Growing awareness of the environmental impacts associated with the excessive use of synthetic materials and the accumulation of non-biodegradable waste has intensified global interest in more sustainable alternatives. This shift aligns with the principles of the circular economy, which emphasize recycling, resource efficiency, and reduced dependence on virgin raw materials [

1]. Despite growing environmental concerns, the footwear industry continues to rely heavily on petroleum-based synthetics and animal-derived leather [

2]. Consumption patterns are shaped by rising disposable incomes, changing fashion trends, an expanding working-class population, and the rapid growth of e-commerce platforms. According to the European Environment Agency (EEA), average per capita footwear consumption in the EU rose from approximately 3.2 kg in 2019 to 4.4 kg in 2022, reflecting a significant 38% increase [

3]. Footwear is commonly manufactured using a variety of materials, including leather, canvas, polyurethane (PU), polyvinyl chloride (PVC), vulcanized rubber, and ethylene-vinyl acetate (EVA), along with accessories like shoelaces and eyelets. These components collectively contribute to the industry's substantial environmental footprint, not only because of energy-intensive production methods but also, in the case of leather, due to hazardous chemical treatments necessary to make it usable [

4,

5]. Leather, traditionally sourced as a by-product of the livestock industry, is prized for its exceptional properties, including durability, mechanical strength, water vapor permeability, abrasion resistance, biodegradability, and biocompatibility [

6,

7]. However, achieving specific performance enhancements, such as increased water resistance or breathability, requires intensive chemical processing. Processes like tanning and surface finishing introduce considerable environmental and human health hazards [

8]. Chromium salts are central to tanning, with chromium (III) employed in approximately 90% of global operations [

9]. During processing, a fraction of chromium remains unfixed and is discharged into wastewater, where it can oxidize into chromium (VI), a recognized carcinogen and persistent environmental pollutant [

10]. Similarly, polyvinyl chloride (PVC), a widely used synthetic leather substitute, presents severe ecological and health challenges throughout its lifecycle, from production to disposal [

11]. PVC releases hazardous compounds including dioxins and phthalates. Dioxins are persistent, bioaccumulative endocrine-disrupting chemicals (EDCs) with serious implications for both human health and ecosystems. Phthalates, frequently added in high concentrations as plasticizers to enhance flexibility, are also known EDCs, raising significant public health concerns [

12,

13]. Consequently, governments and manufacturers worldwide are actively pursuing safer and more sustainable alternatives to these materials.

In response, increasing scrutiny of materials derived from both animal and synthetic sources has driven the development of plant-based or vegan leathers made from renewable feedstocks such as pineapple leaf fibres [

14], sawdust [

6], and mushroom-derived chitin [

15]. Additionally, composites incorporating agro-biomass residues as bio-fillers, such as bacterial cellulose and tree leaves (e.g., maple leaves) have also emerged as promising alternatives. These bio-fillers are often combined with polymer matrices such as polycaprolactone (PCL), polylactic acid (PLA), and polyvinyl alcohol (PVA), which have been widely used in the development of sustainable alternatives to leather materials [

16]. Other footwear components, such as insoles and toe-puffs have also been developed using clothes and agro-industrial wastes [

6,

17]. Biodegradable materials have gained significant attention as viable solutions. These materials not only support environmental sustainability but also help educate producers and consumers about responsible consumption and end-of-life disposal [

18]. Among the most promising biodegradable materials are polyhydroxyalkanoates (PHAs), a class of thermoplastic polyester produced via microbial fermentation. PHAs naturally degrade across diverse environmental conditions without leaving persistent residues [

19,

20]. Within the PHA family, the copolymer poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) (PHBHHx) has attracted considerable interest due to its balanced flexibility, mechanical strength, and biodegradability [

21]. Produced from renewable feedstocks via microbial fermentation, PHBHHx offers a substantially reduced environmental footprint compared to conventional petroleum-based polymers [

22]. Unlike traditional synthetic coatings, PHBHHx is fully biodegradable under appropriate conditions, effectively addressing critical issues related to plastic waste and microplastic pollution [

23]. Despite its potential, the practical application of PHBHHx as a coating on cotton fabrics used in footwear components remains insufficiently explored, particularly regarding adhesion to textile substrates, water vapor permeability, abrasion resistance, and durability under repeated mechanical stress and laundering.

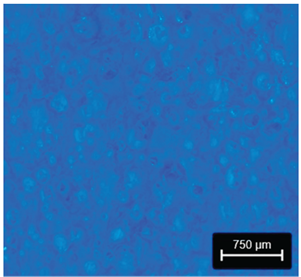

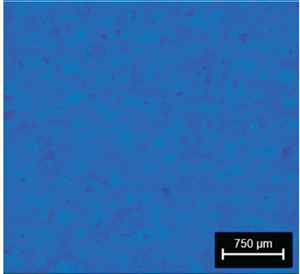

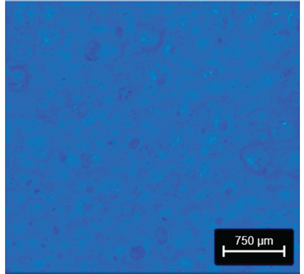

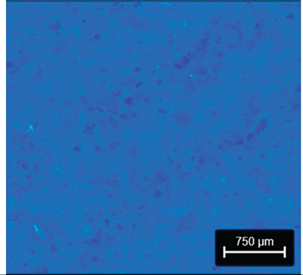

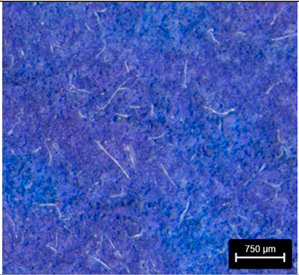

This study aims to develop a PHBHHx coating applied via the controlled knife coating technique onto cotton fabric and systematically evaluate its potential as a sustainable, high-performance alternative for footwear component applications. The PHBHHx formulation was precisely deposited using the knife coating method to ensure uniformity and optimal film formation. The coated textiles were subjected to targeted evaluations, including breathability, surface wettability (contact angle measurements), abrasion resistance, and wash durability tests. This comprehensive investigation critically assesses whether PHBHHx coatings can meet the stringent environmental and functional requirements of the footwear industry. The findings provide valuable insights into the viability of PHBHHx as an eco-friendly material that maintains high performance, presenting a promising pathway toward advancing sustainable footwear manufacturing technologies.