1. Introduction

Bituminous pavement proves excellent structural and functional characteristics, including load-bearing capacity and smoothness [

1,

2]. Furthermore, the construction may be executed without interrupting air service during the pavement resurfacing phase, and the prompt rectification of pavement defects during the operational stage can be accomplished for the bituminous pavement. This is a considerable benefit on concrete pavement and is crucial for airports, which frequently require continuous servicing for air traffic [

3].

In the contemporary world, where distances between nations are swiftly diminishing and time is regarded as the most precious resource, both freight and passenger transportation hold significant importance [

4]. Products have transcended local markets to reach global markets, and individuals' leisure and business travels have extended to intercontinental scales. Individuals are opting for the swiftest, most convenient, and least hazardous modes of transportation. This has resulted in a rise in the frequency of flights and the dimensions of aircraft fuselages. This circumstance has heightened the significance of airports. Airport runways are intended to be durable, providing a temporal advantage over financial considerations in maintenance and repair [

5]. Aircraft mobility areas at airports are comprised of either flexible or rigid pavement [

6]. While the basic design, construction, and maintenance of airport pavements resemble that of roadways, the design traffic of airplanes requires higher performance standards [

7]. This is due to airplanes being heavier, possessing high tire pressures, being more sensitive to pavement surface irregularities, and potentially incurring severe damage to delicate aircraft engines from loose stones [

8]. This leads to a delayed adoption of new technology, including the integration of recycled materials. Nevertheless, considerable movement exists among many governments to diminish and repurpose garbage for environmental sustainability, with instances of policies explicitly advocating for the incorporation of recycled materials in pavements [

9,

10,

11]. Therefore, it is essential to comprehend the efficacy of recycled materials in airport pavements and their total sustainability advantages [

11,

12].

Remarkably, most of the pavement inventory at airports is flexible, with all surfaces being bituminous [

13]. Airport bituminous surface options typically consist of hot or warm mixed asphalt, sprayed seals, and micro-surfacing [

4,

14,

15]. Each bituminous surface type presents distinct financial and environmental costs, along with various advantages and disadvantages [

14]. All runway surfaces must comply with the performance standards established by international regulations for airport pavements.

In the middle of the 1900s, Germany was the birthplace of stone mastic asphalt, which is a mixture that is formed from a design that contains a large amount of bitumen and coarse aggregate. Alternatively, when combined with hot mastic asphalt (HMA); stone mastic asphalt (SMA), which is a gap-graded mix consisting of 75–80 percent coarse aggregate, 8–12 percent filler, and more than 6 percent binder, offers greater durability, load distribution, and resistance to rutting [

16,

17,

18,

19]. This entails iterative modifications of aggregate gradation to reduce binder content while preserving essential porosity and voids in mineral aggregate (VMA) [

20]. Deformations appear at airports typically take place on the surface layer, which is where SMA mostly operates [

21,

22]. Based to its unique structure, this bituminous mixture has outstanding pavement performances. Its resistance to deformation is provided by the stone-on-stone contact skeleton, and its durability is assured by the high binder concentration [

23,

24]. Superior resistance to rutting, improved resistance to reflecting fractures, enhanced sliding resistance, and reduced noise pollution are some of the benefits of this asphalt mixture over more traditional mixes [

25,

26]. SMA, typically utilized as a wearing course, is excluded from the criteria of the Federal Aviation Administration (FAA) in the United States and the General Directorate of Infrastructure Investments of Turkey's Ministry of Transportation and Infrastructure. In the majority of nations having stone mastic asphalt specifications, as well as in the Highway Technical Specifications, there are no stipulated limits on Marshall stability or flow values for stone mastic asphalt.

The Marshall design method is applicable to tightly graded hot mixes comprising aggregates with particle sizes less than 25 mm. Performance-indicated bitumen serves as the bitumen. This approach has also been modified for stone mastic asphalt configurations [

27]. The Marshall design is utilized in both laboratory mix designs and for quality assurance in asphalt pavements. Most airport pavements are designed using the Marshall design process, which is widely used all around the world. The ideal bitumen content for a single aggregate gradation is determined by testing different asphalt contents for different volumetric and durability parameters. Three identical compacted samples are used to average the test results. According to Manual Series-2 (2014), engineers must use their best judgment when considering traffic, weather, and local materials when deciding on the ideal bitumen content [

28].

Airports rely on grooved densely graded asphalt (DGA) to fulfill skid resistance and friction standards. This gradation promotes water runoff and improves friction; however, it also entails drawbacks including gutter blockage, maintenance requirements, and associated costs. SMA is recognized as a viable alternative due to its coarser grain size and resistance to rutting, enabling it to achieve the necessary skid resistance without the need for grooving. The research evaluated the performance of non-grooved SMA in two nominal sizes, 10 mm and 14 mm, utilizing various aggregate sources to determine compliance with the performance criteria established for Australian airport asphalt. The findings indicate that SMA may reduce or eliminate the necessity for grooves, potentially lowering maintenance costs, decreasing the risk of gutter closure, and simplifying surface maintenance [

29].

Another pilot research investigated whether SMA might be used on a non-grooved runway surface instead of the more customary DGA, which is usually grooved, to meet wet-weather skid resistance standards. The goal was to evaluate whether SMA's material qualities would give the required safety performance without the need for grooves. The study findings showed that this gradation is compatible with SMA. Furthermore, with DGA, compliance is often delayed until the grooves open, which can take up to 4-8 weeks following installation. SMA thus provides operational advantages [

30].

Thermal cracking has emerged as a critical issue due to its potential impact on the safe operation of airplanes. A novel SMA design methodology has been introduced for airport bituminous pavements in cold climates, and testing in diverse low-temperature conditions has shown its substantial efficacy in improving the cracking resistance of engineered bituminous mixtures. [

31,

32]. Conventional laboratory tests and advanced imaging techniques were used to experimentally verify coarse aggregate voids. The relationships among the coarse aggregate ratio, microstructure parameters, and the mechanical response of stone mastic asphalt were investigated in five different stone mastic asphalt mixtures designed with different coarse aggregate skeletons [

33]. X-ray CT and image analysis techniques were used to measure the microstructure of the stone mastic asphalt mixtures. Air voids, grain distributions, and the Weibull cumulative distribution function were used to identify the mixtures and thus confirm the presence of a stone-to-stone coarse aggregate skeleton. Dynamic modulus and static creep tests were conducted to measure the mechanical response. It was suggested that stone mastic asphalt be modified with a lower critical coarse aggregate ratio to ensure optimum performance.

Another comparative analysis of the field efficacy of asphalt pavement mixtures utilized in steel bridges [

34]. The pavement mixtures comprised an epoxy asphalt pavement and a composite pavement consisting of SMA and Gussasphalt (GA). Chemical studies were conducted on core samples extracted from each bridge. The analyses revealed that the two pavement combinations often demonstrated comparable field performance. Both bridges exhibited multiple issues stemming from inadequate adhesion between the layers or between the pavement and the steel deck. An additional research used PMB 40 bitumen (polymer-modified) to create a SMA design mixture and investigated its properties through laboratory tests to help define the performance characteristics. This research conducted laboratory tests to compare the properties of the DGA mixtures with the traditional HMA ones [

35]. Another conducted study to assessed the performance of SMA in comparison to conventional DGA mixtures prior to its implementation as a non-grooved runway surface in Australia. Laboratory performance tests indicated that SMA mixtures with 10 mm and 14 mm aggregates, sourced from four different origins, typically satisfied airport asphalt performance standards. The 14 mm mixture demonstrated superior performance compared to the 10 mm mixture, especially regarding surface macrotexture and resistance to deformation. The study concluded that airports ought to consider 14 mm SMA as a non-grooved runway surface for future implementation [

36]. An extra inquiry developed SMA mixtures utilizing three methodologies: the vertical vibration test method (VVTM), the Marshall method, and the Superpave gyratory compactor method (SGC). The performances of SMA, designed using all three methods, were measured and compared. The optimum bitumen content of the VVTM designed SMA mixture was found to be 5% lower than that of the Marshall and SGC designed asphalt mixtures. The VVTM designed SMA exhibited superior density, mechanical properties, rutting resistance, low-temperature cracking resistance, water stability, and fatigue life compared to the asphalt mixtures designed by Marshall and SGC. The SMA mixture developed using the VVTM method demonstrated superior road performance and durability compared to the conventional design method [

37].

