Submitted:

05 September 2025

Posted:

09 September 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

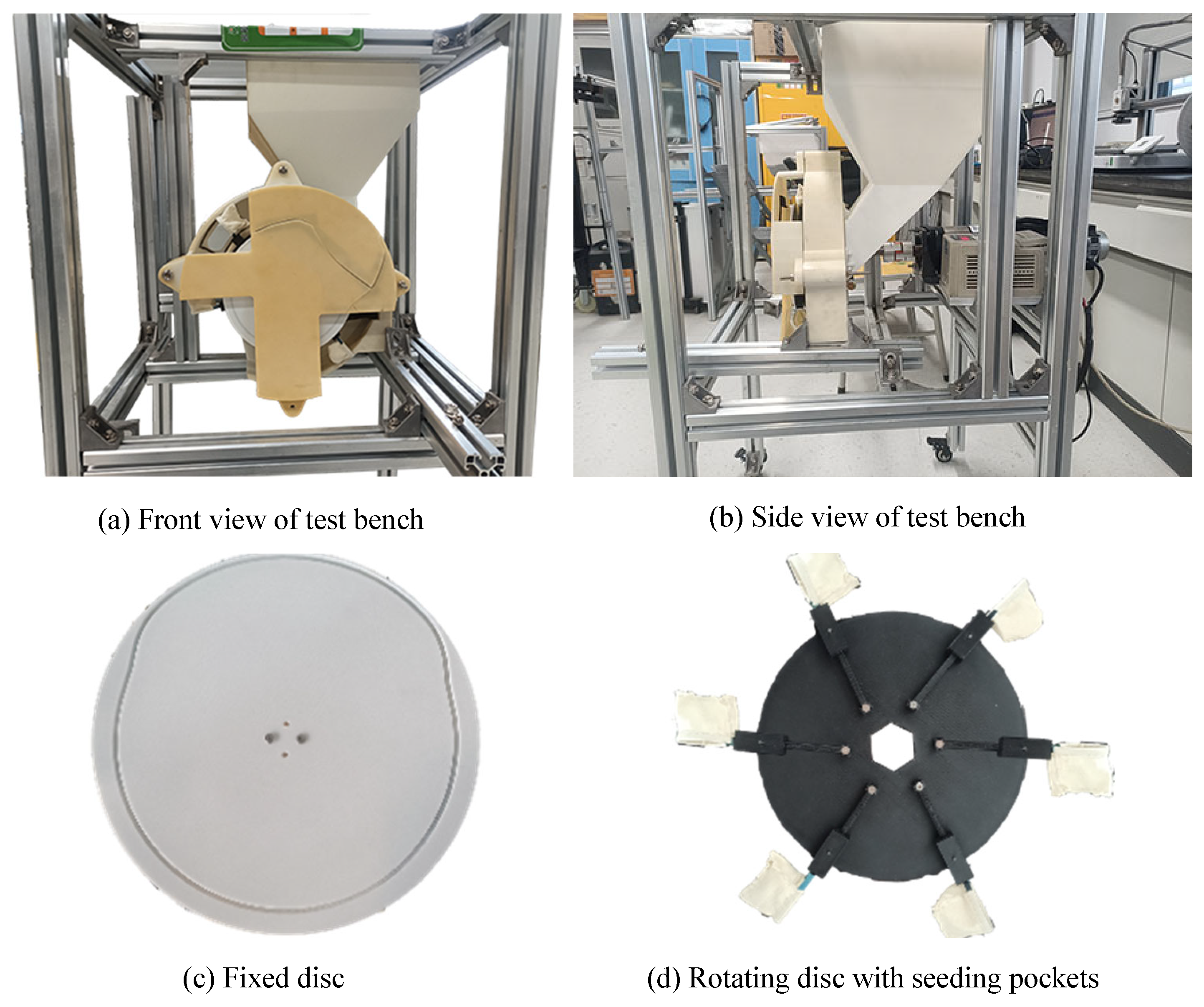

2. Design of the Seeding Device

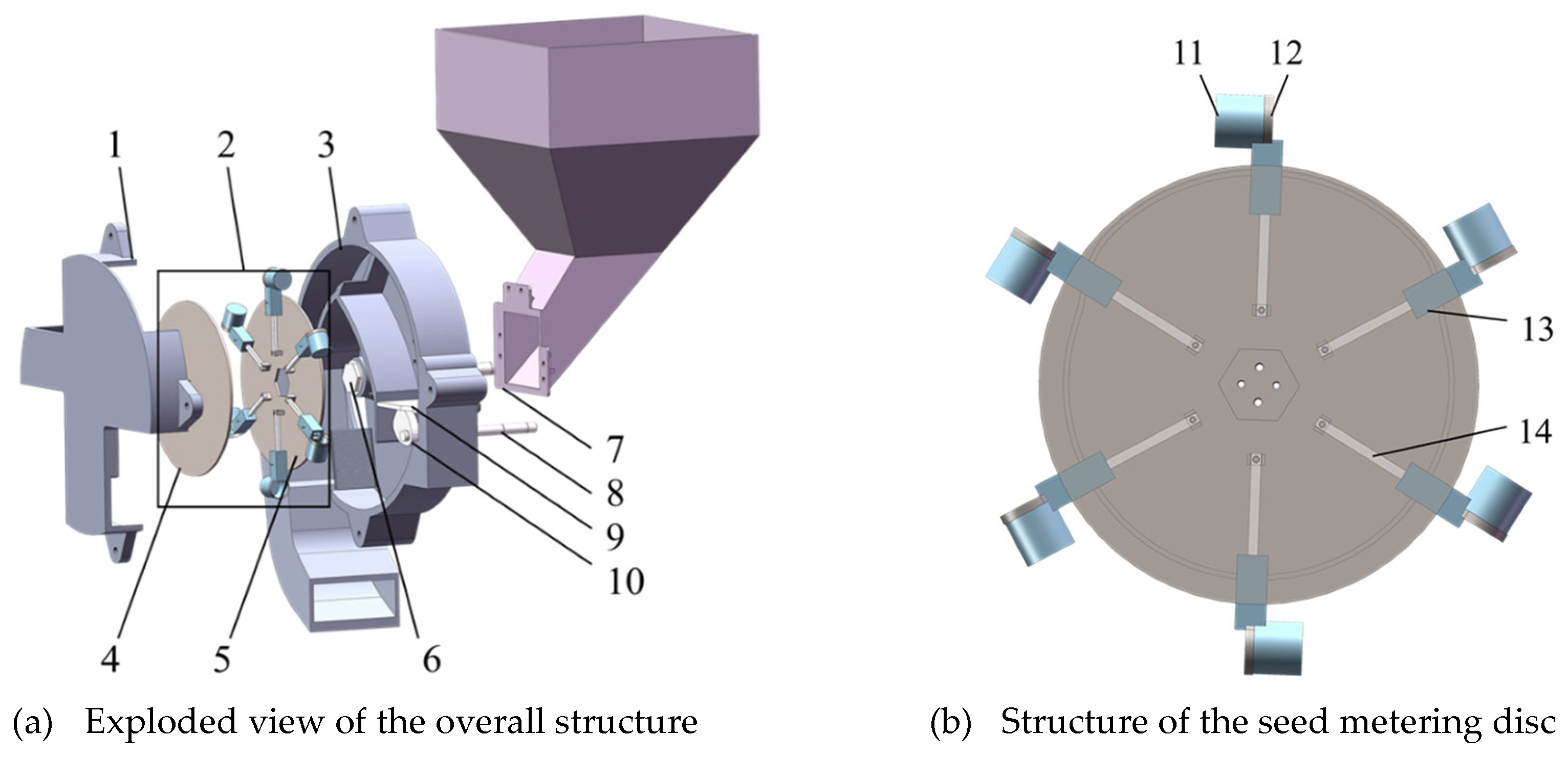

