1. Introduction

Jacket platforms are fixed platforms secured to the seabed by steel piles penetrating a certain depth, which are widely used in offshore oil and gas production. Due to structural characteristics and operating environment, jacket platforms are susceptible to various marine environmental loads, such as earthquakes, wind, waves, ice loads, and ship impacts. Long-term exposure to these marine environments can cause structural vibrations of jacket platforms, which can cause fatigue damage to the steel structure, impacting platform production efficiency and even leading to catastrophic failure [

1,

2]. Furthermore, external disturbances inevitably affect worker productivity and comfort, negatively impacting production cost control. Extensive research has been conducted on vibration control of jacket platforms under marine environmental loads [

3]. However, most efforts have focused on suppressing vibrations caused by wave excitation, while limited research has considered seismic excitation [

4,

5,

6]. This is because waves are the most common loads on offshore platforms, constantly impacting structural stability [

3,

7]. However, structural damage caused by waves is long-term, and the initial site selection of offshore platforms usually considers local hydrological conditions. Therefore, limit wave loads can cause irreversible damage to the platform in a single instance. However, seismic loads are unpredictable and have a wide frequency range (mostly concentrated between 0.7 and 3.0 Hz) [

8,

9]. Strong earthquakes often have catastrophic effects on offshore platforms and can cause severe damage to these structures [

5,

6,

10,

11]. Furthermore, the first-order vibration mode of most offshore platform falls within the frequency range of seismic energy [

4,

12], which can trigger resonance in the offshore platform and amplify the destructive power of the earthquake. Statistics indicate that approximately hundreds of offshore platforms are currently located in seismically active areas [

5]. Therefore, studying the vibration control of jacket offshore platforms under seismic loads is of great significance.

The jacket offshore platform exhibits a low fundamental natural frequency and a high modal density in its vibrational characteristics. The overall structure has strong coupling and nonlinearity, and the external load has uncertainty, making offshore platform vibration control a very challenging problem [

3,

12]. Active and semi-active control are not suitable for long-term vibration control of large structures such as offshore platforms due to their high energy consumption and the need for accurate models of the controlled objects [

2,

12]. Passive control is the earliest and most widely used vibration control method due to reliability, low cost, and the advantages of no electronic equipment. Passive control achieves the purpose of vibration reduction by arranging absorption, dissipation or vibration isolation devices in the target structure and utilizing the characteristics of the device itself [

3,

13,

14]. Dissipation mothed primarily utilizes the energy dissipation mechanism of the damping structure, i.e., by irreversibly converting the mechanical energy (kinetic and potential energy) that causes vibration into other forms of energy (primarily heat) and dissipating it, thereby suppressing the vibration response. For example, Mostafa Vaezi et al. [

15] numerically simulated jacket offshore platforms with various distributions and three different support-viscous damper system configurations (knuckle, herringbone, and diagonal configurations) and various support stiffnesses under irregular wave loads, and proposed a spatially optimized layout for the support-viscous damper system. Jiang et al. [

16] investigated the effectiveness of viscous dampers (VDs) in reducing vibration on offshore platforms under the combined effects of wind, waves, and earthquakes. The results showed that VDs placed diagonally at each structural level can effectively suppress platform vibration under both isolated earthquakes and wind-wave-earthquake conditions. According to their research results, passive control systems based on these devices are effective for offshore platforms under wave loads. Absorption method is the dominant approach in passive vibration control on offshore platforms. Its core principle is to attach a substructure (a mass-spring-damper system) and tune its frequency to the natural frequency of the main structure, absorbing the main structure’s vibration energy through anti-phase motion. For example, Cui et al. [

17] applied tuned liquid multi-column damper (TLMCD) to the columns of tension leg platforms (TLP) to attenuate the heave response of TLP. Ghasemi et al. [

18] used shape memory alloy pounding tuned mass damper (SMA-PTMD) to control the wave-induced vibration of jacket offshore platforms. The results showed that SMA-PTMD can effectively reduce the displacement response of the platform deck. Liu et al. [

19] investigated the dynamic response of jacket offshore platforms under the action of wave and seismic excitation using multiple tuned mass dampers (MTMDs), considering the influence of soil-structure interaction (SSI). Furthermore, the core concept of isolation method is to insert a “flexible layer” (i.e., an isolation system) between the vibration source (e.g., waves, earthquakes) and the objective structure to be protected (e.g., platform deck, equipment). This modifies the dynamic characteristics of system, thereby reducing the transfer of vibration energy. It also shifts the system’s natural frequency away from the frequencies of major environmental loads (such as earthquakes and waves), avoiding resonance. For example, Ou et al. [

11] employed a rubber vibration isolation system to reduce the vibration response of jacket offshore platforms under wave loads. The isolation system consists of passive dampers, which primarily dissipate vibration energy through their damping properties. However, these passive control devices are designed based on the characteristics of the structure or specific excitation and can only perform optimally at a certain frequency ratio. That is, they cannot work properly when the dynamic characteristics of the structure or load change [

3,

20]. The frequency band of earthquakes is relatively wide, and existing passive control facilities cannot achieve ideal vibration control. In summary, it is very important to develop a passive vibration control method that can be customized according to different load requirements and resonant frequencies, is basically maintenance-free, and is effective across the entire seismic frequency range.

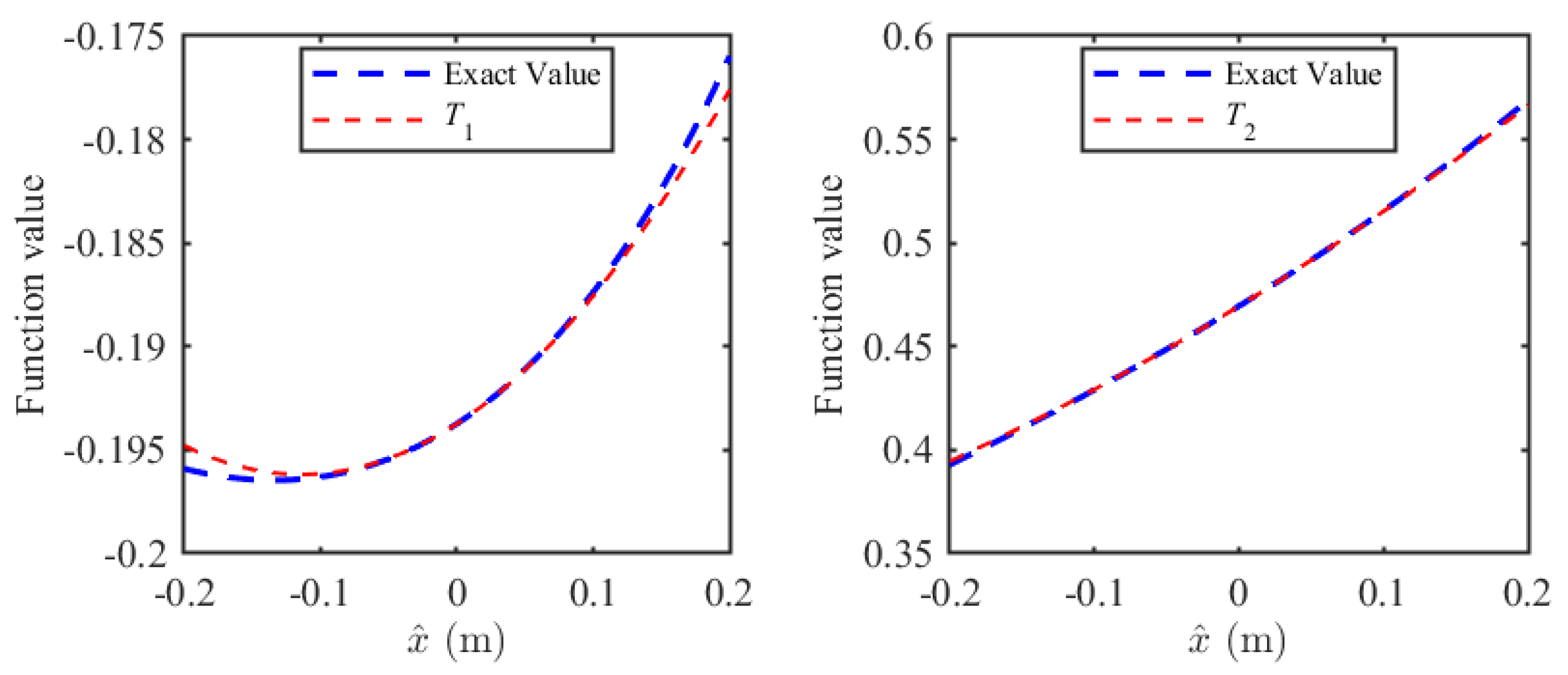

In recent years, passive vibration isolators, developed by leveraging the advantages of nonlinearity, may offer an effective solution. Traditional linear passive vibration isolators cannot resolve the contradiction between low-frequency vibration isolation and load-bearing capacity [

21]. To isolate low-frequency vibrations, it is necessary to reduce stiffness; however, soft springs exhibit large static deformations and suffer from poor static stability and load-bearing capacity. An ideal vibration isolation system should meet the requirements of low-frequency and broad-band frequency vibration suppression without reducing the system’s load-bearing capacity [

22]. Nonlinear passive vibration isolation systems represent a significant advancement in the field, marking a transition from static, fixed-performance technologies toward dynamic and adaptively capable solutions. Through ingenious mechanical design, these systems achieve nonlinear dynamic characteristics that lead to breakthrough performance, particularly in addressing challenges such as ULF vibration isolation and high load-bearing/counter-impact capacity [

23,

24,

25]. To this end, many novel structures or control methods have been proposed to improve vibration isolation performance, such as quasi-zero structures, compliant mechanisms based quasi zero stiffness isolator, origami structures, smart materials and bionic X-shaped mechanisms [

