2. Analysis of Recent Research and Publications

The primary factors determining the gas content of coal-bearing strata include adsorption capacity, gas pressure, and gas permeability [

4,

5]. According to [

6], the adsorption capacity of coal-bearing strata is defined by the primary gas content:

where: хaa, хfg—correspond to the amount of adsorbed and free gas, respectively; a, b—sorption constants; Р, Р1- gas pressure in the seam and at the Earth’s surface, respectively; mп- porosity; k—gas compressibility factor.

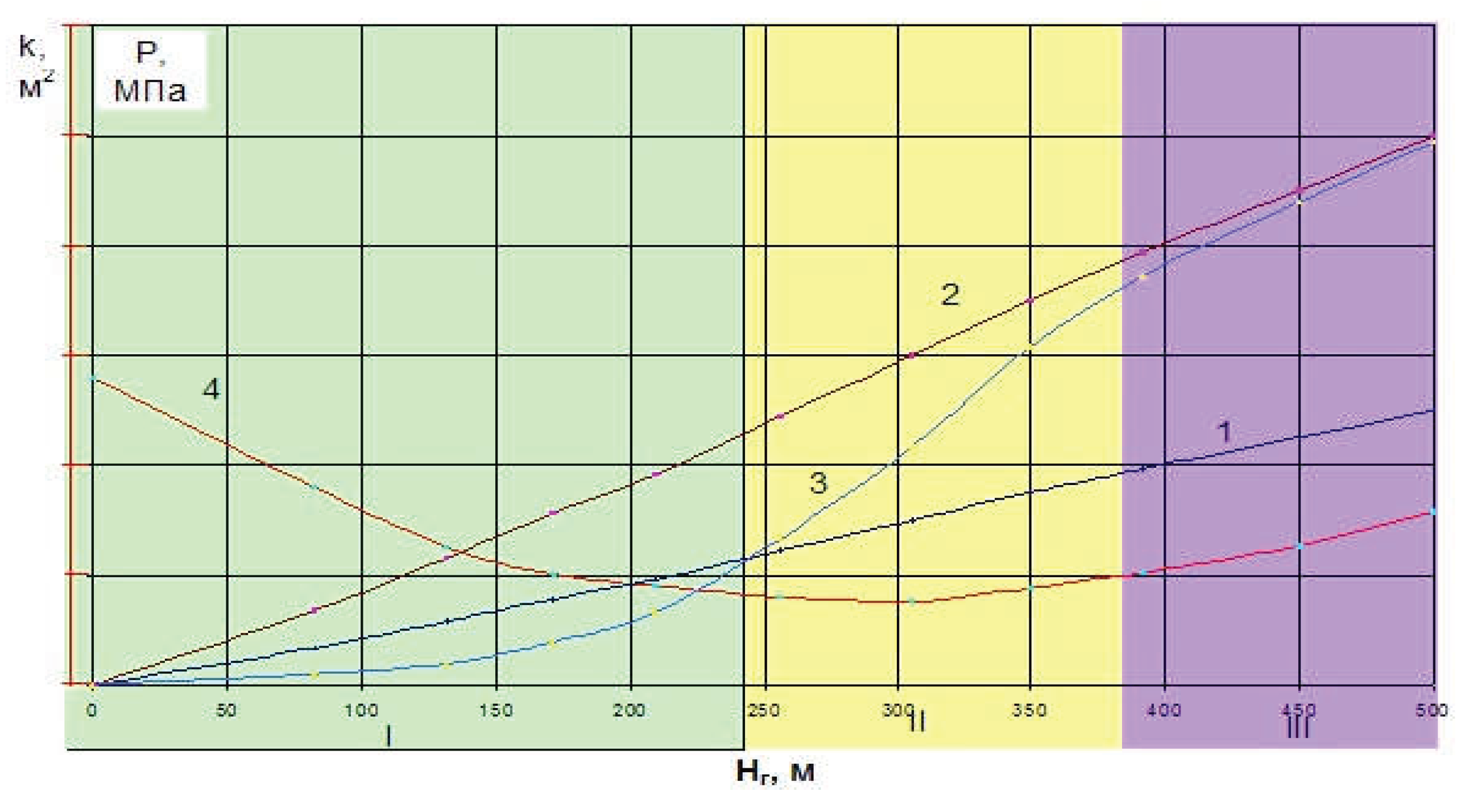

The main properties of the “coal-gas-liquid” system are its structure and sorption surface. These properties are determined by the particle sizes of coal and rocks, which range from 10-1 to 10-7 cm. The sorption surface of coal is influenced by molecular and colloidal systems with particle sizes of 10-5 to 10-6 cm. Adjacent to these are coarse-dispersed systems with particle sizes of 10-1 to 10-4 cm, and atomic systems with particle sizes less than 10-6 cm. Higher porosity in coal and rocks correlates with increased gas content. The sorption gas capacity of the mass largely depends on its moisture content, which reduces porosity and gas release. Additionally, the sorption gas capacity of the mass is influenced by gas pressure, which increases with depth. Different zones with varying gas pressure levels and characteristics are identified with increasing depth within the seam [

6] (

Figure 1).

In the first zone, gas pressure approaches hydrostatic pressure. In the second zone, located in the upper part of the methane zone, gas pressure exceeds hydrostatic pressure but remains below the static pressure of the rock formations. The third zone is situated in the deepest part of the methane zone, where gas pressure approaches the static pressure of the rock formations. The variation in gas pressure with depth follows the law calculated by G. D. Lidin [

6].

where Н1- Depth of pressure measurement; Н

o—Depth of the upper boundary of the methane zone В, v- Empirical coefficients