In previous years, the use of cellulose fibers in asphalt mixtures has emerged as a significant research focus, especially in Stone Mastic Asphalt (SMA) applications. Cellulose fibers are among the additives incorporated to enhance the performance of these asphalt mixtures. Numerous studies have shown that cellulose fibers improve the durability and performance of asphalt in SMA mixes. Many research investigations have evaluated the incorporation of 0.3% cellulose fibers into SMA mixtures with varying nominal maximum aggregate sizes, revealing that cellulose fibers markedly increase the rutting resistance and fatigue strength of asphalt. Dynamic modulus and flow number tests show cellulose fibers strengthen the high-temperature performance of asphalt and improve fatigue resistance. The tests have shown that cellulose fibers enhance the deformation resistance of asphalt mixtures [

38,

39]. The interaction between cellulose fibers and bitumen increases the bond strength of aggregates, hence improving the overall durability of asphalt. Some research studies suggest that cellulose fibers enhance the dynamic modulus of asphalt, hence improving its resistance to rutting and allowing bitumen to maintain a more stable structure at elevated temperatures [

39]. This produces asphalt surfaces that exhibit notable resistance to temperature fluctuations.

Moreover, cellulose fibers play a crucial function to improve the aging resistance of asphalt. In aged asphalt mixtures, cellulose fibers enhance the viscosity of the asphalt, inhibiting hardness from aging and promoting increased flexibility. This enhances the durability of the asphalt and diminishes maintenance needs. The incorporation of cellulose fibers has enhanced the performance of these materials, especially in combinations with recycled asphalt (RAP) [

40]. Certain research indicate that cellulose fibers yield more potent synergistic effects both independently and in conjunction with other fiber types. The synergistic application of cellulose and basalt fibers markedly enhances characteristics including rutting, low-temperature bending, fatigue, and moisture damage resistance in asphalt mixtures. These hybrid changes amalgamate the advantages of both fiber types, markedly enhancing the overall performance of asphalt [

41]. Addition of cellulose fibers in asphalt mixtures provides the benefits of waterproofing and antifouling. Cellulose fibers enhance the water repellency of asphalt, inhibiting water infiltration and so increasing the durability of the roadway surface. Additionally, cellulose fibers assist in maintaining the cleanliness of the asphalt surface, inhibiting dirt collection and minimizing maintenance needs [

42]. Thus, the incorporation of cellulose fibers in SMA asphalt mixtures is a significant approach to enhancing durability and optimizing asphalt performance. Research indicates that including these fibers into asphalt mixtures can prolong the lifespan of asphalt and save maintenance expenses by enhancing rutting resistance, aging resistance, and fatigue strength [

38,

39]. This additive facilitates the development of sustainable roadways and enhances the safety and durability of facilities. The extensive application of cellulose fibers enhances the efficiency and durability of asphalt mixtures while providing environmental and economic advantages.

The research evaluates aggregate and gradation selections in compliance with the Turkish Highway Technical Specifications. This guarantees that the study follows local rules and is directly applicable to local contexts. This research offers an optimum design specifically for Turkish highways, in contrast to previous literature that predominantly emphasizes international standards or general methodologies. This offers a pragmatic contribution to local engineering methodologies and regional construction initiatives. Moreover, the study's focus on the equivalency of the Turkish Highway Technical Specifications with European and American standards is a notable contribution. This guarantees that local applications fit to international engineering standards. This investigation provides creative solutions for international engineering practices and local projects taking into account local materials and environmental variables. The study enhances asphalt mix design, while including an engineering approach aligned with international norms in Turkey.

The research assessed the effects of modifications to the ratios of coarse aggregate, fine aggregate, and filler on the performance of both elastomeric (styrenebutadiene-styrene (SBS), Kraton® D1101) and fiber modified asphalt mixtures. This study presents more detailed and creative technique by experimentally altering the ratios and conducting performance tests for each aggregate gradation, despite the frequent examination of factors such as aggregate gradation and bitumen ratio in existing literature.

2. Materials and Methods

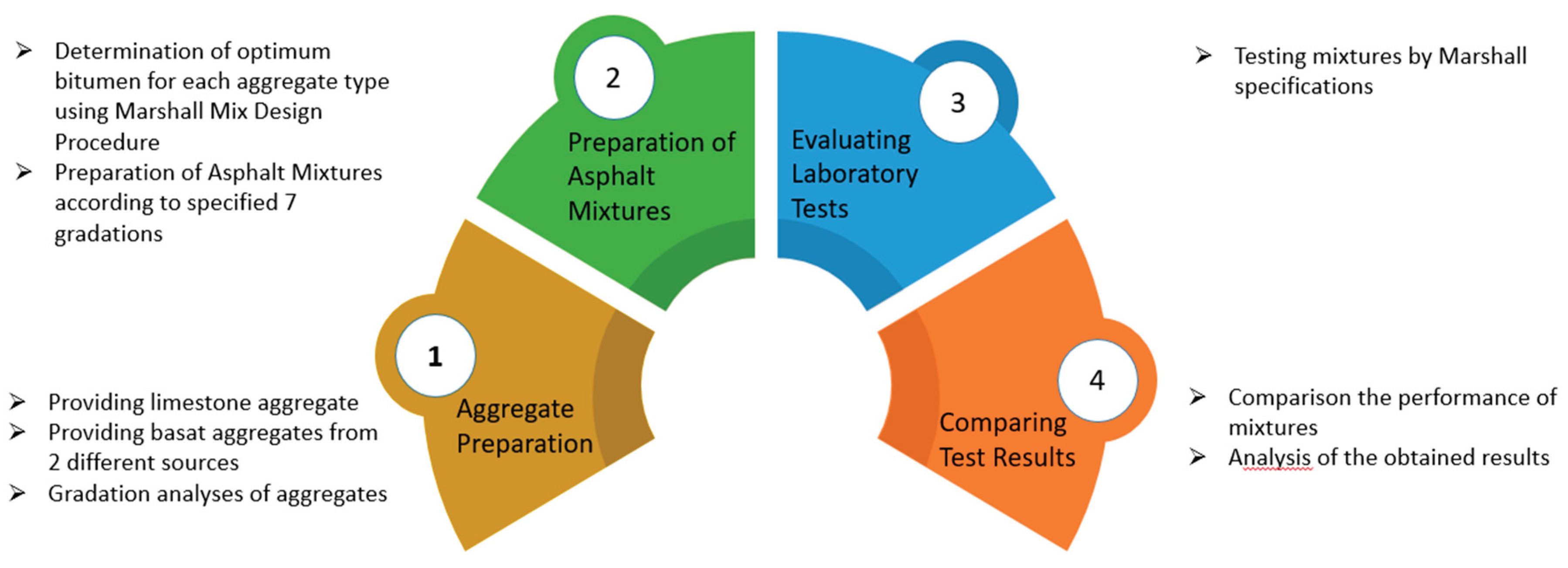

The methodology used in this study is illustrated schematically in

Figure 1. The process completed in four steps. This schematic diagram clearly illustrates the fundamental phases in the design and assessment of asphalt mixtures. The initial step is to obtain materials. This phase entails supplying limestone and basalt aggregates, along with bitumen. These aggregates are sourced from multiple origins, followed by the execution of gradation analysis. Aggregate qualities are critical determinants that directly influence the overall performance of the asphalt mixture. The following step entails the preparation of asphalt mixtures. This phase uses the Marshall Mix Design methodology to ascertain the optimal bitumen ratio for each aggregate type, utilizing seven distinct gradation categories. This procedure seeks to enhance the longevity and efficacy of the asphalt. The third stage involves the assessment of laboratory tests. Subjecting the created mixtures to diverse tests elucidates the performance attributes of the asphalt. The final stage entails the comparison of the test results. The tests are assessed according to Marshall standards, and the discrepancies in the results are subjected to statistical analysis. This phase is essential for ascertaining the optimal mixture performance.

According to first step, all the materials obtained needed for the experiment. The bitumen was supplied by the General Directorate of Highways' bitumen refinery.

Table 3 shows the tests that were performed on the bitumen samples. Kraton was blended into the provided 50/70 grade bitumen at a dosage of 4.5 percent by weight to produce a performance-grade modified bitumen (PG 76-22). All blends included modified bitumen. The predominant addition for bitumen modification in highway applications is the SBS-based product known as Kraton® D 1101. The material modifies bituminous mixtures, maintaining road pavement durability against detrimental conditions such as rutting, aggregate stripping, undulation development, and low-temperature cracking [

43]. The tests performed on the polymer-modified bitumen are presented

Table 3.

Aggregates were obtained from quarries situated in the vicinity of Ankara, Turkey. Two different kinds of basalt (classified as a durable substance, whereas the latter has low specific gravity) and limestone aggregates were mixed. The aggregates were divided into nine distinct fractions and prepared appropriately for the design. The overall physical characteristics and specifications are presented in the

Table 1. The mechanical properties represent critical characteristics that significantly influence the durability and performance of the ultimate design. The tests conducted to evaluate suitability for use are presented in

Table 2.