2.1. Structure of the Seeding Device

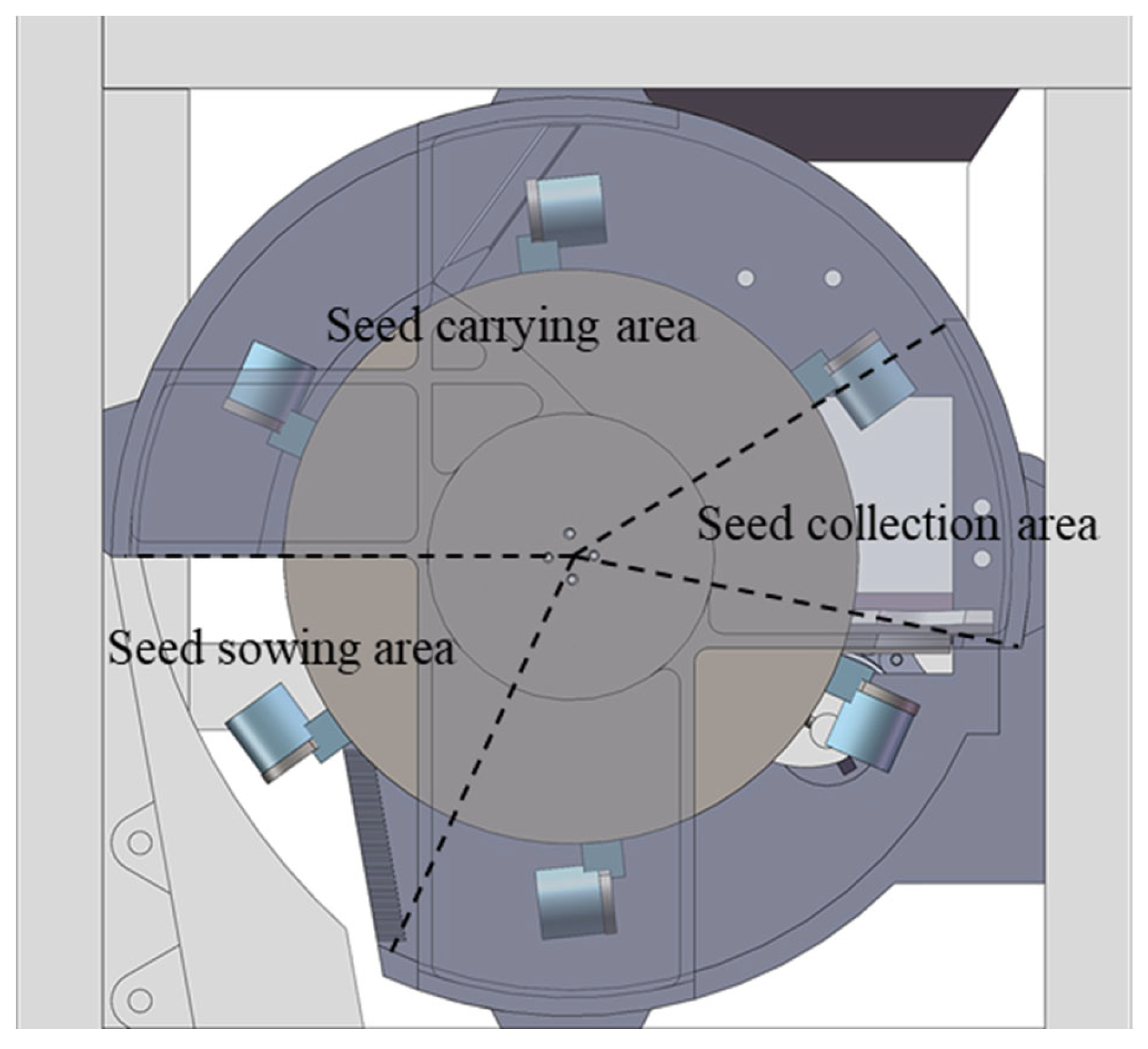

2.2. Principle of the Seeding Device

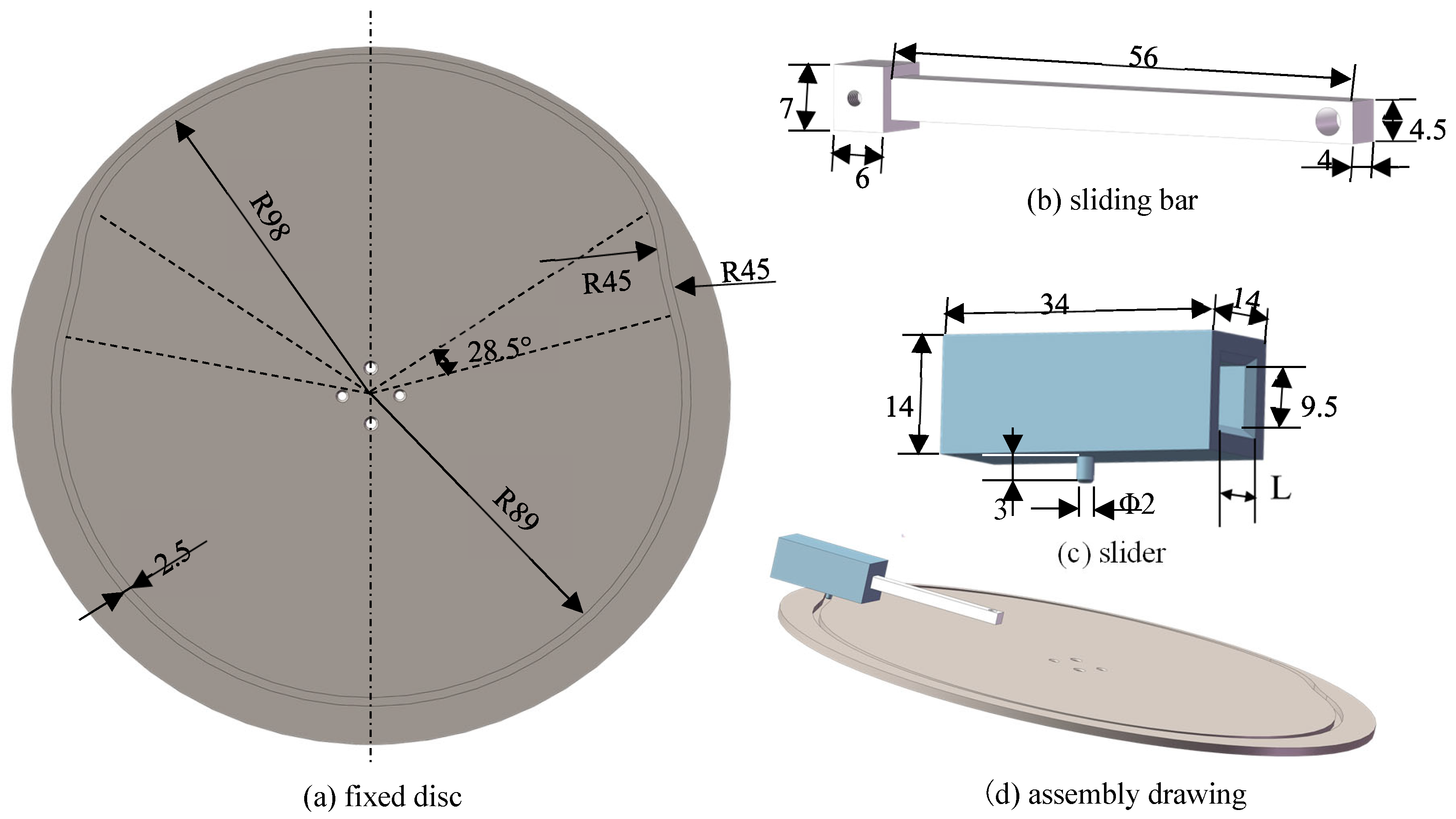

2.3. Design of Rotating Disc

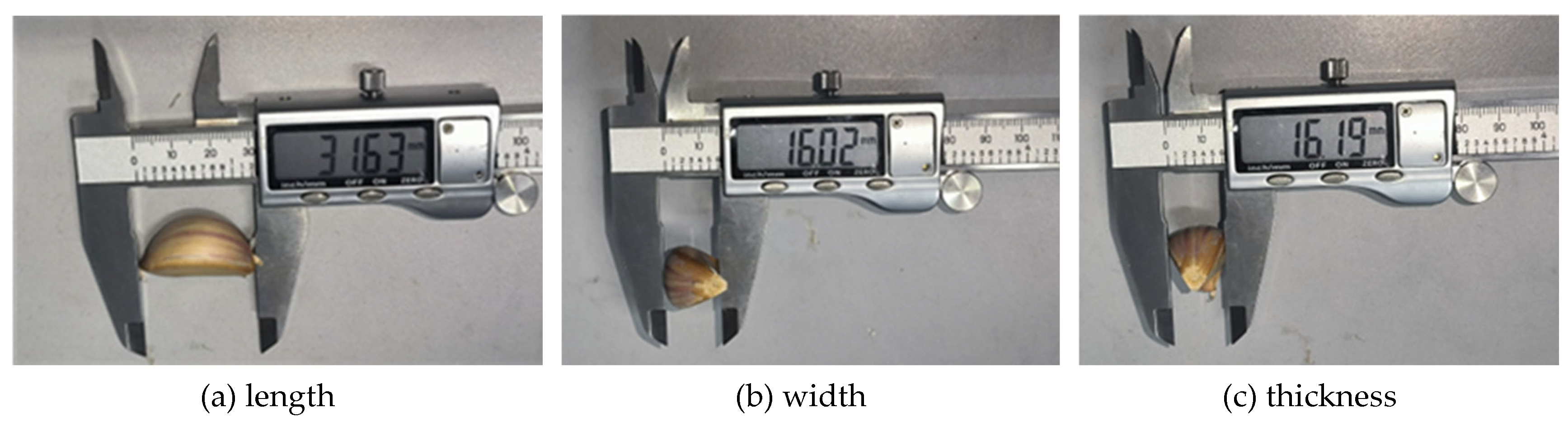

2.4. Design of the Seeding Pocket