Calculations show that gas pressure at achieved depths in coal basins of the CIS countries ranges from 3 to 5 MPa, and in some cases reaches 12 MPa or more. Indeed, experimental measurements of gas pressure in the D6 seam of the Karaganda Basin at depths of 450 to 500 m showed that it varies between 2 to 3.5 MPa.

The gas content of coal seams is determined by natural gas permeability, which depends on the conditions of seam deposition, the degree of seam exposure, and the duration of erosion cycles. There exists a quantitative relationship between formation pressure and gas permeability, expressed by equation [

6]:

where k0—initial gas permeability; b—coefficient; е—the natural logarithm base

In natural conditions, the gas permeability of fossil coals depends on the macrostructure of the coal seam, the degree and nature of filling of the filtering volume of pores with natural moisture, the methane pressure gradient, and the characteristics of the manifestation of rock pressure.

In undisturbed coal formations, the filtering skeleton of coal exhibits high resistance and comparatively low permeability, hence the gas permeability of a coal seam largely depends on the integrity of the formation.

Regarding gas permeability, coal seams are classified into: highly permeable—λ > 2–3·10

−3 mD; of medium permeability—λ = 1—2·10ˉ3 mD; low gas permeability—λ <1 · 10ˉ3 mD [

2].

The gas permeability of coals in the main basins of CIS countries is 3 to 5 times higher than that of rocks. The gas permeability of the K18 seam in the Karaganda coal basin at depths of 400 to 500 m varies within 0.6- 0,9 ∙10-2 mD [

7].

In

Table 1, average values of gas permeability for the developed coal seams of the Karaganda Basin are presented [

8].

In

Table 2, calculated values of gas permeability changes with depth for the developed coal seams of the Karaganda Basin are provided by Akimbekov A.K. and Makhov A.A. from Karaganda Technical University (KarTU). The anisotropy coefficient for the seams in the Karaganda Basin ranges from 5 to 6. Comparative analysis of the data from

Table 1 and

Table 2 indicates a high reliability and consistency of the results.

