1. Introduction

As many existing asphalt pavements gradually reach the end of their design life, coupled with the increasing shortage of gravel aggregate resources, rising environmental protection pressures, and economic considerations, it has become urgent to improve the efficiency of recycled asphalt mixture [

1,

2]. In response to these challenges, the recycling of asphalt pavement is an effective measure to achieve resource recovery, energy conservation, and environmental protection, and it is also a crucial approach to realizing the ‘carbon neutrality’ strategy [

3]. Through the separation and screening of asphalt pavement milling materials, and the fine regeneration of the screened milling materials, a new method for the high-value utilization of waste asphalt mixture has emerged. In the process of fine separation, the RAP coarse material is refined after the milling material is broken and screened, resulting in a higher proportion of RAP fine aggregates and a larger proportion of RAP fine aggregates with a particle size of 0 ~ 5 mm [

4].

With the increasing rut damage of asphalt pavement under the combined action of temperature and load, a variety of solutions have been proposed to address this problem from multiple perspectives, such as road materials and design structures [

5]. Among them, the excellent high-temperature deformation resistance of High Modulus Asphalt Concrete is widely used in preventing rutting damage [

6,

7,

8]. High Modulus Asphalt Concrete (HMAC) originated in France in the early 1980s. It was proposed that HMAC could be used to reduce the thickness of the asphalt surface layer. This technology has been widely applied in heavy load traffic areas, high-temperature zones, long slope sections, and airport runways. It primarily addresses the issues of insufficient load resistance of pavements and deformation diseases such as rutting in asphalt mixture under high-temperature conditions [

9,

10]. In 2010, France paved a test road with high modulus recycled asphalt mixture in Toulouse and found that the water stability and fatigue performance of the high modulus recycled asphalt mixture on the test road still met the specifications, and its low-temperature performance was not significantly different from that of the conventional high modulus mixture [

11]. In 2012, Hongrui Zhang et al. from the Highway College of Chang’an University studied the performance of High Modulus Asphalt Concrete with low-grade asphalt and high old material content [

12]. In 2014, in order to increase the content of recycled old materials, Minghong Ma and Ye Qin referred to the French High Modulus Asphalt Concrete design method. By optimizing the gradation and using 50# low-grade asphalt, the road performance of hot recycled asphalt mixture with high content of old materials was improved [

13]. In 2015, Gaoqiang Ma used the design concept of High Modulus Asphalt Concrete to realize the recycling of high old material content. According to the results of indoor experiments, the addition of a higher proportion of recycled asphalt mixture has little effect on its performance, and it can still maintain its excellent road performance [

14].

In summary, research on the regeneration of pavement recycling materials shows that physical and chemical changes occur under the combined conditions of service time and load of asphalt mixture pavement. Analyzing the three components of asphalt, the increase in asphaltene content leads to a decrease in the penetration of recycled aged asphalt, generally around 20 to 30, and the aged asphalt becomes categorized as hard asphalt [

15]. Currently, there are three commonly used methods for producing High Modulus Asphalt Concretes: (1) directly using low-grade hard asphalt; (2) adding natural asphalt to the base asphalt, such as rock asphalt or lake asphalt; (3) incorporating modifiers into the base asphalt, such as high modulus agents, anti-rutting agents, polyethylene, or polypropylene, among others. [

16,

17,

18].

It has been observed that the aged asphalt in RAP fine aggregate exhibits characteristics similar to hard asphalt. By integrating the design principles of HMAC, it is technically feasible to incorporate RAP fine aggregate into High Modulus Asphalt Concretes, thereby enhancing the utilization rate of RAP fine aggregate. In this study, Class A 70# road asphalt, a self-developed high modulus modifier, and aged asphalt extracted from RAP fine aggregate were blended. The conventional properties such as 25°C penetration, softening point, 25°C ductility, and 60°C dynamic viscosity, along with rheological properties like complex modulus, phase angle, and rutting factor, were analyzed to assess the impact of aged asphalt in waste asphalt mixture on the performance of high modulus recycled asphalt. Subsequently, the high modulus regeneration of RAP fine aggregate was conducted. Through testing the road performance and mechanical properties of the recycled mixture, the changes in high modulus performance of RAP fine aggregate regeneration were further explored. This study provides valuable references for the promotion and application of RAP fine aggregate and the use of high modulus recycled asphalt mixture.

2. Test Materials and Process

2.1. Test Materials

(1) Matrix asphalt

In the experiment, A-grade 70# road petroleum asphalt was used as the base asphalt, and the tested raw materials complied with the specification requirements. The basic technical performance is detailed in

Table 1.

(2) Aged asphalt

The RAP fine aggregate recovered from the upper layer of a highway was subjected to an extraction test to obtain the recycled aged asphalt, hereinafter referred to as JA. The basic technical performance of each index of the aged asphalt is obtained by the basic index test, as shown in

Table 2.

(3) High modulus modifier

The high modulus modifier used in this test is independently developed and manufactured. Its basic technical indicators, as shown in

Table 3, comply with the specification requirements.

2.2. Test Scheme Design

(1) Recycled asphalt production

The raw materials were incorporated using an internal blending method. The content of aged asphalt was 0%, 20%, 40%, 60%, and 80%, respectively. Based on previous test results, the content of the high modulus modifier was set at 10%. In the preparation of recycled asphalt using the “wet” production process, the base asphalt is first mixed with the aged asphalt, and the mixture is heated to 160°C. Then, 1/3 of the high modulus modifier is slowly added while maintaining the temperature rise and stirring. When the temperature reaches 170°C, another 1/3 of the high modulus modifier is added. When the temperature is between 170°C and 180°C, the remaining high modulus modifier is added to the mixture. Finally, after uniform stirring, the mixture is continuously sheared for 30 minutes.

(2) Preparation of recycled asphalt mixture

In the oven, the new mineral aggregate, RAP fine aggregate, and 70# road asphalt were preheated to 150°C, 150°C, and 160°C respectively, and kept for more than 4 hours. The new mineral aggregate was added to the mixing pot at 175°C and stirred for 180 seconds; high modulus modifier was added and stirred for 60 seconds; RAP fine aggregate was added and stirred for 120 seconds; then, 70# road asphalt was added and mixed for 180 seconds to produce the recycled asphalt mixture

(3) Asphalt conventional performance test

According to the Chinese “JTG E20-2011 Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering,” the study investigated the impact of varying amounts of aged asphalt on the penetration at 25°C, softening point, ductility at 25°C, and dynamic viscosity at 60°C of recycled asphalt.

(4) Asphalt rheological properties test

According to the Chinese “JTG E20-2011 Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering,” the study examined the impact of varying amounts of aged asphalt on the rheological properties of recycled asphalt, including complex shear modulus, rutting factor, and phase angle.

(5) Four-Component analysis test

According to the Chinese “JTG E20-2011 Highway Engineering Asphalt and Asphalt Mixture Test Procedures,” the four-component analysis method is used to determine the contents of asphaltenes, resins, aromatics, and saturates in recycled asphalt.

(6) Infrared spectrum test

The EQUINOX-55 Fourier transform infrared spectrometer from EQUINOX company was used to study the changes in functional groups of various recycled asphalts.

