Submitted:

12 September 2025

Posted:

15 September 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Analytical Study

2.1. Structural Overview

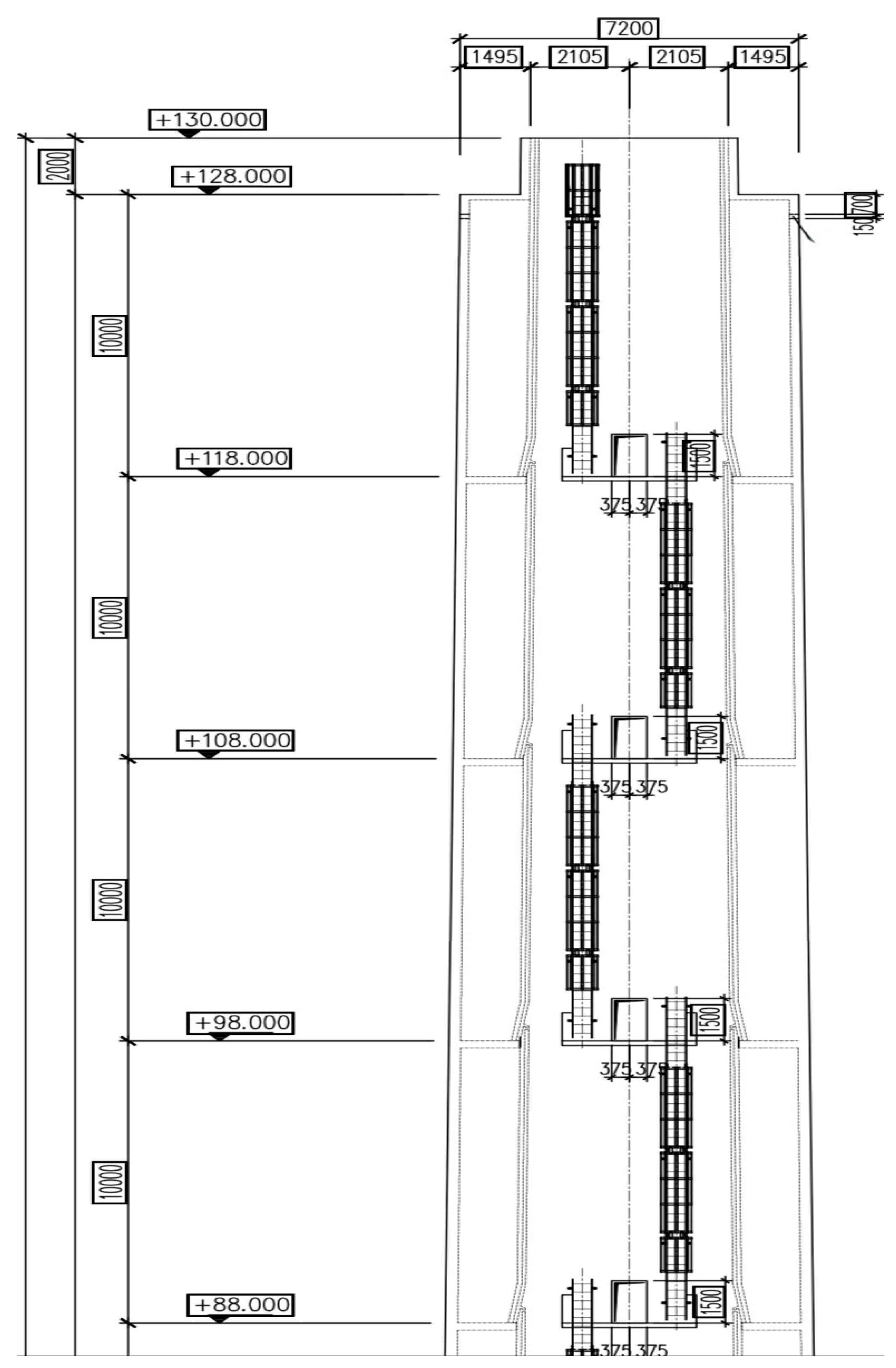

- • Height: 130 m;

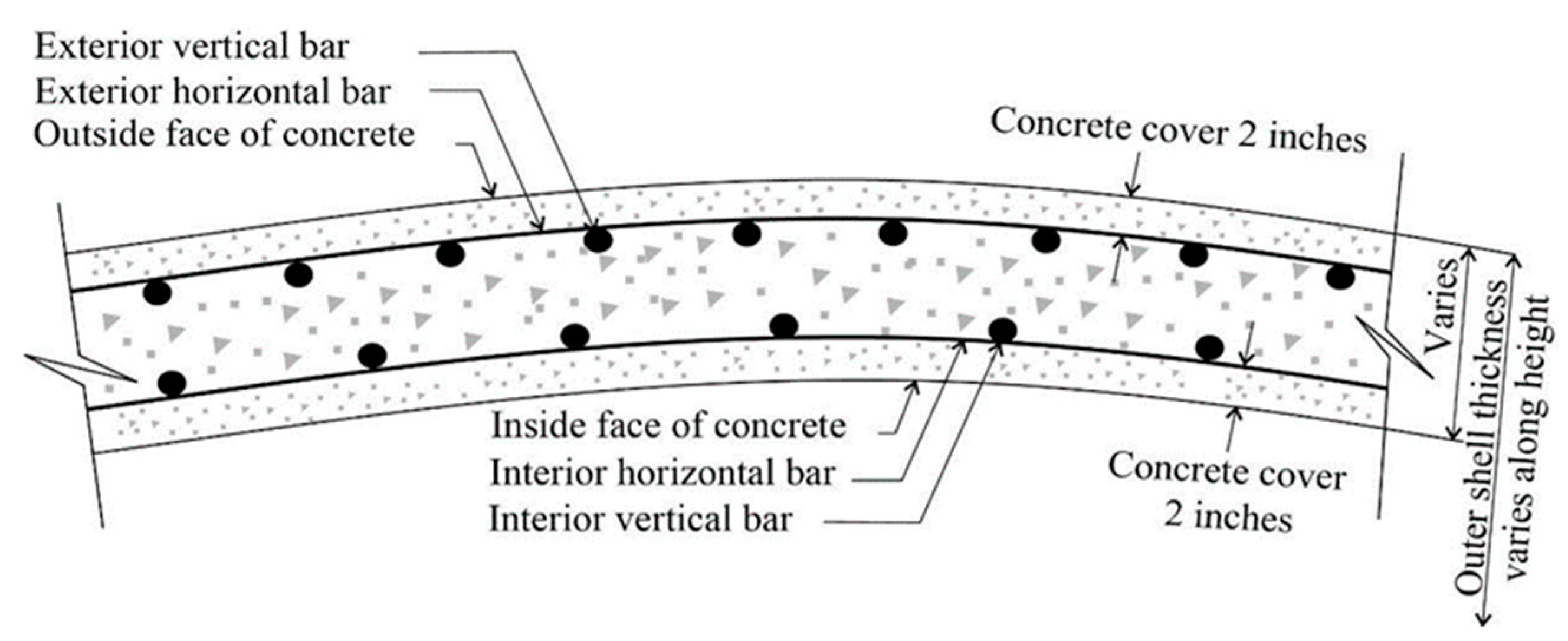

- • Base outer diameter: 9.2 m, thickness: 40 cm;

