Submitted:

24 September 2025

Posted:

26 September 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

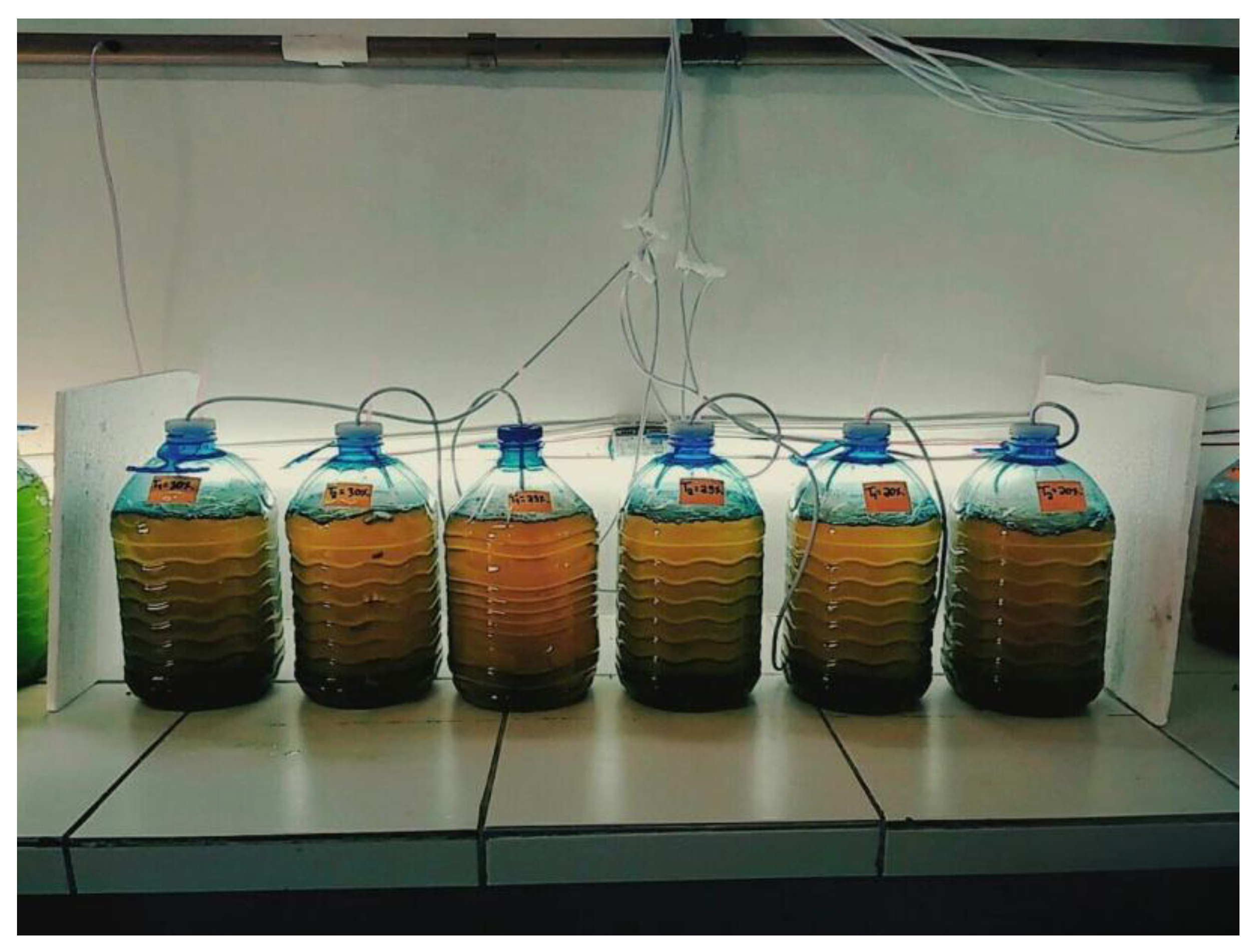

2.1. Microalgae Cultivation

2.2. Experimental Design and Microalgae Performance

2.3. Removal of Phosphorus from Culture Media by Microalgae

2.4. Biomass Recovery

2.5. Statistical Analysis

3. Results

3.1. Culture Performance

3.2. Phosphorus Removal by C. muelleri

3.3. Biomass Yield and Harvesting Efficiency

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Stead, S.M. Rethinking Marine Resource Governance for the United Nations Sustainable Development Goals. Current Opinion in Environmental Sustainability 2018, 34, 54–61. [Google Scholar] [CrossRef]

