Submitted:

28 October 2025

Posted:

30 October 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Design, Simulation, and Fabrication

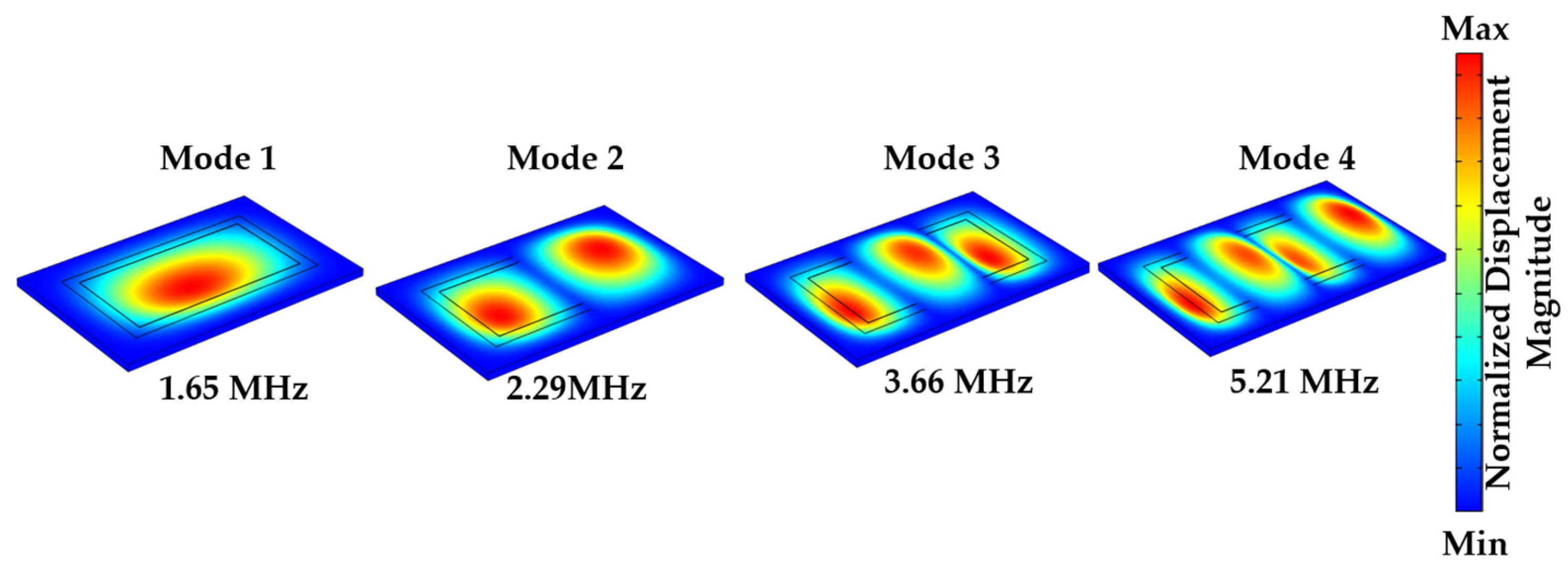

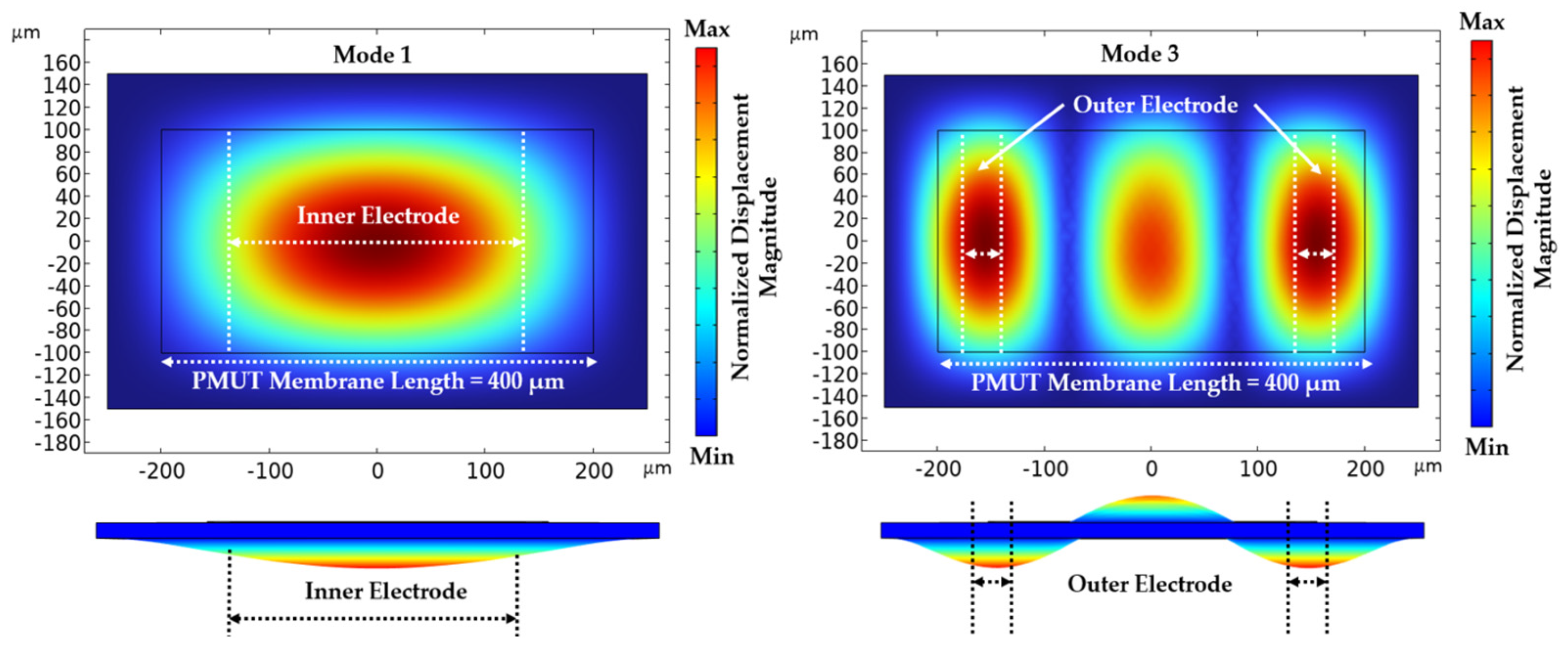

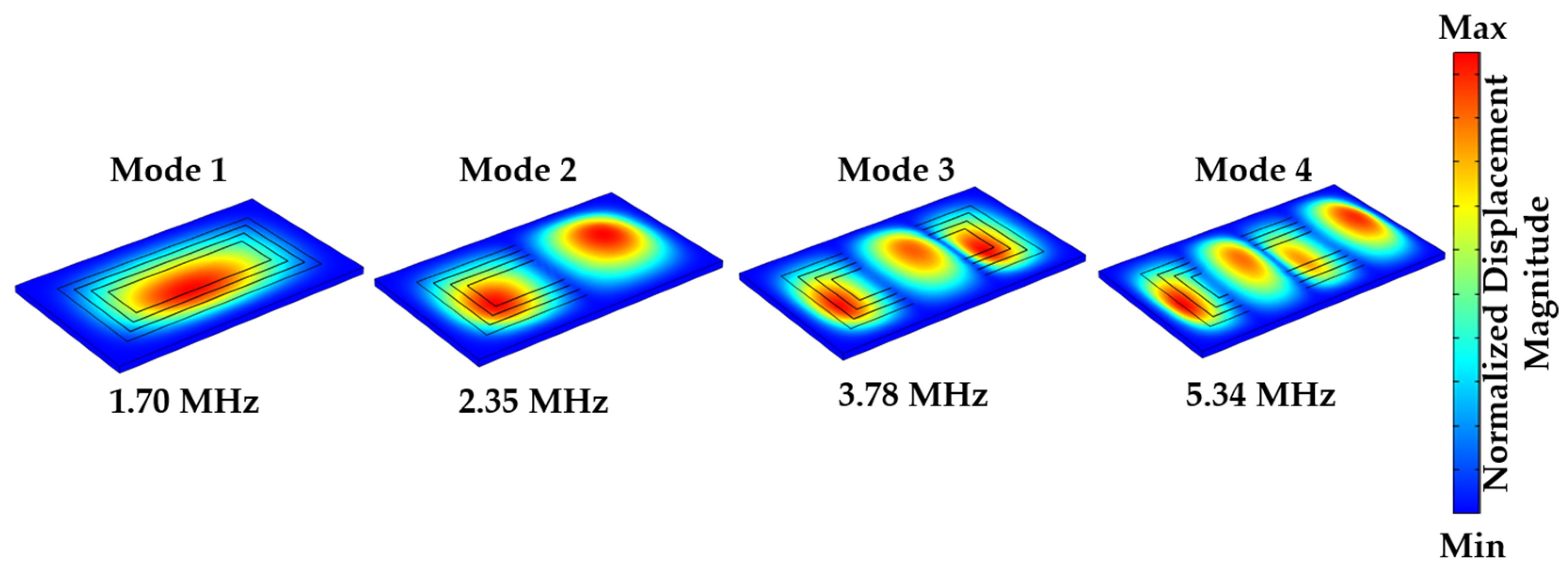

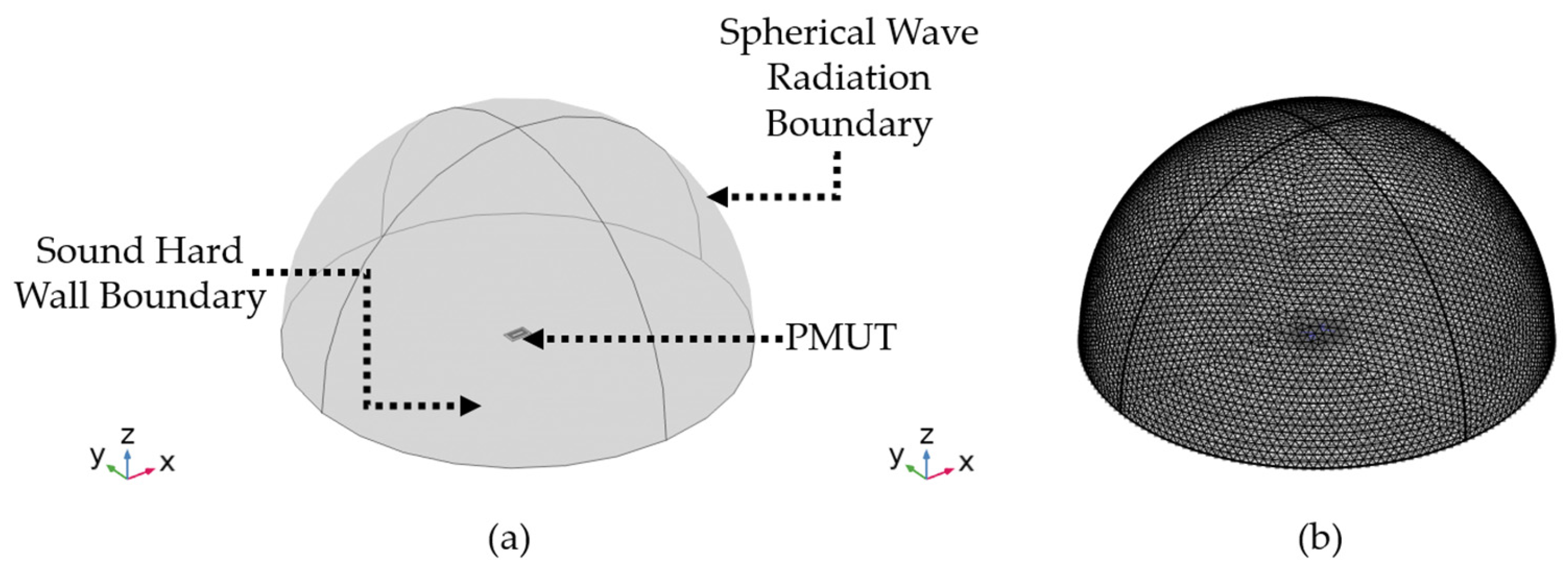

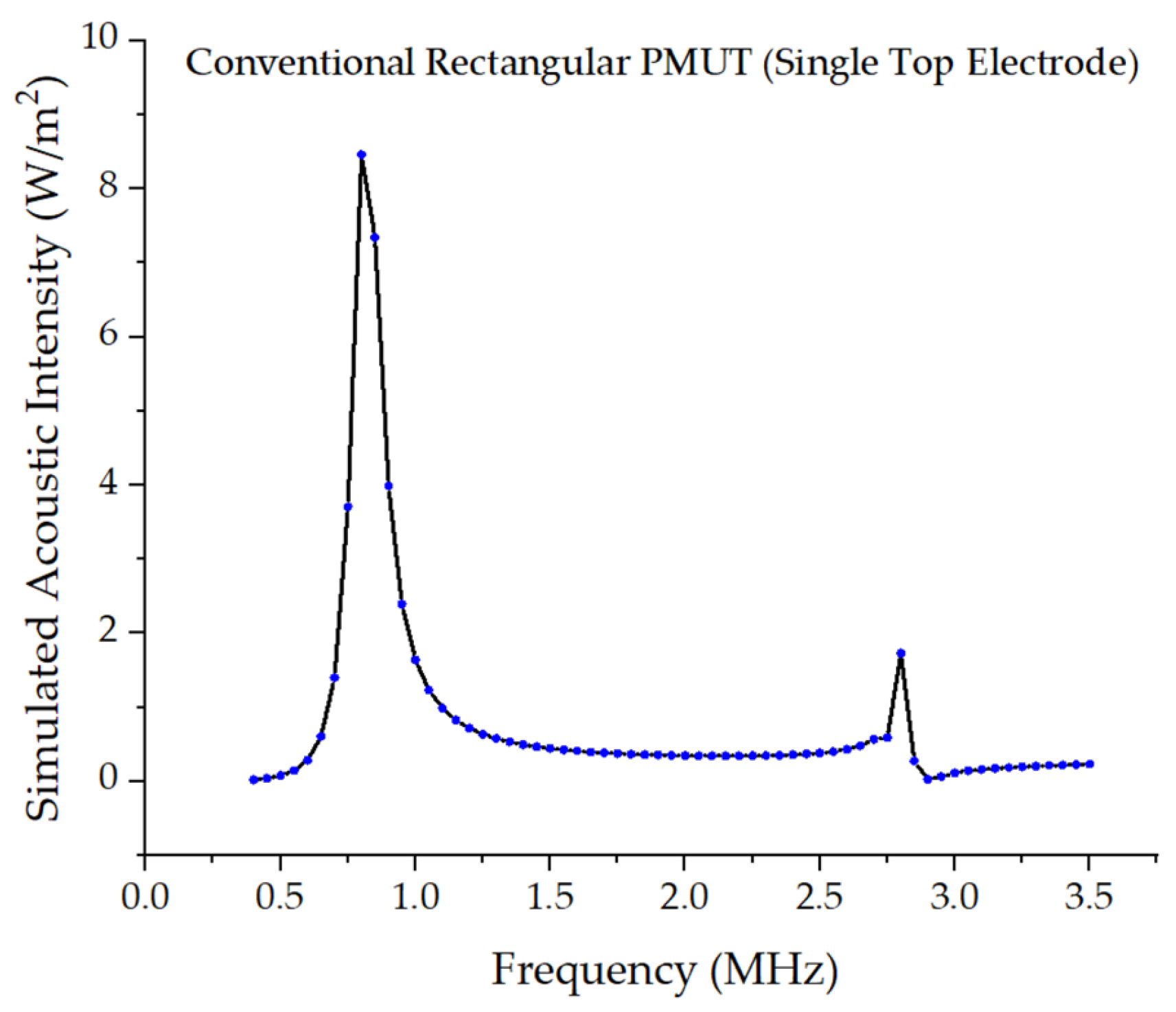

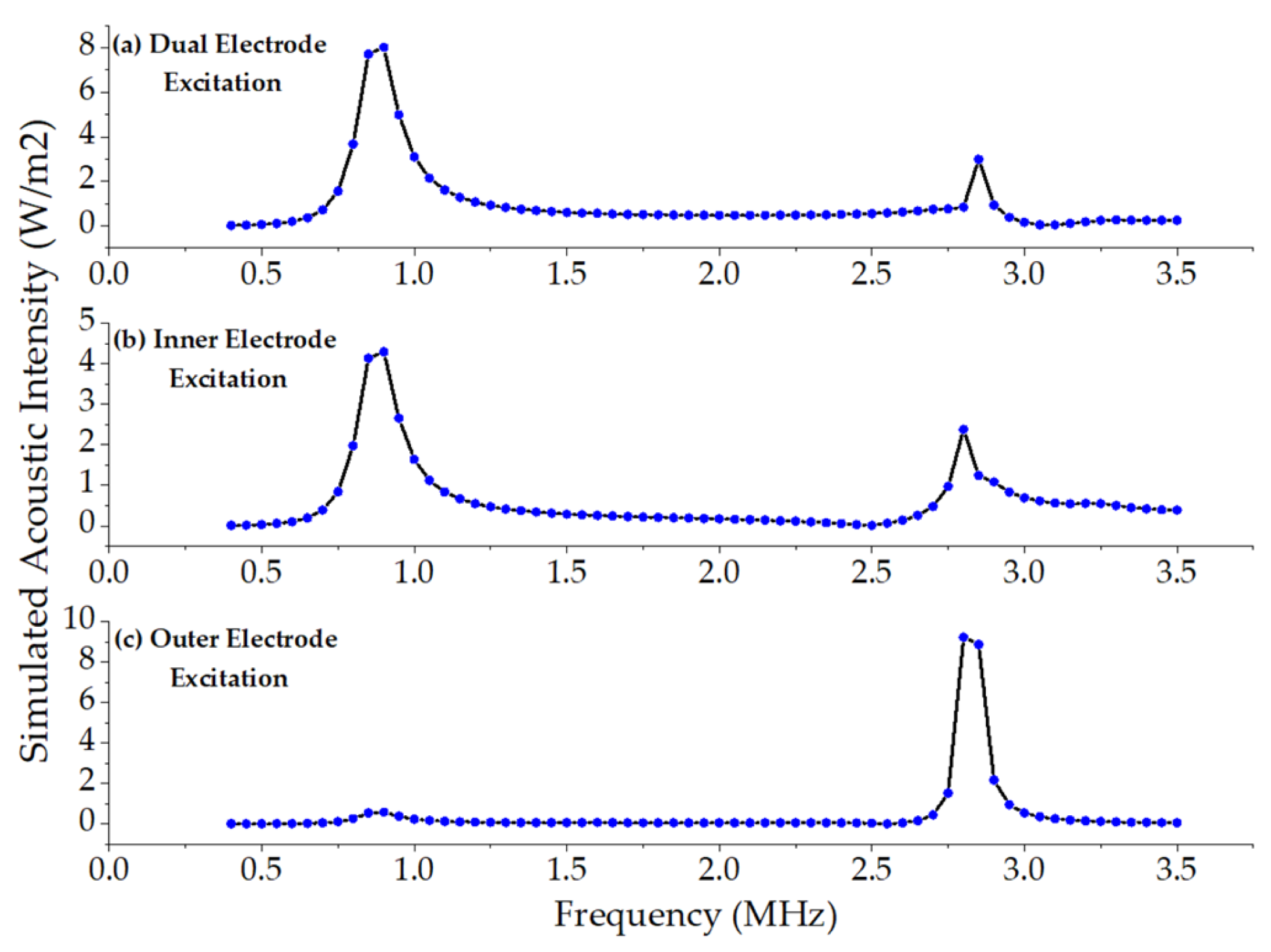

2.1. Design and Simulation

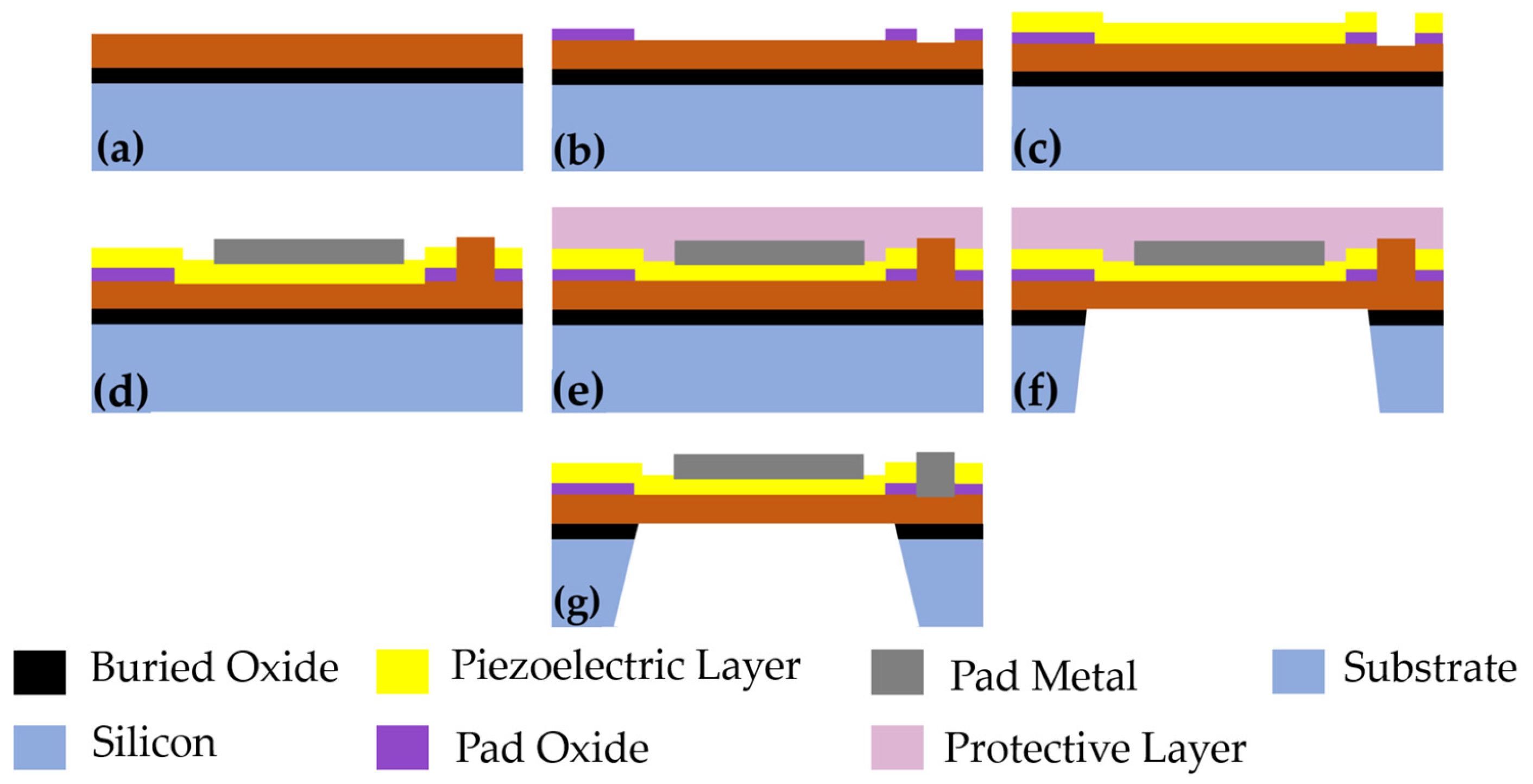