3. Analysis of Test Results of Asphalt Binder

3.1. Conventional Performance Index Test Results and Analysis

In accordance with the “JTG E20-2011 Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering” from China, this section evaluates the impact of varying aged asphalt content on the penetration, softening point, ductility, and dynamic viscosity at 60°C of recycled asphalt. The test results are presented in

Table 4 below.

According to the analysis of

Table 4, it is evident that with the increase in aged asphalt content, the penetration at 25°C, ductility at 25°C, and dynamic viscosity at 60°C of the recycled asphalt all show a regular decrease, while the softening point shows a regular increase. Specifically, for every 20% increase in aged asphalt, the penetration at 25°C decreases by approximately 6.2%, the ductility at 25°C decreases by approximately 15.4%, the softening point increases by approximately 13.3%, and the dynamic viscosity at 60°C decreases by approximately 3.9%. Therefore, it can be concluded that the addition of aged asphalt has a significant impact on the ductility and softening point at 25°C.

3.2. Rheological Performance Index Test Results and Analysis

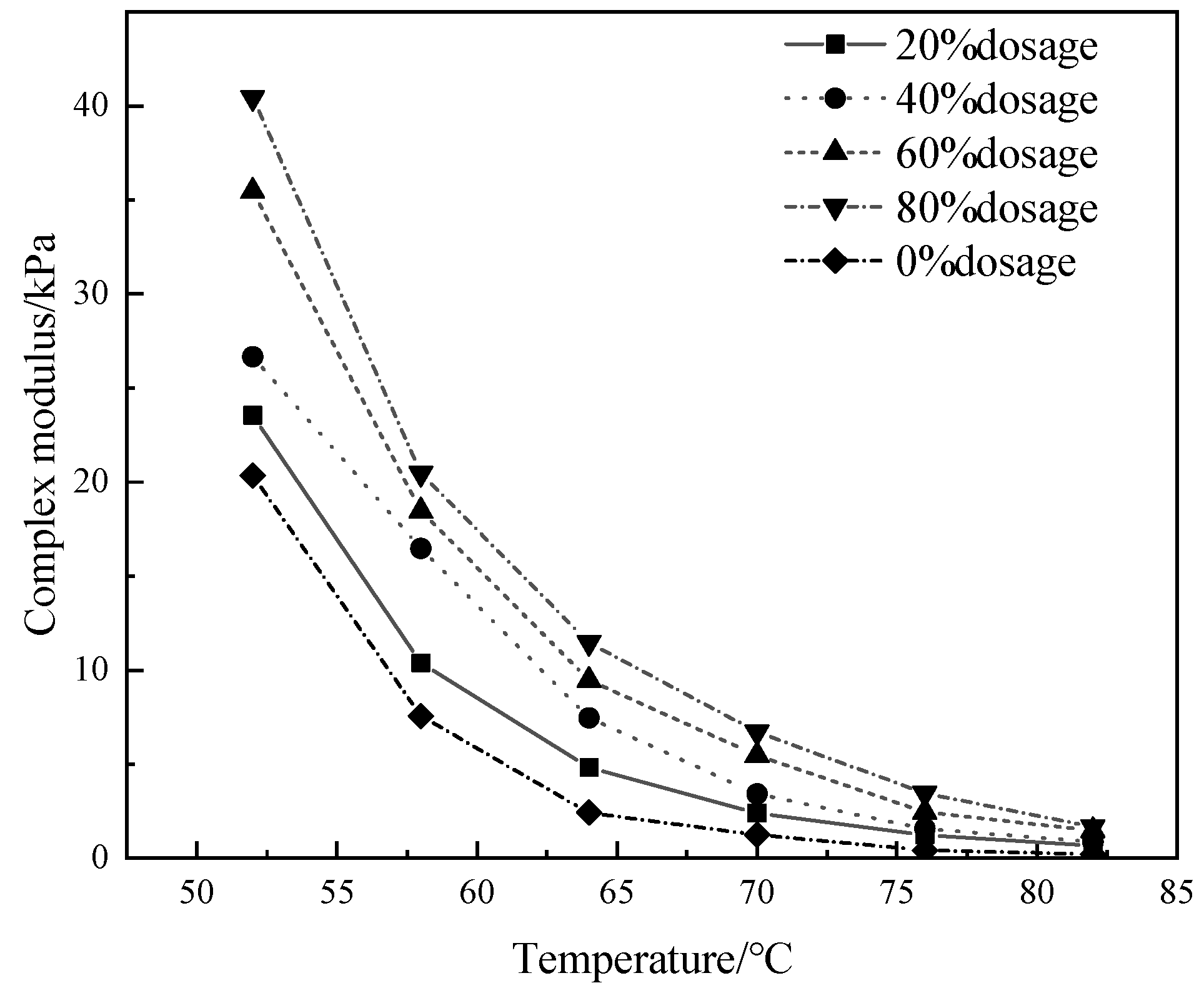

This section of the experiment was conducted in accordance with the “JTG E20-2011 Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering” from China. The test conditions are as follows: the tablets are made of KBr, the resolution is set to 0.2 cm⁻¹, the scanning frequency is 16 times per second, and the spectral range covers from 4000 to 400 cm⁻¹. The complex shear modulus and rutting factor of the recycled asphalt were tested, and the results are shown in

Figure 1 below.

Figure 1 shows the relationship between the complex modulus G* and the temperature of recycled asphalt with different proportions of aged asphalt. An increase in the complex modulus G* indicates stronger deformation resistance. As the temperature increases, the complex modulus of high-modulus recycled asphalt gradually decreases, and the rate of decline also slows down. This is mainly because, with the increase in temperature, the state of recycled asphalt changes from high elasticity to viscosity, weakening the asphalt’s ability to resist permanent deformation. At the same time, different proportions of aged asphalt significantly affect the complex modulus of recycled asphalt. At the same temperature, the complex modulus of recycled asphalt increases with the increase in the aged asphalt content, and the trend is roughly the same. The complex shear modulus index meets the basic requirements of regularity, consistent with the research results of many scholars [

19]. Additionally, this indicates that the incorporation of aged asphalt makes the characteristics of the recycled asphalt binder tend to be similar to elastomers, thereby enhancing the performance of recycled asphalt..