- • Upper outer diameter: 7.2 m at 128 m and 4.2 m at 130 m, thickness: 20 cm;

- • Concrete quality: C30/70;

- Operating temperature: 130°C;

- Concrete unit weight: 2500 kg/m3;

- The chimney is considered as fixed from the bottom;

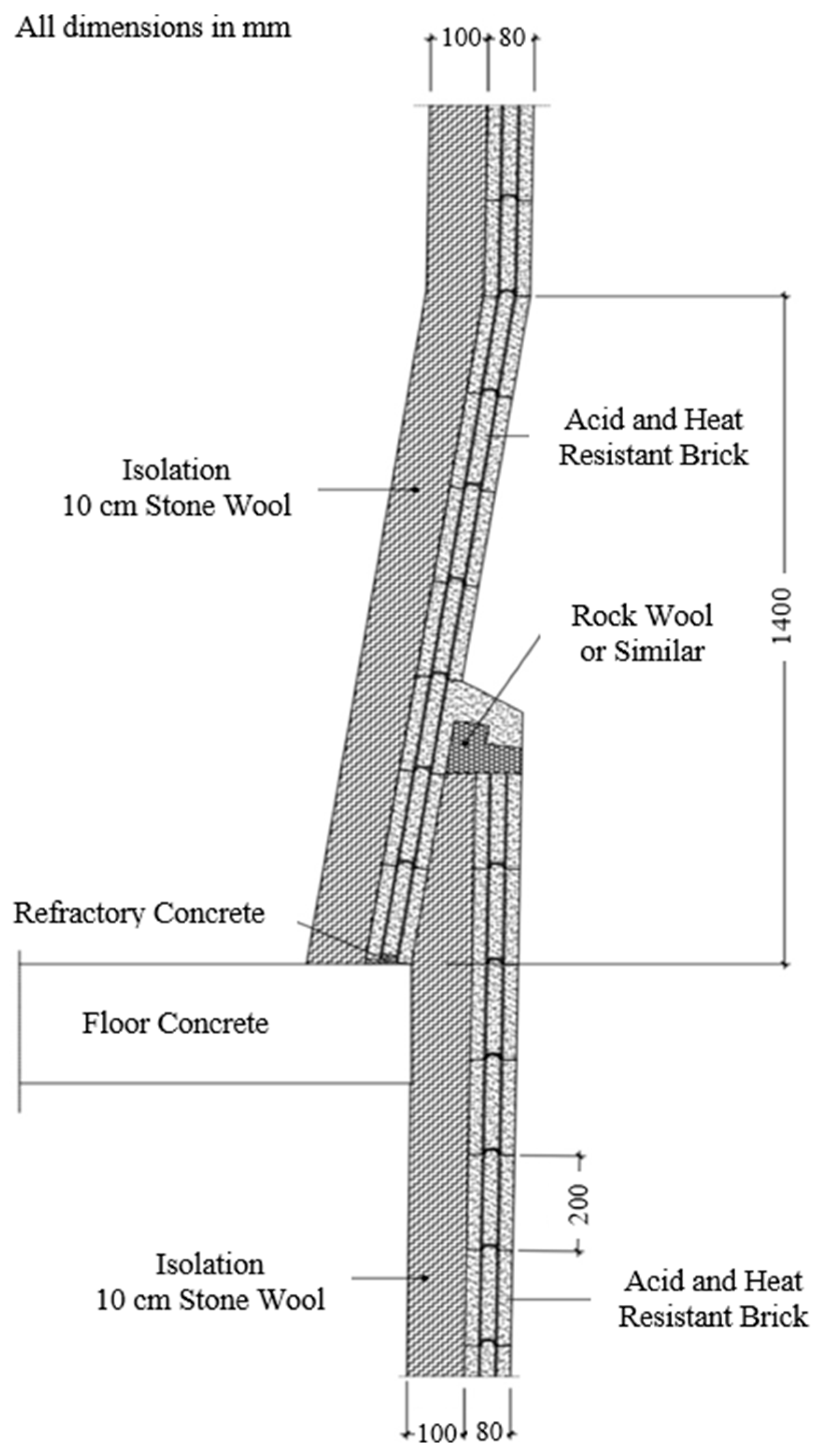

- Internally it is lined with a brick fire extinguishing chimney;

- Insulation: 10 cm rock wool;

- In the order of linear interpolation, the wall thickness and diameter change (decrease) from bottom to top;

- Equivalent surface roughness, for smooth concrete according to EN 1991-1-4 Table 7.13 [29];