The decrease in gas permeability with depth is described by equation (2). The highest values of gas permeability based on stratigraphy are found in the K12 seam and the valley suites D1, D5, and D6.

In the Kuzbass region, the depth of the gas-bearing zone ranges from 50 to 180 m, in the Donbas region from 50 to 500 m, in the Kizelovsk and Chelyabinsk basins from 300 to 600 m, and in the Pechora, Karaganda, and Tungus basins, as well as in the Sugan, Sakhalin Island, and Caucasus deposits, it ranges from 50 to 230 m. At these depths, the gas content of coal seams reaches 25 to 30 m

3/ton, while the gas content of rocks is 4 to 6 m

3/t [

7].

Studies in recent years have established that the change in gas content of coal, rock, and gas permeability with depth is not unlimited. For instance, in the Donbas region, coal seam gas content peaks at a depth of 300 m, after which it decreases. In the Karaganda Basin, maximum gas content is observed at a depth of 500 m. The decrease in gas content with depth is attributed to the reduction in sorption capacity of the strata with increasing rock temperature; however, at these depths, gas content still amounts to tens of cubic meters per ton of coal.

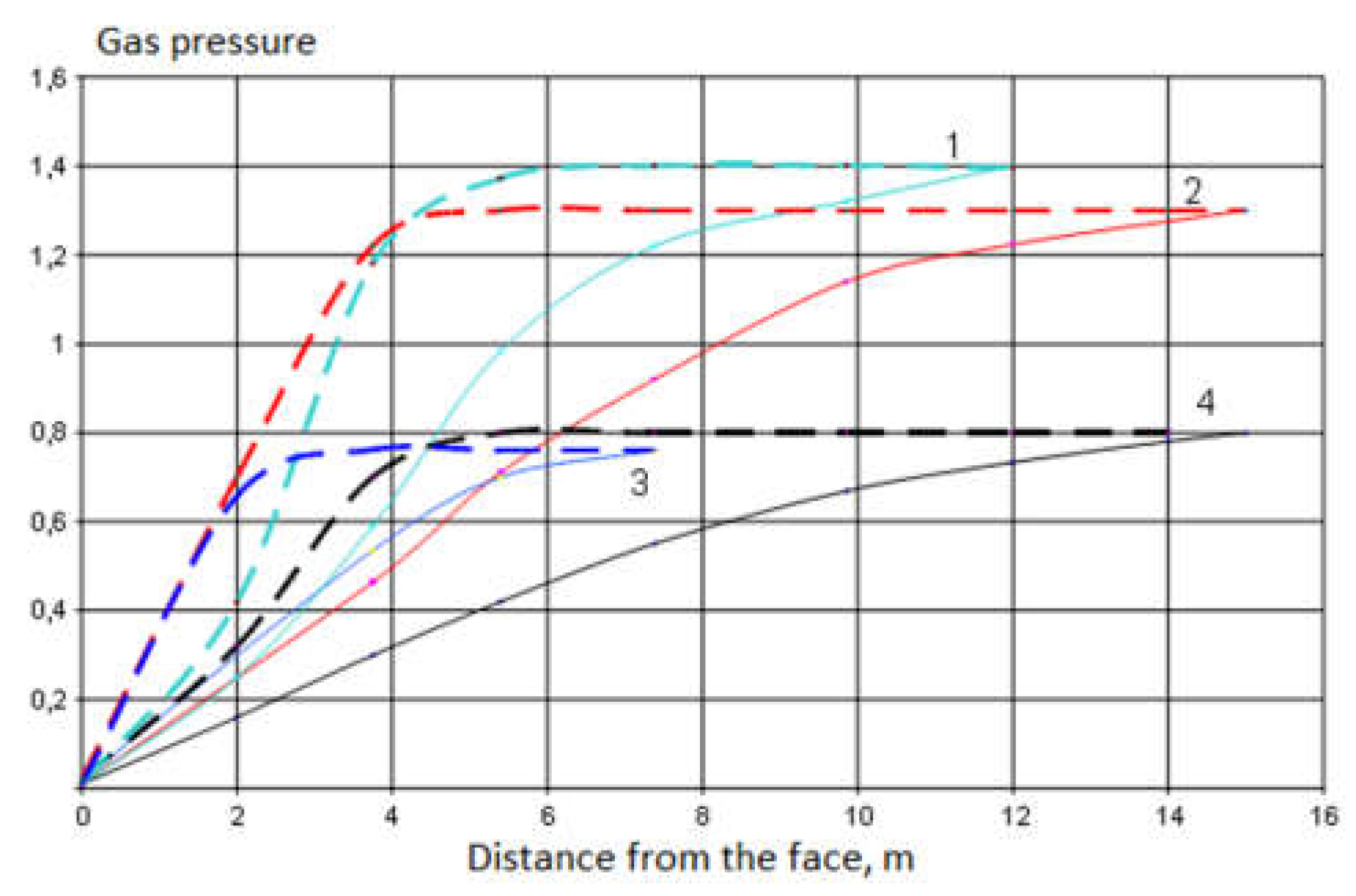

The data above demonstrate that several factors influence the distribution of gas in coal seams, with gas pressure and permeability being primary among them. To calculate gas emission from a coal seam, it is essential to know the initial gas pressure and how it changes under the influence of mining activities. Studies have shown that when entering zones with increased static stress, the gas pressure curve flattens and changes from convex to concave. An empirical function describing gas pressure in a coal seam over time from its exposure until stabilization of stress-strain conditions can be determined using the formula [

6]:

where Рх, Р0—the corresponding gas pressure at any distance from the exposed surface of the seam and the initial pressure in the seam, MPa; Р1—gas pressure at the exposed surface of the seam, MPa; x—depth to the surface of the seam, m; l(t)- depth of the seam unloading zone, m