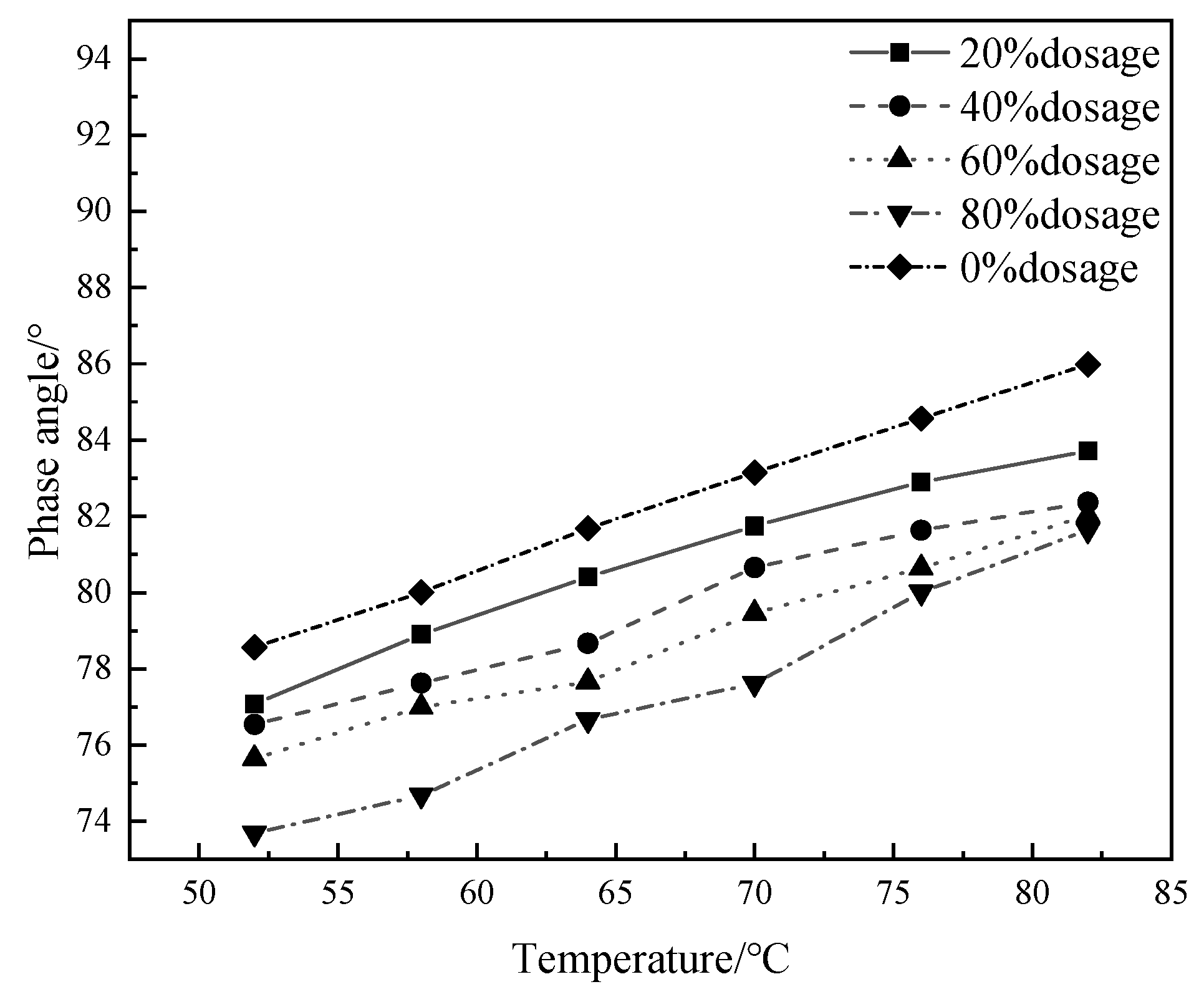

The curve of the phase angle δ of recycled asphalt mixed with different proportions of aged asphalt with temperature is shown in

Figure 2. When the temperature rises, the phase angle of all recycled asphalts increases, indicating that the elastic component is gradually decreasing while the viscous component is increasing. Compared with the high modulus modified asphalt without aged asphalt, the phase angle of recycled asphalt significantly decreases with the increase in the proportion of aged asphalt, indicating that the internal elastic components are increasing and the elastic properties of recycled asphalt are enhanced.

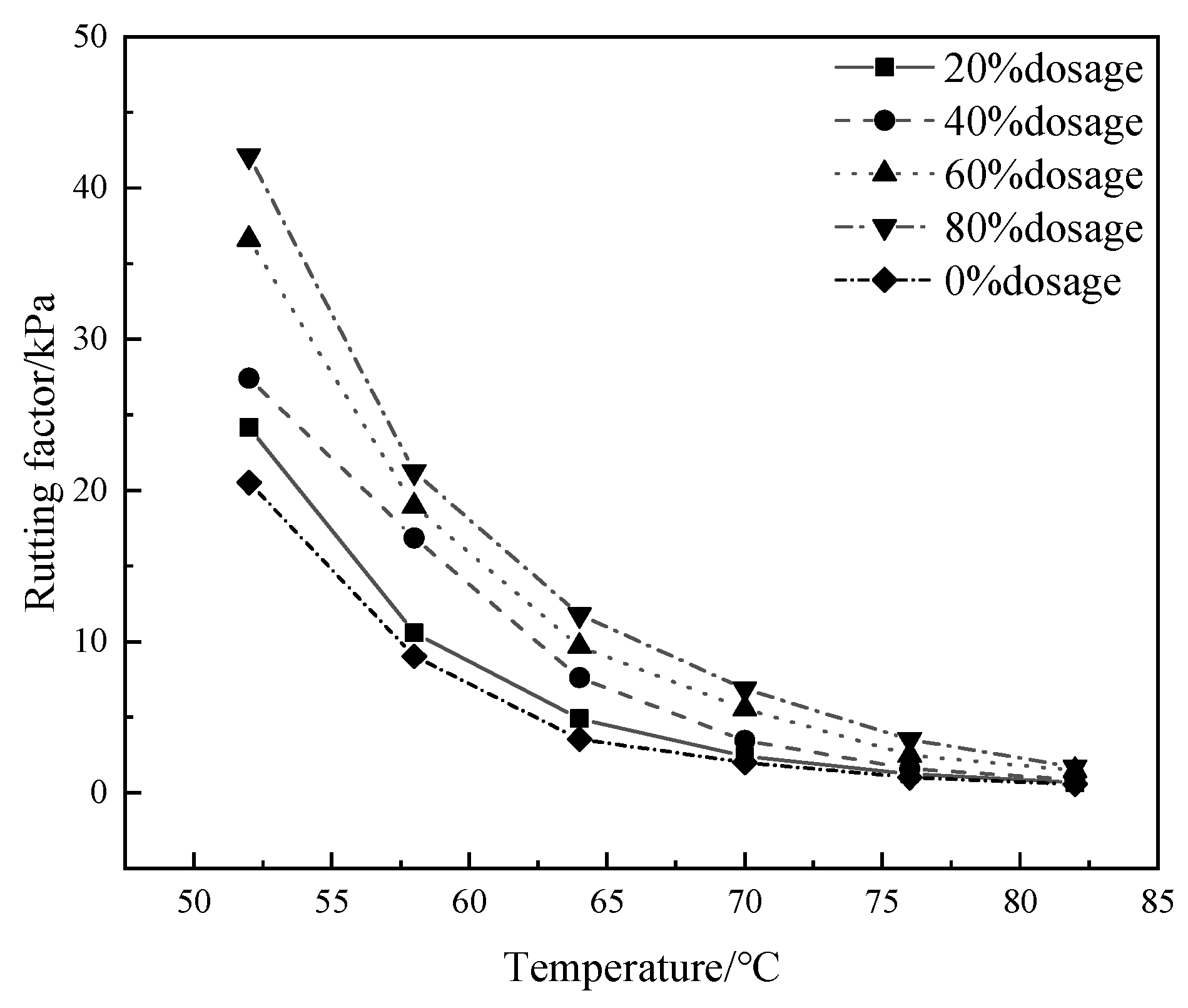

The rutting factor can partially reflect the anti-rutting performance of asphalt pavement.