18,

25,

26,

27,

28,

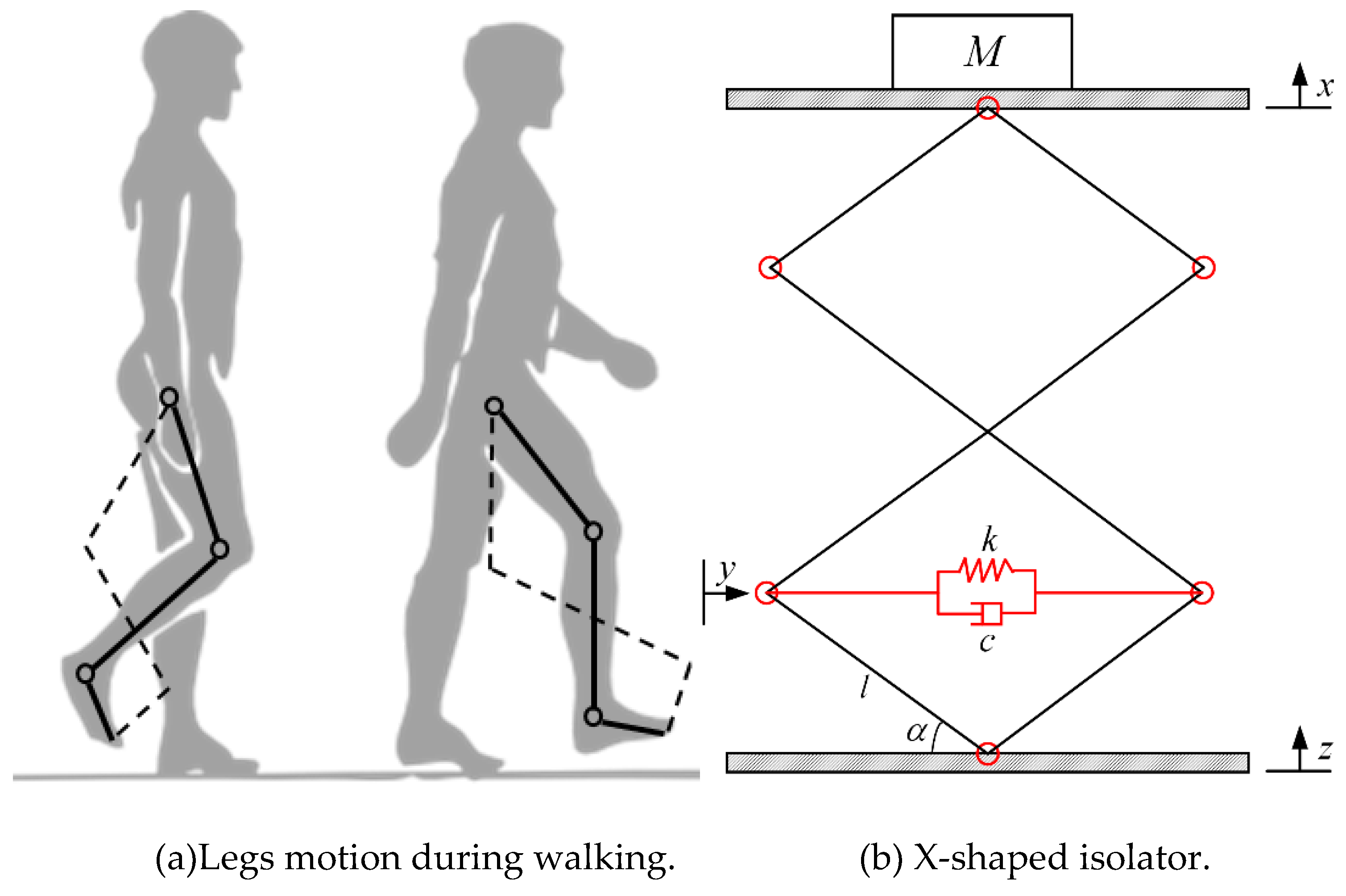

29]. Among them, the bionic NXVIS has received widespread attention. This method is inspired by the vibration-suppressing properties of animal legs/limbs. Jing’s research team has developed a large number of simulated nonlinear X-shaped anti-vibration methods and conducted in-depth research on nonlinear stiffness, damping, and inertia, proving the reliability of the NXVIS [

22]. Due to its excellent nonlinear adjustable characteristics, it enables the design of passive isolators that combine low dynamic stiffness with high load-bearing capacity, achieving tunable ULF and broadband vibration suppression [

21,

22]. In addition, the nonlinear damping in the system can achieve energy dissipation, further reducing the amplitude of structural vibration. It is well known that the deck layer is the part with the most concentrated mass of the offshore platform and is also an important place for oil and gas production and workers’ living [

30]. The nonlinear characteristics of the NXVIS mean that the isolation system can achieve ULF and broadband vibration suppression under seismic loads while ensuring the stability of the deck layer. However, there are no published reports on the results of using the biomimetic NXVIS for offshore platform vibration control under seismic excitation.

In summary, this paper develops a biomimetic NXVIS for vibration control of jacket offshore platforms under seismic loads. Through theoretical research and numerical simulation under real marine conditions, the effectiveness of the proposed NXVIS for vibration control of jacket offshore platforms under seismic loads is systematically discussed. The second part of this paper formulates a mathematical model of the NXVIS, introduces its load-bearing capacity and adjustable nonlinear characteristics, and verifies its ULF and broad-band frequency vibration isolation performance. The third part introduces the structure and characteristics of the NRB’ jacket platform and formulates a dynamic model of the offshore platform equipped with the NXVIS. The fourth part discusses the anti-vibration performance of the NRB’ platform based on the NXVIS using two typical seismic loads as an example. Finally, a summary of the entire paper is given.

3. Jacket Platform with Nonlinear Vibration Isolation System

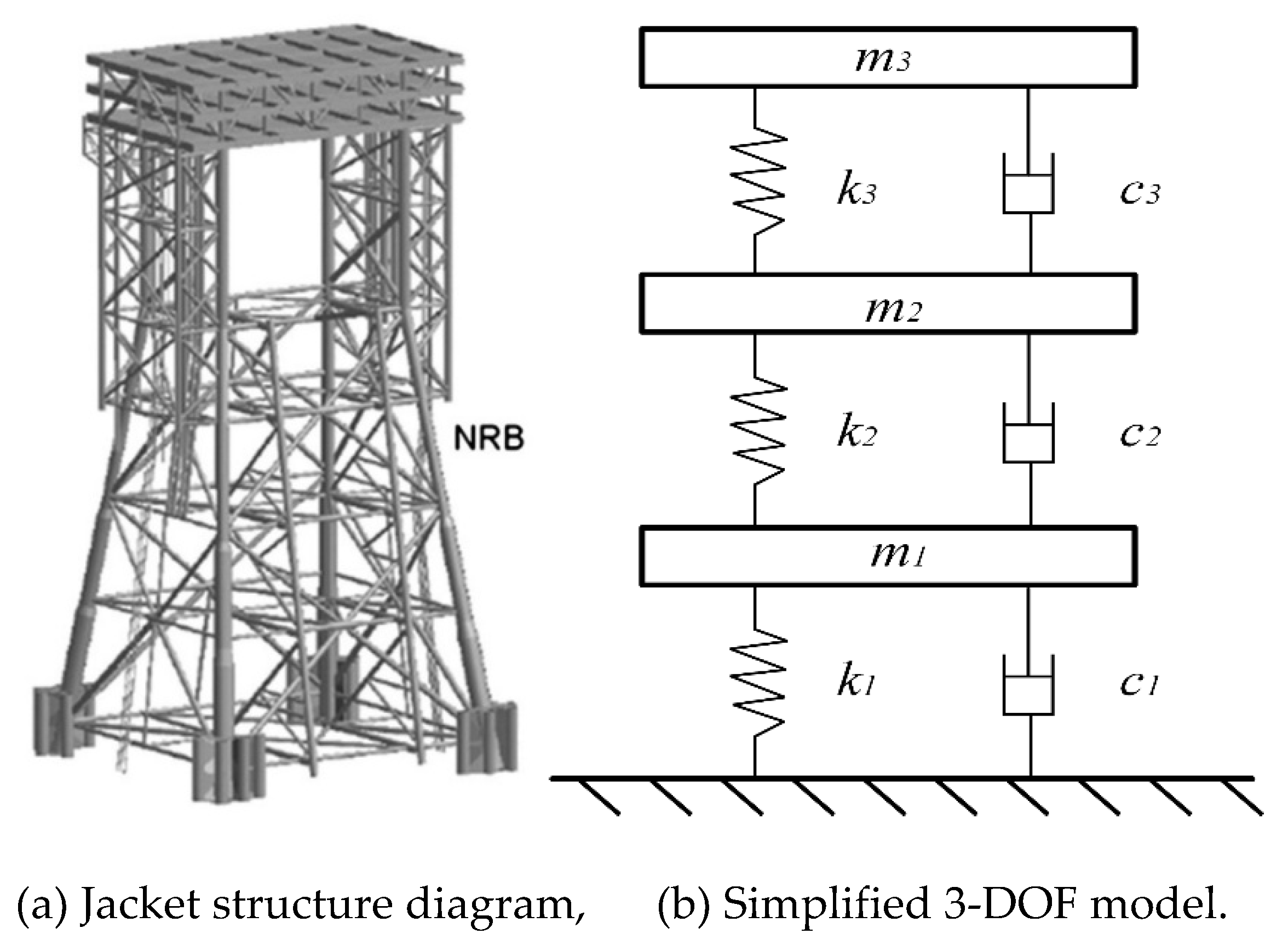

To verify the effectiveness of the proposed nonlinear X-shaped vibration isolation system for jacket offshore platforms, a real offshore platform (North Rankin B’ (NRB’)) [

3] was selected for X-shaped vibration isolation system design and numerical analysis, as shown in

Figure 9a. The NRB’ platform is a major offshore gas platform located approximately 135 kilometers northwest of Dampier, Western Australia. The platform carries out jacket installation, platform hoisting and submarine pipeline laying in a water depth of 125 meters, representing the high technical level of offshore engineering at that time. It was primarily constructed to develop the low-pressure gas reserves of the Rankin field, which the original North Rankin A’ (NRA’) platform could no longer efficiently extract. The platform is physically connected to the NRA’ platform by a 100-meter bridge, creating the integrated Rankin A’B’ hub. This allows for shared utilities and accommodation. With a topsides weight of over 30,000 tons, NRB’ can process up to 1.6 billion standard cubic feet of gas per day. For the convenience of simulation analysis, an idealized 3-DOF system is regarded as a simplified model of the platform by the model reduction method (as shown in

Figure 9b).

