of 80 kg [

26].

The arm lengths of the robot have values of 500 mm for

l1 and 1106 mm for

l2 and

l3 (Figure 1.a), the three arms (A, B, and C) being arranged at 120∘ (

Figure 1.b). The rods

l2 and

l3 are organized on each arm in the configuration of a parallelogram kinematic chain.

The geometric and mass properties of the Delta robot’s component elements, as key factors in determining its dynamic behavior, are systematized in

Table 1.

In the proposed analysis, the following assumptions are considered:

✓ The links are rigid solid bodies;

✓ All elements are made of steel;

✓ The clearances in the spherical joints (distance between the centers of the component spheres) have discrete values between 0.1 mm and 0.6 mm, with a step of 0.1 mm (i.e., six cases) in three scenarios: a) clearances only in the upper spherical joints; b) only in the lower ones; c) the combined variant a)+b).

3. Results and Discussions

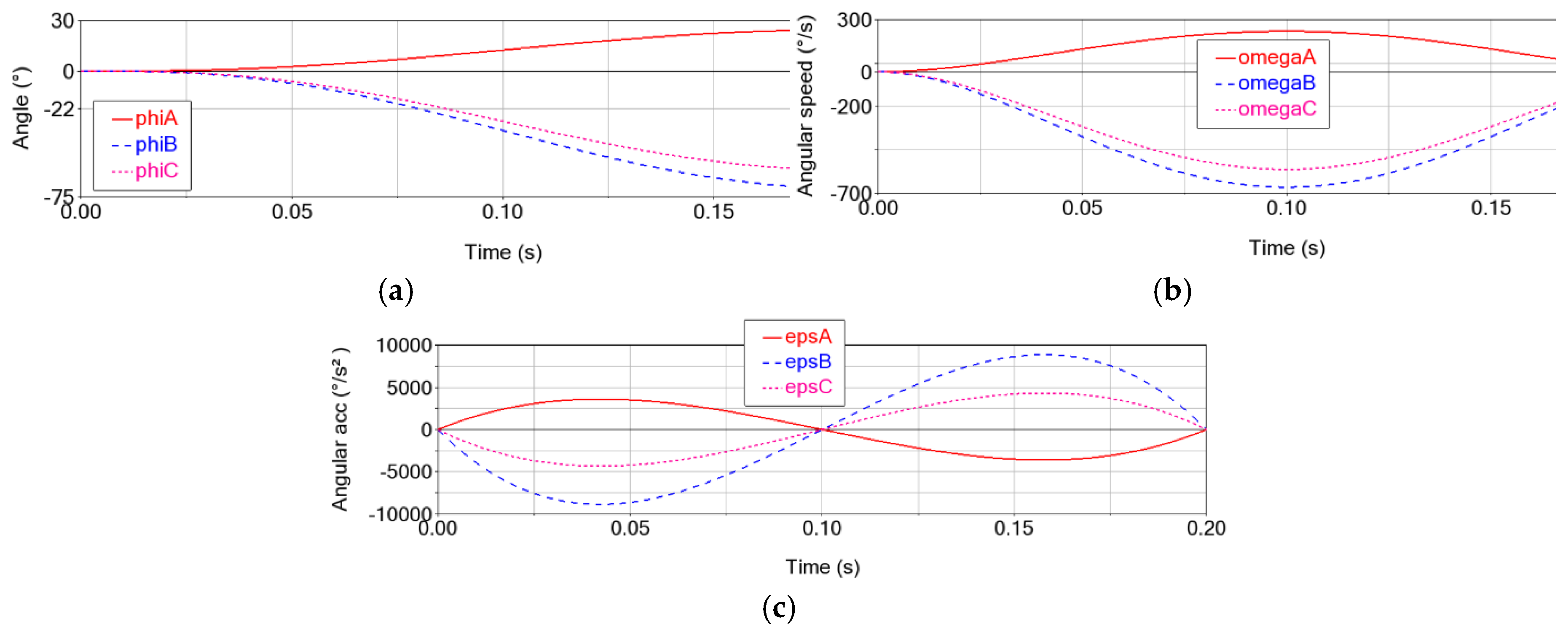

The starting point (P

0) of the Cartesian trajectory corresponds to the robot’s initial position where all three active motor joints (RA, RB, and RC) are in the zero position, and the motor elements are arranged in the same horizontal plane (parallel to X

0Y

0),

Figure 2. The trajectory P

0P

1 is a spatial curve obtained by applying an angular displacement of 25° in joint RA, −70° in joint RB, and −60° in joint RC (

Figure 3a). Along this trajectory, the maximum values of linear speed (8 m/s) and acceleration (120 m/s

2) are reached, which are ensured by commanding angular speeds of 242°/s in RA, 554°/s in RB, and 656°/s in RC (

Figure 3b), as well as angular accelerations of 3003°/s

2 (RA), 8824°/s

2 (RB), and 4123°/s

2 (RC), as shown in

Figure 3c.