2.5. Design of the Retraction Control Mechanism

3. Simulation of the Seeding Process

3.1. Simulation Model Establishment

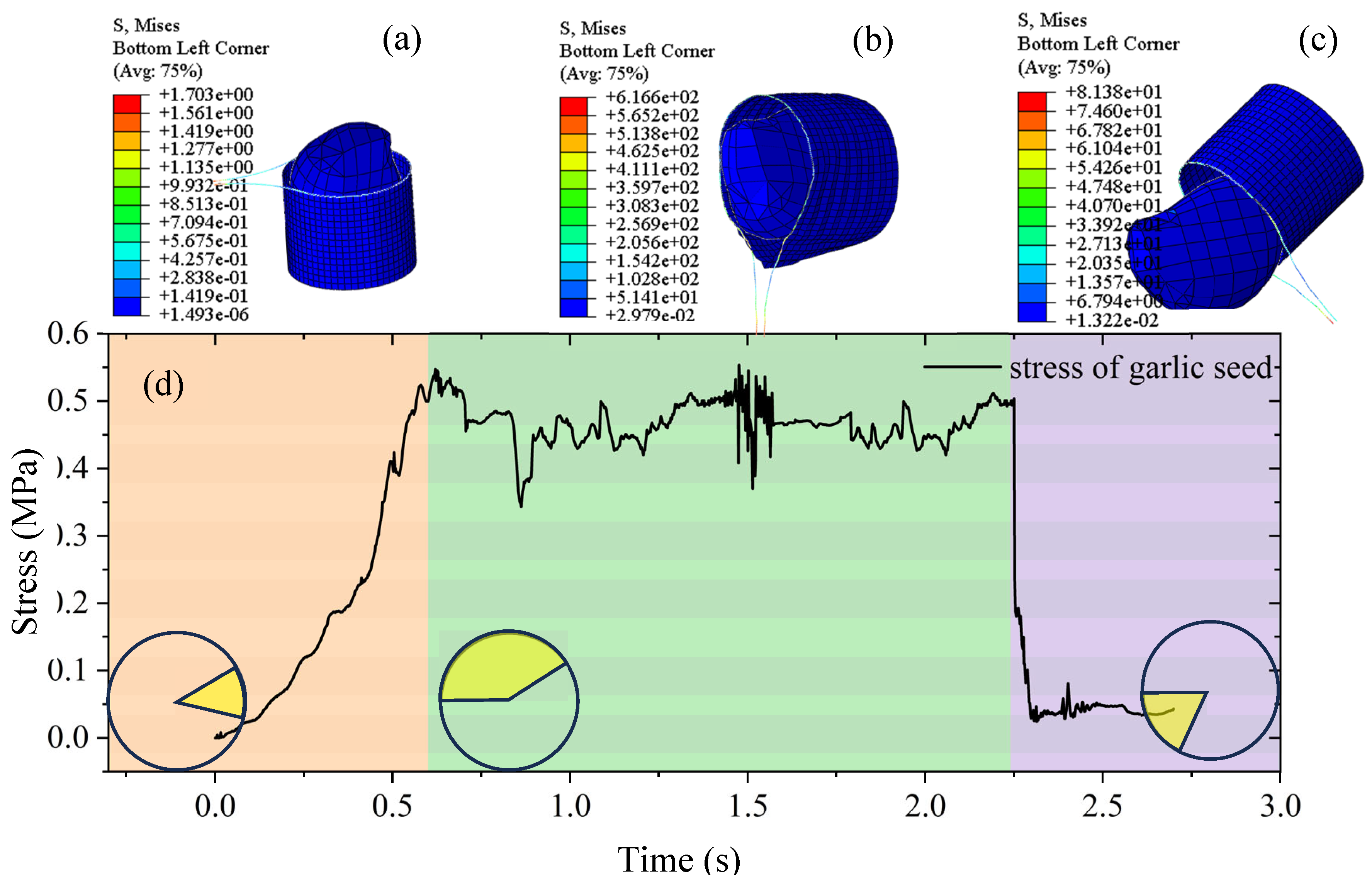

3.2. Simulation Process of the Seeding

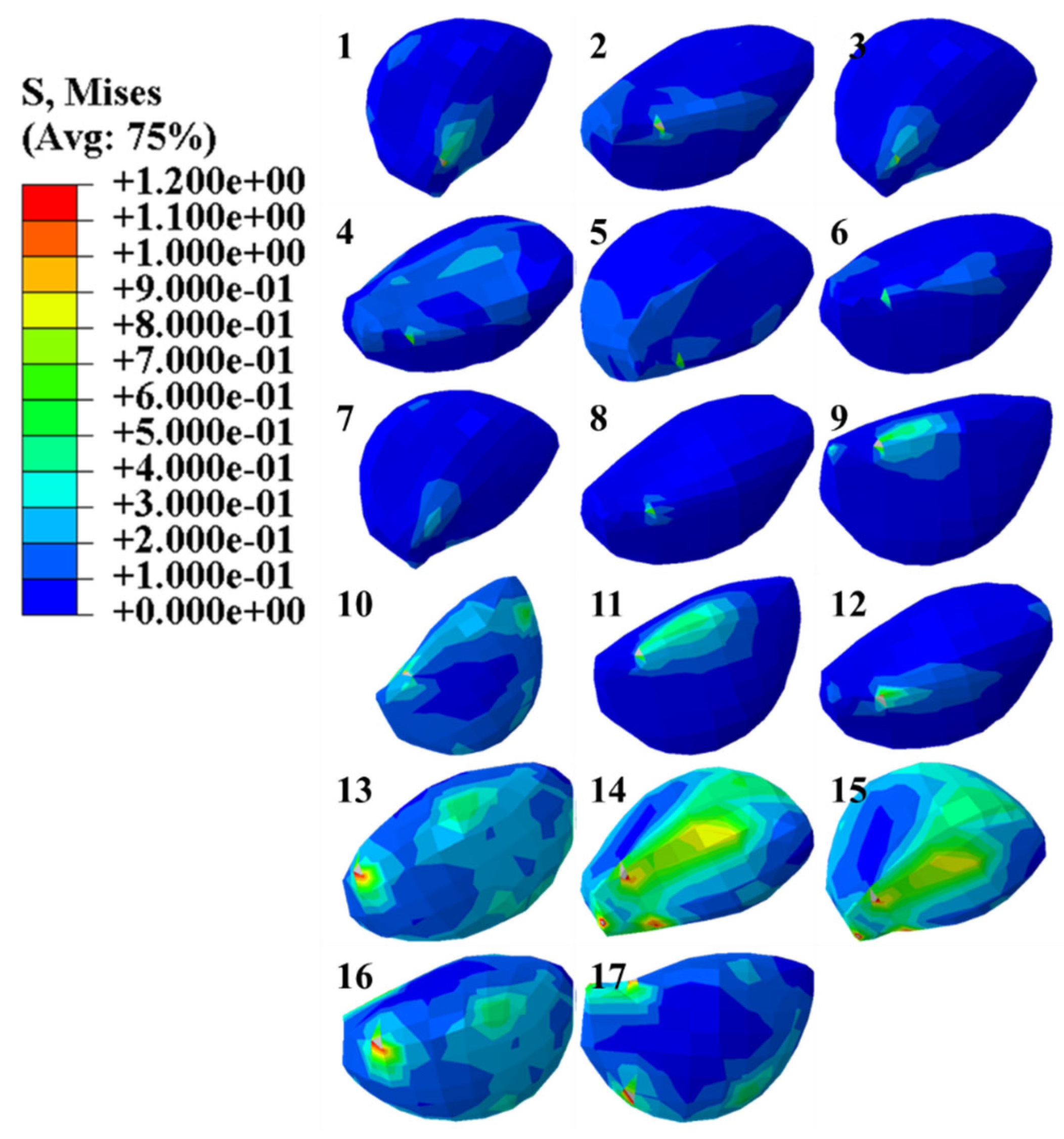