Table 2.

Mechanical properties of Aggregates

Table 2.

Mechanical properties of Aggregates

| Property |

Basalt-I |

Basalt-II |

Limestone |

Standard |

| Los Angeles Abrasion Resistance (%) |

11.8 |

13.7 |

27.2 |

TS EN 1097-2 / ASTM C131 |

| Micro-Deval Abrasion Resistance (%) |

9.7 |

10.3 |

17.8 |

TS EN 1097-1 / ASTM D7428 |

| Methylene Blue Value (g/100g) |

3 |

3 |

6 |

TS EN 933-9 / ASTM C837 |

| Flakiness Index (%) |

12 |

14.5 |

22.8 |

TS EN 933-3 / ASTM D4791 |

Table 3.

Binder Test Results

Table 3.

Binder Test Results

| Property |

Value |

Standart |

| Density (g/cm³) |

1.03 |

TS EN 15326+A1/ASTM D70 |

| Penetration (0.1 mm) |

30.5 |

TS EN 1426/ASTM D5 |

| Softening Point (°C) |

75.6 |

TS EN 1427/ASTM D36 |

| Ductility (cm) |

100+ |

TS EN 13589/ASTM D113 |

| Elastic Recovery Test (%) |

83.5 |

TS EN 13398/ASTM D6084 |

| Thin Film Loss of Mass (%) |

0.14 |

TS EN 12607-1/ASTM D1754 |

| Post-Aging Penetration (0.1 mm) |

24 |

TS EN 1426/ASTM D2872 |

| Post-Aging Softening Point (°C) |

79.5 |

TS EN 1427/ASTM D36 |

Bitumen market provides mixtures for many types of highways. To guarantee an extended service life, it is crucial that these mixtures incorporate a significant amount of bitumen. Cellulose fibers, particularly in compressed form, function as drainage inhibitors, allowing for an increase in binder content without adverse consequences such as drainage from aggregates during mixing, storage, transportation, paving, compaction, and cooling to the final temperature. Pelletized cellulose fibers, such as VIATOP premium, facilitate the automatic incorporation of these goods into the mixing plant using a dosing system during asphalt mix production. VIATOP® products consist of functional pellets made from bitumen-coated cellulose fibers and additives, providing high quality for contemporary asphalt solutions in a cost-effective and sustainable manner (

Figure 2). VIATOP® Premium is utilized to reinforce asphalt pavement and limit the absorption of bitumen in SMA mixtures. As a result of the percolation test performed on Viatop Premium pellets (

Table 4), 0.35% was determined as the most suitable ratio and this ratio was used in all Stone Mastic Asphalt mixtures.

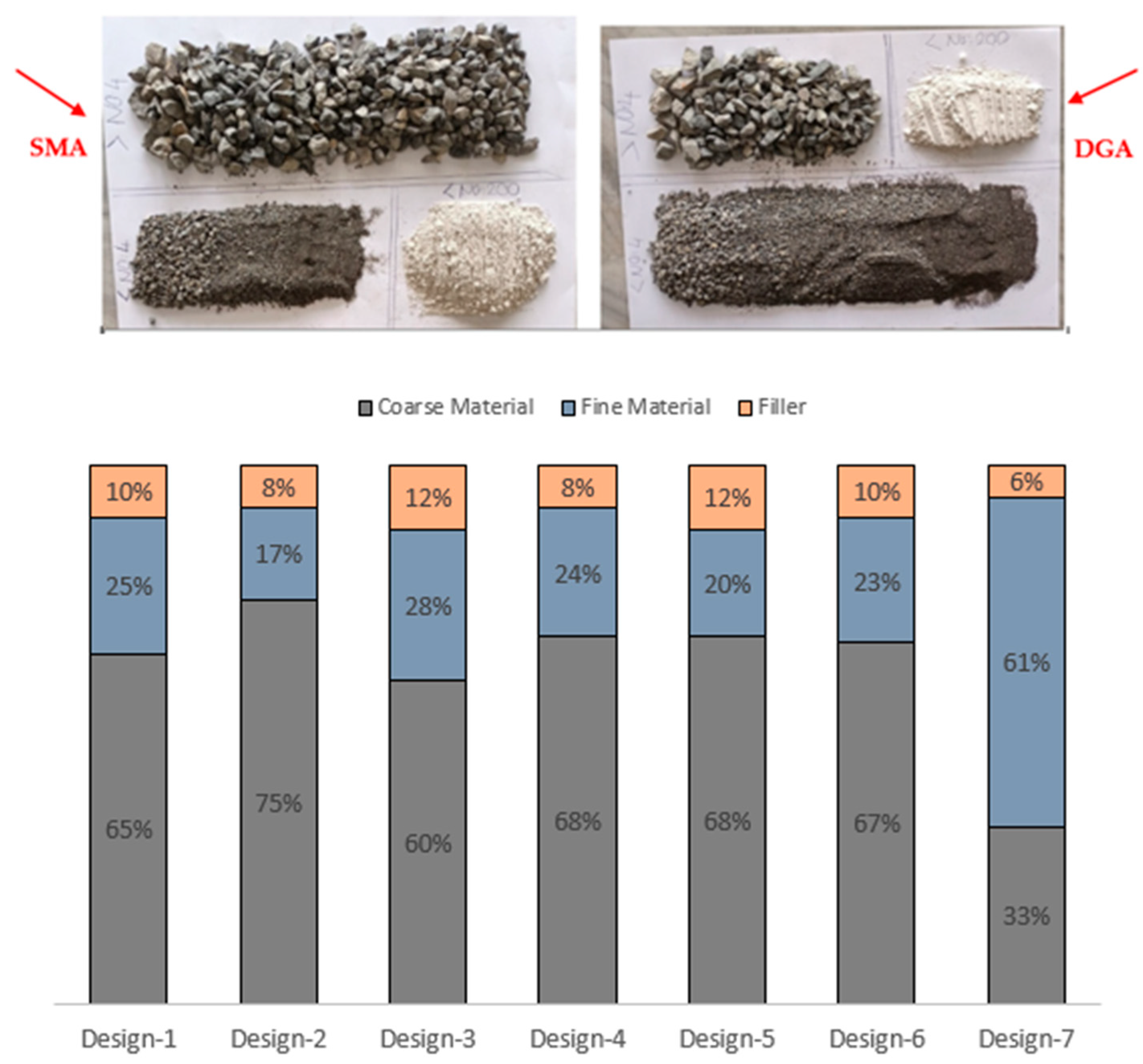

As mentioned before two types of aggregates as basalt and limestone are used in the study. As part of the research that was carried out within the parameters of the study, a comprehensive experimental investigation was carried out based on the bitumen content and gradations that were utilized. Varying the gradation of the same aggregate type while maintaining the same amount of bitumen content is one of the modifications that are employed in accordance with different scenarios. The second step is to change the volume of bitumen while maintaining the same material and gradation. Changing the filler type while keeping the bitumen content and coarse aggregate percentage are constant. Seven different designs were performed, with the variables defined in detail

Figure 3.

All samples in the study were prepared in accordance with the Marshall design method as outlined in the TS EN 12967-30 standard. Mixtures were formulated using 1150 g of aggregate (

Table 5). The fiber incorporated into the design constituted 0.35% of the total mix material, based on the findings from the percolation test. Aggregate, subjected to a 24-hour drying period in an oven, was assessed for weight loss prior to its transfer to the mixing vessel. The vessel was positioned in the mixer and subjected to a heat source to sustain the existing temperature. The designated quantity of fiber was incorporated and blended at a low speed (

Figure 4). The mixing process lasted 45-50 seconds, resulting in the complete dispersion of the fiber material over the aggregate. Bitumen, heated to the manufacturer's specified mixing temperature (approximately 160°C-165°C), was incorporated into the aggregate and fiber mixture. The mixture was blended for approximately 2 minutes while maintaining the temperature in the mixer. The subsequent processes were completed according to the Marshall design method. In order to guarantee the dependability of the outcomes, three specimen replicates were set up for each design granulometry system.