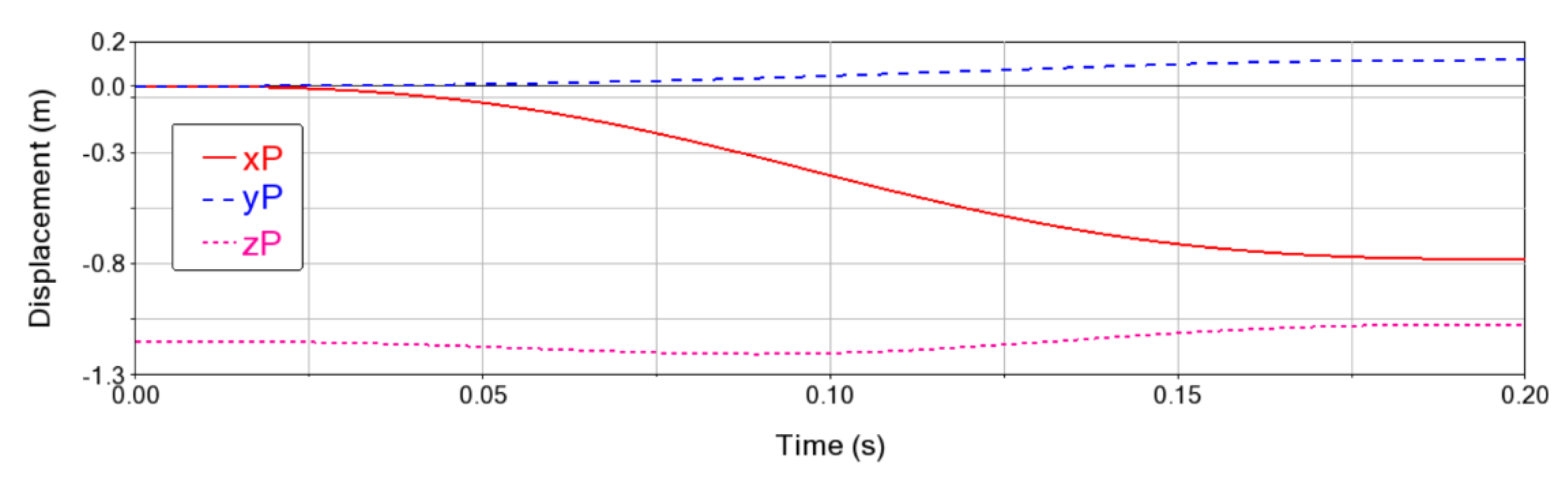

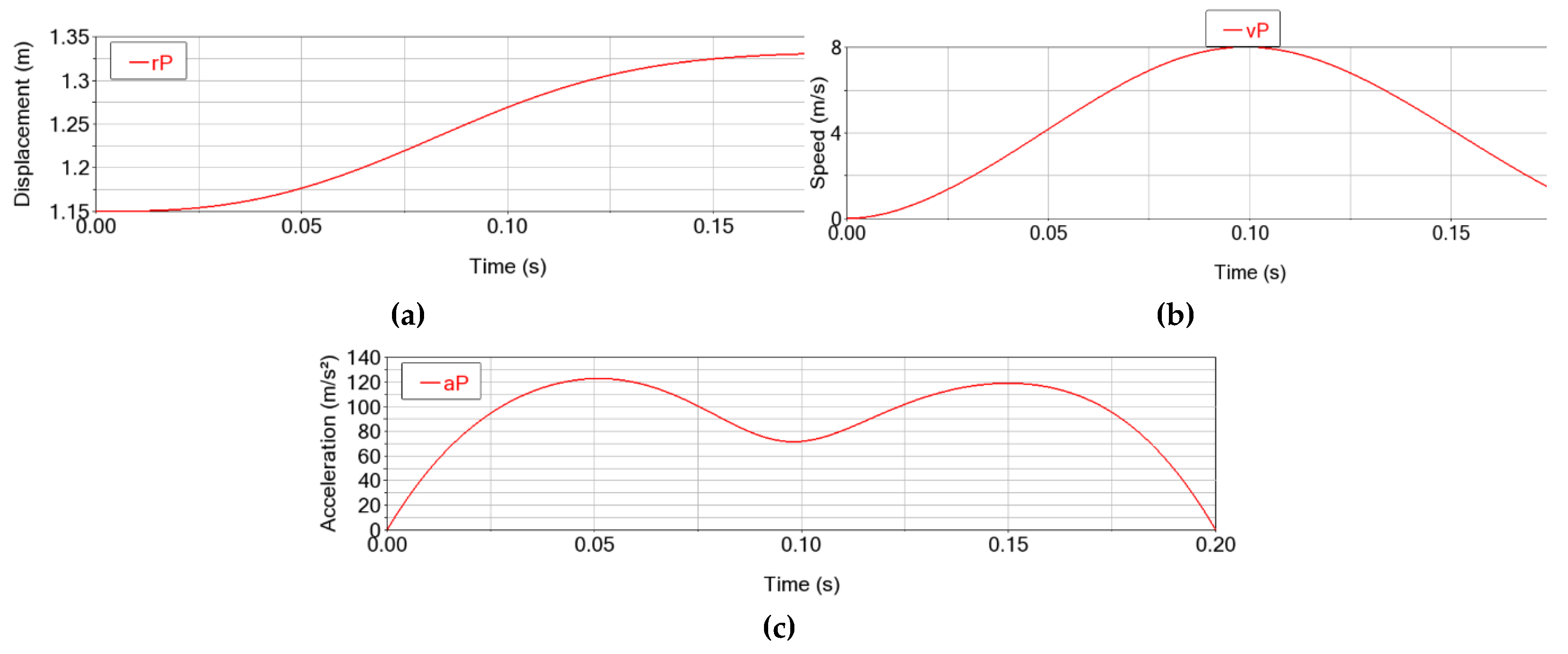

The Cartesian trajectory P

0P

1 (

Figure 2) is obtained by applying a fifth-degree polynomial motion trajectories in the active joints. This trajectory is characterized by the movement of the characteristic point P along all three axes of the global coordinate system X

0Y

0Z

0 (Fig. 4) and it reaches a final position rP = 1.245 m (

Figure 5a). Also, the point P reaches the maximum speed vPmax = 8 m/s at 0.1 s (

Figure 5b) and the maximum acceleration aPmax = 120 m/s

2 at approximately 0.052 s and 0.158 s (

Figure 5c).

Figure 4.

The end-effector’s displacement projected onto the axes of the global coordinate system O0X0Y0Z0.

Figure 4.

The end-effector’s displacement projected onto the axes of the global coordinate system O0X0Y0Z0.

Figure 5.

The motion of the Delta parallel robot end-effector: (a) displacement; (b) speed and (c) acceleration.

Figure 5.

The motion of the Delta parallel robot end-effector: (a) displacement; (b) speed and (c) acceleration.

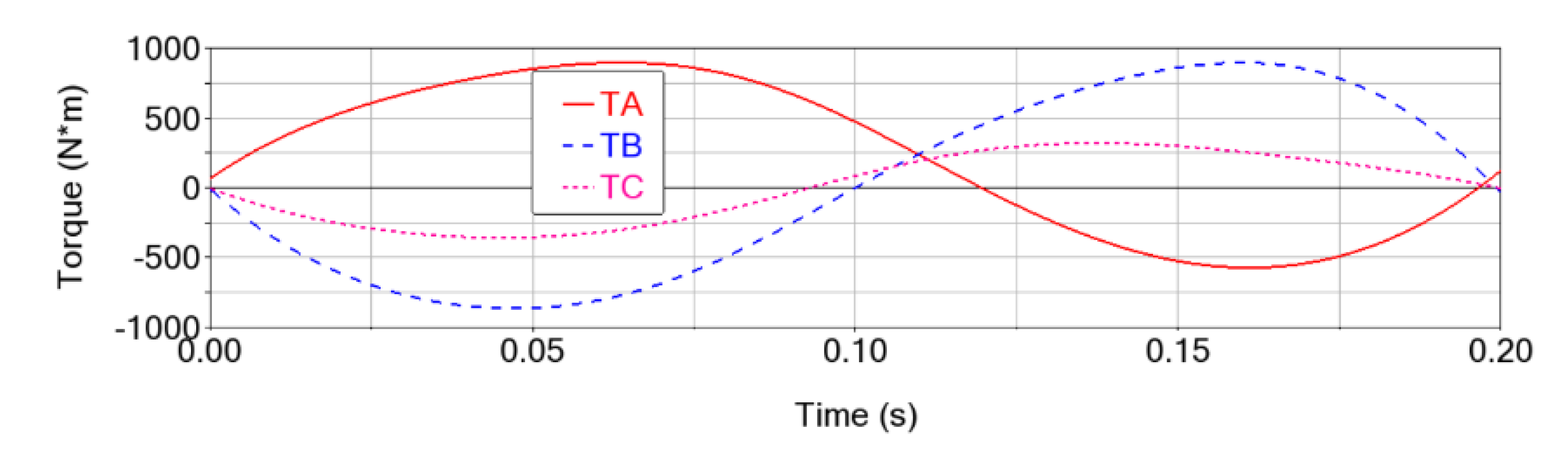

The torques in the active joints along the mentioned trajectory (

Figure 6) have a profile like the angular acceleration (see

Figure 3c); higher values are observed for torques TA and TB (up to 898 N⋅m) due to higher angular accelerations (and consequently higher angular speeds and displacements) compared to torque TC (up to 358 N⋅m).

