Submitted:

30 October 2025

Posted:

30 October 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

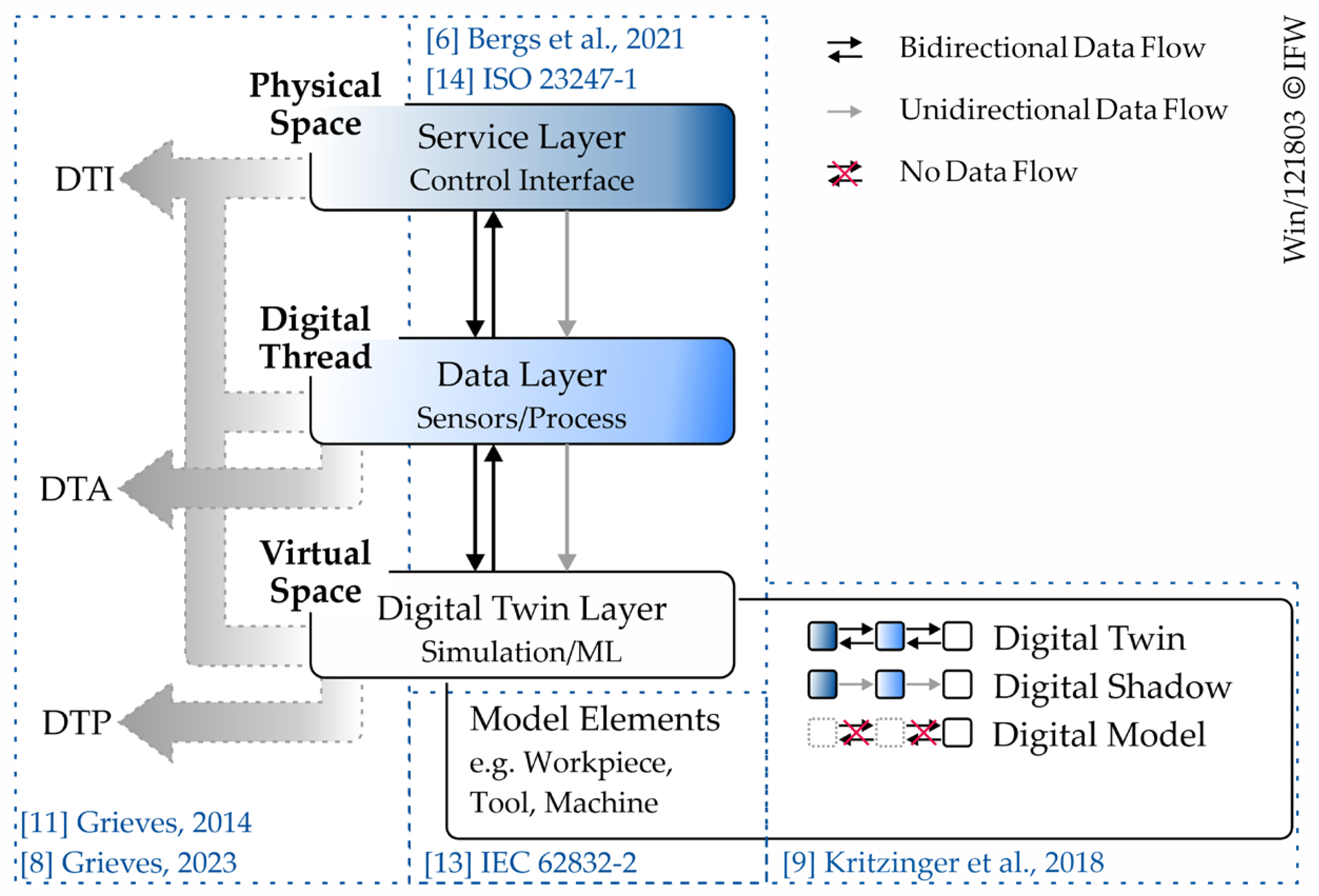

Digital Twin Systems in Manufacturing

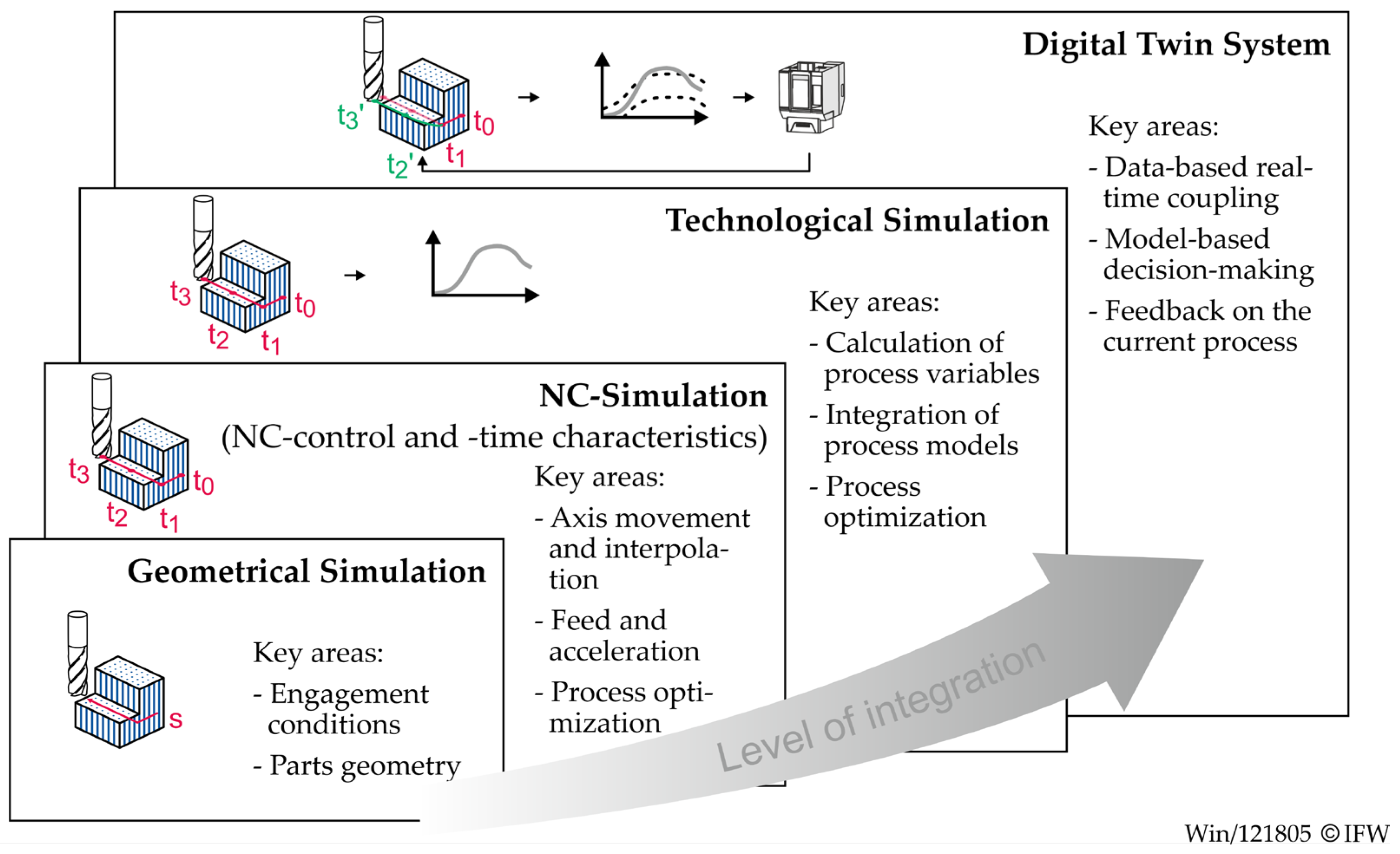

Process Simulation

- Realizing a complete DTS with a bidirectional data flow for closed-loop integration of real and virtual machining states, and

- validating the system’s capability for process-parallel monitoring and intervention through representative use cases in orthopedic implant manufacturing.