Studies have shown that calculated values of gas pressure in a coal seam within the influence zone of mining operations, determined by formula (3), exhibit minor discrepancies compared to data obtained experimentally (see

Figure 2).

The effectiveness of conducted degassing measures in coal seams is typically determined by the gas state of the coal mass (pressure, gas temperature, and gas content), its properties (permeability, porosity, gas yield capacity, gas storage capacity, etc.), coal structure, mining technology, and economic feasibility.

When seams with gas content of 15-20 m3/t are developed using high-productivity mining faces with daily loads exceeding 2000 t/day, significant delays between preparatory and mining works are observed. As a result, the time for preliminary seam degassing is reduced, potentially leading to gas-related downtime. Additionally, with increasing depth of mining operations, the natural gas release rate into degassing wells may not meet the required gas extraction levels. This is primarily due to low natural filtration and diffusion permeability, high gas storage capacity, and low porosity of coal compared to gas reservoirs.

Common patterns of methane content variation, as one of the primary characteristics of the gas state in a coal seam, include increasing gas content with the stratigraphic depth of the seam and with increasing degree of coal metamorphism. The relationship between gas content and the degree of metamorphism is complex. Coal seams with the highest gas content (up to 40 m

3/t) are typically found in low metamorphic anthracites and semi-anthracites. Coals with volatile matter content ranging from 4.5% to 24% generally exhibit gas contents exceeding 20 m

3/t. Gas contents ranging from 10 to 20 m

3/t are observed in coals with volatile matter content between 4.5% to 14.5% and between 23% to 43% [

5,

6].