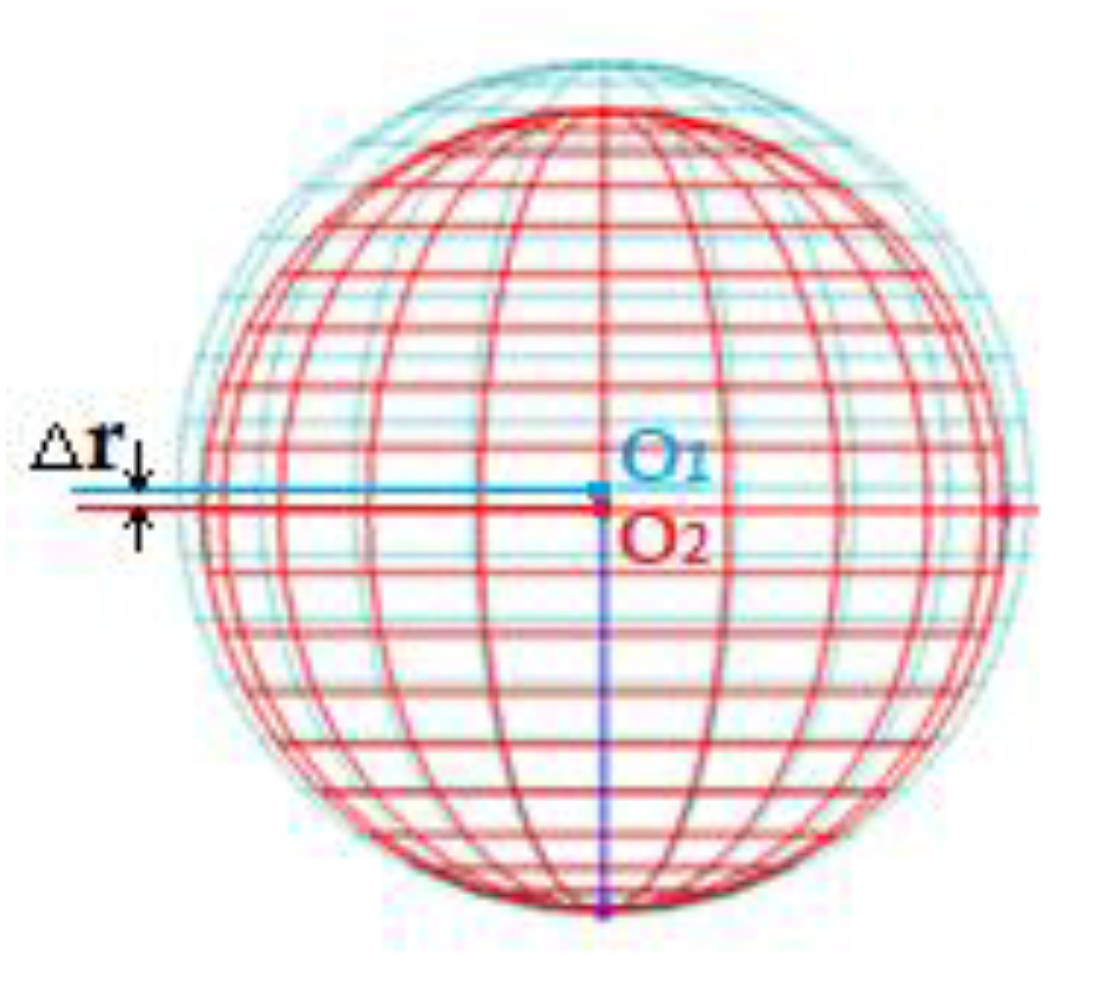

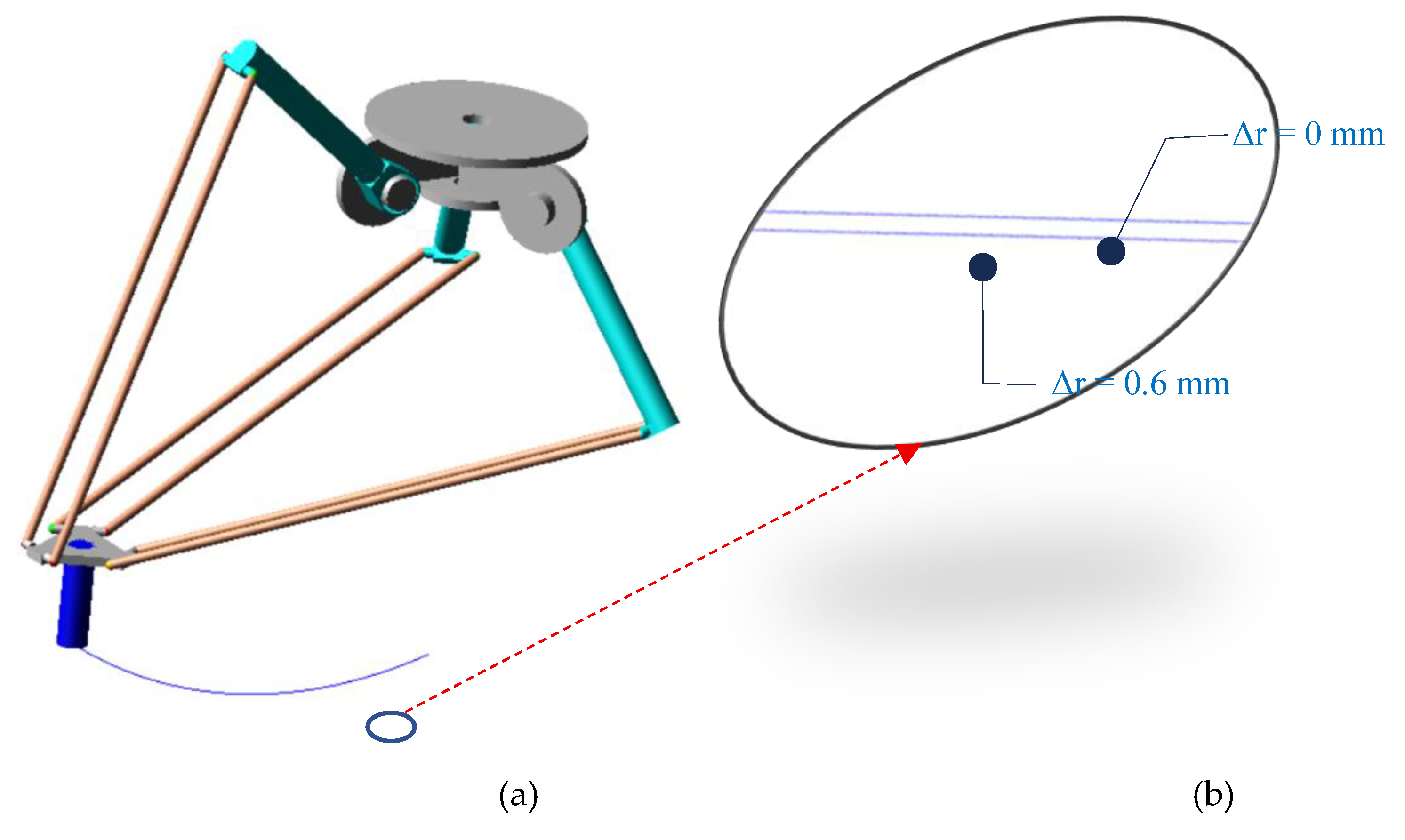

The dynamic influence of the spherical joint clearances is analyzed considering the set of values Δr = [0.1, 0.2, 0.3, 0.4, 0.5, 0.6] mm, defined as the distance between the centers of the spheres (O

1 and O

2) (

Figure 7).

Next, the numerical results obtained in three scenarios are presented and discussed: clearances only in the upper joints (&3.1), only in the lower ones (&3.2) and in both categories of spherical joints (&3.3).

3.1. Analysis of the Kinematic and Dynamic Errors of the Delta Parallel Robot with Clearances in the Upper Spherical Joints

The first case considers clearances in the upper spherical joints, analyzing the influence of clearances in the upper spherical joints, with values between 0.1 mm and 0.6 mm, on the kinematic and dynamic behavior of the Delta parallel robot.