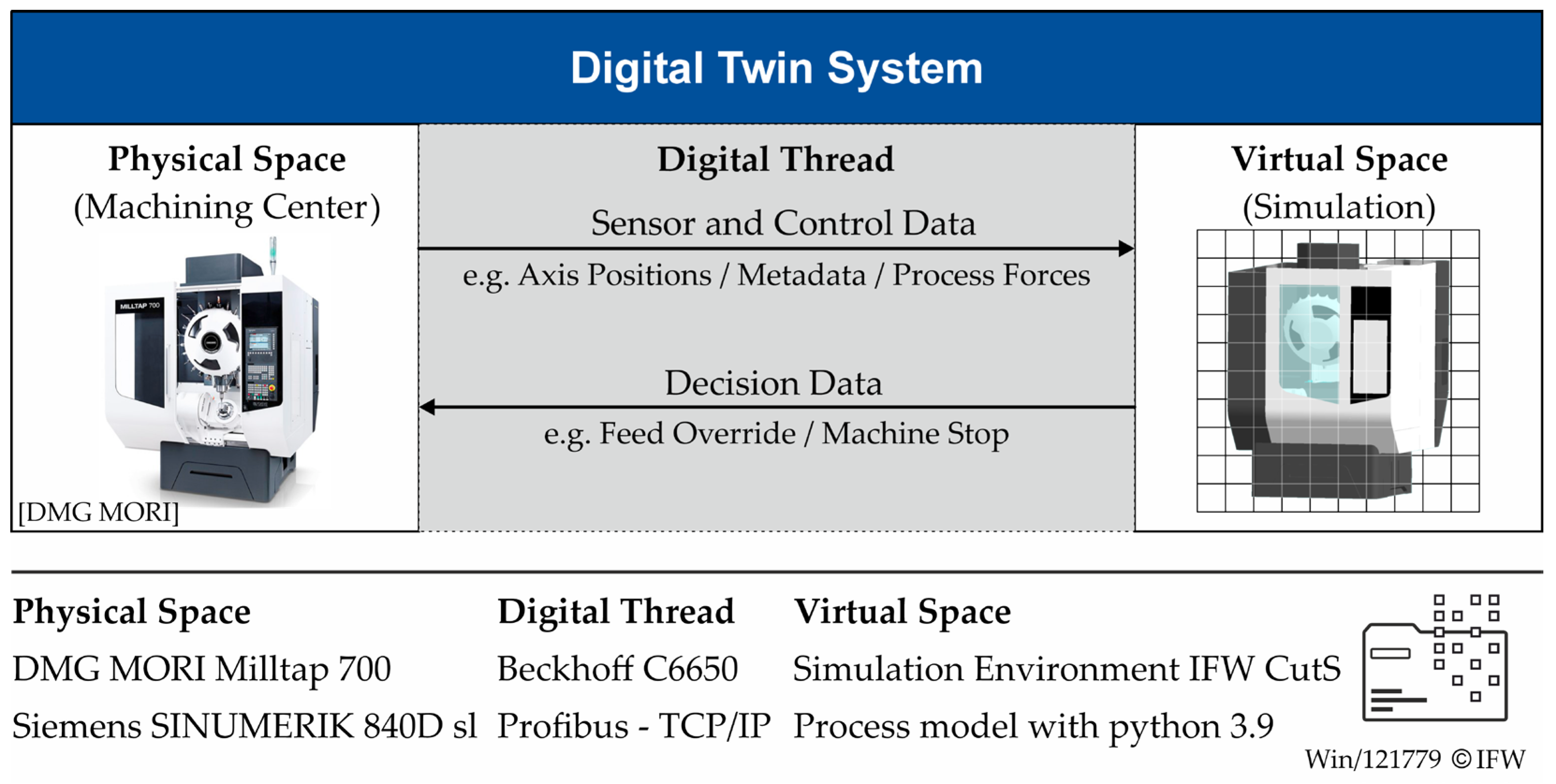

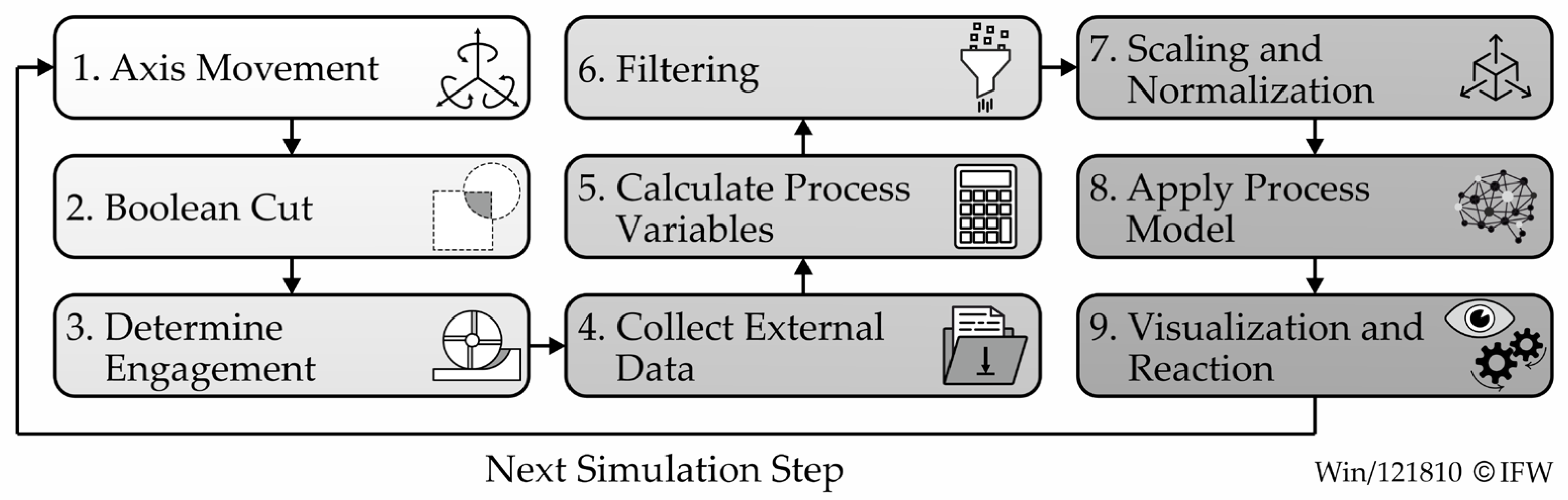

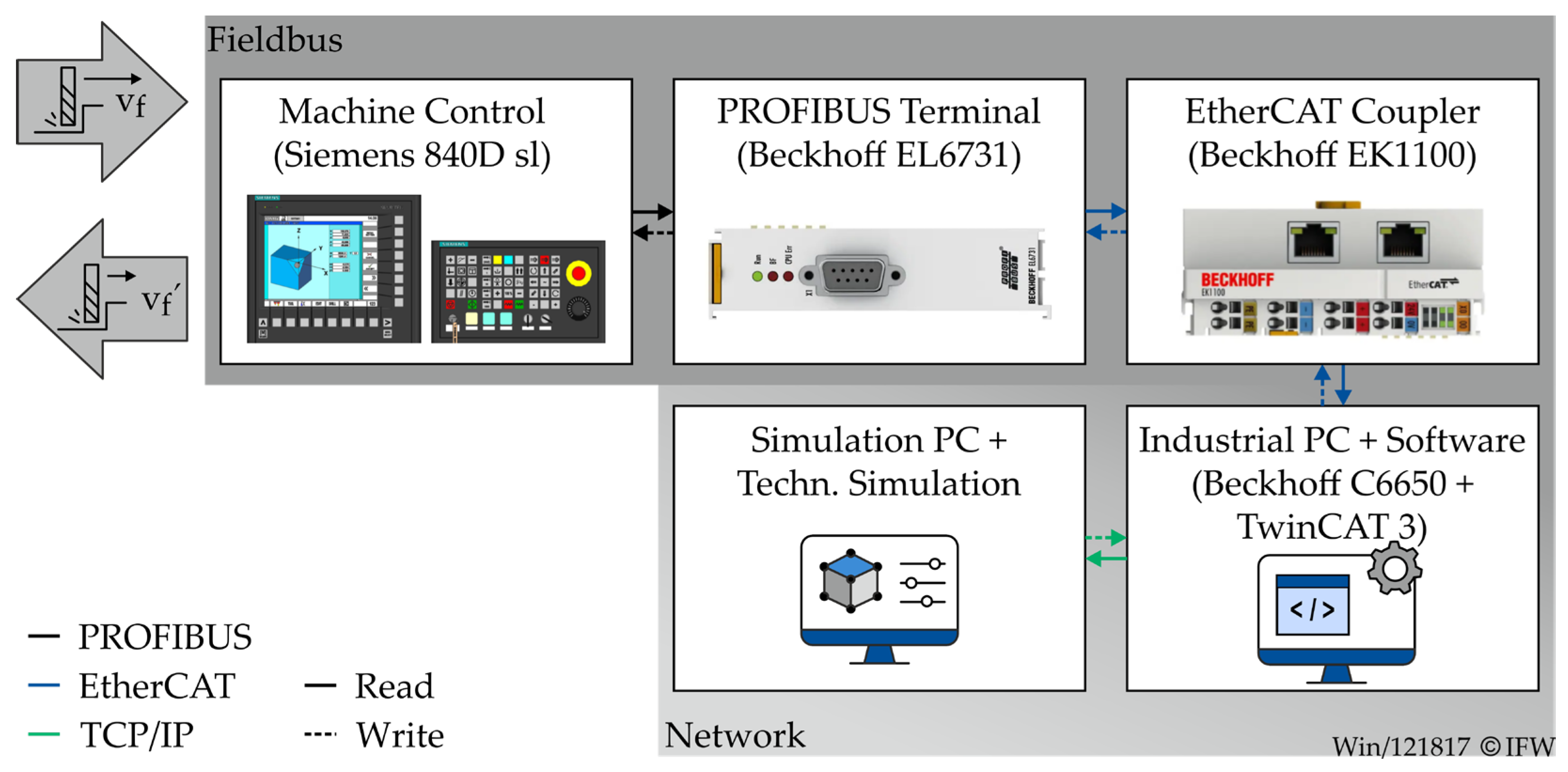

2. Architecture of the Digital Twin System

- Real-time coupling between machine and simulation at the controller level