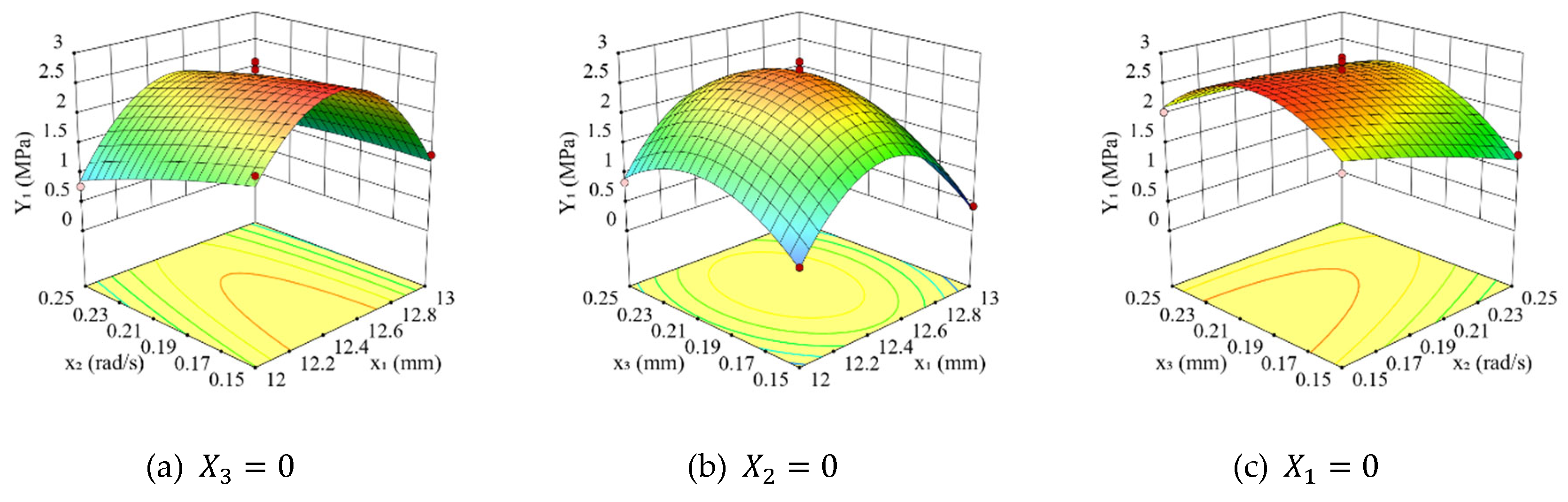

3.3. Multifactorial Analysis of Damage to Garlic Seed

4. Bench Test

4.1. Test Preparation

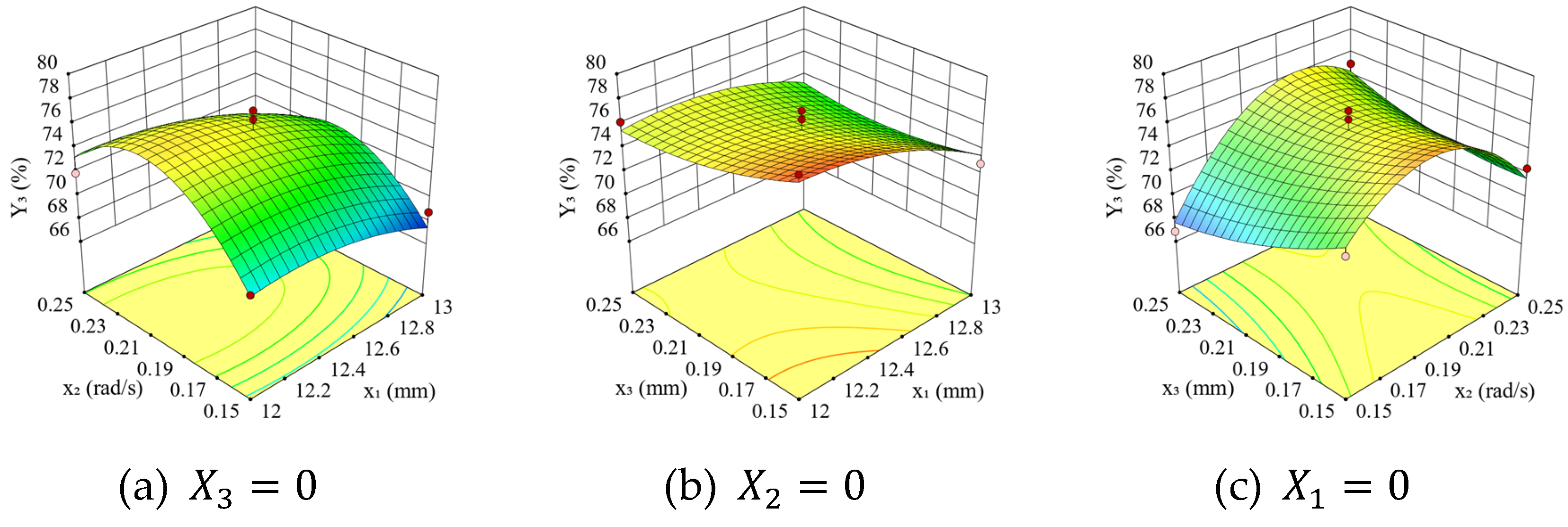

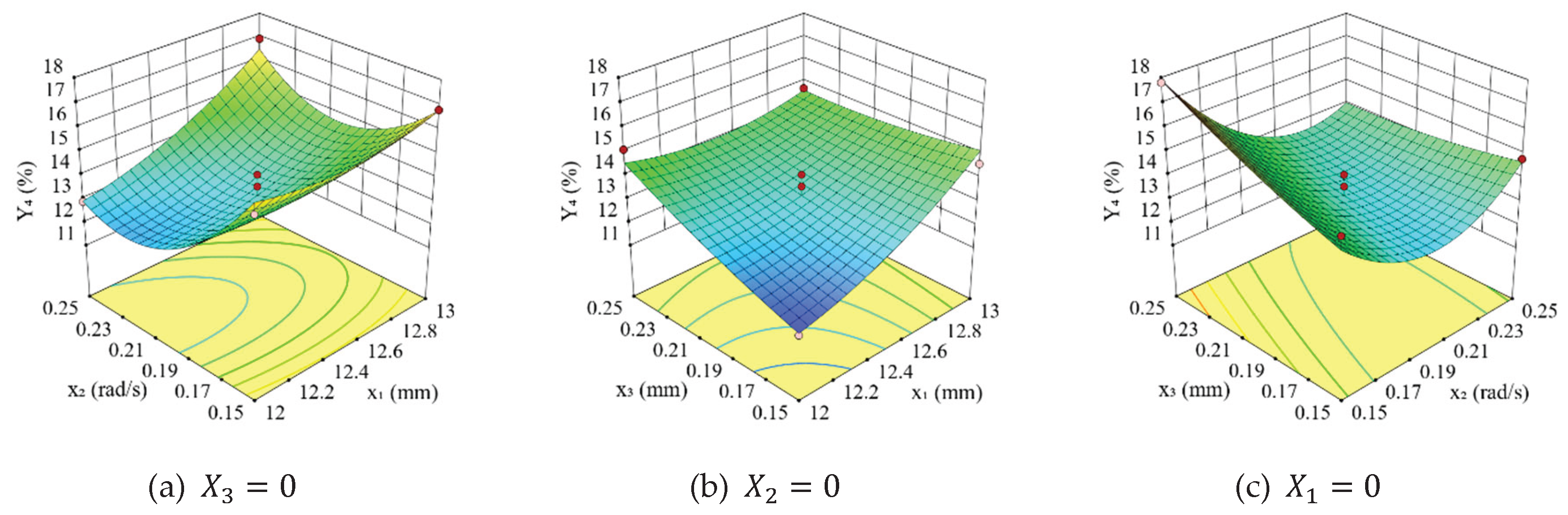

4.2. Analysis of Test Results

5. Conclusions

Author Contributions

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cui, Z.C.; Liu, X.C; Chen, Y.S. Status, problems and countermeasures of whole mechanized production of garlic in China. Journal of Chinese Agricultural Mechanization, 2023, 44, 239-243. [CrossRef]

- Zhu, H.M; Evaluation and analysis on China's garlic export trade and international competitiveness. China Cucurbits and Vegetables, 2022, 35, 111-116. [CrossRef]