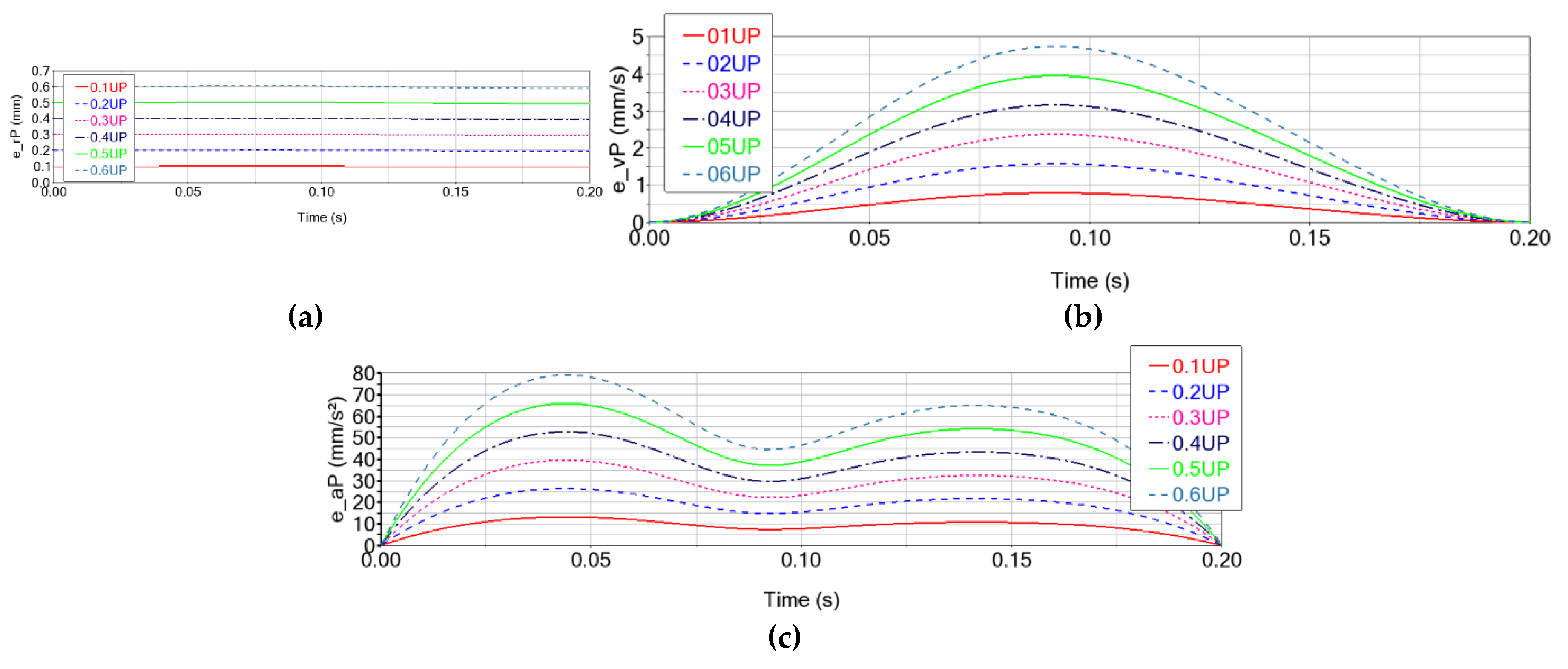

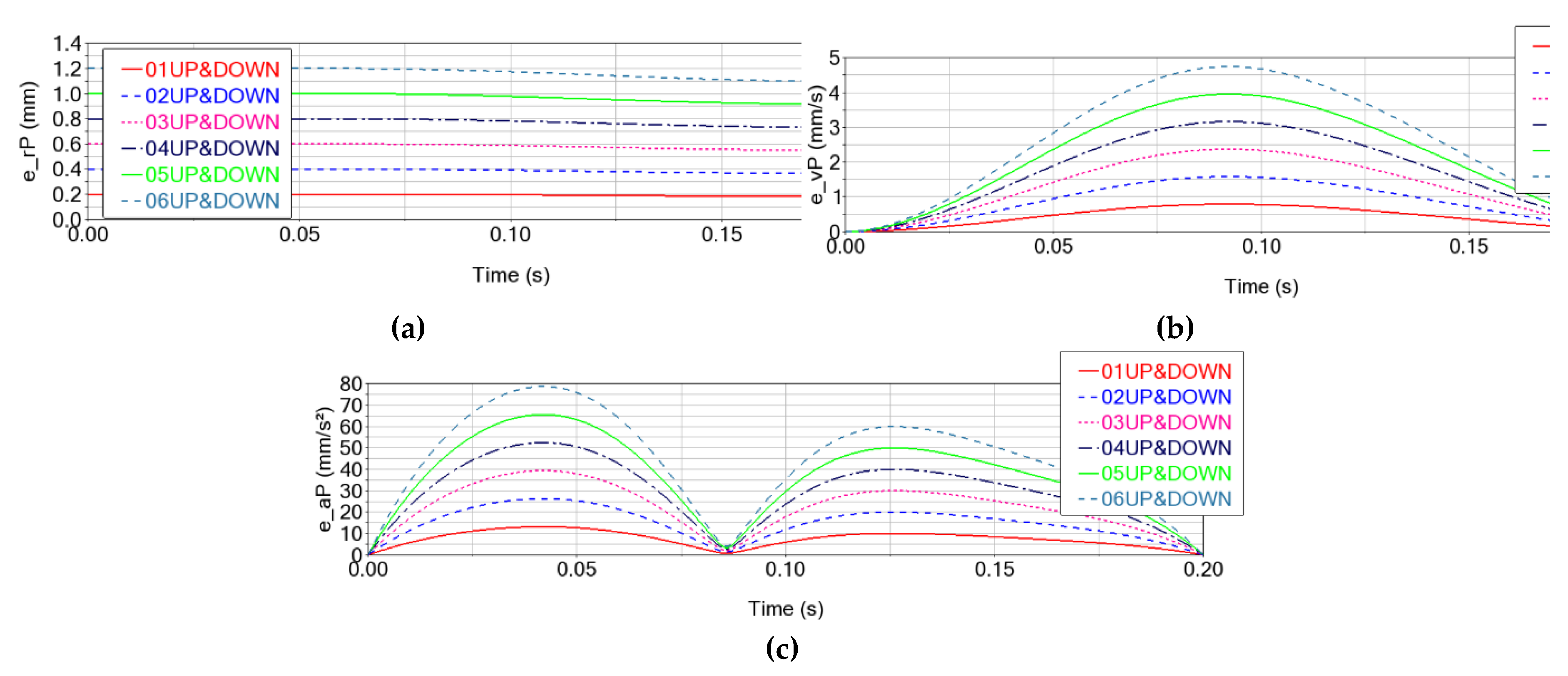

For Δr = [0.1, 0.6] mm in the upper spherical joints, the errors on the end-effector trajectory record values of up to 0.0147 mm for displacements, up to 4.744 mm/s for speeds, and 79.204 mm/s

2 for accelerations (

Figure 8 and

Table 2).

As depicted in

Figure 8, an increase in trajectory errors can be observed as the clearance increases, but the variation shape is maintained.