- Utilization of machine-native signals for scalable process diagnostics

- Integration of explainable, domain-specific predictive models

- Feedback of condition evaluations into process control or user interface

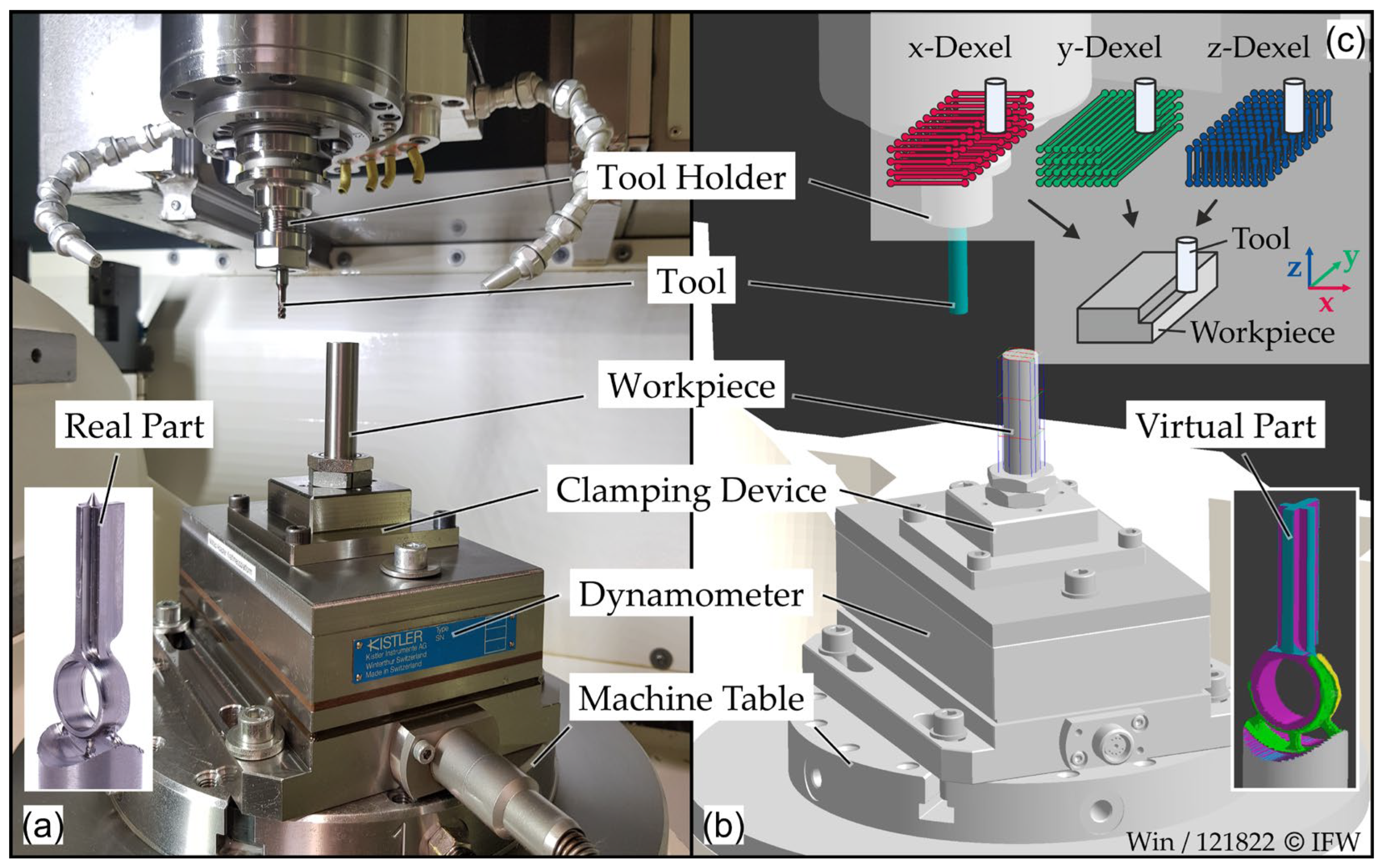

2.1. Physical Space

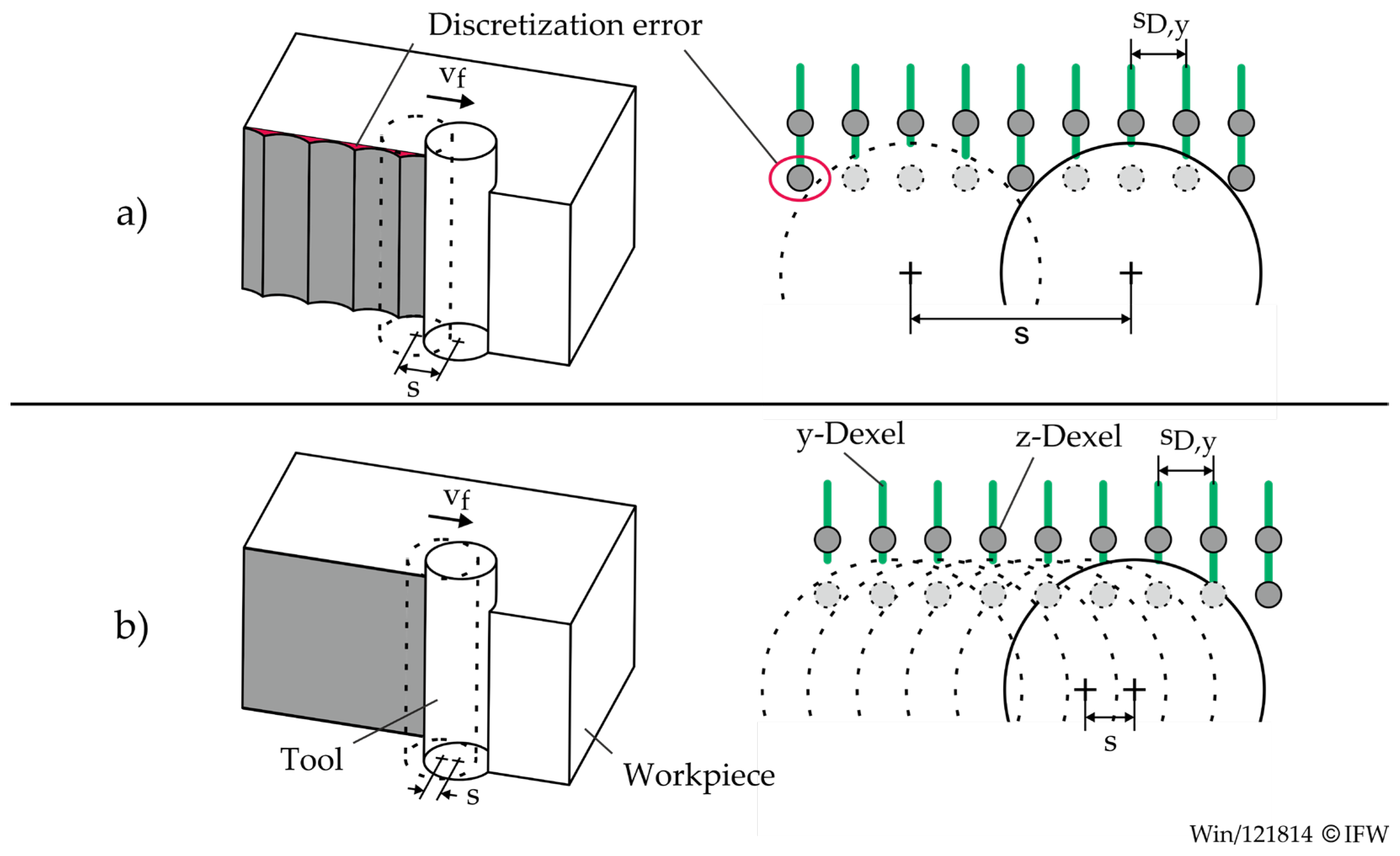

2.2. Virtual Space

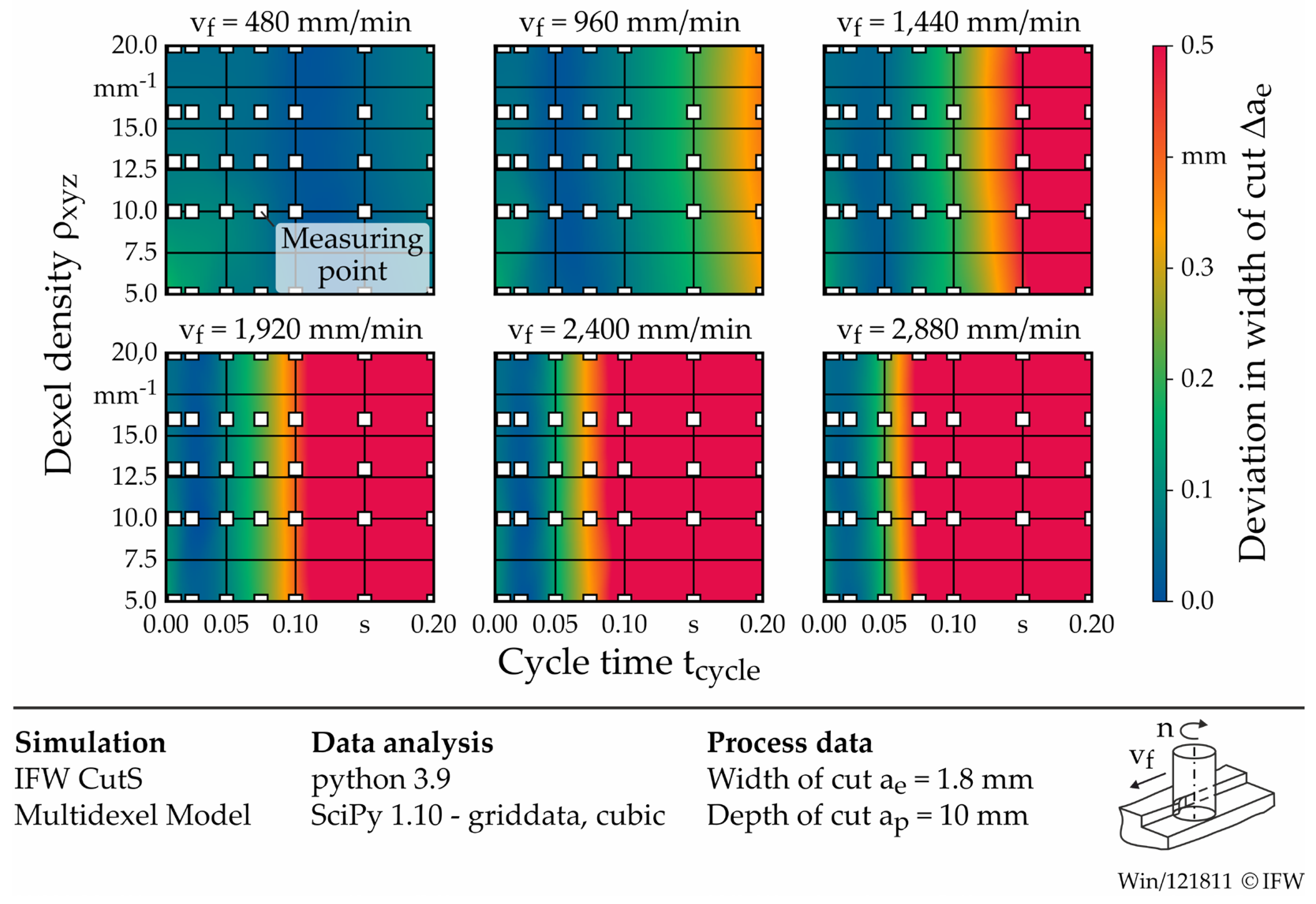

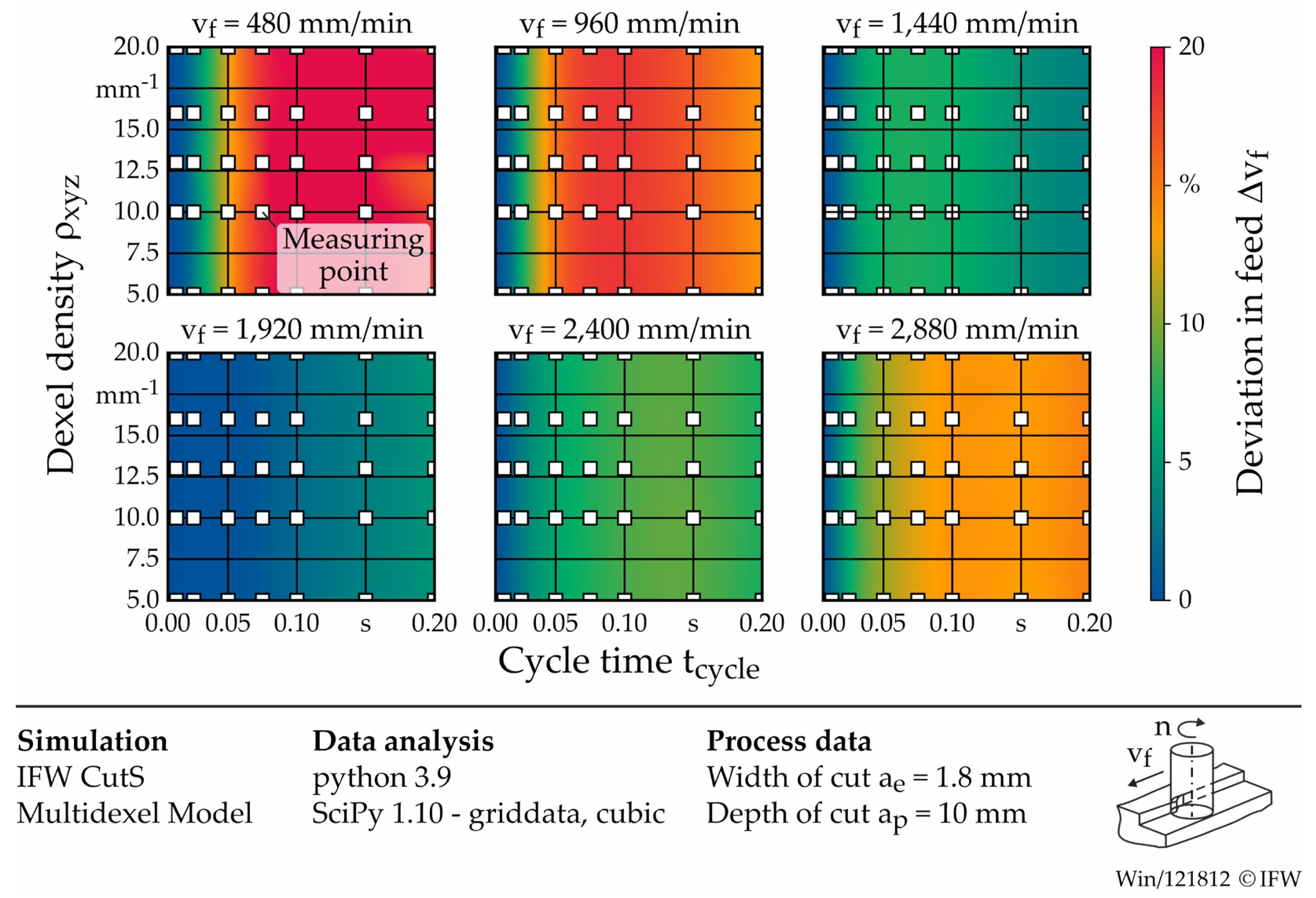