- Techera, E.J. Supporting Blue Economy Agenda: Fisheries, Food Security and Climate Change in the Indian Ocean. Journal of the Indian Ocean Region 2018, 14, 7–27. [Google Scholar] [CrossRef]

- Ryan, M.H.; Tibbett, M.; Lambers, H.; Bicknell, D.; Brookes, P.; Barrett-Lennard, E.G.; Ocampo, C.; Nicol, D. Pronounced Surface Stratification of Soil Phosphorus, Potassium and Sulfur under Pastures Upstream of a Eutrophic Wetland and Estuarine System. Soil Res. 2017, 55, 657–669. [Google Scholar] [CrossRef]

- Sarelli, A.; Sykas, D.; Miltiadou, M.; Bliziotis, D.; Spastra, Y.; Ieronymaki, M. A Novel Automated Methodology That Estimates the United Nations (UN) Sustainable Development Goal (SDG) 14. 1.1.: Index of Coastal Eutrophication Using the Copernicus Marine Environment Monitoring Service (CMEMS). In Proceedings of the Sixth International Conference on Remote Sensing and Geoinformation of the Environment (RSCy2018); International Society for Optics and Photonics, August 6 2018; Vol. 10773, 1077302.

- Shore, M.; Murphy, S.; Mellander, P.-E.; Shortle, G.; Melland, A.R.; Crockford, L.; O’Flaherty, V.; Williams, L.; Morgan, G.; Jordan, P. Influence of Stormflow and Baseflow Phosphorus Pressures on Stream Ecology in Agricultural Catchments. Science of The Total Environment 2017, 590–591, 469–483. [Google Scholar] [CrossRef]

- Jarvie, H.P.; Sharpley, A.N.; Withers, P.J.A.; Scott, J.T.; Haggard, B.E.; Neal, C. Phosphorus Mitigation to Control River Eutrophication: Murky Waters, Inconvenient Truths, and “Postnormal” Science. J. Environ. Qual. 2013, 42, 295–304. [Google Scholar] [CrossRef] [PubMed]

- Rivers, M.R.; Weaver, D.M.; Smettem, K.R.J.; Davies, P.M. Estimating Farm to Catchment Nutrient Fluxes Using Dynamic Simulation Modelling – Can Agri-Environmental BMPs Really Do the Job? Journal of Environmental Management 2013, 130, 313–323. [Google Scholar] [CrossRef]

- Sharpley, A.N.; Bergström, L.; Aronsson, H.; Bechmann, M.; Bolster, C.H.; Börling, K.; Djodjic, F.; Jarvie, H.P.; Schoumans, O.F.; Stamm, C.; et al. Future Agriculture with Minimized Phosphorus Losses to Waters: Research Needs and Direction. AMBIO 2015, 44, 163–179. [Google Scholar] [CrossRef]

- Gobler, C.J. Climate Change and Harmful Algal Blooms: Insights and Perspective. Harmful Algae 2020, 91, 101731. [Google Scholar] [CrossRef]

- Uddin, S.; Bebhehani, M.; Al-Musallam, L.; Kumar, V.V.; Sajid, S. Po Uptake in Microalgae at Different Seawater pH: An Experimental Study Simulating Ocean Acidification. Marine Pollution Bulletin 2020, 151, 110844. [Google Scholar] [CrossRef]

- Ishika, T.; Moheimani, N.R.; Bahri, P.A.; Laird, D.W.; Blair, S.; Parlevliet, D. Halo-Adapted Microalgae for Fucoxanthin Production: Effect of Incremental Increase in Salinity. Algal Research 2017, 28, 66–73. [Google Scholar] [CrossRef]