3. Results and Discussions

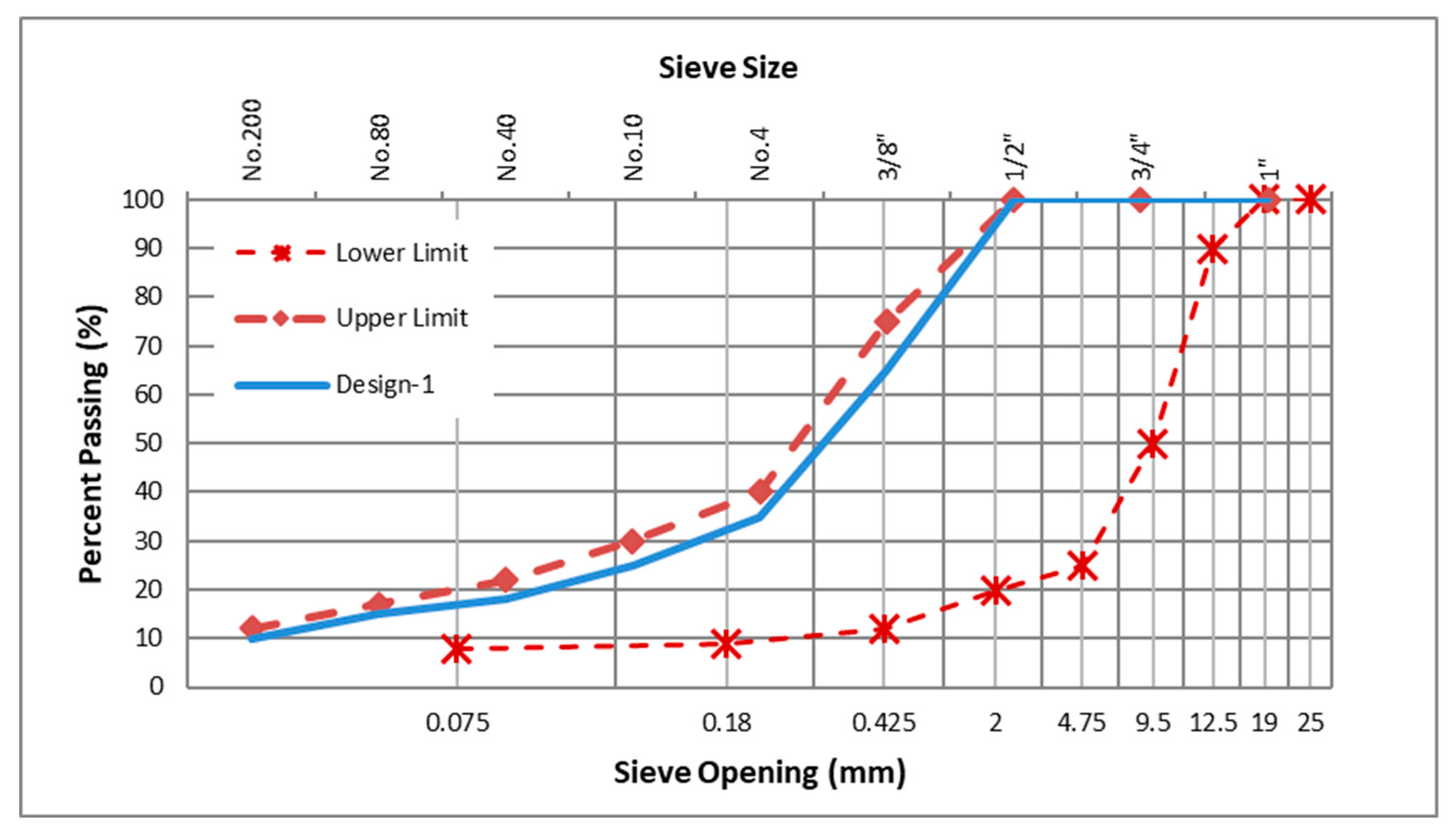

This part defines the experimental results of tests, compares the mixtures, and assesses them in accordance with prevalent specification limitations. The Marshall performance of Basalt-1 and Limestone, classified as Gradation-1 (

Figure 4) in the study, at the identical gradation was observed as follows. Following a comparison between basalt and limestone of the same gradation, it was found that basalt showed better stability results, flow values were better, inter-mineral aggregate voids (VMA) were similar for all bitumen contents and asphalt void space occupied the specified limits for the basalt wearing course (

Figure 5). Thus, when choosing SMA, basalt was considered to be the appropriate material to employ.

Figure 6 indicates a general pattern whereby the stability and flow values of both the Basalt and Limestone groups reduce with an increase in bitumen concentration. This suggests that the bitumen content adversely impacts the durability of both materials. For Basalt, the stability values decrease from 11.5 kN at a bitumen level of 5.0 to 7.0 kN at a bitumen content of 7.0. A comparable reduction is noted for Limestone, with stability diminishing from 10.5 kN at a 5.0 bitumen percentage to 6.0 kN at a 7.0 bitumen level. This trend suggests that the stability of the materials fluctuates considerably according on the bitumen content. Error bars are a crucial element of the uncertainty associated with each data item. The length of the error bar indicates the possible variance surrounding the data point. The error bars for the Basalt and Limestone groups are closely aligned, suggesting that the uncertainty in the data for both groups is comparable. Error bars represent a certain range of dispersion surrounding each data point and are essential for assessing the dependability of the data. Shorter error bars signify greater precision in the data, but larger error bars suggest increased variability, hence amplifying uncertainty. The margin of error in the data indicates the horizontal or vertical uncertainties noted in the stability assessments of both groups. This graph illustrates the reliability of each data point by computing the standard deviation for each stability value within the Basalt and Limestone groups and incorporating error bars. Uniform error bars across the data sets from both groups signify comparable levels of reliability.

A one-way ANOVA was performed to analyze the differences in mean values between the Basalt and Limestone groups (

Table 6). The research revealed a substantial disparity between the group means. The F-value derived from the ANOVA analysis was 6.965914, whereas the crucial F-value was 5.987378. An F-value surpassing the critical value signifies a substantial difference among the groups. Moreover, the p-value of 0.038576 is below the 5% significance threshold. This results in the rejection of the null hypothesis and the acceptance of the statistically significant difference between aggregates.