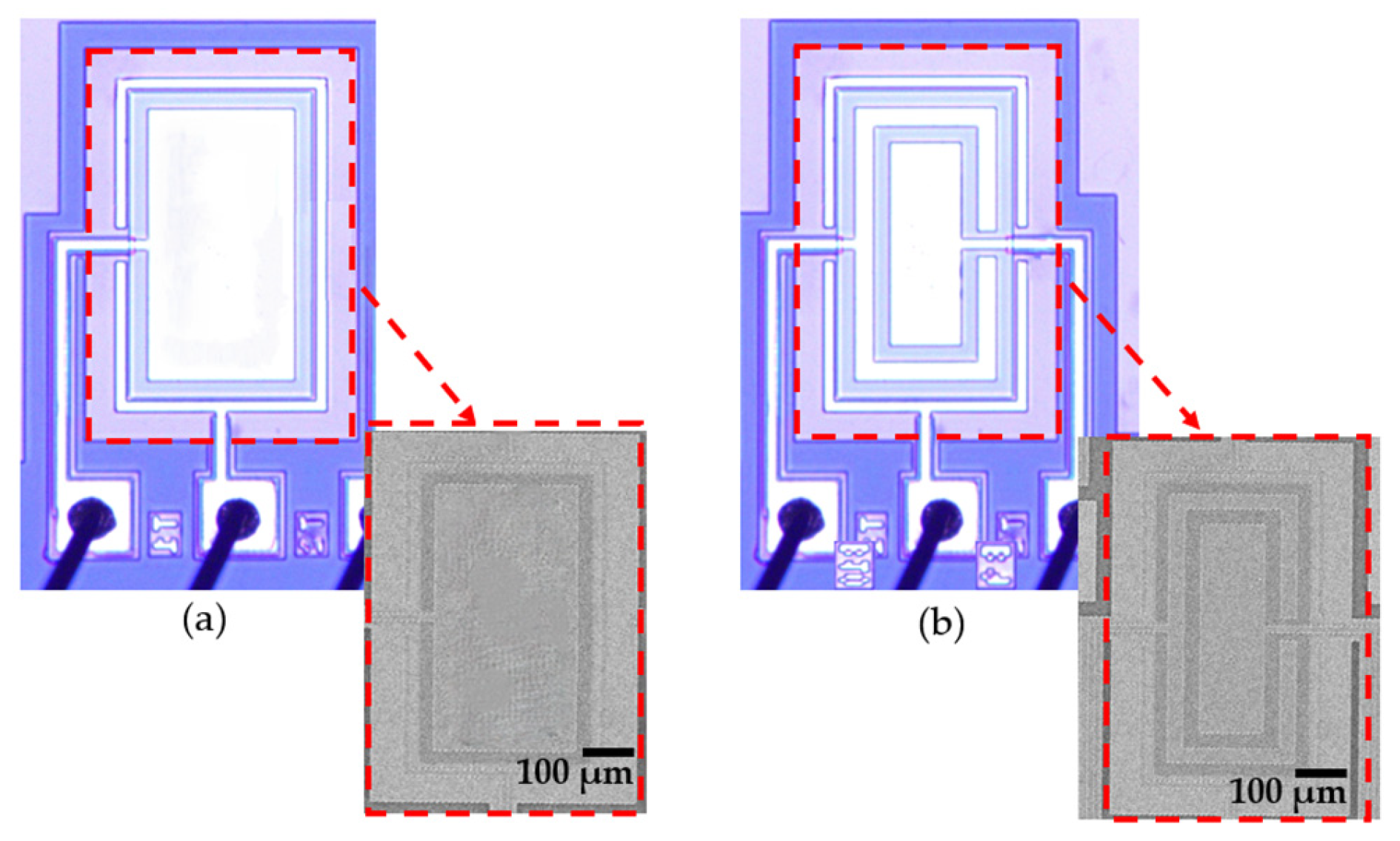

2.2. PMUT Microfabrication

3. Experimental Characterization

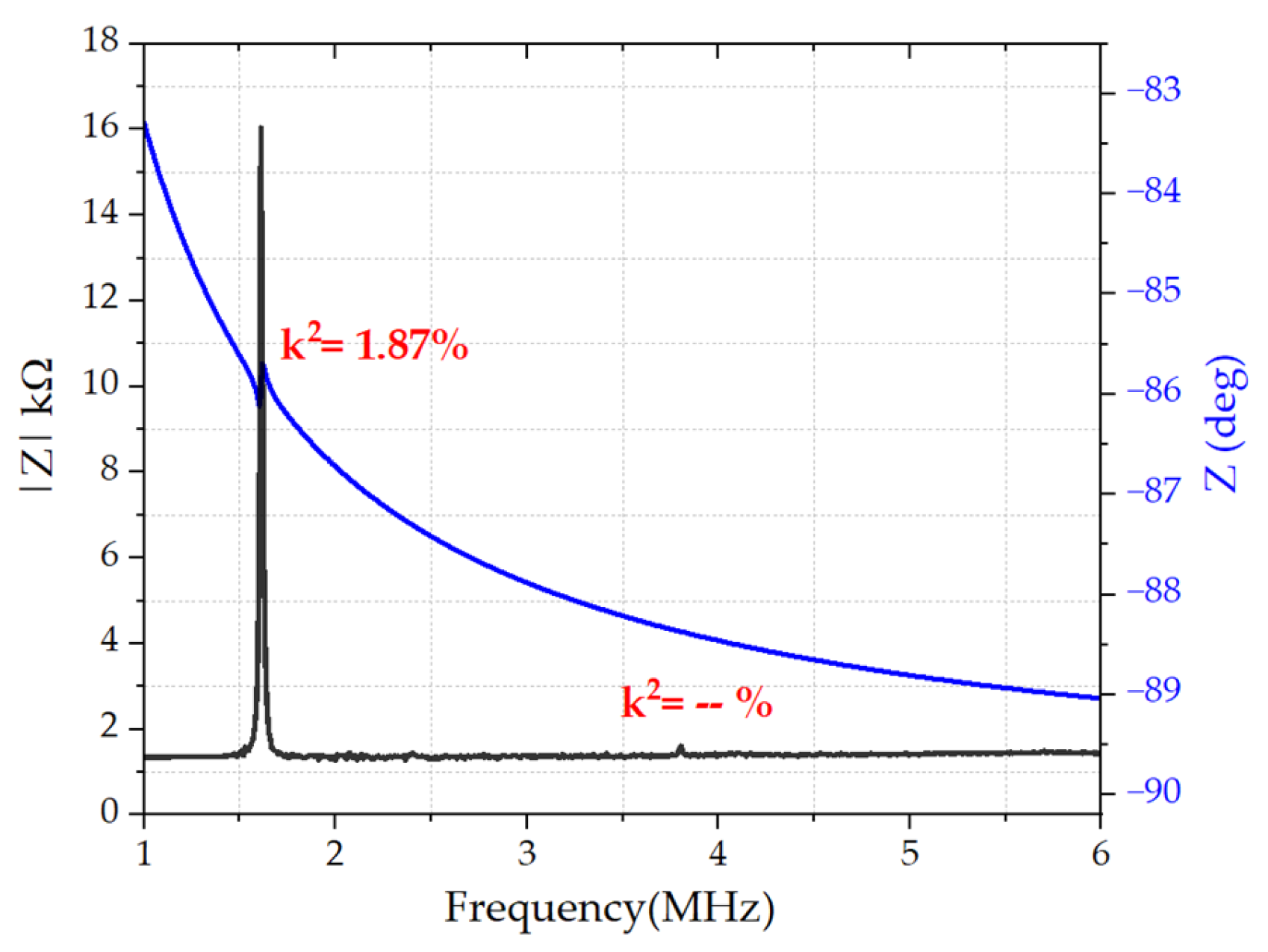

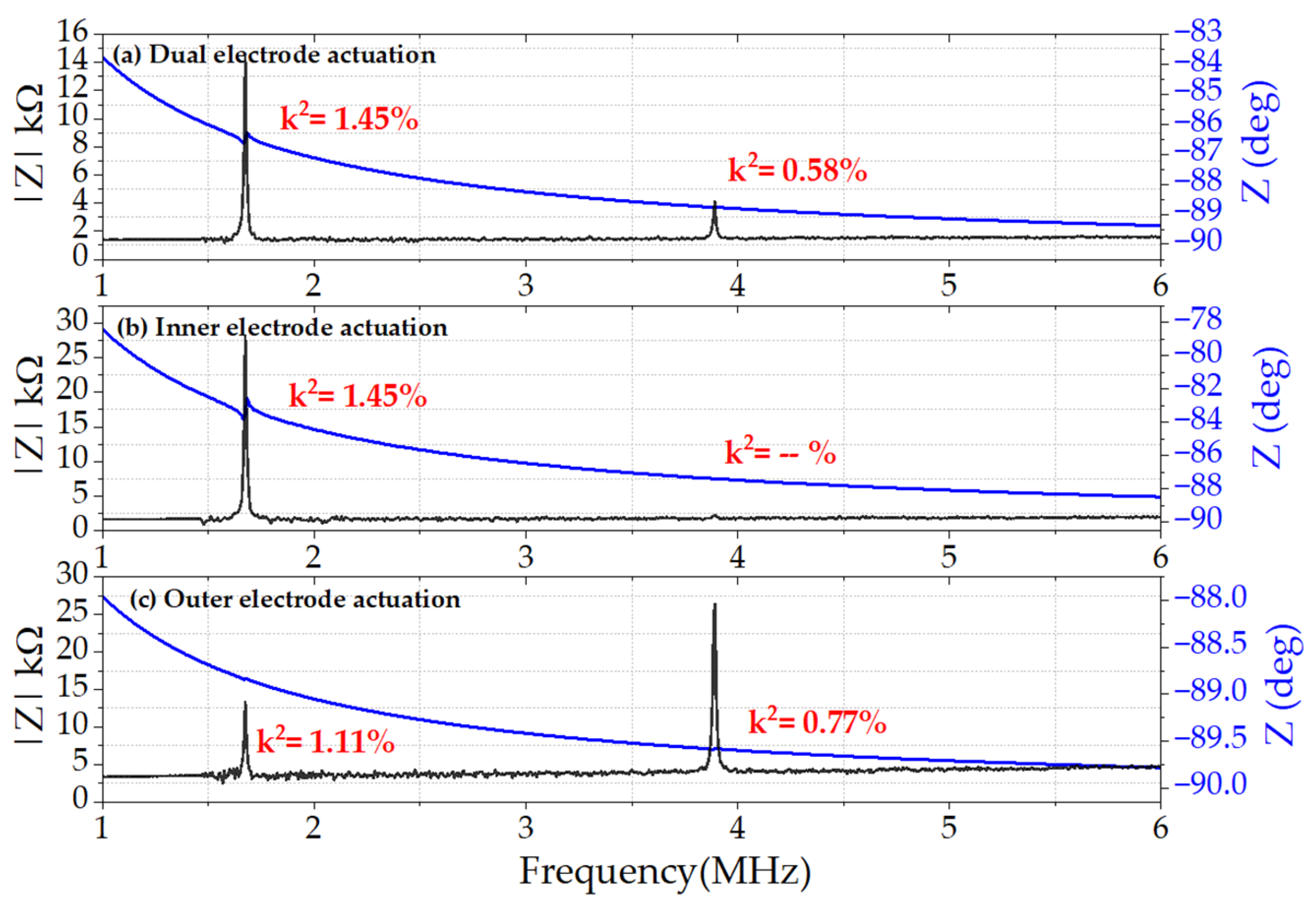

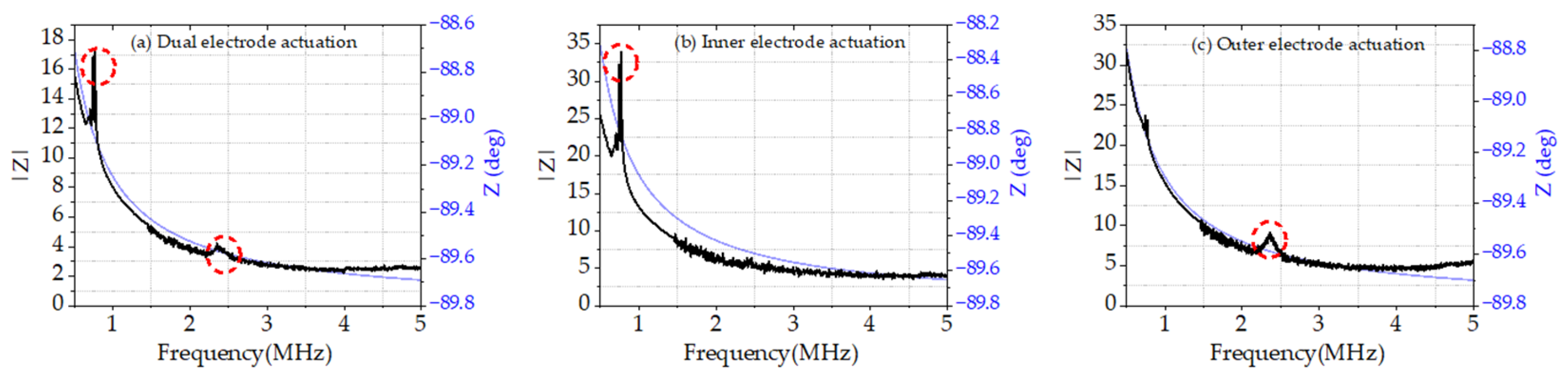

3.1. Electrical Characterization

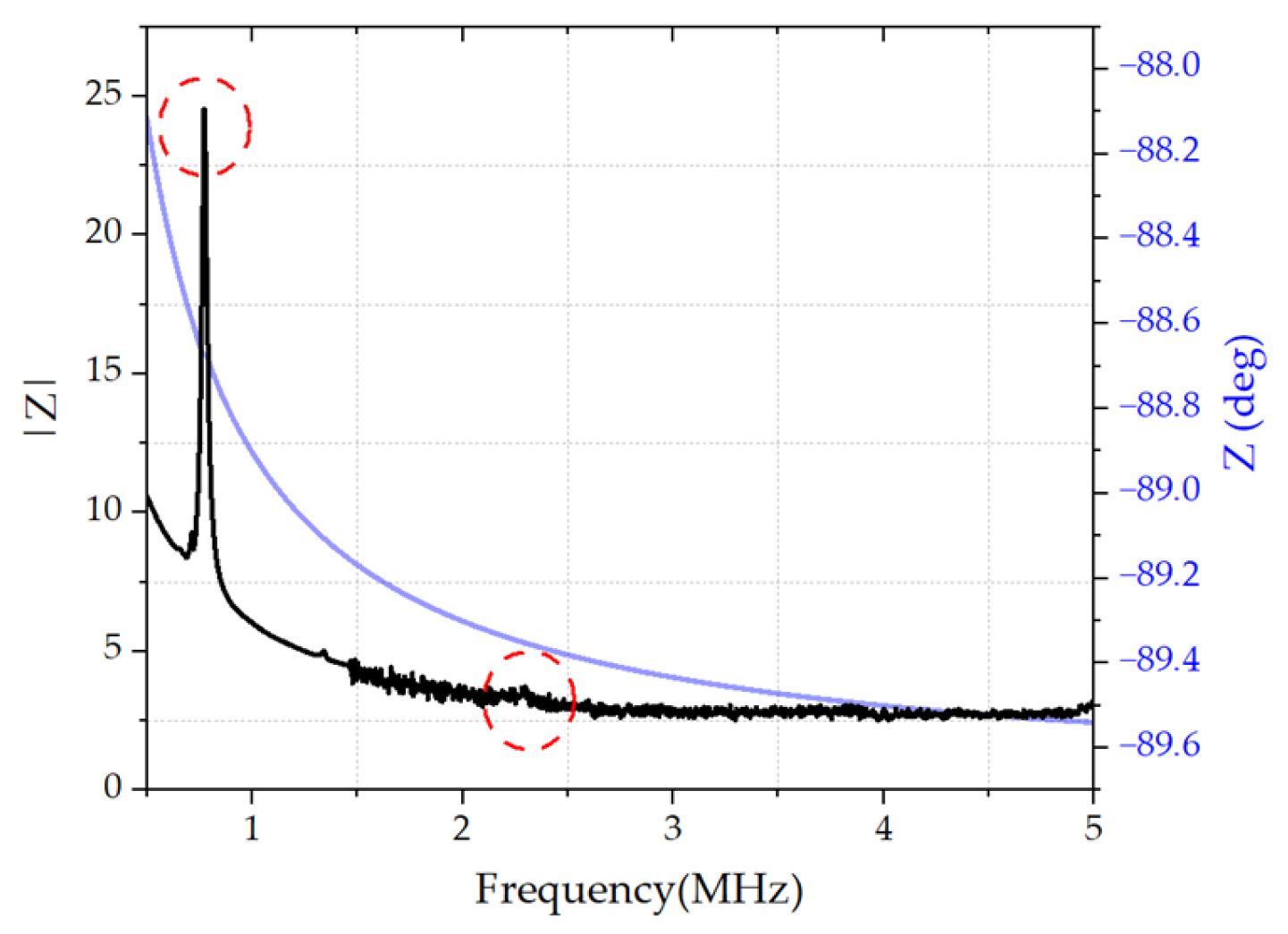

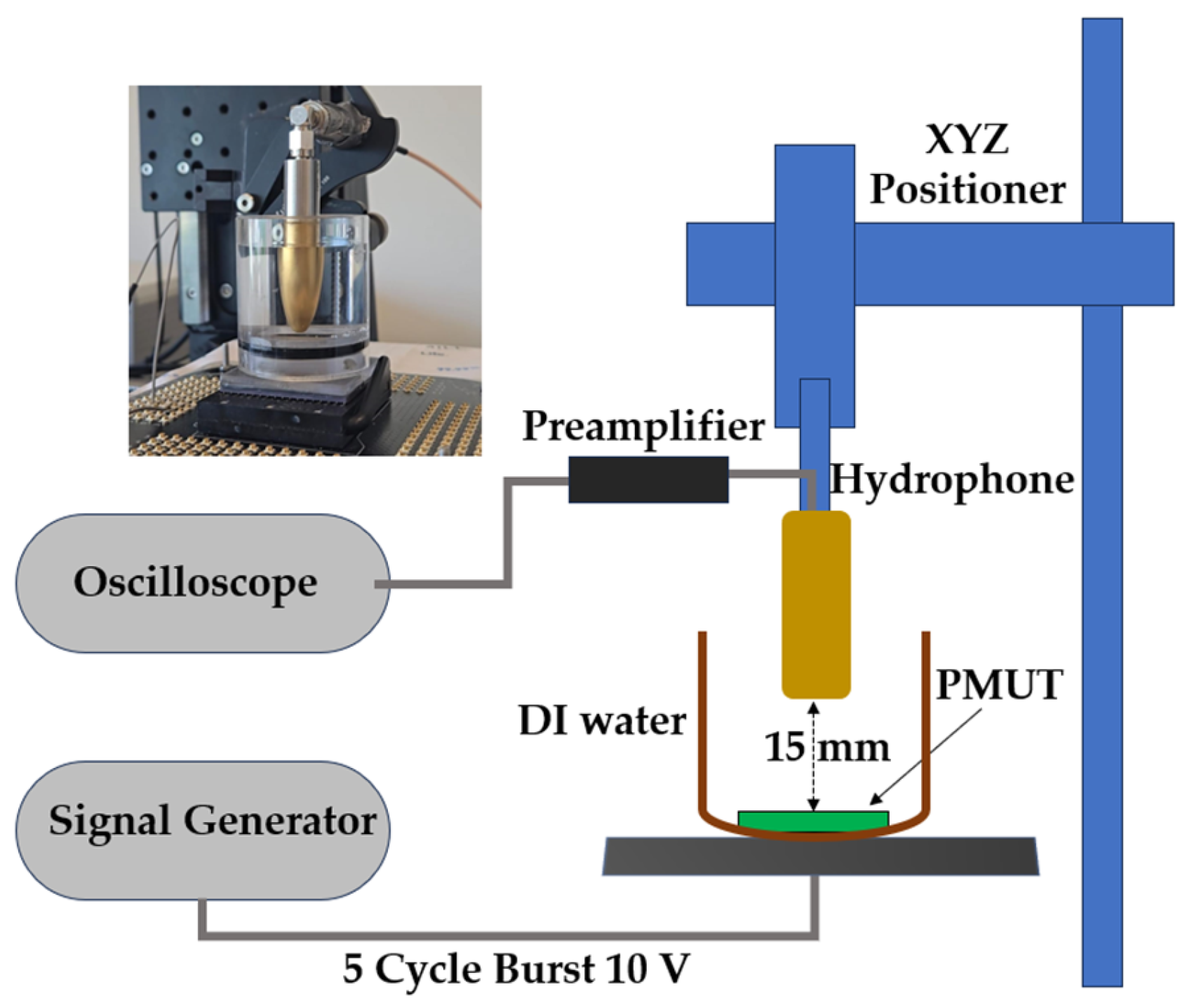

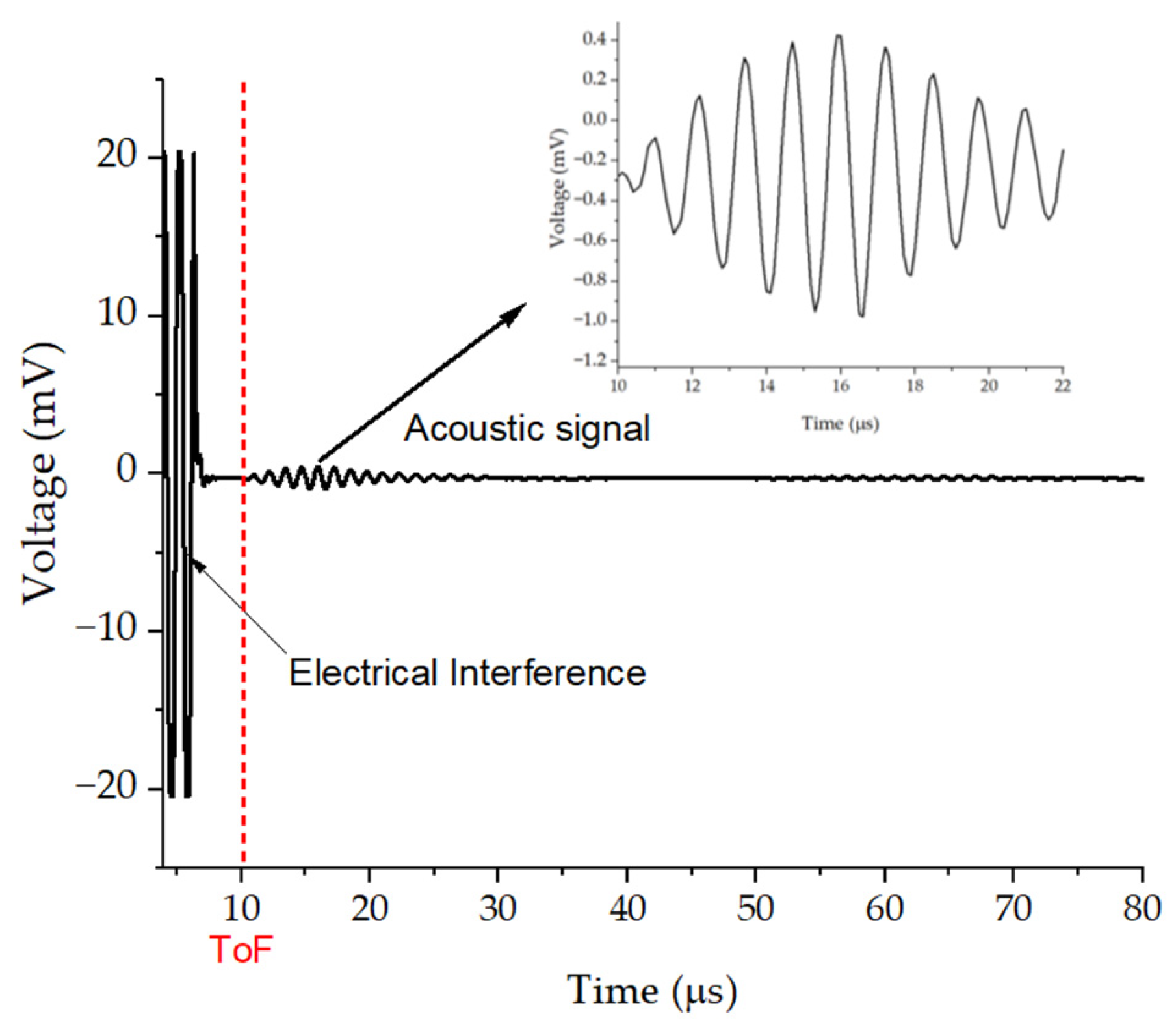

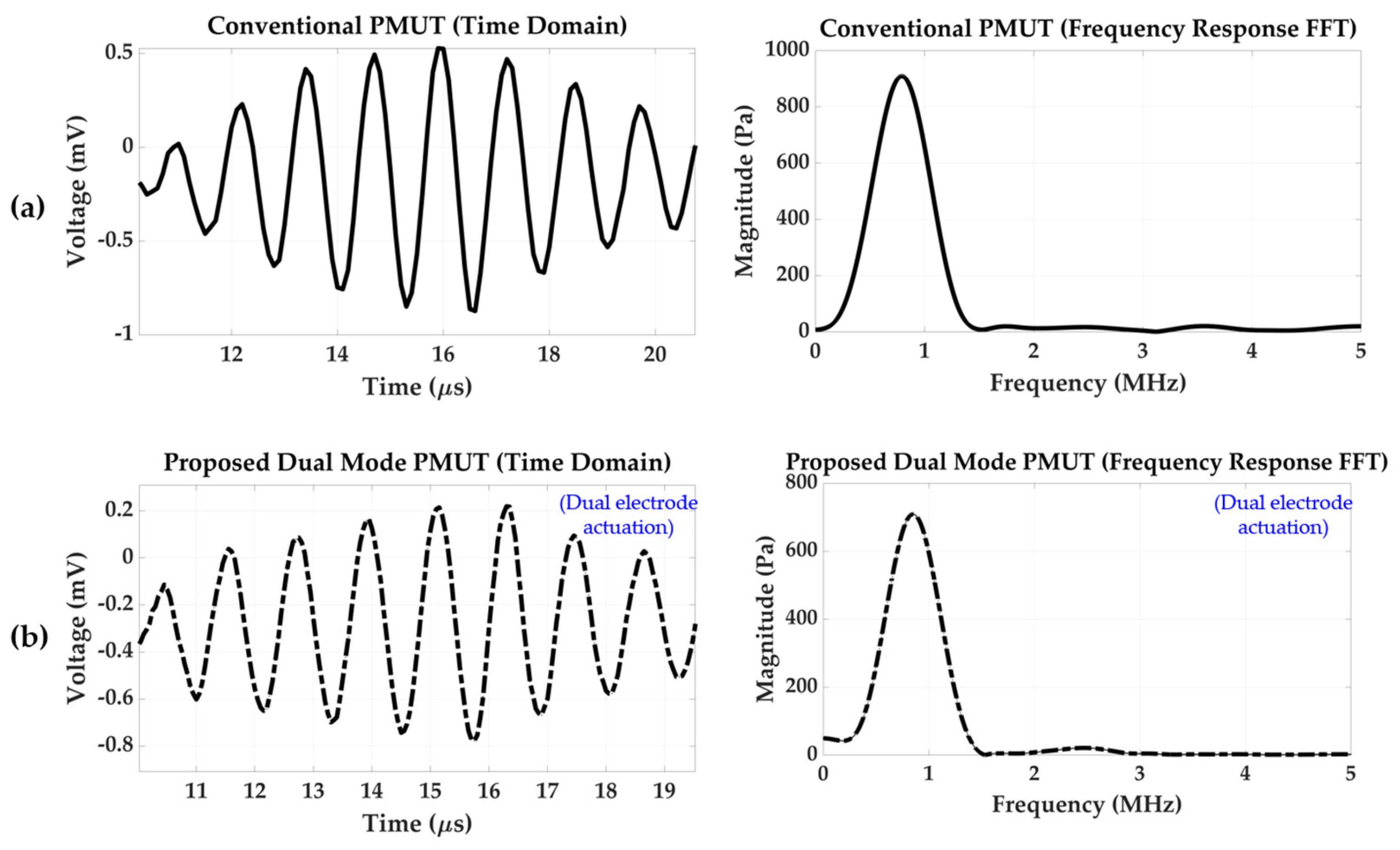