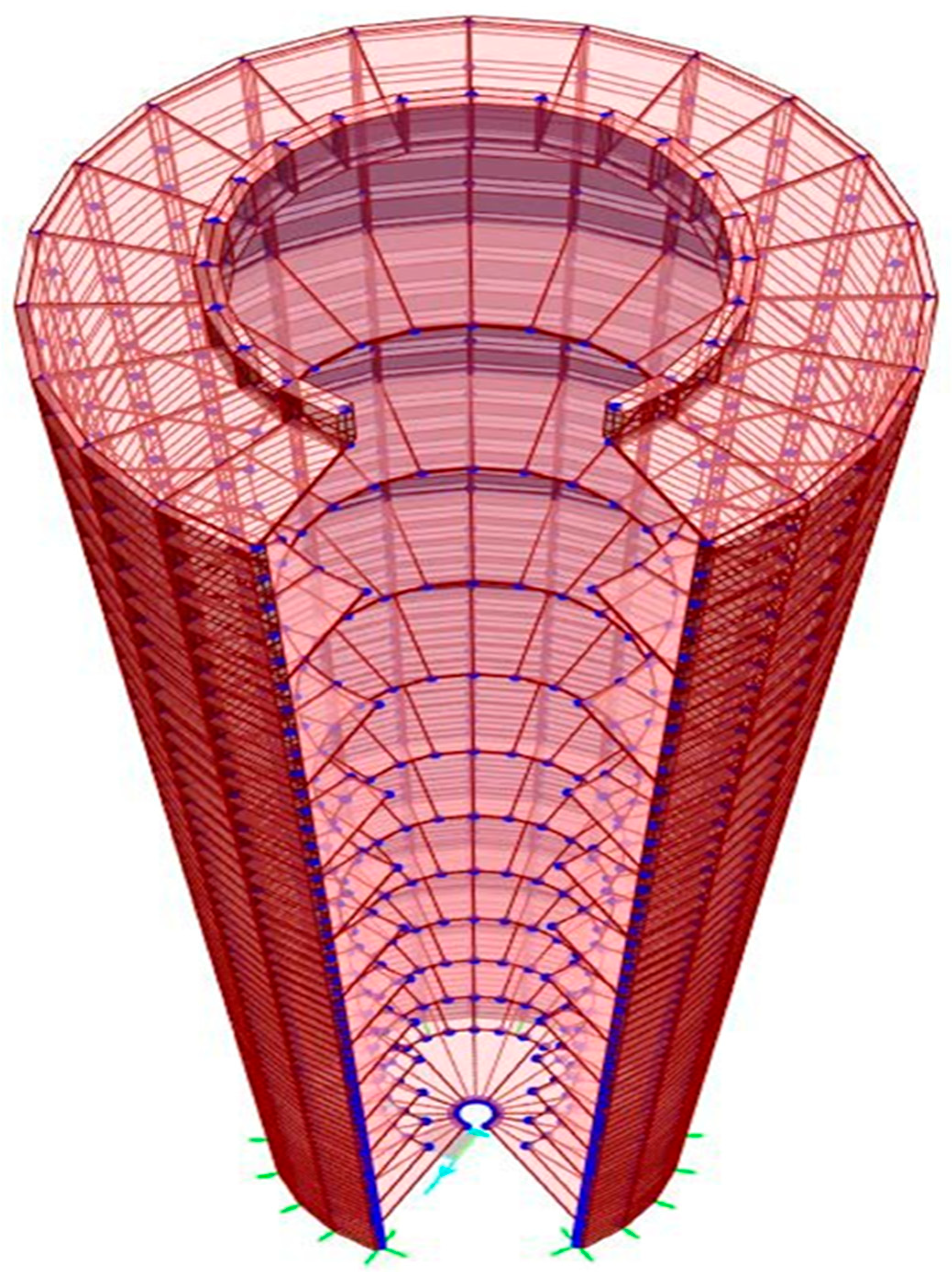

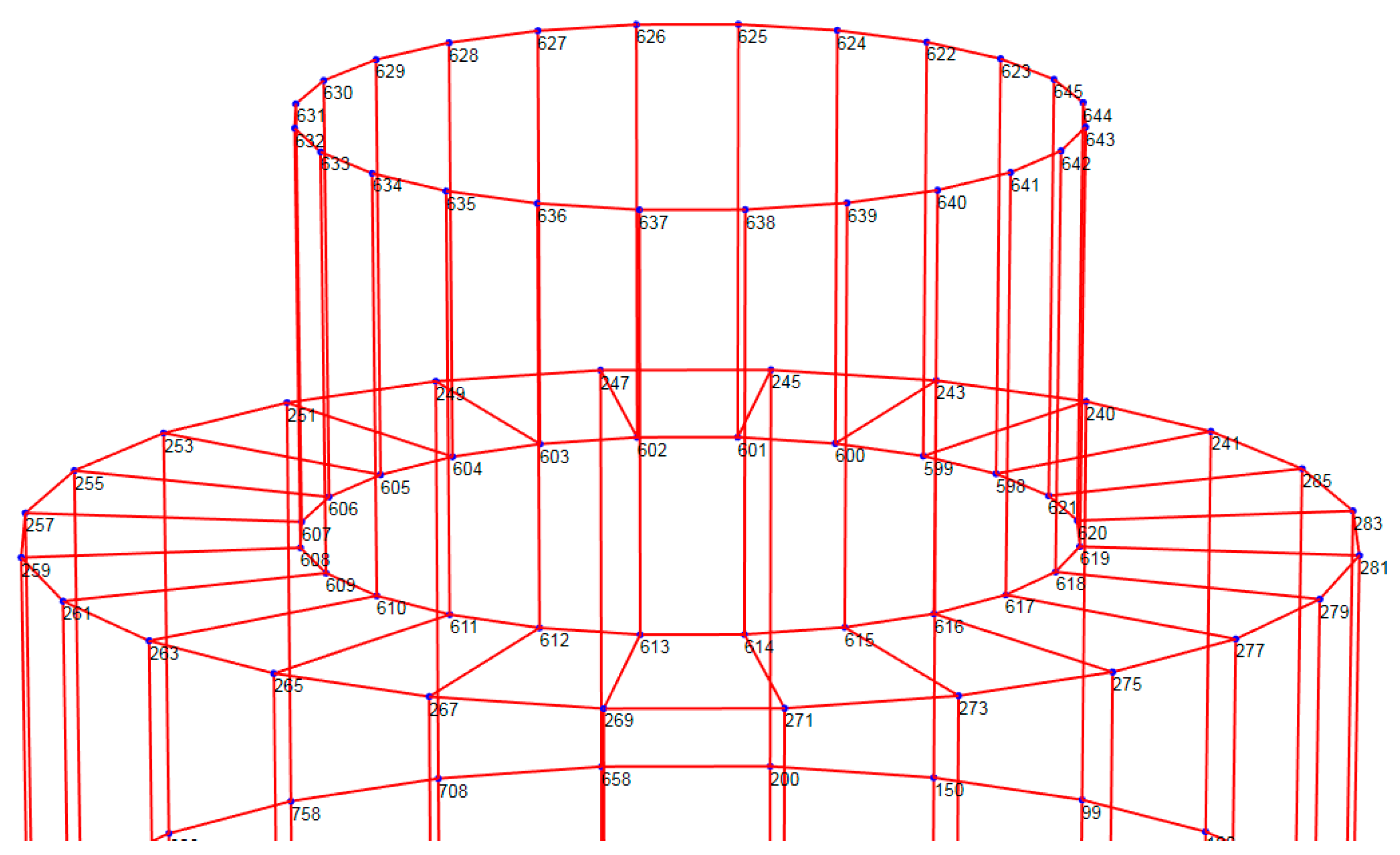

- Internal concrete floors at 6 m, 9.6 m, 18 m, and above at intervals of 10 m (average radius of 1.45 m) and steel platforms covering 45° from the outer diameter radius;

- Steel platform of 360° at the height of 68 m;

- At the height of 6 m, the radius is 3.5 m.