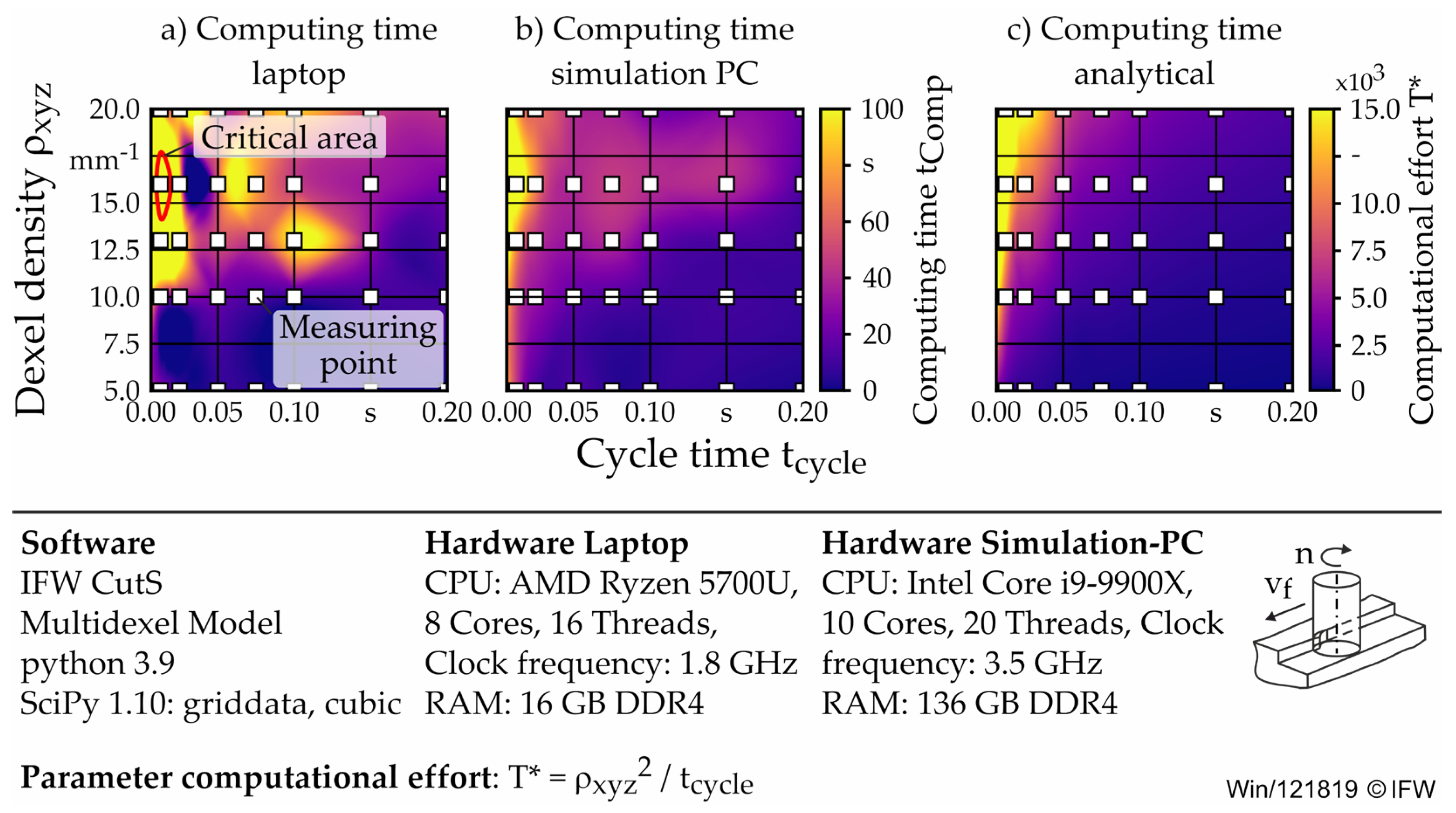

Simulation Study: Influence of Parameters on Model Accuracy and Runtime

- Mean deviation of simulated width of cut (Aae)

- Relative error in simulated feed rate (Avf)

- Total simulation runtime (AT)