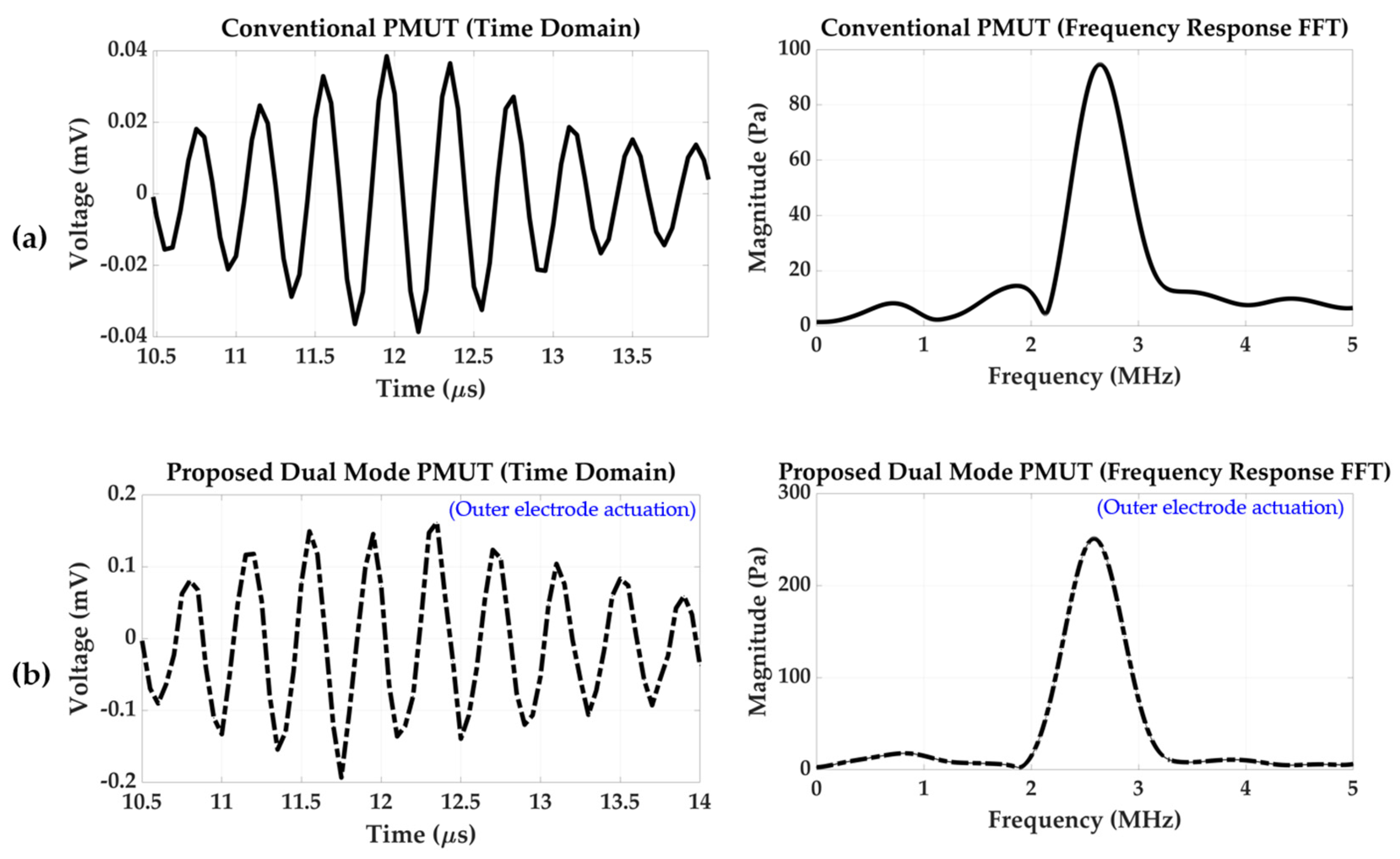

3.2. Underwater Acoustic Characterization

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| AC | Alternating Current |

| AlN | Aluminum Nitride |

| EMCC | Electromechanical Coupling Coefficient |

| FEA | Finite Element Analysis |

| PMUT | Piezoelectric Micromachined Ultrasonic Transducer |

| PZT | Lead Zirconate Titanate |

References

- Szabo, T.L. Diagnostic Ultrasound Imaging: Inside Out: Second Edition; 2004; ISBN 9780123964878.