2.2. Material Properties

- Concrete compressive strength: 27.5 MPa;

- Elasticity modulus of concrete : 25 GPa;

- Poisson ratio of concrete: 0.2;

- Unit volume weight of concrete: 2400 kg/m3;

- Yield strength of steel: 414 MPa;

- Tensile strength: 620 MPa;

- Modulus of elasticity of steel : 200 GPa;

- Unit volume weight of steel: 7750 kg/m3.

2.3. Loading Conditions

- Dead loads: self-weight of concrete, steel platforms, ladders, insulation (10 cm rock wool, , and fire brick lining (8 cm thickness,);

- Live loads: maintenance and operational loads;

2.3.1. Wind Load Calculation

- 28 m/s (0–8 m);

- 36 m/s (8–20 m);

- 42 m/s (20–100 m), and;

- 46 m/s (>100 m).

2.3.2. Seismic Load Calculation

- Soil class: ZE

- Short-period spectral acceleration coefficient: ;

- 1-second period spectral acceleration coefficient: ;

- Short-period design spectral acceleration coefficient: ;

- 1-second period design spectral acceleration coefficient: .

2.4. Load Combinations

- Vertical loads only;

- 2.

- Wind load cases;

- 3.

- Seismic load cases;

- 4.

- Lateral soil pressure cases.