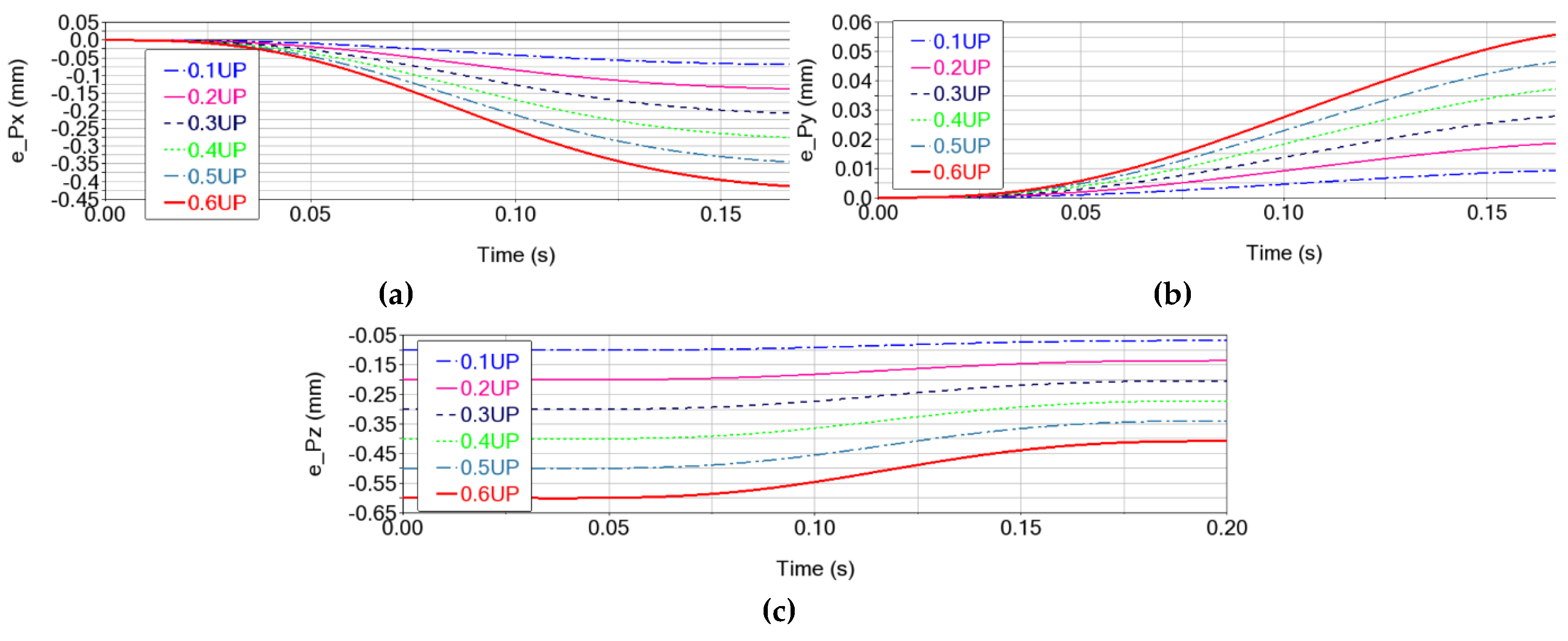

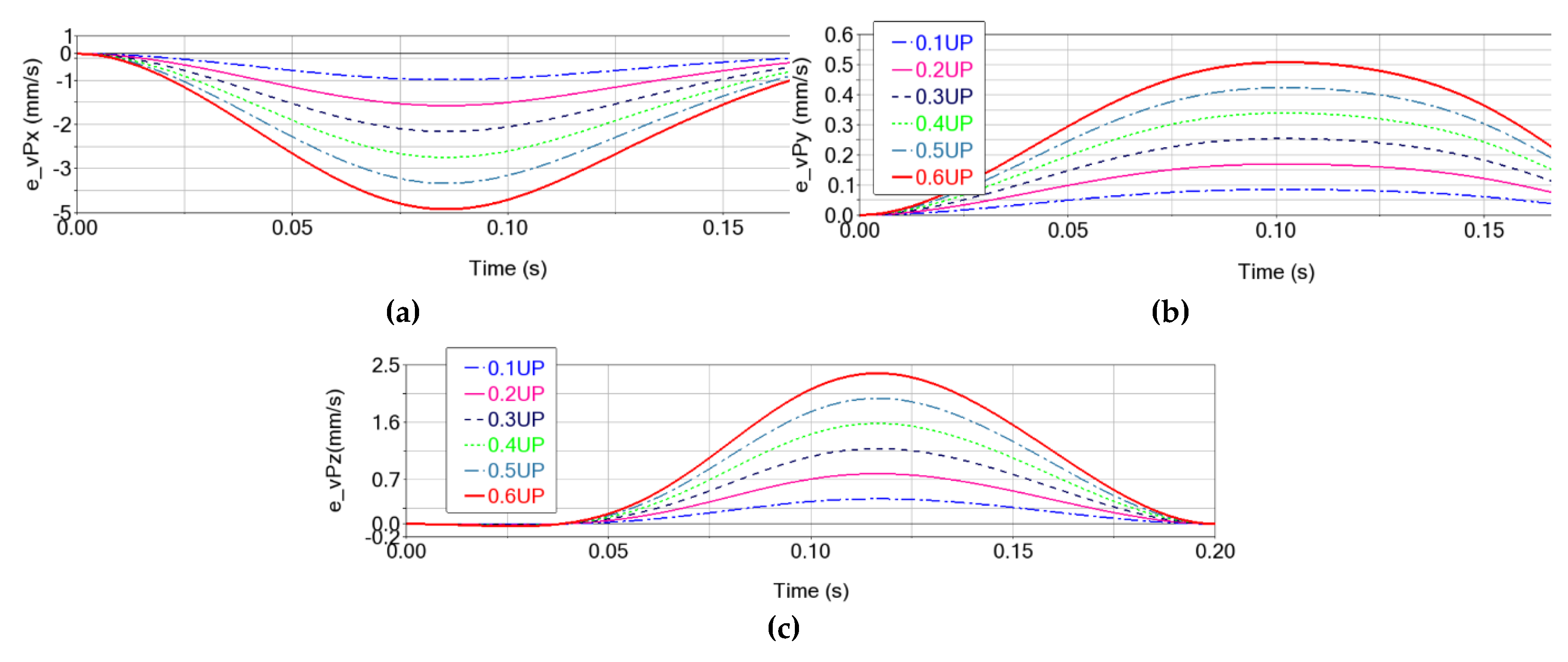

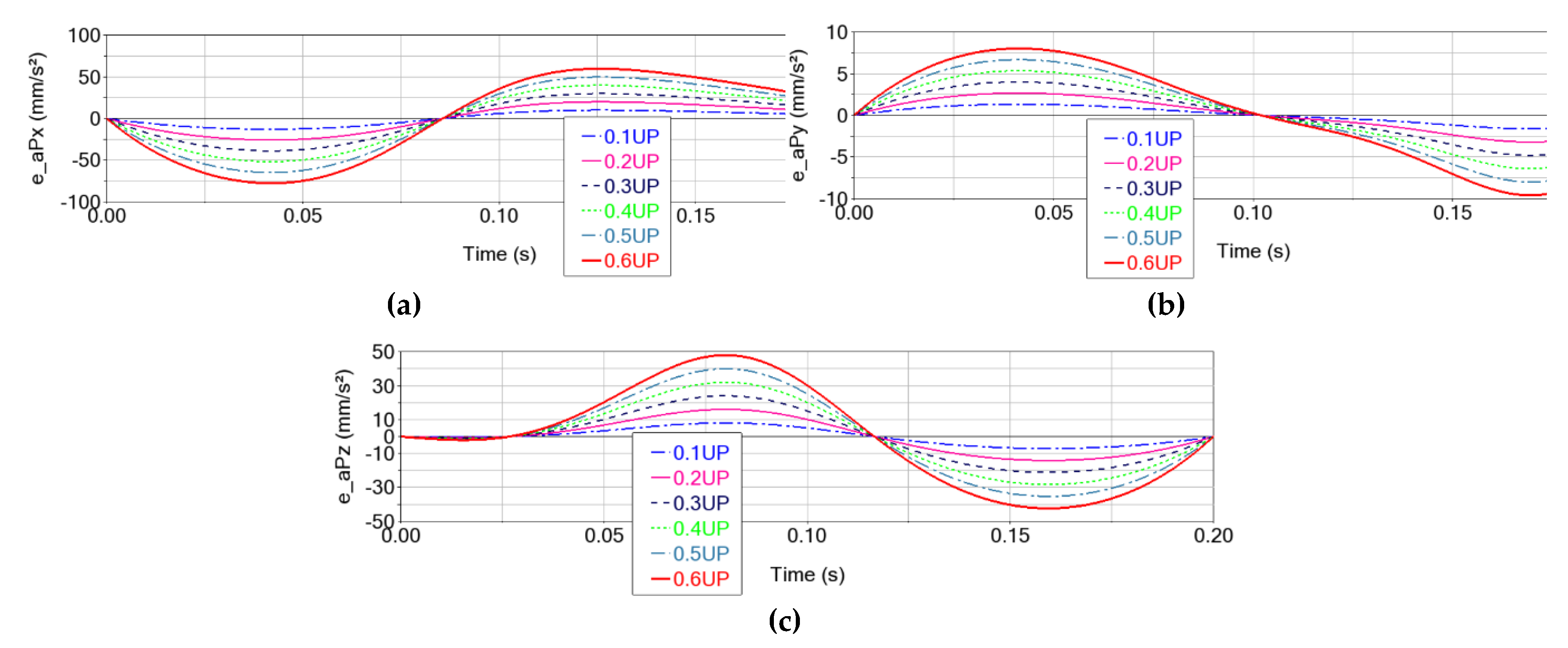

In addition to the resultant errors in 3D space, graphically represented in

Figure 8, the components of these errors along the three axes (X, Y, and Z) are further analyzed for displacements (

Figure 9), speeds (

Figure 10), and accelerations (

Figure 11). Thus, it can be remarked that errors are recorded on all three axes: a) they start from 0 for the X and Y axes, and have a value equal to the clearance for the Z axis; b) the errors increase as the clearances increase; c) the errors change over time (increase/decrease) following shapes similar to those recorded by the movement of the characteristic point P: as the absolute values of the kinematic parameters increase, the errors of these parameters also increase.

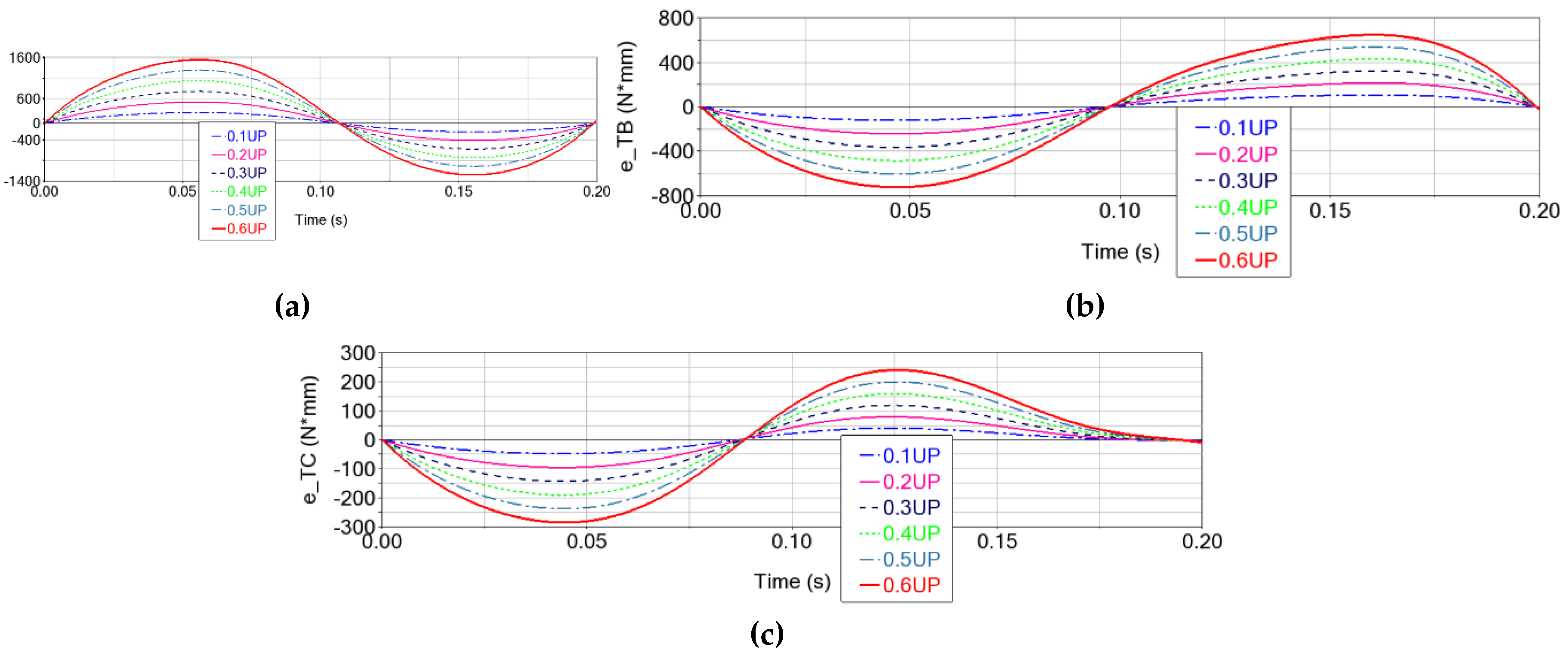

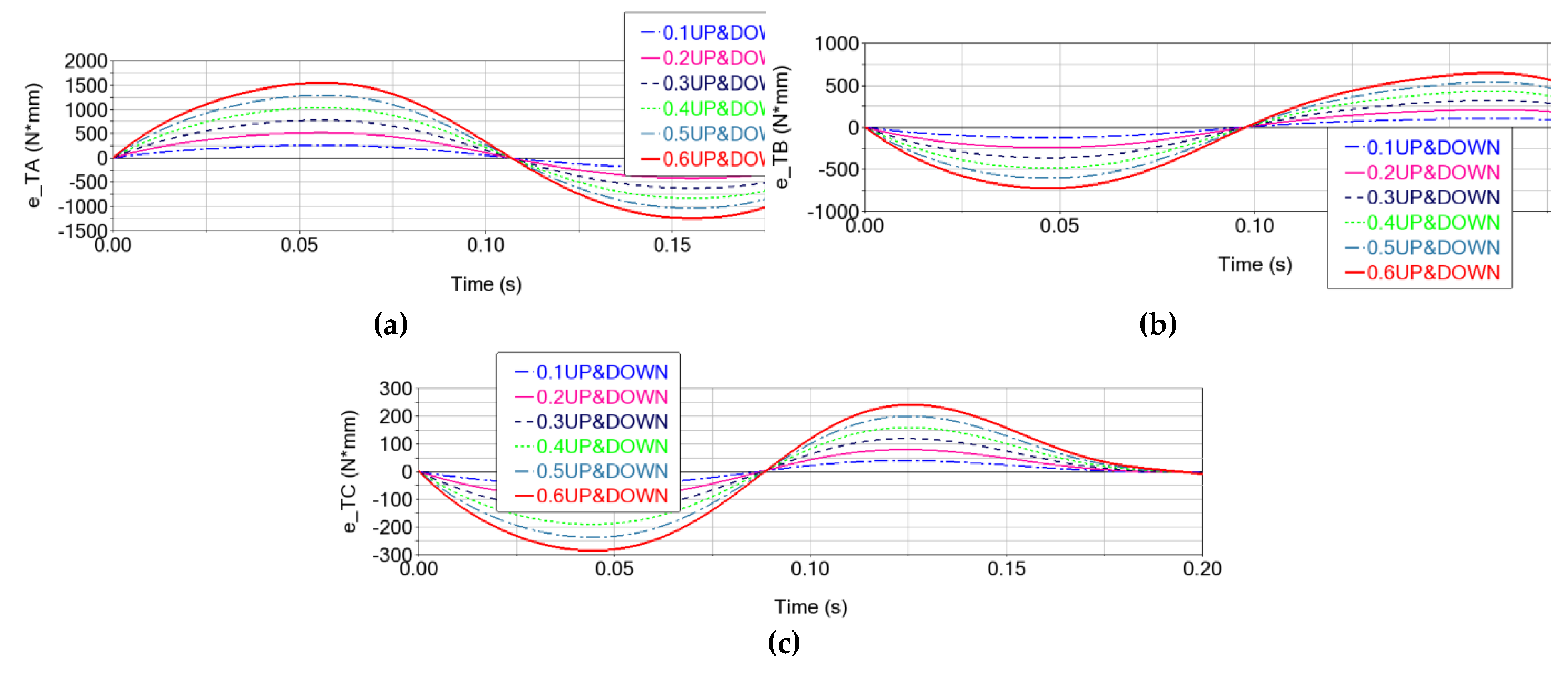

The motor torques are influenced by the clearances in the upper spherical joints, which record increasing errors as the joint clearance increases, up to 0.16% as can be observed in

Figure 12 and

Table 3. In conclusion, the motor torque errors tend to increase in absolute value as the clearances increase, with an approximately linear dependence on the clearances in the motor joints.