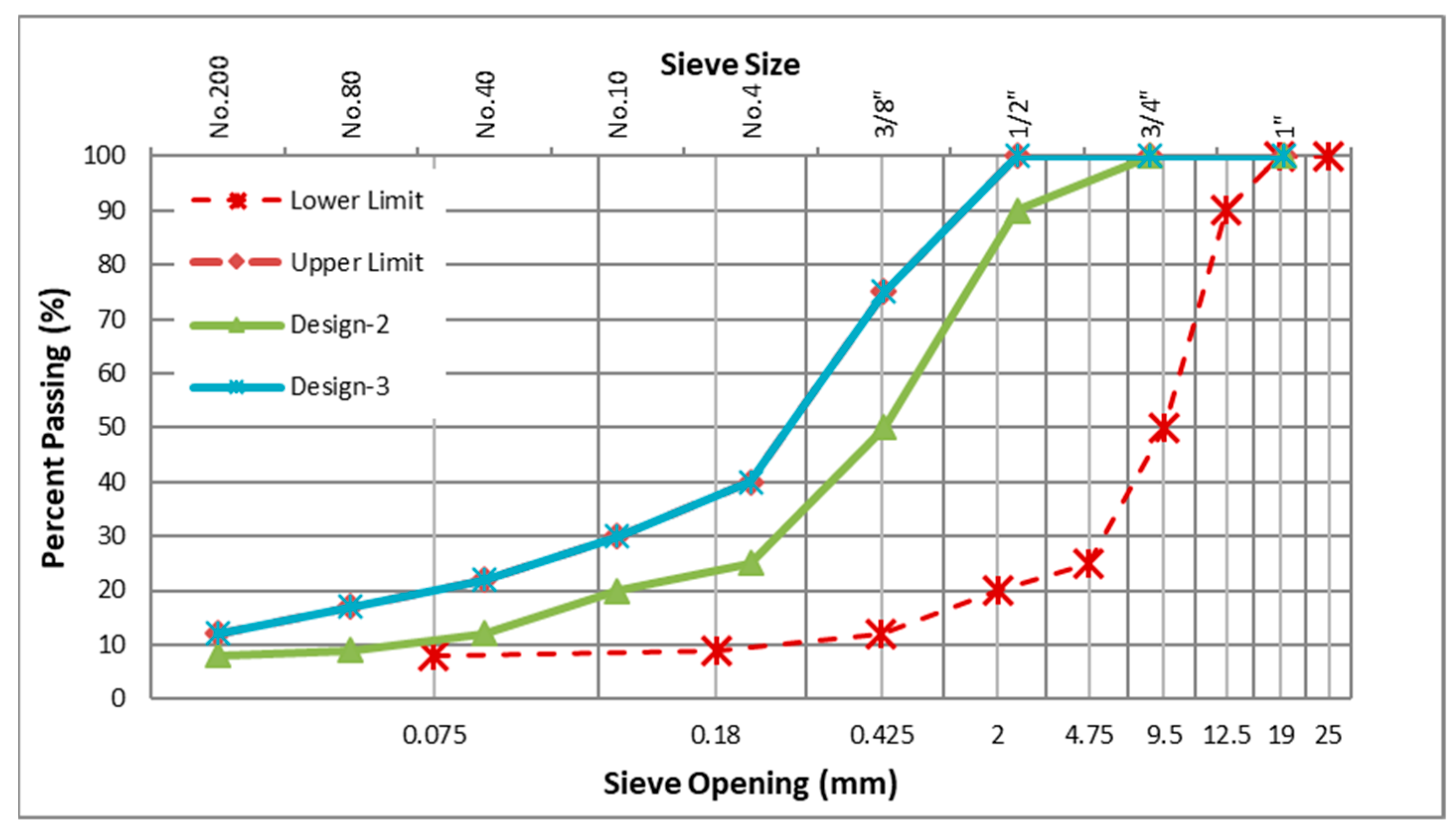

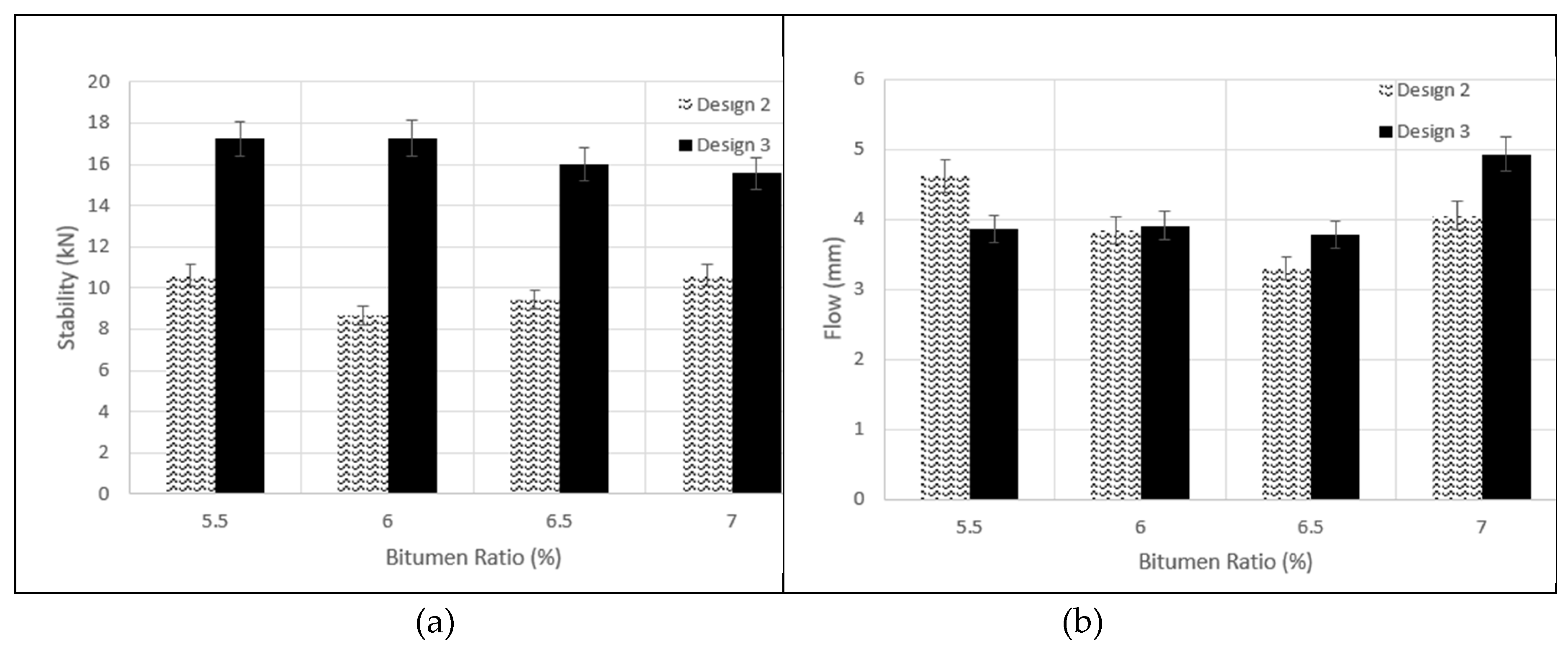

Design-2, in comparison with Design-3, demonstrates a wider distribution, indicating of a conventional gap-graded structure. This design displays notable intervals between the mesh sizes. In contrast, Design-3 features a more consistent and compact gradation envelope, providing a tighter distribution. This distinction illustrates the divergence between the two designs, with Design-3 exhibiting a more homogenous structure. (

Figure 6).

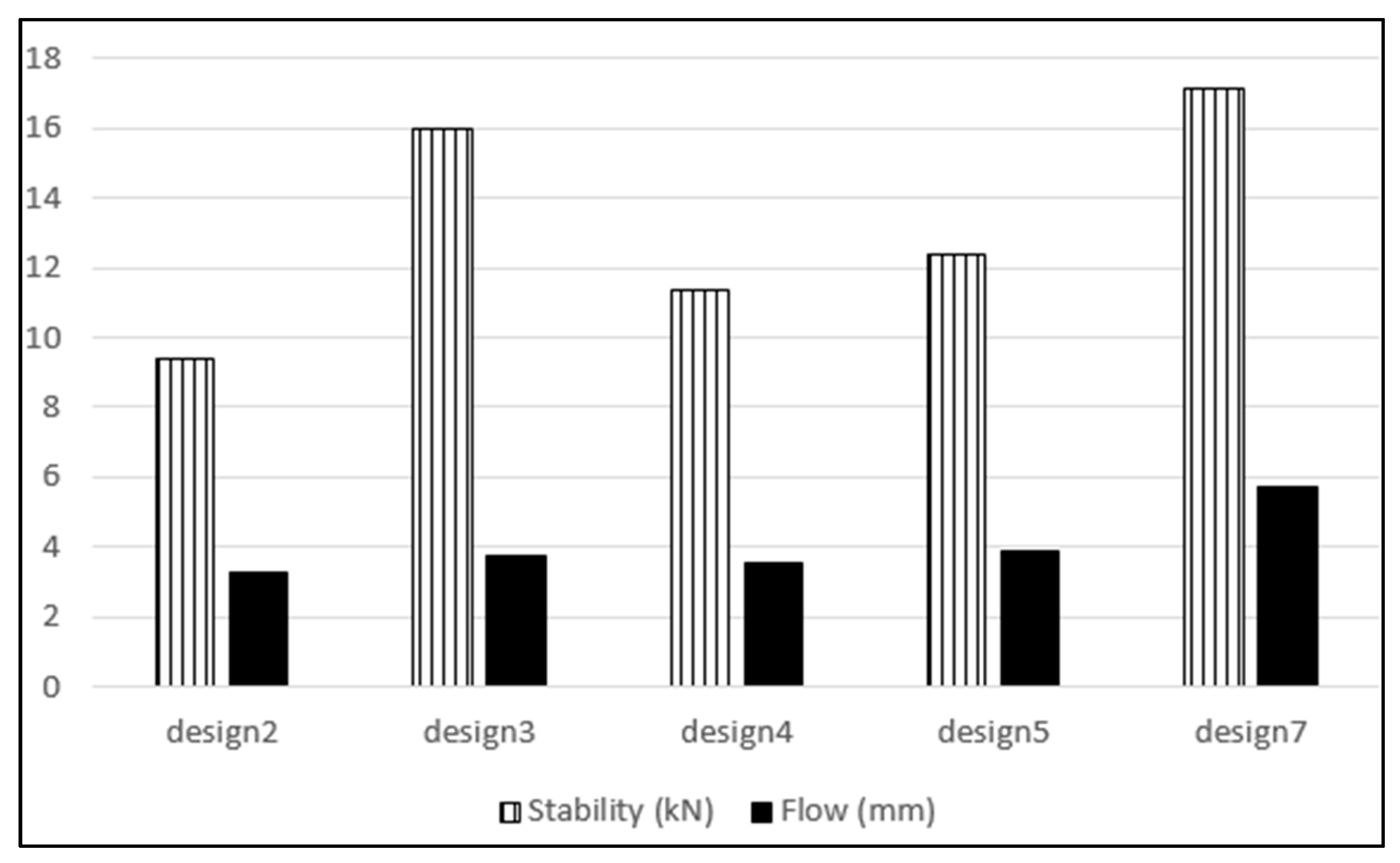

Figure 7 shows the relatiomships between design 2 and design 3 according to stability and flow ratio. Stability results of design 2 are remarkably higher than design 3. According to

Table 7 the numbers imply that a significant proportion of the total variance is attributable to the intergroup differences. The computed F-statistic is 107.3232, significantly exceeding the critical F value of 5.987. Moreover, the p-value is 4.73×10⁻⁵, far below than the 5% (0.05) significance threshold. This outcome unequivocally suggests that the null hypothesis (indicating no difference between the groups) ought to be rejected. The means of the two groups are statistically significantly different. Upon evaluating the direction of this difference through the means, the mean of the second group is markedly superior to that of the first. Moreover, the effect size is substantial; around 95% of the overall variance (η² = 0.95) is attributable to group differences.