3. Research Methods

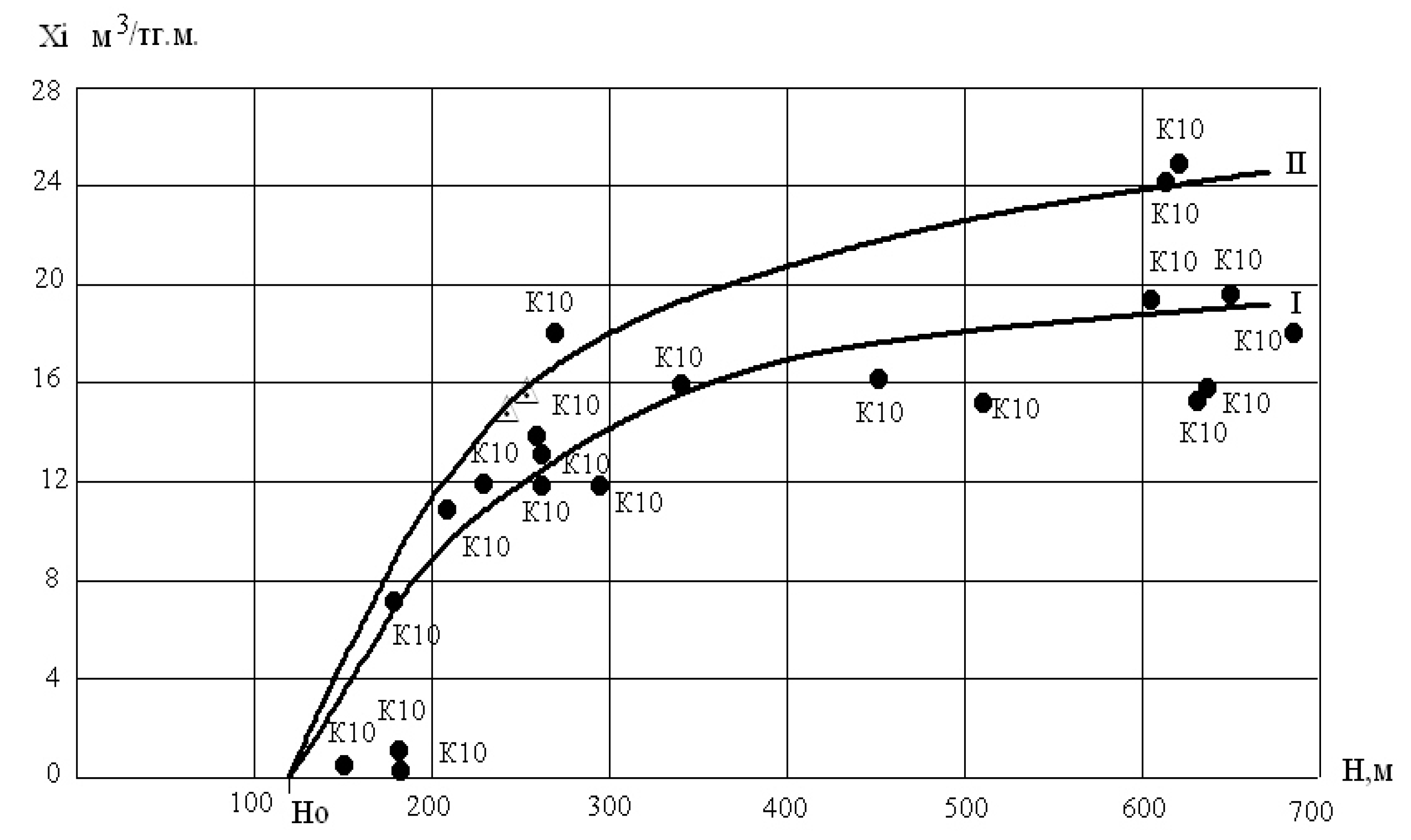

The depth of the coal seam significantly influences its gas content [

7]. The methane content of coal seams in the Sherubainurinsky area increases with depth following a hyperbolic law (see

Figure 3) and generally conforms to the Langmuir equation [

4].

This graph likely illustrates how methane content varies with increasing depth in the K10 coal seam at the Sherubainurinsky site, showing both scenarios with and without accounting for sampling losses.

where Хг—natural methane content of dry ash-free coal mass, m

3/t d.a.f.; W—Natural moisture content of coal, %; Аз—Ash content of coal, %.