- Sigman, D. M.; Hain, M. P. The Biological Productivity of the Ocean. Nature Education Knowledge 2012, 3, 21. [Google Scholar]

- de-Bashan, L.E.; Bashan, Y. Immobilized Microalgae for Removing Pollutants: Review of Practical Aspects. Bioresource Technology 2010, 101, 1611–1627. [Google Scholar] [CrossRef]

- Tomaselli, L. The Microalgal Cell. In Handbook of Microalgal Culture; John Wiley & Sons, Ltd, 2007; pp. 1–19 ISBN 978-0-470-99528-0.

- Kuczynska, P.; Jemiola-Rzeminska, M.; Strzalka, K. Photosynthetic Pigments in Diatoms. Marine Drugs 2015, 13, 5847–5881. [Google Scholar] [CrossRef]

- Chisti, Y. Biodiesel from Microalgae. Biotechnology Advances 2007, 25, 294–306. [Google Scholar] [CrossRef]

- Molazadeh, M.; Ahmadzadeh, H.; Pourianfar, H.R.; Lyon, S.; Rampelotto, P.H. The Use of Microalgae for Coupling Wastewater Treatment With CO2 Biofixation. Front. Bioeng. Biotechnol. 2019, 7, 42. [Google Scholar] [CrossRef]

- Tahmasebi, A.; Kassim, M.A.; Yu, J.; Bhattacharya, S. Thermogravimetric Study of the Combustion of Tetraselmis Suecica Microalgae and Its Blend with a Victorian Brown Coal in O2/N2 and O2/CO2 Atmospheres. Bioresource Technology 2013, 150, 15–27. [Google Scholar] [CrossRef] [PubMed]

- Field, C.B.; Behrenfeld, M.J.; Randerson, J.T.; Falkowski, P. Primary Production of the Biosphere: Integrating Terrestrial and Oceanic Components. Science 1998, 281, 237–240. [Google Scholar] [CrossRef] [PubMed]

- Falkowski, P. Do Tiny Floating Microorganisms in the Ocean’s Surface Waters Play a Massive Role in Controlling the Global Climate? 2012, 4.

- Yaakob, Z.; Ali, E.; Zainal, A.; Mohamad, M.; Takriff, M.S. An Overview: Biomolecules from Microalgae for Animal Feed and Aquaculture. Journal of Biological Research-Thessaloniki 2014, 21, 6. [Google Scholar] [CrossRef]

- Roy, S.S.; Pal, R. Microalgae in Aquaculture: A Review with Special References to Nutritional Value and Fish Dietetics. Proc Zool Soc 2015, 68, 1–8. [Google Scholar] [CrossRef]

- Lourenço, S.O. Cultivo de microalgas marinhas: princípios e aplicações; RiMa, 2006; ISBN 978-85-7656-113-2.

- Khan, M.I.; Shin, J.H.; Kim, J.D. The Promising Future of Microalgae: Current Status, Challenges, and Optimization of a Sustainable and Renewable Industry for Biofuels, Feed, and Other Products. Microbial Cell Factories 2018, 17, 36. [Google Scholar] [CrossRef] [PubMed]

- Reijnders, M.J.M.F.; van Heck, R.G.A.; Lam, C.M.C.; Scaife, M.A.; Santos, V.A.P.M. dos; Smith, A.G.; Schaap, P.J. Green Genes: Bioinformatics and Systems-Biology Innovations Drive Algal Biotechnology. Trends in Biotechnology 2014, 32, 617–626. [Google Scholar] [CrossRef]

- Bahadar, A.; Bilal Khan, M. Progress in Energy from Microalgae: A Review. Renewable and Sustainable Energy Reviews 2013, 27, 128–148. [Google Scholar] [CrossRef]

- Valenzuela B, A.; Sanhueza C, J.; Valenzuela B, R. Las microalgas: una fuente renovable para la obtención de ácidos grasos omega-3 de cadena larga para la nutrición humana y animal. Rev. chil. nutr. 2015, 42, 306–310. [Google Scholar] [CrossRef]