Table 1 lists some dynamic characteristics of the platform model, such as the stiffness of each layer and the lumped mass values.

The damping matrix for the NRB’ platform is formulated using Rayleigh damping coefficients, derived from the modal damping ratios associated with the first two frequencies [

3]. The damping ratios of the first three vibration modes are set to 0.05, 0.03, and 0.02, respectively [

3]. Based on the simplified structural model of the jacket platform, the governing dynamic equation is given by,

Where, ,andare mass, damping and stiffness matrices of the simplified 3-DOF model, respectively; and,andare the vectors of displacement, velocity and acceleration of structural response, respectively. is the earthquake acceleration signal. According to the Eq. (14), the displacement and acceleration of deck layer of NRB’ platform can be calculated.

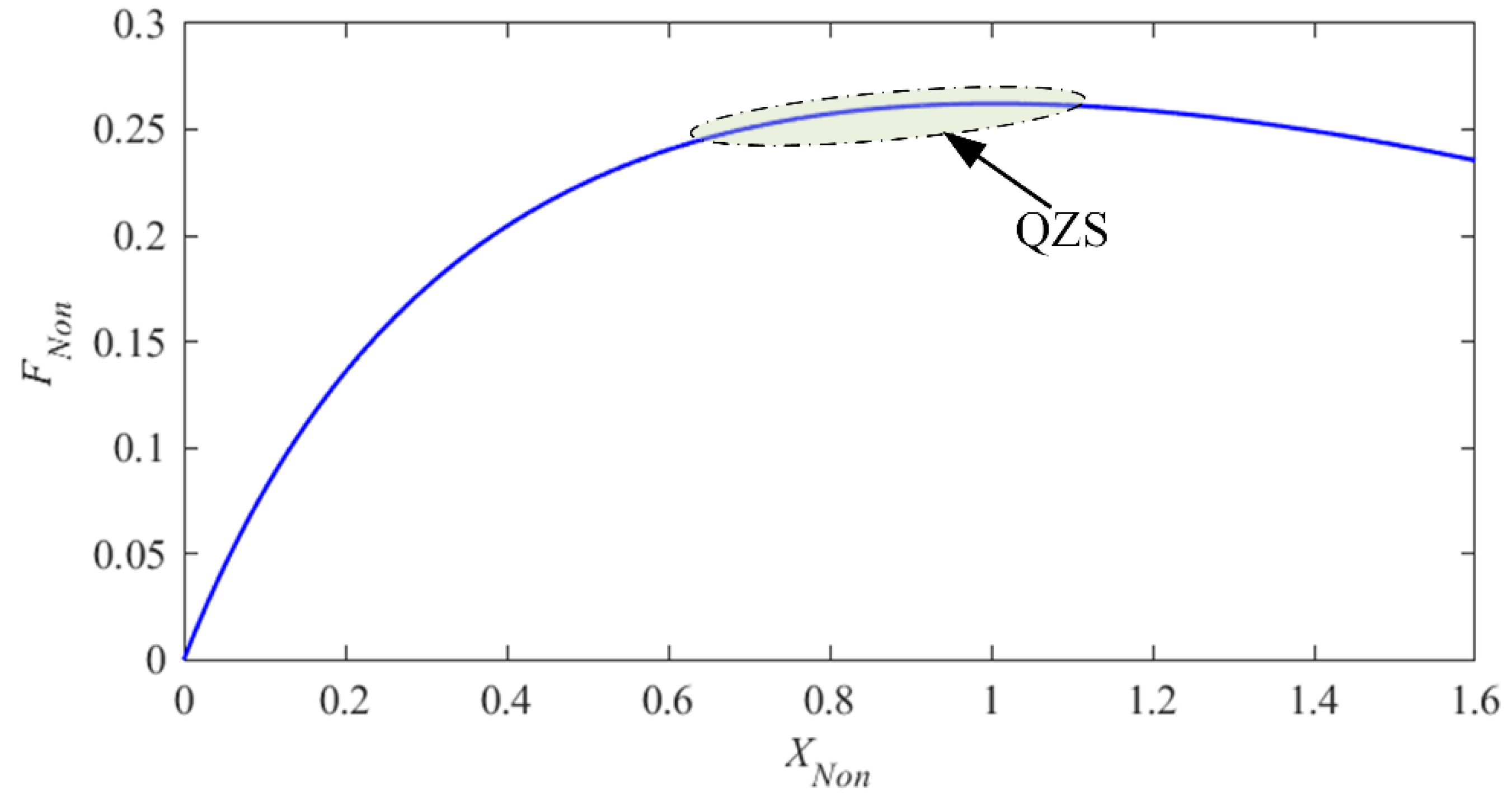

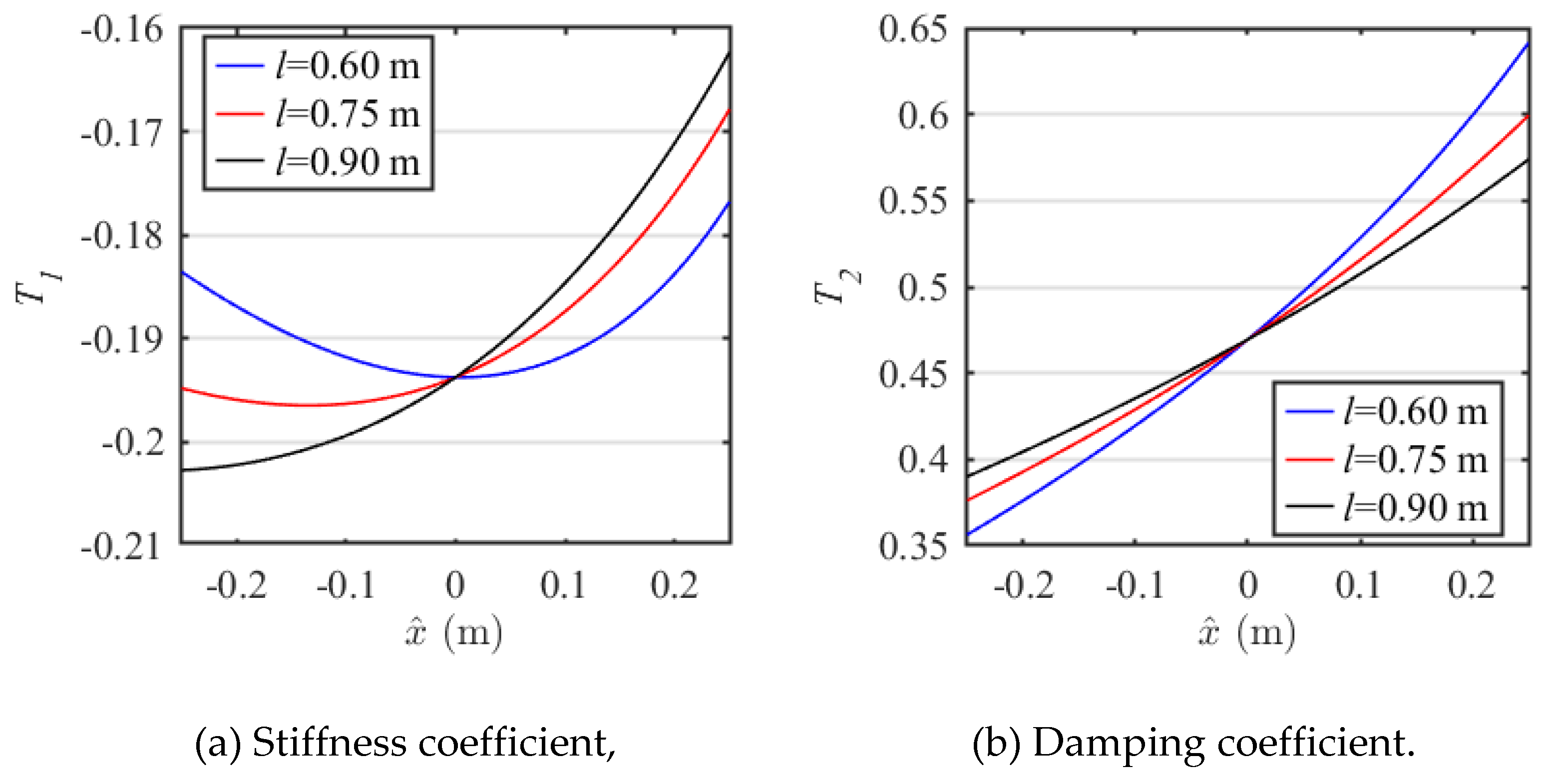

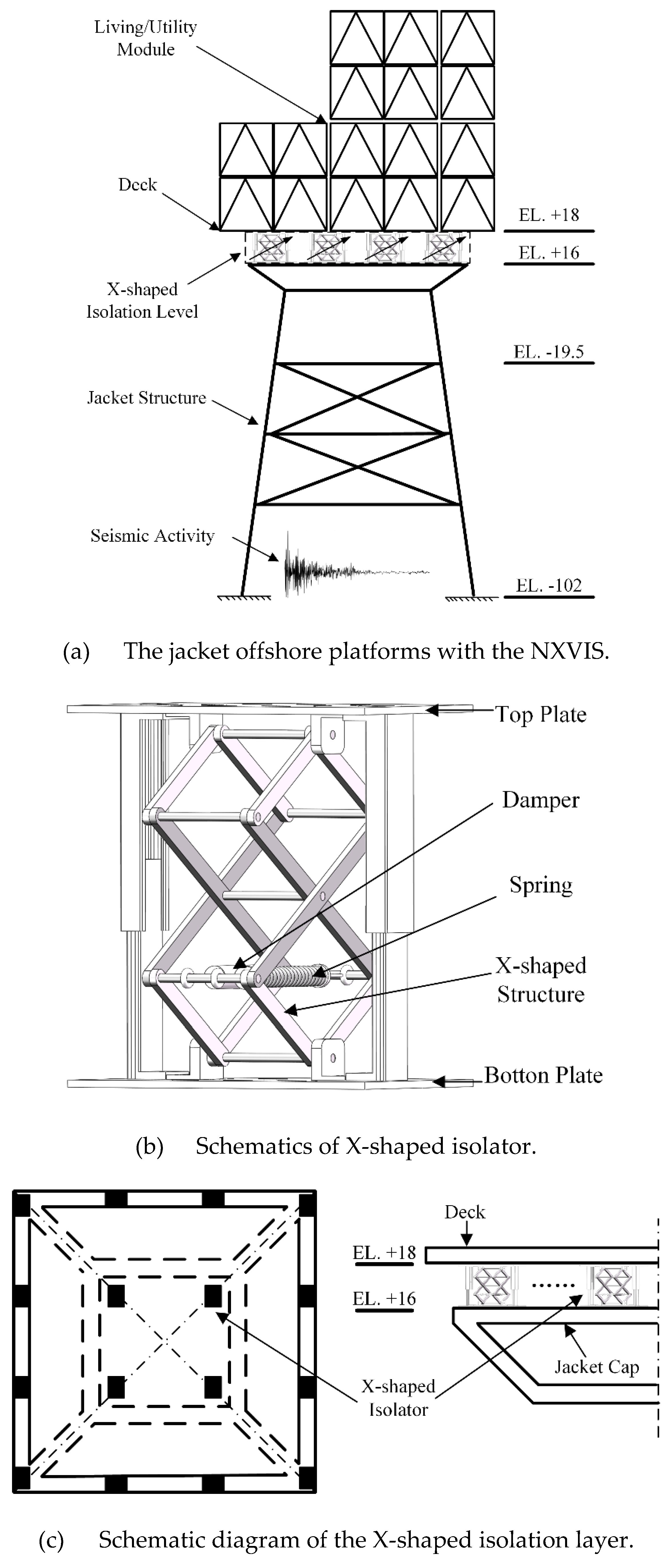

The proposed vibration isolation system for jacket offshore platforms places an NXVIS between the deck and the jacket structure of NRB’ platform, as shown in

Figure 10a. To avoid excessively increasing the overall height of the NRB’ platform and thus introducing unforeseen risks, the bar length

l of the X-shaped isolator is set to 0.75 m, which makes the height of the NXVIS only about 2m. The X-shaped isolator’s primary function is to carry the upper load and achieve vibration isolation through nonlinear dynamic stiffness and damping. The structure of the X-shaped isolator is shown in

Figure 10b. However, the X-shaped isolator corresponding to a bar length

l of 0.75 m cannot bear the weight of the deck layer alone. Considering the weight of the deck and the QZS range of the system, 16 isolators were selected and evenly distributed in the nonlinear X-shaped isolation layer.