Figure 3 illustrates the relationship between the rutting factor and temperature variation for recycled asphalt with different contents of aged asphalt. According to the test results, when the strain level is standardized to 12%, the rutting factor changes exhibit a generally consistent trend for all samples at a test frequency of 10 Hz under simulated normal conditions. Under these test conditions, the rutting factor increases with the rise in the amount of aged asphalt. Therefore, from the perspective of regularity, the rutting factor index meets the expected requirements.

3.3. Four-Component Analysis

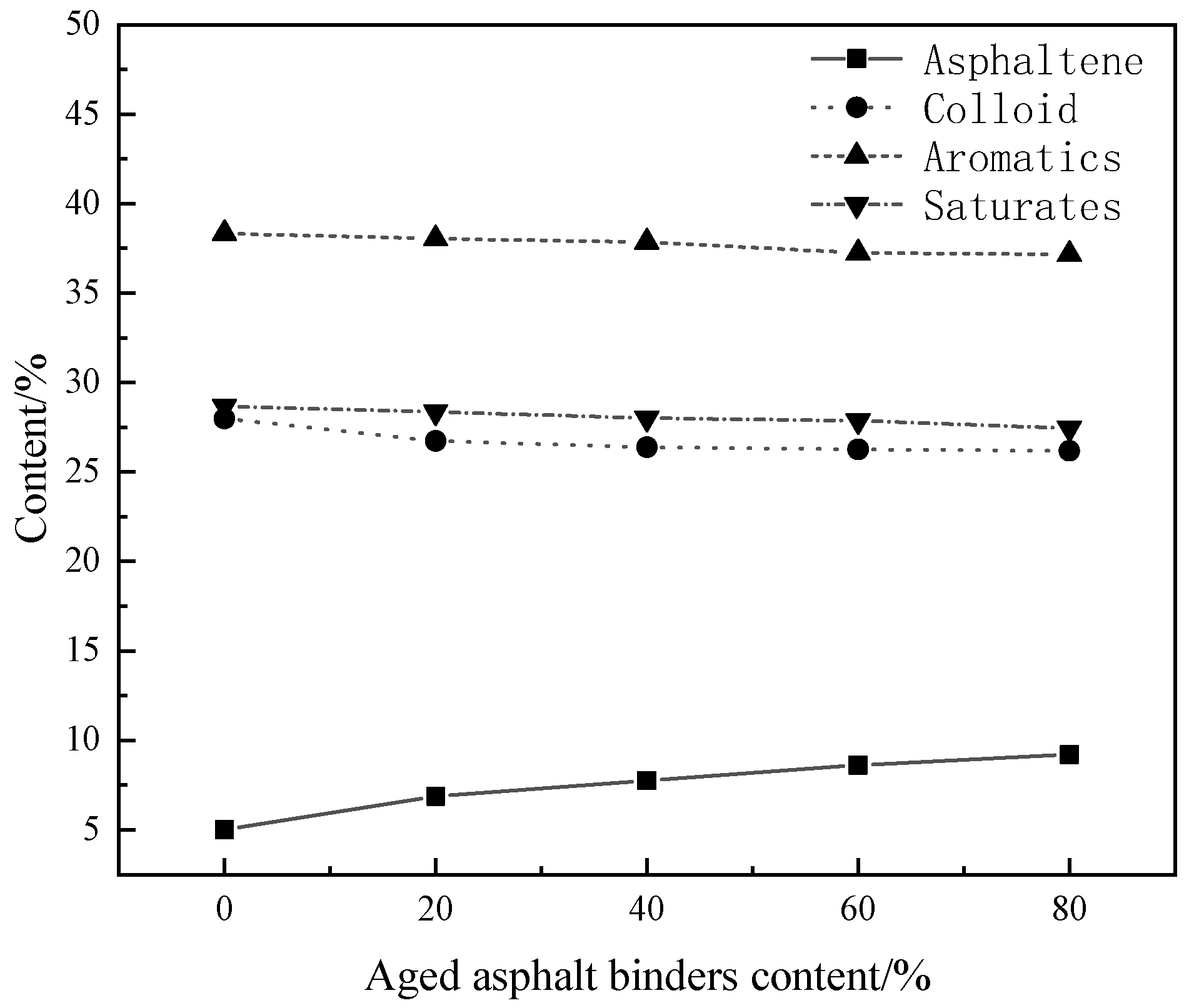

To study the changes in the components of recycled asphalt when mixed with different amounts of aged asphalt, this paper conducted tests based on the asphalt chemical composition (four-component method) outlined in China’s “Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering” JTG E20-2011. The test results are shown in

Figure 4.

From the results shown in

Figure 4, it can be observed that with the increase in the content of aged asphalt, the asphaltene content in the recycled asphalt increases due to the high asphaltene content of 9.86% in the aged asphalt, while the other three components do not change significantly. This is because, during the configuration process of recycled asphalt, only the eutectic recombination of chemical components occurs.