- Lethiecq, M.; Levassort, F.; Certon, D.; Tran-Huu-Hue, L.P. Piezoelectric Transducer Design for Medical Diagnosis and NDE. In Piezoelectric and Acoustic Materials for Transducer Applications; 2008 ISBN 9780387765389.

- Birjis, Y.; Nazemi, H.; Munirathinam, P.; Shamsuddin, A.; Khuri-Yakub, B. (Pierre) T.; Ergun, A.S.; Oralkan, Ö.; Yaralioglu, G.G.; Emadi, A. 2.06 - Ultrasonic Transduction. In Comprehensive Microsystems (Second Edition); Gianchandani, Y.B., Ed.; Elsevier: Oxford, 2025; pp. 166–212 ISBN 978-0-323-95479-2.

- Roy, K.; Lee, J.E.Y.; Lee, C. Thin-Film PMUTs: A Review of over 40 Years of Research. Microsyst Nanoeng 2023, 9.

- Birjis, Y.; Swaminathan, S.; Nazemi, H.; Raj, G.C.A.; Munirathinam, P.; Abu-Libdeh, A.; Emadi, A. Piezoelectric Micromachined Ultrasonic Transducers (PMUTs): Performance Metrics, Advancements, and Applications. Sensors 2022, 22.

- Qiu, Y.; Gigliotti, J. V.; Wallace, M.; Griggio, F.; Demore, C.E.M.; Cochran, S.; Trolier-McKinstry, S. Piezoelectric Micromachined Ultrasound Transducer (PMUT) Arrays for Integrated Sensing, Actuation and Imaging. Sensors (Switzerland) 2015.

- Perçin, G.; Khuri-Yakub, B.T. Piezoelectrically Actuated Flextensional Micromachined Ultrasound Transducers. In Proceedings of the Ultrasonics; 2002.

- Birjis, Y.; Nazemi, H.; Park, J.; Emadi, A. Design, Fabrication, and Characterization of Dual-Electrode Piezoelectric Micromachined Ultrasonic Transducer (PMUT) Geometries. IEEE Sens J 2025. [CrossRef]

- Wang, T.; Lee, C. Electrically Switchable Multi-Frequency Piezoelectric Micromachined Ultrasonic Transducer (PMUT). In Proceedings of the Proceedings of the IEEE International Conference on Micro Electro Mechanical Systems (MEMS); 2016; Vol. 2016-February.