- Du, Z.-Y.; Benning, C. Triacylglycerol Accumulation in Photosynthetic Cells in Plants and Algae. In Lipids in Plant and Algae Development; Nakamura, Y., Li-Beisson, Y., Eds.; Subcellular Biochemistry; Springer International Publishing: Cham, 2016; pp. 179–205. ISBN 978-3-319-25979-6. [Google Scholar]

- Paliwal, C.; Mitra, M.; Bhayani, K.; Bharadwaj, S.V.V.; Ghosh, T.; Dubey, S.; Mishra, S. Abiotic Stresses as Tools for Metabolites in Microalgae. Bioresource Technology 2017, 244, 1216–1226. [Google Scholar] [CrossRef] [PubMed]

- Sajjadi, B.; Chen, W.-Y.; Raman, Abdul. Aziz.A.; Ibrahim, S. Microalgae Lipid and Biomass for Biofuel Production: A Comprehensive Review on Lipid Enhancement Strategies and Their Effects on Fatty Acid Composition. Renewable and Sustainable Energy Reviews 2018, 97, 200–232. [Google Scholar] [CrossRef]

- Borowitzka, M.A. High-Value Products from Microalgae—Their Development and Commercialisation. J Appl Phycol 2013, 25, 743–756. [Google Scholar] [CrossRef]

- Gangl, D.; Zedler, J.A.Z.; Rajakumar, P.D.; Martinez, E.M.R.; Riseley, A.; Włodarczyk, A.; Purton, S.; Sakuragi, Y.; Howe, C.J.; Jensen, P.E.; et al. Biotechnological Exploitation of Microalgae. EXBOTJ 2015, 66, 6975–6990. [Google Scholar] [CrossRef]

- LeuStefan; BoussibaSammy Advances in the Production of High-Value Products by Microalgae. Industrial Biotechnology 2014. [CrossRef]

- Ryckebosch, E.; Bruneel, C.; Termote-Verhalle, R.; Goiris, K.; Muylaert, K.; Foubert, I. Nutritional Evaluation of Microalgae Oils Rich in Omega-3 Long Chain Polyunsaturated Fatty Acids as an Alternative for Fish Oil. Food Chemistry 2014, 160, 393–400. [Google Scholar] [CrossRef]

- Mondal, M.; Goswami, S.; Ghosh, A.; Oinam, G.; Tiwari, O.N.; Das, P.; Gayen, K.; Mandal, M.K.; Halder, G.N. Production of Biodiesel from Microalgae through Biological Carbon Capture: A Review. 3 Biotech 2017, 7, 99. [Google Scholar] [CrossRef]

- Kenny, P.; Flynn, K.J. In Silico Optimization for Production of Biomass and Biofuel Feedstocks from Microalgae. J Appl Phycol 2015, 27, 33–48. [Google Scholar] [CrossRef]

- Fuentes, J.-L.; Montero, Z.; Cuaresma, M.; Ruiz-Domínguez, M.-C.; Mogedas, B.; Nores, I.G.; González del Valle, M.; Vílchez, C. Outdoor Large-Scale Cultivation of the Acidophilic Microalga Coccomyxa Onubensis in a Vertical Close Photobioreactor for Lutein Production. Processes 2020, 8, 324. [Google Scholar] [CrossRef]

- Guedes, A.C.; Amaro, H.M.; Malcata, F.X. Microalgae as Sources of High Added-Value Compounds-a Brief Review of Recent Work. Biotechnol Progress 2011, 27, 597–613. [Google Scholar] [CrossRef] [PubMed]

- Metsoviti, M.N.; Papapolymerou, G.; Karapanagiotidis, I.T.; Katsoulas, N. Comparison of Growth Rate and Nutrient Content of Five Microalgae Species Cultivated in Greenhouses. Plants 2019, 8, 279. [Google Scholar] [CrossRef]