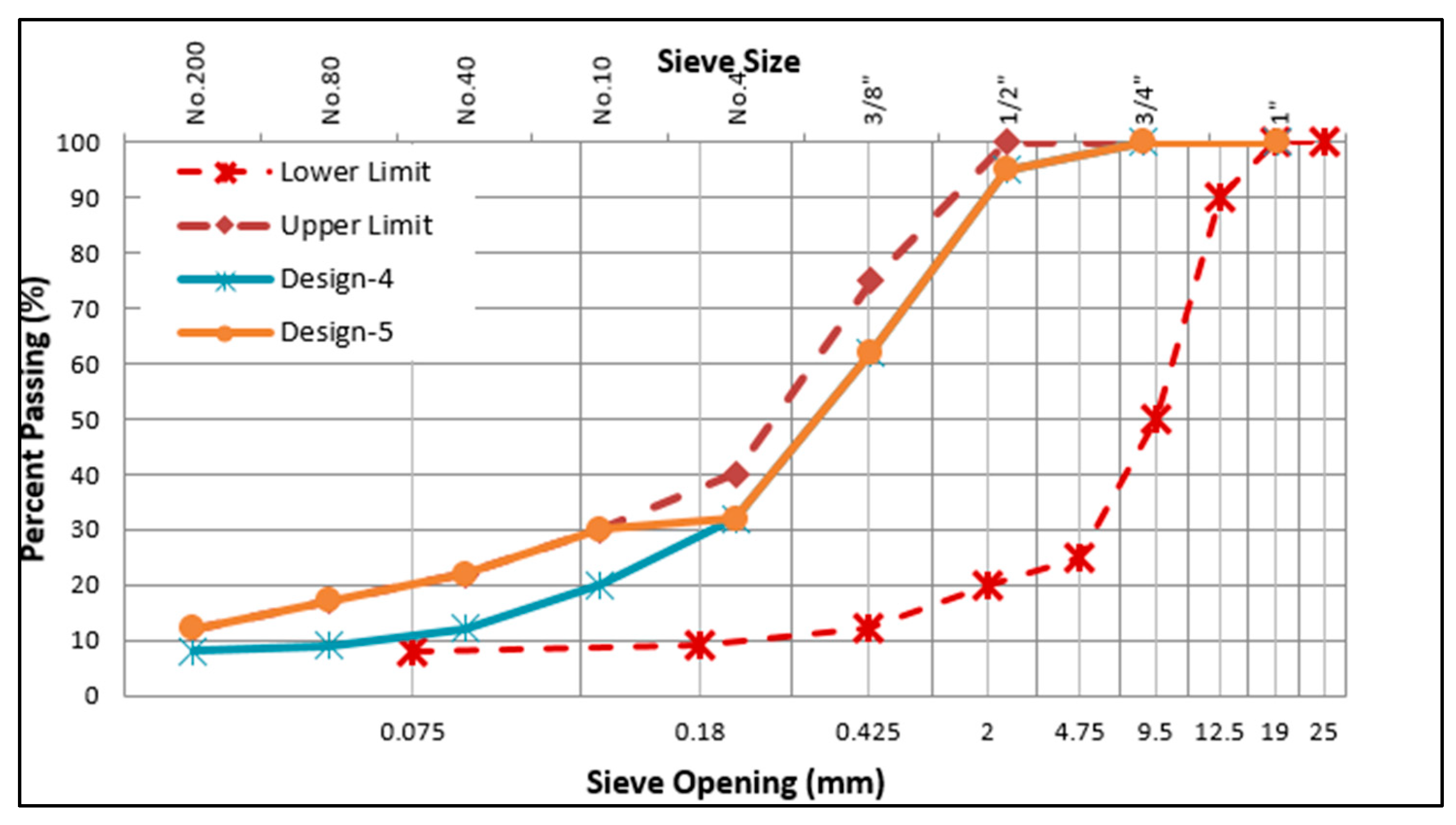

Figure 8 shows gradations 4 and 5 that are prepared with basalt 2 type aggregate and coarse aggregate percentages equal whereas fine parts fit upper limit for design 5. According to stability and flow numbers, the results are almost the same with each other that shows there is no significant effecet neither aggregate type nor gradation.

Table 8 shows the statistical comparison of results. From the table, it can clearly be understood that there is no significant difference between performance of that two groups.

Figure 8.

Comparison of aggregate gradation on Design 4 and 5.

Figure 8.

Comparison of aggregate gradation on Design 4 and 5.

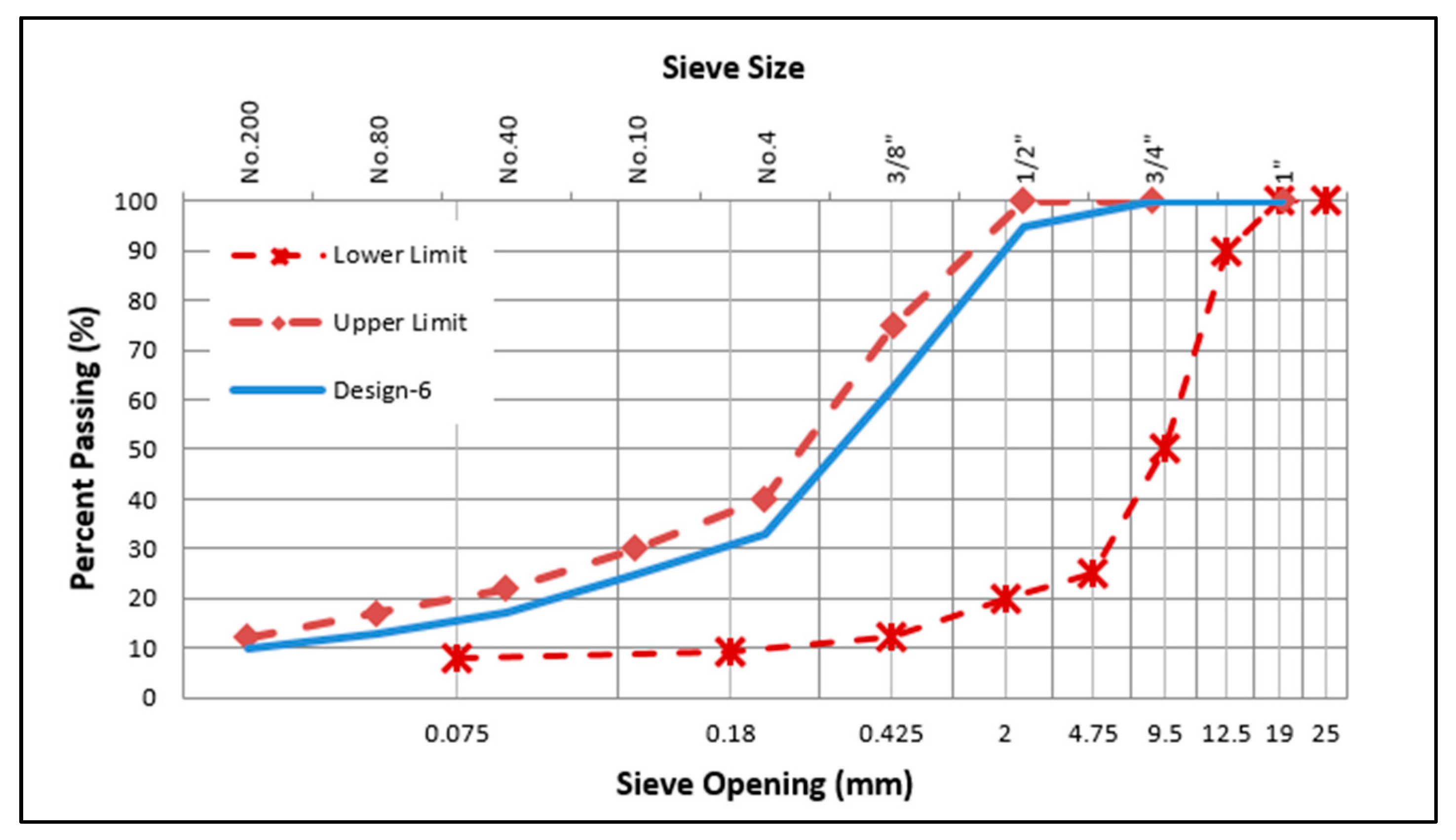

Figure 9.