- Li, S.P.; Lu, S.; Cui, A.L. Treatment Effect of Garlic Extract on Escherichia coli-induced Rabbit Endometritis. Progress in Veterinary Medicine, 2025, 46, 52-57. [CrossRef]

- Meng, L.Y; Zhang, J.L; Song, X.T. Study on the function of lowering blood lipid of garlic oil. Chinese Journal of Public Health Engineering, 2016, 15, 247-249. [CrossRef]

- Pu, C; Hu, H.B; Kuang, H.X. Research progress on antiviral effects of Allium sativum and its active ingredients. Chinese Traditional and Herbal Drugs, 2022, 53, 2174-2183. [CrossRef]

- Gao, L.X.; Li, X.F.; Jie; X. Investigation on Characteristics and Ratio of Soybean Kernel Mechanical Damage. Journal of Shenyang Agricultural University, 2010, 41, 55-58. [CrossRef]

- Li, J.Y; Su, N.N.; Hu, J.L. Numerical analysis and experiment of abrasive flow machining microhole structure based on CFD-DEM coupling. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34, 80-88. [CrossRef]

- Gao, X.J.; Cui, T.; Zhou, Z.Y. DEM study of particle motion in novel high-speed seed metering device. Advanced Powder Technology, 2021, 32, 1438-1449. [CrossRef]

- Li, C.; Cui, T.; Zhang, D.X. Design and experiment of a centrifugal filling and cleaning high-speed precision seed metering device for maize. Journal of Cleaner Production, 2023, 426, 139083. [CrossRef]

- Landahl, S.; Terry, L.A. Detection of internal defects in onion bulbs by means of single-point and scanning laser Doppler vibrometry. Biosystems Engineering, 2022, 221, 258-273. [CrossRef]

- Wang, S.S.; Zeng, Q.T.; Ni, W.J. ODP-Transformer: Interpretation of pest classification results using image caption generation techniques. Computers and Electronics in Agriculture, 2023, 209, 107863. [CrossRef]

- Ding, Y.; Li, H.; Gao, J.; Yu, H.; Wang, Y.; Feng, D. Parameter Optimization of Finger Clip Plate Garlic Seed-Metering Device. Agriculture, 2023, 13, 2071. [CrossRef]

- Li, T.H.; Huang, S.H.; Niu, Z.R. Optimization and experiment of planting perpendicularity of planetary wheel garlic planter. Transactions of the Chinese Society of Agricultural Engineering, 2020, 36, 37-45. [CrossRef]

- Hou, J.L.; Wang, H.X.; Niu, Z.R. Discrete element simulation and experiment of picking and clearing performance of garlic seed-picking device. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35, 48-57. [CrossRef]

- Hou, J.L.; Liu, Q.C.; Li, T.H. Design and experiment of the garlic seed metering device with double seed-filling chambers. Transactions of the Chinese Society of Agricultural Engineering, 2021, 37, 21-32. [CrossRef]

- Geng, A.J.; Li, X.Y.; Hou, J.L. Design and experiment of automatic directing garlic planter. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34, 17-25. [CrossRef]

- Zilpilwar, S; Yadav, R.; Jakasania, R. Development and Performance Evaluation of Metering Mechanism for Planting Garlic Cloves. Agricultural research (India : Online), 2021, 10, 274-284. [CrossRef]

- Ling, L.; Wu, G.W.; Wen, C.K. Influence of speed measurement method on performance of an electric-drive maize precision planter. Biosystems Engineering, 2024, 238, 175-187. [CrossRef]

- Zhang, C.L.; Zhang, X.Y.; Zheng, Z.H. Numerical Simulation and Test of the Disturbance Air Suction Garlic Seed Metering Device. Machines, 2022, 10, 11-27. [CrossRef]

- Ding, L.; Yang, L.; Zhang, D.X. Effect of seed adsorption posture of corn air-suction metering device on seed feeding performance. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52, 40-50. [CrossRef]

- Zhang, Q.; Wang, Y.J.; Li, H.; Gao, J.F.; Ding, Y.G. Optimization of A Precision Symmetric Finger Clamping Garlic Seed-Metering Device. Frontiers of Agricultural Science & Engineering, 2024, 11(4): 626–641. [CrossRef]

- Li, H.; Meng, Y.B.; Qi, X.D. Discrete Element Modelling Method and Parameter Calibration of Garlic Species Based on Bonding V2 Model. Transactions of the Chinese Society for Agricultural Machinery, 2025, 56,150-157+159. [CrossRef]

- Hu, M.J.; Zhou, Y.; Tang, Z.C. Mechanical properties of the delinted and coated cottonseed. Journal of Anhui Agricultural University, 2018, 45, 175-180. [CrossRef]

- GB_T6973-2005; Testing methods of single seed drills (precision drills). China Standards Press: Beijing, Chian, 2005.