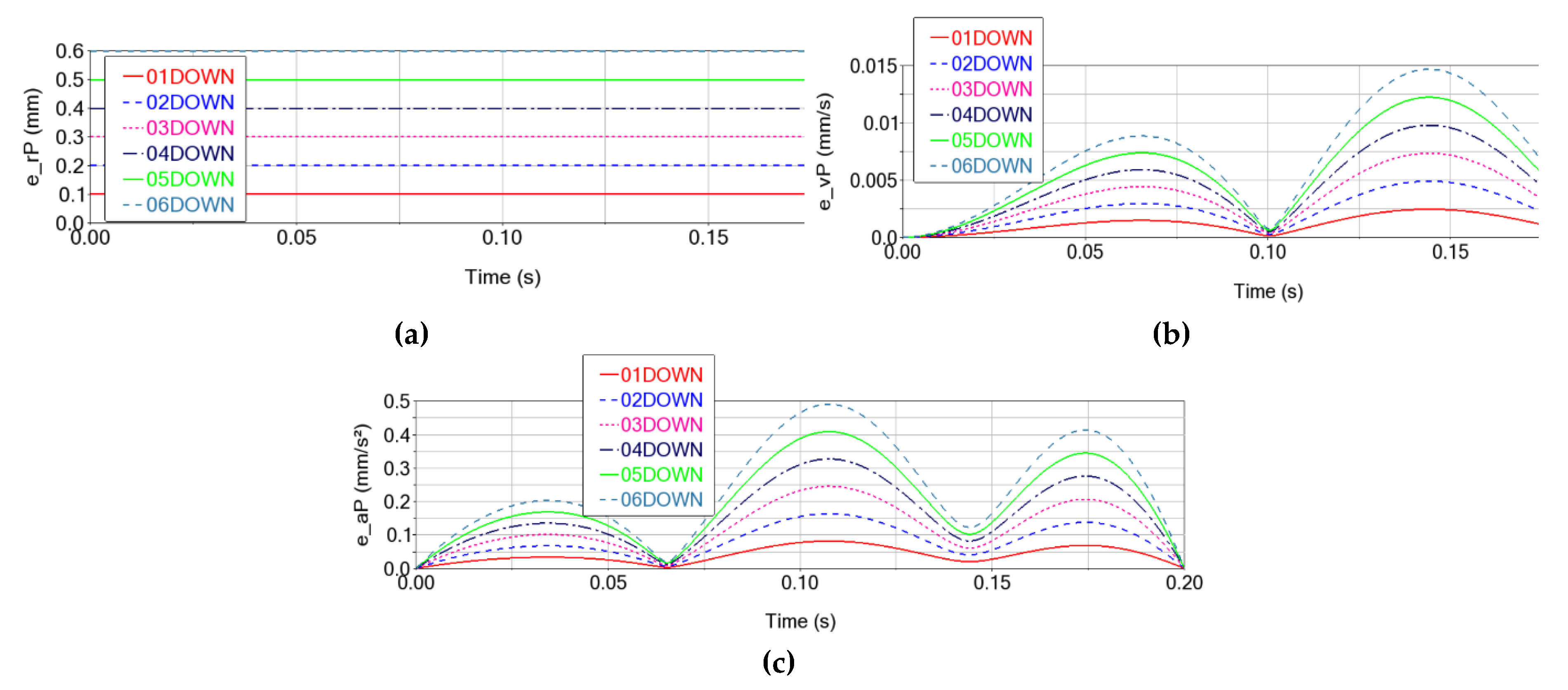

3.2. Analysis of the Kinematic and Dynamic Errors of the Delta Parallel Robot with Clearances in the Lower Spherical Joints

Like the approach in section 3.1, the influence of the clearance in the lower spherical joints of the Delta parallel robot is analyzed, assuming zero clearance in the upper spherical joints and considering the same set of clearance values of 0.1 mm, 0.2 mm, 0.3 mm, 0.4 mm, 0.5 mm and 0.6 mm.

The numerical simulation results reveal a quasi-constant displacement error of the characteristic point P, which does not exceed the initial clearance value (

Figure 13a), the end-effector trajectory in this case being practically parallel to the commanded one at a quasi-constant distance along the z axis equal to the clearance (

Figure 14). The speed and acceleration errors (

Figure 13b and c) increase as the clearance increases, with a curve profile similar to the error curves, but are significantly smaller than in the case of clearances in the upper joints (∼300 times smaller for speeds and ∼150 times smaller for accelerations, see

Table 4 vs

Table 2).

The torque errors (

Figure 15) have relatively small values, up to a maximum of ∼1.47 N⋅mm for active joint RB, which practically generate insignificant variations in motor torques (max. 0.000163%). The effect of increasing torque errors as the clearance in the lower joints increases remains valid in this case as well, with maximum values of ∼0.45 N⋅mm for TA, ∼1.47 N⋅mm for TB, and ∼0.98 N⋅mm for TC (for 0.6 mm clearances, see

Table 5).

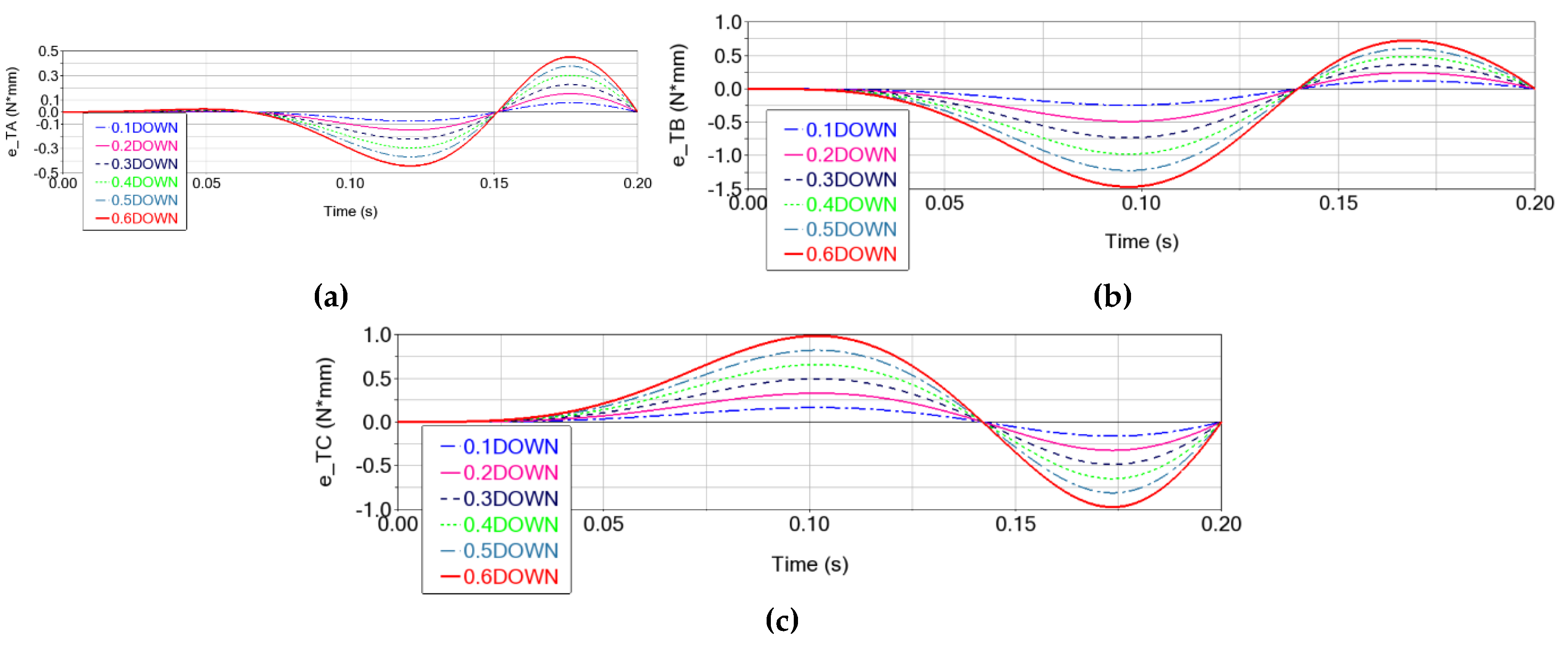

3.3. Analysis of the Kinematic and Dynamic Errors of the Delta Parallel Robot with Clearances in the Upper and Lower Spherical Joints

In this scenario, the cumulative case of clearances in both the upper and lower spherical joints is considered, with values in the interval [0.1, 0.6] mm, considering identical values in all spherical joints of the Delta robot.