Figure 10c shows the installation details of the X-shaped isolation layer.

Figure 10c shows the installation details of the X-shaped isolation layer. As shown in

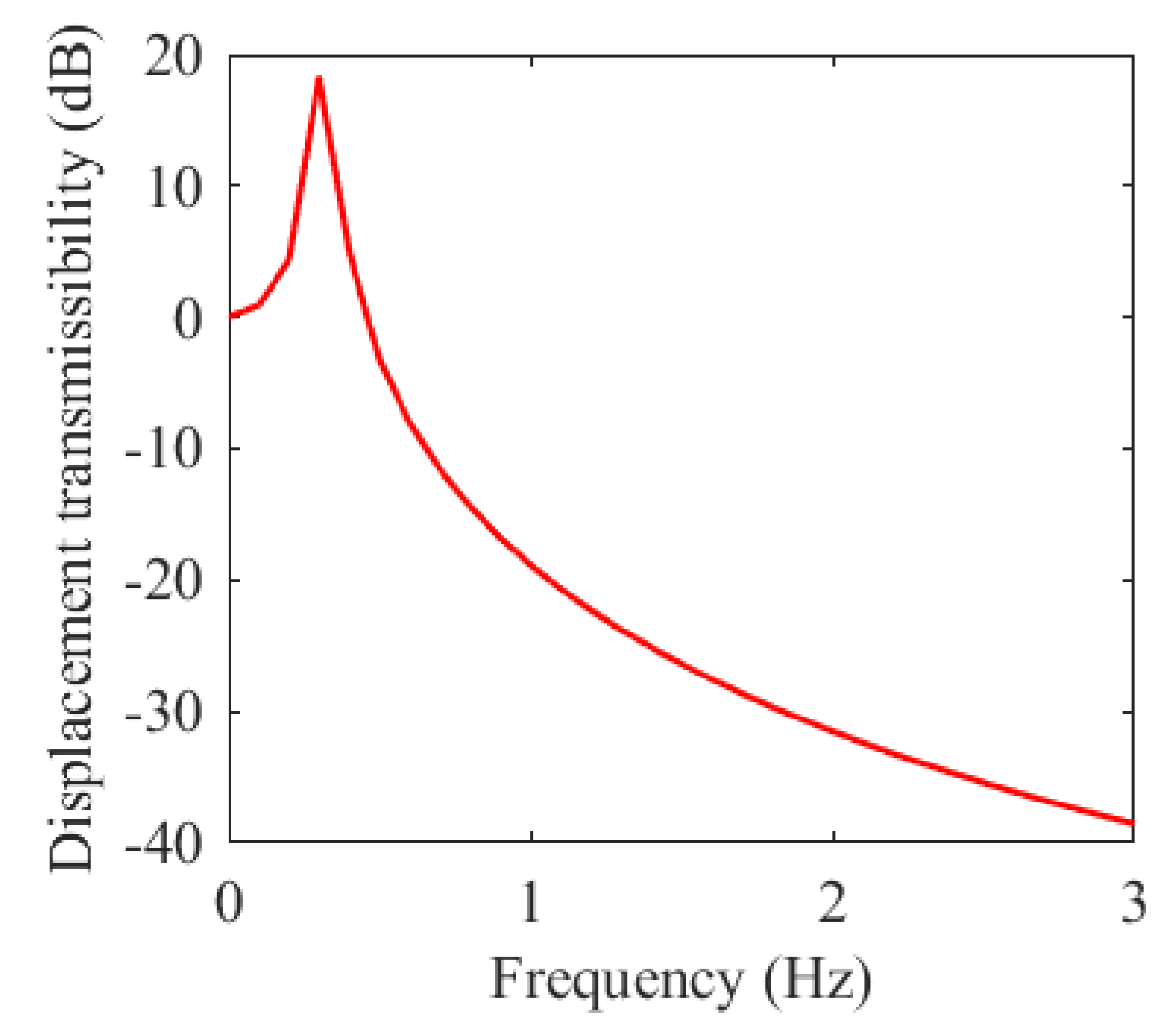

Figure 10c, sixteen isolators are installed evenly between the jacket cap and the deck. This configuration results in the NXVIS being positioned between 16 and 18 m above the water surface. The X-shaped isolation layer not only isolates vibration transmission but also provides a compliant, localized deformation layer between the jacket structure and the deck, making the isolator in a QZS range. The validation of passive vibration isolation layers has been discussed previously [

3,

21]. Conventional vibration isolation approaches are frequently tailored to environmental load profiles. Consequently, their adaptability is generally deficient, and their efficacy in handling the intricacies of complex maritime environments—especially broadband excitations—remains limited. The proposed NXVIS can achieve ULF and wide-band vibration isolation under high loads, enabling the offshore platform to cope not only with low-frequency wave loads but also with wide-band seismic loads. The vibration isolation characteristics of the NXVIS have been verified in

Section 2, demonstrating its effectiveness in reducing vibrations within the frequency band above 0.4 Hz. In addition, the NXVIS can dissipate vibration energy through its damping properties. Although low-frequency wave loads constantly cause platform vibration, seismic loads are the primary threat to platform safety, especially for jacket offshore platforms located in seismic zones. Therefore, this study focuses on vibration control of jacket offshore platforms under seismic loads.