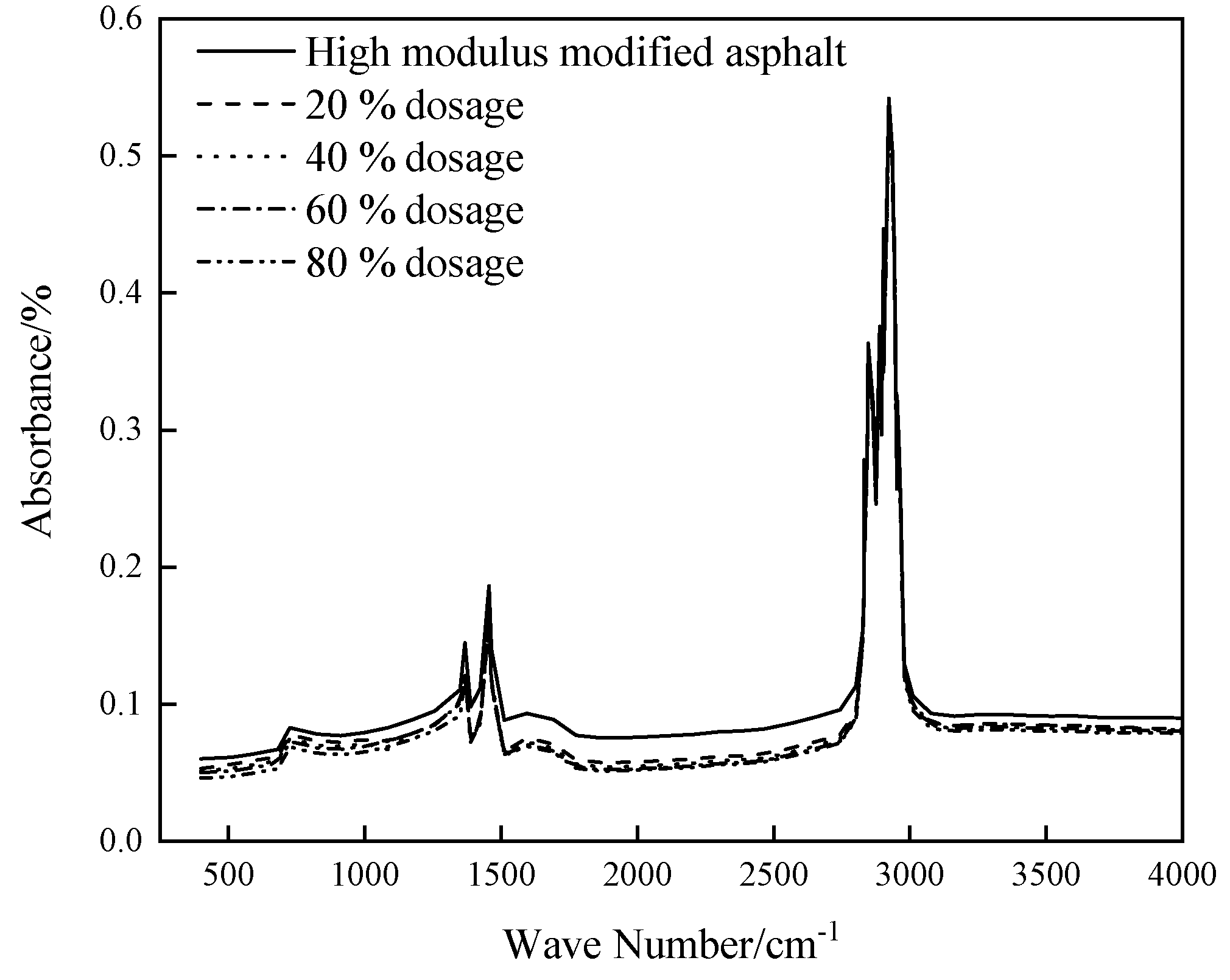

3.4. Infrared Spectrum Analysis

Infrared spectroscopy tests are mainly used to analyze the changes in molecular structure and functional groups of five groups of recycled asphalt. Infrared spectroscopy tests were carried out on five groups: HMA, HMA + 20% JA, HMA + 40% JA, HMA + 60% JA, and HMA + 80% JA. The results of the infrared spectroscopy tests are shown in

Figure 5.

From the analysis of

Figure 5, it can be seen that, compared to high-modulus modified asphalt, no new absorption peaks appear in the infrared spectra of recycled asphalt with different contents of aged asphalt. However, strong absorption bands appear at around 1400 ~ 1600 cm-1 and 2700 ~ 3000 cm-1, and the absorption peak positions of each asphalt group are basically the same. This indicates that the incorporation of aged asphalt is merely a physical mixture, with no chemical reaction occurring and no new functional groups being generated.

4. Analysis of Asphalt Mixture Test Results

In this section, HMAC-20 is selected as the reference gradation. The asphalt-to-aggregate ratio of RAP fine aggregate is known to be 5.6%, and the theoretical maximum content of RAP fine aggregate in the HMAC-20 mixture gradation is calculated to be 36% through inverse calculation. Three types of recycled asphalt mixture with RAP fine aggregate contents of 0%, 18%, and 36% were designed. The road performance and mechanical properties of the recycled asphalt mixture were tested.

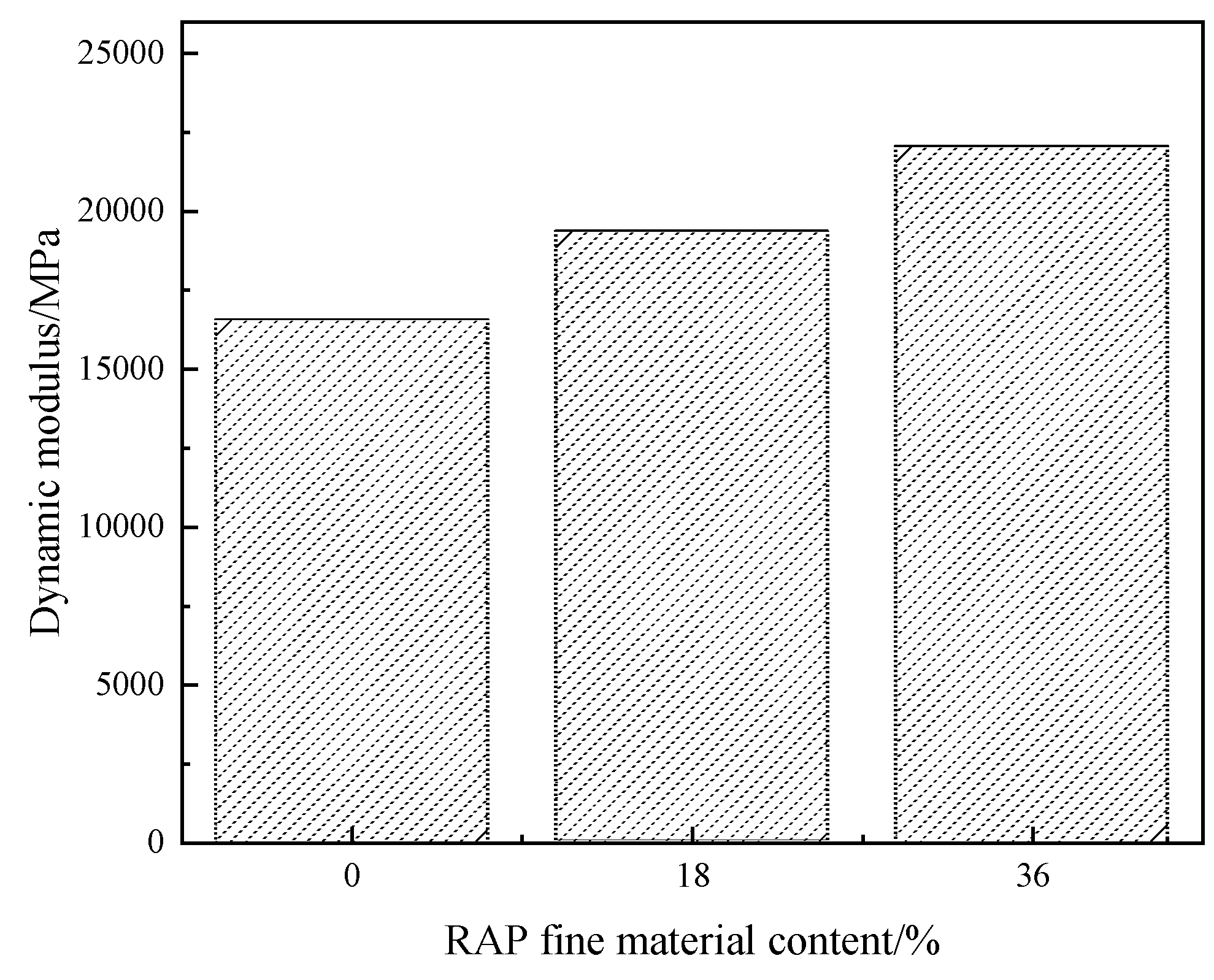

4.1. Dynamic Modulus

The dynamic modulus of asphalt mixture is a critical mechanical parameter in the design of asphalt pavement structures, used to characterize the mechanical properties of asphalt pavement under dynamic load. According to the Chinese standard JTG E20-2011 “Test Procedures for Asphalt and Asphalt Mixture for Highway Engineering,” the dynamic modulus of each mixture group was measured at a test temperature of 20°C and a loading frequency of 10Hz. The results are shown in

Figure 6.