Natural methane content of dry ash-free coal (Xg, m

3/t d.a.f.) is determined by the expression [

5]:

where Н—Depth of mining, m; H

0—Depth of gas weathering zone, m; с and b—The coefficients of the Langmuir equation.

The meanings of the parameters in equations (4) and (5) are determined according to the “Classifier of Methane Content in Coal Seams of the Karaganda Basin,” taking into account refined parameters based on actual methane emission in the development workings, and for new fields, based on geological report data. The residual methane content of coal remaining in the mined space in unextracted blocks of the seam is determined by formula [

5].

where Н—Residual gas content of dry ash-free coal mass at atmospheric pressure, m

3/t d.a.f., is taken from

Table 3.

If coal seams or closely associated layers were overlain or underlain before development, the natural methane content of the seam (X) is replaced in the calculation formulas by the residual methane content (X o.g.), the value of which is determined by formula (7).

With repeated overlying or underlying operations, the residual methane content is determined using the same formulas by substituting the value of Ho.g. instead of X after the previous overlying or underlying operation.

Based on the fact that the isotherm of coal gas capacity flattens at high methane pressures, it can be assumed that with increasing depth of occurrence, the rate of gas content increase slows down.

It has been established (I.M. Pechuk, L.N. Bykov, A.I. Pokrovsky, M.A. Yermekov, et al.) that methane pressure Pg in coal seams increases according to a law close to hydrostatic [

6]:

Numerous measurements of gas pressure under mining conditions confirm this relationship.

Equation (5) reflects a gradual increase in gas pressure with depth of seam occurrence. However, practical observations have noted significant methane emissions from fluvial-type coal seams, indicating the presence of localized zones within the coal seam with anomalous increases in gas pressure and gas content compared to neighboring areas [

6,

7].

The calculated variation of natural gas content of the seam K10, taking into account ash content, is presented in Figure 4. When calculating, Langmuir coefficients c and b were taken as 0.265 and 0.0119 respectively. Ho—133 m, Az—25.4%, W—4.3% (Classifier of Methane Content in Coal Seams of the Karaganda Basin).

As seen in the figure, the variation in gas content is described by the equation.:

where Х—Natural gas content of the seam, considering moisture and ash content., m

3/t; Н—Depth of seam occurrence, ms.; А, В, С—empirical coefficients, respectively equal to -0.00006, 0.0686, and 1.9857.

Practical gas content of coal seams can be determined by sampling from the coal mass and by recalculating gas abundance during mining operations in the seam.

At the “Special Mine Construction and Gasification Management” of ArcelorMittal Temirtau, there is a laboratory equipped with equipment from the German company DMT, which employs its methodology for sampling and preparing samples [

12]. A specialized pneumatic drilling tool is used to drill holes through the seam. Coal samples are taken every 2 m and placed in sealed containers. The length of each borehole ranges from 20 to 22 m. In the laboratory, a gas analyzer is used to determine the amount of gas released from each sample container. The sample is then ground and the amount of methane released is determined again. Additionally, besides methane content, the lab determines its moisture, ash content, and volatile matter yield.

Based on the methane content from multiple samples taken at different depths, a resulting methane content curve of the coal is constructed [

10]. This curve reflects the state of the coal mass. The coal mass directly adjacent to the excavation walls undergoes unloading and fragmentation into blocks, resulting in significant fracturing. In this zone, the gas content of the seam is minimal. As the distance from the excavation walls increases, the influence of unloading diminishes, and the block fragmentation zone transitions to a zone of less elastic deformation, with a gradual decrease in the number of fractures in the mass. In this zone, gas content increases. At a distance of 10-15 m from the excavation walls, where the influence of unloading on the mass is minimal, there exists a zone of elastic deformation, and the gas content approaches natural levels.