- Jaramillo-Madrid, A.C.; Ashworth, J.; Ralph, P.J. Levels of Diatom Minor Sterols Respond to Changes in Temperature and Salinity. JMSE 2020, 8, 85. [Google Scholar] [CrossRef]

- Rampen, S.W.; Abbas, B.A.; Schouten, S.; Sinninghe Damste, J.S. A Comprehensive Study of Sterols in Marine Diatoms (Bacillariophyta): Implications for Their Use as Tracers for Diatom Productivity. Limnol. Oceanogr. 2010, 55, 91–105. [Google Scholar] [CrossRef]

- Nelson, D.M.; Tréguer, P.; Brzezinski, M.A.; Leynaert, A.; Quéguiner, B. Production and Dissolution of Biogenic Silica in the Ocean: Revised Global Estimates, Comparison with Regional Data and Relationship to Biogenic Sedimentation. Global Biogeochemical Cycles 1995, 9, 359–372. [Google Scholar] [CrossRef]

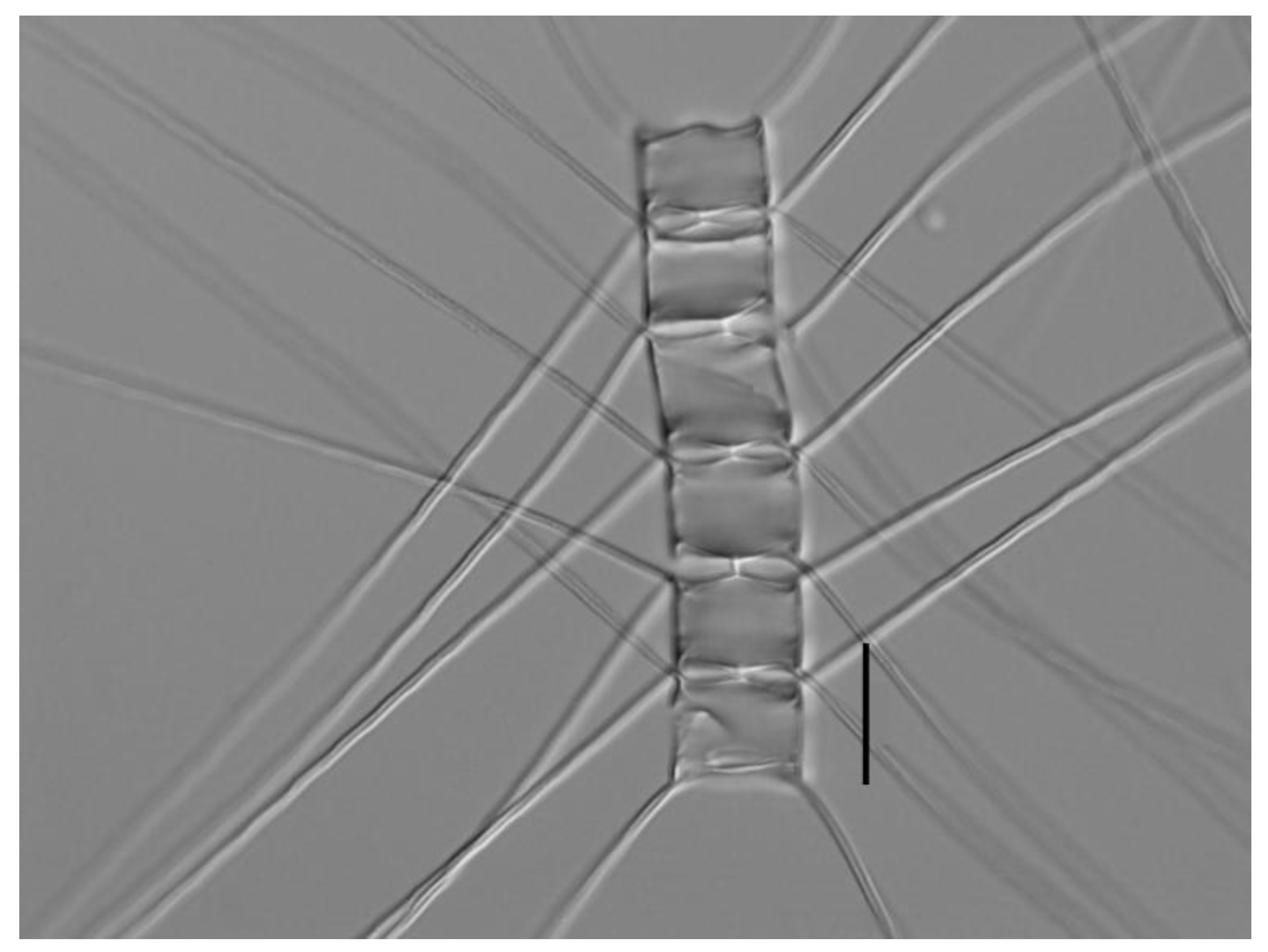

- Liang, C.; Zhang, Y.; Wang, L.; Shi, L.; Xu, D.; Zhang, X.; Ye, N. Features of Metabolic Regulation Revealed by Transcriptomic Adaptions Driven by Long-Term Elevated p CO 2 in Chaetoceros Muelleri: Metabolic Regulation Driven by Long-Term Elevated p CO 2. Phycological Res. 2020. [Google Scholar] [CrossRef]

- de Jesús-Campos, D.; López-Elías, J.A.; Medina-Juarez, L.Á.; Carvallo-Ruiz, G.; Fimbres-Olivarria, D.; Hayano-Kanashiro, C. Chemical Composition, Fatty Acid Profile and Molecular Changes Derived from Nitrogen Stress in the Diatom Chaetoceros Muelleri. Aquaculture Reports 2020, 16, 100281. [Google Scholar] [CrossRef]