2.3. Digital Thread

Communication Latency Analysis

3. Application Scenarios for Process Monitoring and Control Using the Digital Twin System

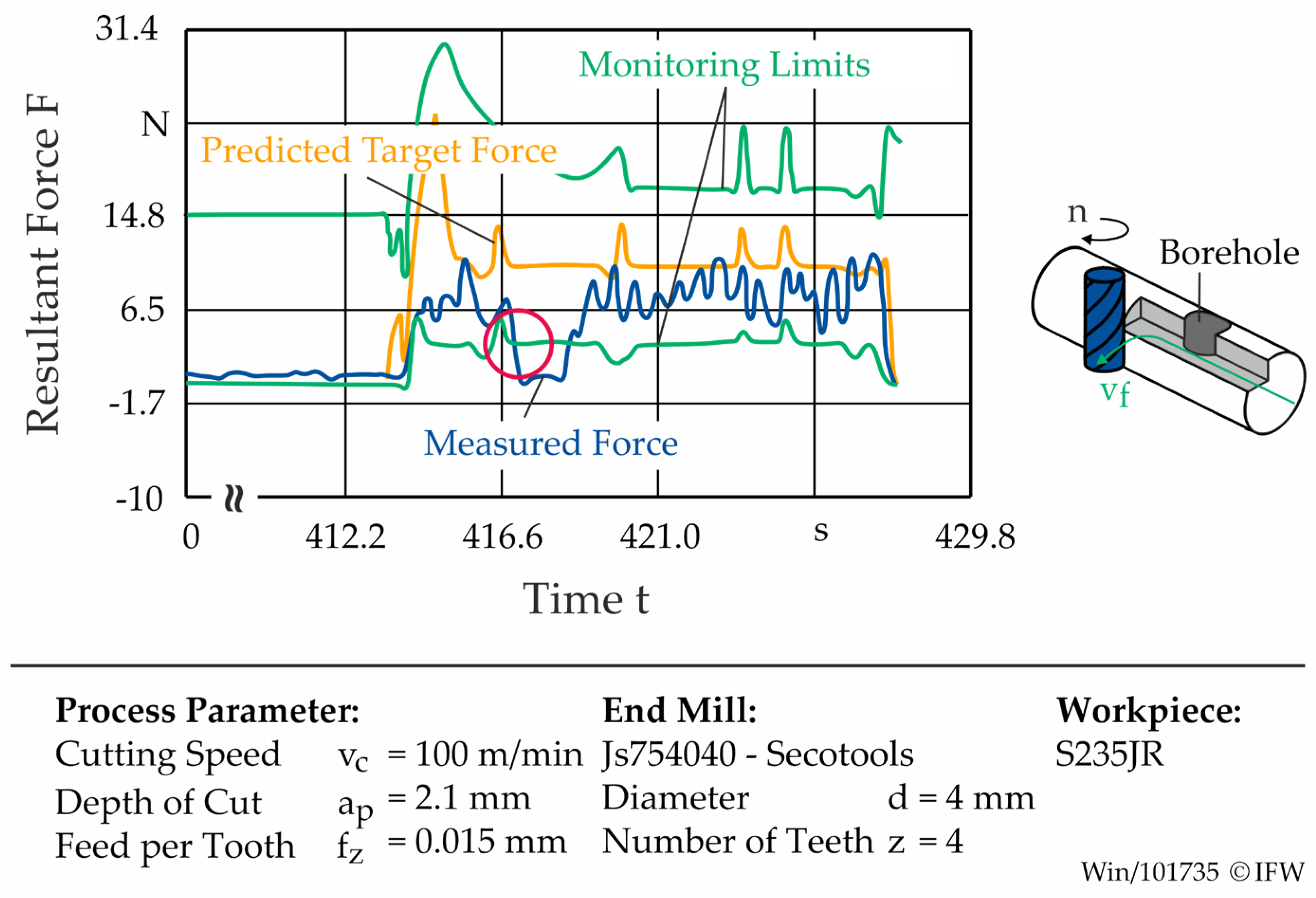

3.1. Use Case 1: Process Force Monitoring and Machine Halt

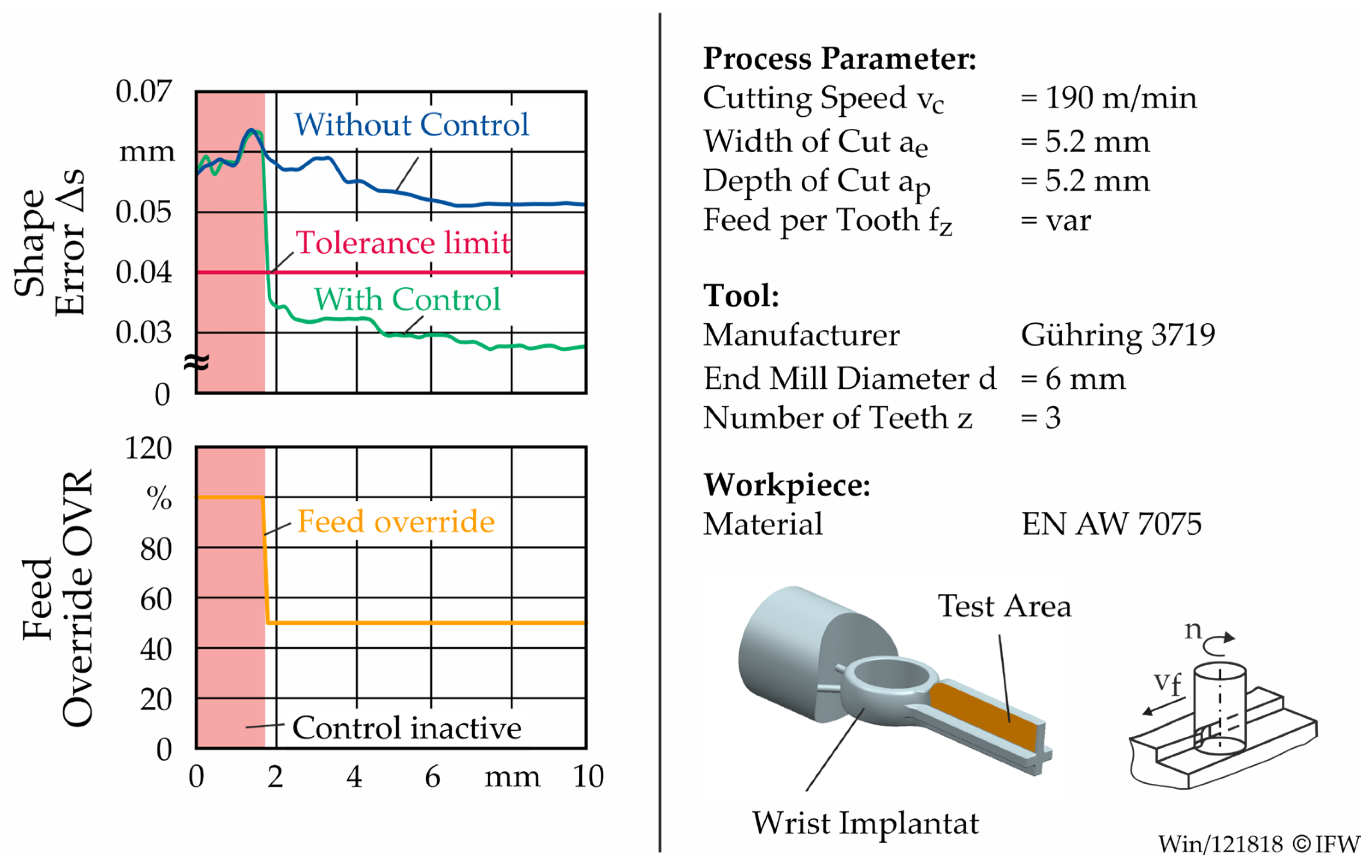

3.2. Use Case 2: Shape Error Control and Feed Rate Adjustment

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ADS | Automation Device Specification |

| C# | C Sharp (programming language) |

| CNC | Computerized Numerical Control |

| DT | Digital Twin |

| DTA | Digital Twin Aggregate |

| DTI | Digital Twin Instance |

| DTP | Digital Twin Prototype |

| DTS | Digital Twin System |

| EtherCAT | Ethernet for Control Automation Technology |

| IPC | Industrial PC |

| ML | Machine Learning |

| NC | Numerical Control |

| ONNX | Open Neural Network Exchange |

| PC | Personal Computer |

| PROFIBUS | Process Field Bus |

| TCP/IP | Transmission Control Protocol / Internet Protocol |

References

- Europäische Union. Verordnung (EU) 2017/745 des Europäischen Parlaments und des Rates: MDR, 2017.

- Springer Fachmedien Wiesbaden GmbH. Whitepaper 2025: Aktuelles zu MDR, AI Act und Cybersecurity, Wiesbaden, 2025.

- International Medical Device Regulators Forum. Unique Device Identification System (UDI System) Application Guide: IMDRF/UDI WG/N48 FINAL:2019, 2019.

- Bergs, T.; Biermann, D.; Erkorkmaz, K.; M'Saoubi, R. Digital twins for cutting processes. CIRP Annals 2023, 72, 541–567. [CrossRef]