The results from coal sample collection from wells drilled at distances of 65 and 55 m from the mounting chamber 33K10-S of the “Abaiskaya” shaft confirm the previously described variations in gas content.

For the well drilled at a distance of 65 m:

Total gas content of the coal: 19.3 m3/ton

Gas content at 1 bar pressure: 2.8 m3/ton

Desorbable gas: 16.5 m3/ton

For the well drilled at a distance of 55 m:

Total gas content of the coal: 18.9 m3/ton

Gas content at 1 bar pressure: 3.0 m3/ton

Desorbable gas: 15.9 m3/ton

The gas content of the coal in the interval of the well from 2 to 4 m increases at a slow rate due to the formation of significant fractures resulting from unloading (block fragmentation). From 4 to 8 m, an increase in gas content is observed (zone of less elastic deformation, with a sharp reduction in the number of fractures). From 8 to 9 m, the growth curve flattens out, reaching its maximum in the zone of elastic deformation. The gas content of the K10 seam in the area of mounting chamber 33K10-S of the “Abaiskaya” shaft at a depth of 520 m ranges from 18.9 to 19.3 m3/ton.

At the “Abaiskaya” mine, work was conducted to determine the gas content of the K10 seam in the southern block. The depth of the seam at the sampling location was 435 m. Samples were taken from a borehole drilled through the seam using the SBG-1M machine at depths of 38, 40, and 42 m. Research results indicate that in the nearly undisturbed mass within 38-42 m from the borehole mouth, the gas content remains constant. Variations may occur in zones affected by geological disturbances, increased rock pressure, and other factors. The total gas content was 14.5 m3/ton, gas content at 1 bar pressure was 2.7 m3/ton, and desorbable gas was 11.8 m3/ton.

The variation in gas content characteristics with distance from the mining walls is determined by properties of the coal mass such as plasticity, moisture content, fracturing, degree of unloading, among others.

For example, at the T. Kuzembayev mine, coal samples were collected from the paired development in ventilation heading 37K10-B of the K10 seam. Processing results showed that at a depth of 570 m, the gas content of the K10 seam steadily increases to its maximum value, indicating that block fragmentation is practically absent or occurs within 2 m from the mining wall. The zone of less elastic deformation extends from 2 to 10 m. From 10 to 21 m, there is a zone of elastic deformation where no fracturing occurs, and the gas content of the coal mass remains nearly unchanged. The total gas content of the seam at this depth is 17.2 m3/ton, gas content at 1 bar pressure is 2.7 m3/ton, and desorbable gas is 14.5 m3/ton.

If a straight line is drawn through a point within the zone of elastic deformation, the tangent of its slope angle characterizes the state of the coal mass as a whole. Specifically, a higher tangent indicates that the mass is less susceptible to deformation and fracturing, whereas a lower tangent suggests that the mass has undergone more significant changes.

Natural gas content of coal seams can also be determined by measuring the amount of methane released during their extraction.

At the “Abaiskaya” mine, from May 2011 to February 2012, mining operations were conducted in the southern wing of the K10 seam using the 321k10-S roadway. The ventilation roadway 321k10-S was located at a depth of 540 m, while the conveyor roadway 321k10-S was at a depth of 480 m. The thickness of the seam being extracted was 3.2 m. According to the classification, the calculated gas content of the K10 seam ranged from 16.2 to 16.9 m3/ton.

During the operation of this area, 74.8 million cubic meters of methane were extracted through ventilation means, alongside a total coal production of 629 thousand tons. Additionally, 40.2 million cubic meters of methane were captured through pre-drainage and advance degassing wells. Consequently, when the methane released from the mined coal into the ventilation stream and degassing wells is divided by the total coal production, the relative gas content of the mining area amounts to 14.6 m3/ton.