| Grade | Length/mm | Width/mm | Thickness/mm |

| 1 | 26.5~30.1 | 13.1~19.8 | 13.7~16.8 |

| 2 | 29.7~33.2 | 16~22.5 | 18.1~21.1 |

| 3 | 32.9~37 | 19.4~23.7 | 20.9~22.8 |

| Inner wall spacing/mm | 6 | 6.5 | 7 | 7.5 | 8 |

| Max stress of garlic seed/MPa | 4.94 | 3.66 | 3.47 | 2.86 | 1.48 |

| Material | Modulus of elasticity/MPa | Poisson's ratio | Density/t/mm3 |

| Garlic seed | 23.82 | 0.25 [22] | 5.110-9 |

| Metal sheet | 210000 | 0.3 | 10-9 |

| Seeding Pocket [23] (cotton fabric) |

915 | 0.142 | 10-9 |

| Code | Factors | ||

| Pocket radius /mm |

Rotational speeds of seeding disc /rad/s |

Thickness of metal sheet /mm |

|

| -1 | 12 | 0.15 | 0.15 |

| 0 | 12.5 | 0.2 | 0.2 |

| 1 | 13 | 0.25 | 0.25 |

| No. | Factors | Y1/MPa | ||

| 1 | -1 | -1 | 0 | 1.99 |

| 2 | 1 | -1 | 0 | 1.31 |

| 3 | -1 | 1 | 0 | 0.77 |

| 4 | 1 | 1 | 0 | 0.91 |

| 5 | -1 | 0 | -1 | 0.603 |

| 6 | 1 | 0 | -1 | 0.428 |

| 7 | -1 | 0 | 1 | 0.84 |

| 8 | 1 | 0 | 1 | 0.684 |

| 9 | 0 | -1 | -1 | 2.03 |

| 10 | 0 | 1 | -1 | 1.31 |

| 11 | 0 | -1 | 1 | 2.03 |

| 12 | 0 | 1 | 1 | 2.17 |

| 13 | 0 | 0 | 0 | 2.55 |

| 14 | 0 | 0 | 0 | 2.86 |

| 15 | 0 | 0 | 0 | 2.73 |

| 16 | 0 | 0 | 0 | 2.57 |

| 17 | 0 | 0 | 0 | 2.37 |

| Source of variance | Garlic stress | |||

| Sum of squares | Degree of freedom | F | P | |

| Model | 10.91 | 9 | 28.58 | 0.0001 |

| 0.0948 | 1 | 2.23 | 0.1786 | |

| 0.6050 | 1 | 14.26 | 0.0069 | |

| 0.2288 | 1 | 5.39 | 0.0532 | |

| 0.1681 | 1 | 3.96 | 0.0868 | |

| 0.0001 | 1 | 0.0021 | 0.9645 | |

| 0.1849 | 1 | 4.36 | 0.0752 | |

| 7.21 | 1 | 169.94 | < 0.0001 | |

| 0.0164 | 1 | 0.3861 | 0.5541 | |

| 1.88 | 1 | 44.36 | 0.0003 | |

| Residual | 0.2970 | 7 | ||

| Lack of Fit | 0.1575 | 3 | 1.51 | 0.3418 |

| Pure error | 0.1395 | 4 | ||

| Cor Total | 11.21 | 16 | ||

| No. | Factors | Performance indexes | |||||

| X1 | X2 | X3 | Damage rate /% | Single seed rate /% | Leakage rate /% | ||

| 1 | 0 | 0 | 0 | 0 | 74.8 | 13.6 | |

| 2 | 1 | 0 | -1 | 0 | 72.9 | 14.6 | |

| 3 | 0 | 0 | 0 | 0 | 73.9 | 14.1 | |

| 4 | 1 | 1 | 0 | 0 | 68.6 | 16.9 | |

| 5 | 1 | 0 | 1 | 0 | 72.8 | 14.7 | |

| 6 | -1 | -1 | 0 | 0 | 70.0 | 16.1 | |

| 7 | 0 | 0 | 0 | 0 | 75.5 | 13.2 | |

| 8 | 0 | -1 | -1 | 0 | 73.0 | 15.3 | |

| 9 | -1 | 0 | -1 | 0 | 79.1 | 11.4 | |

| 10 | 1 | -1 | 0 | 0 | 68.8 | 16.8 | |

| 11 | 0 | 1 | 1 | 0 | 75.0 | 13.5 | |

| 12 | 0 | 0 | 0 | 0 | 76.5 | 12.8 | |

| 13 | 0 | 1 | -1 | 0 | 72.5 | 14.8 | |

| 14 | 0 | 0 | 0 | 0 | 77.2 | 12.4 | |

| 15 | -1 | 0 | 1 | 0 | 76.2 | 15.1 | |

| 16 | 0 | -1 | 1 | 0 | 66.9 | 17.8 | |

| 17 | -1 | 1 | 0 | 0 | 71.9 | 12.9 | |

| Source of variance | Single seed rate | Leakage rate | ||||||||

| Sum of squares | Degree of freedom | F | P | Sum of squares | Degree of freedom | F | P | |||

| Model | 161.33 | 9 | 8.91 | 0.0044 | 45.33 | 9 | 10.29 | 0.0028 | ||

| 24.64 | 1 | 12.24 | 0.0100 | 7.03 | 1 | 14.37 | 0.0068 | |||

| 11.03 | 1 | 5.48 | 0.0518 | 7.80 | 1 | 15.94 | 0.0052 | |||

| 5.55 | 1 | 2.76 | 0.1406 | 3.12 | 1 | 6.39 | 0.0394 | |||

| 1.12 | 1 | 0.5589 | 0.4791 | 2.72 | 1 | 5.56 | 0.0504 | |||

| 2.00 | 1 | 0.9935 | 0.3521 | 3.24 | 1 | 6.62 | 0.0368 | |||

| 18.86 | 1 | 9.37 | 0.0183 | 3.61 | 1 | 7.38 | 0.0299 | |||

| 6.01 | 1 | 2.98 | 0.1277 | 1.17 | 1 | 2.39 | 0.1657 | |||

| 88.24 | 1 | 43.85 | 0.0003 | 15.64 | 1 | 31.97 | 0.0008 | |||

| 3.05 | 1 | 1.51 | 0.2581 | 0.1727 | 1 | 0.3528 | 0.5712 | |||

| Residual | 14.09 | 7 | 3.43 | 7 | ||||||

| Lack of Fit | 7.55 | 3 | 1.54 | 0.3349 | 1.66 | 3 | 1.25 | 0.4028 | ||

| Pure error | 6.54 | 4 | 1.77 | 4 | ||||||

| Cor Total | 175.42 | 16 | 48.76 | 16 | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).