Thus, the displacement errors of the characteristic point P (

Figure 16a) record double the clearance value at the beginning of the trajectory, because of the accumulation of clearances from upper and lower spherical joints. These initial values slightly reduce along with the trajectory, with deviations smaller than ∼0.11 mm (in the case of 0.6 mm clearance,

Table 6). The maximum values of the displacement errors (

Table 6) increase as the clearance in the spherical joints increases, with the impact of the clearance in the upper spherical joints being predominant.

The speed error of the characteristic point P (

Figure 16b) has a curve profile like the one obtained in the case of clearances in the upper joints (

Section 3.1), reaching a maximum of ∼4.75 mm/s for the 0.6 mm clearance case. Similarly, the acceleration errors on the trajectory (

Figure 16c) increase as the joint clearance increases, reaching a maximum of ∼79 mm/s

2 (for the 0.6 mm clearance).

The motor torque errors in this scenario are presented in

Figure 17, and the maximum values in

Table 7. Thus, a maximum value of ∼1549 N⋅mm is reached in motor joint RA, for the 0.6 mm clearance. Since the major contribution is due to clearances in the upper joints, the shape of the torque error curves is similar to that presented in

Section 3.1,

Figure 12.

As can be observed from both

Figure 17 (time evolution of errors) and

Table 7 (maximum values), the torque errors increase as the clearances increase, with amplitude variations that progressively increase with the value of the clearance in the Delta robot’s spherical joints.

As with motion errors, the dynamic behavior is predominantly influenced by the clearances in the upper spherical joints, the influence of clearances in the lower joints being practically insignificant. For this reason, the non-linear coupling effect of clearances in the upper spherical joints with those in the lower ones is diminished to negligible values. Thus, the kinematic and dynamic errors in this case of combining clearances from all spherical joints can be acceptably approximated by the sum of the errors obtained in the scenarios from

Section 3.1 and, respectively,

Section 3.2.

Figure 1.

Parameterization of the Delta parallel robot: (a) 3D view; (b) top view; (c) fixed base; (d) mobile platform.

Figure 1.

Parameterization of the Delta parallel robot: (a) 3D view; (b) top view; (c) fixed base; (d) mobile platform.

Figure 2.

The Cartezian trajectory of the Delta parallel robot: (a) the initial position; (b) the final position.

Figure 2.

The Cartezian trajectory of the Delta parallel robot: (a) the initial position; (b) the final position.

Figure 3.

The motion trajectories in the joint space of the active joints (RA, RB, and RC): (a) angular displacement; (b) angular speed and (c) angular acceleration.

Figure 3.

The motion trajectories in the joint space of the active joints (RA, RB, and RC): (a) angular displacement; (b) angular speed and (c) angular acceleration.

Figure 6.

The motor torques (TA, TB and TC) on the considered trajectory for the Delta parallel robot without clearances.

Figure 6.

The motor torques (TA, TB and TC) on the considered trajectory for the Delta parallel robot without clearances.

Figure 7.

The clearance in the spherical joints of the Delta parallel robot in the initial position.

Figure 7.

The clearance in the spherical joints of the Delta parallel robot in the initial position.

Figure 8.

Motion errors of the end-effector (point P) in the case of clearances in the upper spherical joints of 0.1 mm (red, solid line), 0.2 mm (blue, dash line), 0.3 mm (magenta, dot line), 0.4 mm (midnight_blue DotDash line), 0.5 mm (green, solid line) and 0.6 mm (blue gray, DotDash line), for: (a) displacement; (b) speed and (c) acceleration.

Figure 8.

Motion errors of the end-effector (point P) in the case of clearances in the upper spherical joints of 0.1 mm (red, solid line), 0.2 mm (blue, dash line), 0.3 mm (magenta, dot line), 0.4 mm (midnight_blue DotDash line), 0.5 mm (green, solid line) and 0.6 mm (blue gray, DotDash line), for: (a) displacement; (b) speed and (c) acceleration.

Figure 9.

The displacement error of the characteristic point P in the case of clearances in the upper spherical joints of 0.1 mm (blue, dotdash line), 0.2 mm (magenta, solid line), 0.3 mm (midnight_blue, dash line), 0.4 mm (green, dot line), 0.5 mm (blue gray, dotdash line) and 0.6 mm (red, solid line), on: (a) the X axis; (b) the Y axis and (c) the Z axis.

Figure 9.

The displacement error of the characteristic point P in the case of clearances in the upper spherical joints of 0.1 mm (blue, dotdash line), 0.2 mm (magenta, solid line), 0.3 mm (midnight_blue, dash line), 0.4 mm (green, dot line), 0.5 mm (blue gray, dotdash line) and 0.6 mm (red, solid line), on: (a) the X axis; (b) the Y axis and (c) the Z axis.

Figure 10.

The speed error of the characteristic point P in the case of clearances in the upper spherical joints of 0.1 mm (blue, dotdash line), 0.2 mm (magenta, solid line), 0.3 mm (midnight_blue, dash line), 0.4 mm (green, dot line), 0.5 mm (blue gray, dotdash line) and 0.6 mm (red, solid line), on: (a) the X axis; (b) the Y axis and (c) the Z axis.

Figure 10.

The speed error of the characteristic point P in the case of clearances in the upper spherical joints of 0.1 mm (blue, dotdash line), 0.2 mm (magenta, solid line), 0.3 mm (midnight_blue, dash line), 0.4 mm (green, dot line), 0.5 mm (blue gray, dotdash line) and 0.6 mm (red, solid line), on: (a) the X axis; (b) the Y axis and (c) the Z axis.

Figure 11.

The acceleration error of the characteristic point P in the case of clearances in the upper spherical joints of 0.1 mm (blue, dotdash line), 0.2 mm (magenta, solid line), 0.3 mm (midnight_blue, dash line), 0.4 mm (green, dot line), 0.5 mm (blue gray, dotdash line) and 0.6 mm (red, solid line), on: (a) the X axis; (b) the Y axis and (c) the Z axis.

Figure 11.

The acceleration error of the characteristic point P in the case of clearances in the upper spherical joints of 0.1 mm (blue, dotdash line), 0.2 mm (magenta, solid line), 0.3 mm (midnight_blue, dash line), 0.4 mm (green, dot line), 0.5 mm (blue gray, dotdash line) and 0.6 mm (red, solid line), on: (a) the X axis; (b) the Y axis and (c) the Z axis.

Figure 12.

The motor torque error in the case of clearances in the upper spherical joints with values of 0.1 mm (red, solid line), 0.2 mm (blue, dash line), 0.3 mm (magenta, dot line), 0.4 mm (midnight_blue DotDash line), 0.5 mm (green, solid line) and 0.6 mm (blue gray, DotDash line), for: (a) arm A; (b) arm B and (c) arm C.

Figure 12.

The motor torque error in the case of clearances in the upper spherical joints with values of 0.1 mm (red, solid line), 0.2 mm (blue, dash line), 0.3 mm (magenta, dot line), 0.4 mm (midnight_blue DotDash line), 0.5 mm (green, solid line) and 0.6 mm (blue gray, DotDash line), for: (a) arm A; (b) arm B and (c) arm C.

Figure 13.

The error of the characteristic point P motions in the case of clearances in the lower spherical joints of 0.1 mm (red, solid line), 0.2 mm (blue, dash line), 0.3 mm (magenta, dot line), 0.4 mm (midnight_blue DotDash line), 0.5 mm (green, solid line) and 0.6 mm (blue gray, DotDash line), for: (a) displacement; (b) speed and (c) acceleration.

Figure 13.

The error of the characteristic point P motions in the case of clearances in the lower spherical joints of 0.1 mm (red, solid line), 0.2 mm (blue, dash line), 0.3 mm (magenta, dot line), 0.4 mm (midnight_blue DotDash line), 0.5 mm (green, solid line) and 0.6 mm (blue gray, DotDash line), for: (a) displacement; (b) speed and (c) acceleration.

Figure 14.

The Cartesian trajectory of the Delta parallel robot with 0.6 mm clearances in the lower spherical joints: (a) final position; (b) comparative detail of the trajectory with error (Δr = 0.6 mm) vs. the commanded (ideal, Δr = 0 mm) trajectory.

Figure 14.

The Cartesian trajectory of the Delta parallel robot with 0.6 mm clearances in the lower spherical joints: (a) final position; (b) comparative detail of the trajectory with error (Δr = 0.6 mm) vs. the commanded (ideal, Δr = 0 mm) trajectory.

Figure 15.

The motor torque error in the case of clearances in the lower spherical joints with values of 0.1 mm (red, solid line), 0.2 mm (blue, dash line), 0.3 mm (magenta, dot line), 0.4 mm (midnight_blue DotDash line), 0.5 mm (green, solid line) si 0.6 mm (blue gray, DotDash line), for: (a) arm A; (b) arm B and (c) arm C.

Figure 15.

The motor torque error in the case of clearances in the lower spherical joints with values of 0.1 mm (red, solid line), 0.2 mm (blue, dash line), 0.3 mm (magenta, dot line), 0.4 mm (midnight_blue DotDash line), 0.5 mm (green, solid line) si 0.6 mm (blue gray, DotDash line), for: (a) arm A; (b) arm B and (c) arm C.

Figure 16.