The results of the research [

13] showed that approximately 80% of methane contained in coal is released due to mechanical destruction during the operation of the mining machine, while about 20% remains in a bound state. Therefore, the gas content of the K10 seam can be estimated on average at 17.5 m

3/ton. However, the method of calculating the natural gas content of seams based on the amount of methane released provides a highly averaged value, as it is challenging to accurately account for the exact amount of methane released from the extracted part of the seam, unextracted part of the seam, mined coal, and surrounding rocks.

From September 2012 to December 2013, mining operations were conducted on the northern block of the K10 seam using the 33k10-S roadway at the “Abaiskaya” mine.

The ventilation drift was conducted at a depth of 470 m, and the conveyor drift at 540 m. The calculated gas content of the seam was 16.3–16.9 m3/ton. During the operation of the seam, 1.15 million tons of coal were extracted, with 112.5 million m3 of methane extracted by ventilation means, and 4.6 million m3 captured by seam degassing wells. Thus, the relative gas content of the extraction area was 6.5 m3/ton. Considering that 20% of the gas remains in the coal, the average gas content of the seam was 7.8 m3/ton.

It should be noted that the absolute gas content of the extraction areas reached 140 m3/min with a load on the seam of approximately 3000 tons/day. However, the degassing methods employed at the mine ensured the necessary level of methane emission reduction from the mine workings.

Studies to determine the specific content of hydrogen sulfide and sulfur-containing gases in the seams during the extraction of hydrogen sulfide zones in the Karaganda Basin mines were conducted under laboratory conditions using coal samples from the d6 and d10 seams.

Samples of coal were collected from hydrogen sulfide zones with freshly exposed surfaces of the breast of the longwall panels 264-d6-1B, 274-d6-1B, 134-d6-2B, 254-d6-2B, 284-d6-1B at the “Kazakhstanskaya” mine and 316-d6-C at the “Molodezhnaya” mine at depths of 0.4–0.5 m into hermetically sealed glass bottles with a capacity of 0.5 L.

It should be noted that sulfur-containing gases are almost not released from coal at temperatures of 18–22 °C under vacuum conditions.

To initiate gas release, the coal samples were heated to 90–100 °C. Subsequently, the measurement of hydrogen sulfide released and the determination of gas content were conducted using the GH-4 apparatus according to the methods of the Central Research Institute for Mining and Fuel Research (McNII) and the Eastern Scientific Research Institute (VostNII) [

14,

15].

In laboratory conditions, it was found that hydrogen sulfide was completely pumped out from the coal samples of layer d6 within 3.1–4.7 days. Actual data from the analysis of coal samples taken from layer d6 of the “Kazakhstanskaya”, named after V.I. Lenin, and “Molodezhnaya” mines are presented in

Table 4 [

16].

As seen from

Table 4, the gas content varies significantly among these results. Particularly notable for higher gas content are the coal samples from the “Kazakhstanskaya” mine (lava 274-d6-1B). The coal seam d6, developed at the named after V.I. Lenin mine, shows lower gas content. In all cases, gas content is not influenced by the dip angle, seam thickness, or depth of mining.

Laboratory studies of gas content in seams d6 and d10 yielded the following results. During artificial degassing and sample heating, 0.0001 m3/ton of hydrogen sulfide was released. Conversely, spontaneous combustion tendencies were observed without heating.

The highest hydrogen sulfide concentration was recorded on April 4, 1983, during the excavation of conveyor roadway 134-d6-2B. Its concentration in the mine atmosphere reached 1000 mg/m3.

In November 1983, during the excavation of conveyor roadway 284-d6-1B, hydrogen sulfide emission from the extracted coal was detected. The hydrogen sulfide zone extended over 150 m. The concentration of hydrogen sulfide ranged from 0.5 to 25 norms, exceeding safety regulations by 25 times.

It should be noted that in most cases, the gas content isolines are nearly parallel to the gas yield isolines. However, the latter significantly depend on the mining method adopted, the type of mining machinery used, and the loading onto the conveyor of the rock mass.