- Griffiths, M.J.; Harrison, S.T.L. Lipid Productivity as a Key Characteristic for Choosing Algal Species for Biodiesel Production. J Appl Phycol 2009, 21, 493–507. [Google Scholar] [CrossRef]

- Indrayani, I. ISOLATION AND CHARACTERIZATION OF MICROALGAE WITH COMMERCIAL POTENTIAL. 225.

- Ishika, T.; Laird, D.W.; Bahri, P.A.; Moheimani, N.R. Co-Cultivation and Stepwise Cultivation of Chaetoceros Muelleri and Amphora sp. for Fucoxanthin Production under Gradual Salinity Increase. J Appl Phycol 2019, 31, 1535–1544. [Google Scholar] [CrossRef]

- Minggat, E.; Roseli, W.; Tanaka, Y. , Nutrient Absorption and Biomass Production by the Marine Diatom Chaetoceros muelleri: Effects of Temperature, Salinity, Photoperiod, and Light Intensity. Journal of Ecological Engineering 2021, 22, 231–240. [Google Scholar] [CrossRef]

- Guillard, R.R.L. Culture of Phytoplankton for Feeding Marine Invertebrates. In Culture of Marine Invertebrate Animals; Smith, W.L., Chanley, M.H., Eds.; Springer US: Boston, MA, 1975; pp. 29–60. ISBN 978-1-4615-8716-3. [Google Scholar]

- Cotas, J.; Figueirinha, A.; Pereira, L.; Batista, T. The effect of salinity on Fucus ceranoides (Ochrophyta, Phaeophyceae) in the Mondego River (Portugal). J. Ocean. Limnol. 2019, 37, 881–891. [Google Scholar] [CrossRef]

- Duarte, António A. L. S.; Vieira, José M.P.; Neto, J.M.; Pardal, M.A. Monitorização da Hidrodinâmica e da Qualidade da Água no Estuário do Rio Mondego. Engenharia Civil. 2008, 65–74.