The error of the characteristic point P motion in the cumulative case of clearances in the upper and lower spherical joints of 0.1 mm (red, solid line), 0.2 mm (blue, dash line), 0.3 mm (magenta, dot line), 0.4 mm (midnight_blue DotDash line), 0.5 mm (green, solid line), and 0.6 mm (blue gray, DotDash line), for: (a) displacement; (b) speed, (c) acceleration.

Figure 16.

The error of the characteristic point P motion in the cumulative case of clearances in the upper and lower spherical joints of 0.1 mm (red, solid line), 0.2 mm (blue, dash line), 0.3 mm (magenta, dot line), 0.4 mm (midnight_blue DotDash line), 0.5 mm (green, solid line), and 0.6 mm (blue gray, DotDash line), for: (a) displacement; (b) speed, (c) acceleration.

Figure 17.

The motor torque error in the cumulative case of clearances in the upper and lower spherical joints of 0.1 mm (red, solid line), 0.2 mm (blue, dash line), 0.3 mm (magenta, dot line), 0.4 mm (midnight_blue DotDash line), 0.5 mm (green, solid line), and 0.6 mm (blue gray, DotDash line) for: (a) arm A; (b) arm B and (c) arm C.

Figure 17.

The motor torque error in the cumulative case of clearances in the upper and lower spherical joints of 0.1 mm (red, solid line), 0.2 mm (blue, dash line), 0.3 mm (magenta, dot line), 0.4 mm (midnight_blue DotDash line), 0.5 mm (green, solid line), and 0.6 mm (blue gray, DotDash line) for: (a) arm A; (b) arm B and (c) arm C.

Table 1.

Geometric and Mass Details of the Delta Robot Elements [

2].

Table 1.

Geometric and Mass Details of the Delta Robot Elements [

2].

| Element |

Length [mm] |

Diameter

[mm]

|

Mass

[kg]

|

| Fixed platform (0) |

- |

434 |

5 |

| Element (1) |

500 |

62 |

1.6 |

| Element (2) and (3) |

1106 |

20 |

0.34 |

| Mobile platform (4) |

- |

195 |

0.46 |

| Additional mass (5) |

212 |

50 |

5 |

Table 2.

Maximum kinematic errors on the trajectory (absolute values and percentages of the maximum kinematic parameter value) due to clearances in the upper spherical joints of the Delta robot.

Table 2.

Maximum kinematic errors on the trajectory (absolute values and percentages of the maximum kinematic parameter value) due to clearances in the upper spherical joints of the Delta robot.

Jocul

[mm]

|

e_rPmax

[mm]

|

Δe_rPmax

[mm]

|

e_vPmax

[mm/s]

|

e_aPmax

[mm/s2]

|

| 0.1 |

0.1008 |

0.0025 |

0.791 (0.009%) |

13.201 (0.011%) |

| 0.2 |

0.2015 |

0.0049 |

1.581 (0.019%) |

26.402 (0.022%) |

| 0.3 |

0.3023 |

0.0074 |

2.372 (0.029%) |

39.602 (0.033%) |

| 0.4 |

0.4030 |

0.0098 |

3.163 (0.039%) |

52.803 (0.044%) |

| 0.5 |

0.5038 |

0.0123 |

3.953 (0.049%) |

66.004 (0.055%) |

| 0.6 |

0.6045 |

0.0147 |

4.744 (0.059%) |

79.204 (0.066%) |

Table 3.

Maximum dynamic errors on the trajectory (absolute values and percentages of the maximum torque value) due to clearances in the upper spherical joints of the Delta robot.

Table 3.

Maximum dynamic errors on the trajectory (absolute values and percentages of the maximum torque value) due to clearances in the upper spherical joints of the Delta robot.

Clearance

[mm]

|

e_TAmax

[N·mm]

|

e_TBmax

[N·mm]

|

e_TCmax

[N·mm]

|

| 0.1 |

260.0 (0.029%) |

121.6 (0.014%) |

47.7 (0.013%) |

| 0.2 |

519.2 (0.057%) |

243.0 (0.027%) |

95.4 (0.026%) |

| 0.3 |

777.5 (0.086%) |

364.0 (0.040%) |

143.0 (0.039%) |

| 0.4 |

1035.2 (0.115%) |

484.6 (0.053%) |

190.6 (0.053%) |

| 0.5 |

1292.3 (0.144%) |

604.7 (0.067%) |

238.1 (0.066%) |

| 0.6 |

1548.9 (0.172%) |

724.3 (0.080%) |

285.5 (0.079%) |

Table 4.

Maximum kinematic errors on the trajectory (absolute values and percentages of the maximum kinematic parameter value) due to clearances in the lower spherical joints of the Delta robot.

Table 4.

Maximum kinematic errors on the trajectory (absolute values and percentages of the maximum kinematic parameter value) due to clearances in the lower spherical joints of the Delta robot.

Clearance

[mm]

|

e_rPmax

[mm]

|

Δe_rPmax

[mm]

|

e_vPmax

[mm/s]

|

e_aPmax

[mm/s2]

|

| 0.1 |

0.1000 |

0.1·10-9

|

0.0025 (0.000031%) |

0.0819 (0.000068%) |

| 0.2 |

0.2000 |

0.1·10-9

|

0.0049 (0.000061%) |

0.1637 (0.000136%) |

| 0.3 |

0.3000 |

0.1·10-9

|

0.0074 (0.000092%) |

0.2456 (0.000204%) |

| 0.4 |

0.4000 |

0.1·10-9

|

0.0098 (0.000122%) |

0.3274 (0.000272%) |

| 0.5 |

0.5000 |

0.1·10-9

|

0.0123 (0.000153%) |

0.4093 (0.000341%) |

| 0.6 |

0.6000 |

0.1·10-9

|

0.0147 (0.000183%) |

0.4911 (0.000409%) |

Table 5.

Maximum dynamic errors on the trajectory (absolute values and percentages of the maximum kinematic parameter value) due to clearances in the lower spherical joints of the Delta robot.

Table 5.

Maximum dynamic errors on the trajectory (absolute values and percentages of the maximum kinematic parameter value) due to clearances in the lower spherical joints of the Delta robot.

Clearance

[mm]

|

e_TAmax

[N·mm]

|

e_TBmax

[N·mm]

|

e_TCmax

[N·mm]

|

| 0.1 |

0.0754 (0.0000083%) |

0.2448 (0.0000272%) |

0.1644 (0.0000459%) |

| 0.2 |

0.1509 (0.0000168%) |

0.4896 (0.0000545%) |

0.3289 (0.0000918%) |

| 0.3 |

0.2209 (0.0000245%) |

0.7344 (0.0000817%) |

0.4933 (0.0000137%) |

| 0.4 |

0.3018 (0.0000336%) |

0.9792 (0.000109%) |

0.6578 (0.0000183%) |

| 0.5 |

0.3772 (0.0000420%) |

1.2240 (0.000136%) |

0.8222 (0.0000229%) |

| 0.6 |

0.4526 (0.0000504%) |

1.4687 (0.000163%) |

0.9867 (0.0000275%) |

Table 6.

Maximum kinematic errors on the trajectory (absolute values and percentages of the maximum kinematic parameter value) due to clearances in the upper and lower spherical joints of the Delta robot.

Table 6.

Maximum kinematic errors on the trajectory (absolute values and percentages of the maximum kinematic parameter value) due to clearances in the upper and lower spherical joints of the Delta robot.

Clearance

[mm]

|

e_rPmax

[mm]

|

Δe_rPmax

[mm]

|

e_vPmax

[mm/s]

|

e_aPmax

[mm/s2]

|

| 0.1 |

0.200 |

0.018 |

0.791 (0.009%) |

13.117 (0.0109%) |

| 0.2 |

0.400 |

0.036 |

1.582 (0.019%) |

26.234 (0.0218%) |

| 0.3 |

0.600 |

0.053 |

2.372 (0.029%) |

39.351 (0.0327%) |

| 0.4 |

0.800 |

0.071 |

3.163 (0.039%) |

52.468 (0.0437%) |

| 0.5 |

1.001 |

0.089 |

3.954 (0.049%) |

65.585 (0.0546%) |

| 0.6 |

1.201 |

0.107 |

4.745 (0.059%) |

78.702 (0.0655%) |

Table 7.

Maximum dynamic errors on the trajectory (absolute values and percentages of the maximum kinematic parameter value) due to clearances in the upper and lower spherical joints of the Delta robot.

Table 7.

Maximum dynamic errors on the trajectory (absolute values and percentages of the maximum kinematic parameter value) due to clearances in the upper and lower spherical joints of the Delta robot.

Clearance

[mm]

|

e_TAmax

[N·mm]

|

e_TBmax

[N·mm]

|

e_TCmax

[N·mm]

|

| 0.1 |

260.089 (0.029%) |

121.704 (0.013%) |

47.682 (0.013%) |

| 0.2 |

519.164 (0.057%) |

243.113 (0.027%) |

95.3467 (0.026%) |

| 0.3 |

777.530 (0.086%) |

364.170 (0.040%) |

142.967 (0.039%) |

| 0.4 |

1035.208 (0.115%) |

484.818 (0.053%) |

190.523 (0.053%) |

| 0.5 |

1292.324 (0.144%) |

605.001 (0.067%) |

237.985 (0.066%) |

| 0.6 |

1548.976 (0.172%) |

724.655 (0.080%) |

285.324 (0.079%) |