The results indicate that under the same test conditions, the dynamic modulus of recycled asphalt mixture increases with the content of RAP fine aggregate. Compared to the dynamic modulus of high modulus modified asphalt mixture, the dynamic modulus of recycled asphalt mixture containing 18% RAP fine aggregate increased by 15%, and that containing 36% RAP fine aggregate increased by 27%. This is mainly due to the higher content of asphaltene components in the aged asphalt within the RAP fine aggregate. The introduction of aged asphalt increases the viscosity of the recycled asphalt binder, thereby enhancing its mechanical properties [

20].

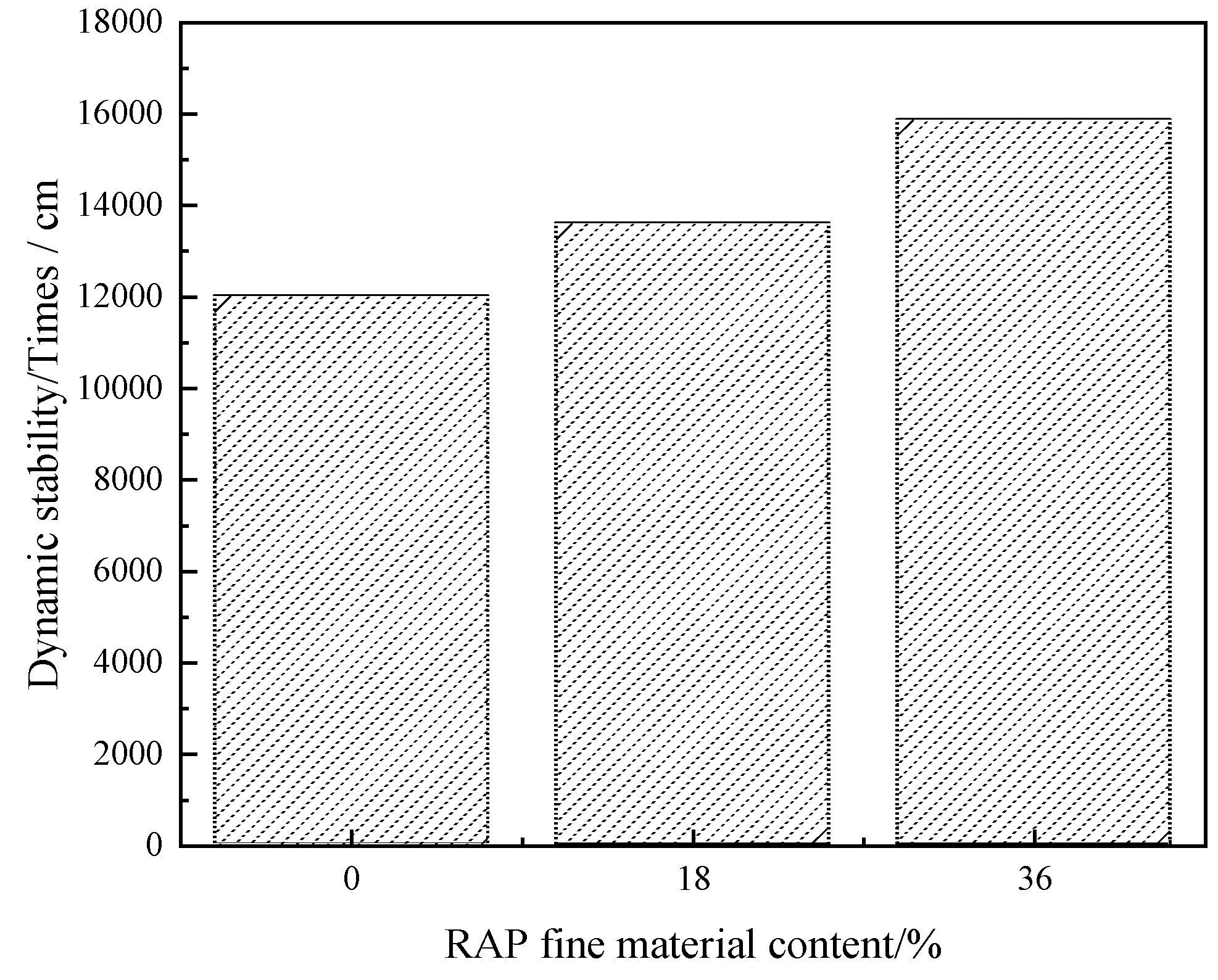

4.2. High Temperature Stability

High temperature stability refers to the performance of asphalt mixture in high temperature environment, which can resist persistent deformation under the action of vehicle load cycle for a long time. In this study, the high temperature (60 °C) rutting test was carried out on the recycled asphalt mixture with different RAP fine aggregate content, and the test results are shown in

Figure 7.

The results show that with the increase of RAP fine aggregate content, the dynamic stability gradually increases. The increase of RAP fine aggregate content improves the high temperature performance of recycled asphalt mixture, because the formation mechanism of high temperature stability comes from the high temperature adhesion of asphalt and the interlocking effect of mineral aggregate gradation [

21]. The aged asphalt in RAP fine aggregate contains a large amount of asphaltene components, which makes the viscosity of recycled asphalt formed by the addition of RAP fine aggregate increase, thus improving the high temperature rutting resistance of recycled asphalt mixture.