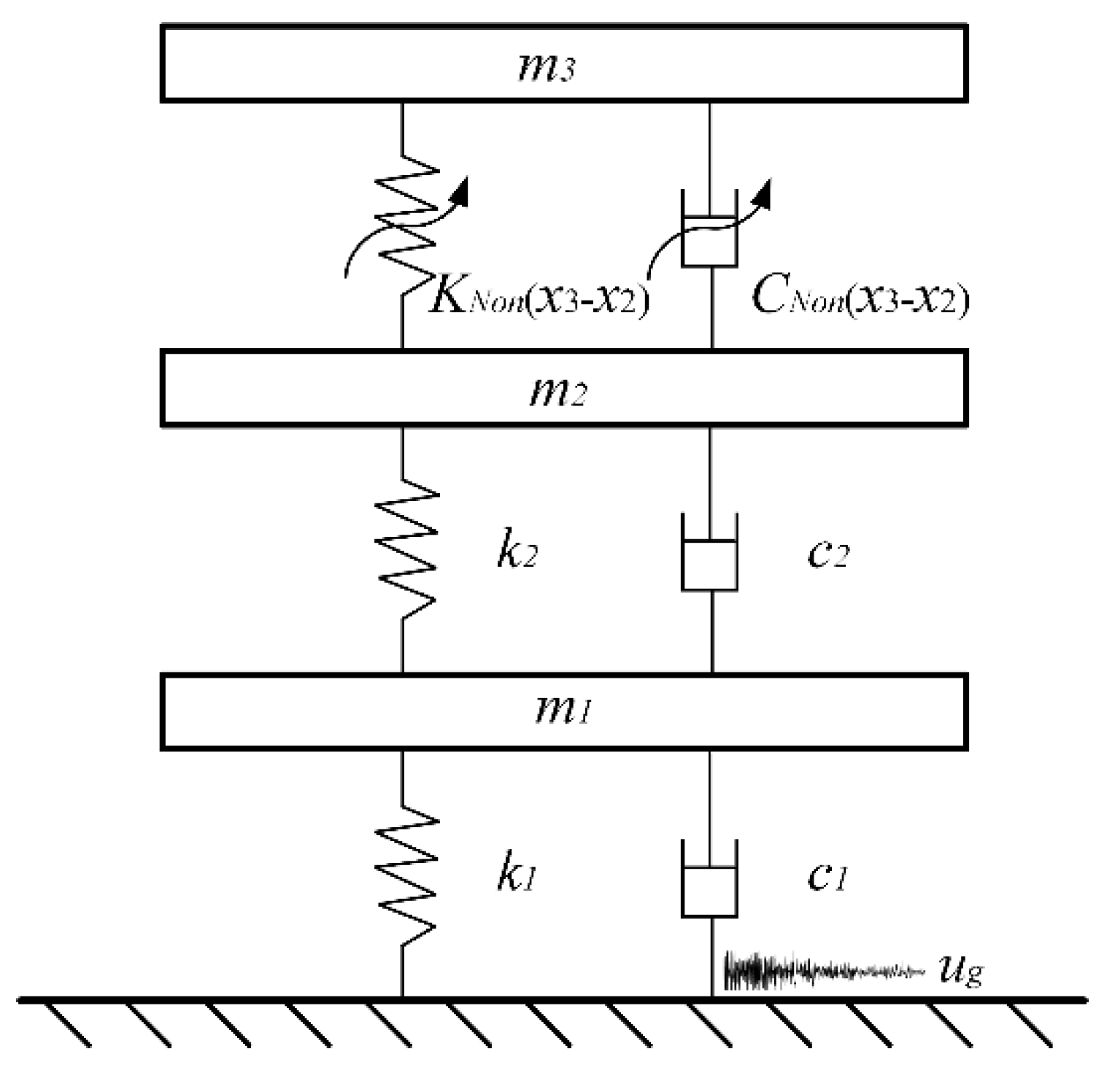

Based on the dynamic characteristics of the NRB’ platform and the designed NXVIS, a simplified 3-DOF platform with NXVIS is shown in

Figure 11. In this figure,

KNon and

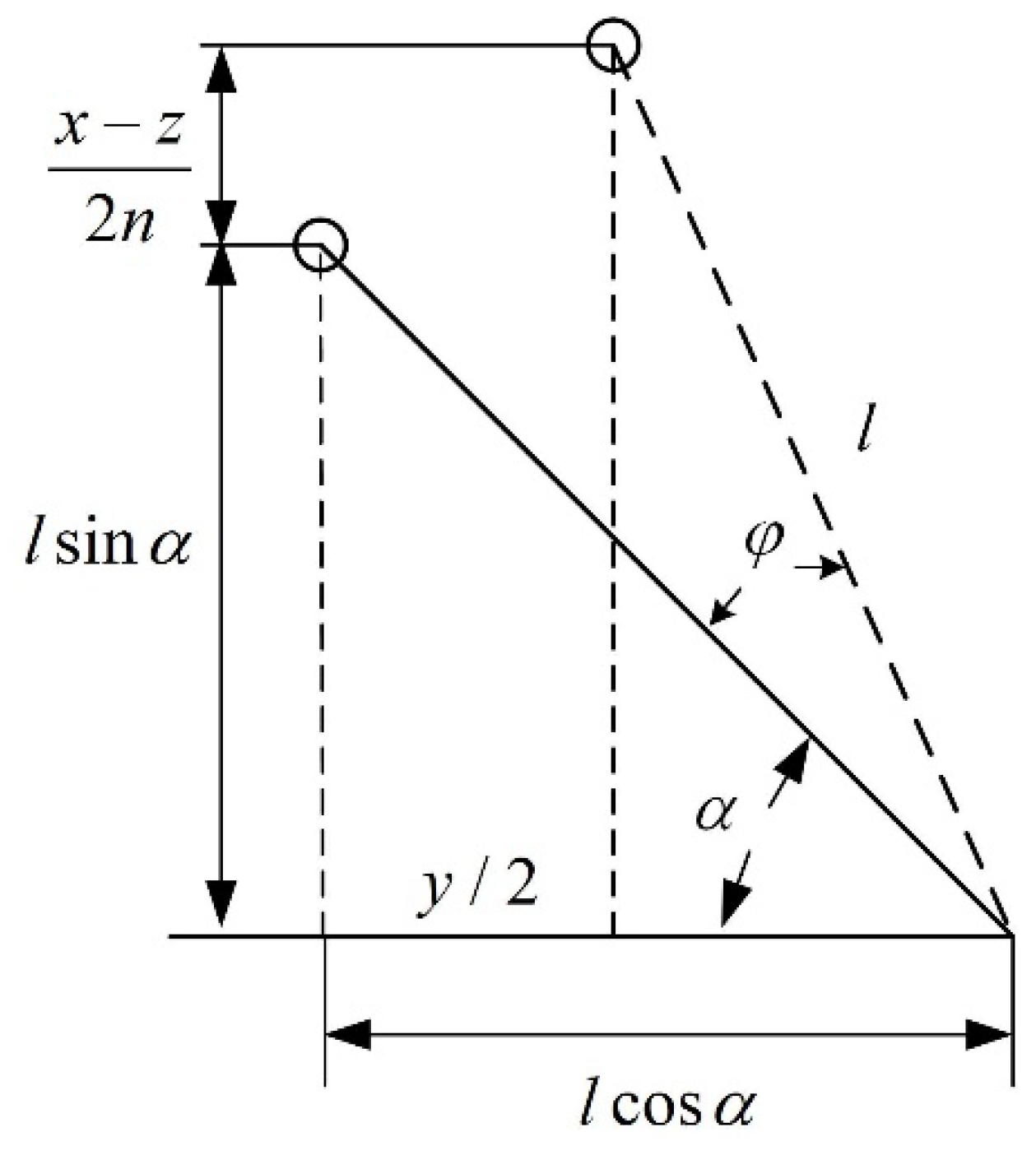

CNon are the dynamic stiffness and damping related to the relative displacement between layers, which can be expressed as,

Where,

x2 and

x3 are the absolute displacements of the second and third layers of the NRB' platform, respectively. The coefficients

are listed in the “

Appendix B”. The Taylor expansion coefficients can be obtained from

Appendix B. Since the NXVIS has strong nonlinearity, the Lagrangian method is used to solve the dynamic equation of the simplified 3-DOF platform with NXVIS. The nonlinear dynamic equation of the NRB’ platform with NXVIS (as shown in Fig. 11) can be written as,

Where,

mi,

ki and

ci are NRB’ platform mass, stiffness and damping coefficient of the

ith floor (

i=1-3), respectively.

xi represents the displacement of the

ith floor relative to ground motion, respectively.

k0 and

c0 are the stiffness and damping coefficient of the proposed X-shaped anti-vibration structure respectively, and their values can be found in

Appendix A. It is important to note that

k0 and

c0 are not the stiffness and damping coefficient of NXVIS. They are only the stiffness and damping coefficient of the spring and damper in NXVIS. The real stiffness and damping coefficients of NXVIS are the dynamic stiffness and damping coefficients determined by the relative displacements

x2 and

x3 between layers, which can be found in Equations (15) and (16). In addition, the gravity term in Equation (19) cancels out the elastic force in the spring caused by gravity. Therefore, the dynamic response of the structure will still fluctuate around the static equilibrium position (zero position). The values of the remaining parameters are provided in

Appendix A.