Comparison of aggregate gradation on Design 6.

Figure 9.

Comparison of aggregate gradation on Design 6.

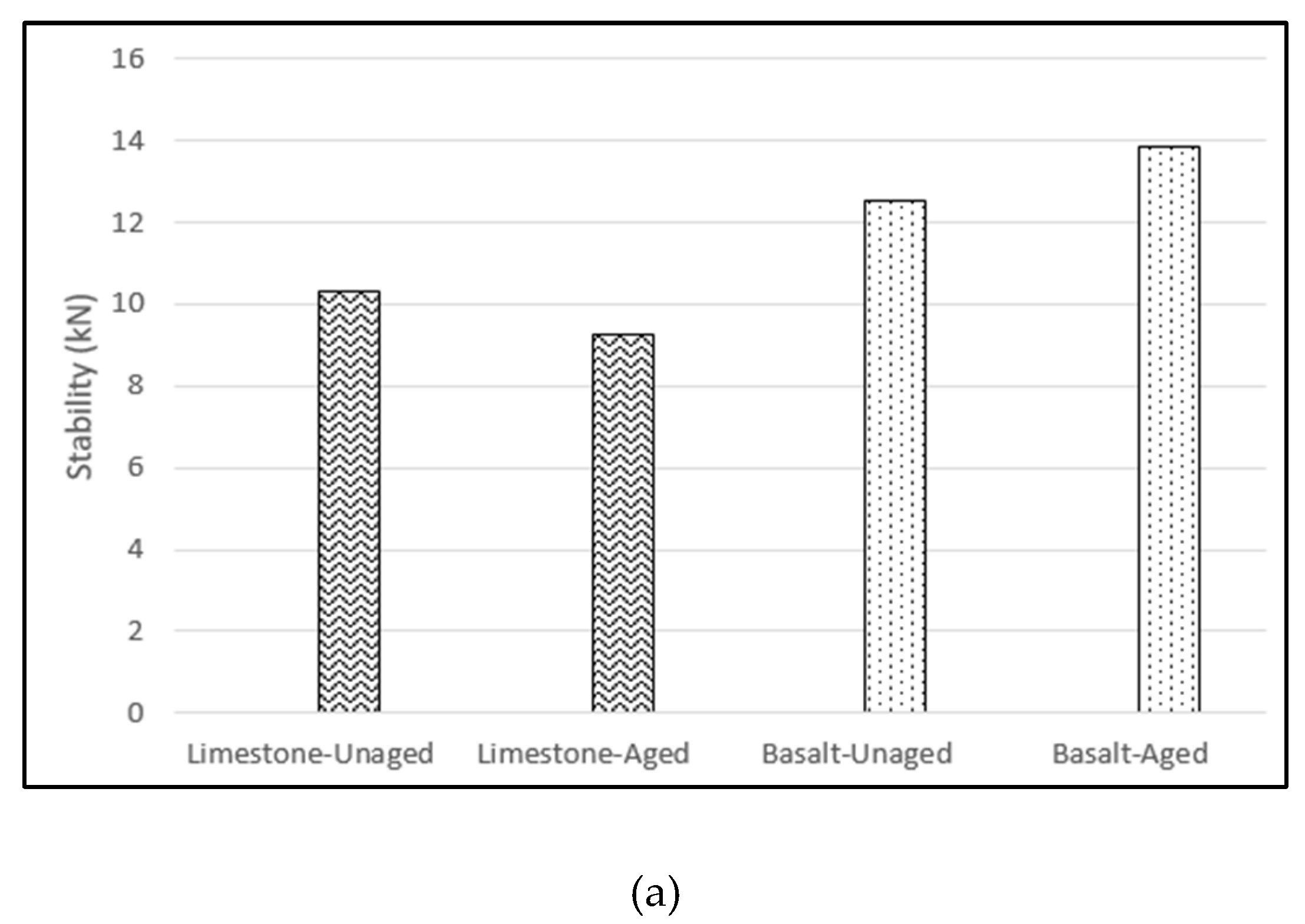

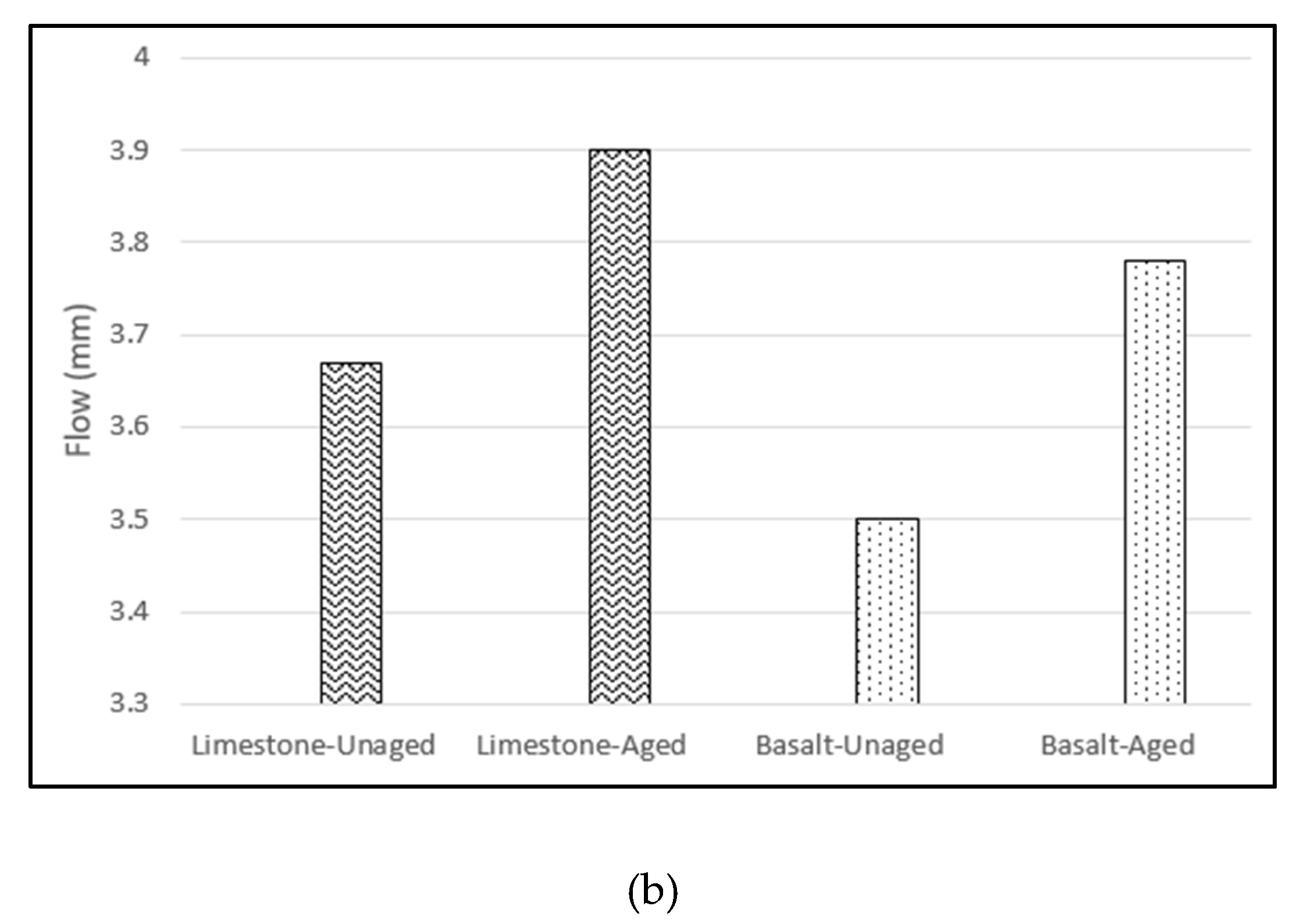

To evaluate the performance impacts of short-term aging on the samples, control samples were subjected to short-term aging in accordance with TS EN 12607-1/AASHTO T240 standards, and the stability and flow values for both aggregate types were compared. Samples subjected to an 85-minute duration at 163°C were analyzed, and the findings are illustrated in the

Figure 10.