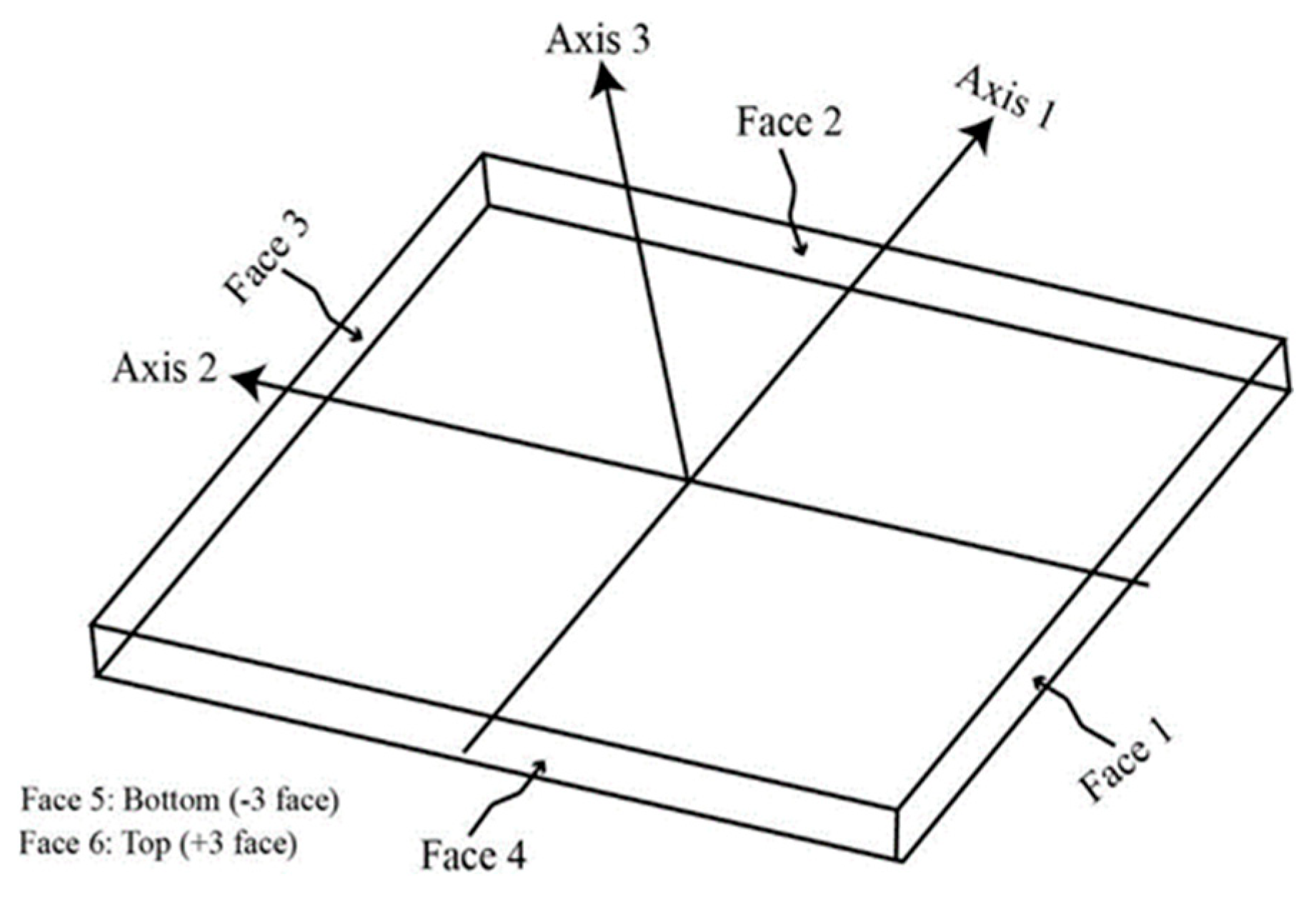

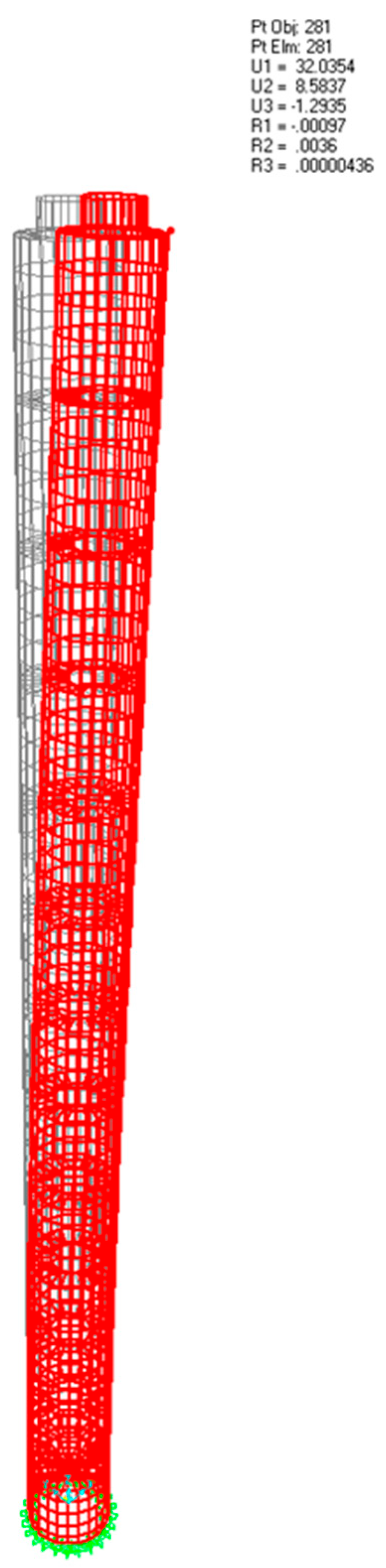

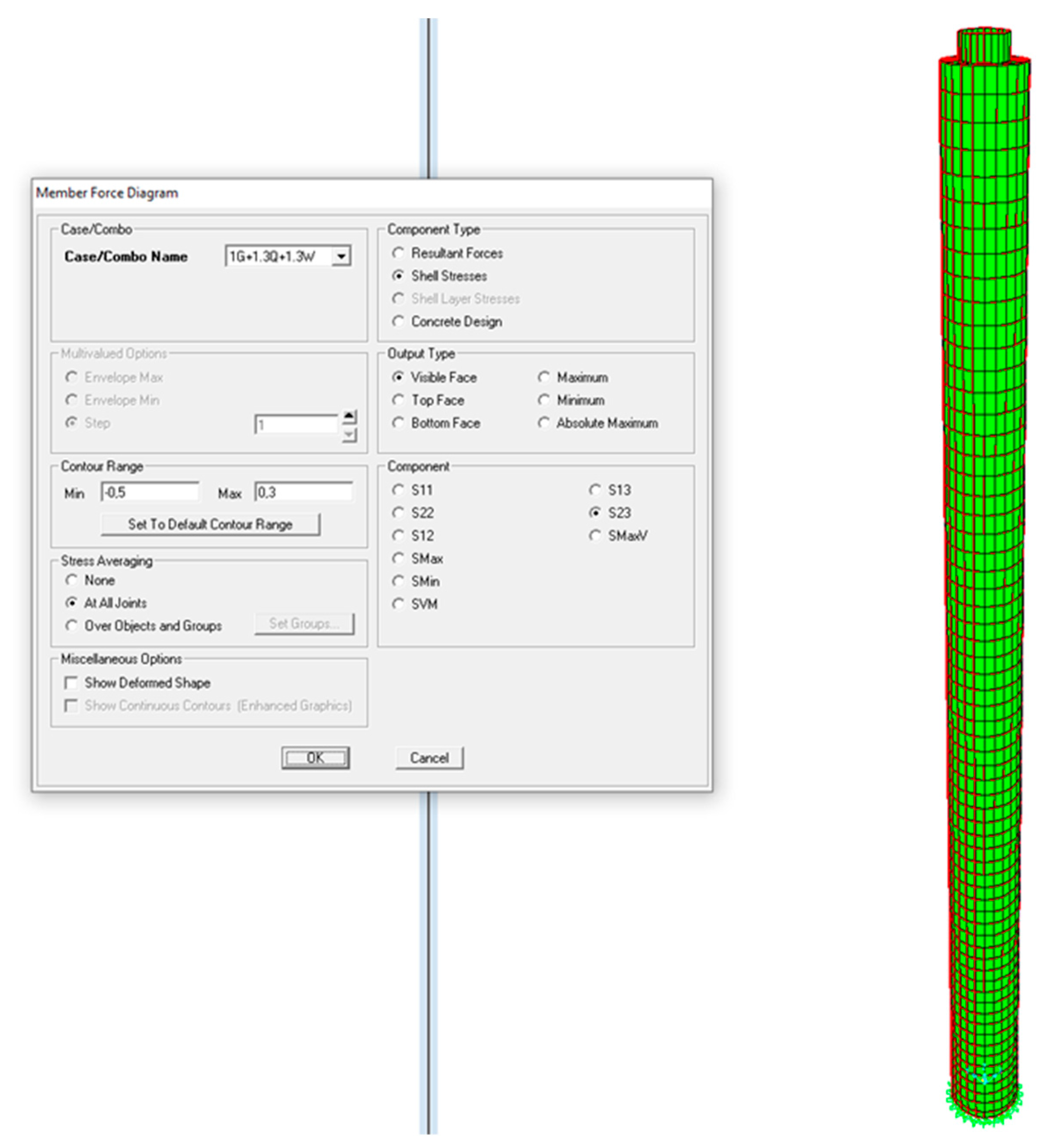

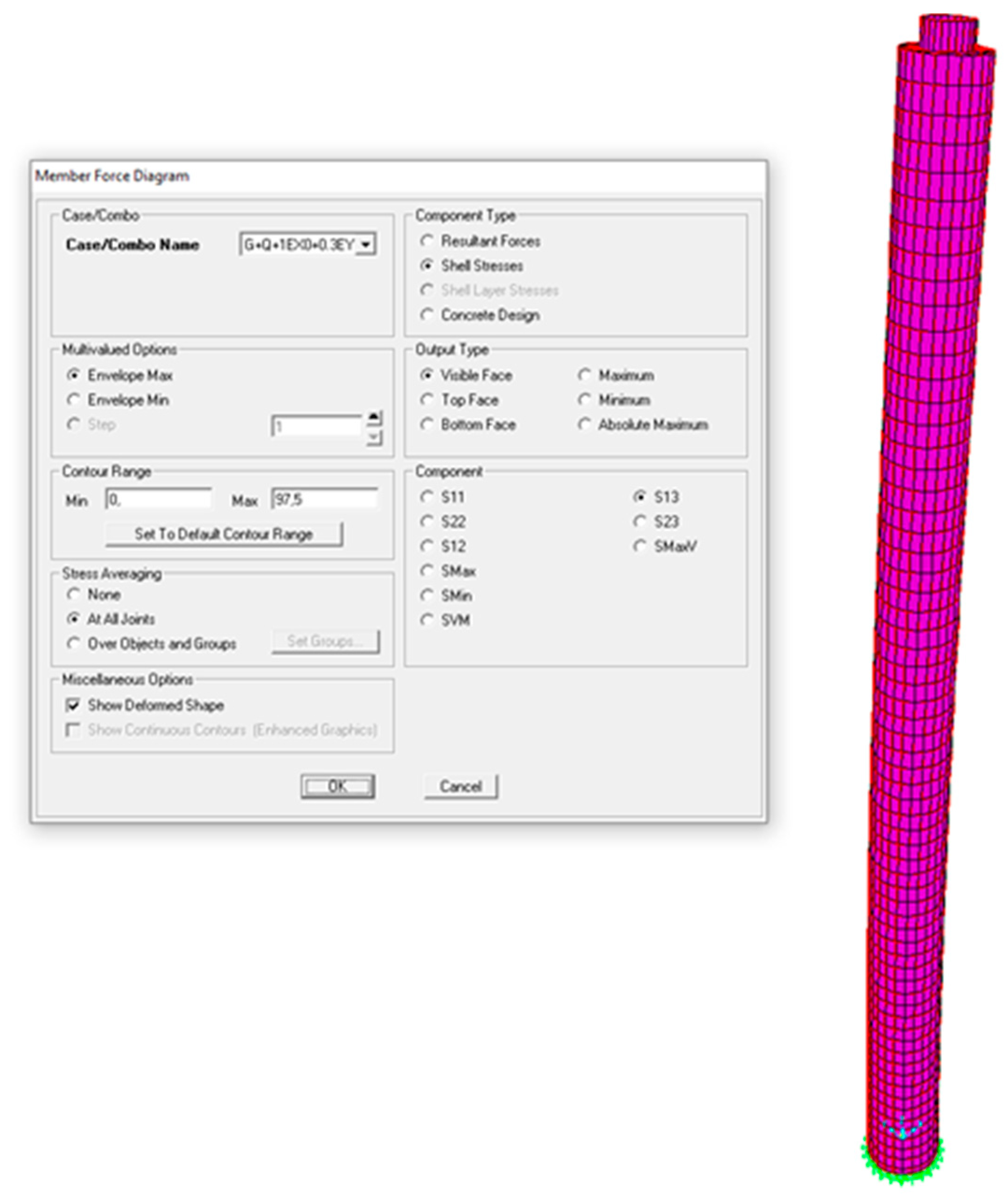

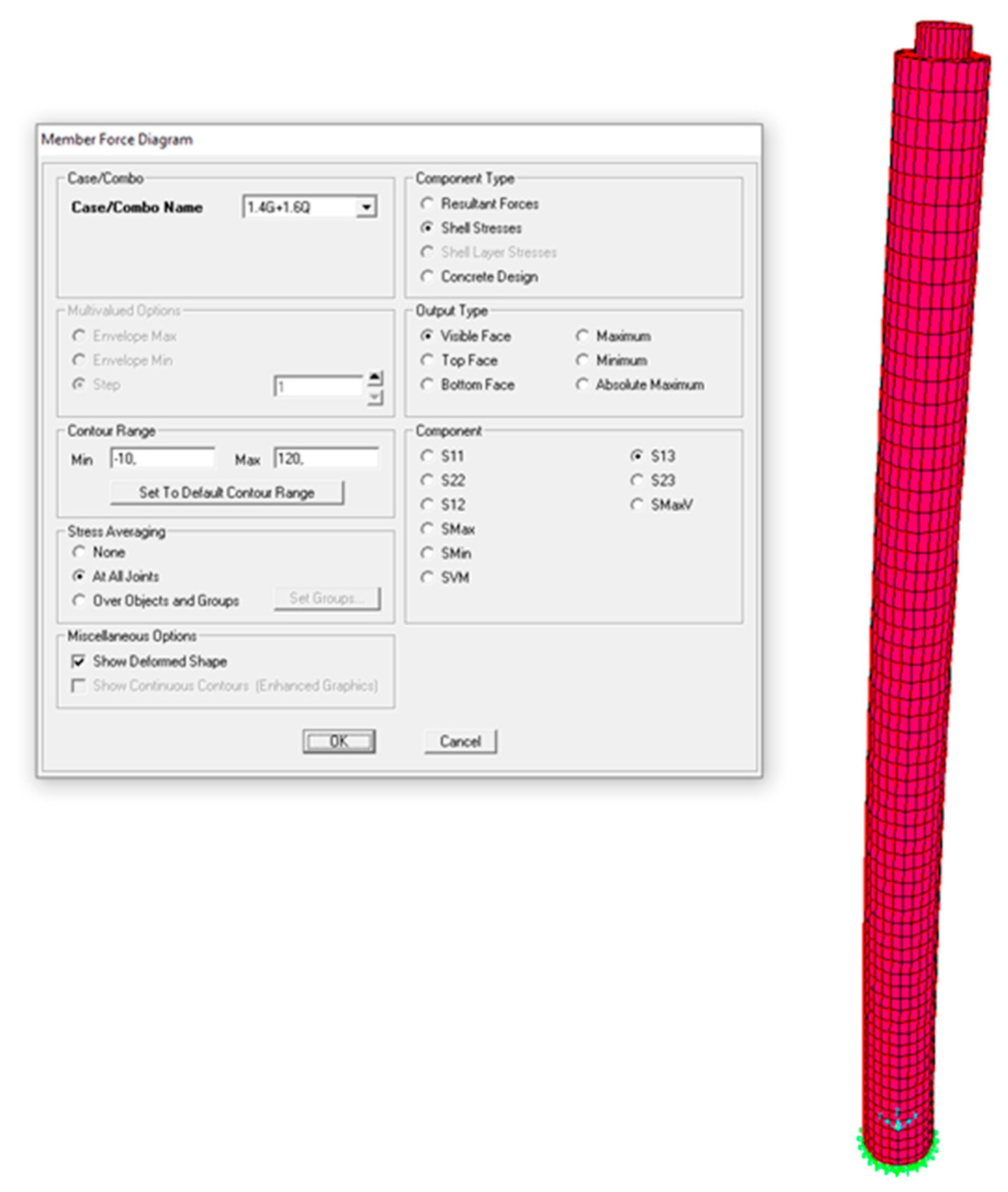

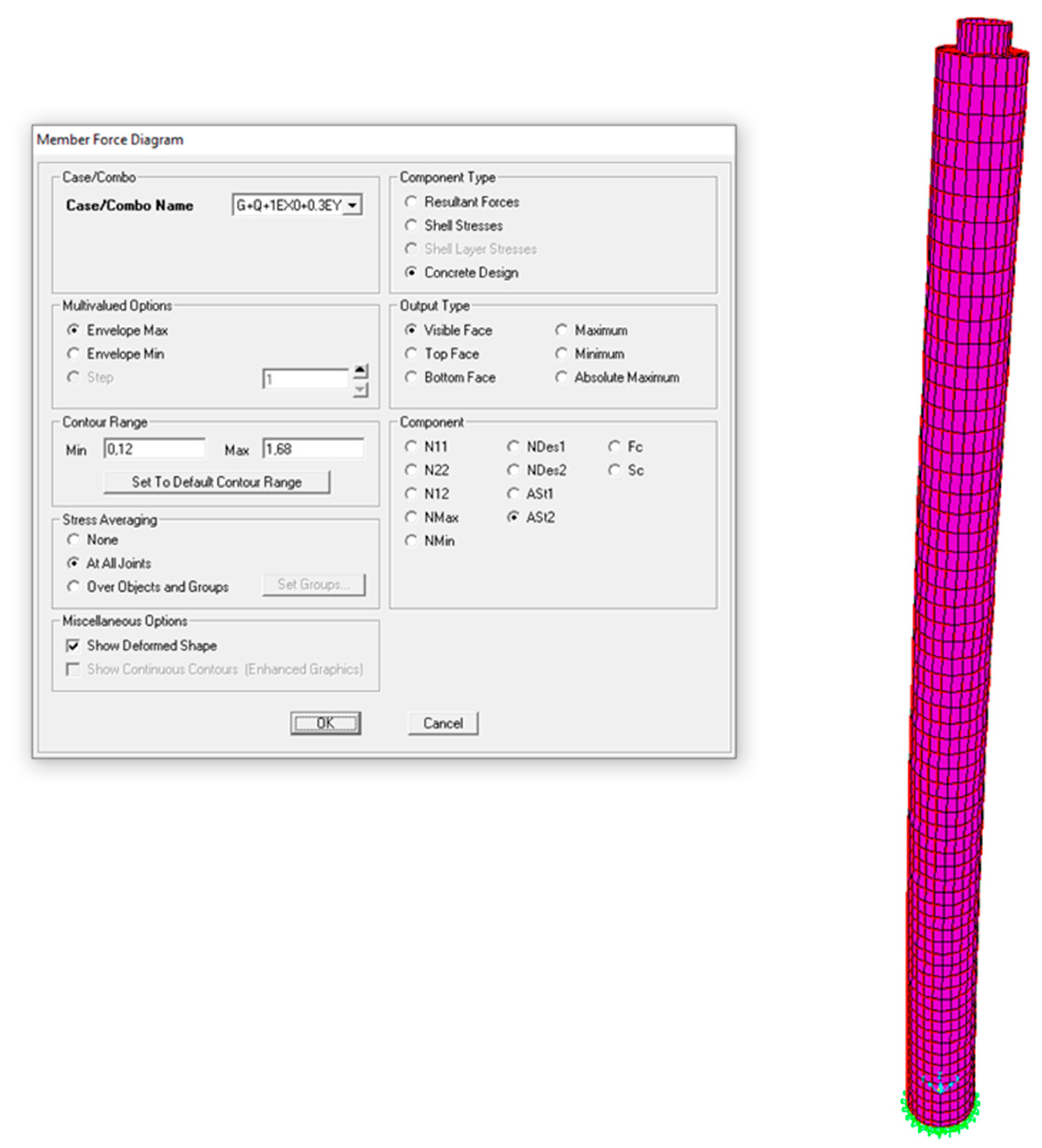

2.5. Structural Modeling

2.6. Load Application

3. Results and Discussion

3.1. Overview of the Analytical Model

3.2. Structural Responses and Comparative Code Evaluation

4. Conclusions and Recommendations

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Computers and Structures, Inc. SAP2000, Integrated Software for Structural Analysis and Design, Version 25.0.0; Computers and Structures, Inc.: Berkeley, CA, USA, 2023.

- AFAD. Turkey Building Earthquake Code; Disaster and Emergency Management Presidency: Ankara, Turkey, 2018.

- Ministry of Public Works and Settlement. Regulation on Buildings to Be Constructed in Earthquake Zones; Ministry of Public Works and Settlement, General Directorate of Disaster Affairs, Earthquake Research Department: Ankara, Turkey, 2007.