4. Results and Discussions

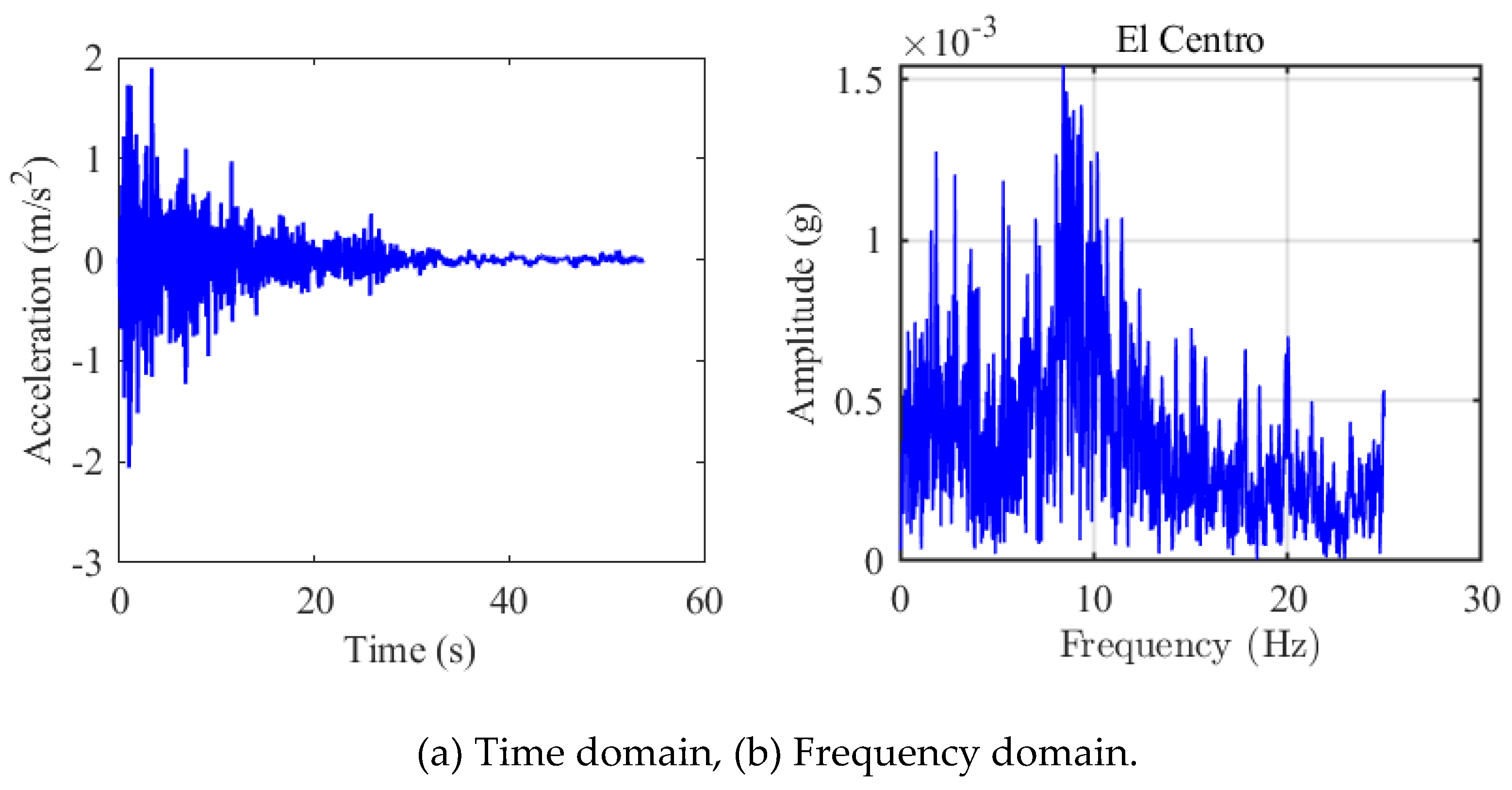

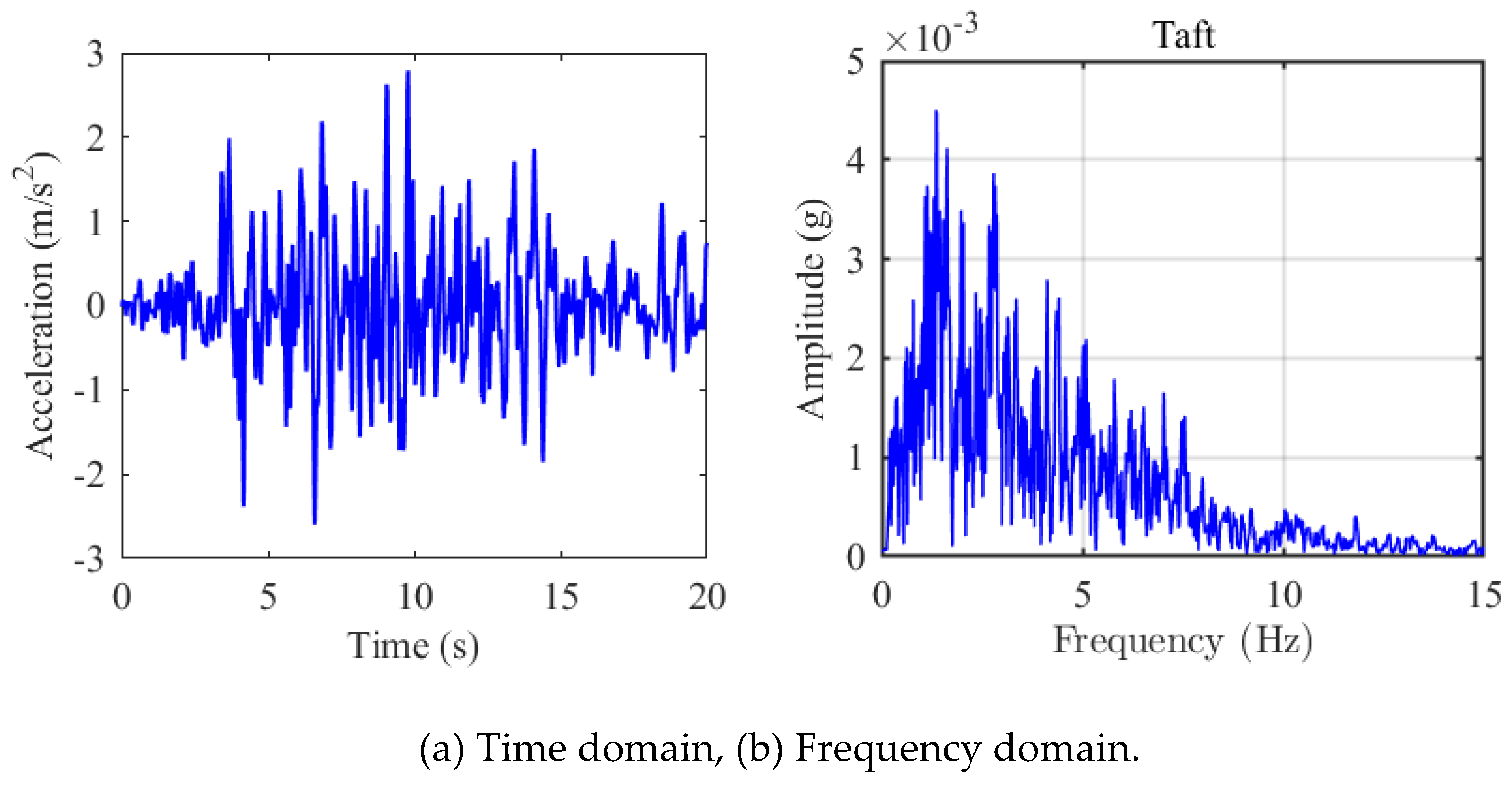

To fully validate the effectiveness of the proposed NXVIS, the NRB’ platform in Western Australia was selected for numerical analysis, which is a very important and representative offshore natural gas production platform. Similarly, to ensure the objectivity of the numerical analysis results, two typical seismic loads (El Centro, 1940; Taft, 1952) were considered, as shown in

Figure 12 and

Figure 13.

Figure 12 shows the Imperial Valley earthquake of May 18, 1940, known as the El Centro earthquake. It is one of the most famous and widely used seismic loads in the world and is a very representative example.

Figure 12a shows that the seismic signal initially has concentrated energy and a large response amplitude, but the energy gradually decays over time.

Figure 12b shows the El Centro earthquake in the frequency domain. The earthquake has two frequency peaks, at 1.88 Hz and 8.43 Hz, with the major energy concentrated between 1.0 Hz and 10.0 Hz. This indicates that larger earthquakes release more low-frequency energy, and vibration control for jacket offshore platforms should primarily address these extreme seismic loads.

Figure 13 shows the seismic acceleration recorded at a seismic station in Taft, California, during the 1952 Kern County earthquake, known as the Taft earthquake. It is one of the earliest fully documented strong earthquake records in the world. Due to its high data quality and typical characteristics, it has become a standard seismic load recognized by international society, widely used in seismic performance testing of structures such as buildings, bridges, and nuclear power plants. Unlike the El Centro earthquake, the Taft seismic load exhibits a strong response throughout the entire period. As shown in

Figure 13b, the Taft seismic load peaks at 1.38 Hz, with most of its energy concentrated between 0.8 Hz and 5.0 Hz.

These two types of seismic loads are highly representative, characteristic, and widely applicable, and therefore can well reflect the effectiveness of vibration isolation solutions. Based on these two typical seismic loads and the dynamic model of an NRB’ offshore platform with an X-shaped anti-vibration structure, a numerical analysis of the offshore platform’s vibration performance was conducted. The deck is a crucial area of offshore platforms for oil and gas production and crew life. The displacement response of the deck can cause structural fatigue damage and equipment damage, and in severe cases, even cause the platform to capsize, resulting in significant losses. The acceleration response of the deck can affect staff comfort and the operation of sensitive equipment, ultimately impacting production efficiency and worker health. Therefore, this study focuses on analyzing the structural response of the deck. The results are presented in

Figure 14 and

Figure 15. It should be clarified that the “Original” denotes the NRB’ platform without any anti-vibration mechanisms, while the “Isolation” refers specifically to the platform integrated with the NXVIS.