- Sun, C.; Shi, Q.; Yazici, M.S.; Kobayashi, T.; Liu, Y.; Lee, C. Investigation of Broadband Characteristics of Multi-Frequency Piezoelectric Micromachined Ultrasonic Transducer (MF-PMUT). IEEE Sens J 2019. [CrossRef]

- Hajati, A.; Latev, D.; Gardner, D.; Hajati, A.; Imai, D.; Torrey, M.; Schoeppler, M. Three-Dimensional Micro Electromechanical System Piezoelectric Ultrasound Transducer. Appl Phys Lett 2012, 101. [CrossRef]

- Wang, T.; Kobayashi, T.; Lee, C. Micromachined Piezoelectric Ultrasonic Transducer with Ultra-Wide Frequency Bandwidth. Appl Phys Lett 2015, 106. [CrossRef]

- Eovino, B.E.; Akhbari, S.; Lin, L. Broadband Ring-Shaped PMUTS Based on an Acoustically Induced Resonance. In Proceedings of the Proceedings of the IEEE International Conference on Micro Electro Mechanical Systems (MEMS); 2017.

- Mansoori, A.; Hoff, L.; Salmani, H.; Halvorsen, E. An Efficient Electrode Optimization Method for Multi-Frequency PMUTs. In Proceedings of the 2022 IEEE International Ultrasonics Symposium (IUS); 2022; pp. 1–4.

- Mansoori, A.; Hoff, L.; Salmani, H.; Halvorsen, E. Electrode Design Based on Strain Mode Shapes for Configurable PMUTs. IEEE Open Journal of Ultrasonics, Ferroelectrics, and Frequency Control 2023, 3, 88–100. [CrossRef]

- Smyth, K.; Bathurst, S.; Sammoura, F.; Kim, S.G. Analytic Solution for N-Electrode Actuated Piezoelectric Disk with Application to Piezoelectric Micromachined Ultrasonic Transducers. IEEE Trans Ultrason Ferroelectr Freq Control 2013, 60. [CrossRef]

- Villeneuve, E.; Volat, C.; Ghinet, S. Numerical and Experimental Investigation of the Design of a Piezoelectric De-Icing System for Small Rotorcraft Part 1/3: Development of a Flat Plate Numerical Model with Experimental Validation. Aerospace 2020, 7. [CrossRef]

- Hambric, S.A.; Fahnline, J.B. Structural Acoustics Tutorial—Part 2: Sound—Structure Interaction. Acoust Today 2007, 3. [CrossRef]

- Cai, J.; Wang, Y.; Wu, T. High-Order Piezoelectric Micromachined Ultrasonic Transducer With Piezoelectric Layer Trench for Ultrasound Imaging. Journal of Microelectromechanical Systems 2025, 34, 359–361. [CrossRef]

- Cowen, A.; Hames, G.; Glukh, K.; Hardy, B. PiezoMUMPs TM Design Handbook a MUMPs® Process.

- Muralt, P.; Ledermann, N.; Paborowski, J.; Barzegar, A.; Gentil, S.; Belgacem, B.; Petitgrand, S.; Bosseboeuf, A.; Setter, N. Piezoelectric Micromachined Ultrasonic Transducers Based on PZT Thin Films. IEEE Trans Ultrason Ferroelectr Freq Control 2005. [CrossRef]

- Yao, Y.; Jia, L.; Liu, C.; Wang, X.; Sun, C.; Liu, S.; Wu, G. A Transceiver Integrated Piezoelectric Micromachined Ultrasound Transducer Array for Underwater Imaging. Sens Actuators A Phys 2023, 359. [CrossRef]

- Joshi, S.V.; Sadeghpour, S.; Kraft, M. Polyimide-On-Silicon 2D Piezoelectric Micromachined Ultrasound Transducer (PMUT) Array. Sensors 2023, 23. [CrossRef]

- Tipsawat, P.; Ilham, S.J.; Yang, J.I.; Kashani, Z.; Kiani, M.; Trolier-Mckinstry, S. 32 Element Piezoelectric Micromachined Ultrasound Transducer (PMUT) Phased Array for Neuromodulation. IEEE Open Journal of Ultrasonics, Ferroelectrics, and Frequency Control 2022, 2. [CrossRef]

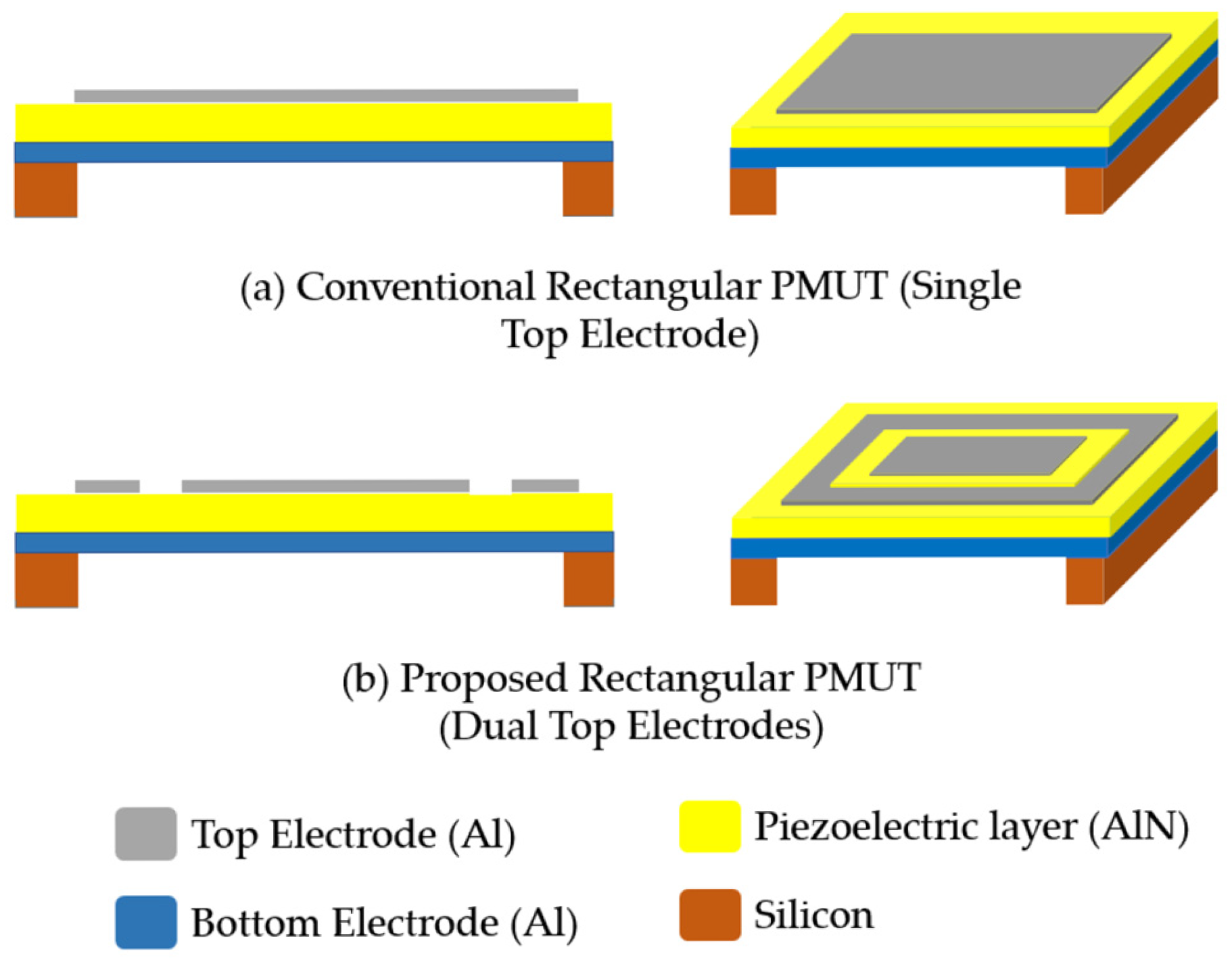

| PMUT Layers |

Material | Membrane Length (L) and Width (W) (μm) |

|

|---|---|---|---|

| Piezoelectric Layer | Aluminum Nitride (AlN) |

L x W = 400 x 200 | |

| Bottom Electrode |

Aluminum (Al) | L x W = 400 x 200 | |

| Top Electrode |

Aluminum (Al) | Single Top Electrode | L x W = 360 x 180 |

| Dual Top Electrode | Outer Electrode =L x W = (360 x 160) - (320 x 120) Inner Electrode =L x W = 280 x 80 |

||

| Device Layer |

Silicon (Si) |

L x W = 500 x 300 | |

| Trench | -- | L x W = 400 x 200 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).