- Kareem, A.; Hseih, J. Reliability Analysis of Concrete Chimneys under Wind Loading. J. Wind Eng. Ind. Aerodyn. 1986, 25, 93–112. [Google Scholar] [CrossRef]

- Wilson, J.L. Earthquake Response of Tall Reinforced Concrete Chimney. Eng. Struct. 2003, 25, 11–24. [Google Scholar] [CrossRef]

- Huang, W.; Gould, P.L.; Martinez, R.; Johnson, G.S. Non-linear Analysis of a Collapsed Reinforced Concrete Chimney. Earthquake Eng. Struct. Dyn. 2004, 33, 485–498. [Google Scholar] [CrossRef]

- Chmielewski, T.; Górski, P.; Beirow, B.; Kretzschmar, J. Theoretical and Experimental Free Vibrations of Tall Industrial Chimney with Flexibility of Soil. Eng. Struct. 2005, 27, 25–34. [Google Scholar] [CrossRef]

- Huang, W.; Gould, P.L. 3-D Pushover Analysis of a Collapsed Reinforced Concrete Chimney. Finite Elem. Anal. Des. 2007, 43, 879–887. [Google Scholar] [CrossRef]

- Öz, E. Linear and Nonlinear Structural Analysis Methods of Reinforced Concrete Chimneys; Master’s Thesis, Karadeniz Technical University: Trabzon, Turkey, 2007.

- Şengün, İ. Computer Aided Design of Reinforced Concrete Industrial Chimneys; Master’s Thesis, Istanbul Technical University: Istanbul, Turkey, 2010.

- International Committee for Industrial Construction (CICIND). Model Code for Concrete Chimneys with Commentaries; International Committee for Industrial Construction: Moers, Germany, 2001.

- American Concrete Institute (ACI). Code Requirements for Reinforced Concrete Chimneys (ACI 307-08); ACI World Headquarters: Farmington Hills, MI, USA, 2008.

- British Standards Institution (BSI). Free-Standing Chimneys: General Requirements (BS EN 13084-1); British Standards Institution: London, England, 2007.

- Turkish Standards Institution (TSE). Calculation Values of Loads to Be Taken in Dimensioning of Building Elements (TS 498); Turkish Standards Institution: Ankara, Turkey, 1997.

- Elias, S.; Matsagar, V.; Datta, T.K. Effectiveness of Distributed Tuned Mass Dampers for Multi-Mode Control of Chimney under Earthquakes. Eng. Struct. 2016, 124, 1–16. [Google Scholar] [CrossRef]

- Akniyazov, D. Effectiveness of Diagonal Opening Reinforcement in Reinforced Concrete Chimneys under Gravity and Lateral Service Loads; Master’s Thesis, Boğaziçi University: Istanbul, Turkey, 2016.