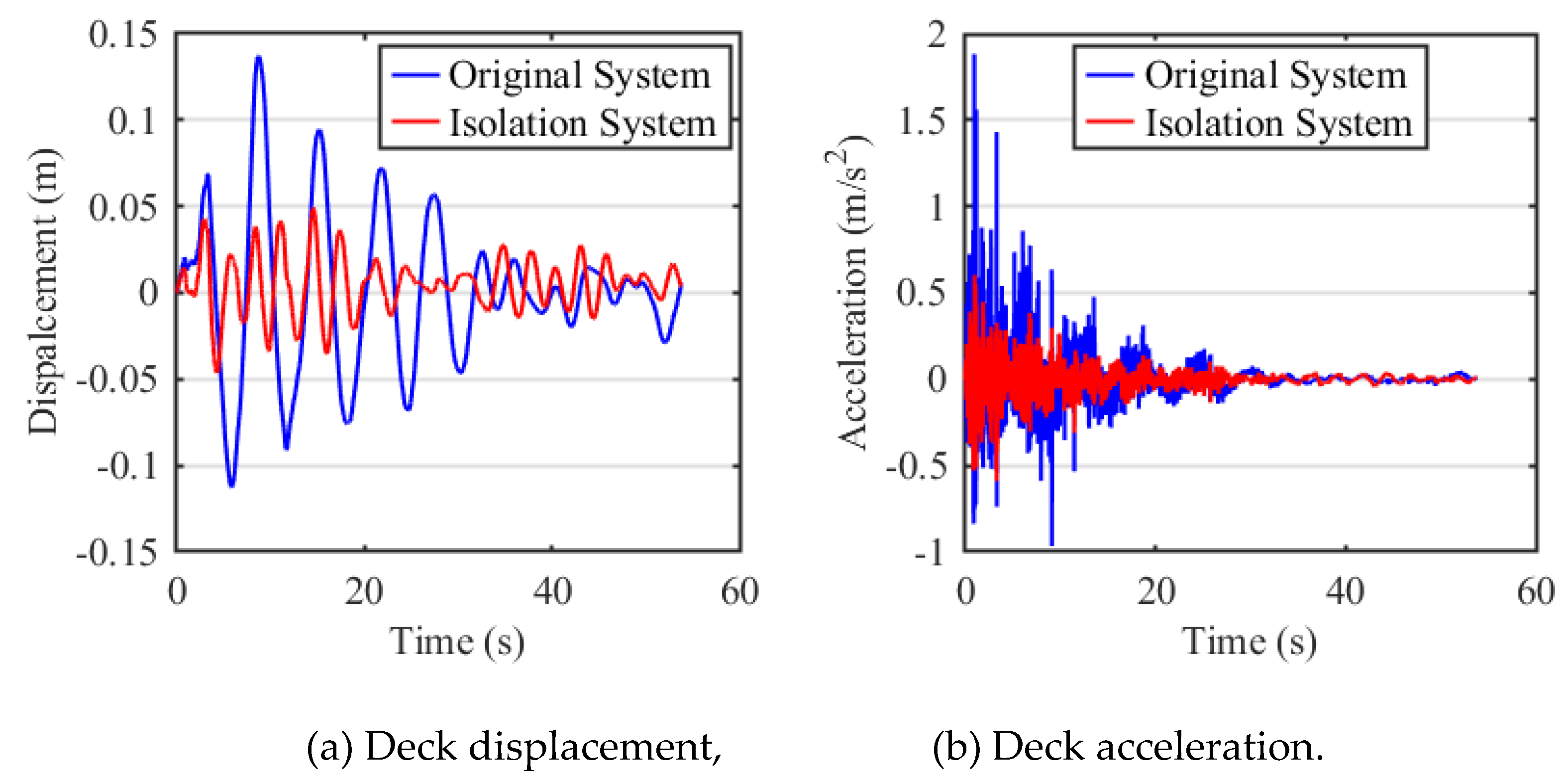

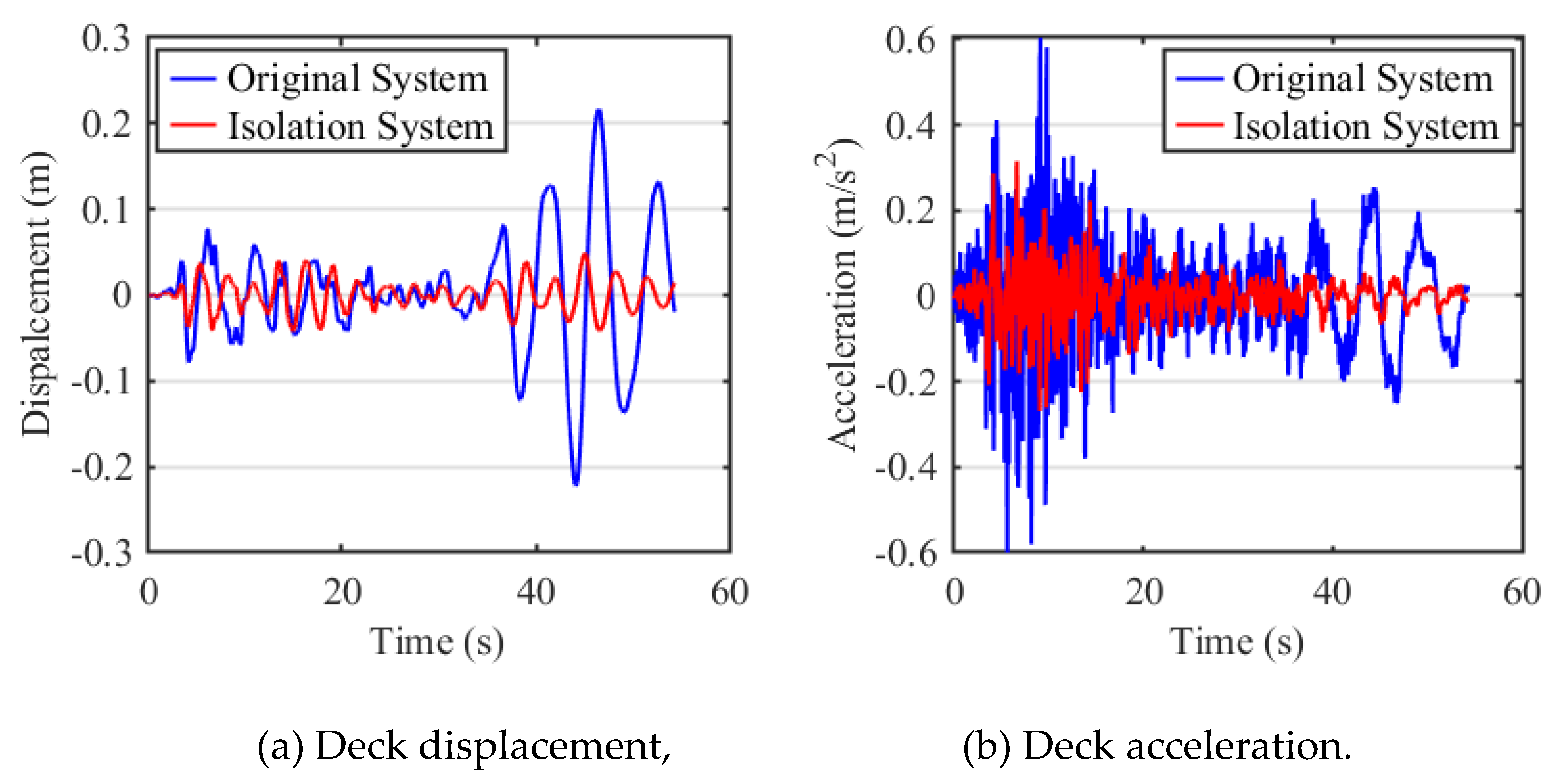

Figure 14 and

Figure 15 show that the NRB’ jacket offshore platform equipped with a NXVIS can significantly reduce the displacement and acceleration response of the deck under seismic loads.

Figure 14 shows the displacement and acceleration response of the deck under the El Centro earthquake load. The maximum displacements of the deck with and without the NXVIS are 4.9 cm and 13.7 cm respectively, reduction by 64.23%. The peak deck accelerations were measured at 0.602 m/s² and 1.883 m/s², corresponding to a significant reduction of 68.03%.

Figure 15 presents the displacement and acceleration time histories of the deck subjected to Taft seismic excitation. The peak deck displacements with and without the NXVIS were measured at 4.9 cm and 21.6 cm respectively, corresponding to a significant reduction of 77.31%. The peak deck accelerations reached 0.315 m/s² and 0.604 m/s², representing a substantial reduction of 47.85%. This demonstrates that the NXVIS can achieve effective vibration reduction within the seismic frequency band by changing the system’s natural frequency. For quantitative comparison,

Table 2 lists the maximum, minimum, and RMS values of the performance indicators under different systems (original system and isolation system) and seismic loads (El Centro Earthquake; Taft Earthquake).

As shown in

Table 2, compared to offshore platforms without NXVIS, offshore platforms equipped with NXVIS significantly reduce deck vibration response under seismic loads, with the maximum reduction reaching 81.08%. Under seismic excitation from both the El Centro and Taft records, the NXVIS achieved substantial reductions in the root mean square (RMS) deck acceleration values, amounting to 32.41% and 53.12%, respectively. Deck acceleration serves as a critical metric for assessing the vibrational performance of marine vessels and offshore structures, with direct implications for crew comfort, as well as the operational safety and reliability of sensitive on-board equipment. Notably, under both loading scenarios, the peak, minimum, and RMS acceleration values of the deck equipped with the NXVIS were consistently reduced compared to the original platform, confirming the system’s superior vibration suppression performance. The minimum deck acceleration under both load conditions was reduced by 32.41% and 53.12%, respectively. This is because the natural mode of the original NRB’ platform is closer to the main earthquake frequency band, making it more susceptible to resonance. However, the offshore platform with the NXVIS can dynamically adjust the system stiffness, achieving effective vibration isolation within the external excitation frequency band, thereby effectively suppressing the vibration response.

It should also be noted that the system stiffness of the isolation layer is relatively low, which generally reduces the acceleration response while increasing the relative motion between deck and jacket structure. This increase in relative displacement may affect the stability of equipment installation and system durability. However, the offshore platform with the NXVIS significantly reduces the relative displacement of the structure while maintaining better acceleration control. This is because nonlinear systems can achieve HSLDS characteristics. For example, under two seismic loads, the RMS value of the deck displacement was reduced by 57.78% and 73.53%, respectively, demonstrating the significant advantage of this control strategy in improving overall stability. This outcome further verifies that the proposed nonlinear isolation approach successfully reconciles the response interplay between acceleration and displacement while surpassing conventional linear passive isolation methods in overall vibration suppression effectiveness, highlighting its potential for practical deployment in offshore platform vibration mitigation.