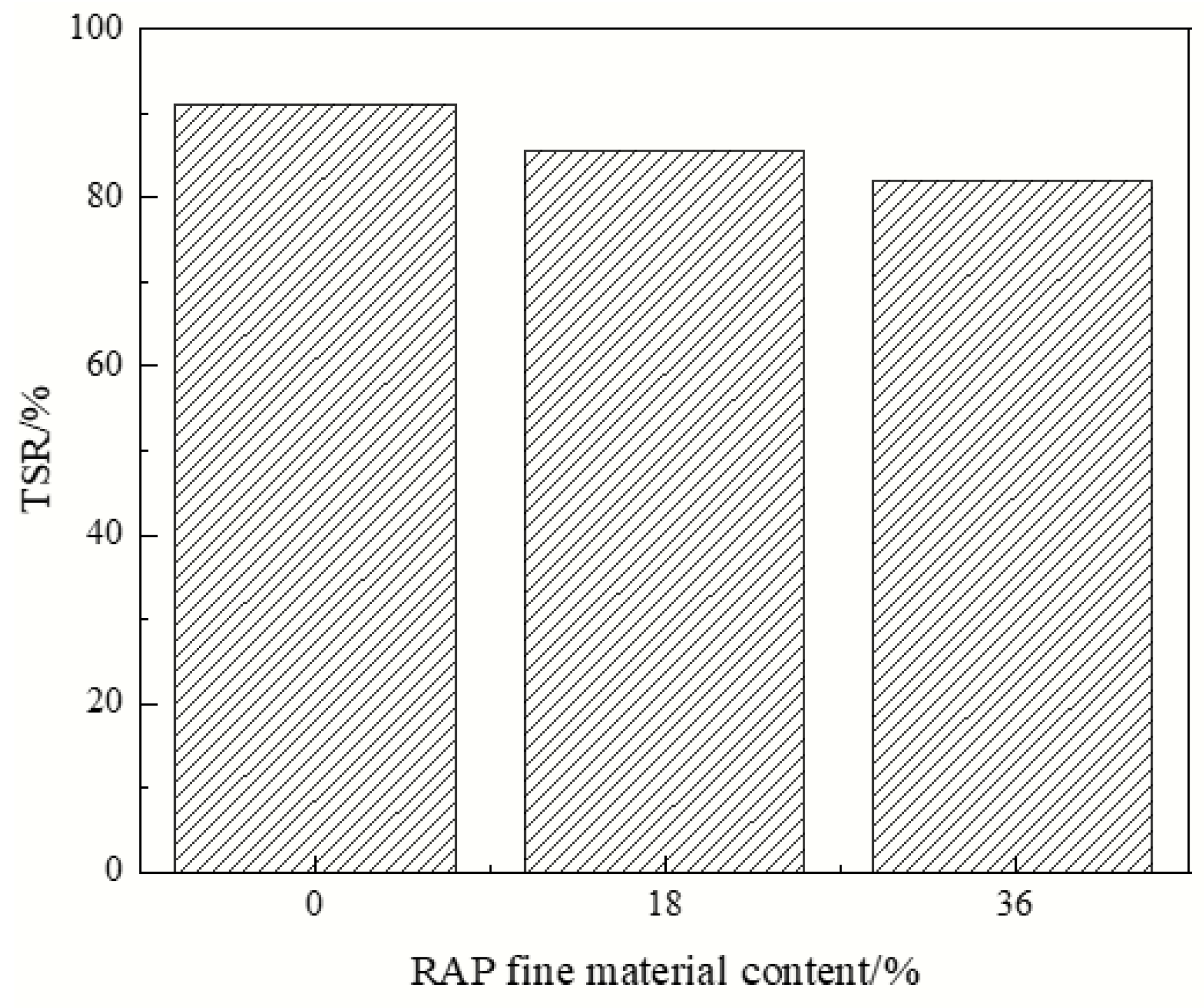

4.3. Water Stability

Water stability can be understood as the ability of asphalt mixture to effectively prevent the spalling of asphalt film after subjected to water penetration or freeze-thaw cycles, as well as the continuous impact of wheel dynamic loads. In this paper, the freeze-thaw splitting test is used to evaluate the water stability of high modulus recycled asphalt mixture with different RAP fine aggregate content. The test results are shown in

Figure 8.

The results show that when the content of RAP fine aggregate increases, the freeze-thaw splitting strength ratio of recycled asphalt mixture does meet the specification requirements. its value will gradually decrease. When the content of RAP fine aggregate reaches 36 %, the freeze-thaw splitting strength ratio at this time is almost equal to the threshold required by the specification. This phenomenon is due to the increase of RAP fine aggregate content, which makes the content of aged asphalt increase, so that the recycled asphalt and mineral aggregate produce a fragile junction area, which further leads to the decrease of adhesion between asphalt and mineral aggregate [

22], resulting in the decrease of water stability of high modulus recycled asphalt mixture.

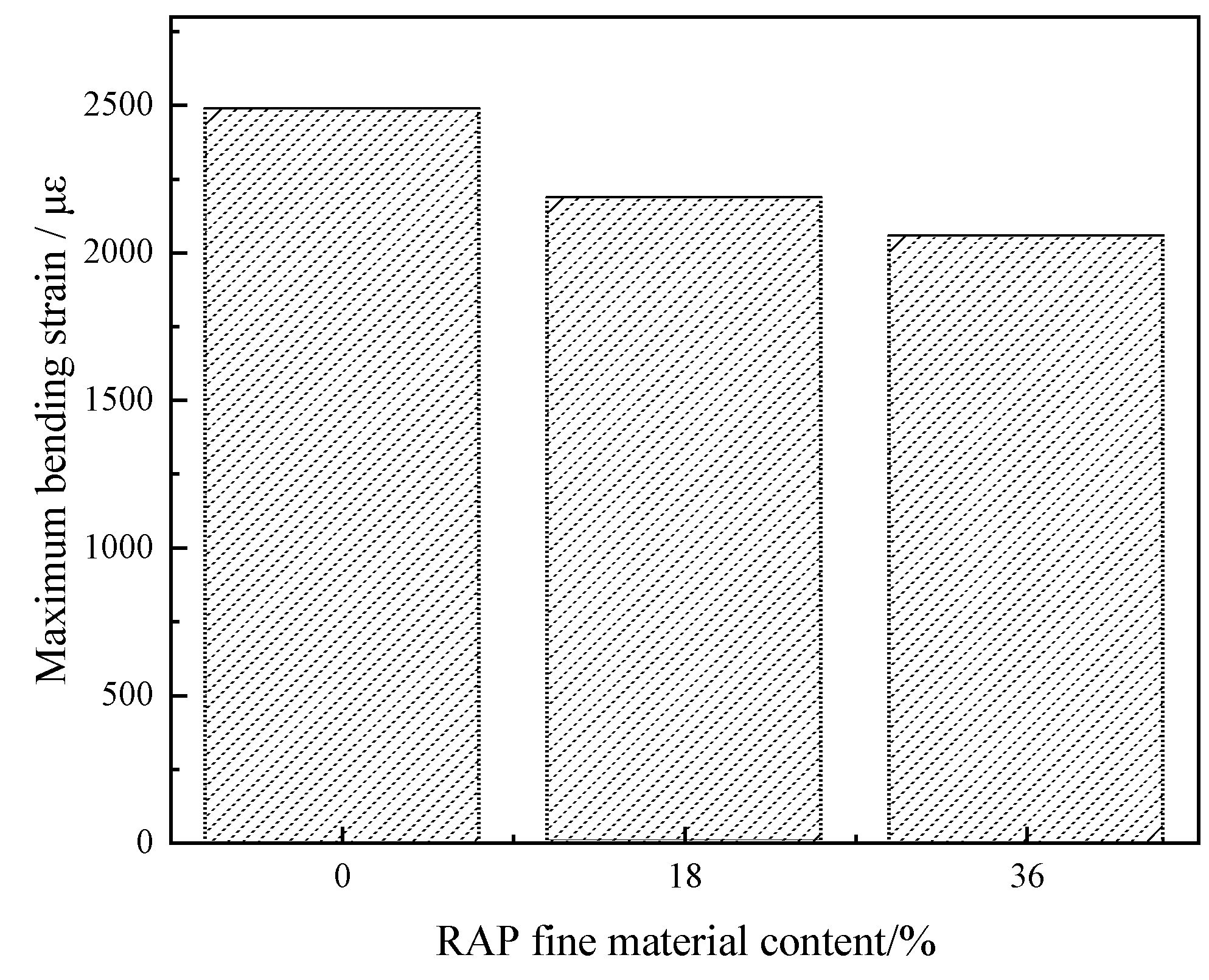

4.4. Low temperature Crack Resistance

Low temperature crack resistance is defined as the performance of asphalt mixture to prevent crack formation under the dual influence of vehicle load and temperature stress in the environment of continuous low temperature or sudden large temperature reduction. In this paper, the low temperature bending test of the beam is carried out under the test conditions of-10 °C and 50mm/min loading speed to measure the low temperature crack resistance of the high modulus recycled asphalt mixture added with different proportions of RAP fine aggregate. The test results are shown in

Figure 9.