- Kılıç, S.A. Modeling of Reinforced Concrete Chimney Section Behavior under Cyclic Loading Using Finite Element Method. J. Çukurova Univ. Fac. Eng. Archit. 2017, 32, 1–8. [Google Scholar]

- Türkeli, E. Effect of Soil-Structure Interaction on the Seismic Behavior of RC Chimneys. Düzce Univ. J. Sci. Technol. 2019, 7, 505–518. [Google Scholar] [CrossRef]

- Bashir, I. Comparative Study of an RC Chimney as per Different Codes; Master’s Thesis, Middle East Technical University: Ankara, Turkey, 2019.

- Küçük, M.M. Comparison of Design and Analysis of a Multi-Storey Reinforced Concrete Building According to the 2007 and 2018 Turkish Earthquake Codes; Master’s Thesis, Bursa, Turkey, 2020.

- Sarı, M. Effect of Structure-Soil Interaction on Dynamic Behavior of Reinforced Concrete Industrial Chimneys; Master’s Thesis, Recep Tayyip Erdoğan University: Rize, Turkey, 2020.

- ANSYS, Inc. ANSYS Analysis System: Engineering Simulation Software; ANSYS, Inc.: Canonsburg, PA, USA.

- Çaycı, B.T.; Eldemir, O. Comparison of Performance Levels of TBDY 2018 and DBYBHT 2007 Earthquake Codes. J. Eng. Sci. Des. 2021, 9, 1386–1397. [Google Scholar]

- Çiçek, A. Investigation of Earthquake Effects on Reinforced Concrete Industrial Chimneys and Calculation of These Structures According to Earthquake Loads; Master’s Thesis, Ondokuz Mayıs University: Samsun, Turkey, 2021.

- Alihassan, A. Analysis of GFRP Strengthened Industrial Reinforced Concrete Chimneys Using Finite Element Method; Master’s Thesis, Samsun University: Samsun, Turkey, 2021.

- Elhıdır, S. Analysis of Reinforced Concrete Chimneys under the Effect of Temperature Change by Using Finite Element Method; Master’s Thesis, Ondokuz Mayıs University: Samsun, Turkey, 2023.

- Turkish Standards Institution (TSE). Design and Construction Rules for Reinforced Concrete Structures (TS 500); Turkish Standards Institution: Ankara, Turkey, 2000.

- Şişecam A.Ş. Construction and Corrosion Control Unit, Mersin Soda Factory; Şişecam A.Ş.: Mersin, Turkey, 2024.

- European Commission (EC). Eurocode 1 - Actions on Structures - Part 1-4: General Actions - Wind Actions (EN 1991-1-4); DG Joint Research Center - Unit E3: Safety and Security of Buildings: Ispra (VA), Italy, 2005.

- Turkish Standards Institution (TSE). Effects on Buildings - Part 1-4: General Effects - Wind Effects (Eurocode 1); Turkish Standards Institution: Ankara, Turkey, 1997.

- AFAD. Official Earthquake Hazard Map of Turkey; Disaster and Emergency Management Presidency: Ankara, Turkey, 2018.

- Turkish Standards Institution. TS 708:2016, Steel for the Reinforcement of Concrete – Classes, Properties, and Tests; Turkish Standards Institution: Ankara, Turkey, 2016.

- Turkish Standards Institution. TS 708:2001, Steel for the Reinforcement of Concrete – Classes, Properties, and Tests; Turkish Standards Institution: Ankara, Turkey, 2001.

| Height above ground (m) | (kN/m2) | Diameter (m) | Reynolds number | Force coefficient | Wind force per m2 (kN) | Ref. area (m2) | Wind force per meter (kN/m) | Wind Pressure (kN/m2) | |

|---|---|---|---|---|---|---|---|---|---|

| 8 | 1.16 | 9.10 | 2.64E+06 | 0.49 | 1.25 | 0.71 | 72.8 | 51.5 | 0.71 |

| 18 | 2.33 | 8.91 | 3.66E+06 | 0.50 | 1.25 | 1.44 | 89.1 | 128.5 | 1.44 |

| 28 | 3.51 | 8.75 | 4.42E+06 | 0.50 | 1.25 | 2.20 | 87.5 | 192.9 | 2.20 |

| 38 | 3.74 | 8.60 | 4.48E+06 | 0.50 | 1.25 | 2.35 | 86 | 202.0 | 2.35 |

| 48 | 3.93 | 8.44 | 4.51E+06 | 0.51 | 1.25 | 2.51 | 84.4 | 211.5 | 2.51 |

| 58 | 4.1 | 8.29 | 4.52E+06 | 0.51 | 1.25 | 2.61 | 82.85 | 216.5 | 2.61 |

| 68 | 4.22 | 8.13 | 4.50E+06 | 0.51 | 1.25 | 2.69 | 81.3 | 218.7 | 2.69 |

| 78 | 4.33 | 7.98 | 4.47E+06 | 0.53 | 1.25 | 2.84 | 79.75 | 226.6 | 2.84 |

| 88 | 4.43 | 7.82 | 4.43E+06 | 0.53 | 1.25 | 2.91 | 78.2 | 227.3 | 2.91 |

| 98 | 4.52 | 7.66 | 4.39E+06 | 0.53 | 1.25 | 2.97 | 76.6 | 227.2 | 2.97 |

| 108 | 5.53 | 7.51 | 4.76E+06 | 0.56 | 1.25 | 3.89 | 75.1 | 292.0 | 3.89 |

| 118 | 5.62 | 7.35 | 4.69E+06 | 0.56 | 1.25 | 3.95 | 73.5 | 290.4 | 3.95 |

| 128 | 5.7 | 7.20 | 4.63E+06 | 0.56 | 1.25 | 4.01 | 72 | 288.6 | 4.01 |

| Parameter | TBEC-2018 [2] | TBEC-2007 [3] |

|---|---|---|

| Wind displacement | 32 cm | 41.5 cm |

| Seismic displacement | 34 cm | 34 cm |

| Base shear (wind) | 274 t | 138 t |

| Base shear (earthquake, dynamic) | 216 t | 147 t |

| Base moment (earthquake, dynamic) | 10,175 t.m | 7,754 t.m |

| Max shell stress (wind) | 0.247 N/mm2 | — |

| Max shell stress (earthquake) | 0.112 N/mm2 | — |

| Total structural weight | 3,190 t | 3,057 t |

| Modal mass participation (dynamic modes) | 91% in 19 modes | ≥79% in 24 modes |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).