5. Conclusions

This paper proposes a biomimetic nonlinear X-shaped vibration isolation system, inspired by the X-shaped supporting structure of the human leg, to mitigate vibrations of jacket offshore platforms under the action of seismic loads. The NXVIS demonstrates superior tunable stiffness, adaptive damping characteristics, and high load-bearing capacity, with all three properties being programmable through strategic configuration of its structural parameters. To verify the effectiveness of the proposed nonlinear X-shaped vibration isolation system for vibration control of offshore platform under the action of seismic loads, theoretical and numerical analyses were conducted on the dynamic response of the NRB’ offshore platform located in the waters of Western Australia under two typical seismic loads. The principal findings of this study can be summarized as follows:

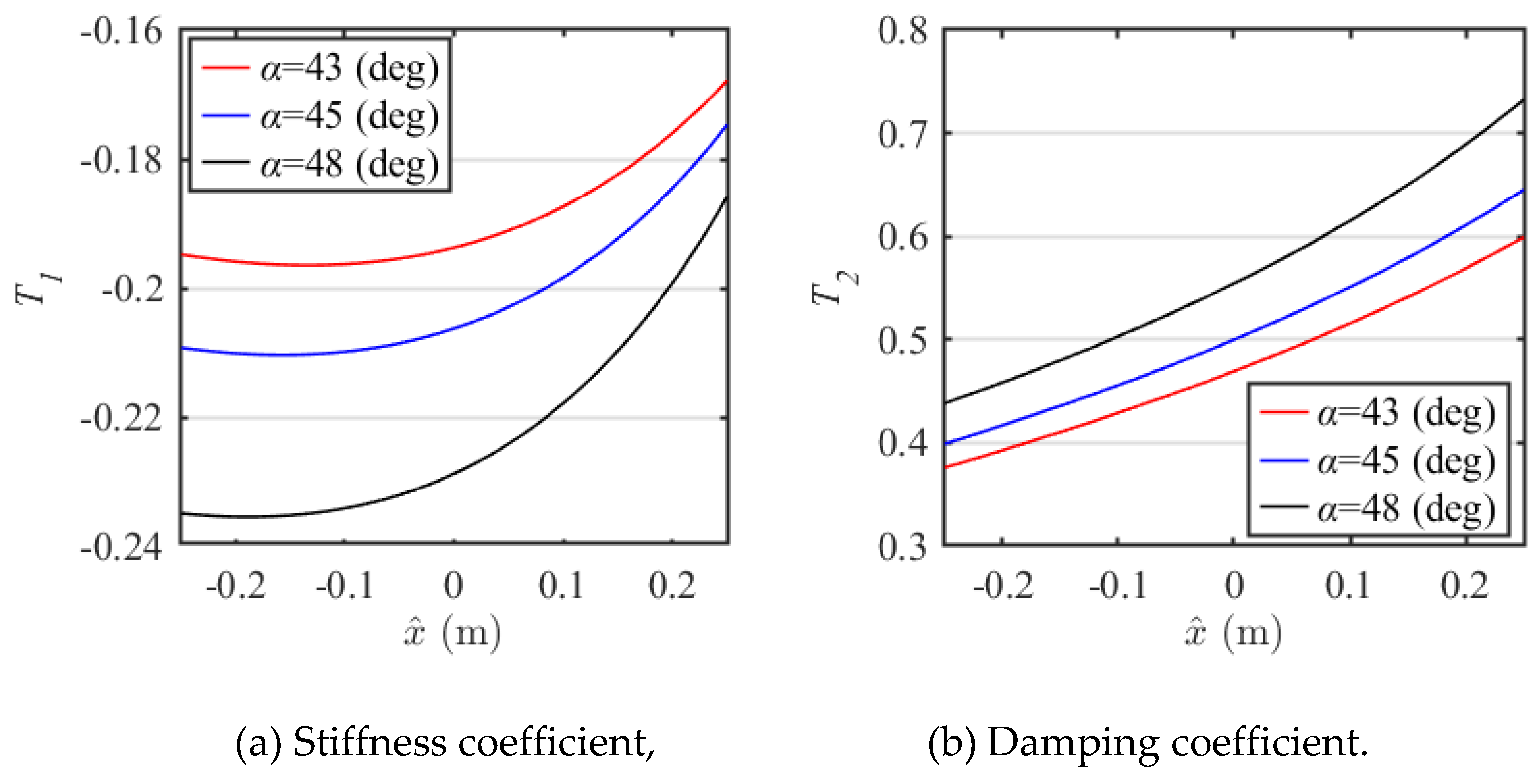

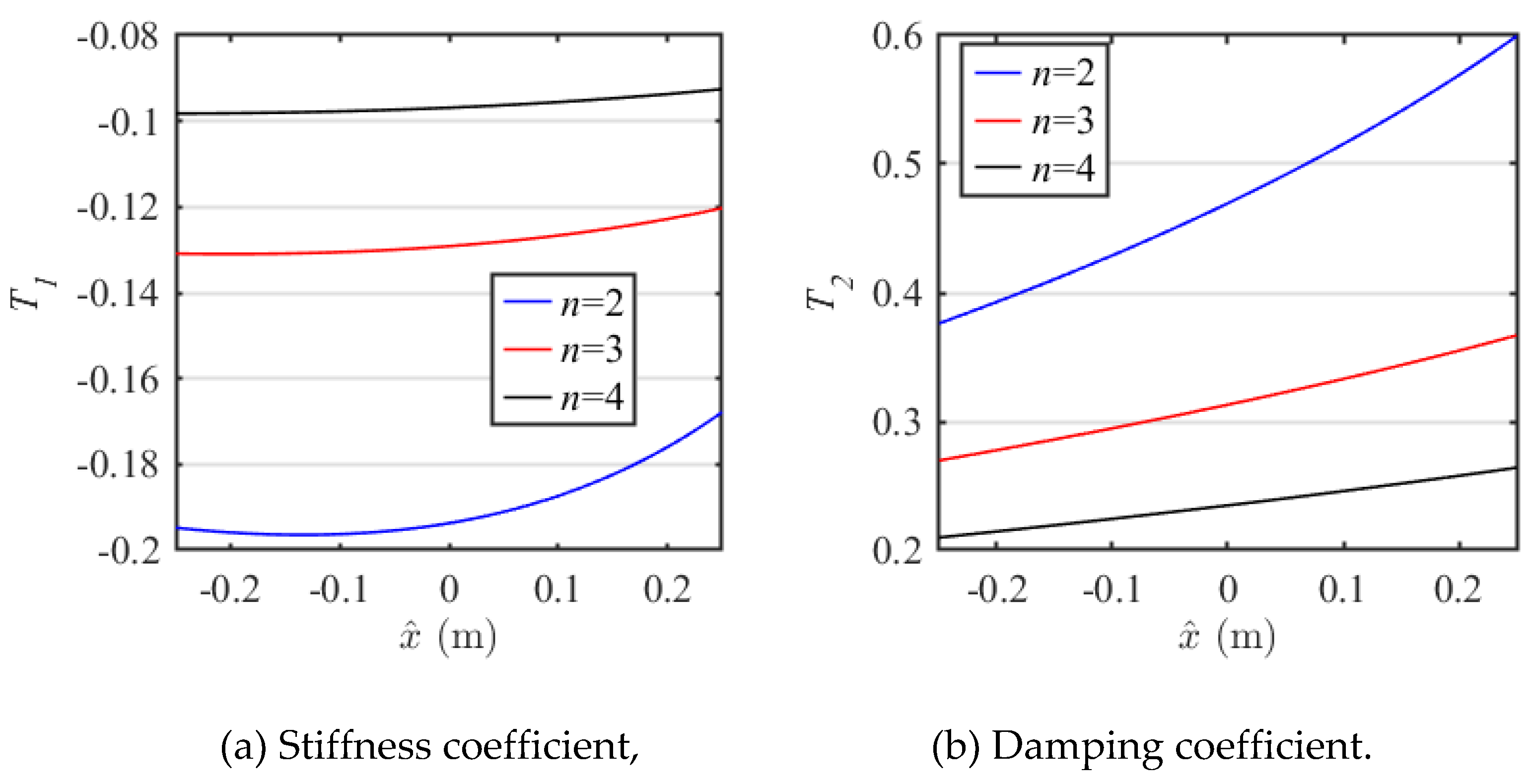

1. System modeling and theoretical analysis demonstrate that the NXVIS exhibits distinct nonlinear quasi-zero stiffness, nonlinear damping, and high load capacity, enabling ULF with minimal peak values and high vertical load capacity. This design provides tunable load-bearing and frequency response characteristics—a significant advantage over traditional passive isolation methods—allowing precise adaptation to specific platform requirements and complex marine loading scenarios.

2. By modulating key structural parameters, including bar length and spring stiffness, the system can be tuned to exhibit diverse nonlinear stiffness profiles and a broad QZS operating range. This characteristic enables ULF vibration suppression without compromising the structural load-bearing integrity.

3. Under typical earthquake loads, the offshore platform equipped with the NXVIS significantly reduced the dynamic response of the offshore platform. Under the El Centro earthquake load, the maximum deck acceleration of the platform with the X-shaped vibration isolation system was reduced by 68.03%, and the maximum deck displacement was reduced by 64.23% compared to the original system. Under the Taft earthquake load, the maximum deck acceleration and displacement were reduced by 77.31% and 47.85%, respectively.

4. Due to the HSLDS characteristic of the X-shaped nonlinear isolator, the proposed NXVIS can effectively suppress the deck acceleration response of the offshore platform with small deck displacements, ensuring structural stability. The results demonstrate that the proposed NXVIS effectively ensures structural safety and provides good comfort.

It is worth emphasizing that the NXVIS is highly flexible in terms of size and load capacity, and its manufacturing and vibration isolation applications are also extremely cost-effective. These outstanding properties and intrinsic nonlinear characteristics make the proposed system an innovative solution for vibration control in jacket-type offshore platforms, providing a novel approach that extends beyond conventional structural vibration mitigation strategies. This system holds significant potential for widespread engineering application, promising considerable advantages across various industrial practices.