- Kellenbrink, C.; Nübel, N.; Schnabel, A.; Gilge, P.; Seume, J.R.; Denkena, B.; Helber, S. A regeneration process chain with an integrated decision support system for individual regeneration processes based on a virtual twin. International Journal of Production Research 2022, 60, 4137–4158. [CrossRef]

- Bergs, T.; Gierlings, S.; Auerbach, T.; Klink, A.; Schraknepper, D.; Augspurger, T. The Concept of Digital Twin and Digital Shadow in Manufacturing. Procedia CIRP 2021, 101, 81–84. [CrossRef]

- Schleich, B.; Dittrich, M.-A.; Clausmeyer, T.; Damgrave, R.; Erkoyuncu, J.A.; Haefner, B.; Lange, J. de; Plakhotnik, D.; Scheidel, W.; Wuest, T. Shifting value stream patterns along the product lifecycle with digital twins. Procedia CIRP 2019, 86, 3–11. [CrossRef]

- Grieves, M.W. Digital Twins: Past, Present, and Future. In The Digital Twin; Crespi, N., Drobot, A.T., Minerva, R., Eds.; Springer International Publishing: Cham, 2023; pp 97–121, ISBN 978-3-031-21342-7.

- Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital Twin in manufacturing: A categorical literature review and classification. IFAC-PapersOnLine 2018, 51, 1016–1022. [CrossRef]

- Grieves, M.; Vickers, J. Digital Twin: Mitigating Unpredictable, Undesirable Emergent Behavior in Complex Systems. In Transdisciplinary Perspectives on Complex Systems; Kahlen, F.-J., Flumerfelt, S., Alves, A., Eds.; Springer International Publishing: Cham, 2017; pp 85–113, ISBN 978-3-319-38754-3.