The results show that with the increase of the proportion of RAP fine aggregate, the recycled asphalt mixture shows a gradual downward trend in the maximum bending strain. In particular, when the incorporation of RAP fine aggregate reaches 36 %, the measured bending tensile strain value is quite close to the limit threshold of the specification. The reason is that the plasticity and ductility of aged asphalt in the service process of asphalt pavement are deteriorated, which leads to the hardening and brittleness of recycled asphalt mixture [

23]. Although its strength is improved, its low temperature deformation resistance is reduced.

5. Conclusion

1. With the increase of aged asphalt content, the conventional properties and rheological properties change. For every 20 % increase of aged asphalt, the penetration at 25 °C, ductility at 25 °C and dynamic viscosity at 60 °C decreased by about 6.2 %, 15.4 % and 3.9 % respectively, the softening point increased by about 13.3 %, the complex shear modulus G * and rutting factor increased, and the phase angle δ decreased. Under the gradient of temperature change, the changes of complex modulus, phase angle and rut factor meet the requirements of regularity.

2. After four-component analysis and infrared spectrum analysis, it can be obtained that there are strong absorption bands near 1400 ~ 1600cm-1 and 1700 ~ 3000cm-1. The absorption peak position of each group of asphalt is basically the same. It can be seen that the addition of different amounts of aged asphalt to high modulus modified asphalt does not form new functional groups, but only physical melting occurs, and the four components are relative.

3. Under the theoretical maximum content of 36 %, the recycled asphalt mixture with the content of 18 % and 36 % was compared with the high modulus modified asphalt mixture. It was found that the dynamic modulus and 60 °C dynamic stability of the recycled material were significantly improved, and the water stability and low temperature crack resistance were lower than that of the high modulus modified asphalt mixture.

Author Contributions

Conceptualization, Kou Xiao; methodology, Kou Xiao; validation, Kou Xiao; formal analysis, Kou Xiao; investigation, Kou Xiao; resources, Kou Xiao; data curation, Kou Xiao; writing—original draft preparation, Kou Xiao; writing—review and editing, Kou Xiao; visualization, Kou Xiao; supervision, Kou Xiao; project administration, Kou Xiao.

Funding

This research received no external funding.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

Thanks to Changsha University of Science and Technology for supporting the experimental equipment.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Editorial Department of ‘China Highway Journal’(China). Chinese Journal of Highway Engineering,2020,33(10):1-66.

- Zhichao Wang,Bin Hu,Mingyan Shen and so on. Research on RAP content of hot recycled asphalt mixture based on road performance [J](China).Highway Transportation Technology,2024,41(01):10-17.

- Haibin Li, Jiang Cao. Design and application of hot recycled mixture ratio of waste aged asphalt mixture [J](China).Road, 2012 (07): 256-260.

- Zou Xiaoyong, Li Ning, Wu Wenxiu, etc. Effect of fine separation on the properties of RAP[J](China). Journal of Dalian Jiaotong University, 2023,44(06):71-76.

- Xinyan Huang,Aimin Sha,Xiaolong Zou and so on. The performance and application of High Modulus Asphalt Concrete [J](China).Highway Transportation Technology, 2016,33(12):35-41.

- Shilv Xu,Jianwei Xu. Study on the performance of recycled asphalt in asphalt pavement RAP material[J](China).China Construction, 2019(10):158-159.

- Ying Cheng,Xiaowen Zhao,Kezhen Yan and so on. Research on the performance of high modulus asphalt and asphalt mixture [J](China).Highway, 2022,67(10):343-349.

- Yumei Han, Guangbin Zhao,Haimei Zhang. Application status and development of High Modulus Asphalt Concrete[J](China). Journal of Guangzhou Maritime University, 2016,24(02):28-31.

- SERFASS J P, BENSE P, PELLEVOISIN P. Properties and new developments of High Modulus Asphalt Concrete[C]//Eighth Inter-national Conference on Asphalt Pavements. Seattle: The International Society for Asphalt Pavement,1997:325-333.

- CORTE J F. Development and uses of hard grade asphalt and of high modulus asphalt mixes in France[J].Transportation Re-search Circular,2001,503:12-31.

- Lei Geng. French high modulus thermal regeneration technology landed in China is not acclimatized[C]//China Highway Society Maintenance and Management Branch(China). Maintenance and management 2015 10th (total 56th), 2015.3.

- Hongrui Zhang,Lu Cao,Lingyun Yin. Performance Evaluation of High Modulus Mixtures of High Volume Recycled Asphalt Pavement Materials[J](China). Sino-foreign Highway, 2012,32(06):254-258.

- Minghong Ma,Qin Ye. Research and Application of High Volume Hot Mix Plant Recycled Asphalt Mixture Technology [J](China).Modern Transportation Technology,2014,11(05):1-4.

- Gaoqiang Ma. Research on the performance of High Modulus Asphalt Concrete with high old material content [J](China).Highway Transportation Technology (Applied Technology Edition), 2015,11(11):59-63.

- Junlin Che. Study on the performance of recycled asphalt pavement material (RAP)[J](China).China Building Materials Technology, 2021,30(02):62-64.

- Lin Yang. Experimental study on durability of High Modulus Asphalt Concrete based on low grade asphalt and rock asphalt blending technology[J](China).Road Engineering, 2016,41(04):297-301.

- GENG H, CLOPOTEL C S, BAHIA H U.Effects of high modulus asphalt binders on performance of typical asphalt pavement structures [J]. Construction & Building Materials,2013, 44 (1):207-213. [CrossRef]

- CHEN Y, WANG H N, XU S B, et al, High Modulus Asphalt Concretes: a state-of-the-art review [J]. Construction and Building Materials,2020,237:117653. [CrossRef]

- Cheng Peifeng, Bai Yue, Li Yiming and so on. Study on the effect of corn straw oil on the rheological properties of aged asphalt and its regeneration effect[J/OL](China).China-foreign highway:1-15[2024-03-14].

- Huagang He,Xiaodong Jia,Xiaolong Li. Study on road performance and heating process of hot recycled mixture with high RAP content[J](China).Chinese and foreign highway, 2021,41(03):286-290.

- Zhang Jian, Wang Daming. Experimental study on road performance of secondary hot in-place recycled asphalt mixture[J](China).China-foreign highway,2017,37(06):283-287.

- Weirong Huang,Peng Song. Study on road performance of fully recycled asphalt mixture [J](China).Journal of Xuzhou Institute of Technology (Natural Science Edition), 2018,33(03):22-26.

- Zhichao Wang,Bin Hu,Mingyan Shen and so on. Research on RAP content of hot recycled asphalt mixture based on road performance[J](China).Highway Transportation Technology, 2024,41(01):10-17.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).