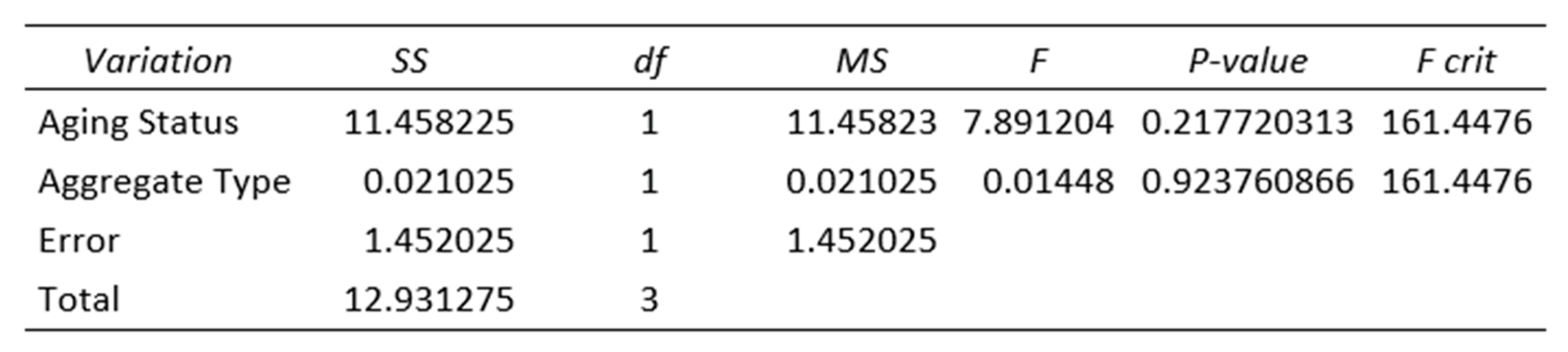

The variations in aging status and aggregate type are not statistically significant based on the two way one factor ANOVA test (

Table 9).

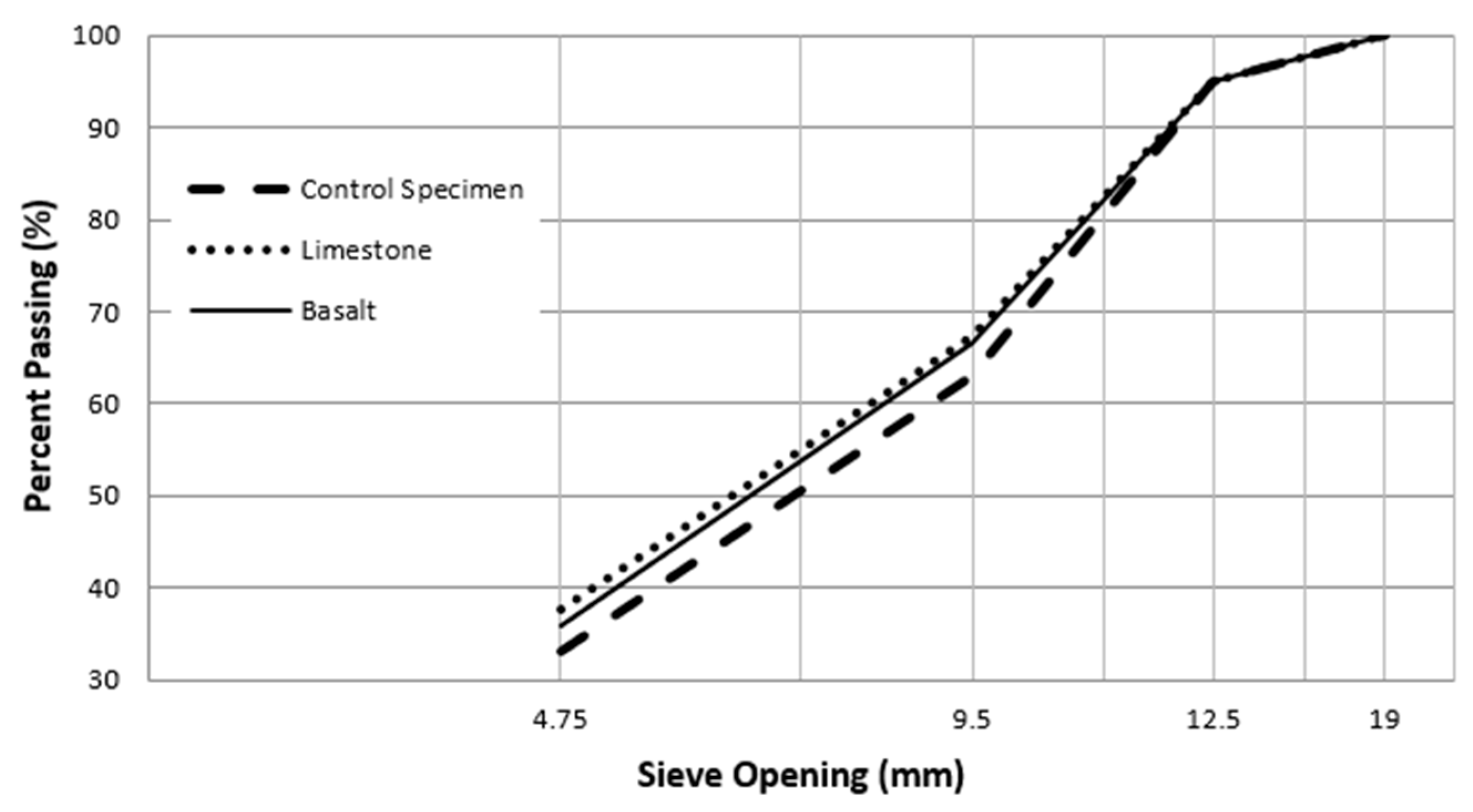

Sample compaction was conducted using a hammer, ensuring that the conditions for Basalt-2 and Limestone materials were same in terms of gradation, bitumen concentration, and number of blows to assess the fragmentation of aggregates due to the mallet's impact. A novel gradation was established using sieve analysis of the coarse material identified as the No. 4 sieve top following the extraction of the impact-compressed specimens (

Figure 11). The correlation between the hammer impact and the fragmentation resistance of Los Angeles was tested. The distribution of materials produced from the extraction is illustrated below. The control specimen has a more pronounced transition curve compared to the other two materials. The limestone and basalt specimens, conversely, display a more uniform curve, indicating elevated transition rates at particular sieve openings. This indicates that the particle size distribution of each material varies, and these variations are evident in the sieve analysis outcomes. However, when evaluating the aggregate distribution of basalt and limestone based on the control sample, it is noted that the gradation of limestone is more pronounced during the design phase.

Designs 2 and 3 exhibit elevated stability values; nevertheless, they also demonstrate very reduced fluidity. This indicates that these designs possess significant durability yet exhibit restricted deformation. Nonetheless, these designs may exhibit certain constraints regarding adaptability. Conversely, Designs 4 and 5 are distinguished by their diminished stability values. Although these designs exhibit more deformation (enhanced fluidity), they concurrently possess diminished durability. This indicates that certain designs may exhibit greater flexibility but reduced durability. Ultimately, design 7 exhibits the most durability alongside the maximum flexibility. This indicates that, although resilient, the design is prone to increased deformation and necessitates structural flexibility (

Figure 12).

The P-value (0.000279) is below 0.05, and the F-value above the crucial F-value (5.317655), indicating that the differences across the groups are statistically significant. This signifies a substantial disparity between the groups, indicating that this difference is not attributable to chance. In summary, a substantial distinction exists between the two groups you analyzed separately, attributable to their inherent traits (

Table 10).

4. Conclusion

This study assesses the stability of stone mastic asphalt mixtures on flexible airport runway pavements utilizing the Marshall design method. A comparative analysis of basalt and limestone at identical gradation indicated: superior stability results, enhanced flow values, comparable inter-mineral aggregate voids (VMA) across varying bitumen contents, void ratio occupied by asphalt adhered to the specified limits for the wearing course in basalt. Consequently, basalt was considered suitable as a stone mastic asphalt material according to comparison of Design 1 results.

According to the findings of the current investigation, increasing the fineness in gradation changes leads to significantly higher strength in comparison to coarser dispersions. On the other hand, it is important to point out that the probability of deformation is significantly higher in these combinations in comparison to other designs. Additionally, it is important to highlight that the strength of the polymer-modified binder can be increased by using fiber reinforcement.

To investigate the impact that alterations in aggregate and gradation characteristics have on the strength and deformation parameters of SMA. In dense mixtures, decreasing the void ratio also reduces the amount of air spaces and porosity, which ultimately results in an increase in strength. The recommended design parameters for fine gradation distribution (Design2-3) have been developed as a result of the suitability of basalt use, which is also backed by statistical evidence.

The results of the statistical analysis indicated that the aggregate change did not have a significant impact on either the aged or the unaged conditions (p-value < 0.05).

It was found that the aggregate had a change in its gradation as a consequence of the extraction process. Even in the design stage, it was noted that the gradation of the limestone was broken down in comparison to the control sample. This was observed when the aggregate distribution of basalt and limestone was evaluated using the control sample. Regard to this, the statistical relevance of the Basalt is strengthened.