- Grieves, M. Digital Twin: Manufacturing Excellence through Virtual Factory Replication, 2014. Available online: https://www.researchgate.net/publication/275211047 (accessed on 8 June 2025).

- Zhang, L.; Liu, J.; Zhuang, C. Digital Twin Modeling Enabled Machine Tool Intelligence: A Review. Chin. J. Mech. Eng. 2024, 37. [CrossRef]

- International Electrotechnical Commission. Industrial-process measurement, control and automation - Digital factory framework: Part 2: Model elements, 2020th ed.; International Electrotechnical Commission: Geneva, 2020, 25.040.40 (62832-2). Available online: https://www.vde-verlag.de/iec-normen/249270/iec-62832-2-2020.html.

- International Organization for Standardization. Digital twin framework for manufacturing – Part 1: Overview and general principles, 2021st ed.; ISO: Geneva, 2021, 25.040.40 (23247-1). Available online: https://www.iso.org/standard/75066.html.

- Stark, R.; Fresemann, C.; Lindow, K. Development and operation of Digital Twins for technical systems and services. CIRP Annals 2019, 68, 129–132. [CrossRef]

- Schleich, B.; Anwer, N.; Mathieu, L.; Wartzack, S. Shaping the digital twin for design and production engineering. CIRP Annals 2017, 66, 141–144. [CrossRef]

- International Electrotechnical Commission. Industrial-process measurement, control and automation - Digital factory framework: Part 1: General principles, 2020th ed.; International Electrotechnical Commission: Geneva, 2020, 25.040.40 (62832-1). Available online: https://www.vde-verlag.de/iec-normen/249268/iec-62832-1-2020.html.

- Uhlemann, T.H.-J.; Lehmann, C.; Steinhilper, R. The Digital Twin: Realizing the Cyber-Physical Production System for Industry 4.0. Procedia CIRP 2017, 61, 335–340. [CrossRef]

- Da Silva, L.R.R.; Pimenov, D.Y.; Da Silva, R.B.; Ercetin, A.; Giasin, K. Review of Applications of Digital Twins and Industry 4.0 for Machining. JMMP 2025, 9, 211. [CrossRef]

- Fu, X.; Li, S.; Song, H.; Lu, Y. Digital Twin-driven multi-scale characterization of machining quality: current status, challenges, and future perspectives. Robotics and Computer-Integrated Manufacturing 2025, 93, 102902. [CrossRef]

- Qi, Q.; Tao, F. Digital Twin and Big Data Towards Smart Manufacturing and Industry 4.0: 360 Degree Comparison. IEEE Access 2018, 6, 3585–3593. [CrossRef]

- Denkena, B.; Wichmann, M.; Reuter, L.; Schlenker, F. Realizing Digital Twins in the Aircraft Industry by Using Simulation-Based Soft Sensors. SSRN Journal 2022. [CrossRef]

- Latif, H.; Shao, G.; Starly, B. A Case Study of Digital Twin for Manufacturing Process Involving Human Interactions. Proceedings of the 2020 Winter Simulation Conference 2020.

- Dittrich, M.-A. Autonome Werkzeugmaschinen: Definition, Elemente und technische Integration; TEWISS Verlag: Garbsen, 2021, ISBN 9783959005920.

- Verein Deutscher Ingenieure. Digitale Fabrik: Digitaler Fabrikbetrieb; VDI-Gesellschaft Produktion und Logistik: Düsseldorf, 2011 (VDI 4499 Blatt 2).

- Rehling, S. Technologische Erweiterung der Simulation von NC-Fertigungsprozessen. Zugl.: Hannover, Univ., Diss., 2008; PZH Produktionstechnisches Zentrum: Garbsen, 2009, ISBN 9783941416086.

- Stautner, M. Simulation und Optimierung der mehrachsigen Fräsbearbeitung. Zugl.: Dortmund, Univ., Diss., 2005; Vulkan-Verl.: Essen, 2006, ISBN 3802787323.

- Denkena, B.; Böß, V. Technological NC Simulation for Grinding and Cutting Processes Using CutS. In Proceedings of the 12th CIRP Conference on Modelling of Machining Operations: May 7 - 8, 2009, Donostia-San Sebastián, Spain; Arrazola, P.J., Ed.; Mondragon Unibertsitateko Zerbitzu Ed: Mondragon, 2009; pp 563–566, ISBN 9788460808640.

- Altintas, Y.; Kersting, P.; Biermann, D.; Budak, E.; Denkena, B.; Lazoglu, I. Virtual process systems for part machining operations. CIRP Annals 2014, 63, 585–605. [CrossRef]

- Niederwestberg, D. Prognose und Kompensation der temperaturbedingten Werkstückverlagerungen beim Trockenfräsen. Dissertation; Gottfried Wilhelm Leibniz Universität Hannover; TEWISS - Technik und Wissen GmbH, 2016.

- Arrazola, P.J.; Özel, T.; Umbrello, D.; Davies, M.; Jawahir, I.S. Recent advances in modelling of metal machining processes. CIRP Annals 2013, 62, 695–718. [CrossRef]

- Yohannes, B. Industrielle Prozessüberwachung für die Kleinserienfertigung. Zugl.: Hannover, Univ., Diss., 2013; PZH-Verl.: Garbsen, 2013, ISBN 9783944586137.

- Denkena, B. Cyber-Physical and Gentelligent Systems in Manufacturing and Life Cycle: Genetics and Intelligence - Keys to Industry 4.0; Elsevier Science: Saint Louis, 2017, ISBN 978-0-12-811939-6.

- Pape, O.; Denkena, B. Entwicklung von Fräswerkzeugen durch geometrische Simulationen. Dissertation; Gottfried Wilhelm Leibniz Universität Hannover; TEWISS - Technik und Wissen GmbH, 2021.

- Böß, V.; Denkena, B.; Breidenstein, B.; Dittrich, M.-A.; Nguyen, H.N. Improving technological machining simulation by tailored workpiece models and kinematics. Procedia CIRP 2019, 82, 224–230. [CrossRef]

- Bate, I.; McDermid, J.; Nightingale, P. Establishing timing requirements for control loops in real-time systems. Microprocessors and Microsystems 2003, 27, 159–169. [CrossRef]

- Denkena, B. Teilautonome Fertigung orthopädischer Implantate: TempoPlant, teilautonome Fertigungszelle für orthopädische Implantate: Abschlussbericht zum BMBF-Verbundprojekt; Ed.; TEWISS Verlag: Garbsen, 2024, ISBN 9783959009157.

| Dexel density ρxyz [mm-1] |

Cycle time tcycle [s] |

Feed velocity vf [mm/min] |

|---|---|---|

| 5 10 13 16 20 |

0.00625 | |

| 0.0125 | 480 | |

| 0.075 | 960 | |

| 0.025 | 1,440 | |

| 0.05 | 1,920 | |

| 0.1 | 2,400 | |

| 0.15 | 2,880 | |

| 0.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).