- Lovio-Fragoso, J.P.; Hayano-Kanashiro, C.; López-Elías, J.A. Effect of Different Phosphorus Concentrations on Growth and Biochemical Composition of Chaetoceros Muelleri. Latin American Journal of Aquatic Research 2019, 47, 361–366. [Google Scholar] [CrossRef]

- Huy, M.; Kumar, G.; Kim, H.-W.; Kim, S.-H. Photoautotrophic Cultivation of Mixed Microalgae Consortia Using Various Organic Waste Streams towards Remediation and Resource Recovery. Bioresource Technology 2018, 247, 576–581. [Google Scholar] [CrossRef] [PubMed]

- Arias, D.M.; Solé-Bundó, M.; Garfí, M.; Ferrer, I.; García, J.; Uggetti, E. Integrating Microalgae Tertiary Treatment into Activated Sludge Systems for Energy and Nutrients Recovery from Wastewater. Bioresource Technology 2018, 247, 513–519. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Chen, Y.-F.; Chen, P.; Min, M.; Zhou, W.; Martinez, B.; Zhu, J.; Ruan, R. Characterization of a Microalga Chlorella Sp. Well Adapted to Highly Concentrated Municipal Wastewater for Nutrient Removal and Biodiesel Production. Bioresour. Technol. 2011, 102, 5138–5144. [Google Scholar] [CrossRef] [PubMed]

- Abou-Shanab, R.A.I.; Ji, M.-K.; Kim, H.-C.; Paeng, K.-J.; Jeon, B.-H. Microalgal Species Growing on Piggery Wastewater as a Valuable Candidate for Nutrient Removal and Biodiesel Production. Journal of Environmental Management 2013, 115, 257–264. [Google Scholar] [CrossRef]

- Li, X.; Yang, W.L.; He, H.; Wu, S.; Zhou, Q.; Yang, C.; Zeng, G.; Luo, L.; Lou, W. Responses of Microalgae Coelastrella Sp. to Stress of Cupric Ions in Treatment of Anaerobically Digested Swine Wastewater. Bioresource Technology 2018, 251, 274–279. [Google Scholar] [CrossRef]

- Gao, Y.; Yang, M.; Wang, C. Nutrient Deprivation Enhances Lipid Content in Marine Microalgae. Bioresource Technology 2013, 147, 484–491. [Google Scholar] [CrossRef]

- Henry-Silva, G.G.; Camargo, A.F.M. Tratamento de efluentes de carcinicultura por macrófitas aquáticas flutuantes. Revista Brasileira de Zootecnia 2008, 37, 181–188. [Google Scholar] [CrossRef]

- Cloern, J.E.; Jassby, A.D.; Schraga, T.S.; Nejad, E.; Martin, C. Ecosystem Variability along the Estuarine Salinity Gradient: Examples from Long-Term Study of San Francisco Bay. Limnology and Oceanography 2017, 62, S272–S291. [Google Scholar] [CrossRef]

- Webster, I.; Atkinson, I.; Radke, L. Salinity. Available online: https://ozcoasts.org.au/indicators/biophysical-indicators/salinity/ (accessed on 22 April 2020).

- Becerra-Dórame, M.; López-Elías, J.A.; Martínez-Córdova, L.R. An Alternative Outdoor Production System for the Microalgae Chaetoceros Muelleri and Dunaliella Sp. during Winter and Spring in Northwest Mexico. Aquacultural Engineering 2010, 43, 24–28. [Google Scholar] [CrossRef]

- Rodolfi, L.; Zittelli, G.C.; Bassi, N.; Padovani, G.; Biondi, N.; Bonini, G.; Tredici, M.R. Microalgae for Oil: Strain Selection, Induction of Lipid Synthesis and Outdoor Mass Cultivation in a Low-Cost Photobioreactor. Biotechnology and Bioengineering 2009, 102, 100–112. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.-W.; Liang, J.-R.; Luo, C.-S.; Chen, C.-P.; Gao, Y.-H. Biomass, Total Lipid Production, and Fatty Acid Composition of the Marine Diatom Chaetoceros Muelleri in Response to Different CO2 Levels. Bioresource Technology 2014, 161, 124–130. [Google Scholar] [CrossRef] [PubMed]

