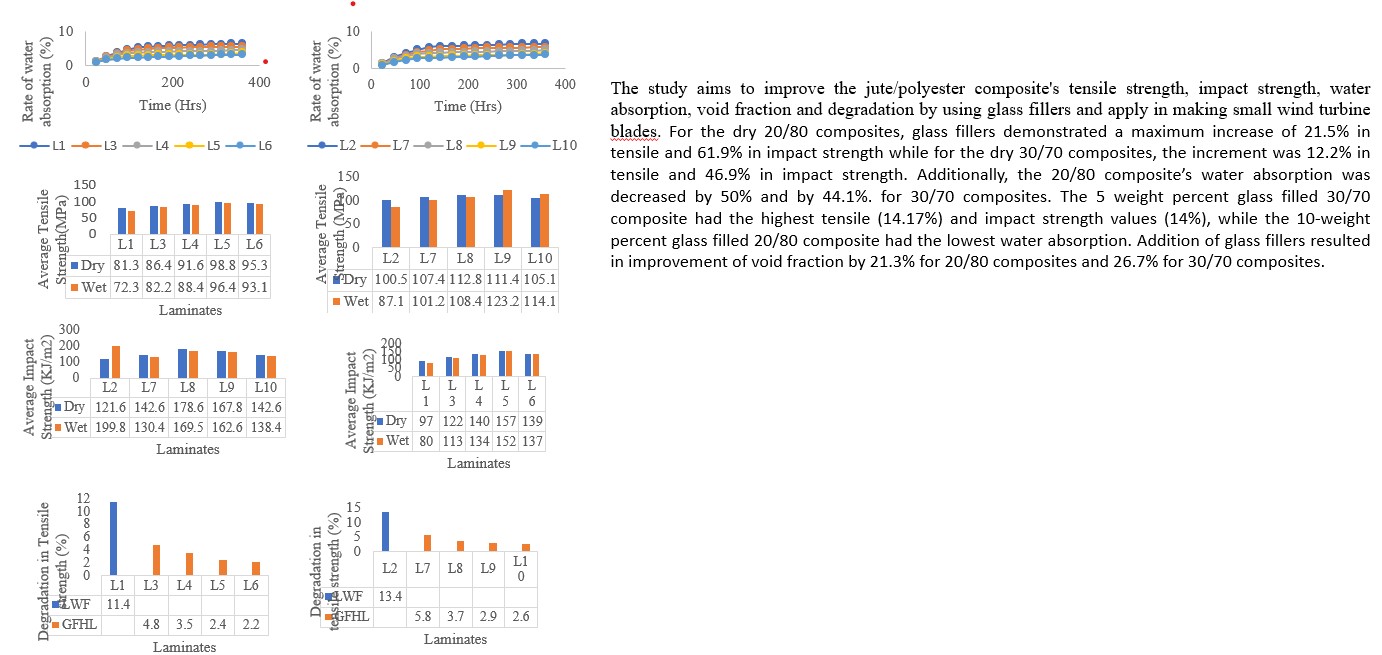

One of the biggest obstacles to use natural fibers for industrial applications is their poor mechanical and water-absorbing qualities. The study aims to improve the jute/polyester composite's void fraction, rate of water absorption, strength of impact, tensile strength and composite degradation by using glass fillers and apply in making small wind turbine blades. Jute fiber of 20, 30 weight percentages and fillers of 2.5%, 5%, 7.5% and 10% weight percentages were utilized to make the composites. The experiments were conducted in compliance with ASTM guidelines. Glass fillers improved the jute/polyester composite's void fraction, rate of water absorption, strength of impact, tensile strength and composite degradation. For dry 20/80 jute/polyester composites, glass fillers demonstrated a maximum increase of 61.9% strength of impact and a tensile strength of 21.5% while 30/70 composites of dry form showed an increment in strength of impact and tensile strength by 46.9%,12.2% respectively. Additionally, 20/80 composite’s water absorption was decreased by 50% and by 44.1%. for 30/70 composites. The 5-weight percent glass filled 30/70 composite had the highest tensile (14.17%) and impact strength values (14%), while the 10-weight percent glass filled 20/80 composite had the lowest water absorption. Addition of glass fillers resulted in improvement of void fraction by 21.3% for 20/80 composites and 26.7% for 30/70 composites.