- Pérez, L.; Salgueiro, J.L.; González, J.; Parralejo, A.I.; Maceiras, R.; Cancela, Á. Scaled up from Indoor to Outdoor Cultures of Chaetoceros Gracilis and Skeletonema Costatum Microalgae for Biomass and Oil Production. Biochemical Engineering Journal 2017, 127, 180–187. [Google Scholar] [CrossRef]

- Zhai, X.; Zhu, C.; Zhang, Y.; Pang, H.; Kong, F.; Wang, J.; Chi, Z. Seawater Supplemented with Bicarbonate for Efficient Marine Microalgae Production in Floating Photobioreactor on Ocean: A Case Study of Chlorella Sp. Science of The Total Environment 2020, 738, 139439. [Google Scholar] [CrossRef]

- Khor, W.H.; Kang, H.-S.; Lim, J.-W.; Iwamoto, K.; Tang, C.H.-H.; Goh, P.S.; Quen, L.K.; Shaharuddin, N.M.R.B.; Lai, N.Y.G. Microalgae Cultivation in Offshore Floating Photobioreactor: State-of-the-Art, Opportunities and Challenges. Aquacultural Engineering 2022, 98, 102269. [Google Scholar] [CrossRef]

| Chaetoceros muelleri | Treatment | |||||

| T30 | T25 | T20 | T15 | T10 | T5 | |

| Salinity | 30 | 25 | 20 | 15 | 10 | 5 |

| Optical Densities (OD700 nm) | ||||||

| T30 | T25 | T20 | T15 | T10 | T5 | |

| Initial | 0,096±0,007 | 0,110±0,012 | 0,103±0,01 | 0,092±0,001 | 0,094±0,002 | 0,103±0,005 |

| Final | 0,404±0,004a | 0,401±0,003b | 0,396±0,004c | 0,347±0,002d | 0,339±0,002e | 0,338±0,003e |

| Percentage of Change | 320.83% | 264.55% | 284.47% | 277.17% | 260.64% | 228.16% |

| Time Period | Quantity (mg L-1) | |||||

|---|---|---|---|---|---|---|

| T30 | T25 | T20 | T15 | T10 | T5 | |

| Initial | 0,562±0,0010 |

0,573±0,0010 |

0,529±0,0010 |

0,571±0,0006 |

0,554±0,0010 |

0,589±0,0010 |

| Final P % removal |

0,303±0,0036 46,08±0,67%a |

0,320±0,0029 44,15±0,77%b |

0,305±0,0018 42,34±0,30%c |

0,350±0,0021 38,80±0,30%d |

0,346±0,0017 37,54±0,41%e |

0,375±0,0026 36,33±0,55%f |

| Microalgae | Biomass yields (g L-1) | ||||||

|---|---|---|---|---|---|---|---|

| T30 | T25 | T20 | T15 | T10 | T5 | ||

| Chaetoceros muelleri | 3,38±0,07a | 3,47±0,04a | 2,88±0,04b | 2,08±0,02c | 1,53±0,03d | 1,35±0,08e | |

| Study | Microalgae Species | P Removal (%) | Biomass Yield (g L⁻¹) | Culture Conditions |

|---|---|---|---|---|

| This study | Chaetoceros muelleri | 28–52% | 1.35–3.47 | Synthetic saline media, 6 salinity levels (T5–T30), 10-day culture |

| Huy et al. (2018) [53] | Chlorella sp. (dominant) | 100% | 0.4 | Textile effluent, open system, 13 days |

| Arias et al. (2018) [54] | Scenedesmus sp. | 100% | Not reported | Secondary effluent, closed 30 L PBR, 8-day HRT |

| Li et al. (2011) [55] | Chlorella sp. | 80.9% | Not reported | Domestic sewage, stationary culture |

| Abou-Shanab et al. (2013) [56] | Chlamydomonas sp. | 28% | Not reported | Synthetic wastewater, batch culture |

| Li et al. (2018) [57] | Coelastrella sp. | 12.6–84.9% | Not reported | Swine effluent, copper oxide stress, 16 days |

| Gao et al. (2013) [58] | C. muelleri | 64% | 0.24 | Nutrient-restricted F/2 medium, 12 days |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).